Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Stay dispersed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

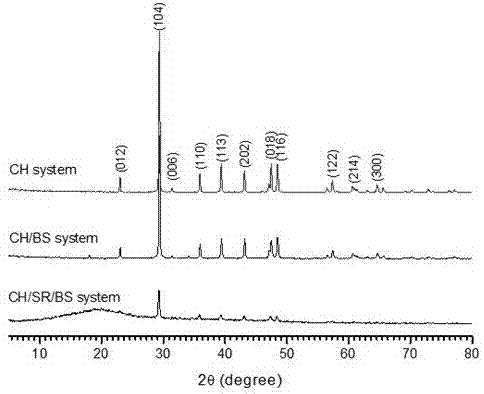

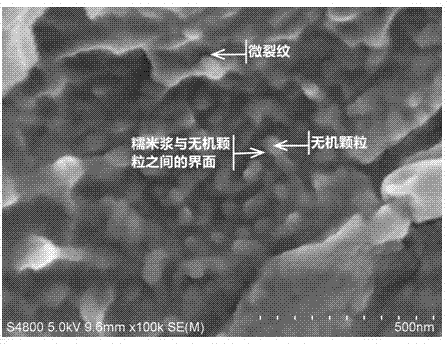

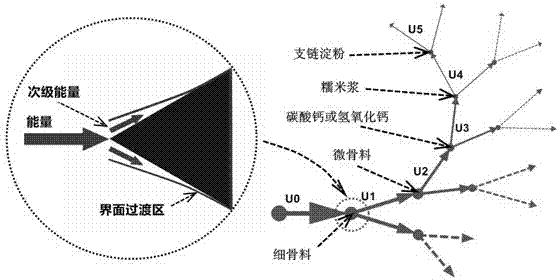

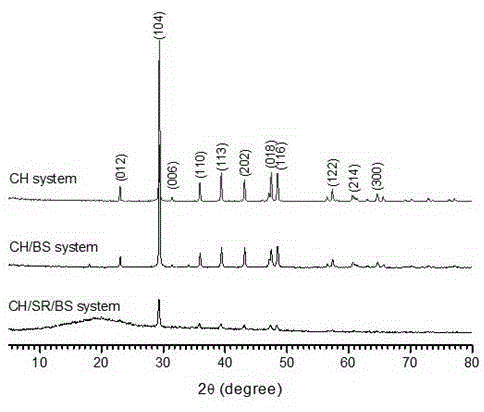

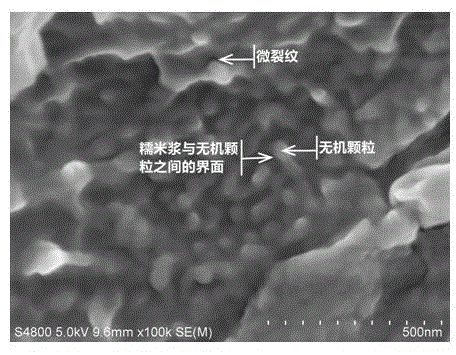

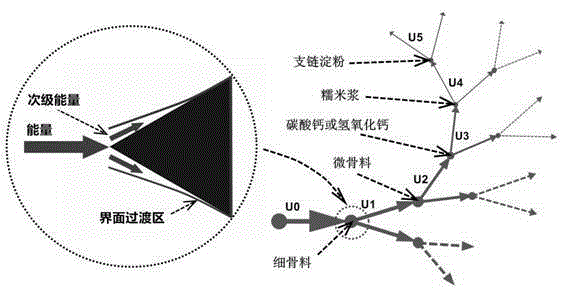

High-performance historic site repair material and preparation method thereof

The invention provides a high-performance historic site repair material and a preparation method thereof. The repair material comprises the following raw materials: 191-287 parts of sticky rice pulp, 115-185 parts of lime, 0-4 parts of brown granulated sugar, 344-398 parts of fine aggregates, 204-268 parts of complex mineral admixture, 11-12 parts of reinforcing agent, and 0-19 parts of mineral pigment. The invention further provides a preparation method of the repair material. The preparation method comprises the following steps: weighing all the raw material according to weight, and forcibly stirring evenly to obtain the repair material. Amylopectin in the sticky rice pulp is a highly branched macromolecule, the setting and hardening processes of the lime and the pozzolanic reaction of the complex mineral admixture are influenced, the strength development of the material is similar to biomineralization process, and a microstructure formed in the process endows the repair material with higher strength and toughness. Furthermore, the material has good compatibility with materials of a historic site body.

Owner:WUHAN UNIV

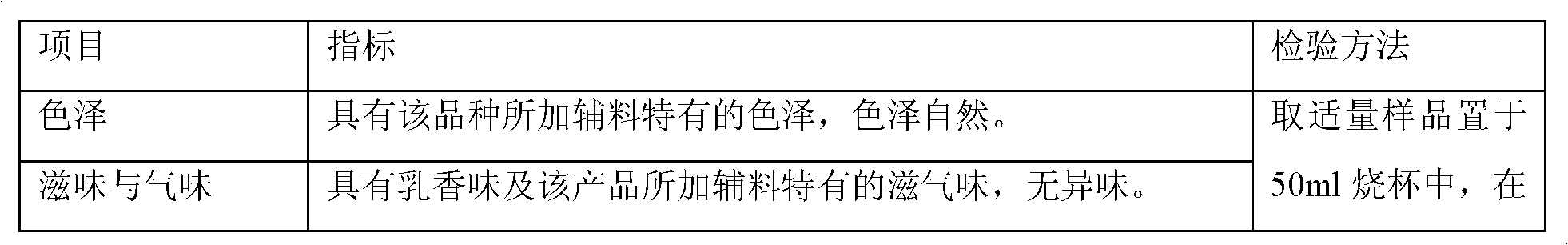

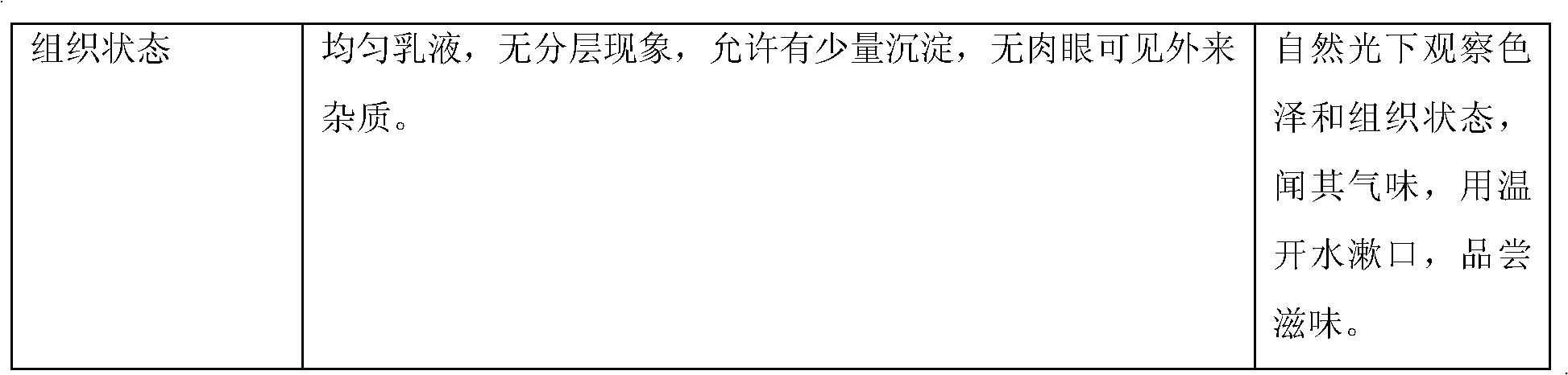

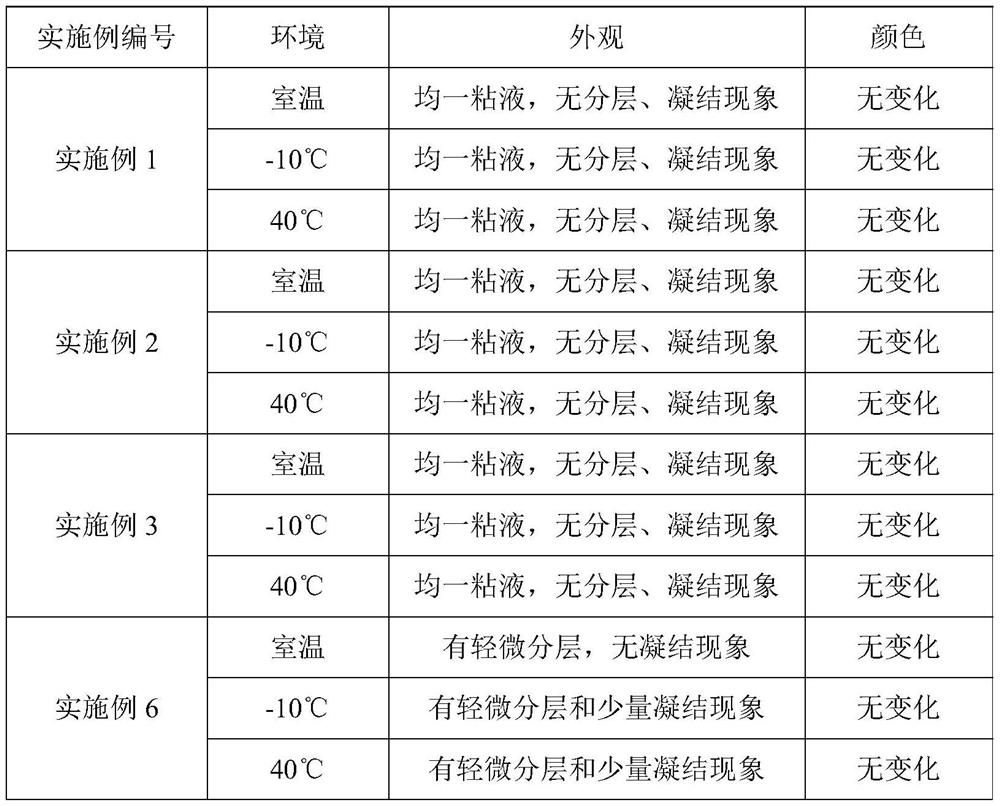

Liquid state dairy product for health care and production method thereof

The invention belongs to the field of the processing of dairy products, and relates to a liquid state stable dairy product which contains black bean powder, siberian solomonseal rhizome powder and cinnamomvine powder and is used for health care and a production method thereof. The liquid state stable dairy product contains 50 to 80 weight percents of skimmed milk, 0.05 to 0.20 weight percent of emulsifier, 0.07 to 0.50 weight percent of thickener, 0.1 to 2.0 weight percents of black bean powder, 0.1 to 2.0 weight percents of siberian solomonseal rhizome powder, 0.1 to 2.0 weight percents of cinnamomvine powder, 0.05 to 0.50 weight percent of polydextrose, 0 to 0.20 weight percent of edible spice and the balance of water, wherein the sum of components is 100 weight percent; and the thickener comprises 0.07 to 0.20 weight percent of gellan gum. The liquid state dairy product has abundant nutrition and is low in fat content, the black bean powder, the siberian solomonseal rhizome powder and the cinnamomvine powder have the health-care effects of reducing blood fat, blood sugar and blood pressure and are convenient to eat. In addition, due to the addition of the black bean powder, thesiberian solomonseal rhizome powder and the cinnamomvine powder, the liquid state dairy product can be stored for a long time, and is kept in a dispersed state.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

