Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Significant emission reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

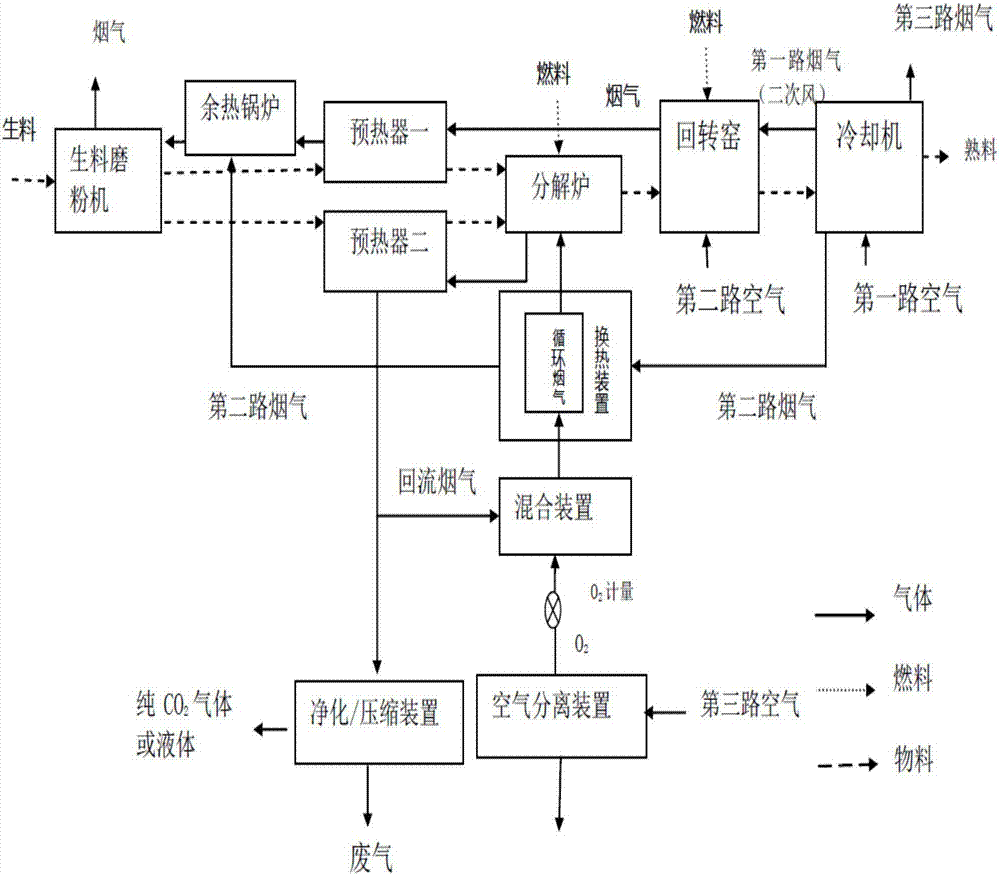

Oxygen/carbon dioxide combustion technique applied to cement clinker production process

InactiveCN107235647ASignificant emission reductionEmission reductionRotary drum furnacesCarbon captureDecompositionMixed gas

The invention discloses an oxygen / carbon dioxide combustion technique applied to a cement clinker production process. The oxygen / carbon dioxide combustion technique comprises the following steps: cooling a clinker by a first path of air, feeding a first path of high-temperature fume as secondary air into a rotary kiln after clinker cooling, preheating a second path of high-temperature fume by a heat exchange device, introducing an O2 / CO2 gas of a decomposition furnace, and feeding into a waste heat boiler for waste heat power generation; feeding a second path of air into the rotary kiln through a combustor; feeding fume discharged from the tail end of the rotary kiln into a preheater I for preheating a raw material, and feeding fume discharged from the preheater I into the waste heat boiler; feeding fume discharged from the decomposition furnace into a preheater II for preheating the raw material; generating backflow fume of which the CO2 concentration is greater than 95% from the preheater II, mixing a part of the backflow fume with oxygen separated from a third path of air, preheating, feeding the mixed gas as an O2 / CO2 atmosphere for raw material decomposition into the decomposition furnace, and performing purification, dust collection and concentration on the other part of the mixed gas, thereby obtaining CO2 of which the concentration is greater than 99%. Compared with a conventional cement clinker production process, the cement clinker production process disclosed by the invention has the advantage that the emission amount of CO2 is reduced by 60-75%.

