Pump body components and variable capacity compressor

A technology of variable capacity compressors and components, applied in the field of compressors, can solve problems such as complex structures, and achieve the effects of simple assembly process, excellent compressor noise, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

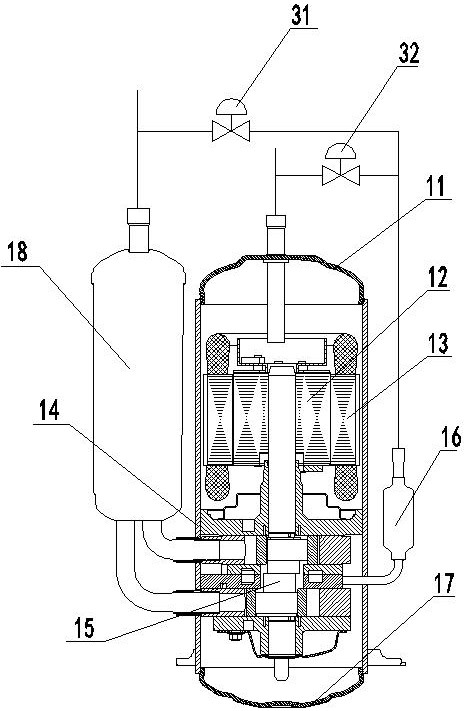

[0041] Such as figure 1 As shown, this embodiment provides a variable displacement compressor, including an upper cover assembly 11, a housing assembly 14, and a lower cover assembly 17, the housing assembly 14 is fixed between the upper cover assembly 11 and the lower cover assembly 17 and Form a closed space; also include a rotor assembly 12, a stator assembly 13, which is connected to a power supply to provide driving force; the stator assembly 13 is fixed on the inner peripheral wall of the housing assembly 14; also includes a pump body assembly 15, the pump body The assembly 15 is fixed on the inner peripheral wall of the housing assembly 14 and connected with the rotor assembly 12; the pump body assembly 15 performs periodic compression work under the drive of the rotor assembly 12; it also includes a suction liquid separator 18. The outlet end of the suction liquid distributor 18 is connected to the pump body assembly 15 to provide low-temperature and low-pressure refri...

Embodiment 2

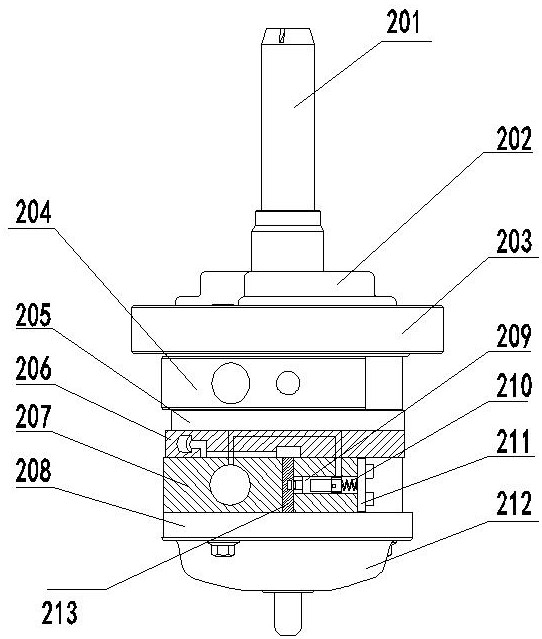

[0054] In the variable displacement compressor of the present invention, when the pump body assembly 15 has two cylinder parts, the variable displacement cylinder part can be an upper cylinder part or a lower cylinder part. Embodiment one is that the lower cylinder part is used as a variable displacement cylinder assembly, such as Figure 10 As shown, the above cylinder parts of embodiment two are used as variable capacity cylinder parts, and the differences with embodiment one are:

[0055] 1. The pin 209 and the spring 210 are installed in the pin hole of the upper cylinder 204 , the upper slide is provided with a slide lock hole 213a, and the pin sealing cover 211 is locked on the upper cylinder 204 .

[0056] 2. The upper flange 203 is provided with a variable volume ventilation hole and a variable volume ventilation channel, which are connected to the tail of the slider.

[0057] 3. The upper partition 205 is provided with a low-pressure vent hole and a low-pressure vent...

Embodiment 3

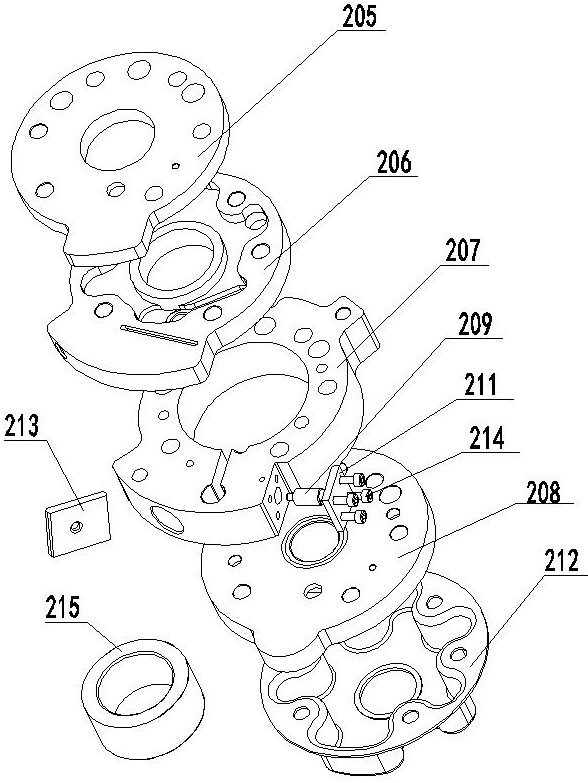

[0059] The invention is a multi-cylinder variable capacity compressor with three or more cylinder parts. Such as Figure 11 As shown, the differences from Embodiment 1 and Embodiment 2 are:

[0060] 1. The pump body assembly 15 also includes a middle cylinder 111 , a middle partition 112 and a middle sliding piece 113 .

[0061] 2. The variable capacity cylinder can be one or more of multiple cylinders, and the variable capacity compressor has multiple operating modes such as single cylinder, double cylinder, and multiple cylinders.

[0062] 3. At least one or more of the plurality of baffle components is provided with a variable volume vent hole and a variable volume vent channel, which communicate with the tail of the slider.

[0063] 4. At least one or more of the baffle assembly, upper flange, and lower flange is provided with a low-pressure vent hole and a low-pressure vent channel, which communicate with the tail of the pin.

[0064] Compared with prior art, the benef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com