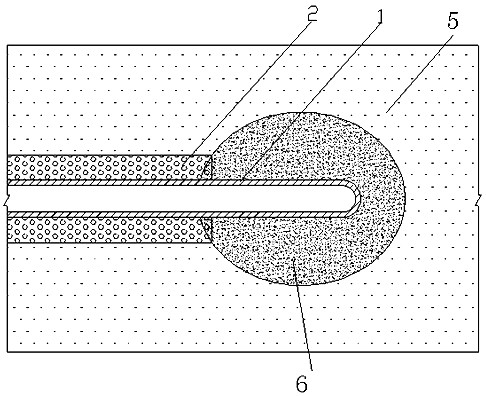

Cryoablation probe shell covered by expandable hydrogel and preparation method thereof

A hydrogel and probe technology, used in cooling surgical instruments, heating surgical instruments, coatings, etc., can solve problems such as inability to effectively prevent needle tract metastasis, incomplete ablation of the target area, and tumor cell shedding, etc. Wound healing, freezing injury prevention, excellent biological activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

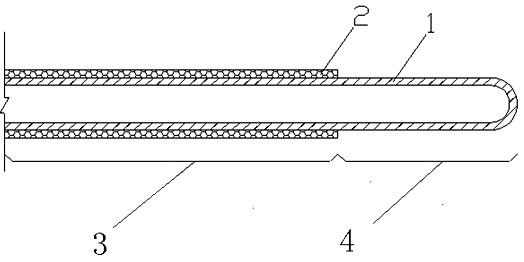

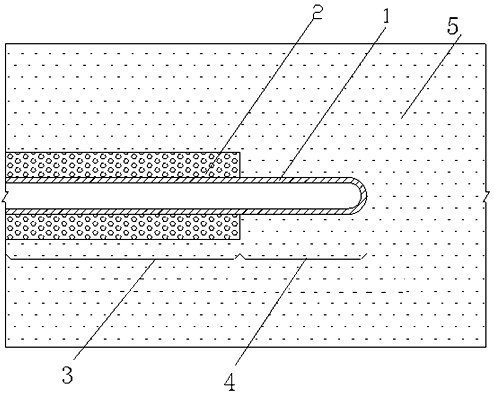

[0037] Thermothermal ablation probe housing covered with expandable sodium alginate hydrogel coating

[0038] (1) Preparation of sodium alginate hydrogel solution

[0039] Dissolve 10 grams of sodium alginate with a viscosity range of 200mpa.s in water to form a 3% aqueous solution;

[0040] (2) Pore formation of sodium alginate hydrogel solution

[0041]Add 20 grams of plant peanut oil as a pore-forming agent and 5 grams of Tween80 as an emulsifier to the sodium alginate hydrogel solution obtained in step (1), stir vigorously until the emulsification is uniform, and place it at a temperature of 37°C and a rotation speed of 120 rpm The constant temperature shaker was used for 24 hours to completely dissolve the sodium alginate in water. At the same time, in order to attract cell growth, the surface of the hydrogel coating must be positively charged, and the pH value of the sodium alginate solution was adjusted to 3.8 with 0.1M hydrochloric acid;

[0042] (3) shell coating, c...

Embodiment 2

[0049] Hot and cold ablation probe housing covered with expandable chitosan hydrogel coating

[0050] (1) Preparation of chitosan hydrogel solution

[0051] Dissolve 0.3 g of chitosan with a deacetylation degree greater than 90% of 100 mesh in 9.7 g of 1% acetic acid aqueous solution;

[0052] (2) Chitosan hydrogel pore making

[0053] Add 2 grams of polyethylene glycol, a pore-forming agent with a molecular weight of 5000, to the solution obtained in step (1). After the polyethylene glycol is evenly dispersed in the chitosan solution, place the temperature at 37°C and rotate at 120 rpm. min constant temperature shaker for 1 hour to completely dissolve chitosan;

[0054] (3) shell coating, curing

[0055] Add 0.2 ml of cross-linking agent, namely 20% formaldehyde solution, to the chitosan hydrogel solution obtained in step (2) after pore making;

[0056] The concentric hollow stainless steel tube is a mould, and the chitosan hydrogel solution adding a crosslinking agent is...

Embodiment 3

[0062] Hot and cold ablation probe housing covered with expandable pectin hydrogel coating

[0063] (1) Preparation of pectin hydrogel solution

[0064] Dissolving 5 grams of pectin with an esterification degree of less than 10% and a galacturonic acid greater than 80% in water to form a 5% aqueous solution;

[0065] (2) Pore making of pectin hydrogel solution

[0066] Add 10 grams of pore-forming agent vegetable peanut oil and 3 grams of emulsifier Tween80 to the pectin hydrogel solution obtained in step (1), stir vigorously until the emulsification is uniform, and place it on a constant temperature shaker at 95°C with a speed of 120 rpm 0.5 hours, the pectin is completely dissolved in water;

[0067] (3) shell coating, curing

[0068] Apply the hole-made pectin gel solution obtained in step (2) evenly on the non-working section of the hot and cold ablation probe shell, with a thickness of about 15mm, and cover the coating with a concentric hollow stainless steel tube as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com