Owner:CHINA BUILDING MATERIALS ACAD

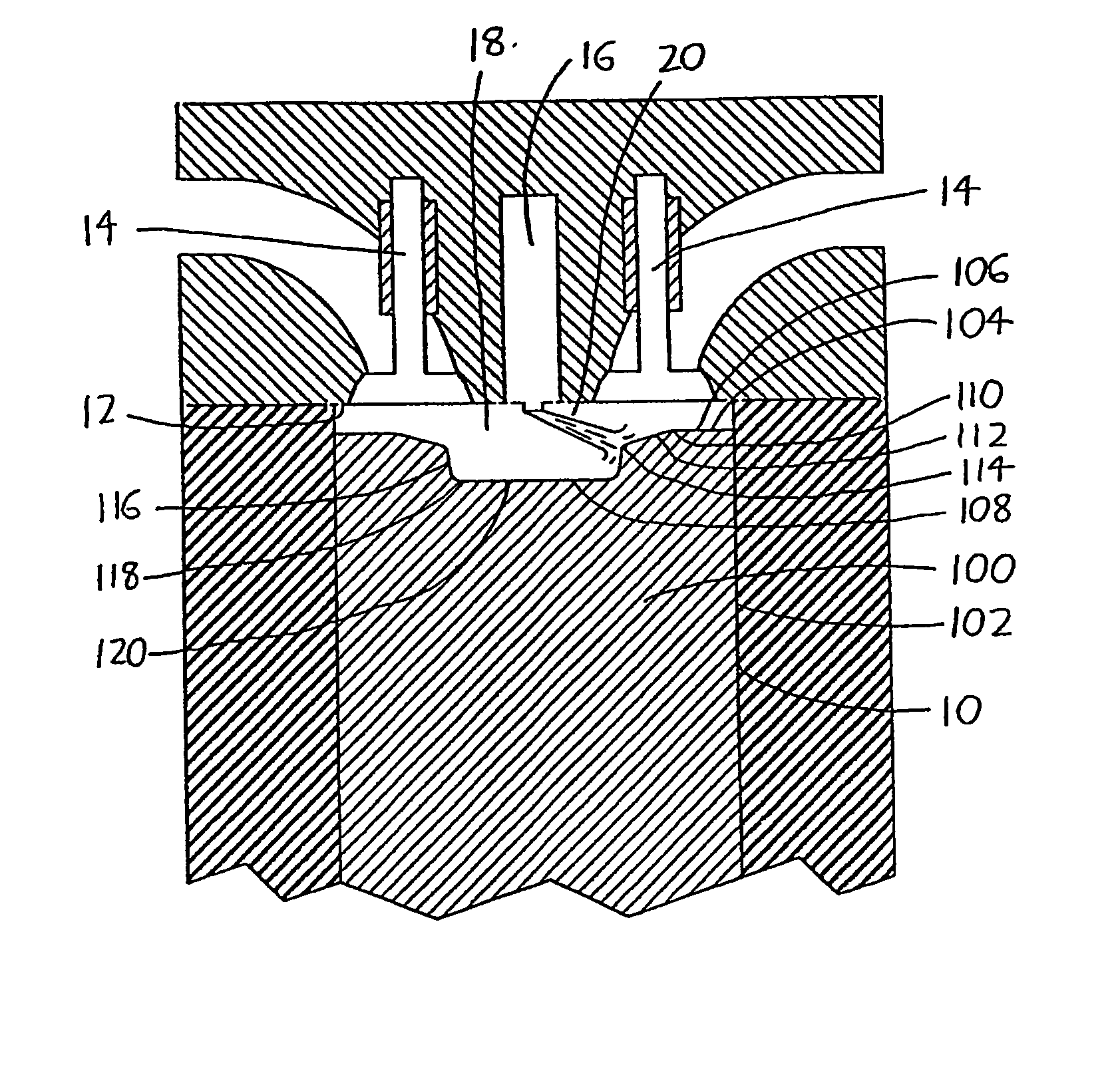

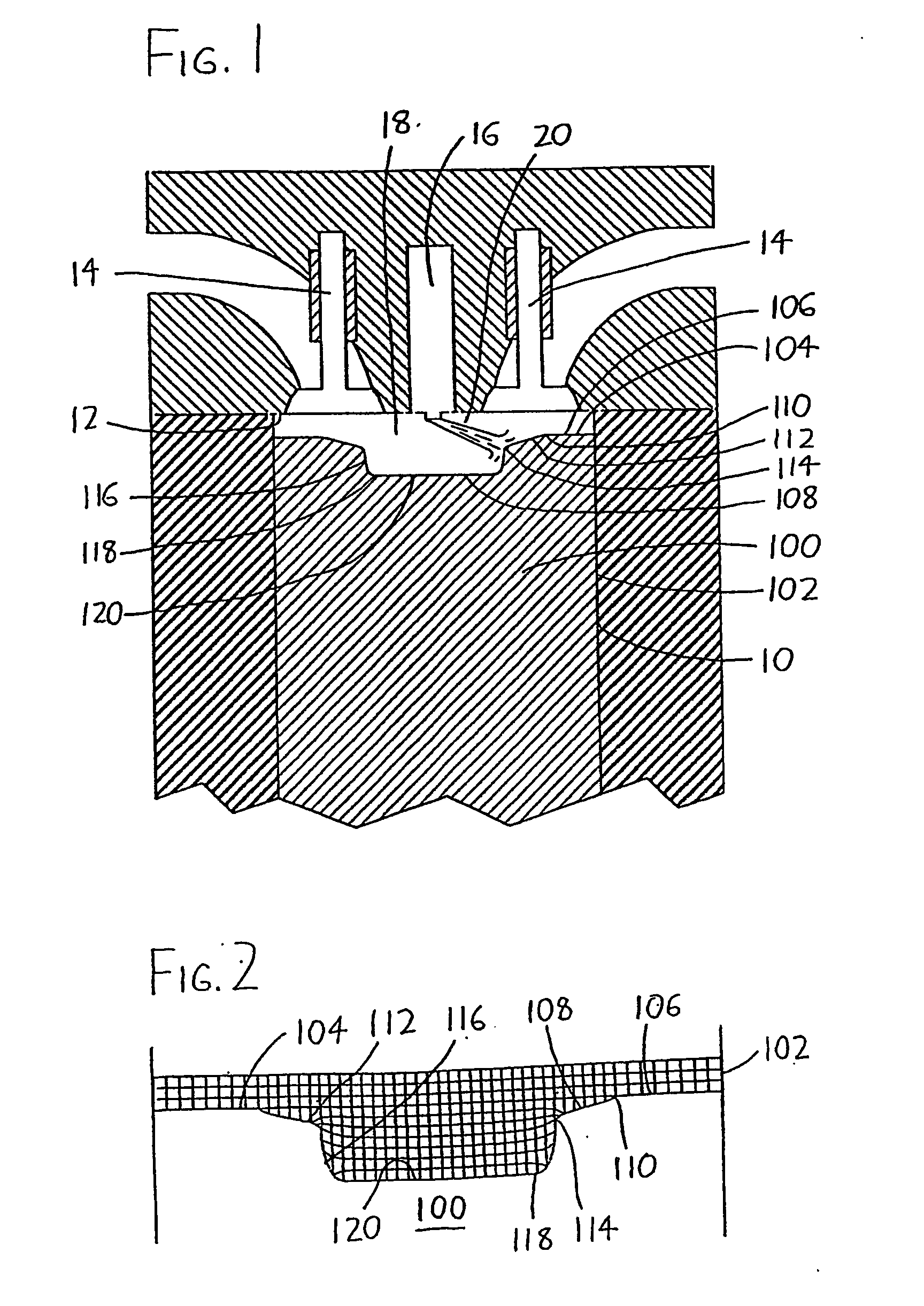

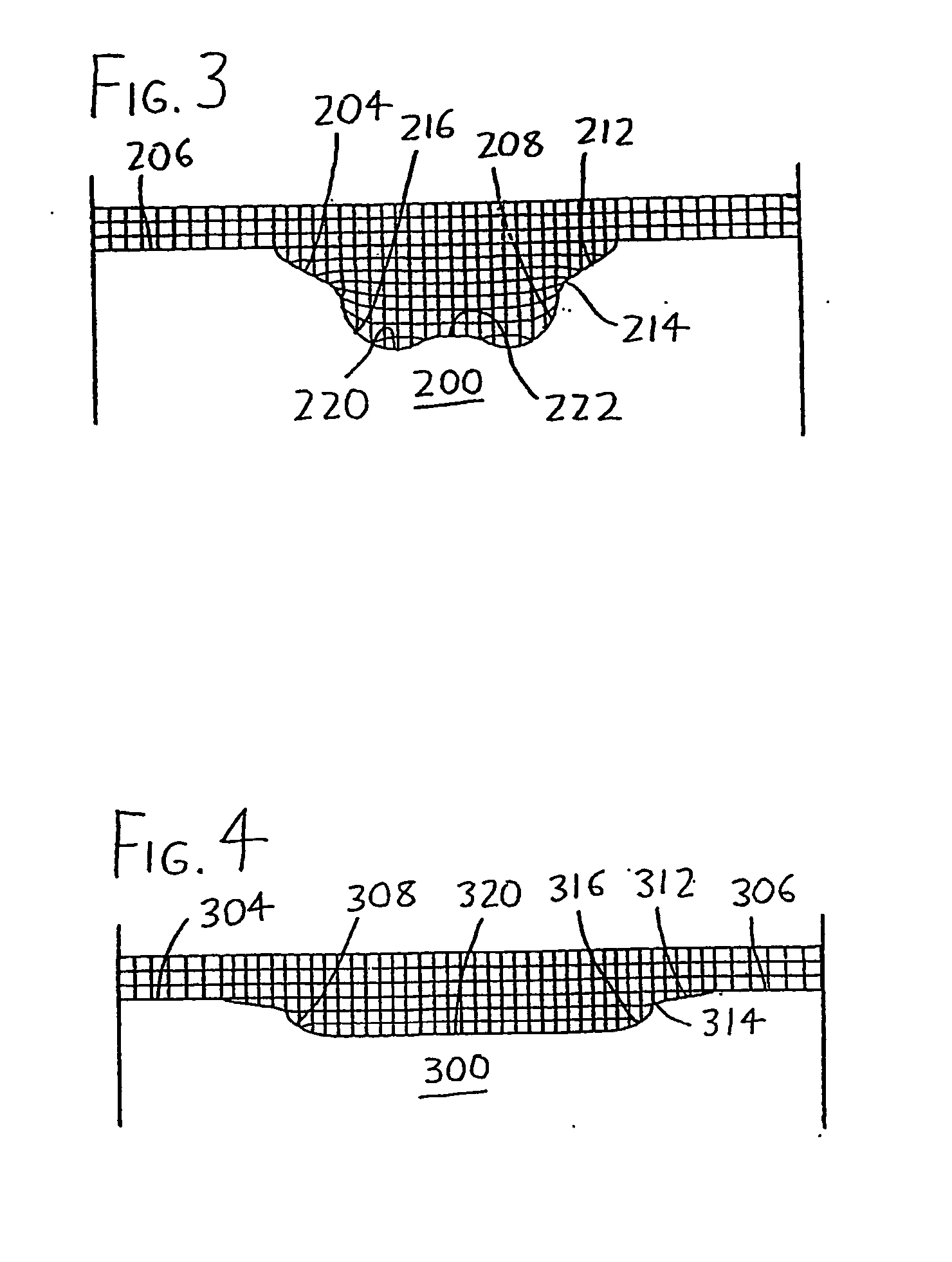

Piston/combustion chamber configurations for enhanced ci engine performace

InactiveUS20050166890A1Significant emission reductionLarge regionInternal combustion piston enginesCylinder headsBrake specific fuel consumptionCombustion chamber

Piston face (104, 204, 304) and combustion chamber (18) designs for use particularly in HSDI (high speed direct injection) diesel engines include an open bowl (108 208, 308) characterized by a large face perimeter region (106, 206, 306) on the piston face (104, 204, 304), and a bowl (18) defined by a first depressed region (112, 212, 312) gently sloping radially inwardly from the face perimeter region (106, 206, 306) and a second depressed region (116, 216, 316) sharply sloping radially inwardly from the first depressed region (112, 212, 312) to the bowl floor (120, 220, 320). Injection is preferably directed towards an intermediate edge which is well-defined between the first and second depressed regions, resulting in portions of the injected fuel plume being directed to both the squish regions and the portion of the bowl situated below the intermediate edge. The designs promote premixed or MK (Modulated Kinetics) combustion, with a concomitant reduction in soot and nitrous oxides (NOx) emissions while maintaining or enhancing brake specific fuel consumption.

Owner:WISCONSIN ALUMNI RES FOUND

Method for preparing magnesium salt modified biochar and application thereof

PendingCN109095955AImprove adsorption efficiencyRelieve stressMagnesium fertilisersAnimal corpse fertilisersMagnesium saltDistilled water

