Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

237results about How to "Stop shedding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Antiflaming plywood or veneer lamination and manufacturing method thereof

ActiveCN102114650ASlow down the rate of carbonizationReduce burnWood veneer joiningWood impregnation detailsAdhesiveCarbonization

The invention discloses an antiflaming plywood or a veneer lamination, which comprises a wood veneer, a phosphorus-nitrogen fire retardant, a boron fire retardant, oxide or hydroxide of magnesium, aluminum, calcium, zinc, titanium and barium, and an adhesive, which have over dry weight percentage ratio being 100:2-50:0.2-30:4-40. The antiflaming plywood or the veneer lamination has the characteristics of low carbonization speed, accordance with related standards on physical mechanics property, flame retardant property and smoke toxicity, low formaldehyde emission values, and the like; the invention further discloses a manufacturing method for the antiflaming plywood or the veneer lamination, which comprises the following steps: impregnating the phosphorus-nitrogen fire retardant, the boron fire retardant, the oxide or hydroxide of magnesium, aluminum, calcium, zinc, titanium and barium on the wood veneer, coating the adhesive, and conducting processing of assembling, prepressing, hot pressing, sand polishing and the like.

Owner:固安盛辉阻燃材料有限公司

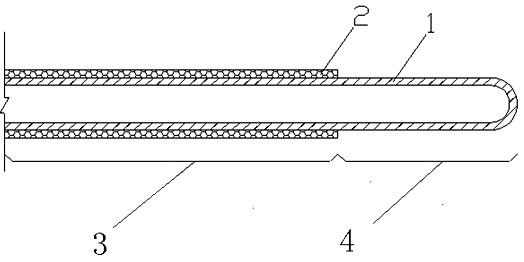

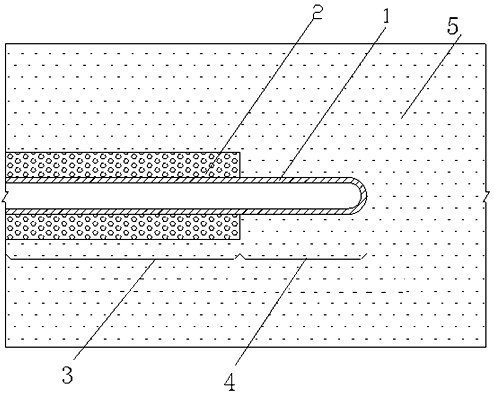

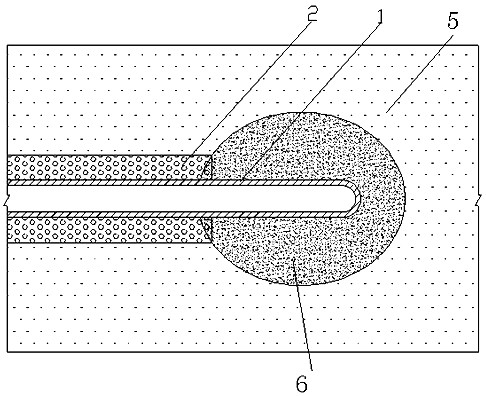

Cryoablation probe shell covered by expandable hydrogel and preparation method thereof

ActiveCN101999931ALowering the freezing pointPrevent Freezing InjuriesSurgical instruments for heatingCoatingsNormal tissueBiomedical engineering

The invention discloses a cryoablation probe shell covered by expandable hydrogel and a preparation method thereof. The cryoablation probe shell is characterized by comprising a cryoablation probe shell made of metal and a hydrogel coating covering the probe shell, wherein the cryoablation probe shell comprises integrated working section and non-working section; the hydrogel coating is uniformly coated on the non-working section of the cryoablation probe shell, and the thickness of the hydrogel coating is 50 mu m to 500 mu m. The hydrogel coating comprises degradable porous hydrophilic hydrogel and absorbs water to rapidly expand to form a hydrogel isolating membrane to isolate the cryoablation probe from normal tissue, and plays the function of protecting the normal tissue of a non-target area.

Owner:ACCUTARGET MEDIPHARMA (SHANGHAI) CO LTD

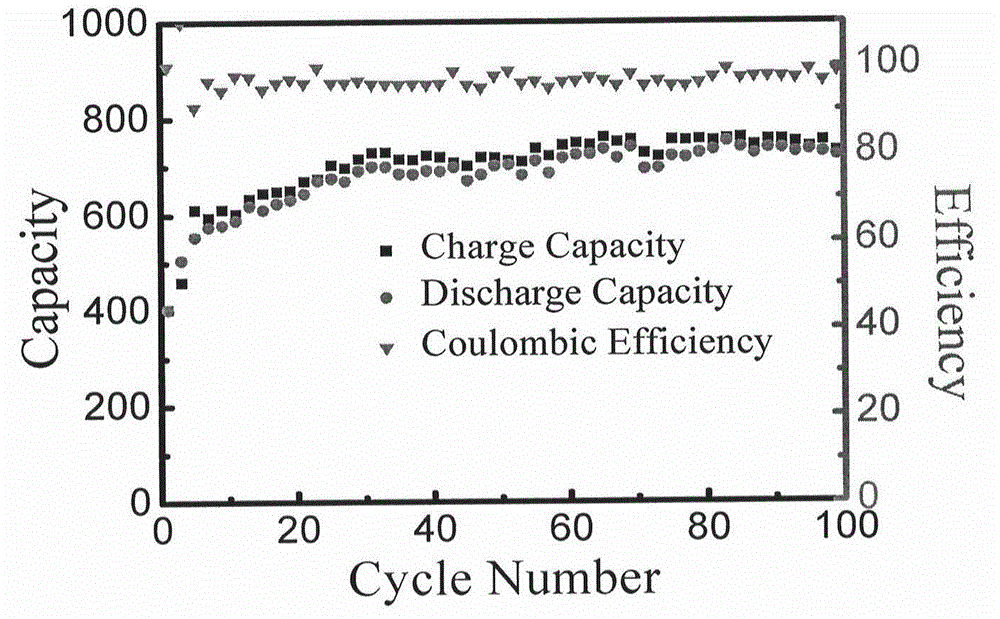

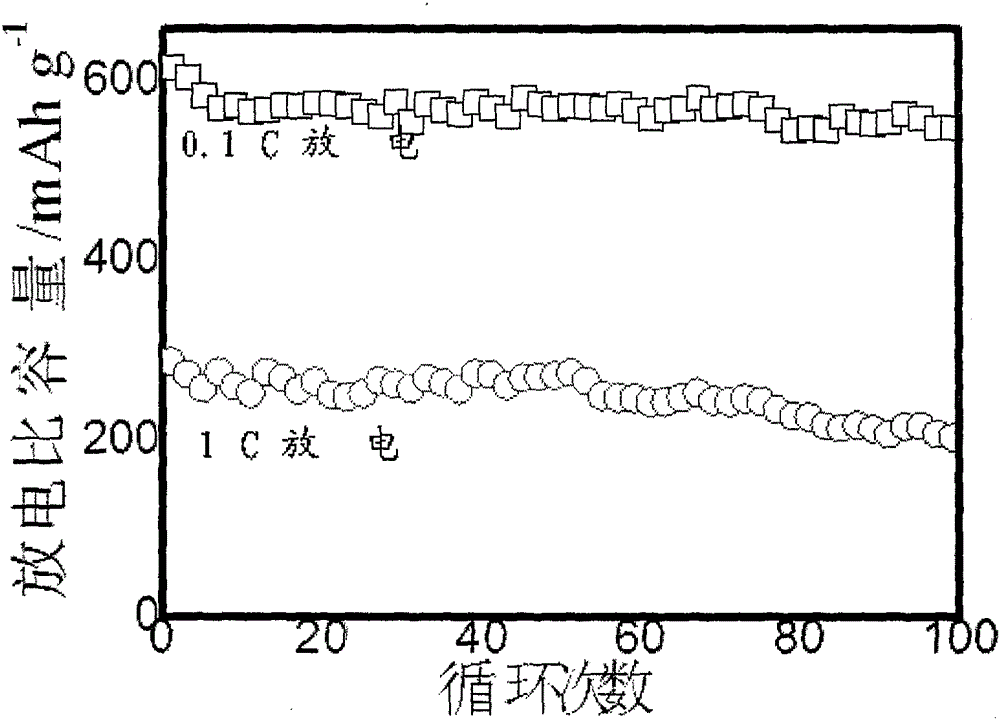

Preparation method for polymer/hollow sulfur composite electrode material

InactiveCN105024054ASimple processEasy to operateCell electrodesLi-accumulatorsCopper saltEnvironmental chemistry

The invention relates to a preparation method for a polymer / hollow sulfur composite electrode material. According to the method, the polymer / sulfur composite electrode material is obtained by taking a molecular sieve with high specific surface area as a carrier, depositing an organic salt, carrying out high-temperature sintering, reduction, sulfur deposition and polymerization and removing the molecular sieve, wherein the molecular sieve is one of SBA-15, MCM-41, KIT-1 and MSU-1; the organic salt is one of an organic copper salt, an organic silver salt, an organic iron salt and an organic nickel salt which can be dissolved in alcohol; the polymer is one of polyaniline, polypyrrole, polythiophene and polyacetylene; and sulfur accounts for 70-90 percent of the total mass of the polymer / hollow sulfur composite electrode material, the polymer accounts for 3-10 percent of the total mass of the polymer / hollow sulfur composite electrode material, and metal accounts for 7-20 percent of the total mass of the polymer / hollow sulfur composite electrode material. When used for the cathode of a lithium-sulfur battery, the polymer / hollow sulfur composite electrode material prepared according to the method has high specific capacity and excellent cycle performance, and has good application prospect in the battery field.

Owner:CHINA JILIANG UNIV

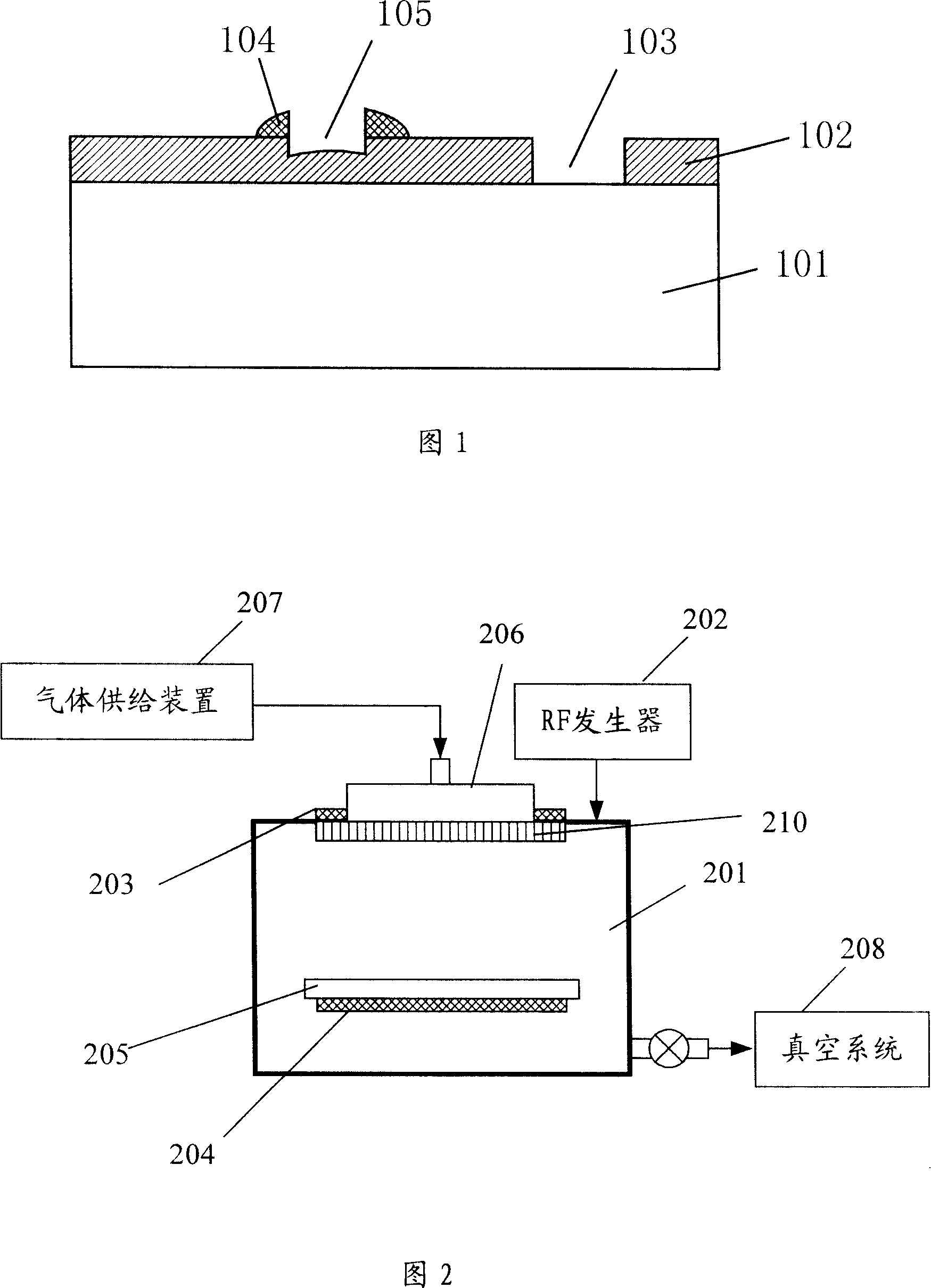

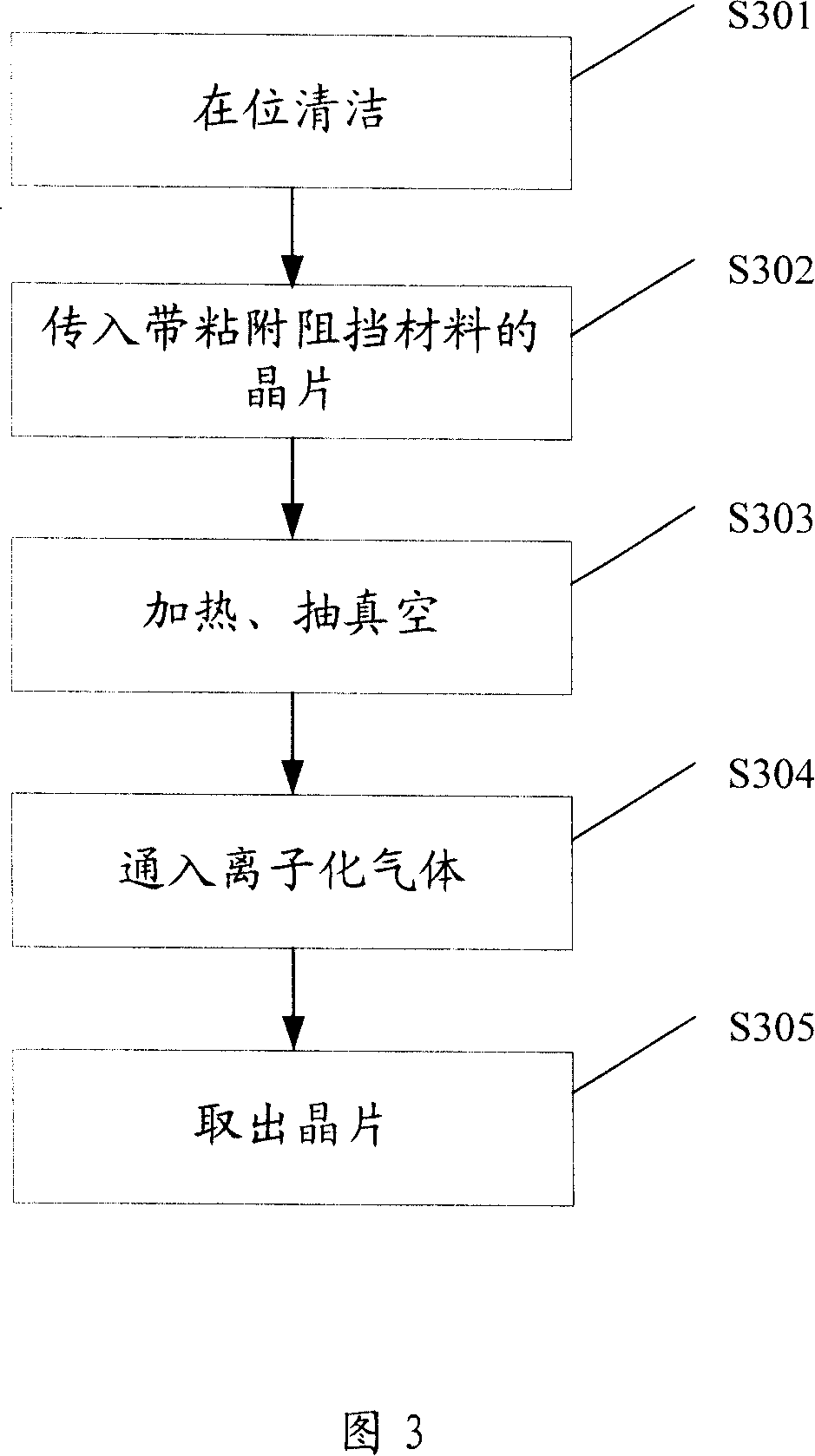

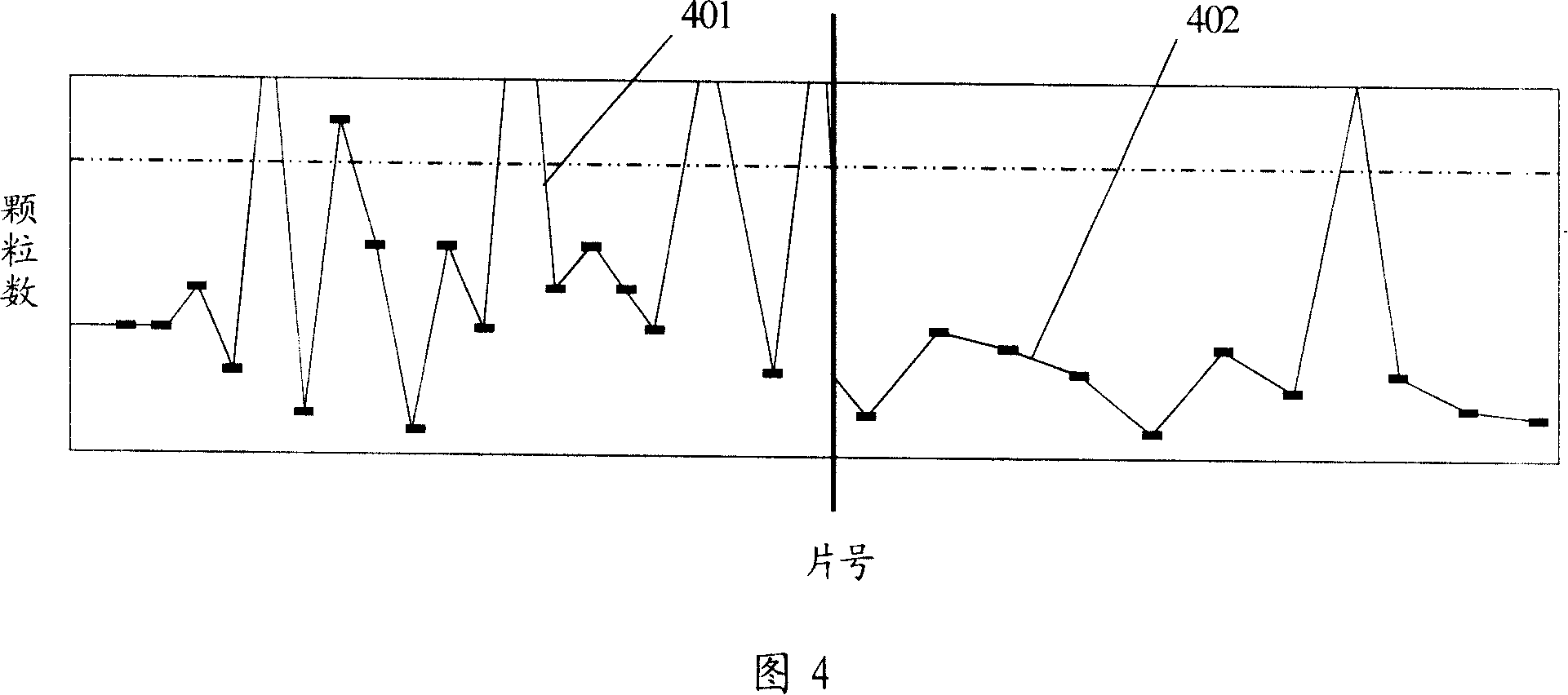

Technique for reducing particle in reaction chamber

InactiveCN101154559AStop sheddingReduce the amount of pollutionSemiconductor/solid-state device manufacturingChemical vapor deposition coatingBlocking layerReaction chamber

The invention discloses a process for reducing particles in reaction chamber, which includes the following steps that: at least one piece of wafer with the surface containing adhering blocking material is sent to the reaction chamber; the reaction chamber undergoes heating and vacuum treatment; the wafer undergoes plasma treatment; the wafer is taken out. The invention can form an adhering blocking layer in the reaction chamber by the method, and reduces the quantity of the particles dropping off in the reaction chamber, which solves the particle pollution problem occurring in the process of production and operation of the prior reaction chamber.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

