Low thermal resistance cast-iron cooling wall and manufacturing method thereof

A manufacturing method and cooling stave technology, applied to furnace cooling devices, etc., can solve problems such as reduced cooling water heat transfer, accelerated stave damage process, and rise in stave body temperature, so as to increase heat transfer efficiency and prevent scaling on the inner wall Effects of slowing down and prolonging life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

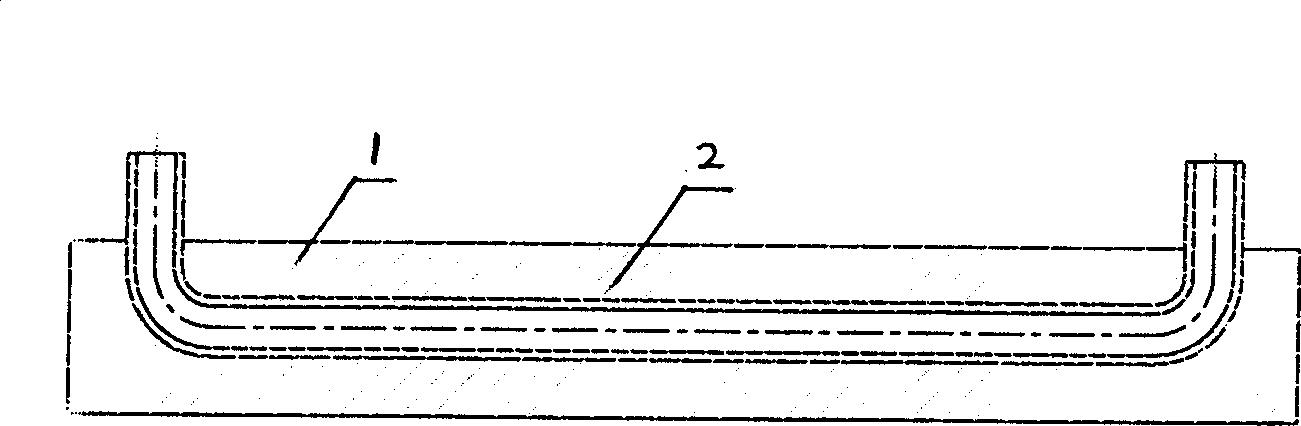

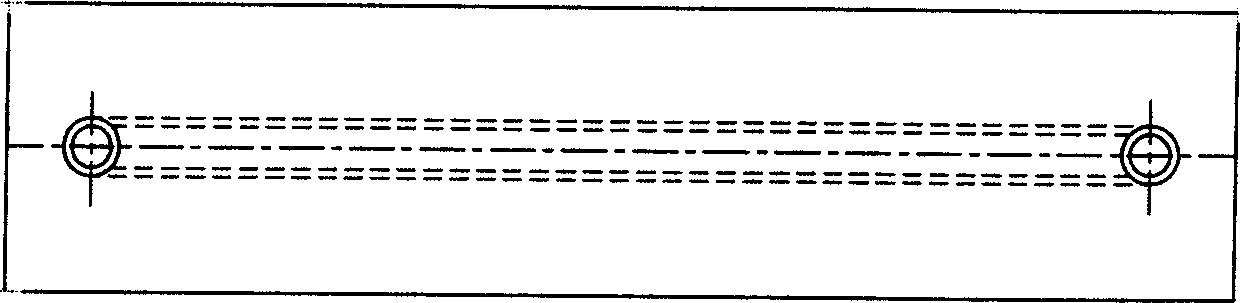

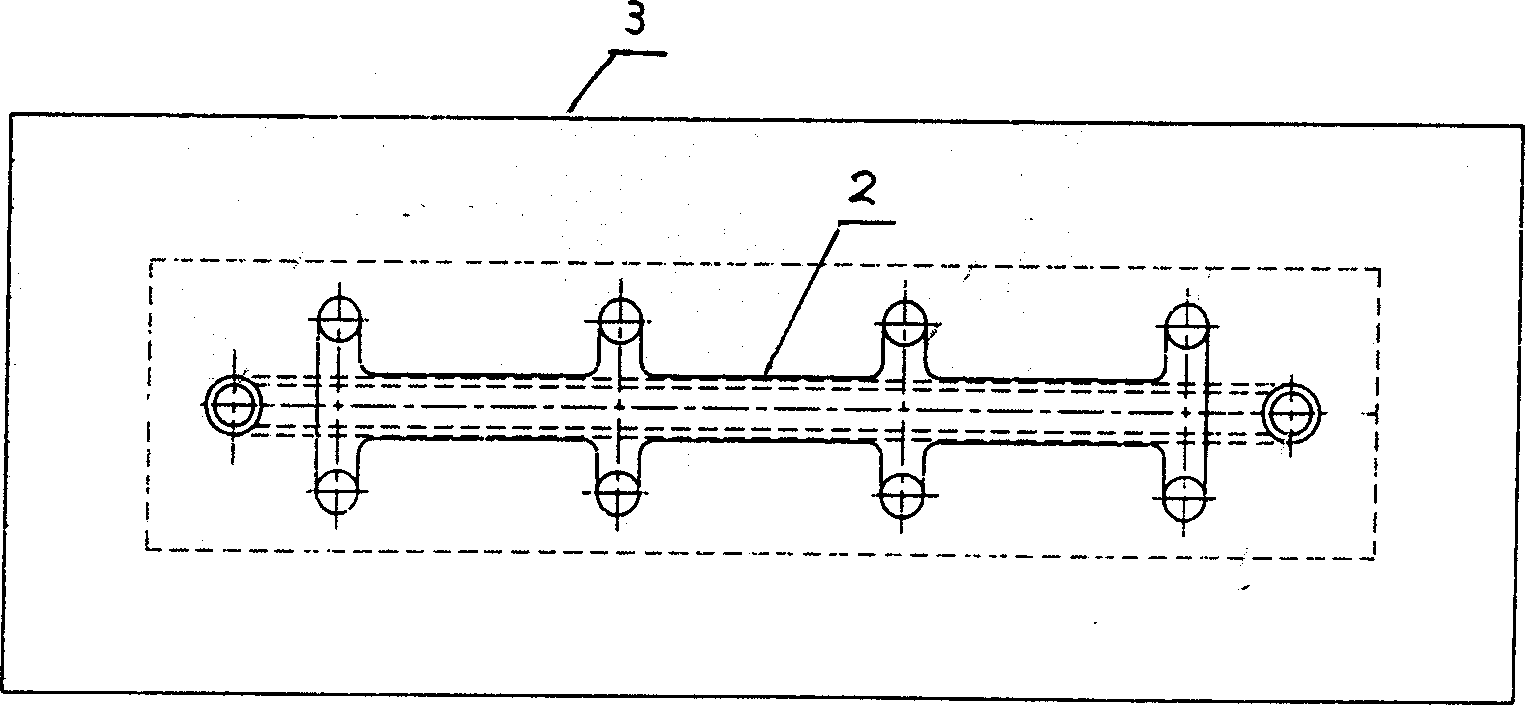

[0029] A new type of low thermal resistance cast iron stave, and its manufacturing process (controlling cooling intensity casting process), see Figure 1 ~ Figure 3 :

[0030] New low thermal resistance cast iron stave: the stave body 1 is made of ductile iron or gray cast iron with high melting point (≥1200°C), and the cooling water channel 2 in the stave is composed of pure copper tube with low melting point (1080°C). The cooling water pipe is a pure copper pipe with anti-carburization, high thermal conductivity (340 kcal / m·h·℃), high elongation (≥30); the gap between the cooling wall body and the outer wall of the pure copper pipe is less than 0.1mm; Pure copper tubes are pure copper tubes with a wall thickness of 6-8 mm.

[0031] The preparation method steps of above structure are as follows:

[0032] Put the shaped pure copper tube into the sand box 3 made according to the shape of the stave and fix it;

[0033] While pouring with molten iron of ductile iron or gray ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com