The invention belongs to the technical field of bio-environmental protection, and particularly relates to a method for preparing magnesium salt modified biochar and application thereof. The method hasthe advantages of being simple to operate and low in manufacturing cost and can perform large-scale industrial production, so that N2O and NH3 gas emissions in the composting process are significantly reduced, the harm to the environment is reduced, and the compost quality is improved. The preparation method includes: 1) pretreatment of biomass: selecting agricultural and forestry waste, pulverizing the waste to a particle size of less than 5 mm, immersing the waste in 0.2-2 mol / L sodium hydroxide for 8-24 hours, washing with distilled water to be neutral, drying at 105 DEG C; 2) preparationof magnesium salt modified biochar: immersing the product of the step 1) in magnesium chloride solution for 12-14 hours, performing ultrasonic treatment, and then drying at 80-105 DEG C; and performing cracking in a nitrogen atmosphere to obtain the magnesium salt modified biochar.

Owner:NORTHWEST A & F UNIV

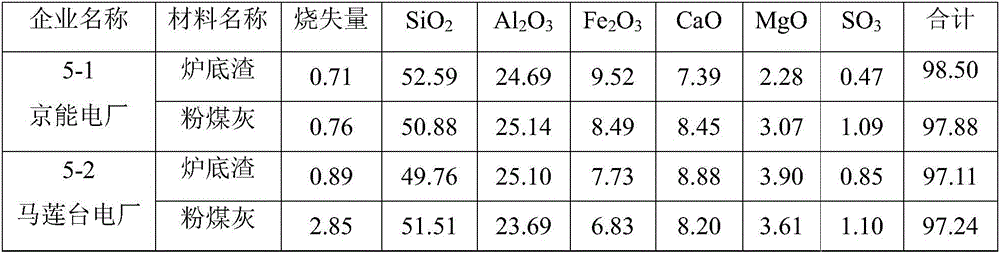

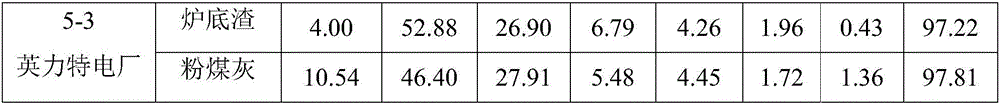

Lightweight aggregate concrete small hollow block with a large doping amount of fly ash slag and production method thereof

InactiveCN106007788ALarge amount of waste residue utilizationHigh utilization rate of industrial wasteSolid waste managementCeramicwareIndustrial wasteHeat engine

The present invention relates to the technical field of building materials, and in particular relates to a lightweight aggregate concrete small hollow block with a large doping amount of fly ash slag. The hollow block comprises the components of: 20-50 parts of fly ash, 35-70 parts of blaster furnace slag, and 8-15 parts of cement. The invention comprehensively utilizes fly ash and blaster furnace slag produced in heat-engine plant, and has large utilization amount of waste; the technology can be used in industrial production to reach high utilization rate and large amount of industrial wastes; the prepared products has stable compressive strength of above 5MPa, density of less than 800kg / m<3>, and excellent properties.