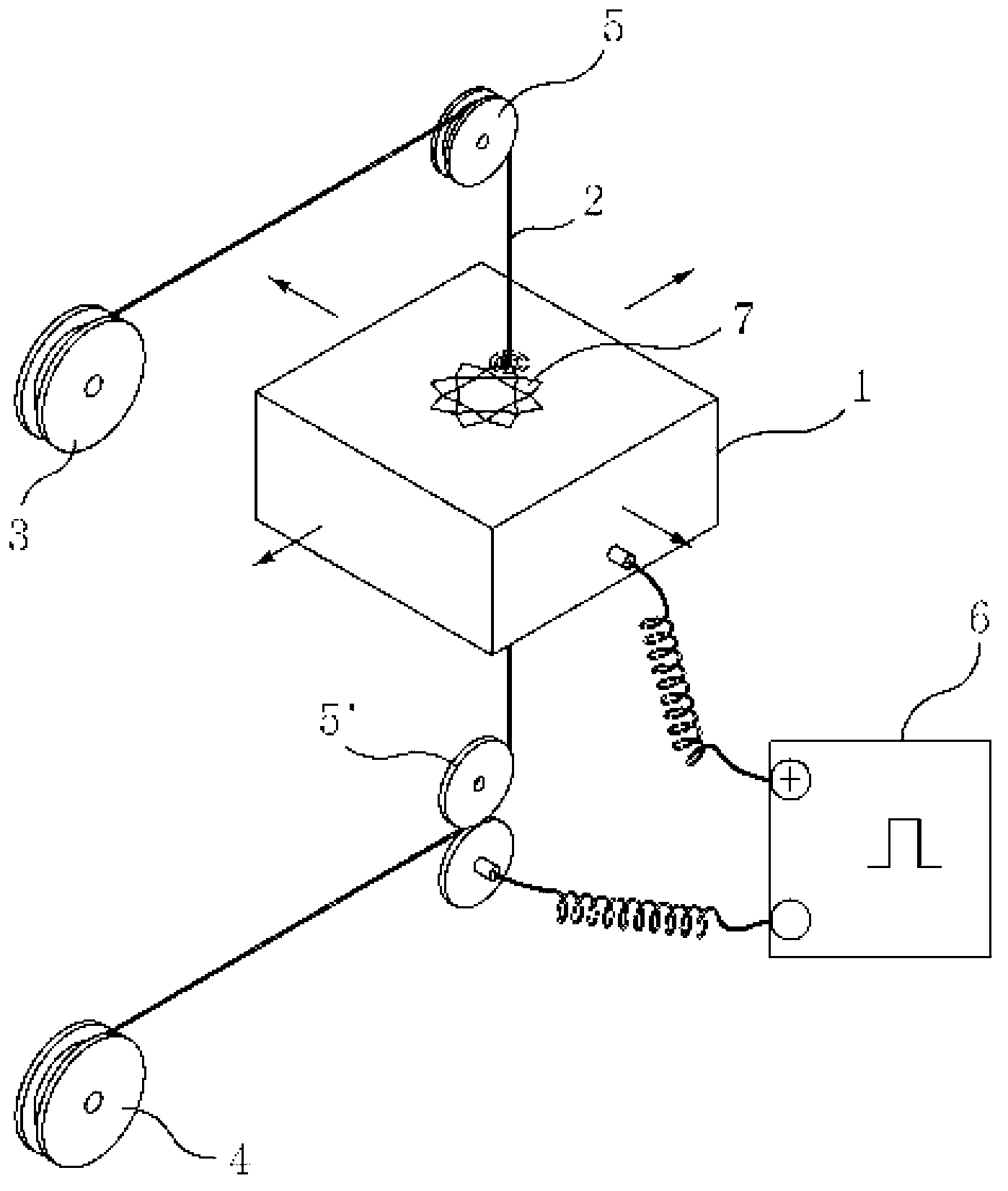

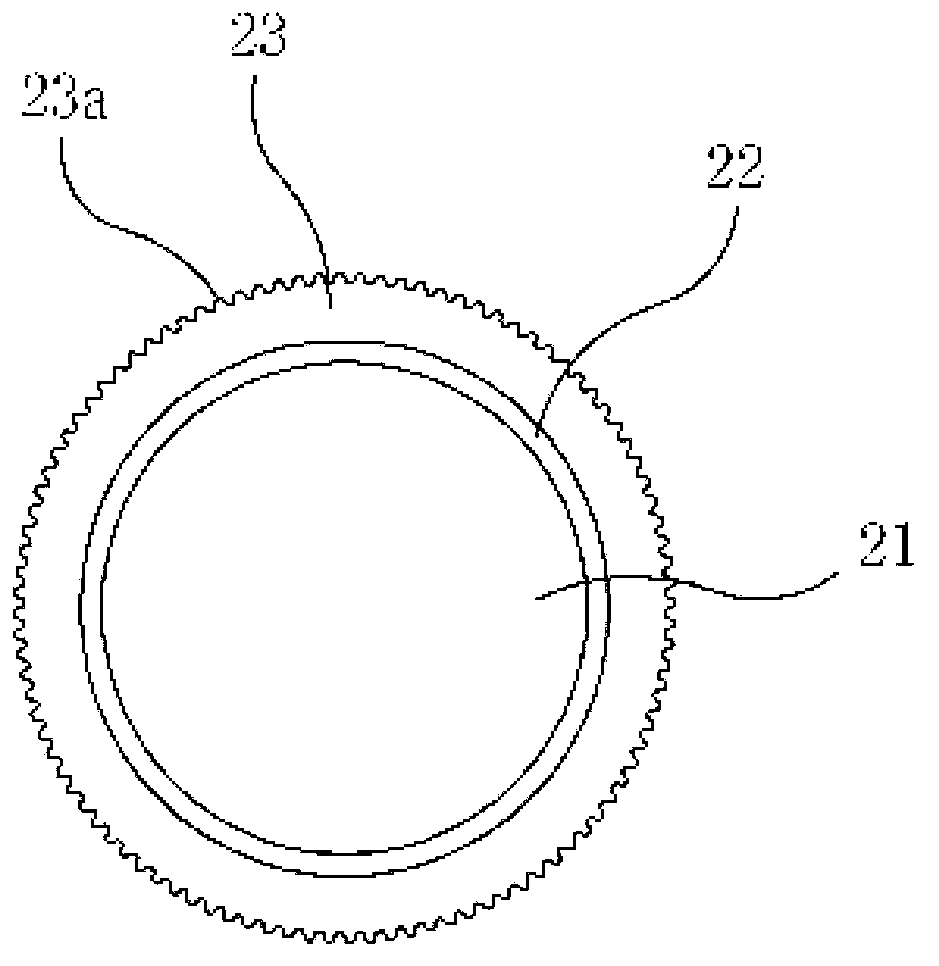

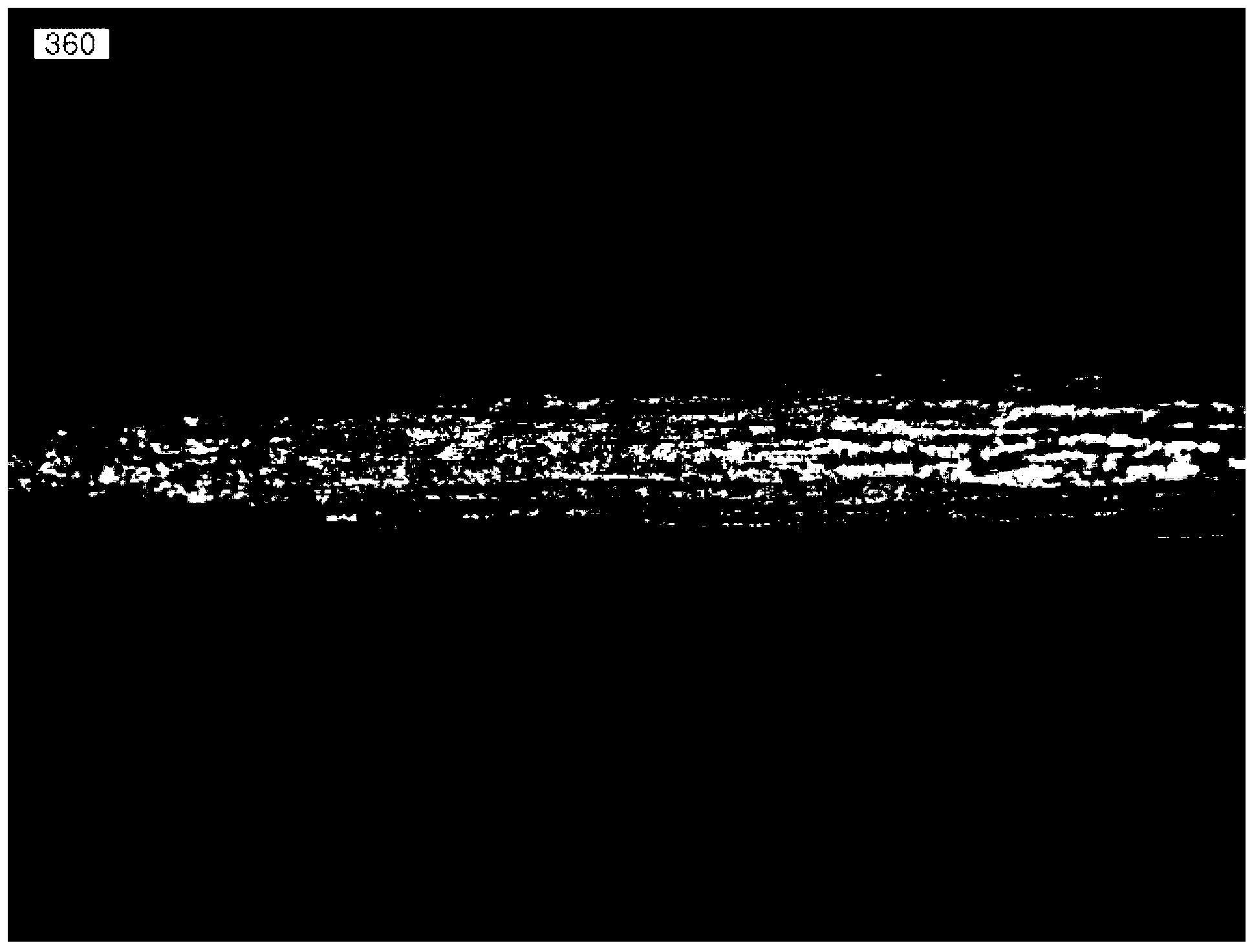

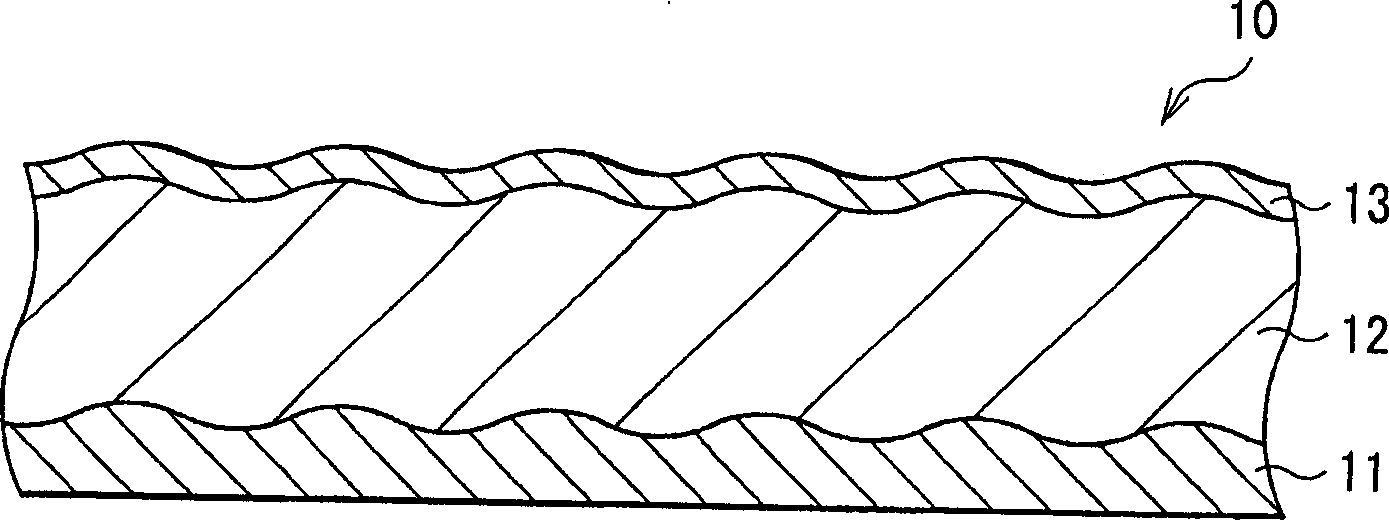

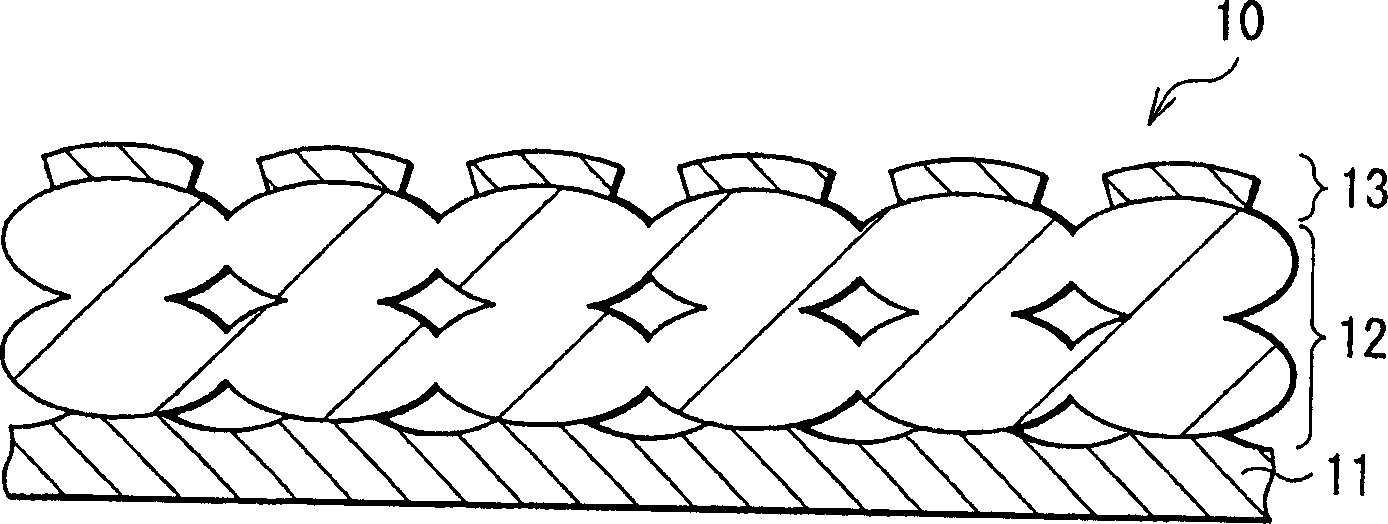

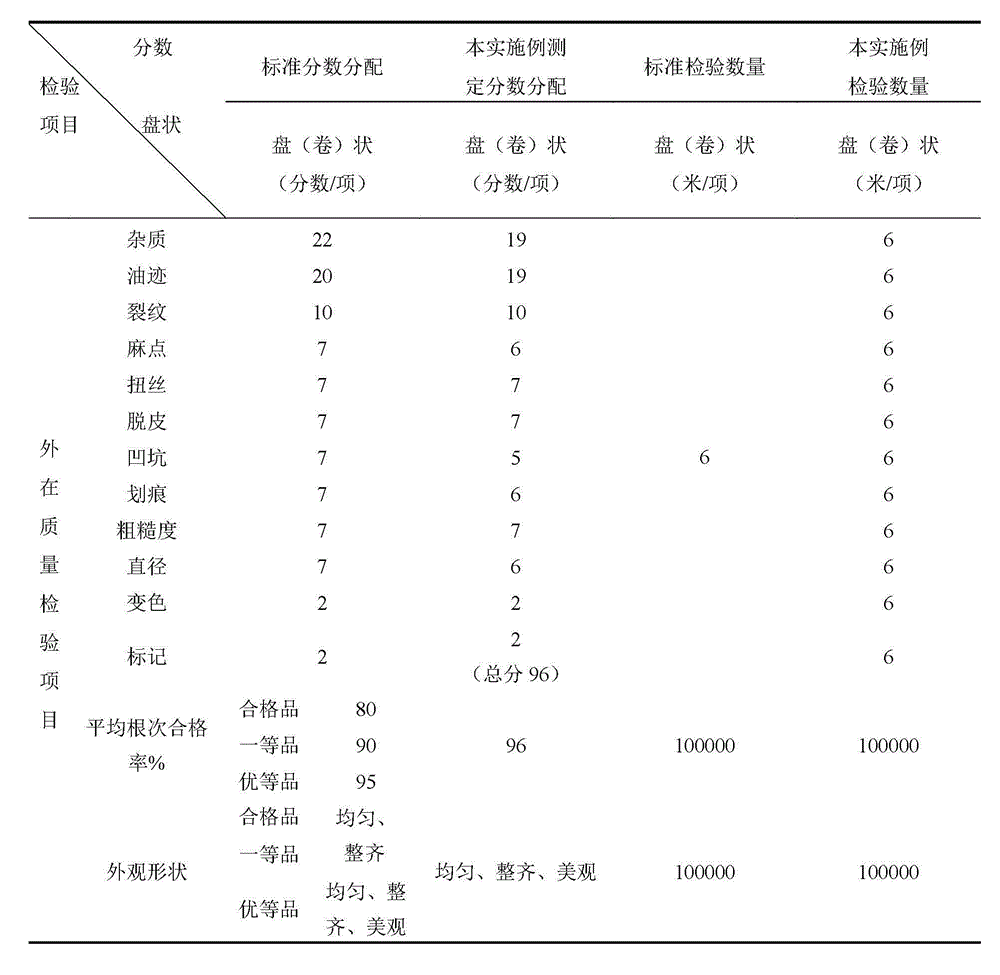

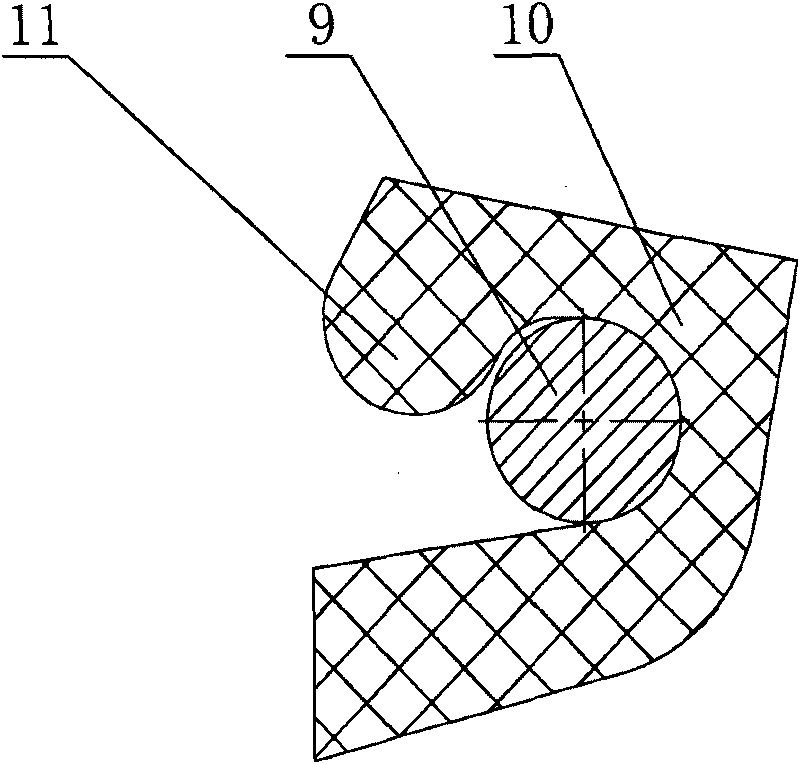

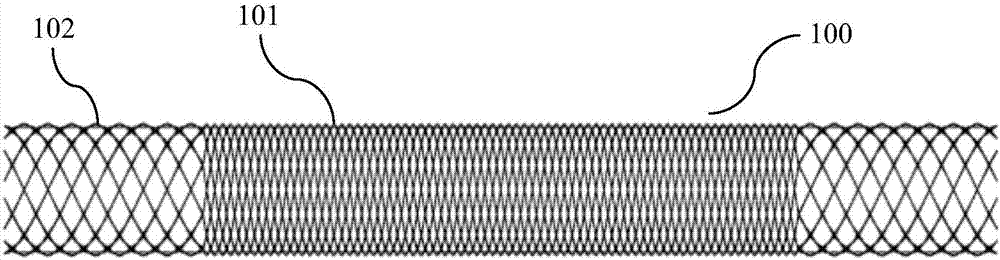

Electrode wire for electro-discharge machining and method for manufacturing the same

ActiveCN102922065ANo crackStop sheddingElectrical-based machining electrodesSuperimposed coating processSurface roughnessAlloy

Disclosed are an electrode wire (2) for electro-discharge machining and a method for manufacturing the same, which reduce micro-particles generated when an electrode wire is subject to the electro-discharge machining and improving the machining speed and the surface roughness of a workpiece. The method includes preparing a wire rod, which includes a first metal (21) and has a first diameter, as a core wire, plating a second metal (23) on the core wire, performing a fine wire process for the core wire plated with the second metal so that the core wire has a second diameter, while forming a corrugation (23a, 24a) having a predetermined pattern on a surface of the core wire having a second diameter, and performing a heat treatment process to form a first alloy layer at a boundary surface between the core wire and the second metal through a mutual diffusion between the core wire and the second metal, and to form a second alloy layer at an outer portion of the first alloy layer through diffusion of the first metal toward the second metal.

Owner:欧佩克梅德美国有限责任公司

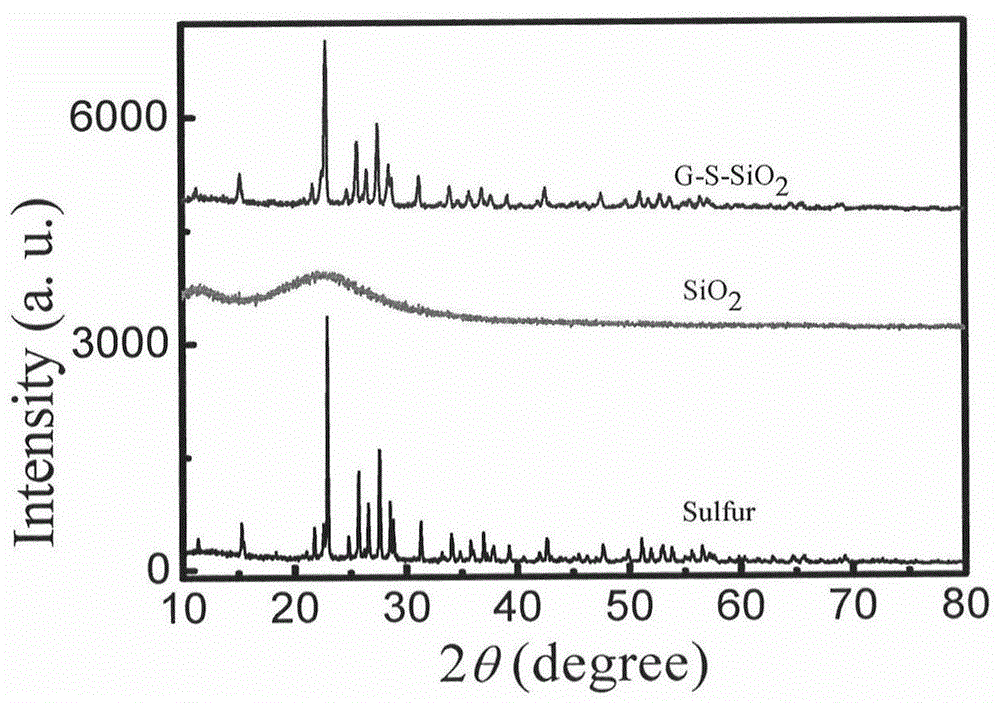

Preparation method of sulfur/carbon/oxide combined electrode material

InactiveCN105006553ASimple processEasy to operateCell electrodesLi-accumulatorsIron(II) oxideCarbon nanotube

The invention relates to a preparation method of a sulfur / carbon / oxide combined electrode material. The preparation method comprises depositing sulfur and oxide on a carbon material as a carrier with excellent performances to obtain the sulfur / carbon / oxide combined electrode material. The carbon material is one of graphene, CMK-3, carbon nanotubes and carbon black. The oxide is one of silica, copper oxide, silver oxide, nickel oxide, ferrous oxide, tin oxide and titanium oxide. The sulfur / carbon / oxide combined electrode material comprises 50-90wt% of sulfur, 5-20wt% of carbon and 5-30wt% of the oxide. Through control of acid types and pH, and organic solvent types and properties, the sulfur / carbon / oxide combined electrode material with fine particles and high coating uniformity is obtained. The sulfur / carbon / oxide combined electrode material as a lithium-sulfur battery positive pole material has high specific capacity and excellent cycling properties and has a good application prospect in the field of batteries.