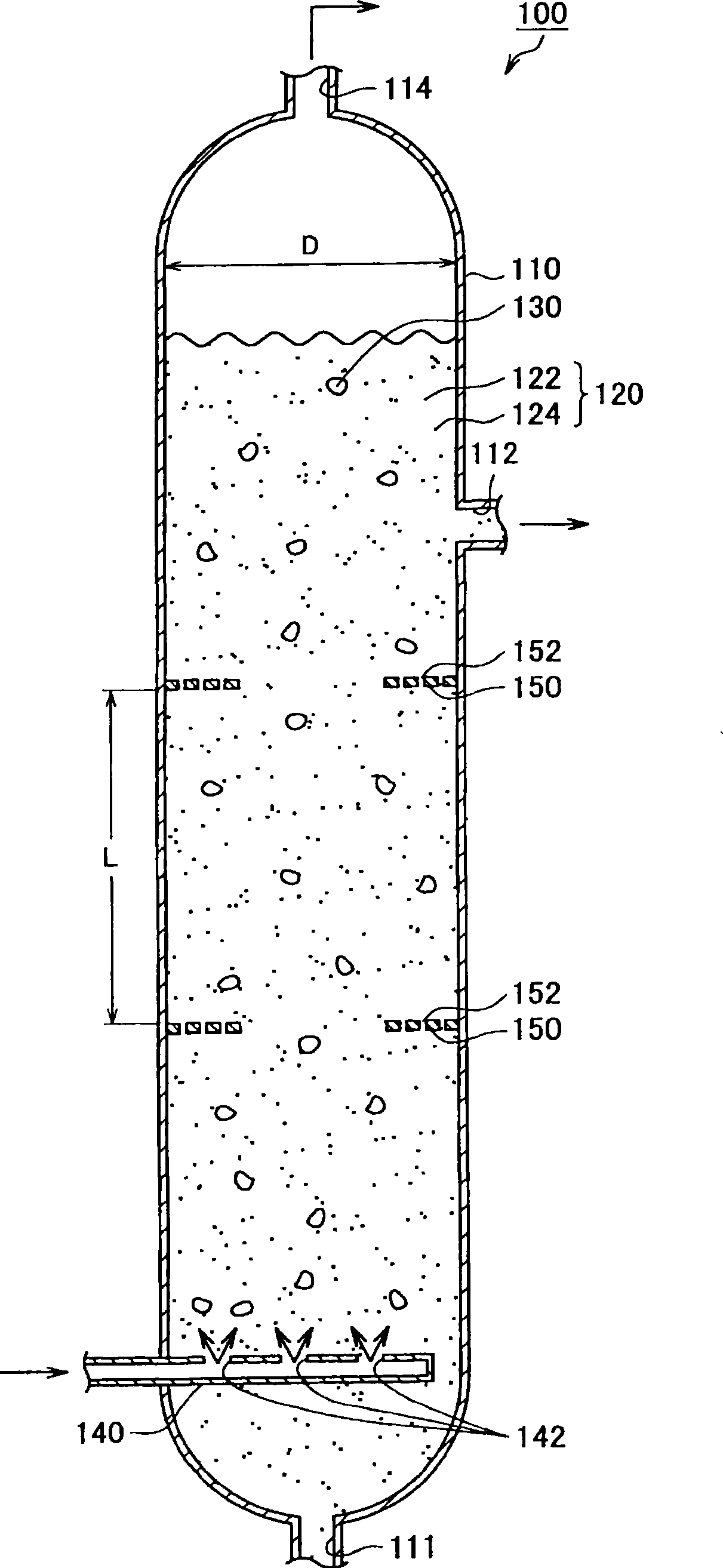

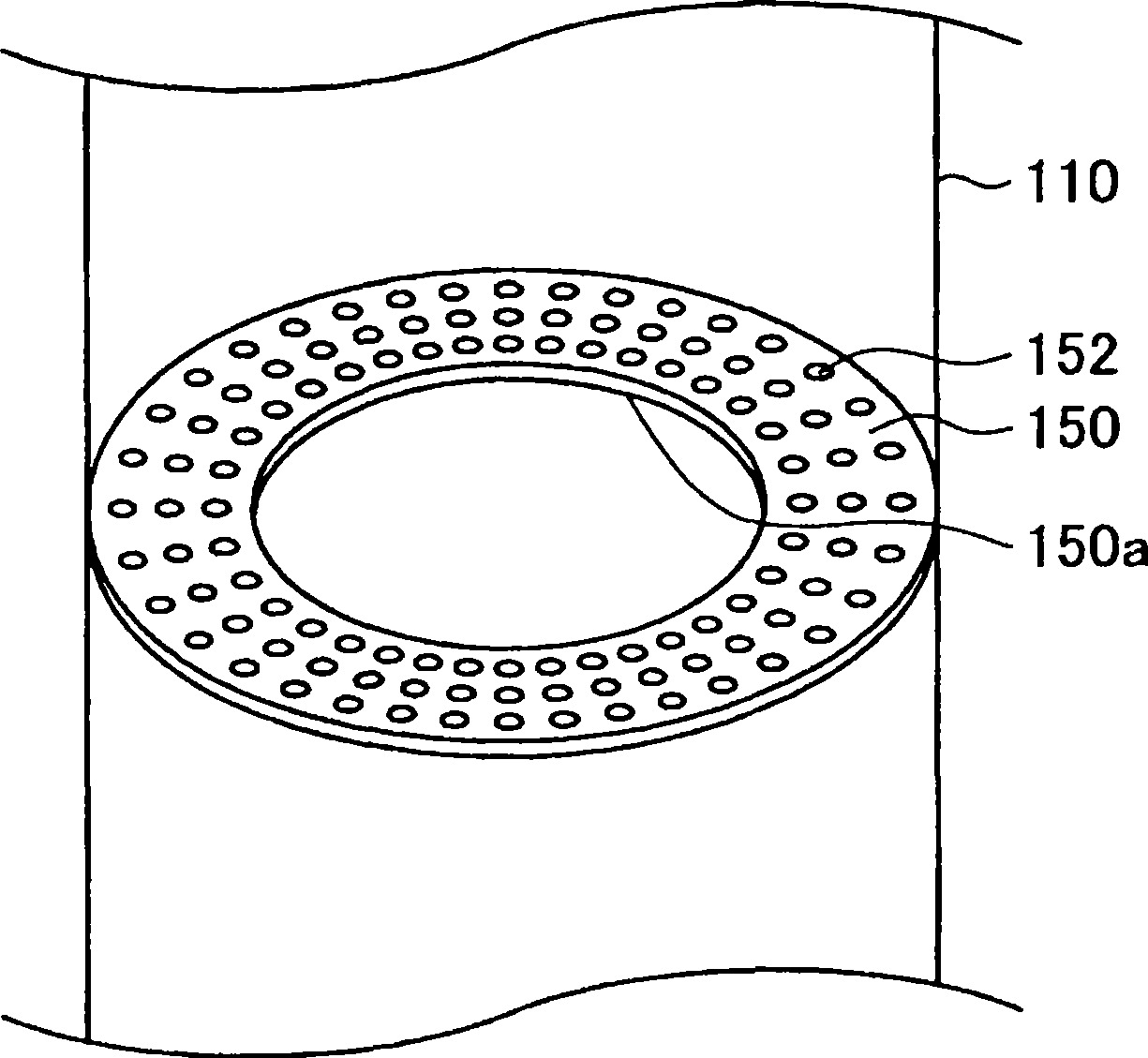

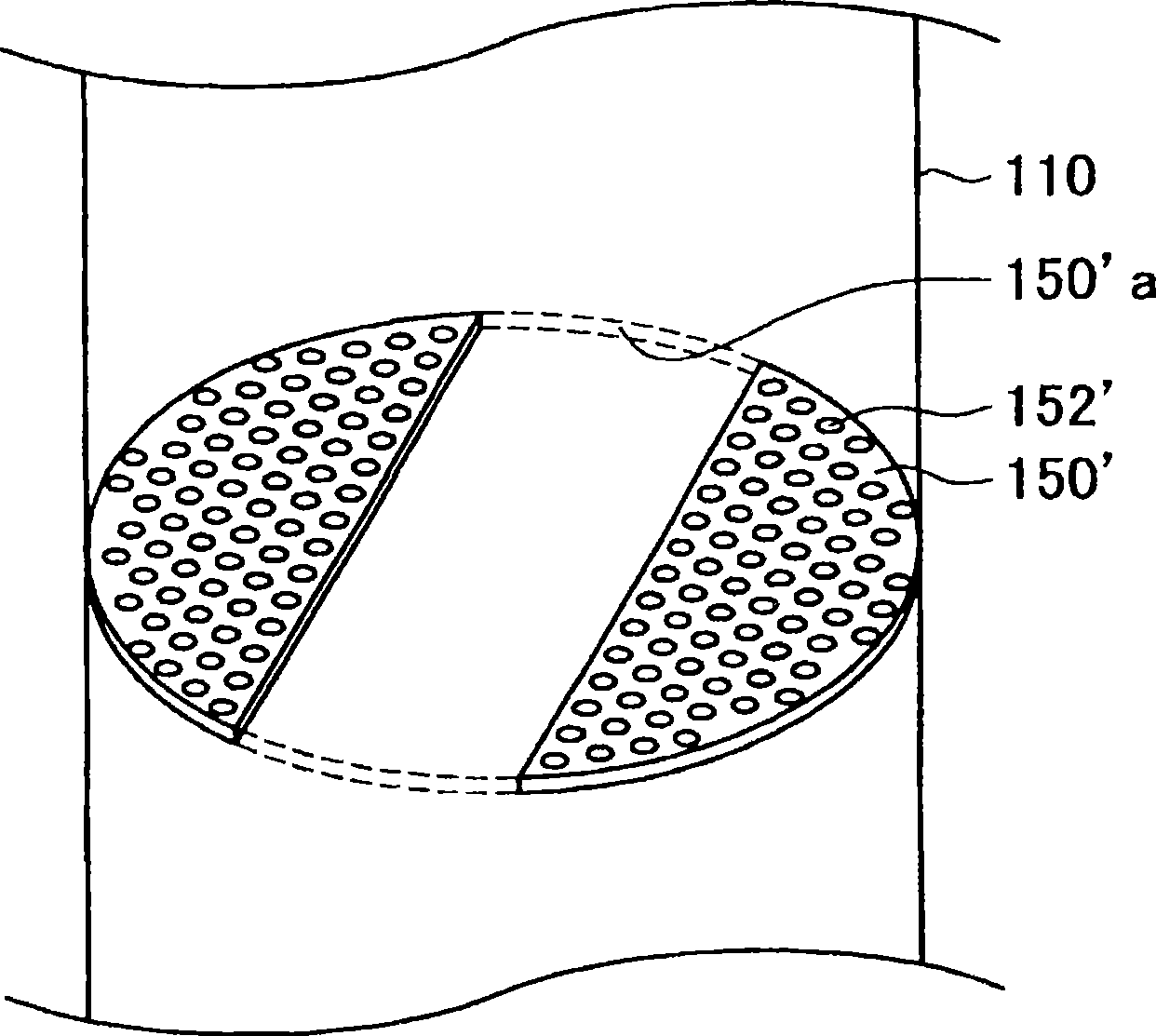

Bubble tower type hydrocarbon synthesis reactor

InactiveCN101432394ASuppress backmixingStay dispersedChemical/physical/physico-chemical reactor detailsLiquid hydrocarbon mixture productionSyngasLiquid hydrocarbons

Bubble tower type hydrocarbon synthesis reactor (100) comprising reactor main frame (110) accommodating slurry (120) having solid catalyst particles (124) suspended in liquid hydrocarbon (122), and distributor (140) disposed at an inferior portion of the reactor main frame (110) and used to feed a synthetic gas composed mainly of hydrogen and carbon monoxide into the slurry (120), wherein the reactor main frame (110) in its interior is provided with baffle plate (150) so as to block the side-wall side of the reactor main frame (110) and open the center part thereof.

Owner:NIPPON STEEL & SUMIKIN ENG CO LTD

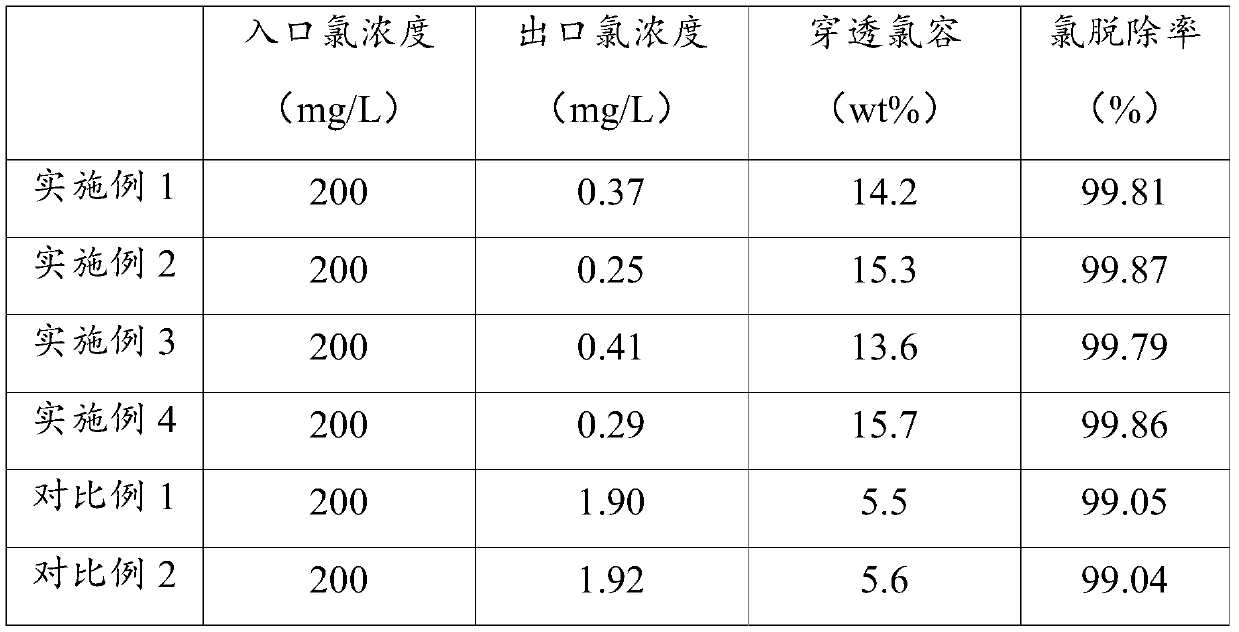

Dechlorinating agent and preparation method and application thereof

InactiveCN111013532AHigh chlorine capacityImprove efficiencyOther chemical processesHydrocarbon oils refiningPotassiumCopper oxide

The invention provides a dechlorinating agent as well as a preparation method and application thereof. The dechlorinating agent comprises a binder and a carrier, and also comprises 3.3-6.6 wt% of copper oxide and 5-25wt% of potassium permanganate, based on the total mass amount of the dechlorinating agent. Manganese atoms in potassium permanganate contain a large number of empty orbits, and chlorine atoms in organochlorine contain three pairs of lone electrons, so that adsorption and removal on organochlorine are improved; moreover, the oxidability of potassium permanganate can change the contents of acidic groups and basic groups on the surface of the carrier, so that the chemical properties of the surface of the carrier are changed, and the adsorption performance of the carrier to organochlorine and hydrogen chloride is improved; on the other hand, potassium permanganate can generate a synergistic effect with copper oxide and an adhesive, so that the affinity between each component and the carrier is improved, the loss of each component in the use process is reduced, and the chlorine capacity and the dechlorination efficiency of the dechlorinating agent are further improved; agglomeration among metal ions can be prevented, so that the metal ions are kept in a dispersed state on the surface of the carrier; and the chlorine capacity and the dechlorination efficiency of the dechlorinating agent are further improved.