Owner:宁夏仁和环保科技发展有限责任公司

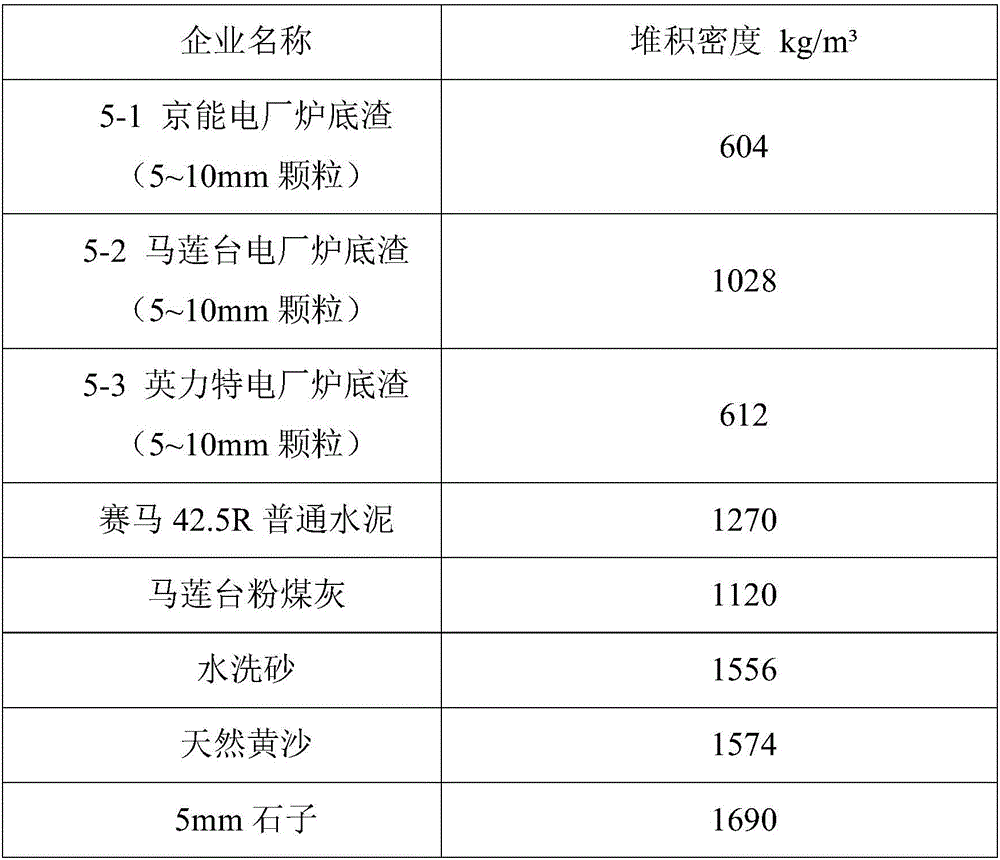

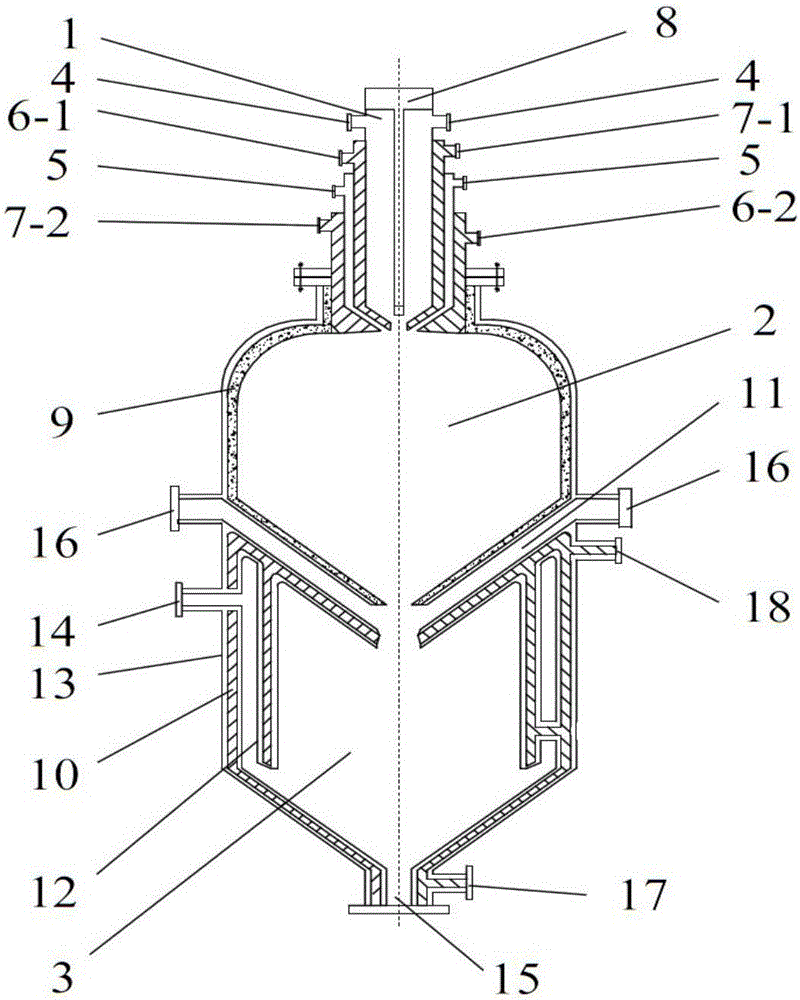

Method and equipment for producing coal gas through biomass pressurized gasification

ActiveCN106635171ALow densityIncrease moistureGasification processes detailsCombustible gas productionCoal waterSyngas

The invention provides a method for producing coal gas through biomass pressurized gasification. The method includes the steps that biomass is added into a gasification furnace, a gasifying agent enters the gasification furnace from the gasification furnace bottom for gasification, dust-containing and oil-containing coal gas generated through the gasification is sent into an integrated oil and gas cracking purifier for cracking and purification, is subjected to high-temperature cracking in a cracker combustion chamber and then enters a purifier, circulating water is pumped in a double-layer water jacket of the purifier, the purifier is filled with porous media which are used for recycling heat in the cracker and adsorbing dust in the coal gas, the coal gas obtained after heat recycling is led out of a coal gas outlet through a coal gas channel, and at the same time, saturated steam is produced. The method has the advantages that synthesis gas which is free of tar and adjustable in H2 / CO specific value is continuously and stably produced, and coal gas water has little pollution.