Owner:CHINA JILIANG UNIV

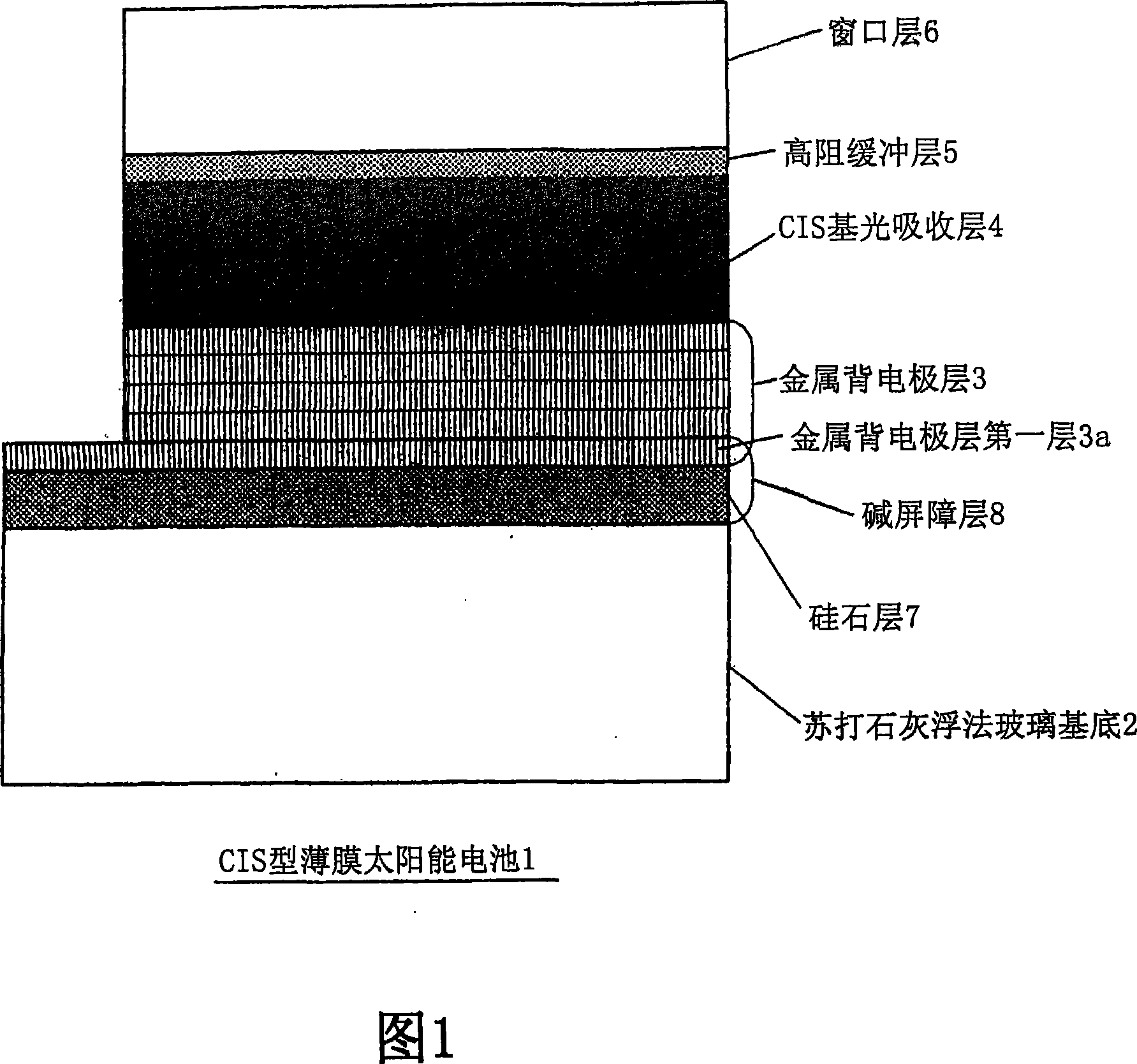

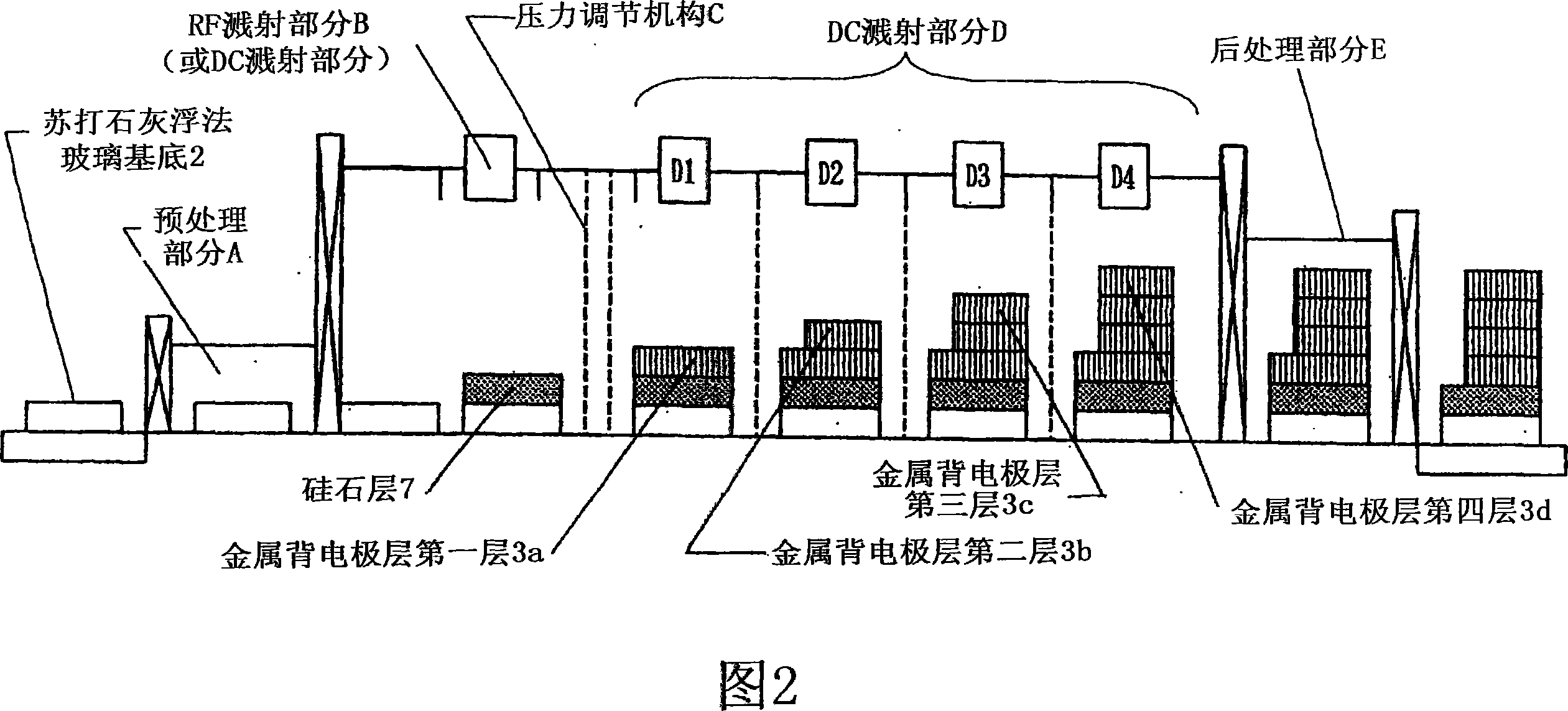

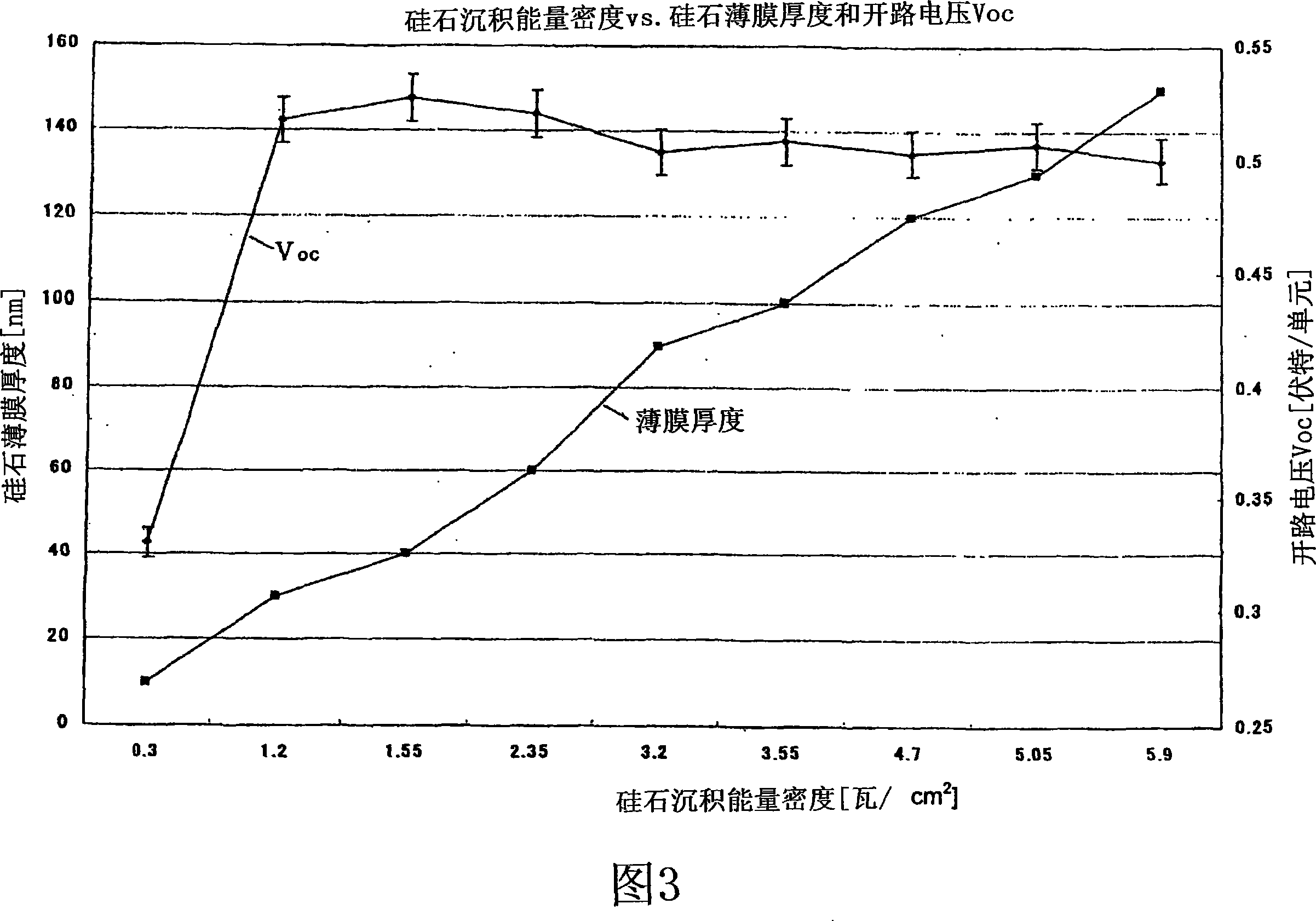

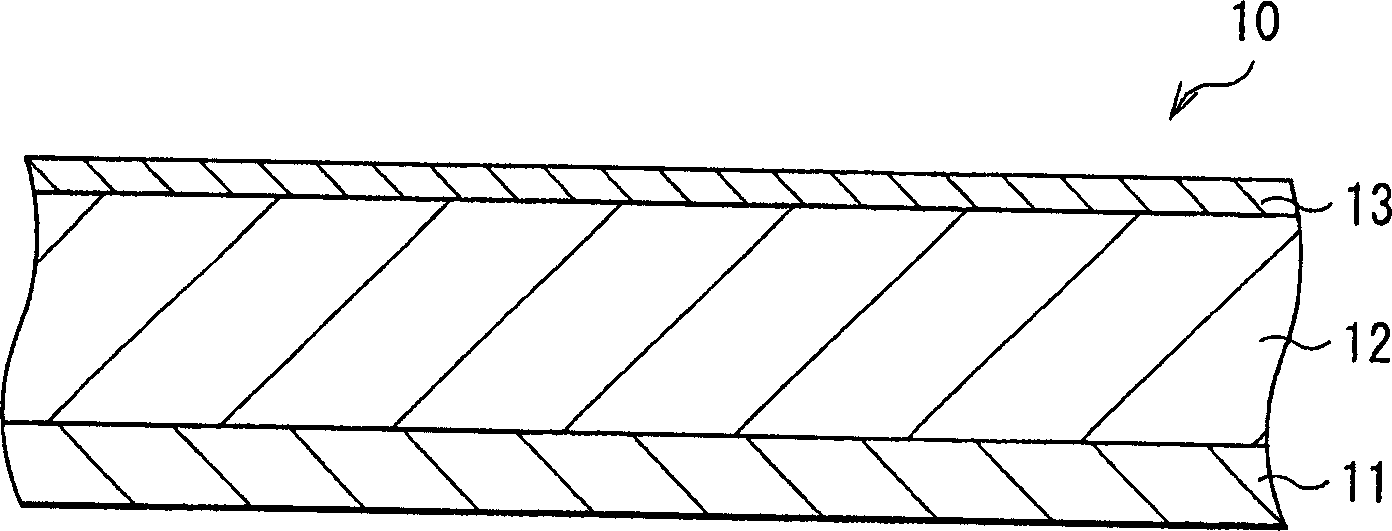

Cis-based thin film solar battery and process for producing the same

InactiveCN101076895AStop sheddingPrevent and control excess heat dissipationFinal product manufacturePhotovoltaic energy generationHigh resistanceSputtering

This invention provides a CIS-based thin film solar battery and a process for producing the same in which the formation of an alkali barrier layer and a metal backside electrode layer is carried out at a low cost in a short time to prevent such an unfavorable phenomenon that a light absorbing layer is separated from the interface of the light absorbing layer and the metal backside electrode layer. The CIS-based thin film solar battery (1) comprises a glass substrate (2), an alkali-free layer (7) such as silica, a metal backside electrode layer (3) having a laminate structure, a p-type CIS-based light absorbing layer (4), a high-resistance buffer layer (5), and an n-type window layer (6) stacked in that order. The layer (7), either alone or together with a first layer (3a) in the layer (3), can function as an alkali barrier layer (8) that can prevent and control the thermal diffusion of an alkali component into the light absorbing layer during the formation of the layer (4) from the substrate (2). In the layer (3a), crystal grains are fine and has high density. After the formation of the layer (7) on the substrate by RF or DC sputtering, the layer (3)is continuously formed on the layer (7) by DC sputtering.

Owner:太阳能先锋株式会社

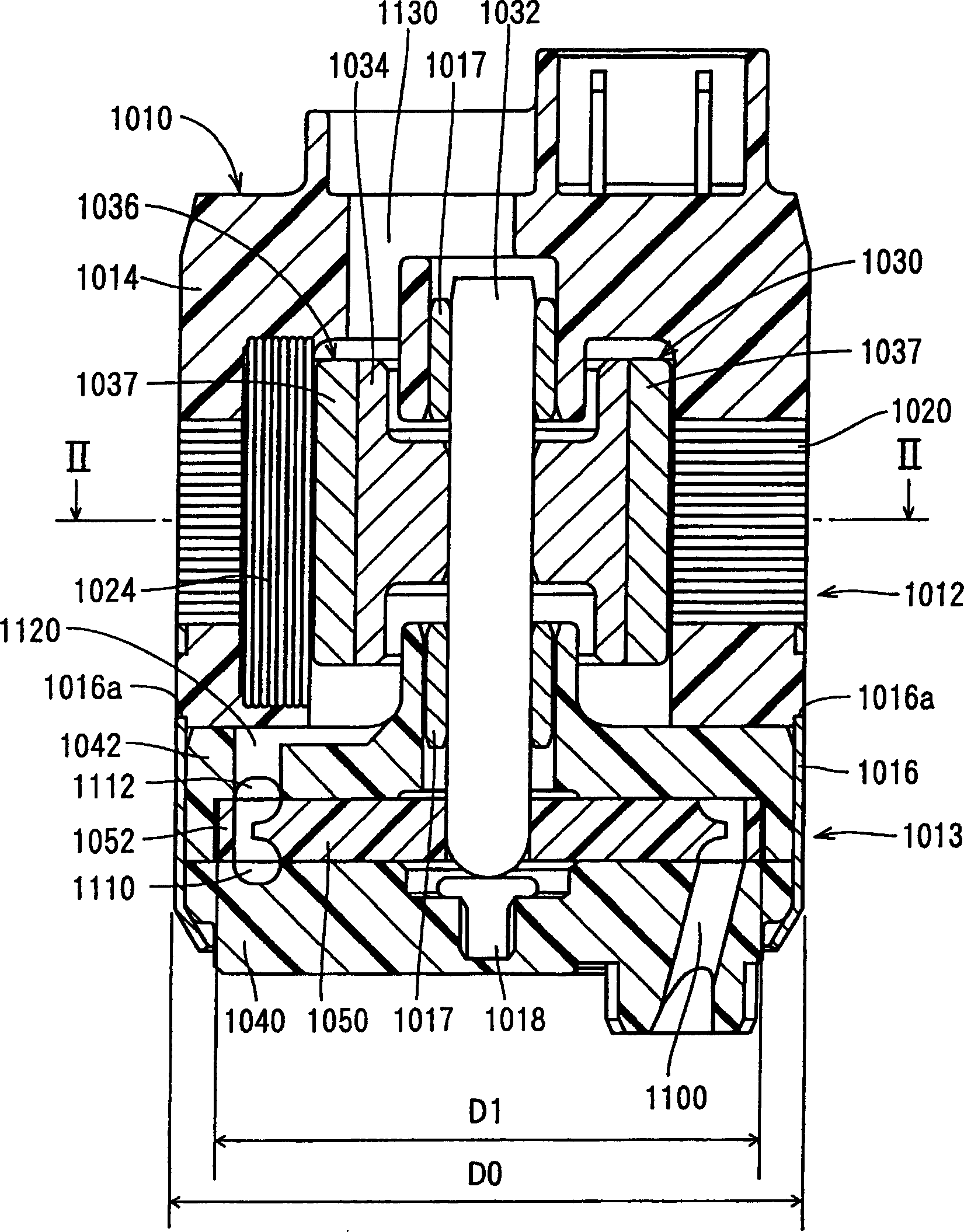

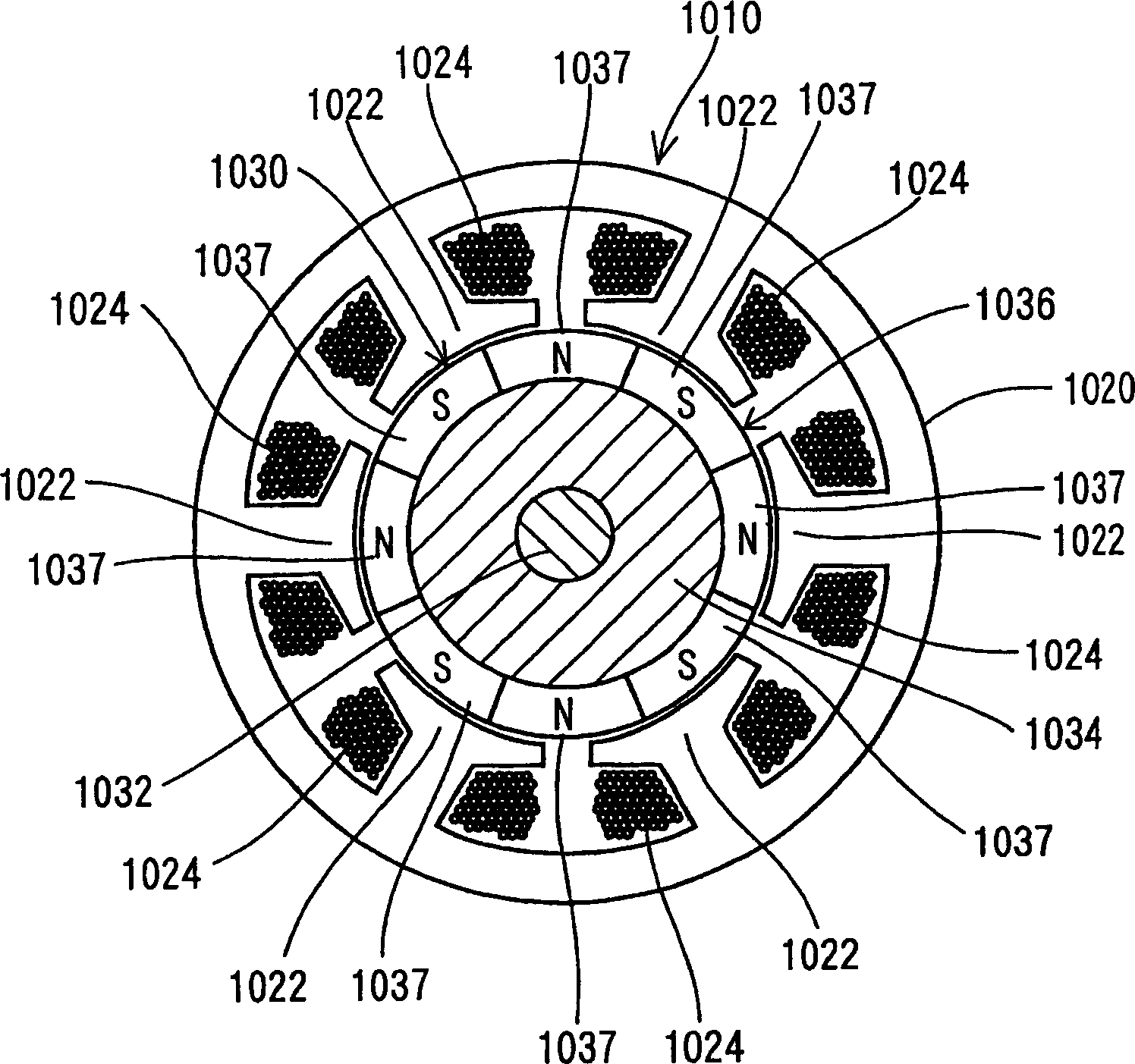

Fuel pump, fuel supply equipment using fuel pump and method for manufacturing fuel pump

ActiveCN1676915AEasy to wrapStop sheddingCircumferential flow pumpsTransverse flow pumpsElectricityBrushless motors

The fuel pump 1010 is installed in a fuel tank for a motorcycle. The fuel pump 1010 comprises a motor 1012 and a pump 1013 driven by the motor 1012 for pressurizing sucked fuel. The motor 1012 is a brushless motor, and has a stator 1020, coils 1024 and a rotor 1030. Current-passage to the coils 1024 wound around the stator core 1020 is controlled on the basis of a rotational position of the rotor, and thereby the rotor 1030 is rotated. The rotor 1030 has a shaft 1032, a rotary core 1034, and a permanent magnet 1036. The rotor 1030 is rotatably mounted on the inner circumstance of the stator core 1020. The permanent magnet 1036 is mounted on the outer circumference of the rotary core 1034, and magnetized so as to form magnetic poles different alternately in the rotation direction on the side of the outer circumferential surface facing to the stator core 1020.