Owner:SHENYANG SANJUKAITE CATALYST

Method for producing bulky graphene

InactiveCN105712322ARequirement to reduce ball milling speedImproved shearing and peelingSolventWater soluble

The invention discloses a method for producing bulky grapheme. The method comprises the following steps: S1) injecting graphite flakes and a stripper in a ball milling jar, wherein the stripper comprises the following components: 100 parts of water, 30-100 parts of an alcohols solvent, 50-80 parts of a polyacrylate or polyacrylate derivative, 1-30 parts of flaky metal powder, and 0.5-5 parts of water-soluble salt; S2) performing ball milling on the components for 4-48 hours, wherein a rotating speed of a bowl mill is more than 2000 rpm / min; S3) stopping a reaction and discharging a fluid suspension for standing; S4) conveying the graphene fluid suspension to a centrifuge for centrifugation, after centrifugation, an upper level clear liquid is taken for vacuum-filtering to obtain a filter cake; and S5) washing the filter cake, performing freeze drying on the filter cake. The method is capable of stripping bulky graphene with high efficiency.

Owner:江苏碳谷二维世界科技有限公司

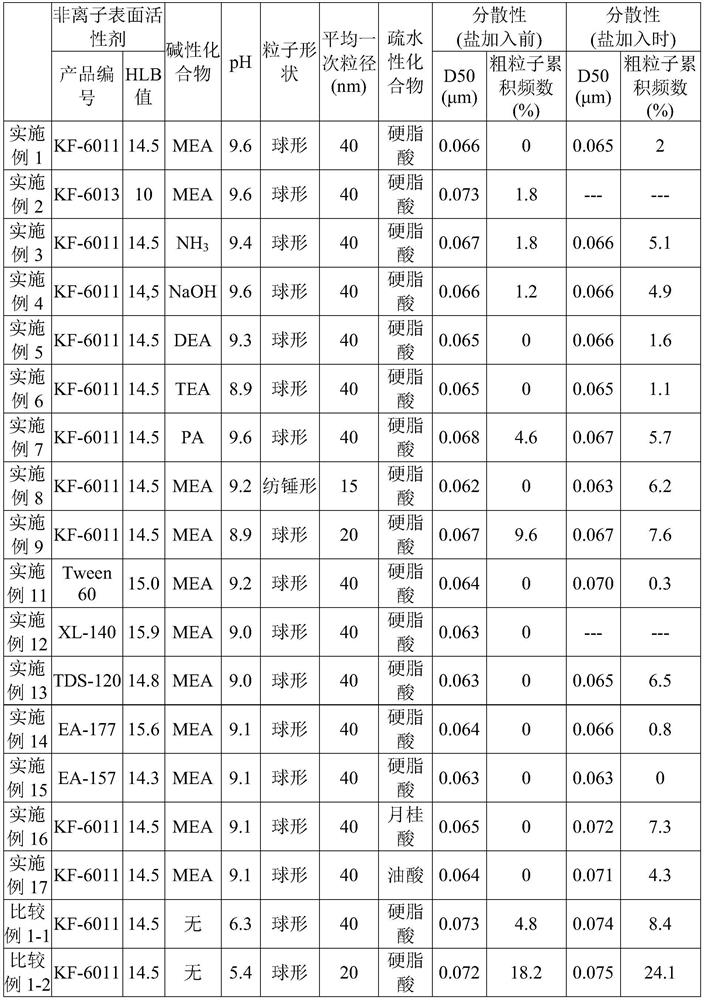

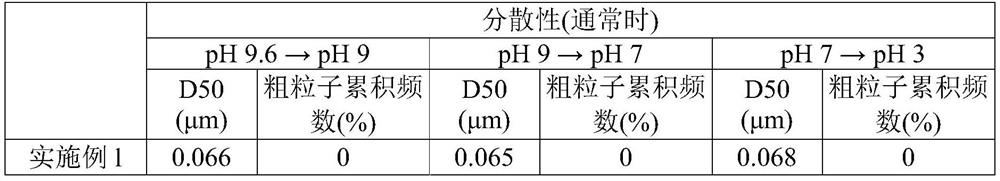

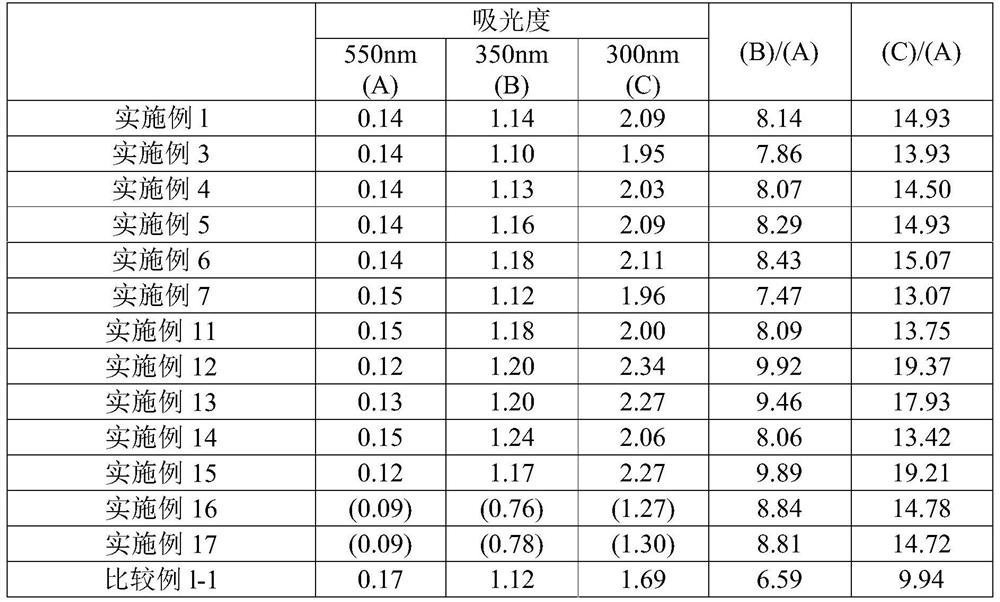

Titanium dioxide aqueous dispersion and method for producing same

ActiveCN111684027AGood dispersionExcellent visible light transparencyPigmenting treatmentCosmetic preparationsActive agentPhysical chemistry

Provided are a titanium dioxide aqueous dispersion having high dispersibility and little aggregation or coarse particles, and a method for producing the same. The titanium dioxide aqueous dispersion contains titanium dioxide particles having a hydrophobic compound such as a higher fatty acid or a salt thereof on the surface, an aqueous dispersion medium, a nonionic surfactant having an HLB value of 10 or higher, and a basic compound such as an alkanolamine, and the pH is in the 8.5-13 range. The method for producing a titanium dioxide aqueous dispersion has a step for mixing the titanium dioxide particles having a hydrophobic compound on the surface, the aqueous dispersion medium, the nonionic surfactant having an HLB value of 10 or higher, and the basic compound to bring the pH of the aqueous dispersion into the 8.5-13 range.

Owner:ISHIHARA SANGYO KAISHA LTD

Efficient plugging film-forming shield slurry material for rescue and emergency

ActiveCN112110682AFully blockedImprove construction qualityLandfill technologiesSlurryPolymer coatings

The invention discloses an efficient plugging film-forming shield slurry material for rescue and emergency, wherein the material comprises the components in percentage by weight: 70-80% of bentonite,10-15% of a polymer coating material, 5-10% of a colloid enhancer, 1-3% of a polymer dispersant and 1-3% of an emulsifier. According to the invention, the polymer coating material and bentonite are combined in water to form elastic particles, so that mud prepared from the efficient plugging film-forming shield slurry material for rescue and emergency can effectively block stratum pores, and the stability of an excavation surface is improved.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +2

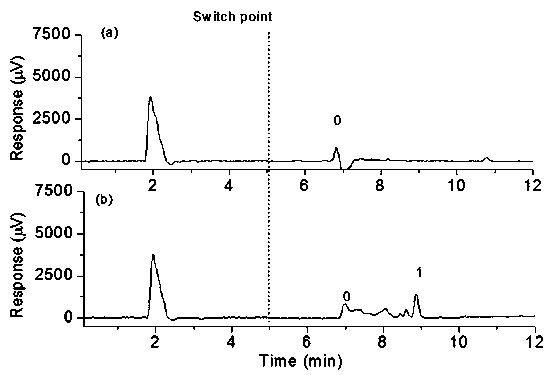

Nucleic acid aptamer functionalized polymerization column for specific recognition of mycotoxin and preparation method of column

ActiveCN110115992ARealization of specific recognitionHigh surface coverage densityOther chemical processesComponent separationInteraction layerMycotoxin

The invention discloses a nucleic acid aptamer functionalized polymerization column for specific recognition of mycotoxin and a preparation method of the column. The polymerization column is an affinity column material prepared by adopting an organic-inorganic hybrid silica gel polymer which is formed by polycondensation of organic siloxane gel and contains abundant sulfhydryl on the surface to serve as a matrix, modifying oligomeric silsesquioxane nanoparticles substituted by sodium acrylate on the basis of the matrix and then modifying anti-mycotoxin nucleic acid aptamers with sulfhydryl onsodium salt nanoparticles. The affinity polymerization column prepared by means of the method is provided with the rigid silica gel matrix; through post-modification of the column, abundant sulfhydrylstructures and multiple acting sites of oligomeric polysilsesquioxane monomers are formed on the surface. The anti-mycotoxin nucleic acid aptamers can be bonded to bridging sites through click chemistry to form aptamer affinity interaction layers with high hydrophilicity and negative charges on the surfaces, and the specific identification of different mycotoxins is realized by class.

Owner:FUZHOU UNIV

Composite stripping medium for graphene stripping

The invention discloses a composite stripping medium for graphene stripping. The stripping medium comprises the following components by weight: 100 parts of water, 30-100 parts of an alcohol solvent, 50-80 parts of polyacrylic ester or polyacrylic ester derivative, 1-10 parts of sheet metal powder, and 0.5-10 parts of rubber powder. According to the invention, polyacrylic ester or polyacrylic ester derivative with glue adhesiveness is added into the stripping medium for graphene stripping, the requirement for grinding or stirring speed can be reduced, and stripping of graphene can be realized without ultra high-speed shearing to a flake graphite layer. The sheet metal powder and rubber powder can generate a stripping force along the flake direction to graphite, and especially high friction coefficient rubber powder is not easy to make graphene broken. Through combined use of the sheet metal powder and rubber powder, the sheet metal powder can conduct and eliminate static electricity on the rubber powder surface, and superimposition of stripped graphene together again due to static electricity can be avoided.

Owner:江苏碳谷二维世界科技有限公司

Viscous graphene stripping combined solution

The invention discloses a viscous graphene stripping combined solution. The combined solution comprises the following components by weight: 100 parts of water, 30-100 parts of an alcoholic solvent, 50-80 parts of polyacrylic ester or polyacrylic ester derivative, and 0.5-5 parts of a water soluble salt. According to the invention, polyacrylic ester or polyacrylic ester derivative with glue adhesiveness is added into the combined solution, the combined solution can be used in coordination with grinding or stirring so as to reduce the requirement for grinding or stirring speed, and stripping of graphene can be realized without ultra high-speed shearing to a flake graphite layer. In addition, the water soluble salt added into the system can improve the conductivity of the system, superimposition of stripped graphene together again due to static electricity can be avoided, and a disperse state after stripping can be maintained. The combined solution can strip graphene, and at the same time has no corrosion to equipment and causes no damage to the graphene structure.

Owner:江苏碳谷二维世界科技有限公司

Plant fermentation extraction component shampoo and preparation method thereof

PendingCN113633597AOil balanceImprove the environmentCosmetic preparationsHair cosmeticsBiotechnologyAlopecia seborrhoeica

The invention discloses plant fermentation extraction component shampoo and a preparation method thereof, and the plant fermentation extraction component shampoo comprises the following components in parts by weight: 20-30 parts of a natural plant extraction component compound, 65-80 parts of a shampoo substrate, 0.05-0.1 part of a preservative and 0.02-0.05 part of essence. Through a specific ratio of the components, the prepared shampoo has strong cleaning power and no irritation, can promote scalp blood circulation, effectively terminate abnormal alopecia and promote hair regeneration, and also can balance scalp grease, improve scalp environment, inhibit bacterial growth, strengthen hair roots, improve hair toughness, and fundamentally condition scalp health, so that the purpose of improving and preventing alopecia seborrhoeica is achieved.

Owner:广州市百爱神生物科技有限公司

Graphene preparation method

The invention discloses a graphene preparation method. The method comprises the steps of: S1. injecting graphite scale and a stripping solution into a stirrer equipped kettle body, starting a motor of the kettle body to perform stirring so as to mix materials evenly, wherein the stripping solution comprises 100 parts of water, 30-100 parts of an alcohol solvent, 50-80 parts of polyacrylic ester or polyacrylic ester derivative, 1-10 parts of sheet metal powder, 0.5-10 parts of rubber powder; S2. heating the kettle body, keeping the internal temperature of the kettle body at 50DEG C-80DEG C, the pressure at 1-3atm and the stirring shaft rotation speed at 1000-2000rpm / min, and carrying out reaction for 3-6h; S3. at the end of the reaction, discharging the upper suspension solution to perform standing; S4. centrifuging the graphene suspension solution, then taking the upper supernatant solution and conducting vacuum filtering to obtain a filter cake; and S5. washing and freeze drying the filter cake. While stripping graphene, the preparation method does not corrode equipment, and also causes no damage to the graphene structure.