Owner:SEDIN ENG

Oil saving and emission reducing device of automobile

InactiveCN102094733APromotes full combustionReduce intermediate linksElectrolysis componentsNon-fuel substance addition to fuelHydrogen fuelElectricity

The invention discloses an oil saving and emission reducing device of an automobile. The device comprises an engine, a direct-current generator, a water electrolysis device and a hydrogen conveying pipeline; the engine is in transmission connection with the direct-current generator; the device also comprises an oxygen conveying pipeline; the anode and the cathode of the output end of the direct-current generator are electrically connected with an electrolytic anode plate and an electrolytic cathode plate in the water electrolysis device respectively; the water electrolysis device is provided with a closed container; an oxygen collecting cavity and a hydrogen collecting cavity are formed in the closed container of the water electrolysis device; the oxygen collecting cavity is positioned above the electrolytic anode plate; the hydrogen collecting cavity is positioned above the electrolytic cathode plate; one end of the oxygen conveying pipeline is connected with the oxygen collecting cavity, and the other end of the oxygen conveying pipeline is connected with an air inlet pipeline of the engine; and one end of the hydrogen conveying pipeline is connected with the hydrogen collectingcavity, and the other end of the hydrogen conveying pipeline is connected with the air inlet pipeline of the engine. The device has a simple structure, and can convert the residual power of the automobile running at medium and low speed into hydrogen fuel for combustion work of the engine, save fuel oil, and reduce the emission of waste gas.

Owner:CHANGZHOU LANZHE INSTR

Water-based zinc-plating coating for refrigerated containers

InactiveCN112521787AImprove anti-corrosion performanceSignificant emission reductionAnti-corrosive paintsPolyurea/polyurethane coatingsCelluloseSolvent based

A water-based galvanized coating for refrigerated containers belongs to the technical field of anticorrosive coatings and is prepared by mixing a component A and a component B. The component A is prepared by mixing deionized water, an antifoaming agent, a dispersing agent, a base material wetting agent, cellulose, water-based acrylic acid or water-based polyurethane and alcohol ester-12 accordingto a weight part ratio of 5:1. The component B is composed of black flaky zinc powder, spherical zinc powder, zinc-aluminum alloy powder and a silane coupling agent. The coating, as a water-based product, can be lower than 50 g / L in VOC, wherein the emission reduction is obvious compared with the VOC content of 450 g / L of solvent type cold spraying zinc, and the zinc-aluminum alloy pigment has theeffective cathodic protection effect of a pure Zn layer on a steel base body. The product is sufficient in aluminum, so that a complete Al2O3 protective film can be formed, and corrosion resistance is improved.

Owner:锌盾化工无锡有限公司

Anti-attrition oil saving agent for structural porcelain

InactiveCN101665739AReduce coefficient of frictionReduce wearAdditivesMachine partsMechanical equipment

The invention relates to an anti-attrition oil saving agent for structural porcelain, comprising lubricating oil or lubricating grease used as a carrier. Natural ore powder with fineness specificationof 500 nanometers-2 micrometer is uniformly added in the lubricating oil or the lubricating grease, the content of the natural ore powder in the lubricating oil or the lubricating grease is 0.01-1%,the natural ore powder comprises the following elements in percentage by weight: 5-20% of silicon, 5-20% of aluminum, 5-20% of calcium, 5-20% magnesium, 1-10% of ferrum and 1-10% of natrium, and the natural ore powder is selected and added in the lubricating oil or the lubricating grease according to a certain proportion, and after emulsification and diffusion treatment, the anti-attrition oil saving agent is prepared. A appropriate amount of the anti-attrition oil saving agent is added in engine oil so as to synthesize a smooth and hard structural porcelain protection layer with machine bodyelements on a negative friction surface in virtue of heat energy generated by high-temperature fuel gas of the engine and friction during the operation of mechanical equipment, thereby reducing the friction coefficients of machine parts and the abrasion and achieving the purpose of saving oil.

Owner:关景瀛

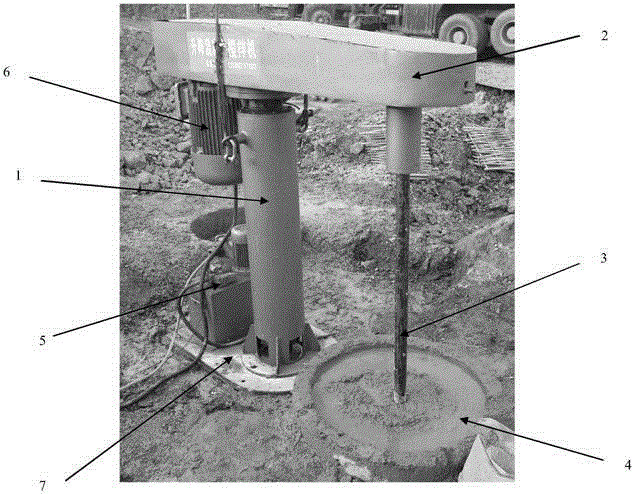

Chiseling-free pile head construction method

ActiveCN105780762AImprove mobilityImprove interface structureBulkheads/pilesStructural engineeringBuilding construction

The invention provides a chiseling-free pile head construction method. The chiseling-free pile head construction method includes the steps that earthwork is excavated to the bottom elevation of a bearing platform; the pile body concrete pouring height is determined; a mud pile head reinforcement material is prepared; an inverted type electric suspension rod stirring machine is installed; laitance is removed; the inverted type electric suspension rod stirring machine stirs the in-situ pile head reinforcement material; curing is conducted; and drilled core sampling pressure test acceptance inspection is conducted. Compared with the traditional construction process for manually chiseling pore-forming pouring pile heads, the construction procedure is greatly simplified, the construction cost is reduced, the requirement for the construction technology of constructors is not high, the construction safety is good, and the construction period is shortened.