Owner:DENSO CORP

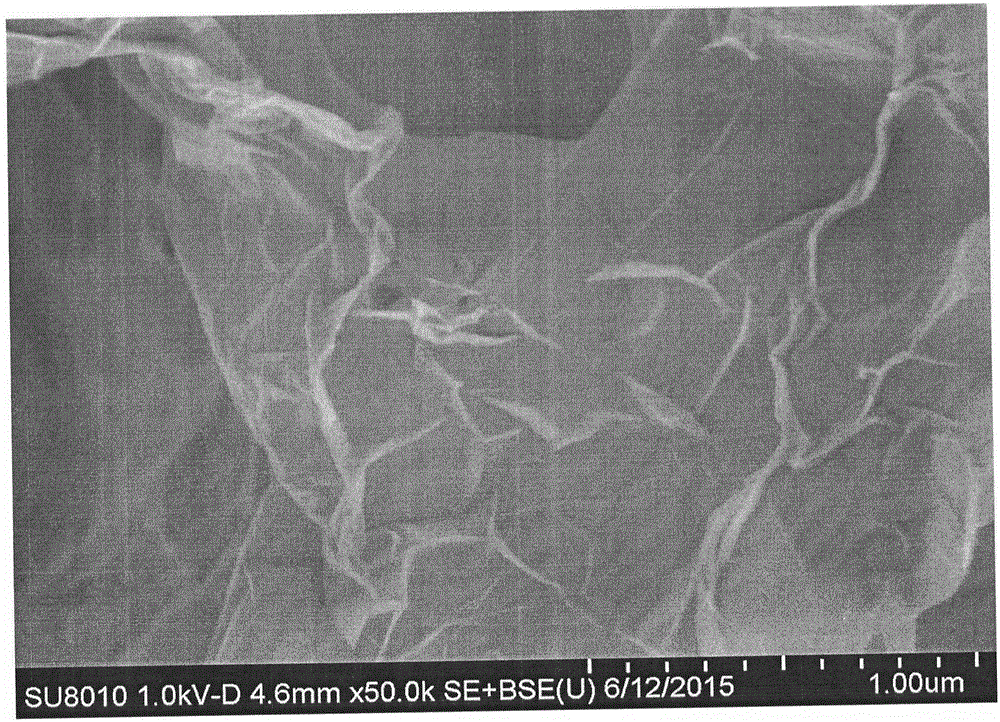

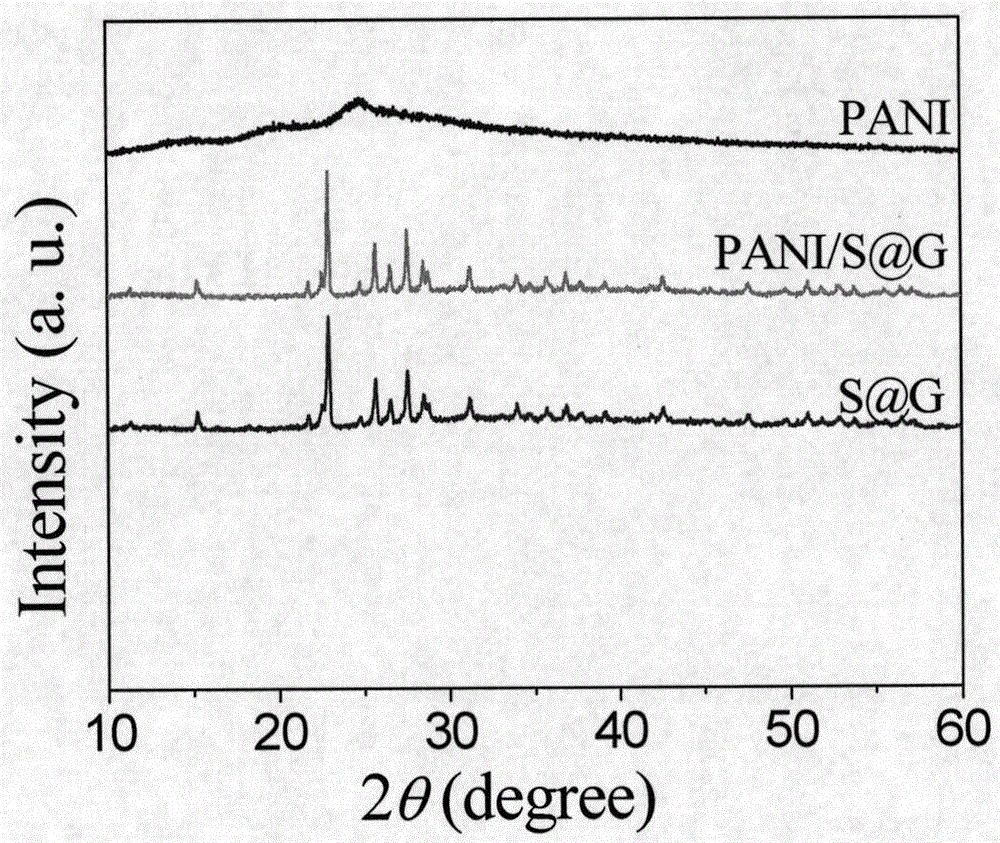

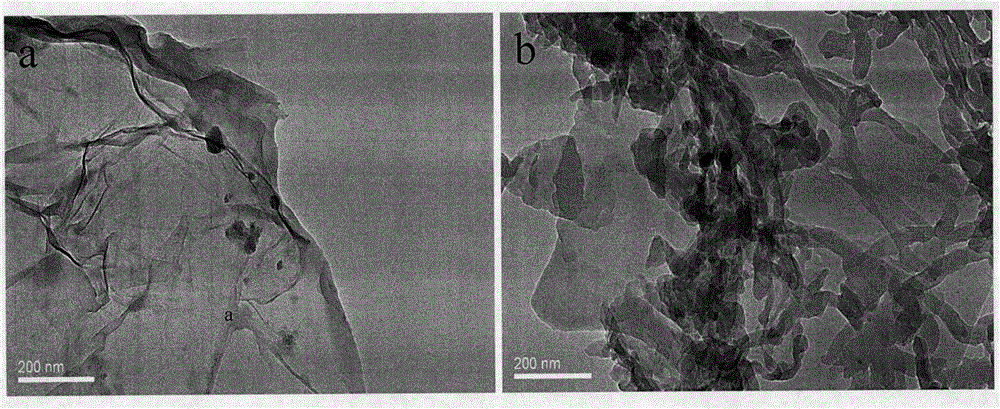

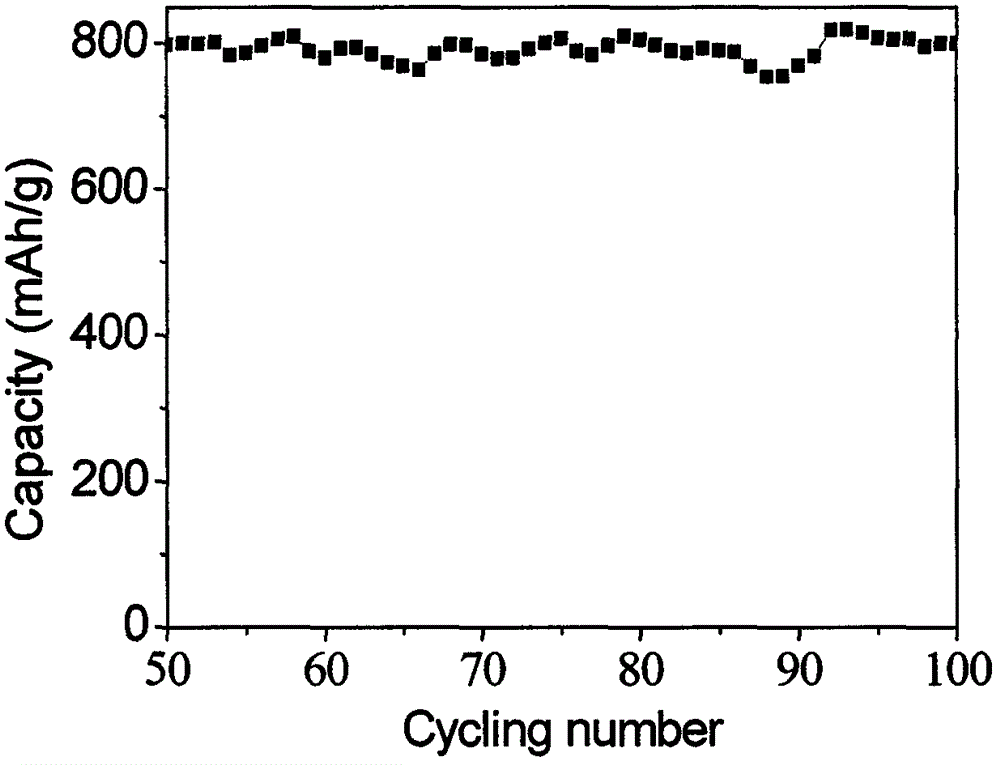

Method for preparing polyaniline/sulfur/graphene composite material

InactiveCN104600268ASimple processEasy to operateElectrode manufacturing processesOrganic acidOrganic solvent

The invention relates to a method for preparing a polyaniline / sulfur / graphene composite material. The method comprises the following steps: taking graphene as a carrier, and enabling sodium thiosulfate to react with an organic acid, so that the sulfur particles are loaded to the surface of the graphene; and performing aniline polymerization encapsulation, thereby obtaining the polyaniline / sulfur / graphene composite material. The types of organic acids, the molar ratio of the organic acids to sodium thiosulfate, the types of organic solvents and the like are regulated, and the polyaniline / sulfur / graphene composite material which is fine in particles and uniform in encapsulation is obtained. When the composite material is used for the positive pole of a lithium sulfur battery, the composite material has high specific capacity and excellent cycle performance and has excellent application prospects in the field of batteries.

Owner:CHINA JILIANG UNIV

Electrode and battery using it

ActiveCN1677723AAvoid structural damageAvoid reactionElectrode thermal treatmentFinal product manufactureLithiumMetallic materials

An electrode and a battery using the same are provided to improve cycle properties by reducing damages in the structure of active materials caused by repeated expansion-and-shrinkage upon charge and discharge processes and also reducing the reactivity with electrolyte. The electrode comprises: a current collector comprising at least one selected from Cu, Ni, Ti, Fe and Cr; a layer of an active material mounted on the current collector, which comprises at least on selected from Si and Ge compounds; a film layer mounted on the active material layer, which comprises at least one Cu and Ni.

Owner:MURATA MFG CO LTD

Preparation method of tin alloy/silicon/carbon electrode material

InactiveCN105470480ASimple processEasy to operateCell electrodesSecondary cellsCarbon compositesPolypyrrole

The invention relates to a preparation method of a tin alloy / silicon / carbon electrode material. The method comprises the following steps: with a porous polymer as a carrier, depositing silicon oxide; mechanically mixing magnesium; carrying out high-temperature thermal reduction and acid treatment; filtering and drying the mixture; mechanically mixing a tin alloy; tabletting the mixture; and carrying out high-temperature sintering to obtain the tin alloy / silicon / carbon electrode material. The porous polymer is one of polyacetylene, polyacrylonitrile, polyaniline, polypyrrole and phenolic resin; the tin alloy is one of a nickel-tin alloy, a copper-tin alloy, an iron-tin alloy and a silver-tin alloy; the silicon source is one of tetraethoxysilane, silicon tetrachloride and trichlorosilane; an inner layer of the tin alloy / silicon / carbon electrode material is carbon and silicon in a porous structure; and an outer layer is the tin alloy with good conductivity and stable structure. The electrode material has the advantages of high specific capacity and long cycle lifetime, and has a good application prospect in the field of batteries.

Owner:CHINA JILIANG UNIV

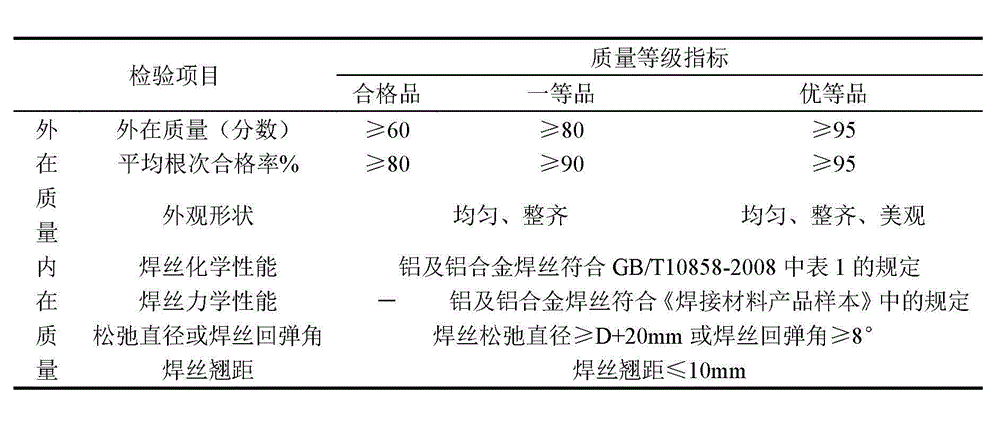

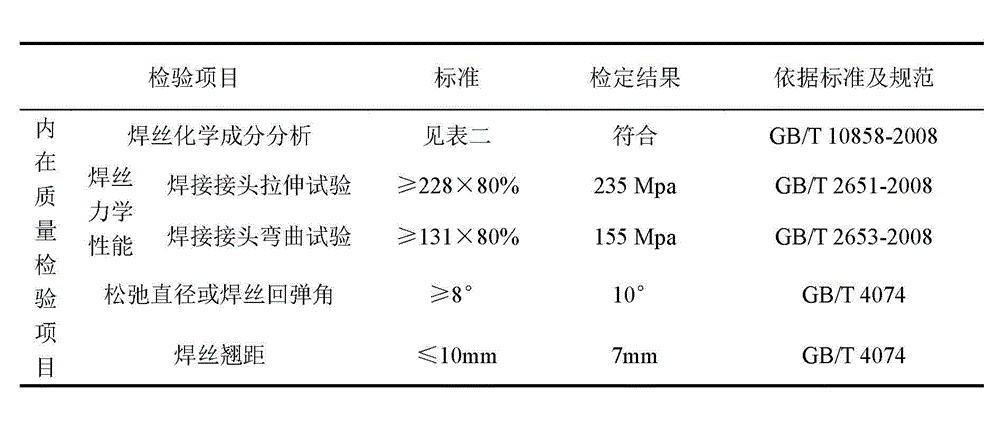

Preparation method of aluminum alloy welding wire

InactiveCN102941423AReduce problemsGrain refinementWelding/cutting media/materialsSoldering mediaWire rodLight treatment

The invention discloses a preparation method of an aluminum alloy welding wire, and belongs to the technical field of aluminum alloy. The preparation method of a high-performance aluminum alloy welding wire comprises the following steps of: (1) coldly and continuously rolling; (2) drawing; (3) shaving; (4) drawing a water tank; (5) carrying out light treatment; (6) cleaning by an ultrasonic wave, and (7) drying by hot air. The preparation method has the characteristics that a partial drawing procedure is replaced by a cold continuous rolling manner, and an aluminum alloy steel wire rod is subsequently processed after being rolled to have specific wire diameter once. Therefore, the drawing passes are reduced; the annealing passes are also reduced; the automation capability of the production process is improved; the utilization rate of the material is greatly improved; the production loss and the labor intensity are reduced; personnel quota is reduced; the production cost is reduced; the shaving procedure is carried out after the traditional water tank is drawn; the procedure is adjusted into the process of firstly shaving and then drawing the water tank; the welding wire is shaved when the wire diameter is large; an oxide skin at the surface of the welding wire is removed early; the welding wire is not easily broken due to high strength when the wire diameter is large; and the quality of the surface of the welding wire and the stability of the quality are greatly improved.

Owner:NO 52 INST OF CHINA NORTH IND GRP CORP

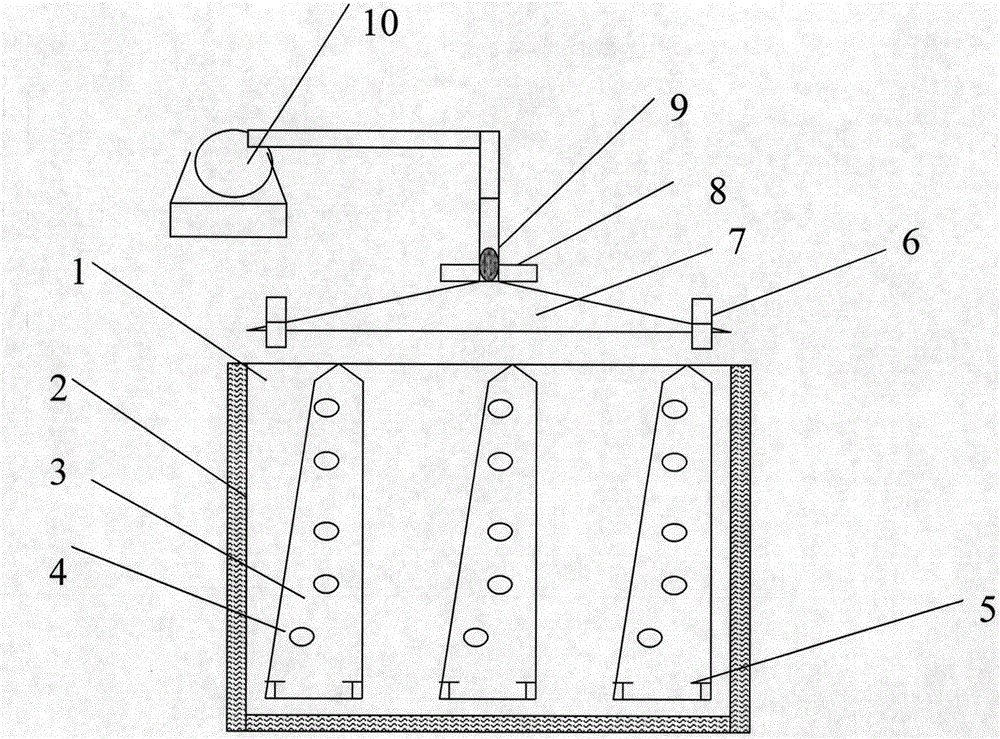

Preparation device and production method for sulfur electrode material

The invention relates to a preparation device and a production method for a sulfur electrode material. The sulfur electrode material preparation device comprises a mixer, a sulfur storage device, a heating system and a vacuum system, wherein the sulfur storage device is as high as the mixer body; a porous stainless steel tube is a trapezoidal stainless tube which is wide in bottom and narrow in top; holes which are 1-20 microns in hole diameter and 2-10 / square centimeters in hole count are symmetrically distributed in the surface of the stainless steel tube; the electrode material is a porous oxide electrode material dispersed with elemental sulfur; particles of the porous oxide electrode material are 10-500 nm; the porous oxide electrode material is one of hollow vanadium pentoxide nano powder, hollow nickel-cobalt-manganese-lithium oxide nano powder, hollow lithium manganate nano powder and hollow nickel-cobalt-lithium oxide nano powder; elemental sulfur accounts for 20-70% (in mass fraction) of the sulfur electrode material; 1-20% (in mass fraction) conductive polymer coats on the surface layer of the sulfur electrode material; the conductive polymer is one of polypyrrole, polyaniline, polythiophene and polyacrylonitrile. While being applied to a positive electrode of a lithium sulfur battery, the composite material has a high specific capacity and excellent circulating performance, and has a good application prospect in the battery field.

Owner:CHINA JILIANG UNIV

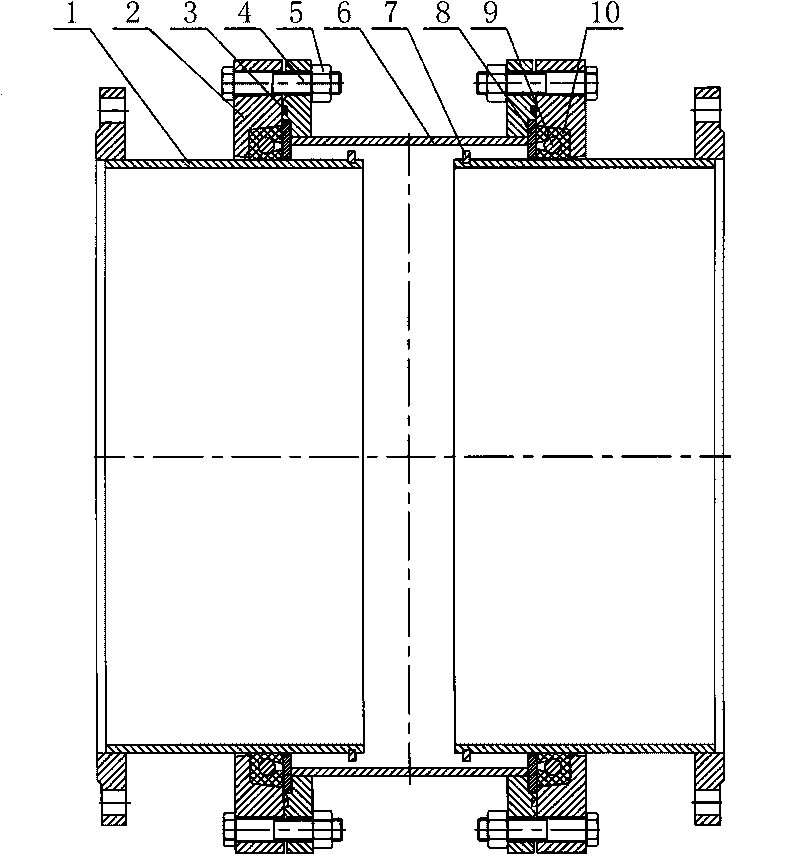

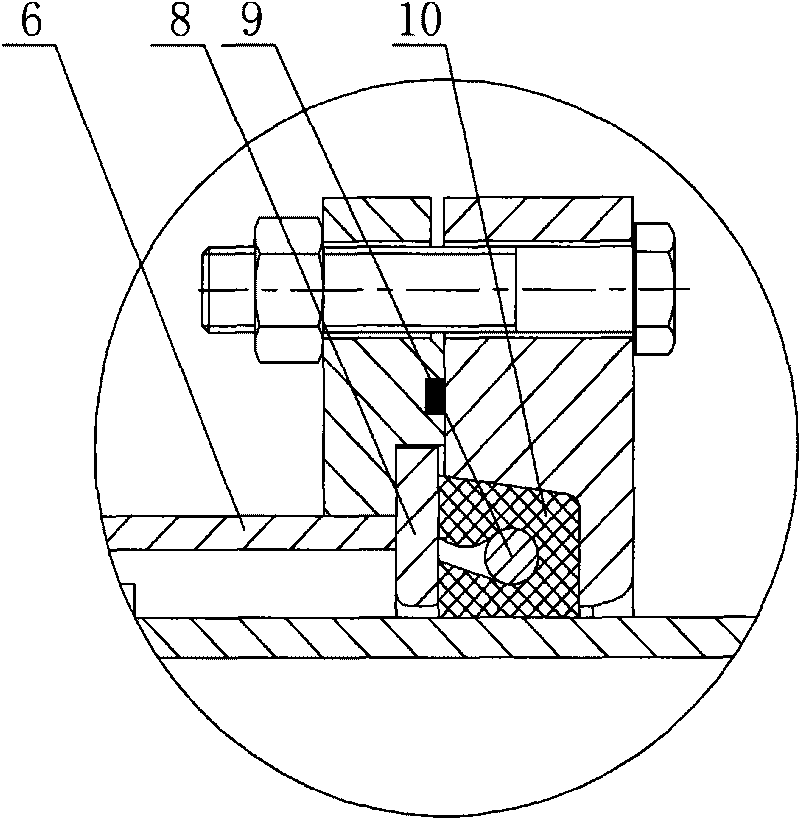

Large deflection loose tube compensation joint

InactiveCN101694257APrevent slippageStop sheddingPipeline expansion-compensationAdjustable jointsEngineeringLarge deflection

Disclosed is a large deflection loose tube compensation joint which comprises a cylindrical body. Two movable short pipes equipped with flanges pass through the inner portion of the body; connecting ends positioned on two sides of the body are respectively connected with pressure covers via bolts and screwed tightly via nuts, a circle of sealing strips are disposed on connecting surfaces of the body and the pressure covers; two retaining rings are respectively installed on the inner sides of two end surfaces of the body and sleeved on the outer sides of the short pipes, limit blocks are mounted on the short pipes; sealing rings mounted among the retaining rings and the pressure covers are U-shaped and embedded into rectangular grooves inside the pressure covers, the sealing rings contact with the outer walls of the short pipes, contacting surfaces of the sealing rings and the outer walls of the short pipes are cylindrical surfaces, O-shaped sealing strips are installed inside the sealing rings, projected lips are arranged on the inner surfaces of the upper portions of the sealing rings, the lips are capable of preventing the sealing strips from shedding off the sealing rings, thereby the sealing strips are capable of guaranteeing the sealing rings to produce continuous pre-tightening force on the outer walls of the short pipes and further ensuring tightness of the body and inner cavities of the short pipes.