Owner:江苏碳谷二维世界科技有限公司

Viscous physical stripping method for graphene

The invention discloses a method for physically exfoliating graphene in a viscous state, comprising steps: S1. injecting graphite flakes and an exfoliation liquid into a ball mill tank, wherein the exfoliation liquid consists of 100 parts of water, 30-100 parts of alcohol solvent, 50-80 parts of polyacrylate or polyacrylate derivatives, 0.5-5 parts of water-soluble salt; S2. Ball milling for 4-48 hours, the speed of the ball mill is above 2000rpm / min; S3. After stopping the reaction, discharge the suspension to the storage material Standing in the tank; S4. Transporting the graphene suspension to a centrifuge for centrifugation, taking the supernatant and vacuum filtering to obtain a filter cake; S5. Washing and freeze-drying the filter cake. This exfoliation method can efficiently exfoliate graphene.

Owner:江苏碳谷二维世界科技有限公司

Preparation method of metal-based ceramic composite powder

InactiveCN110172605AImprove bindingNo need for chemical coatingTransportation and packagingMetal-working apparatusCeramic compositeGranularity

The invention belongs to the field of composite preparation, and particularly relates to a preparation method of metal-based ceramic composite powder and a product. Ceramic powder, metal powder and abinding agent are subjected to wet grinding and mixing according to the mass proportion of (5-90):(10-90):(1-5), binding agent removal treatment is carried out after atomization and granulation, and granules generated after binding agent removal treatment are sintered. The process is simple, a metal phase and a ceramic phase of the prepared powder are combined closely, the variety of composite phases is rich, the degree of sphericity of the powder granules is high, flowability is good, the granularity is adjustable, and element distribution is uniform.

Owner:SF DIAMOND CO LTD

Large graphene stripping production method

The invention discloses a large graphene stripping production method. The method comprises the following steps: S1, injecting graphite flakes and a stripping liquid into a kettle body with a stirrer, and starting a motor of the kettle body for stirring, wherein the stripping liquid comprises the components of 100 parts of water, 30-100 parts of an alcoholic solvent, 50-80 parts of polyacrylate or polyacrylate derivants, 1-30 parts of flaky metal powder and 0.5-5 parts of water soluble salt; S2, heating the kettle body, keeping the temperature in the kettle body to be 50-80 DEG C, keeping the pressure to be 1-3 atm, keeping the rotating speed of a stirring shaft to be 1000-2000 rpm and keeping the reaction time to be 3-6 h; S3, discharging an upper layer suspending liquid after the reaction stops, and performing still standing; S4, conveying the graphene suspending liquid to a centrifuge for centrifugation, taking a supernatant after centrifugation, and conducting vacuum filtration to obtain filter cake; S5, washing the filter cake, and conducting freeze drying. According to the method, equipment cannot be corroded, graphene cannot be damaged, and large graphene can be obtained.

Owner:江苏碳谷二维世界科技有限公司

Efficient conductive agent

InactiveCN109637696AIncrease repulsionIncreased binding sitesNon-conductive material with dispersed conductive materialDispersityOrganic film

The invention discloses an efficient conductive agent, and belongs to the field of battery material preparation. A self-repairing polyurethane material is prepared from 4,4'-diphenylmethane diisocyanate, polypropylene glycol and the like as raw materials, intermolecular repulsion is improved, dispersity in the using process is improved in an auxiliary mode, agglomeration is avoided, conductive performance is stabilized, contact resistance generated in a system is reduced, and the conductive performance is further improved; pretreated steel slag is prepared from steel slag, camellia seed meal,fly ash and the like, tea saponin dissolved out of the camellia seed meal can play a good dispersion role, the flowability in the grinding process is improved, the dispersity is improved, and in the subsequent preparation process, the surfaces of the component particles can be coated with a layer of organic film, so that the agglomerated particles are dispersed again, the components are promoted to be kept in a dispersed state, and the agglomeration phenomenon between the conductive components is avoided. The conductive agent solves the problems that a common conductive agent is prone to caking and the conductive effect is not long at present.

Owner:徐冬

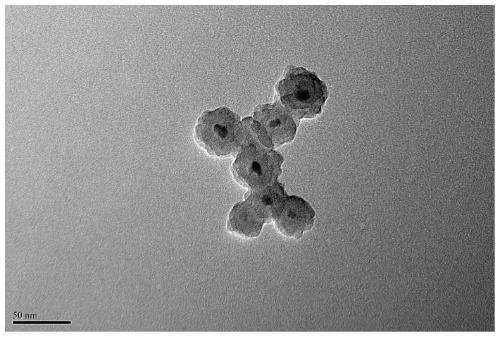

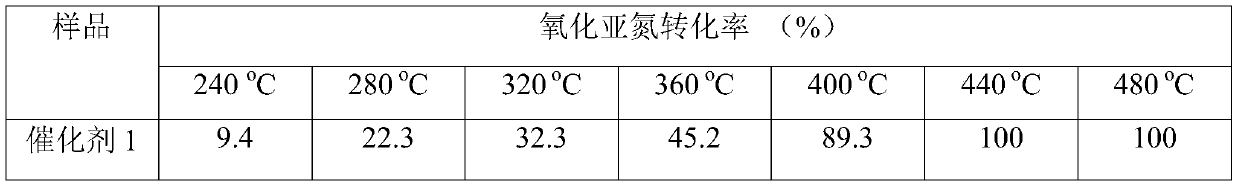

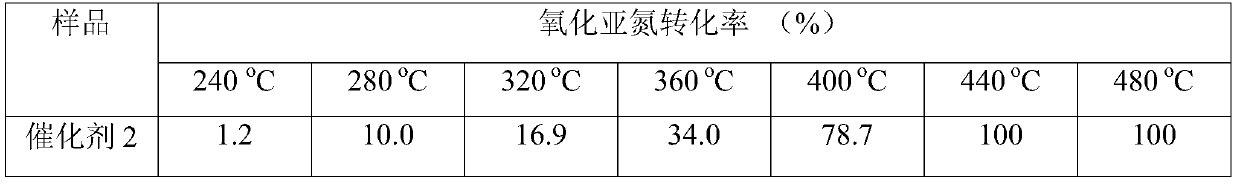

A medium and low temperature catalytic decomposition n 2 Catalyst and preparation method and application of o

ActiveCN106964360BTypical monodisperse core-shell structureHigh catalytic activityNitrous oxide captureGas treatmentPtru catalystPhysical chemistry

The invention discloses a catalyst for catalytic decomposition of N2O at medium and low temperature. The catalyst comprises an active oxide inner core and a porous inert oxide shell layer, wherein the active oxide inner core consists of an active component Co3O4; the porous inert oxide shell layer consists of SiO2-NxOy; NxOy is one of ZrO2 and CeO2; and the catalyst comprises the following components by weight percentage: 10-40wt% of Co3O4, 0.1-3wt% of ZrO2 or CeO2, and the balance of SiO2. The catalyst has the advantages of good activity and long service life.

Owner:SHANXI UNIV

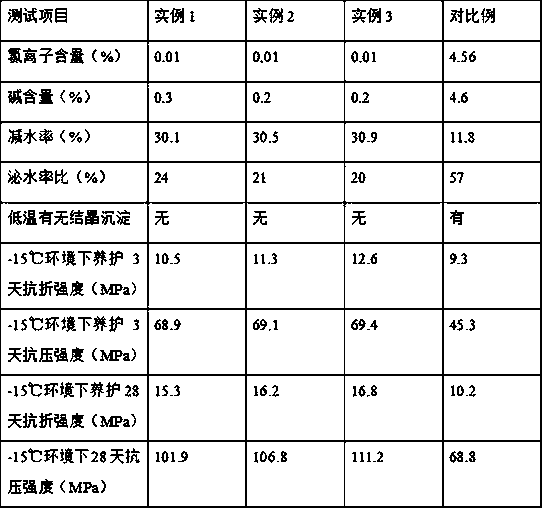

Preparation method of concrete anti-freezing agent

The invention relates to a preparation method of a concrete anti-freezing agent and belongs to the technical field of concrete anti-freezing agent preparation. The preparation method comprises the following steps: preparing reaction liquid from methoxy polyethylene glycol, acrylamide and other auxiliaries; mixing methyl triethoxysilane and quaternary ammonium polyether-based trimethoxy silane, andreacting to obtain reaction powder; mixing fatty alcohol-polyoxyethylene ether, sulfamic acid and the reaction powder, and reacting to obtain a reaction emulsion; finally, stirring and mixing the reaction liquid, the reaction emulsion and other auxiliaries to obtain the concrete anti-freezing agent. According to the preparation method provided by the invention, a nonpolar amide group is introduced into a polycarboxylate water reducing agent, thus the concentration of carboxylate ions is lowered; the carboxylate ions adsorb cement particles, then the electronegativity on the surfaces of the cement ions is enhanced, and aggregation of the cement particles is prevented; by introducing bubbles into concrete, the capillary tubes in the concrete become thinner, thus the concrete strength is maintained, and the anti-freezing ability can be effectively improved; therefore, the preparation method has a broad application prospect.