Owner:UNIJES GRP

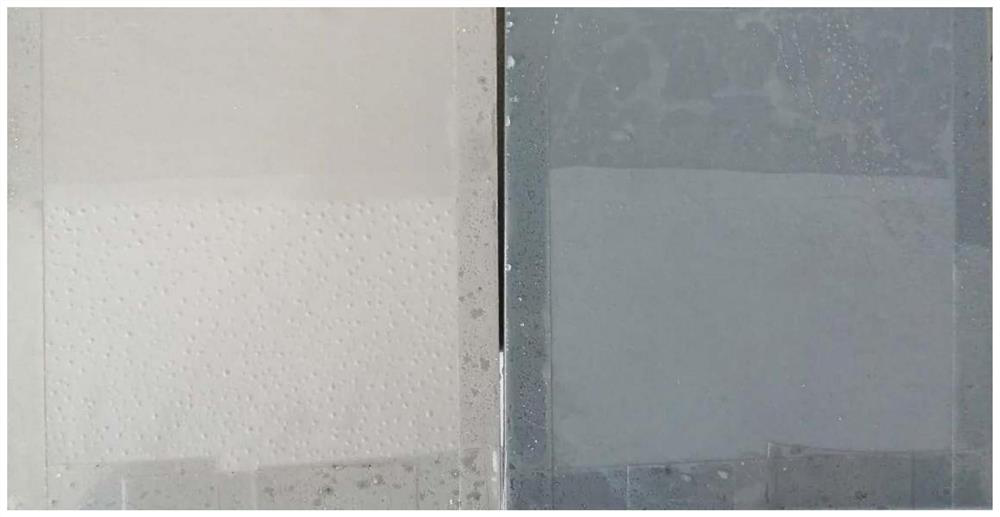

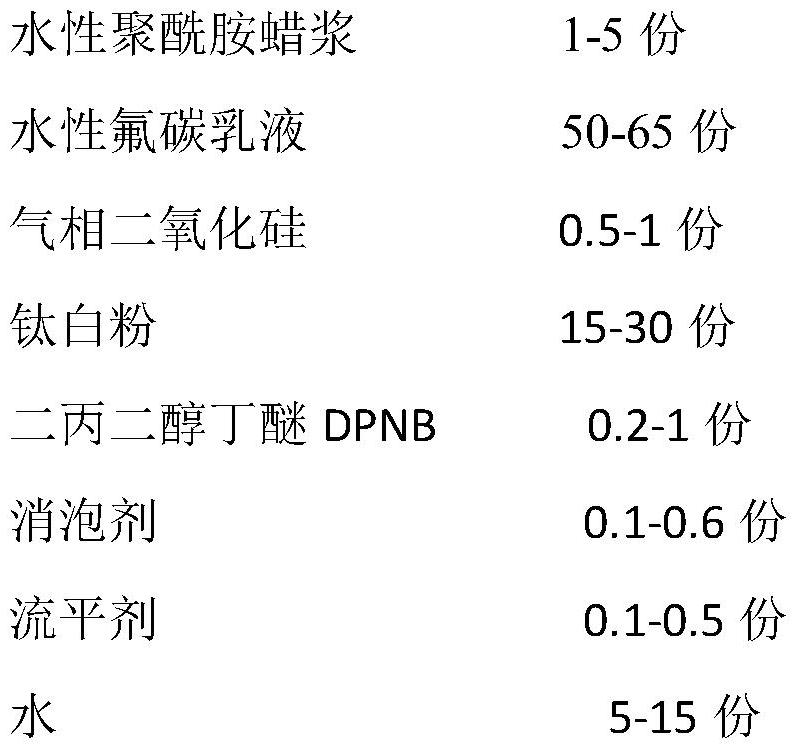

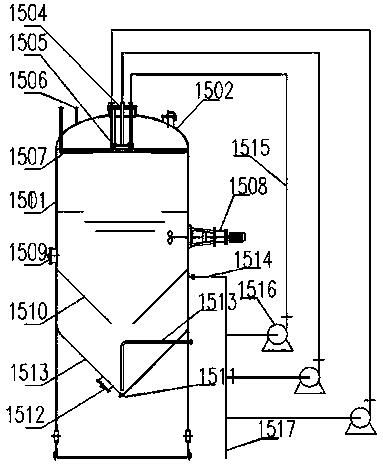

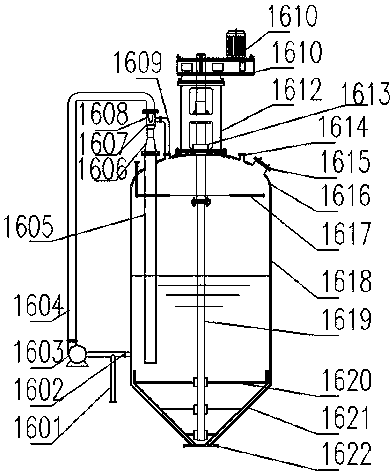

Water-based fluorocarbon finish paint and preparation method and application thereof

InactiveCN112694797AImprove anti-corrosion performanceSignificant emission reductionLiquid surface applicatorsAnti-corrosive paintsPolyamideFirming agent

The invention discloses a water-based fluorocarbon finish paint which comprises a component A and a component B. The component A comprises the following components in parts by weight: 1-5 parts of water-based polyamide wax slurry, 50-65 parts of water-based fluorocarbon emulsion, 0.5-1 part of fumed silica, 15-30 parts of titanium dioxide, 0.2-1 part of DPNB, 0.1-0.6 part of an antifoaming agent, 0.1-0.5 part of a leveling agent, and 5-15 parts of water; the component B is an isocyanate curing agent; and the mass ratio of the component A to the component B is (5-12): 1. The single-layer salt spray resistance of the water-based fluorocarbon finish paint can reach 3000 h or above, the water-based fluorocarbon finish paint has excellent corrosion resistance, the VOC is 85 g / L, emission reduction is obvious compared with 420 g / L of traditional solvent type fluorocarbon finish paint, and a coating matched with water-based cold spray zinc and water-based epoxy intermediate paint has excellent corrosion resistance, neutral salt spray resistance of 5000 h or above and aging resistance of 3000 h or above; the VOC is reduced by more than 80% compared with thetraditional solvent type set, and long-term protection can be provided for the steel structure.