Owner:WUXI JINYANG PIPING FITTING

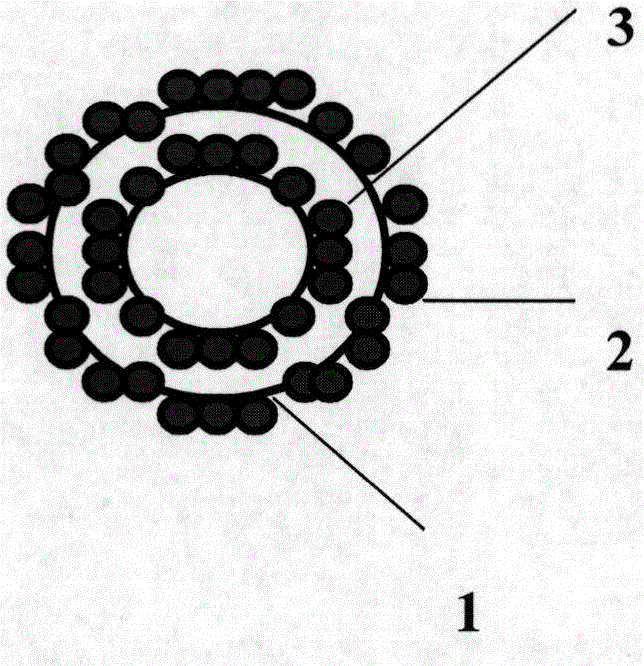

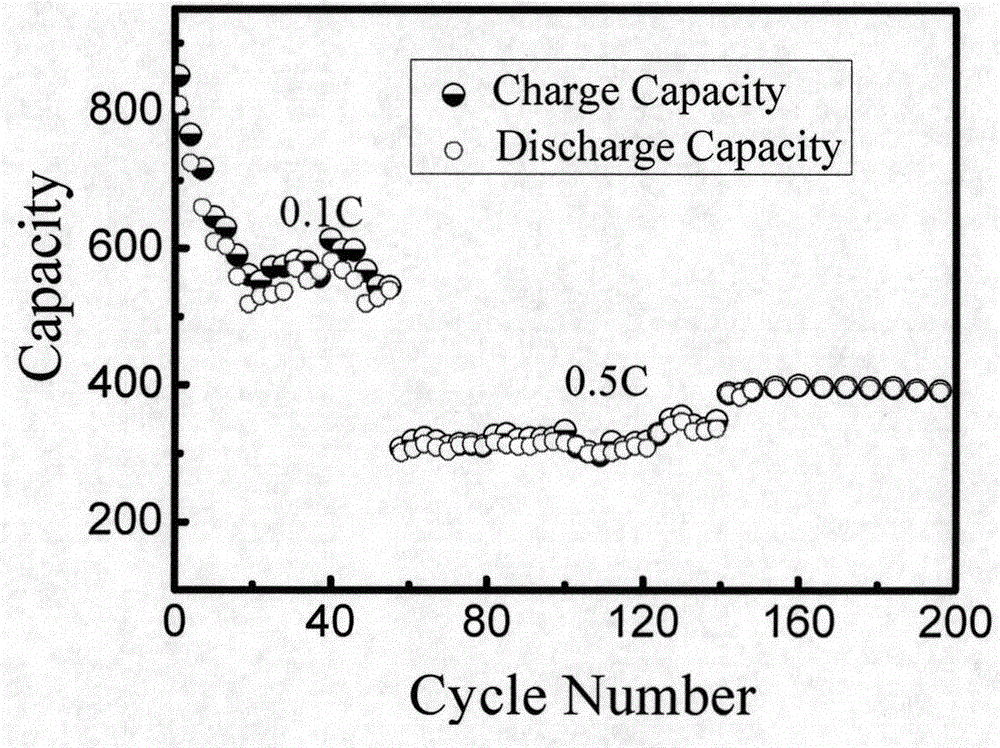

Preparation method of polyaniline/sulfur composite material with hollow core-shell structure

The invention relates to a preparation method of a polyaniline / sulfur composite material with a hollow core-shell structure. The composite material has the core-shell structure with 1-5 layers of polyaniline / sulfur. The preparation method comprises the following steps: by taking nano-silica as a template, coating nano-silica with polyaniline, depositing elemental sulfur, and depositing silicic acid; performing coating with polyaniline, depositing elemental sulfur, performing coating with polyaniline and repeating the operation; and finally removing silicon dioxide and silicic acid. The space between every two polyaniline / sulfur composite layers is controlled within 0-10nm; and the thickness of each polyaniline / sulfur composite layer is controlled within 1-20nm. When applied to the anode of a lithium-sulfur battery, the composite material has excellent cycle performance, namely, the discharge capacity of a0.5C lithium-sulfur battery is greater than 300mAh / g when the cycle number is 200; and the composite has a good application prospect in the field of batteries.

Owner:CHINA JILIANG UNIV

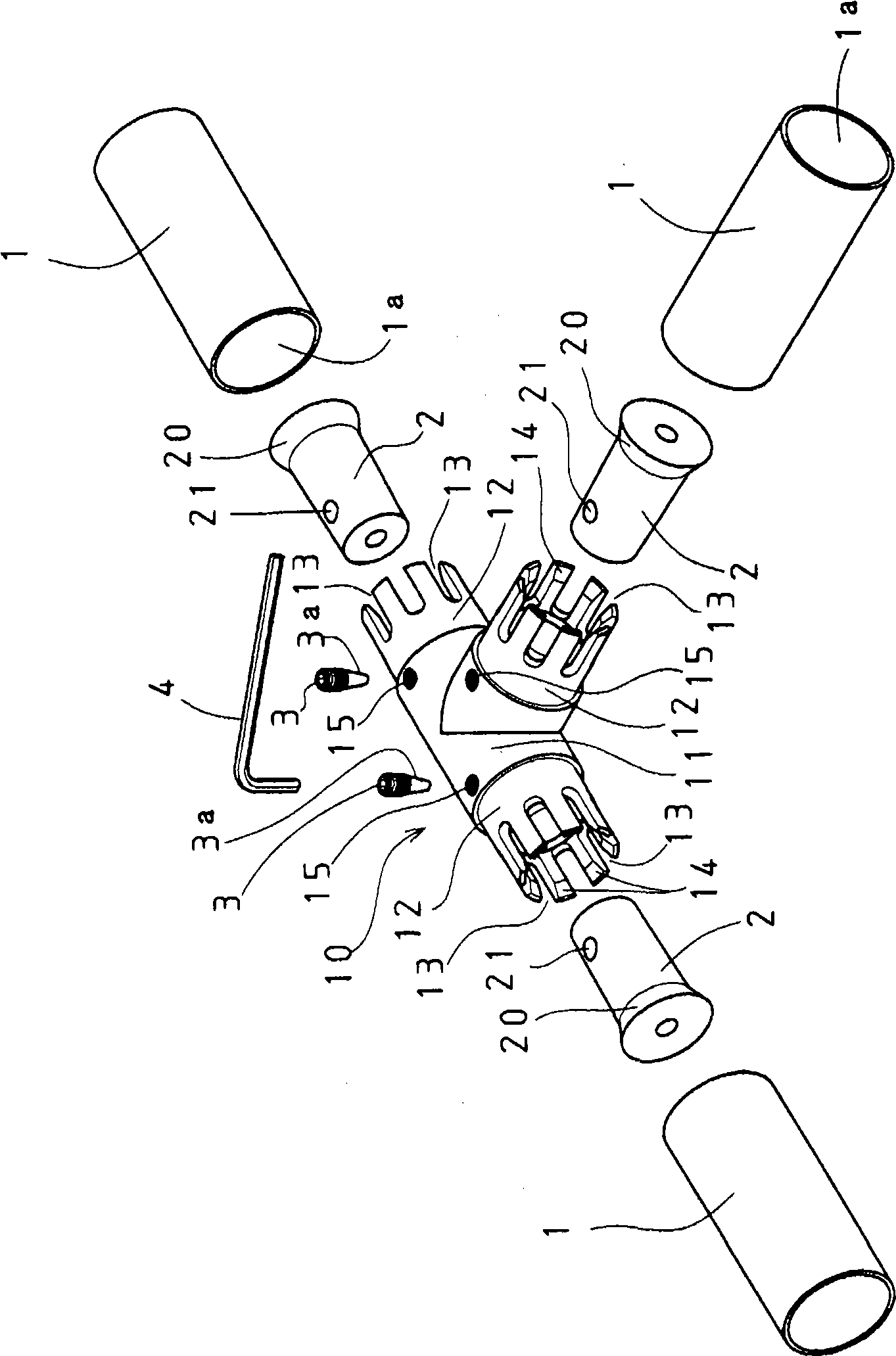

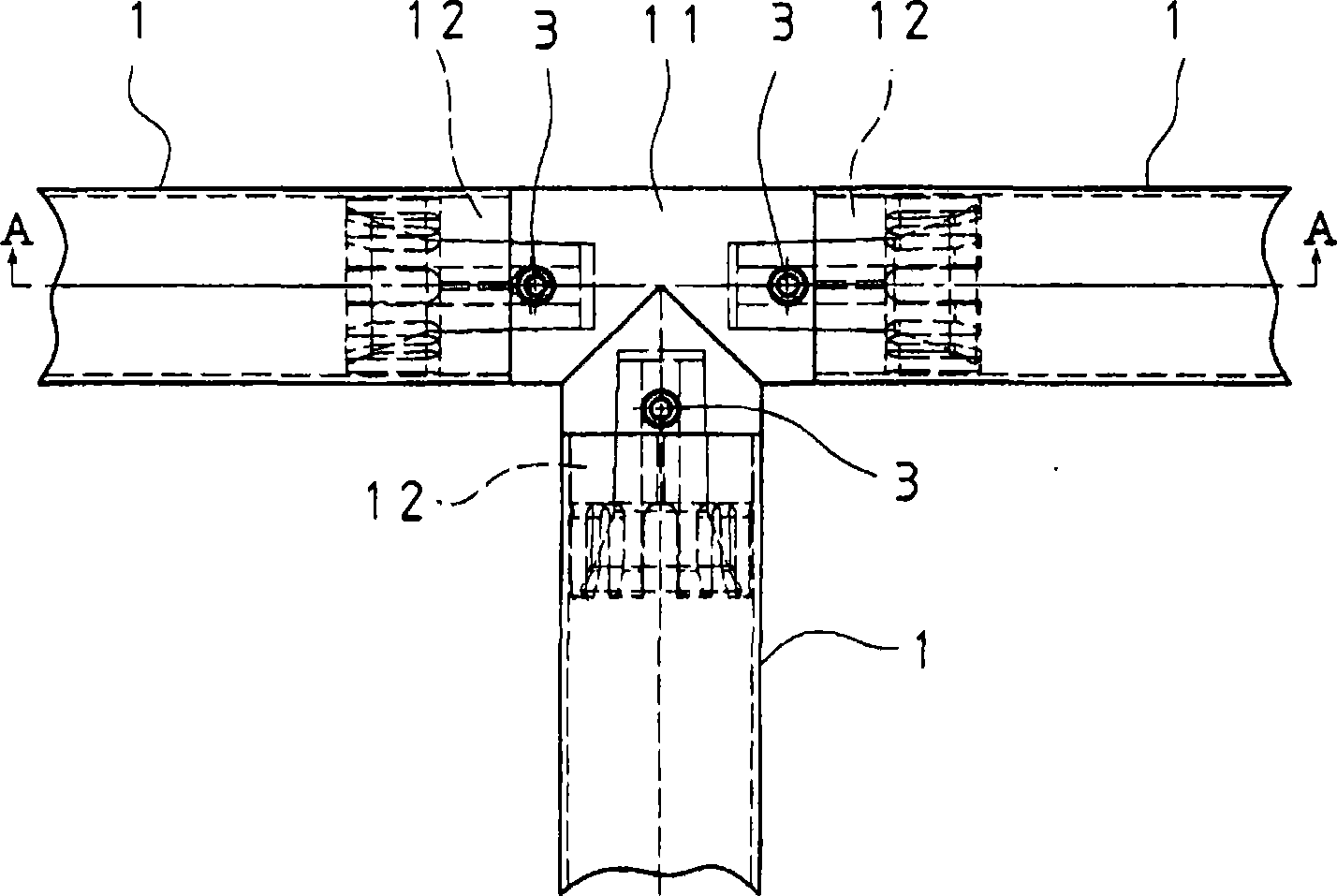

Pipe joint

InactiveCN101479485AReduce presenceExcellent designRod connectionsBuilding constructionsThin layerSynthetic resin

The invention provides a tube body for a light load, specifically, a fit in type joint suitable for connecting tube bodies to assemble them into a flat or a three-dimensional tube body structure, resin adhered / coated tube bodies each formed by adhering and coating a thin layer of a synthetic resin on the outer periphery of a thin wall steel tube having an outer diameter in a range from 28mm to 45mm. The fit in type joint is constructed from a joint body, tapered sleeves, and fixation bolts. The joint body has one or more connecting insertion sections formed in a hollow structure, projected from the joint body, and inserted into the bores of tube bodies that are to be connected, each insertion section having a plurality of axially long slits formed running from the forward end of the insertion section and arranged in the circumferential direction, each insertion section having a tapered section on the hollow section thereof, the tapered section having a bore diameter reduced from the forward end section of the insertion section toward the joint body. The tapered sleeves are inserted into the hollow sections of the insertion sections. The fixation bolts secure the tapered sections to the forward end sections.

Owner:YAZAKI IND CHEM CO LTD

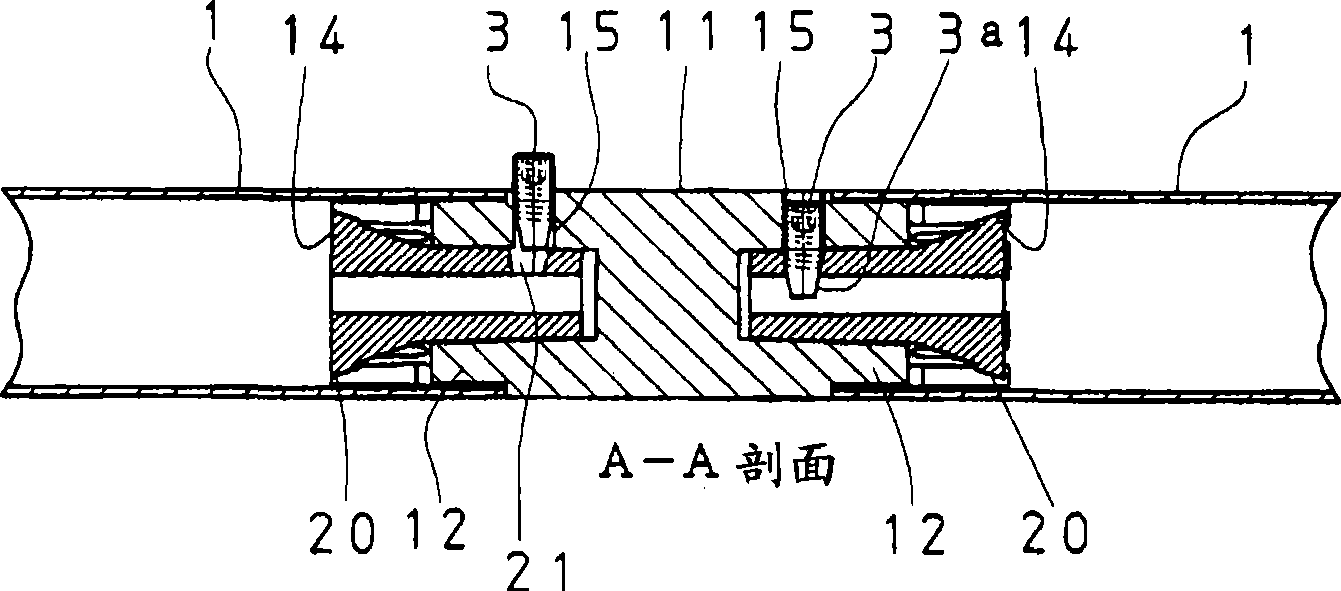

Preparation method of selenium composite electrode material

InactiveCN105161687ASimple processEasy to operatePositive electrodesNon-aqueous electrolyte accumulator electrodesSulfiteLithium

The invention relates to a preparation method of a selenium composite electrode material. The method comprises the steps that soluble sulfite and selenium are used as raw materials, selenosulfate is generates through a reaction, a carbon material with high specific surface area and electrical conductivity is used as a carrier, selenium and polymer are deposited, and the selenium composite electrode material is obtained; the selenium deposition speed can be controlled by controlling the alcoholic solution concentration, variety and dropping-in speed; the small-particle selenium composite electrode material coated evenly is obtained. When used for a positive electrode of a lithium selenium battery, the selenium composite electrode material has the high specific capacity and excellent circulation performance, and has the good application prospect in the battery field.

Owner:CHINA JILIANG UNIV

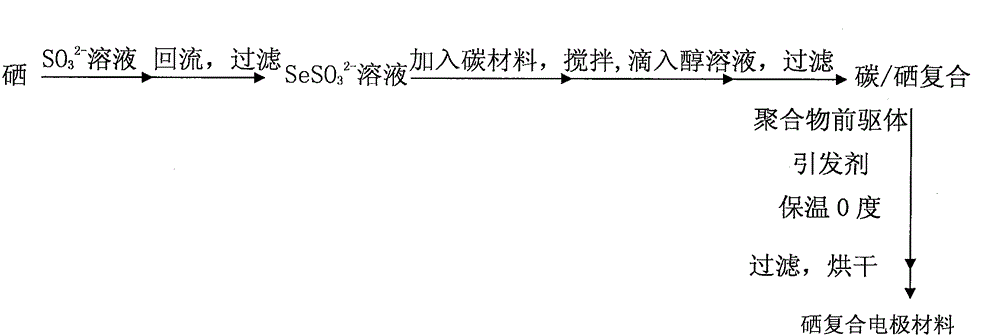

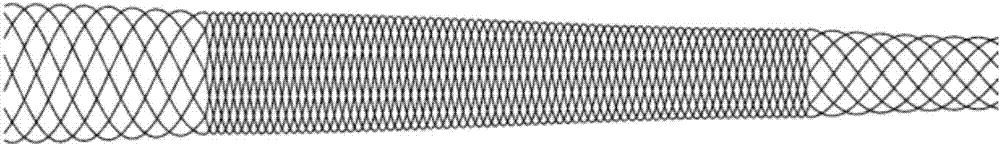

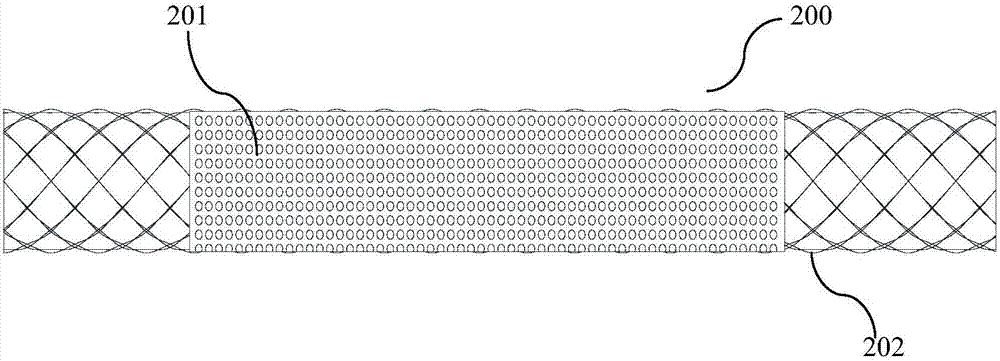

Support used for implanting blood vessel

The invention provides a support used for implanting the blood vessel. The support comprises a section for preventing blood vessel inner wall plaques from entering the support and a supporting section, wherein the section for preventing the blood vessel inner wall plaques frim entering the support is suitable for stopping the plaques on the inner wall of blood vessel from entering the support; thesupporting section provides supporting force enough to prevent the support against displacement in the blood vessel; the pore density of the section for preventing the blood vessel inner wall plaquesfor entering the support is larger than that of the supporting section. The support can effectively stop the plaques on the inner wall of the blood vessel from entering the support, and the support can also be prevented against displacement in the blood vessel.

Owner:SUZHOU INNOMED MEDICAL DEVICE

Skin core structure tombarthite strontium aluminate long afterglow luminescent fiber and preparation method thereof

ActiveCN106480525AImprove water resistanceImprove wear resistanceArtificial filament heat treatmentMelt spinning methodsPolyamidePolystyrene

The invention discloses a skin core structure tombarthite strontium aluminate long afterglow luminescent fiber and preparation method thereof, by mass, the luminescent fiber is prepared from 70-85% of core layer, and 15-30% of skin layer; the core layer is prepared from 10-30% of tombarthite strontium aluminate luminescent powder, 0.02-0.05% of phosphite ester, 0.02-0.2% of antioxidant agent, 0.5-1% of silane coupling agent, the balance polyamide resin; the skin layer adopts the transparent polymethyl methacrylate, or polycarbonate or polystyrene resin with added toughening agent. The prepared luminescent fiber because of the tombarthite strontium aluminate luminescent material being all located on the core layer, effectively prevents the tombarthite strontium aluminate luminescent material from falling, ensures the luminescent brightness of fibers, and raises the water resistance and abrasion resistance of the luminescent fibers, meanwhile the skin layer adopts resins with excellent transparent degree, making the prepared luminescent fibers smooth on surface, and further enhancing the luminescent effect of the luminescent fibers.

