Strippable composite film for optical cable

A composite film and optical cable technology, which is applied in the direction of synthetic resin layered products, layered products, metal layered products, etc., can solve the problems such as the difficulty of removing the PE sheath layer, achieve shortened splicing time, good bonding, and ensure The effect of tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

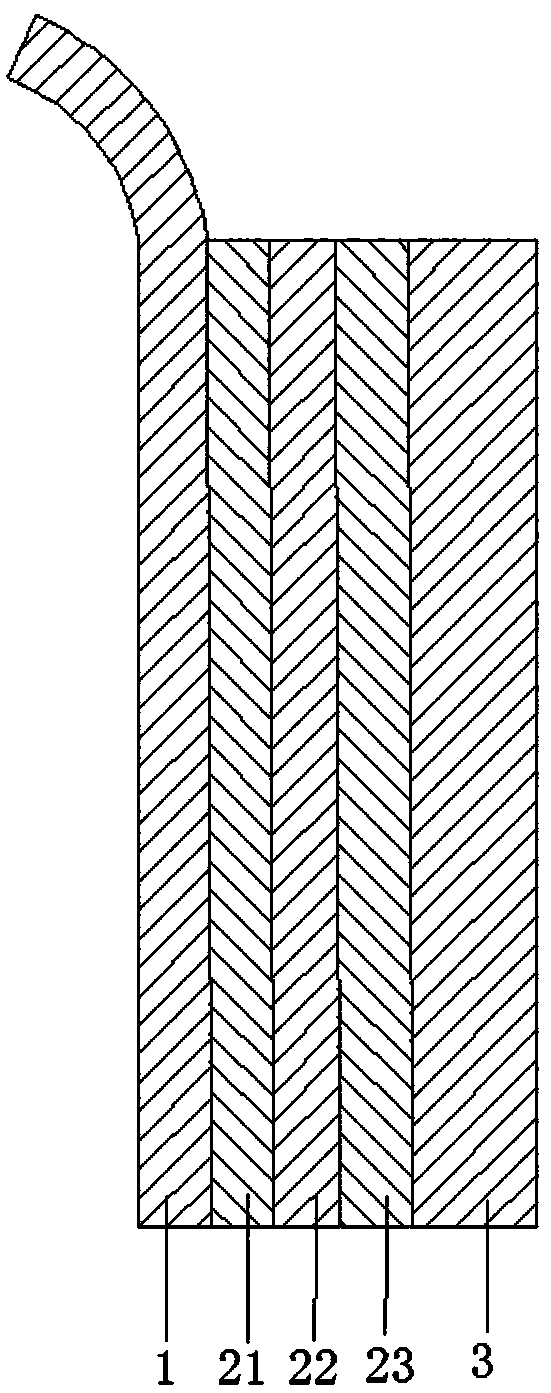

[0016] figure 1 As shown, it relates to a peelable composite film for an optical cable, including a chrome-plated steel strip 3 arranged on the innermost layer, a co-extruded film arranged on the middle layer, and a PE sheath layer 1 arranged on the outermost layer; wherein, the The co-extrusion film comprises the A layer 23 arranged on the outer layer of the chrome-plated steel strip 3, the B layer 22 arranged on the A layer 23 outer layer, and the C layer 21 arranged on the B layer 22 outer layer; wherein, the A layer 23 and the chrome-plated The steel strip 3 is pasted together, and the C layer 21 and the PE sheath layer 1 are pasted together.

[0017] A further preferred solution is that between the B layer 22 and the C layer 21 is a controllable peeling interlayer with a certain delamination strength, the delamination strength is 2-4N / cm, and the optimum is 3N / cm.

[0018] A further preferred solution is that the peel strength of the A layer 23 , the B layer 22 and the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peel strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com