Owner:WUXI HUADONG ZINDN TECH

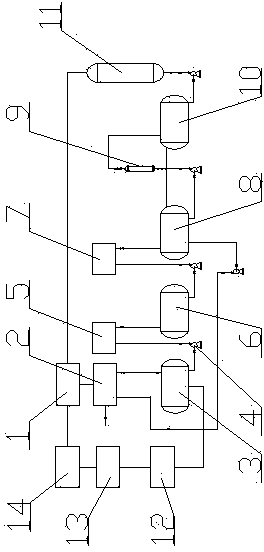

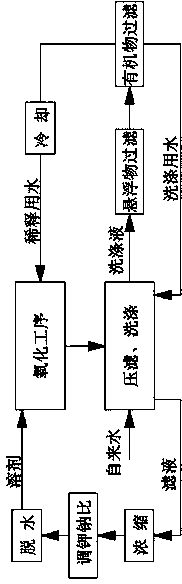

Indigo blue product mixed alkali recovery device

ActiveCN104151859AReduce usageSignificant emission reductionChemical/physical/physico-chemical nozzle-type rreactorsBis-indole indigosCooling towerFiltration

The invention relates to an indigo blue product mixed alkali recovery device comprising a pressure filtration water recovery device and a washing water recovery device. A concentration device is connected to an indigo blue post-treatment pressure filter water outlet port and a sodium-potassium ratio regulation device. The sodium-potassium ratio regulation device is connected with a dehydration device. The dehydration device is connected with an indigo blue oxidation reactor. A water inlet of a washing alkaline water tank is connected with a water outlet of an indigo blue post-treatment pressure filter. A water outlet of the washing alkaline water tank is connected with a water inlet of a suspended-matter-filtering alkaline water tank through a suspended matter filter. A water outlet of the suspended-matter-filtered alkaline water tank is connected with a water inlet of an organic-matter-filtered alkaline water tank through an organic matter filter. A water outlet of the organic-mater-filtered alkaline water tank is connected with a cooled alkaline water tank through a cooling tower. The cooled alkaline water tank is connected to the indigo blue oxidation reactor. According to indigo blue oxidation process requirements, pressure filtration filtrate is concentrated; sodium-potassium ratio is regulated; and the filtrate is returned to and reused in the indigo blue oxidation process. Low-concentration mixed alkali liquid after pressure filtration and washing are collected and applied as washing water and alkali fusion material dilution water. Recycling and utilization are carried out, such that low-concentration mixed alkali full recovery and surplus mixed alkali utilization are realized. Therefore, purposes of reducing emission and reducing fresh tap water consumption are realized.

Owner:JIANGSU TAIFENG CHEM

Method for applying biochar and wood vinegar in rice field and application of biochar and wood vinegar in emission reduction of greenhouse gases in rice field

PendingCN111972233AAchieve production increaseAchieve emission reductionFertilising methodsCarbon preparation/purificationSoil sciencePaddy field

The invention relates to a method for applying biochar and pyroligneous acid in a rice field and application of the biochar and pyroligneous acid in emission reduction of greenhouse gases in the ricefield, which comprises the following steps of: before transplanting rice, applying the biochar to rice field soil, and fully mixing the biochar with surface rice field soil; before rice transplanting,applying a base fertilizer to rice field soil, and the base fertilizer is composed of a chemical fertilizer and pyroligneous acid; after rice is transplanted, applying tillering fertilizer and ear fertilizer to rice field soil at different times, and the tillering fertilizer and the ear fertilizer are both composed of chemical fertilizer and pyroligneous acid; the time for applying the biochar isearlier than the time for applying the base fertilizer. Compared with the prior art, the beneficial effects provided by the invention has the advantages that rice yield increase and remarkable emission reduction of rice field greenhouse gases (N2O and CH4) are realized.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Automobile composite board spring

ActiveCN107314071AReduce weightGuaranteed StrengthHigh internal friction springsResilient suspensionsShear stressRoad surface

The invention belongs to the field of automobile parts and particularly relates to an automobile composite board spring. The automobile composite board spring comprises a steel plate sprig piece located on the upper portion and at least one composite material spring piece located on the lower portion. The steel plate sprig piece and the composite material spring pieces are overlaid up and down and are connected into a whole through fasteners. According to the automobile composite board spring, the composite structure of the steel plate sprig piece and the composite material spring pieces is adopted, structure design is reasonable, the effect is significant, when the automobile composite board spring is installed on an automobile chassis and road jolts are transmitted to the spring through an axle, the high-strength composite material spring pieces absorb most vibration through elasticity of the composite material spring pieces, and good vibration reducing performance is achieved. The steel plate sprig piece mainly achieves the effects of connection with an automobile body and bearing of a small quantity of torsion and shear stress caused by steering and braking, and thus overall strength is ensured. Composite materials are light, so that the weight of the whole automobile board spring is reduced, and the effects of weight reducing, emission reducing and load increasing are very significant.

Owner:SHANDONG LIANMEI SPRINGS TECH CORP +2

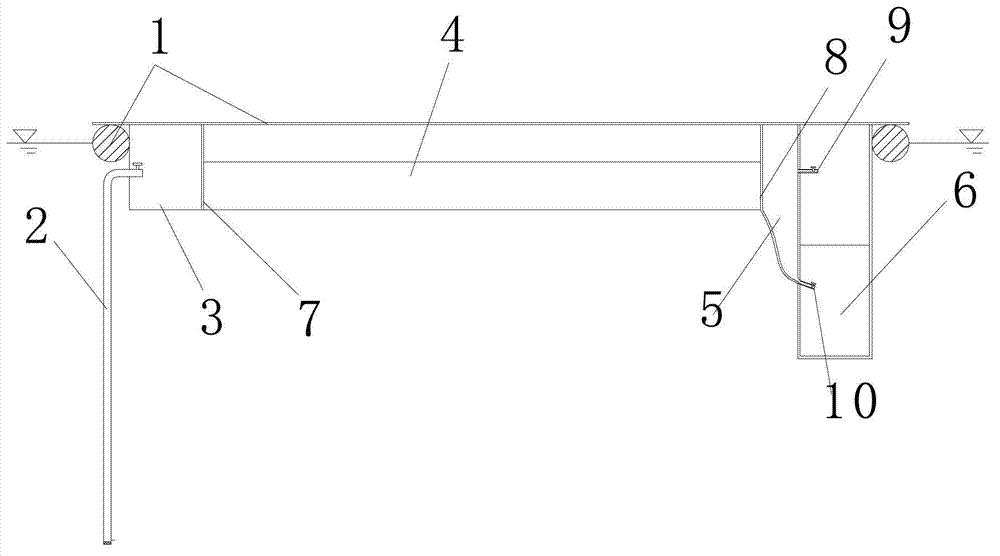

Overwater unpowered microalgae culture method and floating island system

ActiveCN102766567AReduce water consumptionReduce the cost of trainingBioreactor/fermenter combinationsBiological substance pretreatmentsTreatment pondEnvironmental engineering

Disclosed are an overwater unpowered microalgae culture method and a floating island system. The floating island system comprises a circular floating bed which is provided with a treatment tank, a culture tank, a sedimentation tank and a collection tank. The collection tank comprises a water collection tank and an algae collection tank. The treatment tank is connected with a water inlet pipe. A first partition is arranged between the treatment tank and the culture tank. A second partition is arranged between the culture tank and the sedimentation tank. The upper portion of the sedimentation tank is communicated with the water collection tank through a water outlet pipe. The bottom of the sedimentation tank is communicated with the algae collection tank through an algae discharge pipe. Polluted water can be pumped into the floating island culture tank for microalgae culture by atmospheric pressure, algae absorb nutrient salts in the water and carbon dioxide in air, and the water and the algae are primarily separated by sedimentation. Therefore, unpowered microalgae culture, polluted water purification, emission reduction, carbon sequestration, water-algae separation and the like are achieved, and cost in microalgae culture is reduced greatly.