Owner:HENAN INST OF ENG

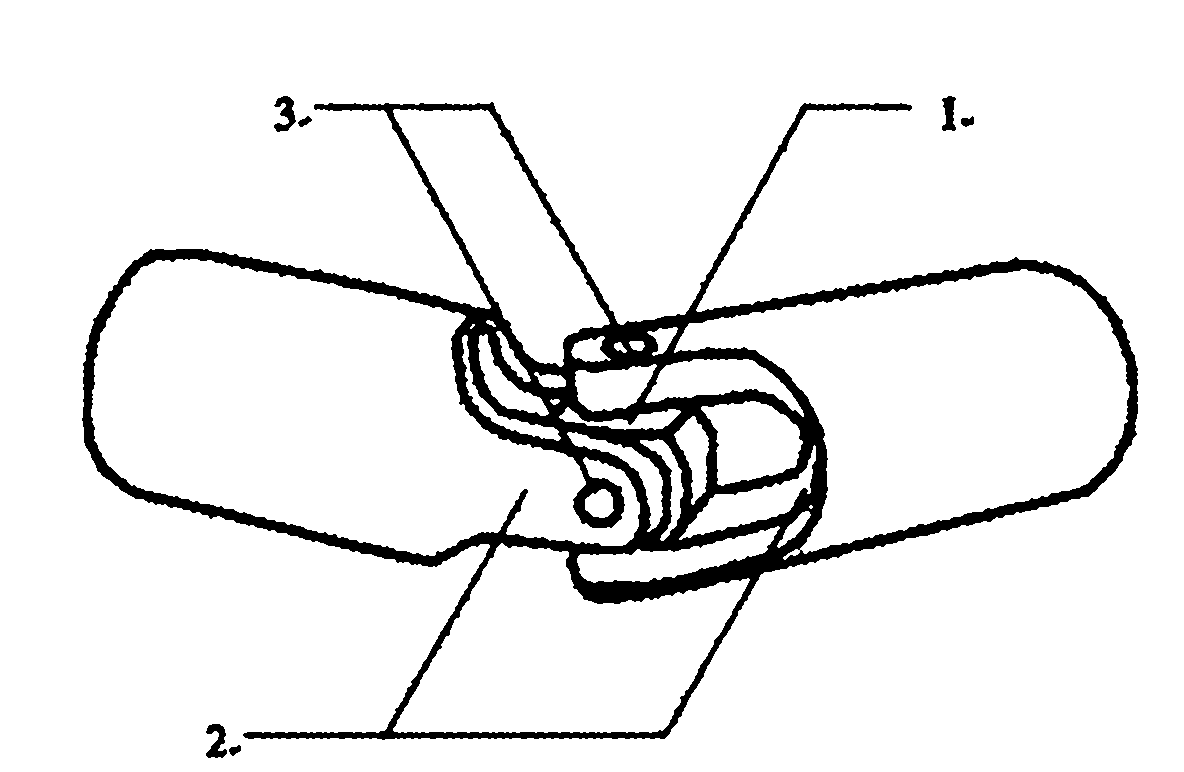

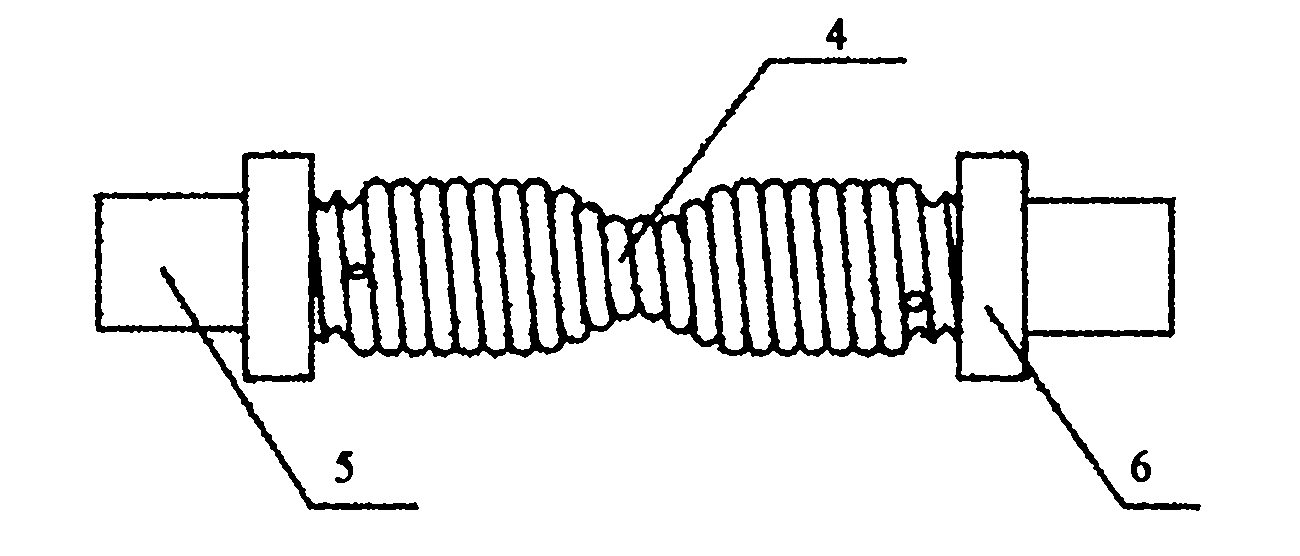

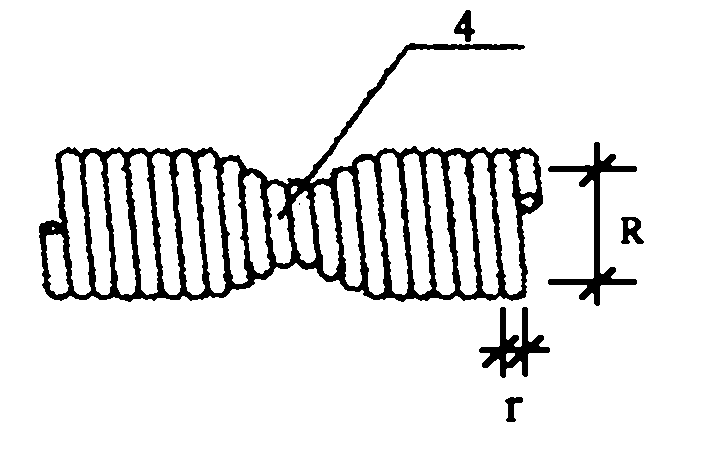

Flexible universal joint

ActiveCN102102712ASimple structureFlexible rotationYielding couplingPivotal connectionsUniversal jointTransmitted power

The invention relates to a flexible universal joint comprising a spring, a first screw and a second screw, wherein the spring is an extension spring which comprises a left segment, a middle segment and a right segment which are continuously and sequentially distributed and take the shape of an hourglass with a thin middle and thick left and right segments; the thread end of the first screw is spirally connected with the left segment of the extension spring; and the thread end of the second screw is spirally connected with the right segment of the extension spring. The flexible universal jointprovided by the invention can transmit power at variable angles in the range of designing rotating torque, can be used for the flexible hinge joint of mechanical parts and has the advantages of simple structure, turning flexibility, shock resistance, difficulty in wear, no looseness and shedding and the like.

Owner:BEIJING TINAVI MEDICAL TECH

Environmentally-friendly multi-effect nanometer water-based paint

InactiveCN105176221AHigh strengthImprove the finishAntifouling/underwater paintsPaints with biocidesWater basedSurface-active agents

The invention discloses environmentally-friendly multi-effect nanometer water-based paint. The water-based paint is prepared from, by weight, 40-60 parts of macromolecular synthesis resin emulsion, 3-6 parts of nanometer scale silicon dioxide, 0.5-2 parts of nanometer titanium dioxide, 1-2 parts of water-based paint thickening agents, 0.5-2 parts of polyether type surface active agents, 0.4-1 part of preservative, 1-3 parts of anti-freezing agents, 1-2 parts of solidifying agents, 0.4-1.2 parts of dispersing agents, 25-45 parts of filling and 10-30 parts of water. The environmentally-friendly multi-effect nanometer water-based paint is waterproof, high in hardness, resistant to washing, high in adhesive force, smoothness and cleanness and resistant to oil stains, ageing and bacteria, meanwhile the content of VOC and formaldehyde is low, and the water-based paint is safe, environmentally friendly, excellent in performance and wide in application range.

Owner:ZIBO KUAKE MEDICINE TECH

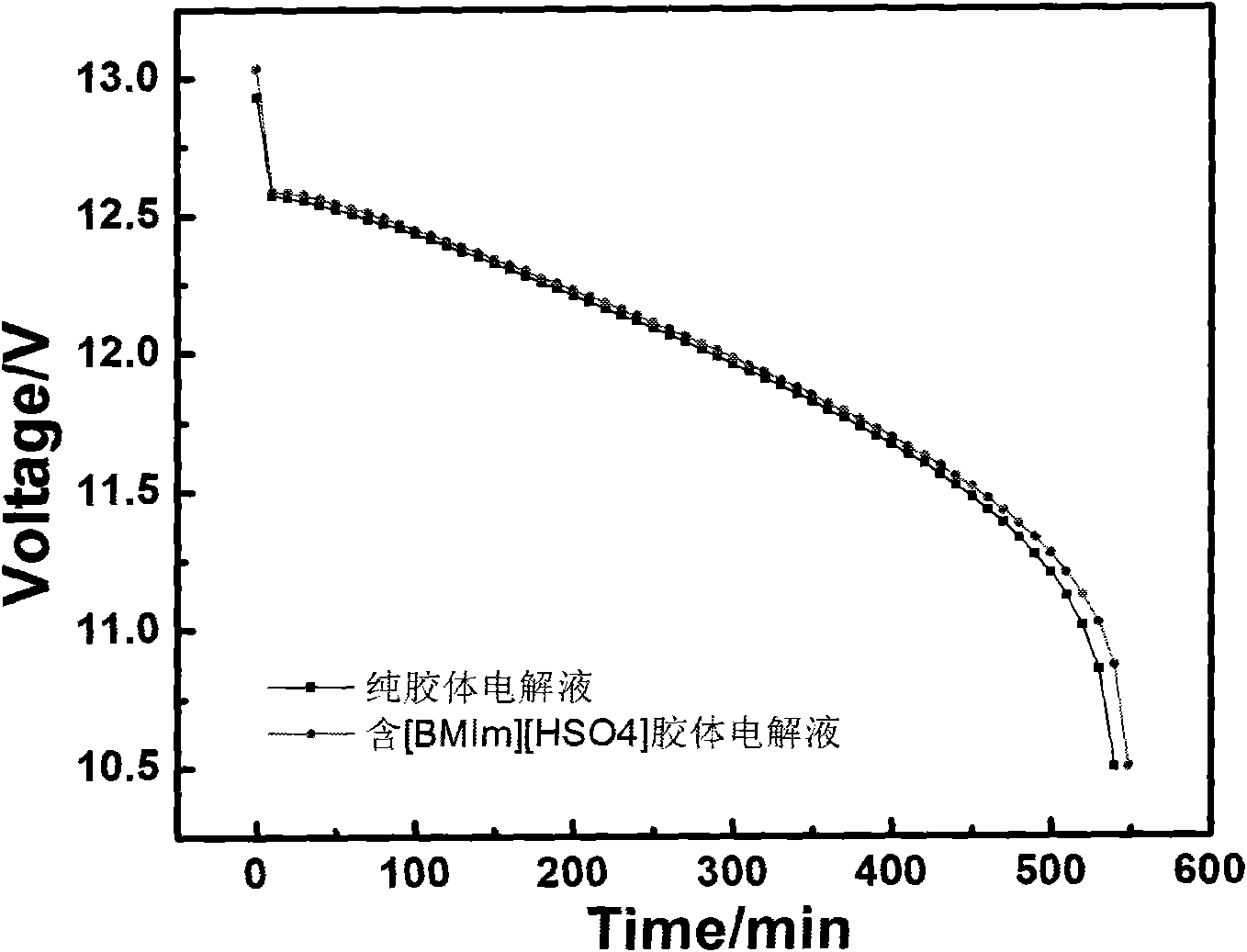

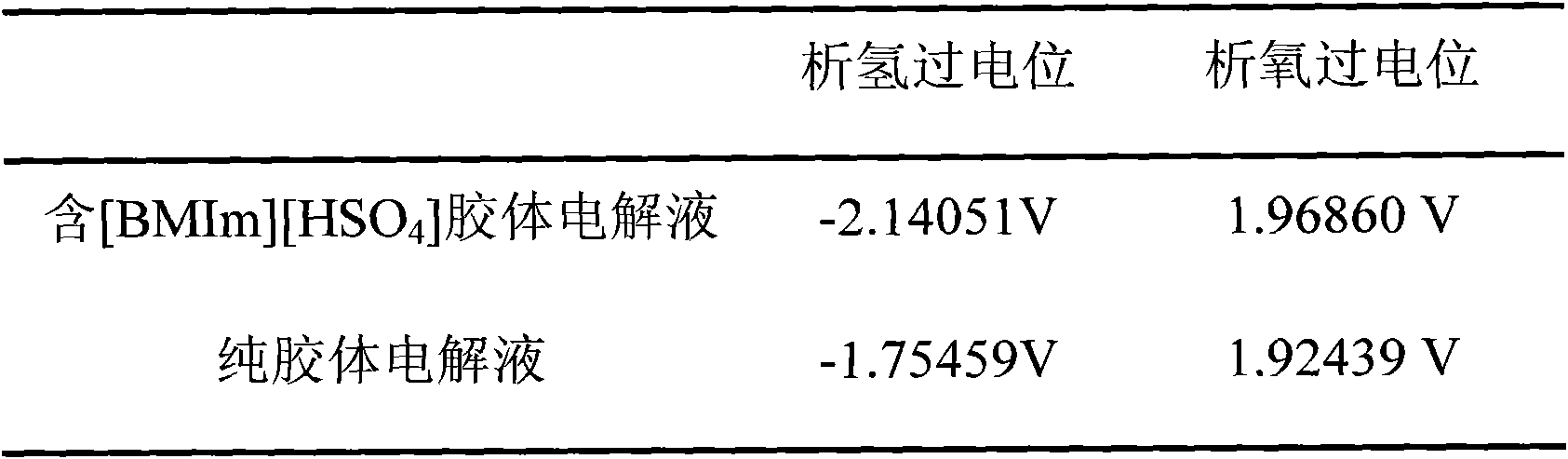

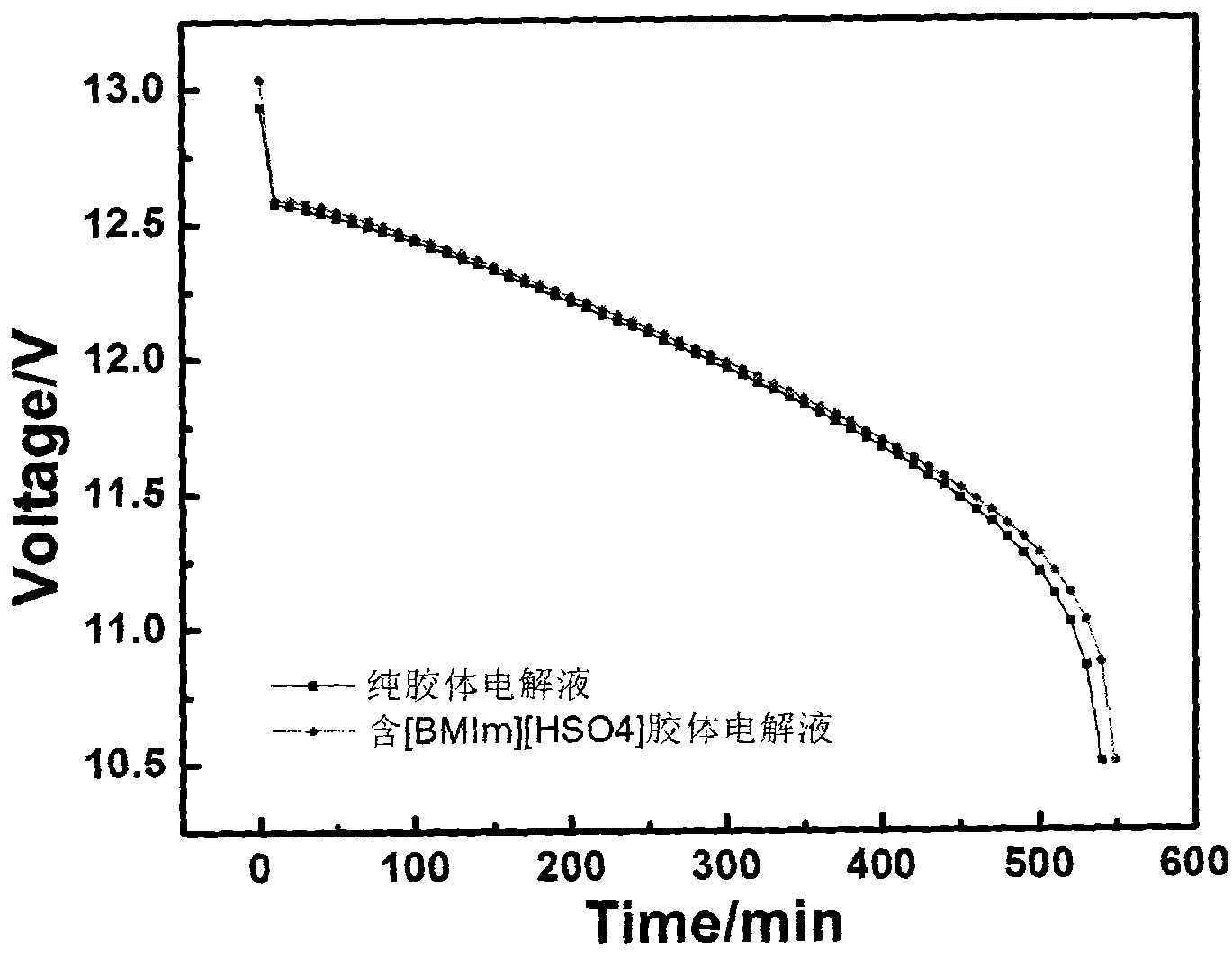

Ionic liquid additive-containing gel battery electrolyte

The invention discloses ionic liquid additive-containing gel battery electrolyte. The gel battery electrolyte comprises 5 to 10 weight percent of silica sol, 30 to 40 weight percent of sulfuric acid, 52 to 62 weight percent of water and 0.01 to 0.03 weight percent of 1-butyl-3-methylimidazole bisulfate ionic liquid. The electrolyte does not flow or acid does not overflow, the charging time is shortened, the discharging time is prolonged, the self-discharge is extremely low, the service life is prolonged, the electrolyte is easy and convenient to maintain, pure water generally needs be added for several times only and acid is not needed. In the production of a gel battery, the gel can be conveniently filled under normal pressure, has reliable performance and is safe to use.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for preparing polymer clad nickel aluminum alloy/sulfur composite electrode material

The invention relates to a method for preparing a polymer clad nickel aluminum alloy / sulfur composite electrode material. The method is characterized by comprising the steps of: by taking hollow nickel aluminum alloy nanometer powder as a carrier for the polymer clad nickel aluminum alloy / sulfur composite electrode material, carrying out heating sublimation, diffusion, and condensation on sulfur to obtain a nickel aluminum alloy / sulfur composite material; ultrasonically dispersing the nickel aluminum alloy / sulfur composite material and a polymeric precursor in an alcohol-water blend, then adding a catalyst, and carrying out polymerization, stirring, deposition, filtering, collecting, and drying to obtain the polymer clad nickel aluminum alloy / sulfur composite electrode material, wherein the nickel aluminum alloy is one of NiAl3 and NiAl2, sulfur accounts for 30-70% of the total mass of the polymer clad nickel aluminum alloy / sulfur composite electrode material, and a polymer accounts for 0.5-10% of the total mass of the polymer clad nickel aluminum alloy / sulfur composite electrode material. When used as the positive electrode for a lithium sulfur battery, the composite material has a good specific capacity and excellent cycling performance, wherein the first discharge capacity is greater than 500mAh / g, and the discharge specific capacity retention rate is greater than 74% after 100 cycles.

