Combine

A technology of combine harvesters and conveyors, which is applied in the directions of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of increasing the number of parts and complex structures, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

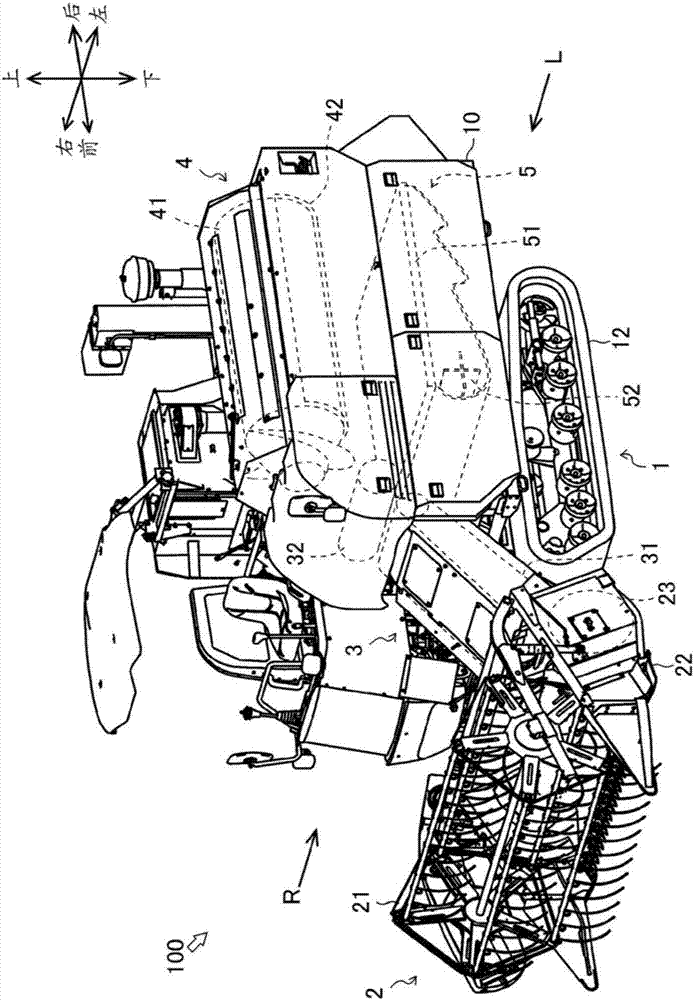

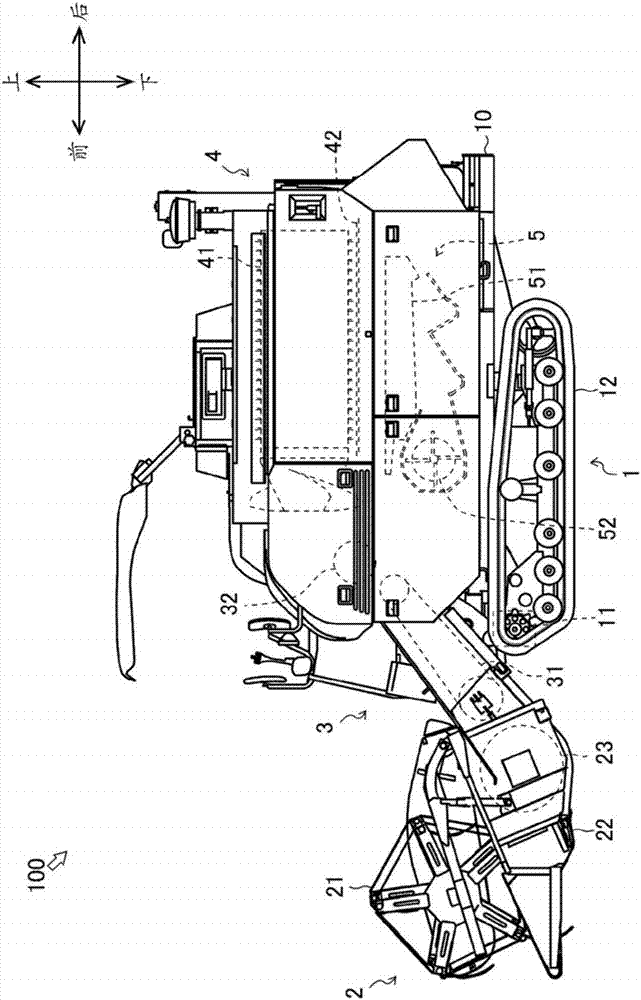

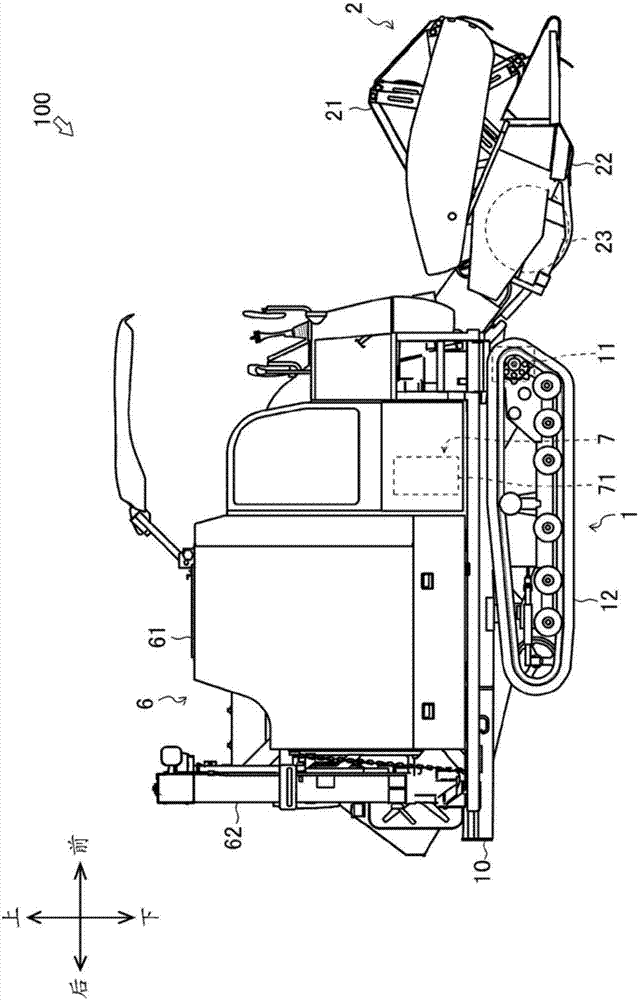

[0055] First, the combine harvester 100 will be briefly described.

[0056] figure 1 A combine harvester 100 is given. figure 2 From figure 1 Arrow L to observe the resulting figure, image 3 From figure 1 The arrow R observed in the resulting figure. In addition, in the figure, the front-back direction, the left-right direction, and the up-down direction of the combine harvester 100 are shown.

[0057] The combine harvester 100 is mainly composed of a traveling device 1 , a harvesting device 2 , a conveying device 3 , a threshing device 4 , a screening device 5 , a storage device 6 , and a power device 7 .

[0058] The traveling device 1 is disposed below the chassis 10 . The travel device 1 is composed of a transmission 11 and crawler belt devices 12 , 12 . The transmission 11 transmits rotational power of an engine 71 to be described later to the crawler belt devices 12 , 12 . Crawler belt apparatuses 12 and 12 run the combine 100 in the front-back direction. More...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com