Owner:CHANGZHOU SIYU ENVIRONMENTAL PROTECTION MATERIAL SCI & TECH

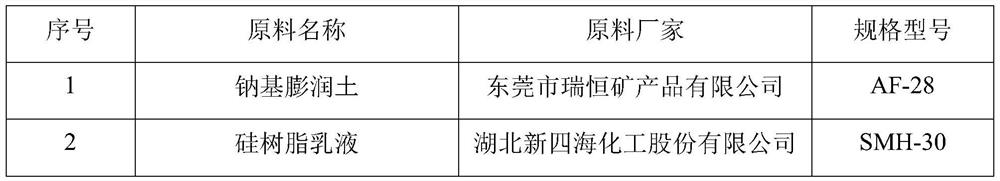

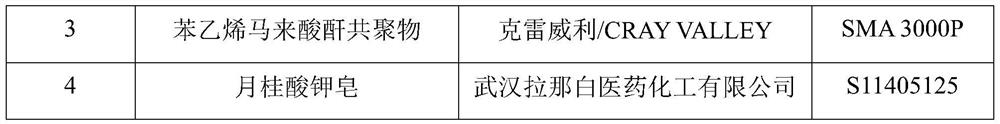

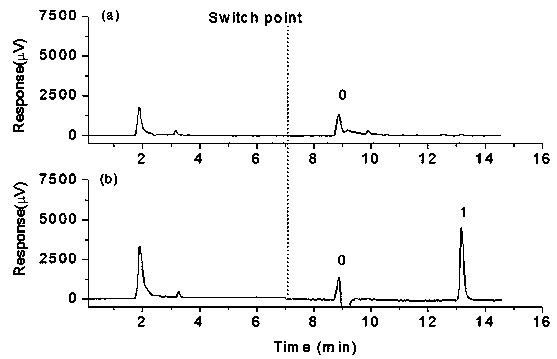

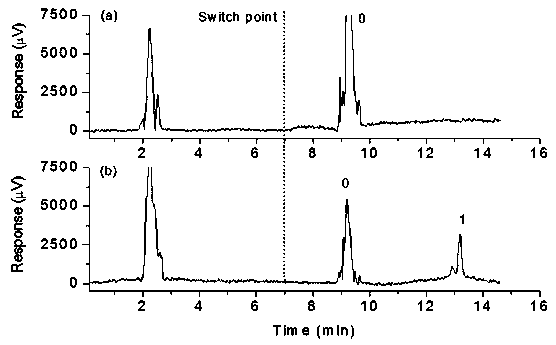

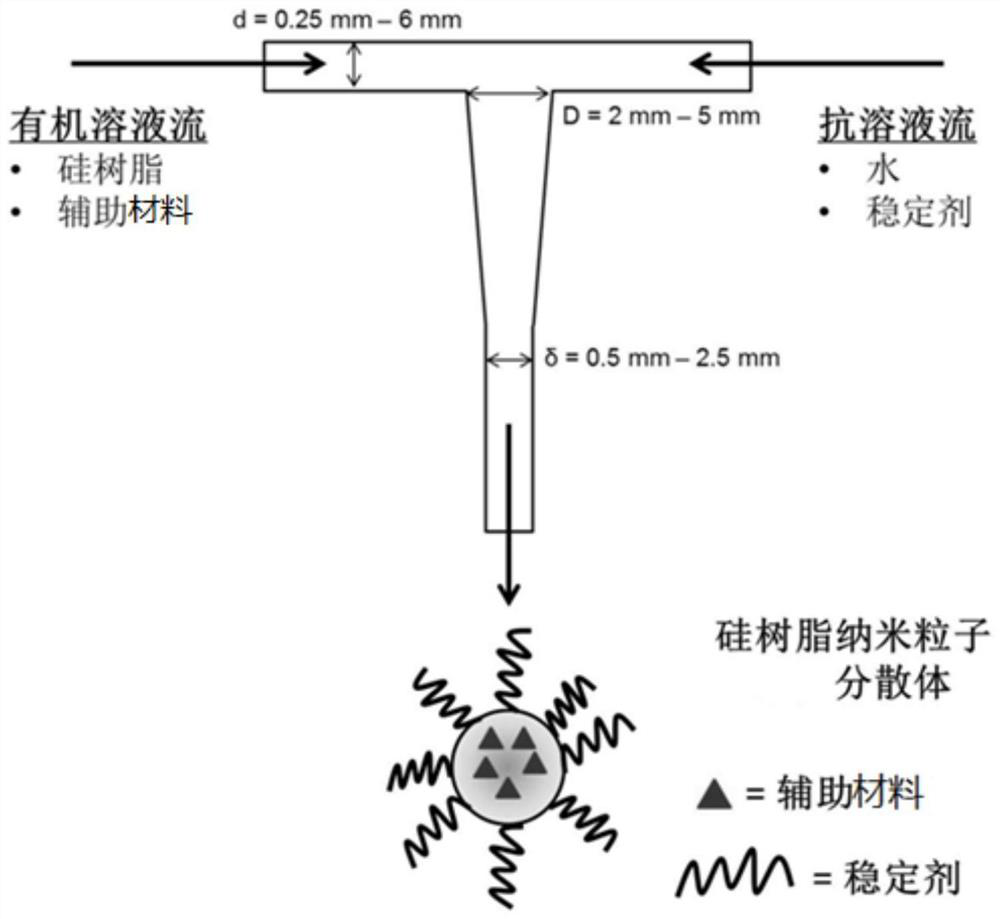

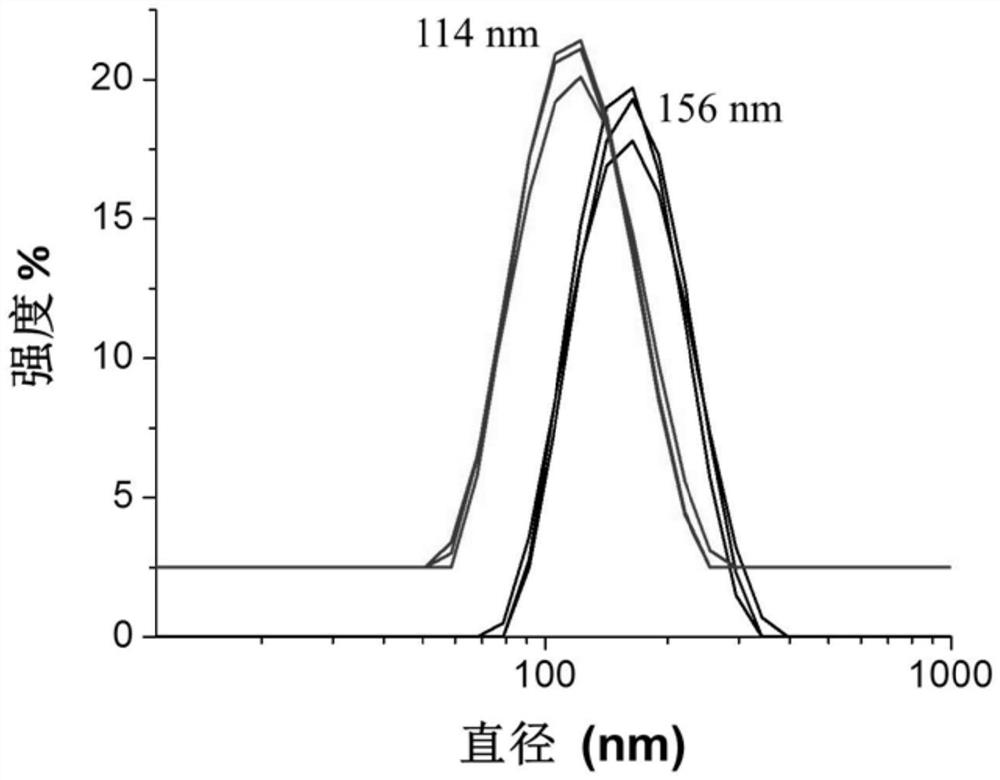

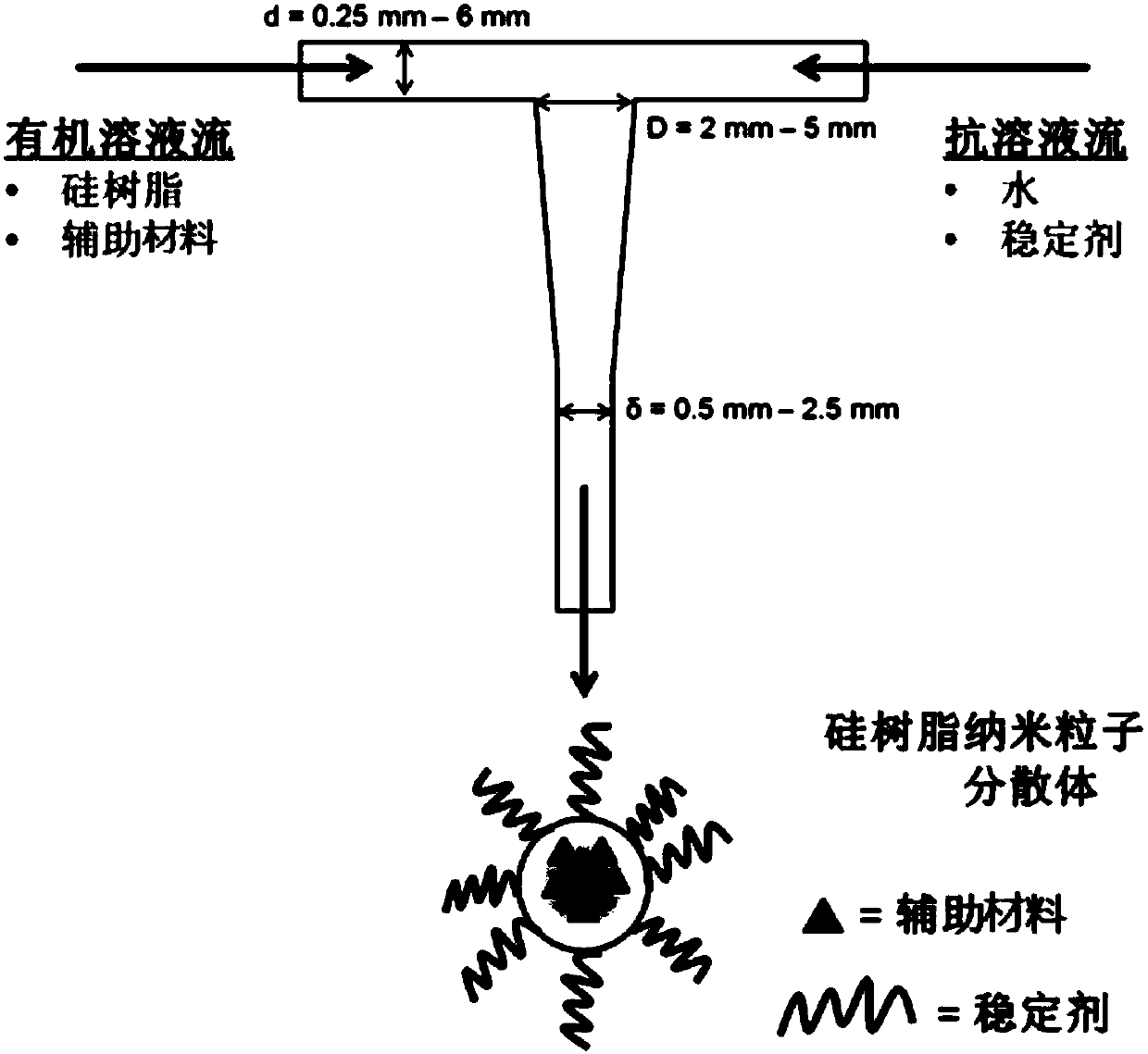

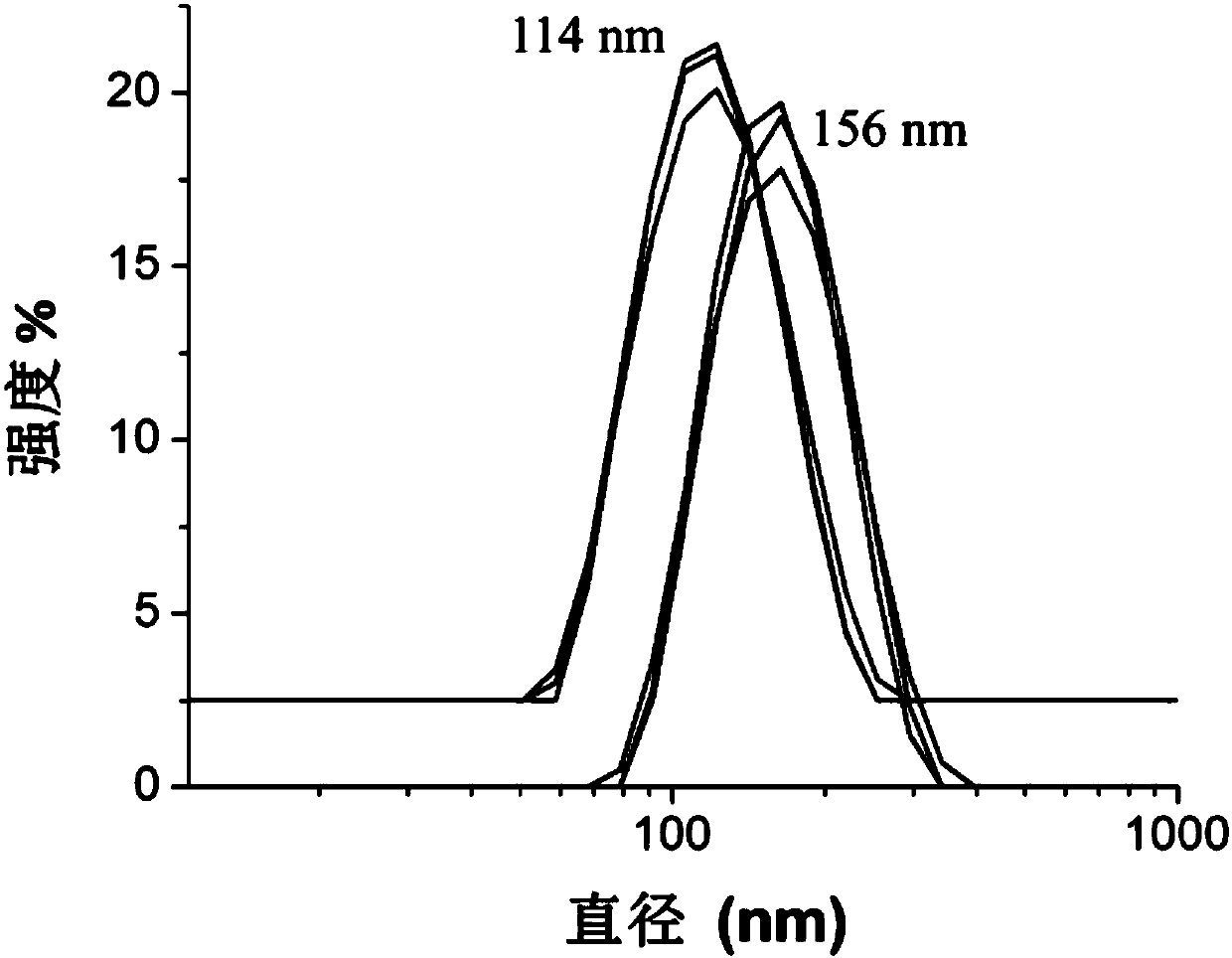

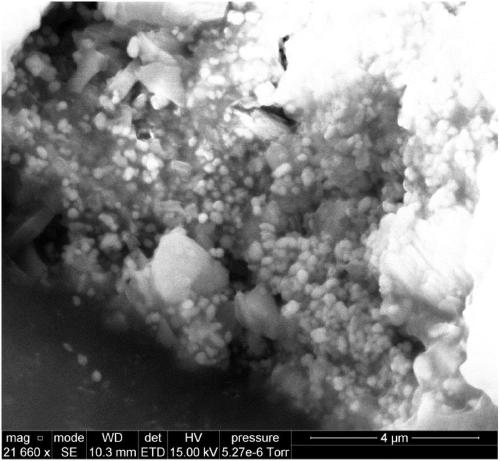

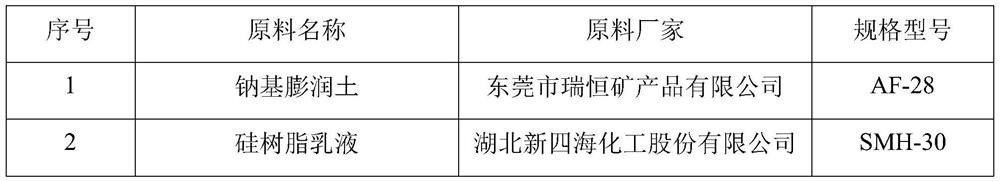

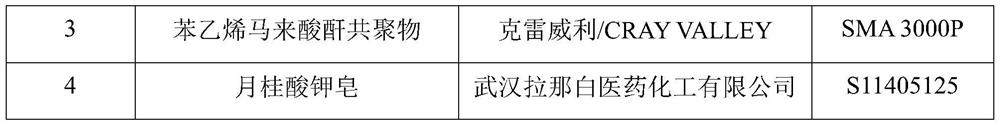

A preparation method of silicone resin nanoparticle dispersion and silicone resin nanoparticle dispersion

ActiveCN109971003BRapid precipitationUniform particle sizeNanotechnologyPolymer scienceNanoparticles dispersion

The invention belongs to the technical field of silicone resin nanoparticle preparation, and provides a preparation method of a silicone resin nanoparticle dispersion and a silicone resin nanoparticle dispersion; the preparation method includes the following steps: (1) dissolving a hydrophobic silicone resin in a water-soluble (2) After the organic solution and the anti-solution are mixed rapidly, the silicone resin nanoparticle dispersion is obtained by precipitation; the rapid mixing is to make the mixing system operate at a Reynolds number > 1600 . The particle size of the silicone resin nanoparticles distributed in the silicone resin nanoparticle dispersion is 20nm-1500nm. The preparation method of the invention can realize rapid (Reynolds number>1600) precipitation of the silicone resin material dissolved in the solvent flow, and obtain silicone resin nanoparticles with uniform particle size distribution.