Owner:CHINA JILIANG UNIV

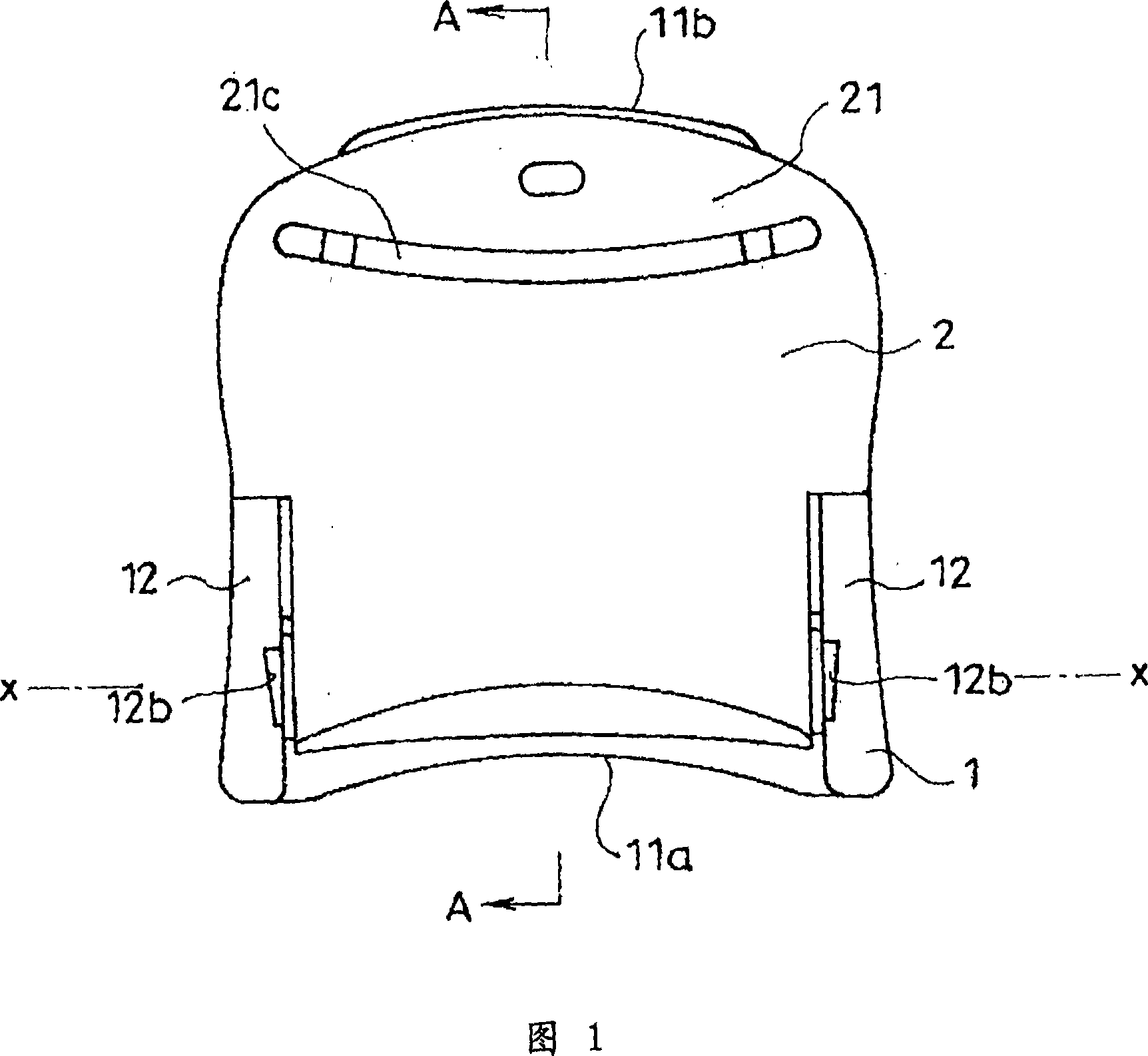

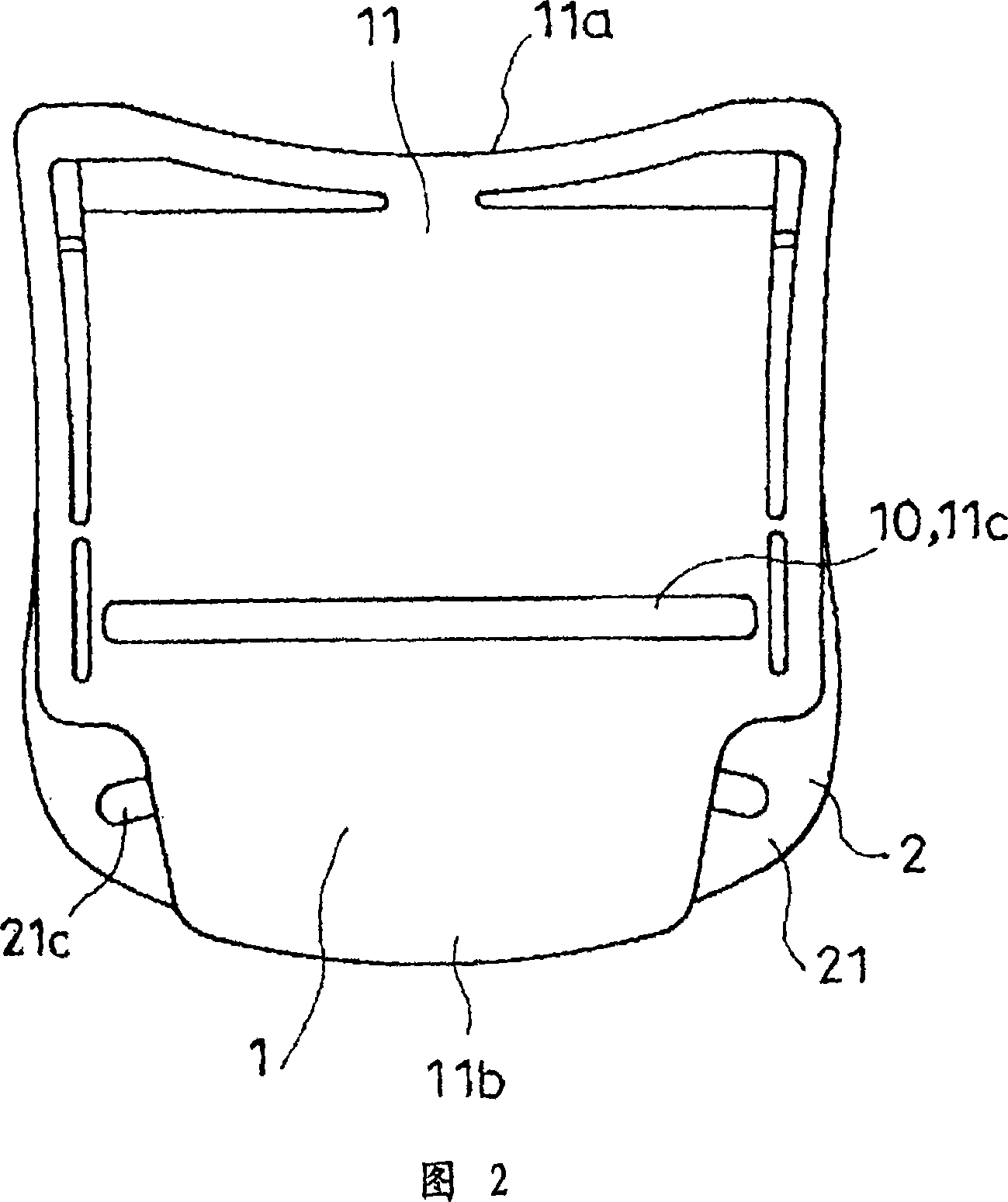

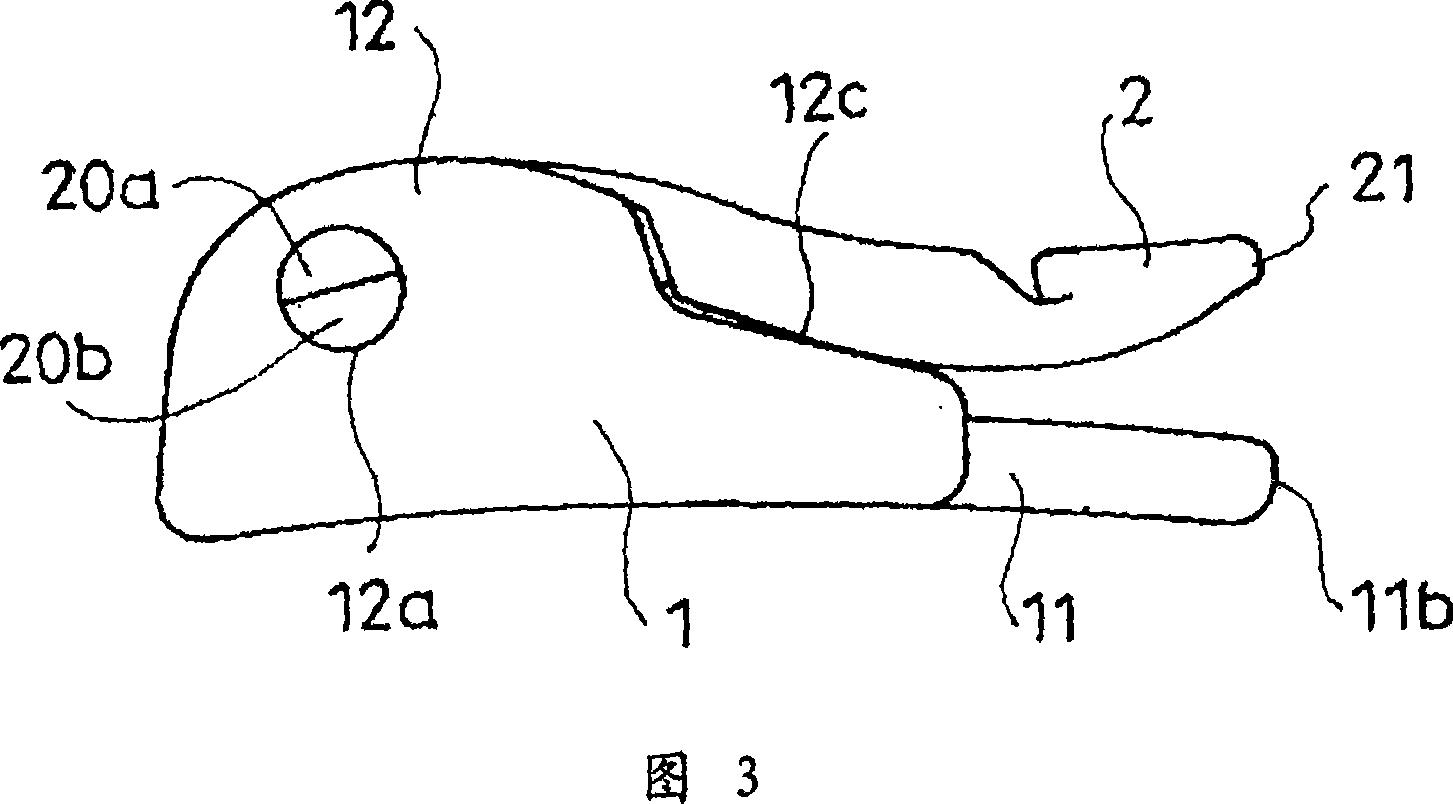

Bracelet

Owner:NIFCO INC

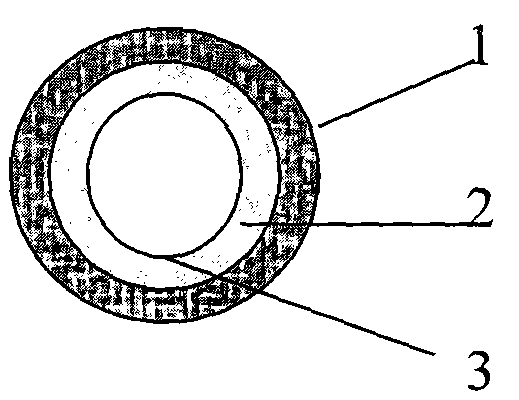

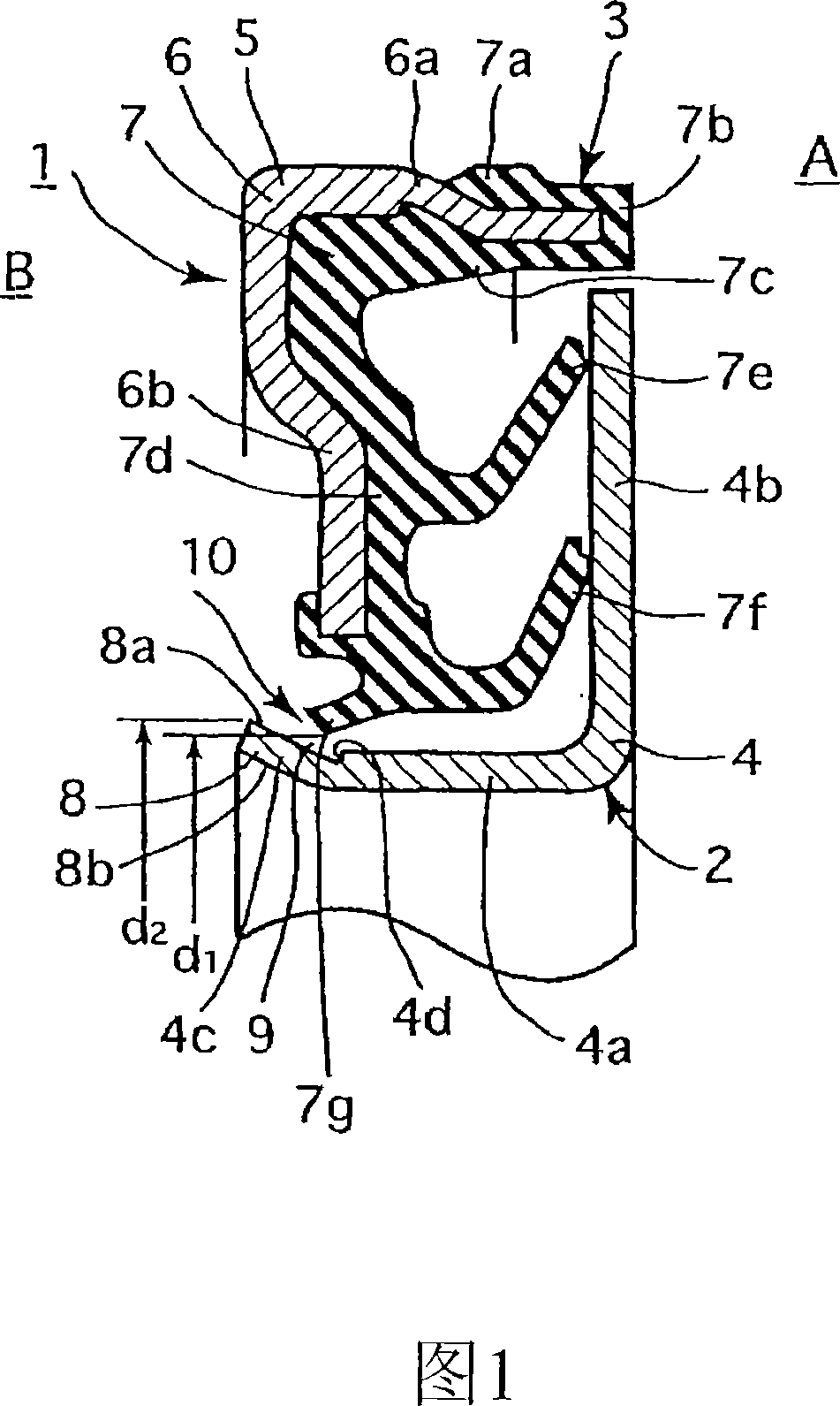

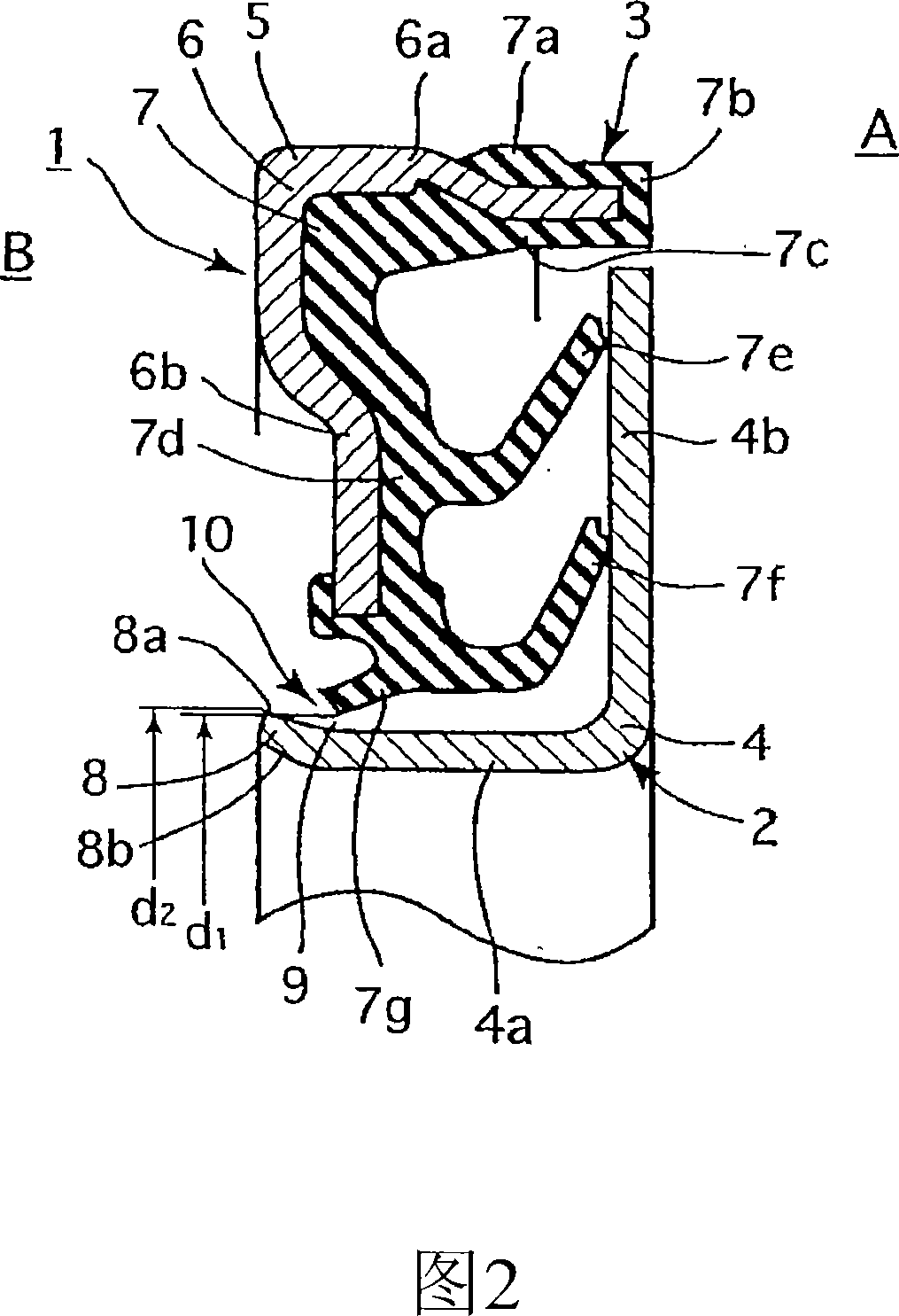

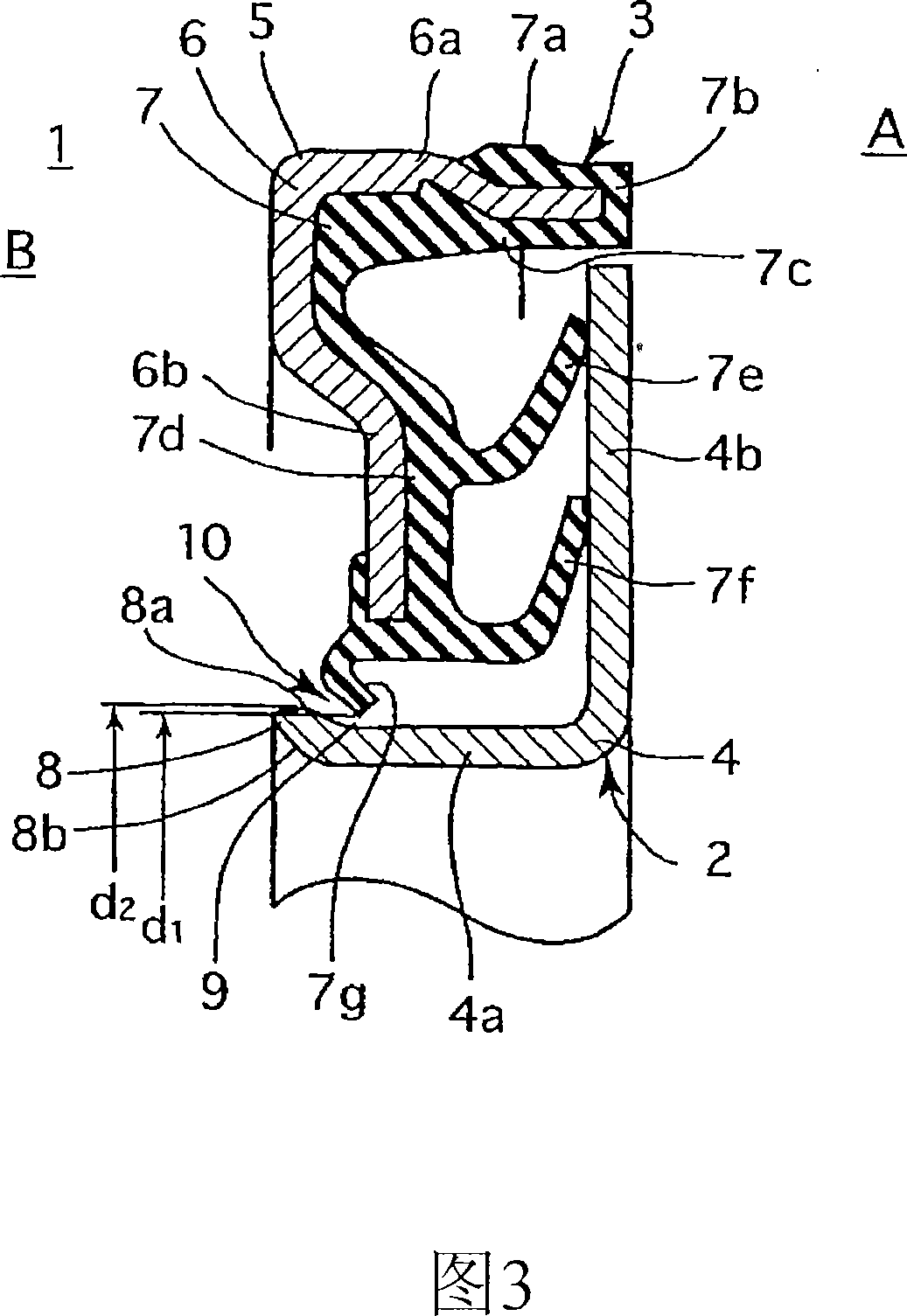

Sealing device

InactiveCN101208550AImprove mud and water resistanceSuppression of increase in slip torqueEngine sealsBearing assemblyEngineeringLip seal

A sealing device (1) formed by combining an inner peripheral sealing member (2) and an outer peripheral sealing member (3), where the inner peripheral sealing member (2) such as a slinger member is prevented from falling out in axially one direction from the outer peripheral sealing member (3) such as a lip seal member. The inner peripheral sealing member (2) has a metal ring (4) provided with a tubular section (4a) and a radially rising section (4b) integrally formed with the tubular section (4a) and extending radially outward from one end of the tubular section (4a). The outer peripheral sealing member (3) has side lips (7e, 7f) in slidable intimate contact with the radially rising section (4b) of the metal ring (4), and also has a radial lip (7g) provided without contact, on the outer peripheral side of the tubular section (4a) of the metal ring (4). The tubular section (4a) has an axial fall-out prevention section (8) having an outer diameter d 2 greater than the inner diameter d 1 of the radial lip (7g) and preventing the metal ring (4) from falling out in axially one direction from the outer peripheral sealing member (3).

Owner:NOK CORP

Preparation method of metal-clad S/Ni-Co-Mn-Li oxide electrode material

InactiveCN105304871ASimple processEasy to operatePositive electrodesNon-aqueous electrolyte accumulator electrodesLithium–sulfur batterySulfur

The invention relates to a preparation method of a metal-clad S / Ni-Co-Mn-Li oxide electrode material. The metal-coated S / Ni-Co-Mn-Li oxide electrode material is obtained through mechanically milling and mixing S / Ni-Co-Mn-Li oxide and then carrying out metal oxide deposition, diol reduction and drying; the mass of S accounts for 65 to 90 percent of the total mass of the electrode material, the mass of the Ni-Co-Mn-Li oxide accounts for 3 to 20 percent of the total mass of the electrode material, and the mass of clad metal accounts for 7 to 15 percent of the total mass of the electrode material; metal is one or two of Cu, Ag, W and Au; very good specific capacity, excellent multiplying power and excellent circulating performance are obtained when the electrode material is used for a positive electrode of a Li-S battery; the preparation method has a very good application prospect in the field of batteries.

