Preparation method of concrete anti-freezing agent

An antifreeze and concrete technology, applied in the field of concrete antifreeze preparation, can solve problems such as the performance decline of concrete antifreeze, and achieve the effects of stable bubbles, equal size and enhanced electronegativity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

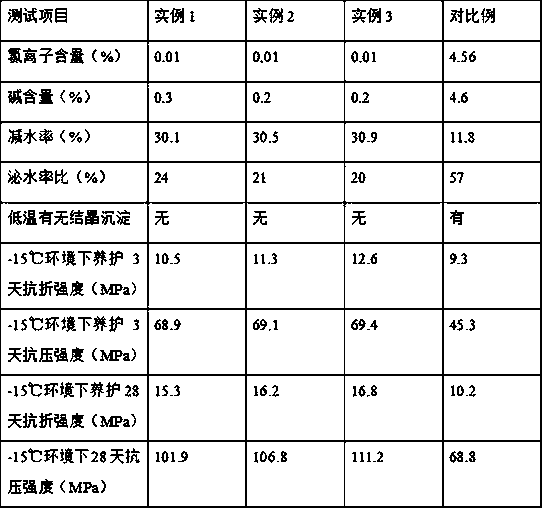

example 1

[0028]In parts by weight, take 20 parts of methoxypolyethylene glycol, 12 parts of methacrylic acid and 1.0 part of hydroquinone and put them into a four-necked flask equipped with a thermometer, a stirrer and a condenser tube, and heat the four-necked flask. Heat the flask to 88°C and keep it warm for 10 minutes to obtain a molten product; add dropwise a sulfuric acid solution with a mass fraction of 3% of the above-mentioned molten product and a mass fraction of 85% to the above four-necked flask, heat the four-necked flask to 120°C, react at a constant temperature for 3 hours, and cool naturally To room temperature, dropwise add a 20% sodium hydroxide solution to neutrality to obtain a coagulation solution; in parts by weight, weigh 30 parts of the above coagulation solution, 18 parts of acrylamide and 1 part of ammonium persulfate into In the reaction kettle, pass nitrogen into the reaction kettle to replace the air, heat the temperature inside the reaction kettle to 60°C, ...

example 2

[0030] In parts by weight, take 22 parts of methoxypolyethylene glycol, 13 parts of methacrylic acid and 1.3 parts of hydroquinone and put them into a four-necked flask equipped with a thermometer, a stirrer and a condenser, and heat the four-necked flask. Heat the flask to 90°C and keep it warm for 13 minutes to obtain a molten product; add dropwise a sulfuric acid solution with a mass fraction of 4% of the above-mentioned molten product and a mass fraction of 87% into the above four-necked flask, heat the four-necked flask to 125°C, react at a constant temperature for 3 hours, and cool naturally to room temperature, dropwise add a 25% sodium hydroxide solution to neutrality to obtain a coagulation solution; in parts by weight, weigh 33 parts of the above coagulation solution, 19 parts of acrylamide and 2 parts of ammonium persulfate into In the reaction kettle, feed nitrogen into the reaction kettle to replace the air, heat the temperature in the reaction kettle to 63°C, stir...

example 3

[0032] In parts by weight, weigh 24 parts of methoxypolyethylene glycol, 15 parts of methacrylic acid and 1.5 parts of hydroquinone into a four-necked flask equipped with a thermometer, a stirrer and a condenser tube, and heat the four-necked flask. Heat the flask to 92°C and keep it warm for 15 minutes to obtain a molten product; add dropwise a sulfuric acid solution with a mass fraction of 5% of the above-mentioned molten product and a mass fraction of 90% to the above-mentioned four-necked flask, heat the temperature of the four-necked flask to 130°C, react at a constant temperature for 4 hours, and cool naturally To room temperature, add dropwise a 30% sodium hydroxide solution to neutrality to obtain a coagulation solution; in parts by weight, weigh 35 parts of the above coagulation solution, 20 parts of acrylamide and 3 parts of ammonium persulfate into In the reaction kettle, feed nitrogen into the reaction kettle to replace the air, heat the temperature in the reaction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com