Owner:WANHUA CHEM GRP CO LTD

A kind of high-performance monument repairing material and preparation method thereof

The invention provides a high-performance historic site repair material and a preparation method thereof. The repair material comprises the following raw materials: 191-287 parts of sticky rice pulp, 115-185 parts of lime, 0-4 parts of brown granulated sugar, 344-398 parts of fine aggregates, 204-268 parts of complex mineral admixture, 11-12 parts of reinforcing agent, and 0-19 parts of mineral pigment. The invention further provides a preparation method of the repair material. The preparation method comprises the following steps: weighing all the raw material according to weight, and forcibly stirring evenly to obtain the repair material. Amylopectin in the sticky rice pulp is a highly branched macromolecule, the setting and hardening processes of the lime and the pozzolanic reaction of the complex mineral admixture are influenced, the strength development of the material is similar to biomineralization process, and a microstructure formed in the process endows the repair material with higher strength and toughness. Furthermore, the material has good compatibility with materials of a historic site body.

Owner:WUHAN UNIV

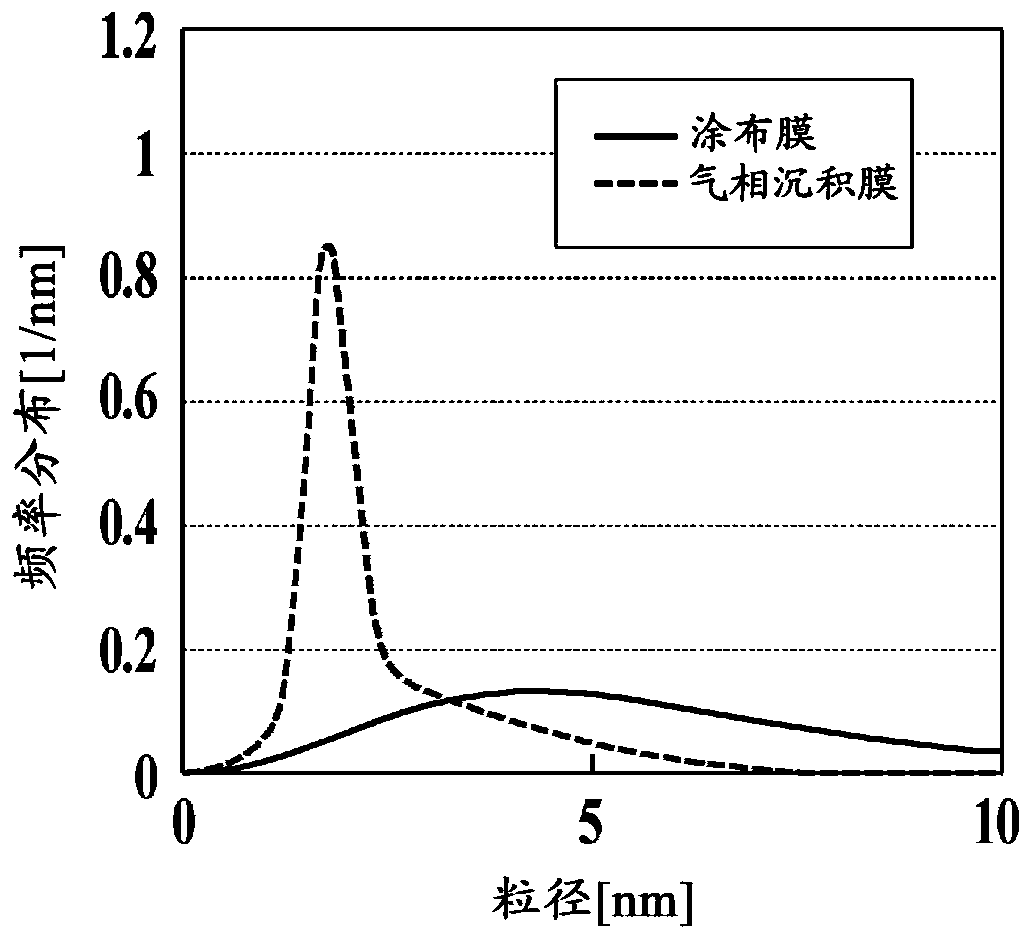

Coating liquid production method, coating production method, coating, organic electroluminsecent element, display device and illumination device

ActiveCN110431196AImprove functionalityImprove storage effectLiquid surface applicatorsLuminescent paintsDisplay deviceOrganic electroluminescence

The present invention addresses the problem of providing: a method for producing a coating liquid which is highly storable and when dried, forms a highly functional coating; a coating production method that uses the coating liquid; a coating formed by drying and solidifying the coating liquid; an organic electroluminescent element provided with the coating as an organic functional layer; and a display device and illumination device provided with the organic electroluminescent element. The production method produces the coating liquid by mixing a solution and a supercritical or subcritical fluid.

Owner:KONICA MINOLTA INC

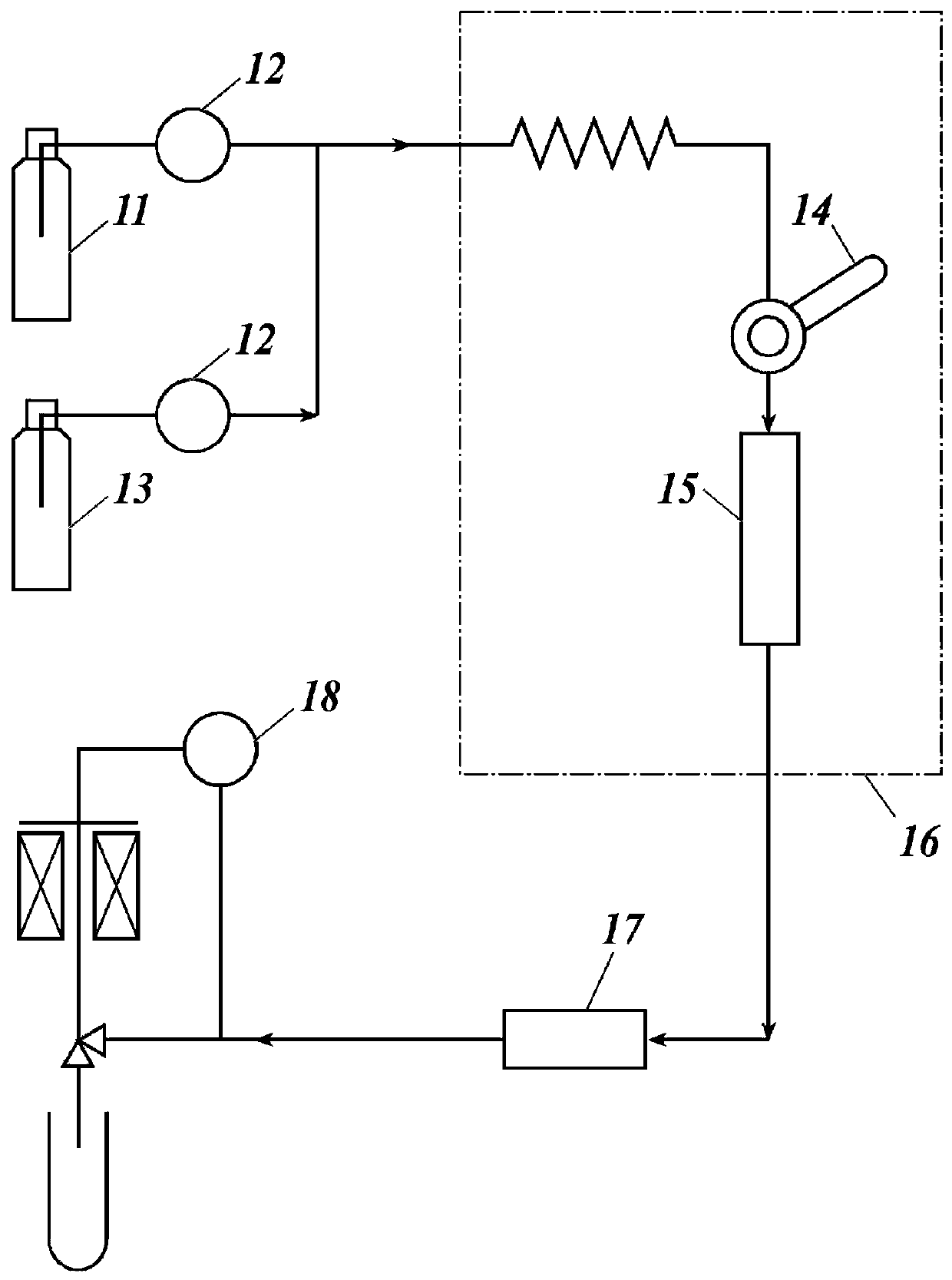

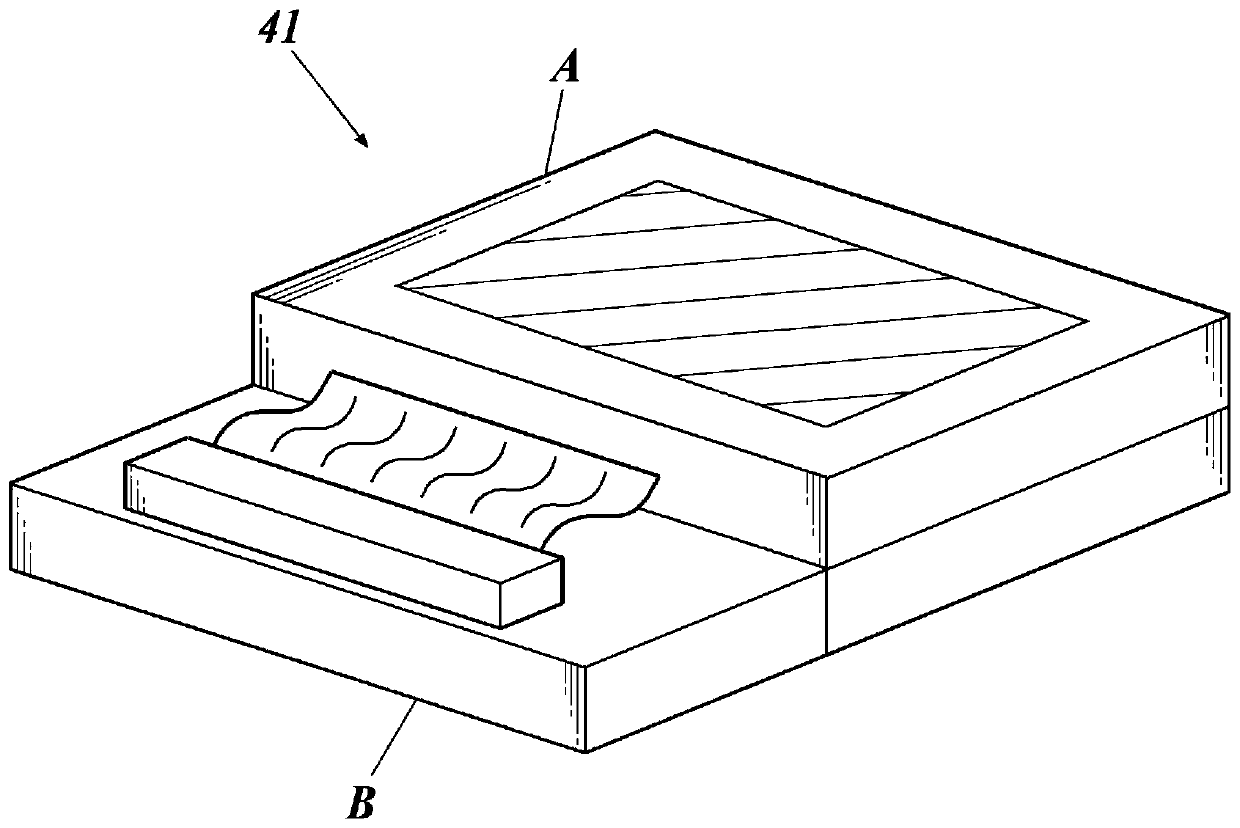

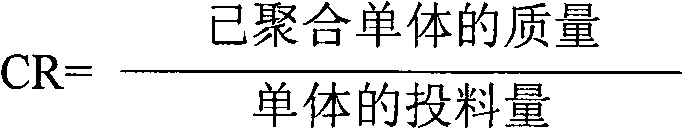

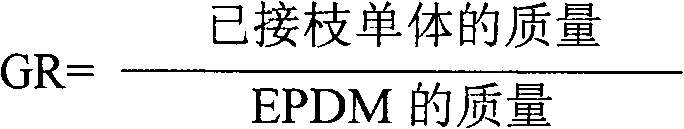

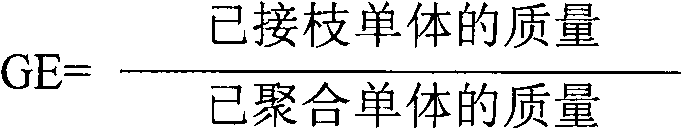

A kind of preparation method and application of EPDM graft copolymer

The invention discloses a preparation method of EPDM graft copolymer and its application in preparing engineering plastics. In the method, EPDM rubber is used as a graft base, and methyl methacrylate and acrylonitrile are used as The grafted monomer is prepared by the suspension method of graft copolymerization to prepare the ethylene-propylene rubber graft copolymer. The graft copolymer is melt-blended with the SAN resin to prepare a weather-aging and yellowing resistance with excellent performance and high gloss. High impact engineering plastics. The present invention adopts the continuous stirring suspension graft copolymerization method, so that the whole polymerization reaction system is a stable aqueous phase suspension polymerization system, so as to form a uniformly distributed graft chain on the EPDM molecular chain. The invention has less solvent consumption, high monomer concentration, and monomer conversion rate as high as 90-99.0%, the product does not need to be recovered by methanol or ethanol precipitation, and the organic solvent and residual monomer are easy to be recovered and recycled, thereby simplifying the post-processing procedure, and significantly Reduce investment and production costs for post-processing equipment for products and solvents.

