Hydraulic hammer

A hydraulic hammer and hydraulic cylinder technology, applied in construction, sheet pile walls, foundation structure engineering, etc., can solve problems such as complex structure, unreliable valve action, and inability to effectively eliminate impact quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

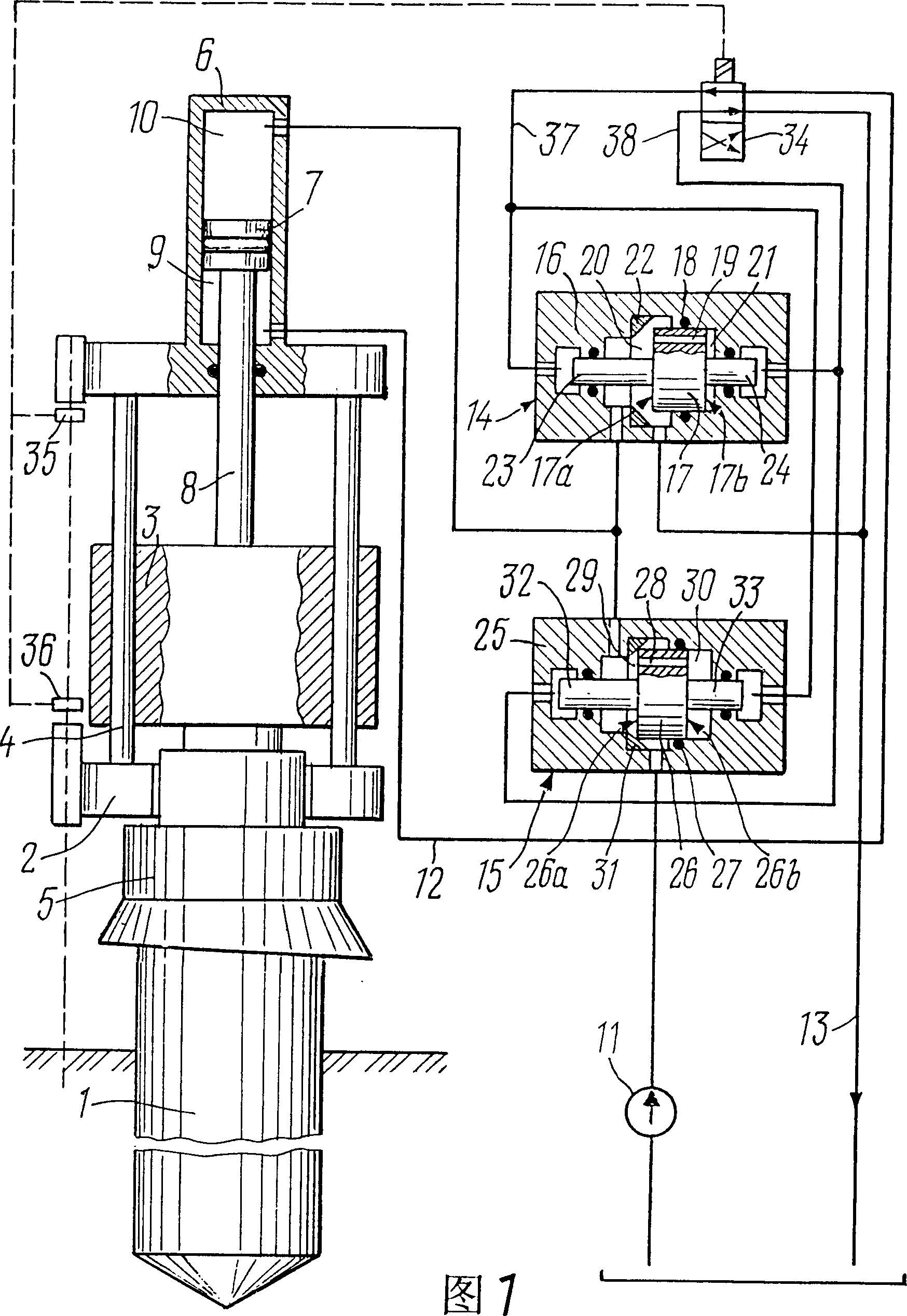

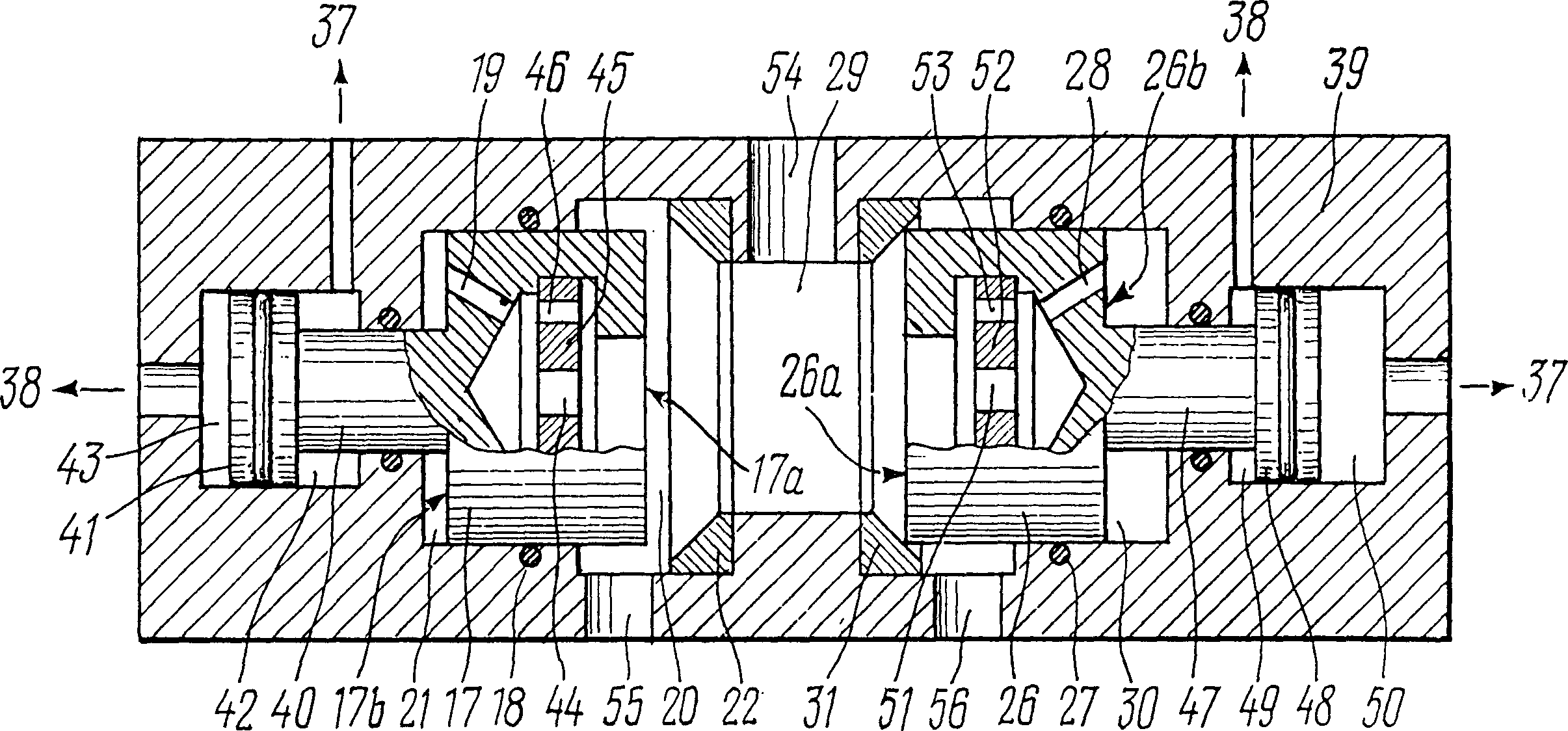

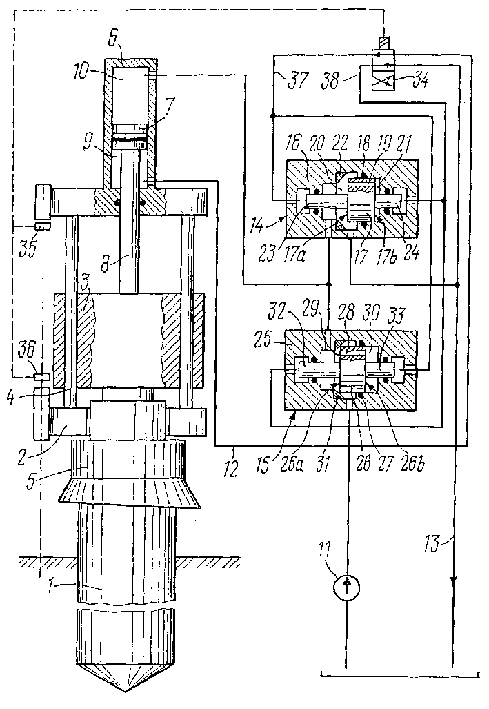

[0018] Figure 1 shows that a pile 1 is driven into the soil with a hydraulic hammer of the present invention. It includes a shell 2; an impact mass 3 that can reciprocate along the guide rod 4 of the shell 2; a pile cap 5 located between the impact mass 3 and the pile 1; a double-acting hydraulic cylinder 6 that moves the impact mass 3, which is fixed In the housing 2, there is a piston 7 with a connecting rod 8, the piston 7 forms a connecting rod cavity 9 in the direction of the pile 1 in the hydraulic cylinder 6, and a piston cavity 10 is arranged on the other side of the piston 7, and the connection The rod 8 is connected with the impact mass 3; the pump 11; the pressurizing pipe 12 and the overflow pipe 13 which are constantly connected with the connecting rod cavity 9; two double-position valves 14 and 15. The valve 14 includes a housing 16, a valve member 17, a gasket 18 of the valve member 17 in the housing 16, a channel 19 in the valve member 17, a chamber 20 in the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com