Owner:CHINA JILIANG UNIV

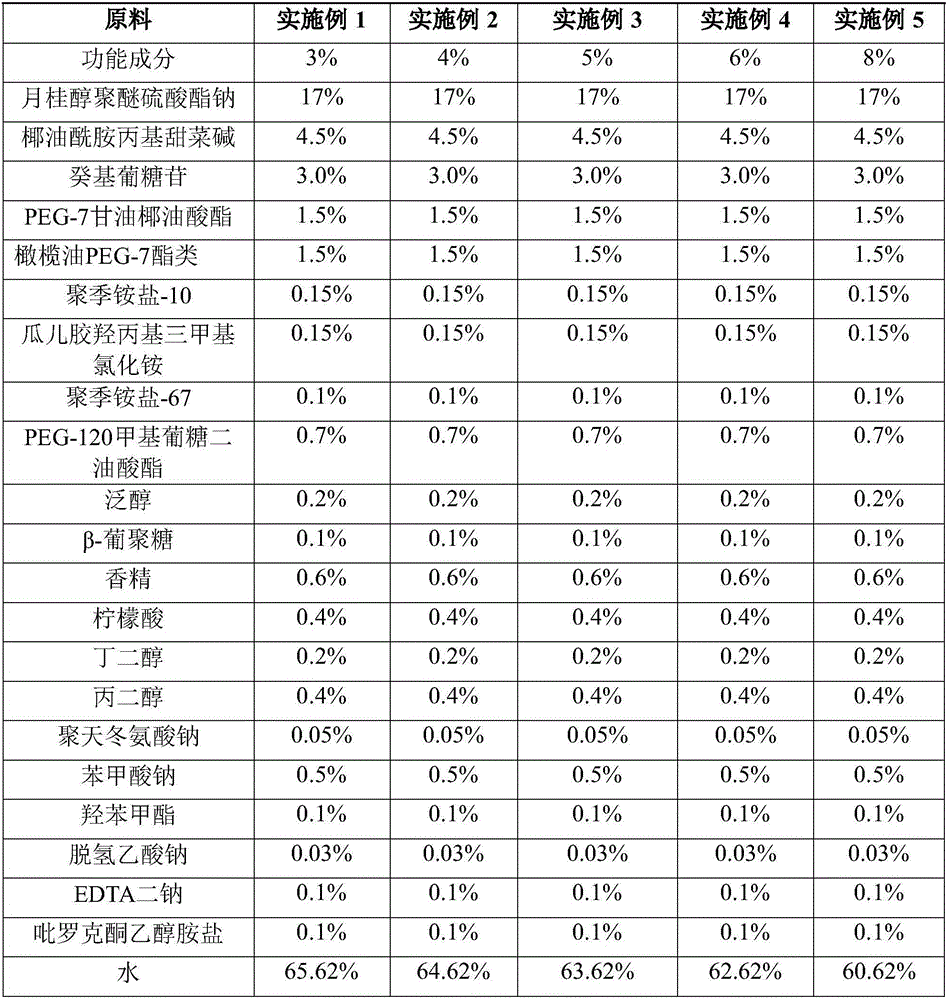

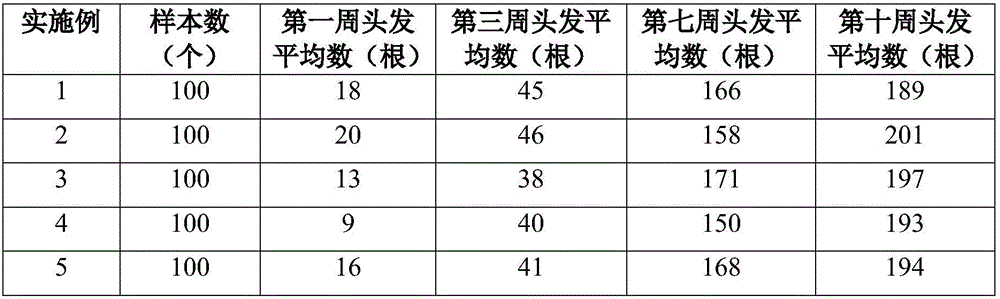

Anti-hair loss hair-nourishing liquid shampoo

ActiveCN106727157AEasy to absorbStop hair fallCosmetic preparationsHair cosmeticsTissue deathTraditional Chinese medicine

The invention discloses anti-hair loss hair-nourishing liquid shampoo which comprises the following functional components in parts by mass: 20-30 parts of a Sarcodon imbricatum extract, 20-30 parts of a cyclocarya paliurus extract, 10-15 parts of a dendrobium officinale extract, 5-10 parts of a cordyceps militaris extract, 1-5 parts of a ginseng extract, 1-5 parts of a ginger extract, 1-5 parts of a cacumen biotae extract and 1-5 parts of an astragalus extract. A great number of optimization tests show that the silicone oil-free hair shampoo with the traditional Chinese medicine compositions is safe and free of irritation and is capable of effectively stimulating growth, differentiation and refreshing of hair follicle stem cells, so that an anti-baldness hair-nourishing effect can be achieved, the effective prevention and treatment rate for baldness caused by hair follicle dysfunction can be up to 80% or above, and particularly the effective treatment rate for hair loss caused by hair follicle tissue death can be up to 100%.

Owner:MEIAISI COSMETICS SUZHOU +1

Aluminum oxide gas suspending calcining furnace breakage inside lining quick-speed repair method

ActiveCN101140141AReduce maintenance workloadExtend your lifeLinings repairRepair materialHigh intensity

The invention provides a method for rapidly repairing the breakage of inner lining of an alumina gas suspension calcining kiln, which is characterized in that the selected repair materials are AL-Cr series high-intensity composite corundum ramming materials and composite corundum coating materials, and coating, ramming, caulking, compaction, smooth treatment of surface and other different overhaul and construction methods are adopted according to breakage type of calcining kiln inner lining, surface wear of inner lining, and large drop block and expansion joint. The invention not only can greatly reduce the overhaul workload of the kiln lining, but also can implement the coating and repair for the breakage position of the wear surface of the calcining kiln inner lining; the coating materials form an enamel layer on the surface of the inner lining materials, which can effectively prevent the kiln lining from being continuously worn and prevent the inner lining particles from falling off and thereby prolong the life of the calcining kiln inner lining. After the broken inner lining is repaired, the heat dissipation can be effectively prevented; the surface temperature of the coating and repair position of the calcining kiln can be reduced by 18 to 40 degrees Celsius.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

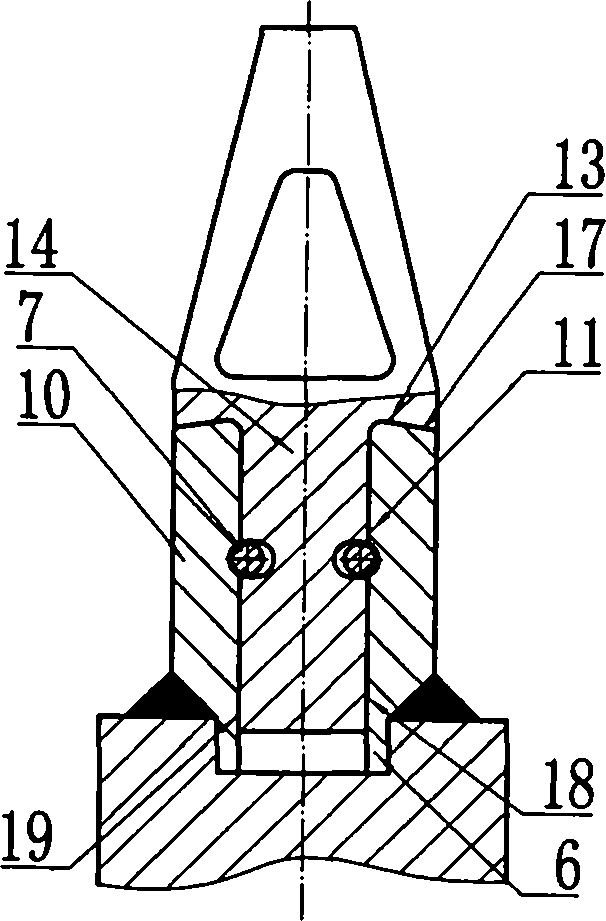

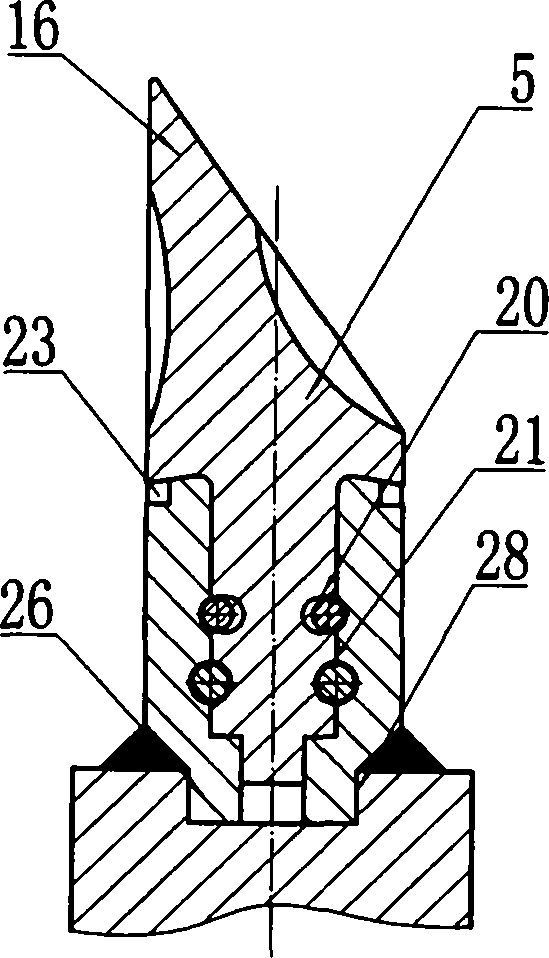

Jack anti-rotating easily-detachable reciprocating impact head of digger

ActiveCN103912273AIncrease intensityImprove efficiencySlitting machinesCutting machinesImpact toothPull force

The invention relates to the field of diggers and especially relates to a jack anti-rotating easily-detachable reciprocating impact head specifically for a reciprocating impact digger. The jack anti-rotating easily-detachable reciprocating impact head comprises a reciprocating impact head device. The reciprocating impact head device comprises a reciprocating impact head. The reciprocating impact head comprises a reciprocating impact tooth, a permanent seat and a clamp spring or an elastic pin or a lock pin. The reciprocating impact tooth comprises an impact tooth and an impact tooth shoulder. The impact tooth is arranged on an impact tooth insertion column or an impact tooth jack member. The impact tooth shoulder is arranged at a lower part of the impact tooth or is arranged at the end of the impact tooth jack member. The reciprocating impact tooth and the permanent seat comprise hole-slots for arrangement of the clamp spring or the elastic pin or the lock pin. The clamp spring or the elastic pin or the lock pin is arranged in the hole-slots and goes through and connects the reciprocating impact tooth and the permanent seat. The clamp spring or the elastic pin or the lock pin bears a backward pull force produced by reciprocating impact motion. The impact tooth insertion column is inserted into a tooth base jack member or a tooth base insertion column is inserted into the impact tooth jack member. The impact tooth shoulder is tightly fastened to a tooth base shoulder so that a reciprocating impact counter-acting force can be born. A jack anti-rotating structure is fastened to a column anti-rotating structure so that reciprocating impact tooth rotation is prevented.

Owner:刘素华

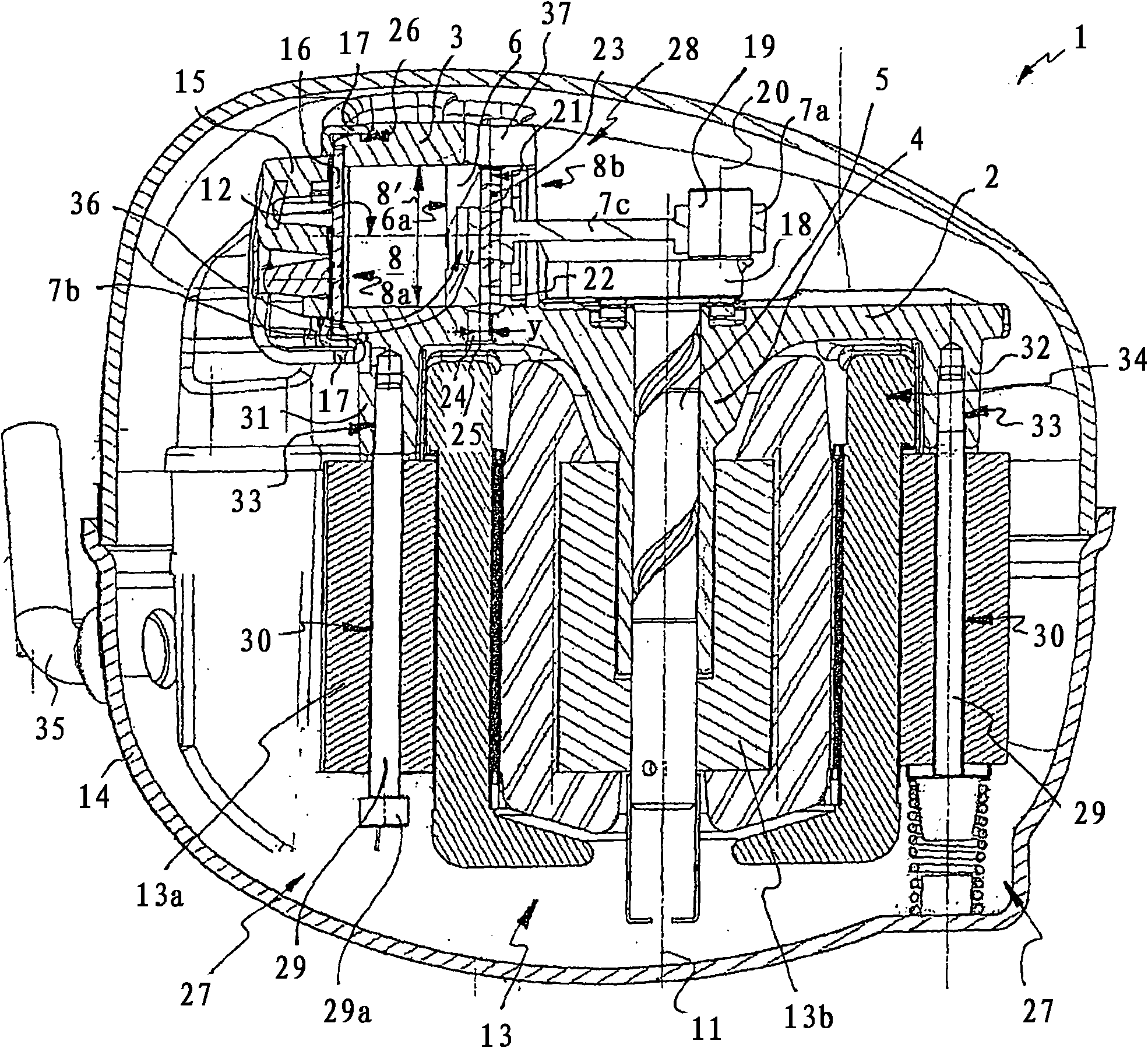

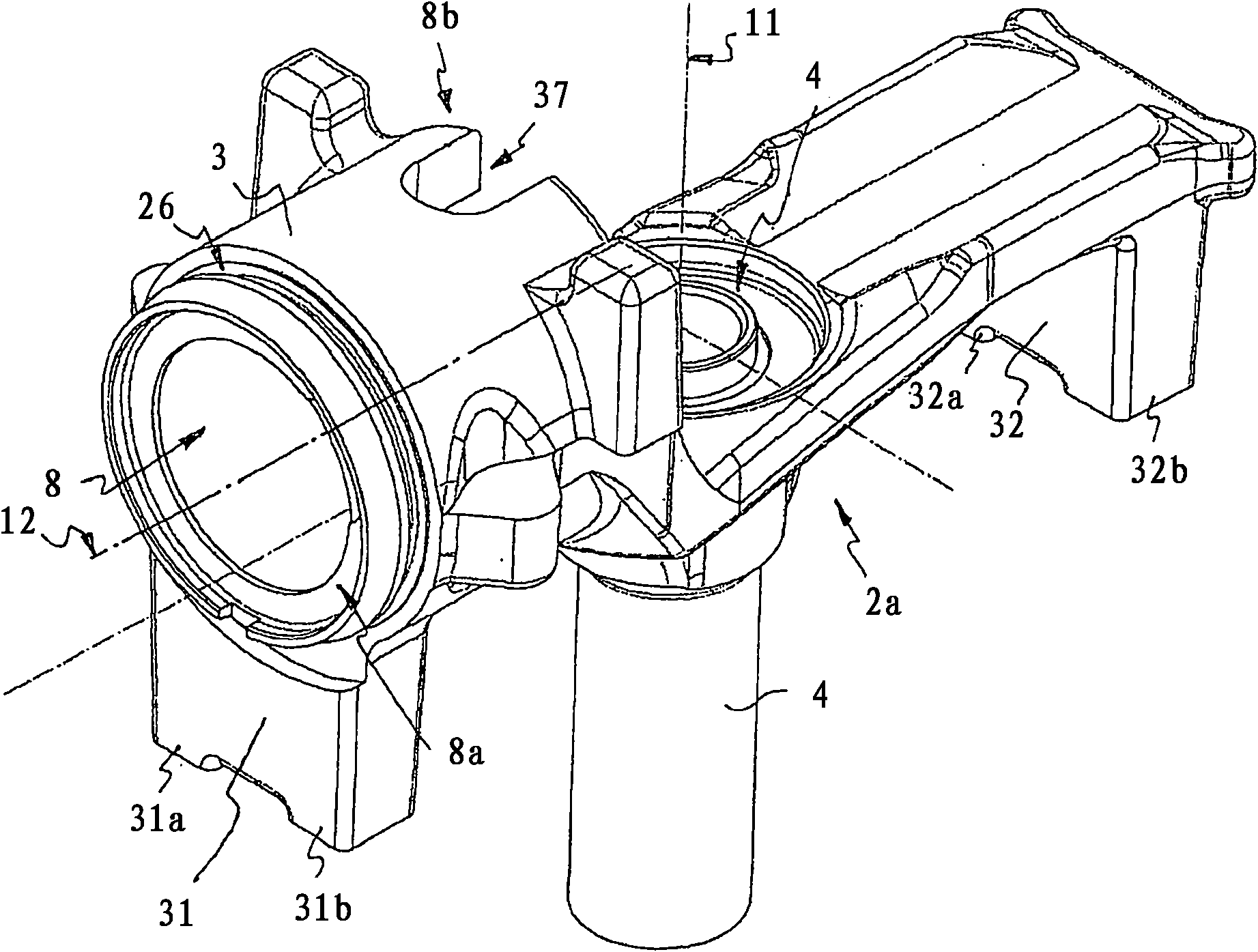

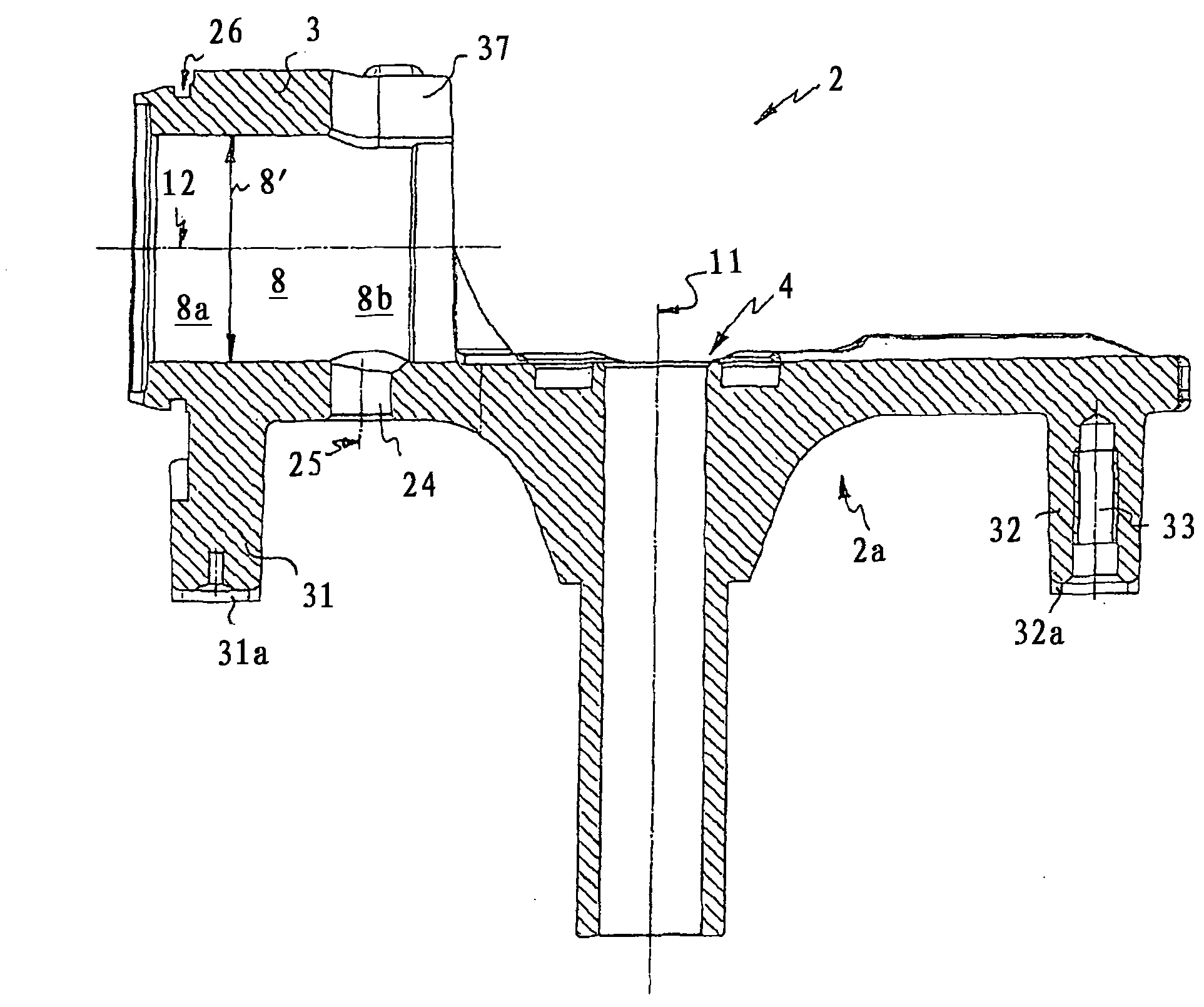

Coolant compressor

ActiveCN102084132AAvoid contactReduce frictionPositive displacement pump componentsPump parameterCylinder headEngineering

Disclosed is a hermetically enclosed coolant compressor (1) comprising a cylinder housing (3) and a piston (6) which is guided along a defined piston bearing area (9) within a piston bore (8) of the cylinder housing (3) and is hinged, by means of a connecting rod (7), to a crankshaft (5) that is driven by an electric motor (13). The crankshaft (5) is mounted in a bearing element (2) that is preferably designed in a monolithic manner along with the cylinder housing (3). The piston bore (8) is closed by a cylinder head (15) encompassing a valve disk (16) in a first end region (8a) while being open for accommodating the piston (6) in a second end region (8b) facing the crankshaft (5). According to the invention, the piston bore (8) has a free-running section (10) that adjoins the piston bearing area (9) and is arranged in the second end region (8b) of the piston bore (8). The width (10') of the internal opening of the free-running section (8b) is greater than the diameter (9') of the piston bearing area (9) in order to prevent contact between the piston (6) and the cylinder housing (3) in said section.

Owner:ACC AUSTRIA GMBH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com