Owner:KINGFA SCI & TECH CO LTD +1

Graphene preparation method

The invention discloses a graphene production method. The method comprises the following steps: 1, injecting graphite flakes and a stripper to a ball milling pot, wherein the stripper comprises 100 parts of water, 30-100 parts of an alcoholic solvent, 50-80 parts of polyacrylate or a polyacrylate derivative, 1-10 parts of sheet metal powder and 0.5-10 parts of rubber powder; 2, carrying out ball millingat a rotating speed of a ball mill of 2000rpm or above for 4-48h; 3, stopping a reaction, discharging a suspension to a material storage pot, and standing the suspension; 4, conveying the graphene suspension to a centrifuge, centrifuging the suspension, taking the obtained supernatant, and carrying out vacuum filtration to obtain a filter cake; and 5, washing the filter cake, and freeze-drying the filter cake. The method allows graphene to be efficiently stripped.

Owner:江苏碳谷二维世界科技有限公司

Preparation method of silicon resin nanoparticle dispersion and silicon resin nanoparticle dispersion

ActiveCN109971003ARapid precipitationUniform particle sizeNanotechnologyOrganic solventWater soluble

Owner:WANHUA CHEM GRP CO LTD

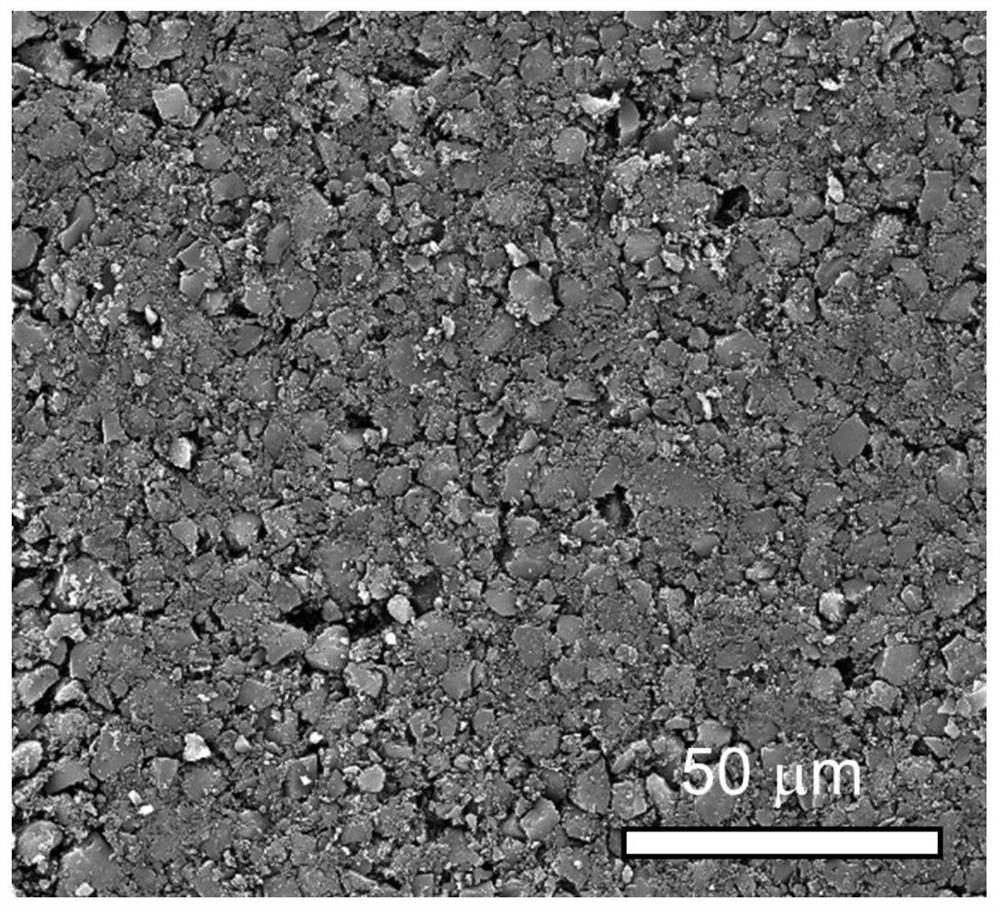

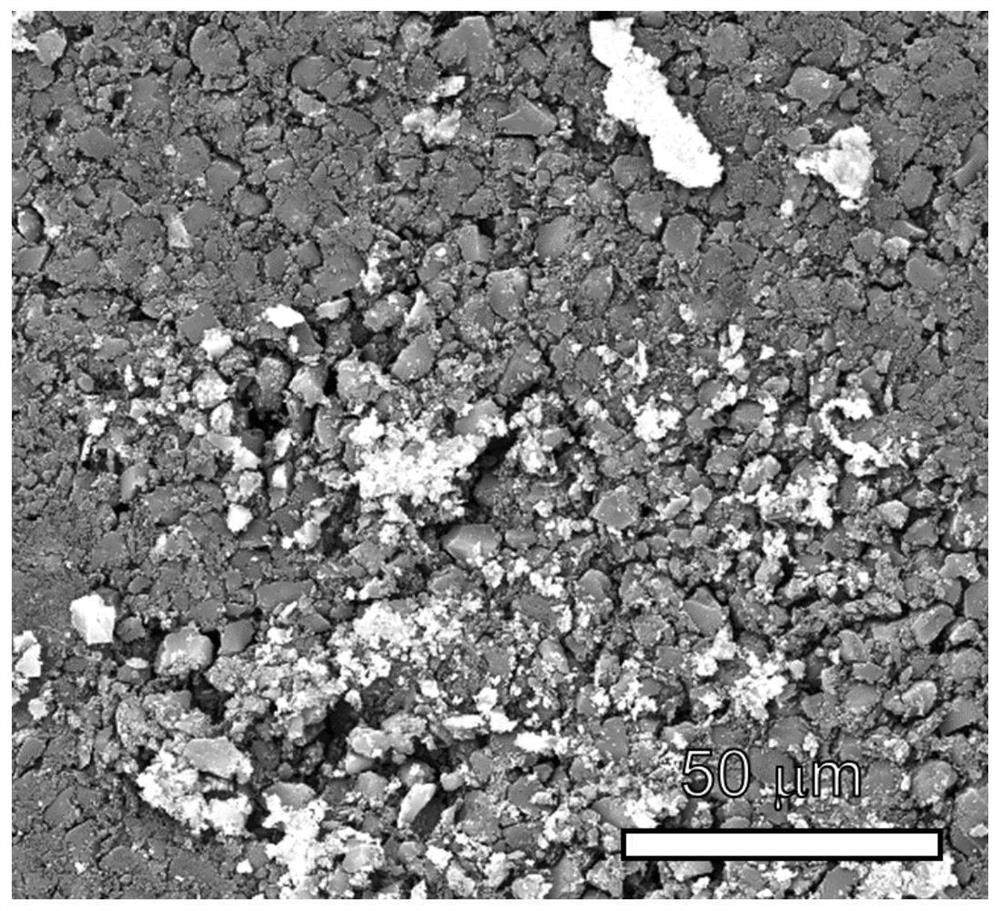

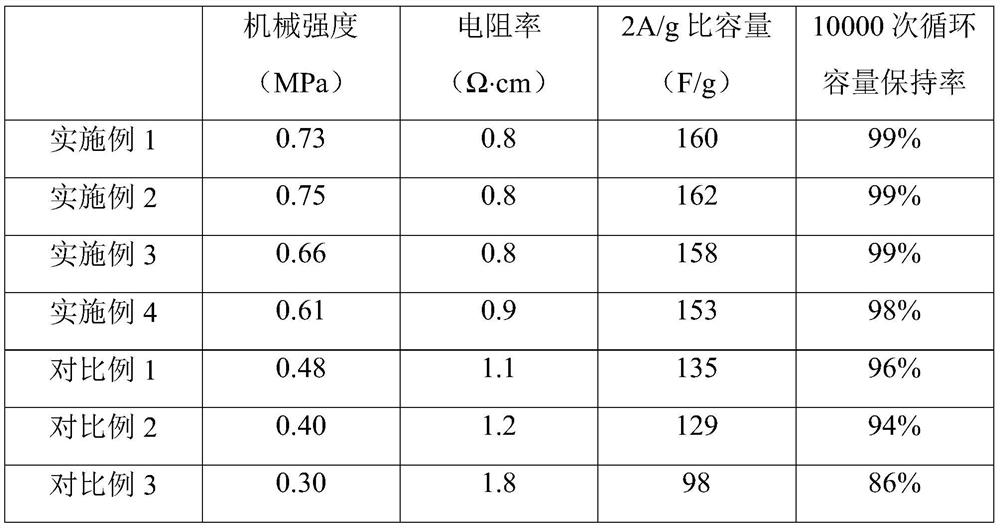

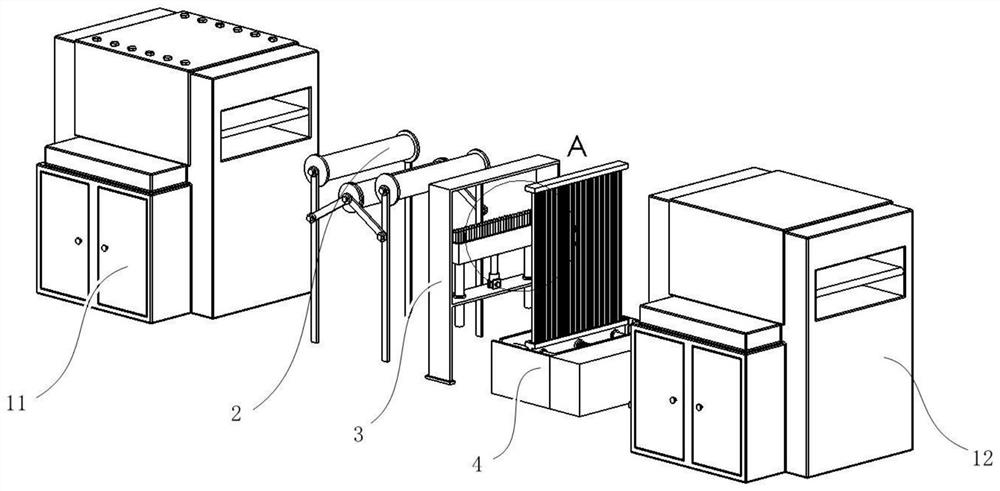

Preparation process of supercapacitor electrode

ActiveCN113270276AImprove stabilityPrevent fibrosisHybrid/EDL manufactureCarbon filmInternal resistance

The invention relates to the technical field of supercapacitor preparation, in particular to a preparation process of a supercapacitor electrode, and creatively proposes that the mixing temperature is reduced, the stability of a PTFE spiral structure is enhanced, fibration of PTFE is effectively inhibited, the agglomeration phenomenon is avoided, by coordinating the mixing temperature and the stirring rotating speed, the uniformity and dispersity of a solid mixture are remarkably improved, and the prepared dry carbon film is high in mechanical strength, small in internal resistance, high in power density and good in cycle performance. The preparation process is simple to operate, convenient to control, high in production efficiency and low in production cost, and can be used for large-scale production.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Large graphene stripping combined solution

The invention discloses a large graphene stripping combined solution, which comprises the following component by weight: 100 parts of water, 30-100 parts of an alcohol solvent, 50-80 parts of polyacrylic ester or polyacrylic ester derivative, 1-30 parts of sheet metal powder, and 0.5-5 parts of a water soluble salt. According to the invention, polyacrylic ester or polyacrylic ester derivative with glue adhesiveness is added into the combined solution, the combined solution can be used in coordination with grinding or stirring so as to reduce the requirement for grinding or stirring speed, and stripping of graphene can be realized without ultra high-speed shearing to a flake graphite layer. Through cooperation with flake zinc powder, a stripping force along the flake direction can be generated to graphite. In addition, the water-soluble salt added into the system can improve the conductivity of the system, superimposition of stripped graphene together again due to static electricity can be avoided, and a stripped disperse state can be maintained.

Owner:江苏碳谷二维世界科技有限公司

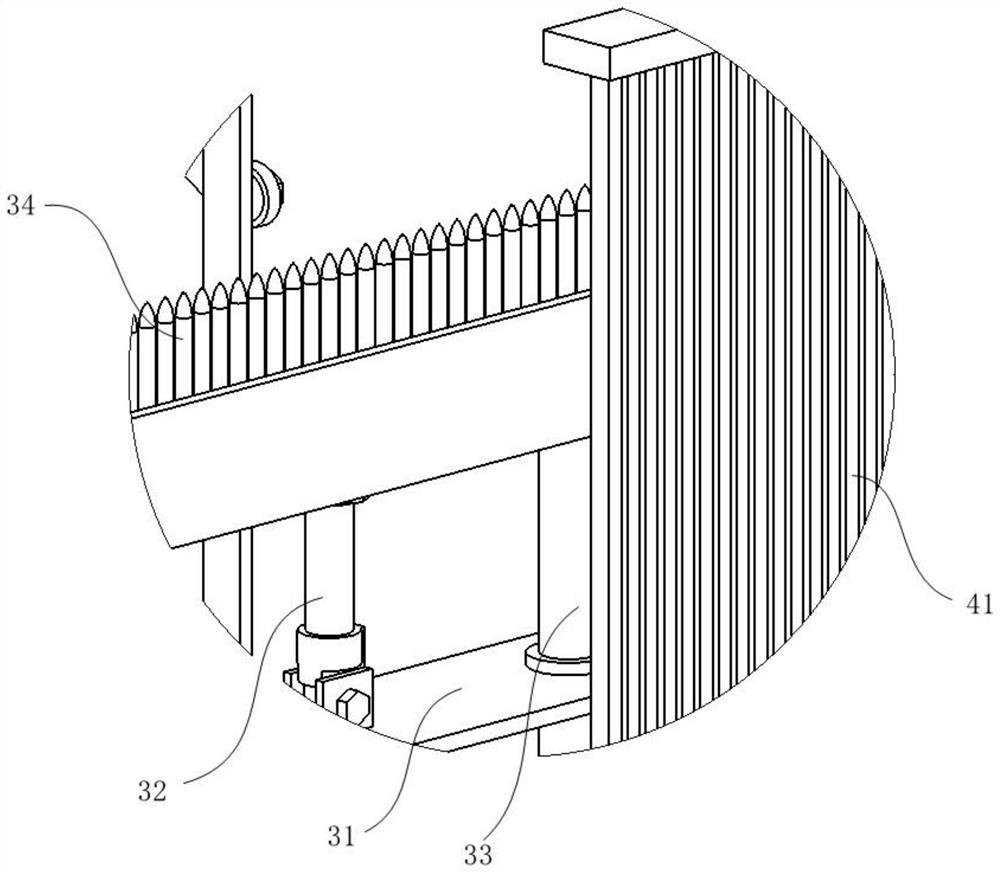

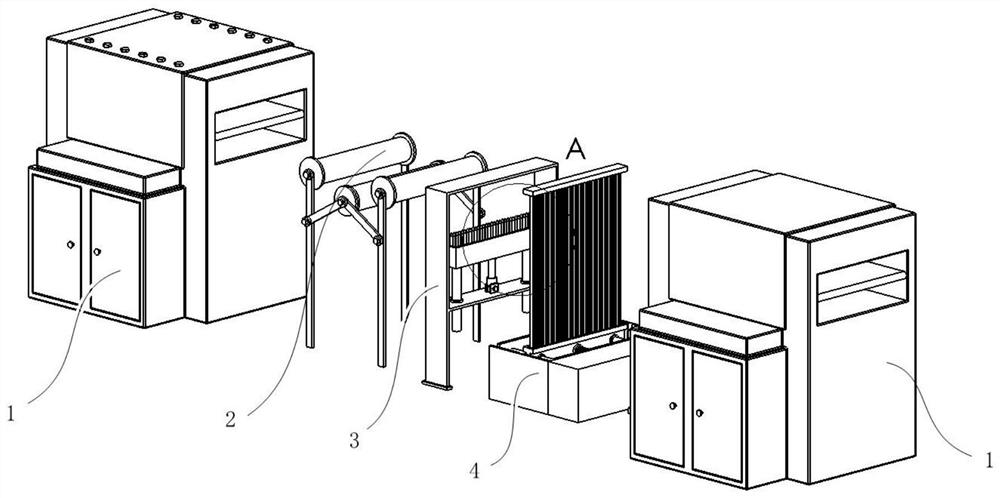

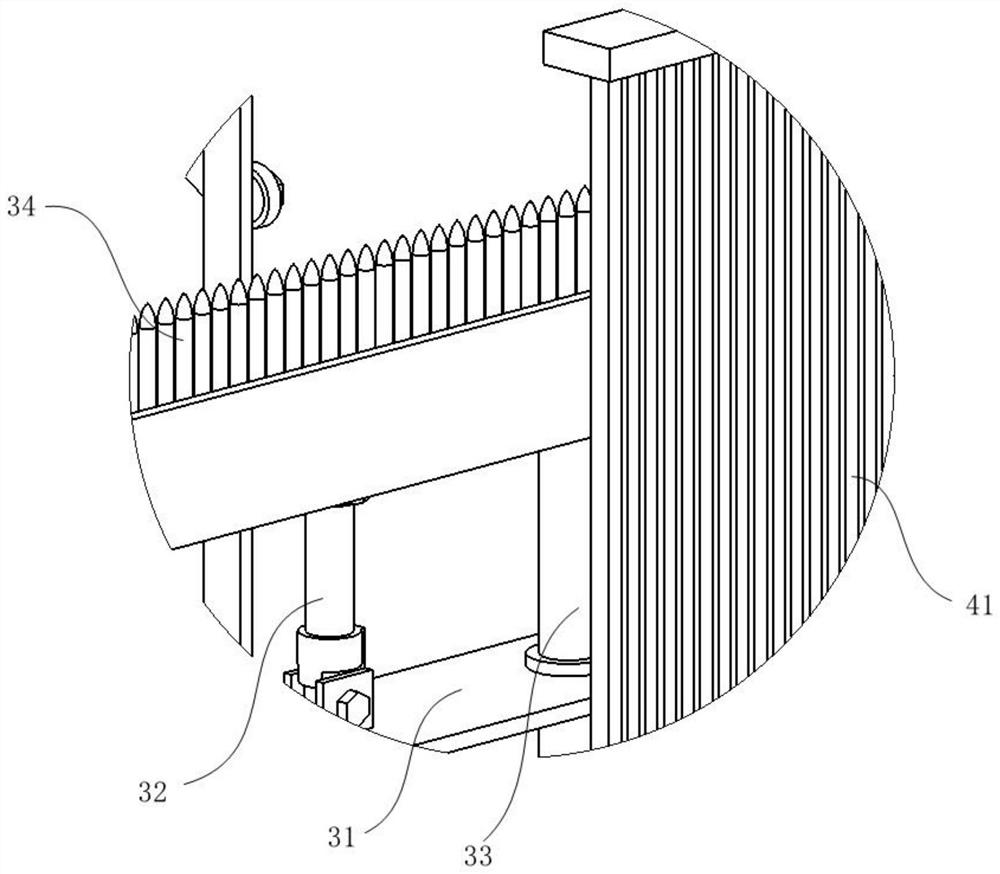

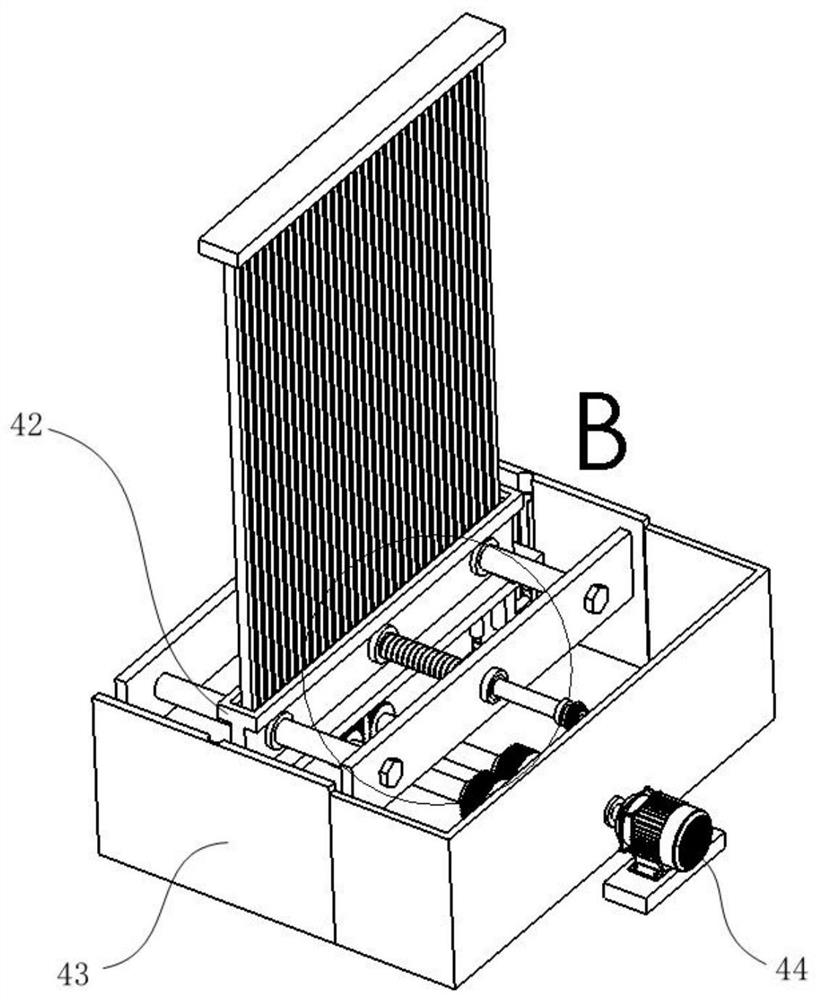

Anti-adhesion and fracture acetate pulp silk equipment and technology

ActiveCN112899944BGuaranteed tensionImprove uniformityLiquid/gas/vapor removalTextile treatment carriersPolymer scienceEngineering

The invention discloses an anti-adhesion and breaking acetic acid slurry silk equipment and process, which comprises sequentially arranged ovens for baking the sized silk threads, and sequentially arranged tensioners for tensioning the silk threads between the ovens. Mechanism, a dividing mechanism for separating the thread, and a reed mechanism for passing the separated thread. The reed teeth of the reed mechanism can only accommodate a single thread to pass through, and the bottom end is provided with a driving reed tooth to move The drive assembly includes a lifting mechanism that drives the reed teeth to move up and down and a traverse mechanism that drives the reed teeth to move back and forth. Through the above method, the present invention adopts a kind of anti-adhesion and fracture acetic acid slurry equipment and technology, by adding a dividing mechanism and a swinging reed mechanism between two ovens to disperse the silk threads and make a single thread pass between the reed teeth, Then through the various movements of the reed, the silk threads are completely dispersed and uniform to avoid adhesion and fracture.

Owner:武汉裕大华纺织有限公司

Steel plant high-salinity wastewater treatment agent and treatment method thereof

ActiveCN112158927AImprove bindingHigh affinityTreatment involving filtrationWaste water treatment from metallurgical processLead chlorideAmmonium carbonate

The invention discloses a steel plant high-salinity wastewater treatment agent and a treatment method thereof, the steel plant high-salinity wastewater treatment agent comprises, by weight, 60%-75% ofa precipitant, 20%-40% of an auxiliary agent, and 0.5%-6.5% of a dispersant; wherein the precipitant is lead silicofluoride, and the auxiliary agent is one or two of ammonium carbonate and ammonium bicarbonate; the dispersant is one or two of polyacrylic acid and polyacrylamide; according to the method, lead silicofluoride is used as the precipitator, and lead ions and carbonate ions in the leadsilicofluoride react to generate basic lead carbonate; ammonium carbonate or ammonium bicarbonate in the auxiliary agent provides a large amount of carbonate ions to promote combination of basic leadcarbonate and sodium ions in the high-salinity wastewater to generate basic lead carbonate sodium precipitate; the lead ions can react with chloride ions in the high-salinity wastewater to generate lead chloride precipitates, and the chloride ions in the wastewater are removed; by adding the dispersant, the affinity with water is effectively improved, so that the treating agent is easy to infiltrate and is kept in a dispersed state, the settling rate of sodium ions and chloride ions is effectively increased, and the effect of efficient purification is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Anti-adhesion and anti-fracture acetic acid silk yarn sizing equipment and process

ActiveCN112899944AGuaranteed tensionImprove uniformityLiquid/gas/vapor removalTextile treatment carriersYarnAcetic acid

The invention discloses anti-adhesion and anti-fracture acetic acid silk yarn sizing equipment and process. The anti-adhesion and anti-fracture acetic acid silk yarn sizing equipment comprises baking ovens for baking sized silk yarns; a tensioning mechanism for tensioning the silk yarns, a silk yarn separating mechanism for separating the silk yarns, and a reed swinging mechanism for allowing the separated silk yarns to pass through are sequentially arranged between the baking ovens; only a single silk yarn can penetrate through reed teeth of the reed swinging mechanism; a driving assembly for driving the reed teeth to act is arranged at the bottom end of the reed swinging mechanism; and the driving assembly comprises a lifting mechanism for driving the reed teeth to move up and down and a traversing mechanism for driving the reed teeth to move front and back. By means of the mode, according to the anti-adhesion and anti-fracture acetic acid silk yarn sizing equipment and process, the silk yarn separating mechanism and the reed swinging mechanism are additionally arranged between the two drying ovens to disperse silk yarns and enable the single silk yarns to penetrate through the reed teeth, all kinds of movement of the reed swinging mechanism enable the silk yarns to be completely dispersed and keep uniformity, and adhesion and fracture are avoided.

Owner:武汉裕大华纺织有限公司

A high-efficiency plugging film-forming shield mud material for emergency rescue

ActiveCN112110682BFully blockedImprove construction qualityLandfill technologiesEmergency rescueColloid

The invention discloses a high-efficiency plugging film-forming shield mud material for emergency rescue, which comprises: 70%-80% of bentonite, 10-15% of polymer wrapping material, and 5-10% of colloidal strengthening agent , polymer dispersant 1‑3%, emulsifier 1‑3%. The invention combines the polymer wrapping material and bentonite in water to form elastic particles, so that the mud prepared by the high-efficiency plugging film-forming shield mud material for emergency rescue can effectively plug the formation pores and improve the stability of the excavation surface.

Owner:CCCC WUHAN HARBOR ENG DESIGN & RES +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com