Owner:CHINA THREE GORGES UNIV

Method for recycling mixed alkali liquor from after-treatment washing process of indigo

ActiveCN103556420AReduce usageSignificant emission reductionTextile treatment machine arrangementsAfter treatmentFresh water

The invention relates to a method for recycling mixed alkali liquor from an after-treatment washing process of indigo. According to the method for recycling the mixed alkali liquor from the after-treatment washing process of the indigo, after an indigo oxidation process, mixed alkali liquor is sent to a filter press for filter pressing, tap water is filled for washing, washing liquid is divided into two paths, one path returns back to the filter press to serve as washing water, and the other path returns back to the indigo oxidation process to serve as diluting water of alkali fusion materials according to the amount of the diluting water of the alkali fusion materials of the indigo oxidation process after being cooled. According to the method for recycling the mixed alkali liquor from the after-treatment washing process of the indigo, the requirements of the indigo oxidation process are combined, the characteristics of a alkali fusion process are utilized, a method of recycling and reusing is utilized, the filter-pressed washed low-concentration mixed alkali liquor is collected and reused as washing water and the diluting water of the kali fusion materials, full recycling of the low-concentration mixed alkali liquor and the utilization of surplus low-concentration mixed alkali liquor can be achieved, and the aims of emission reduction and fresh water tap water consumption reduction can be achieved.

Owner:JIANGSU TAIFENG CHEM

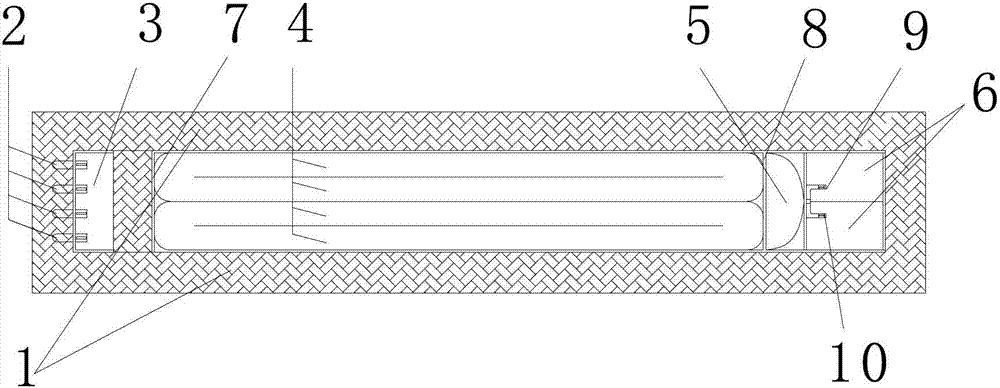

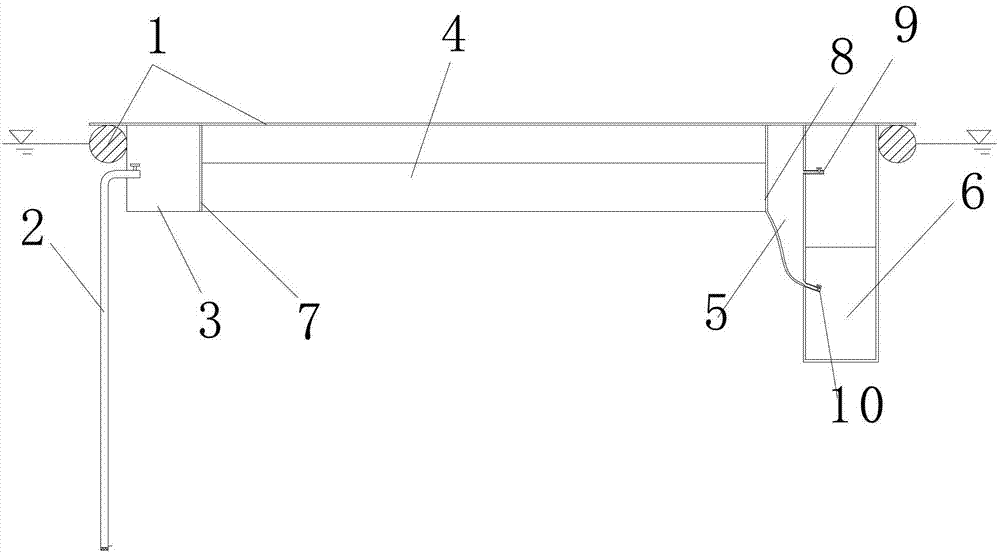

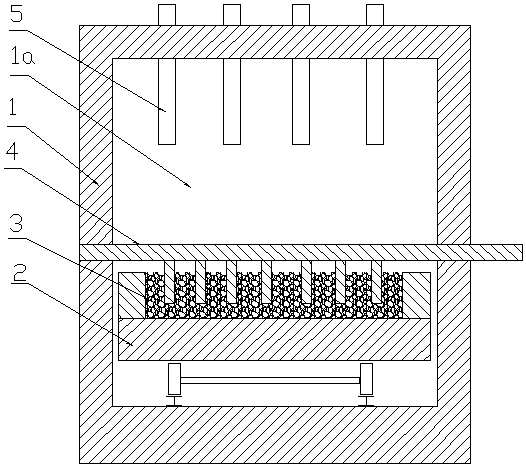

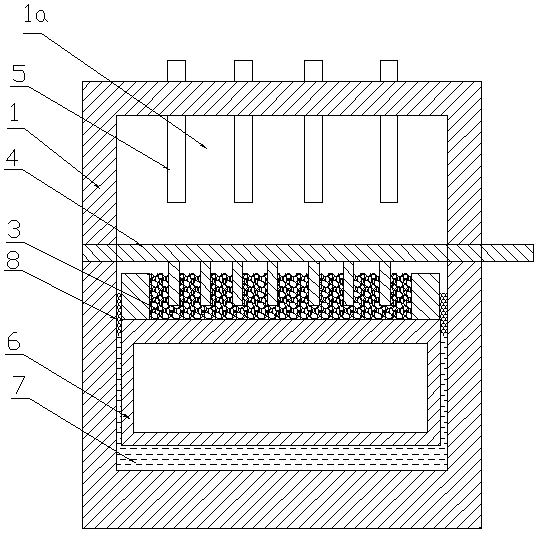

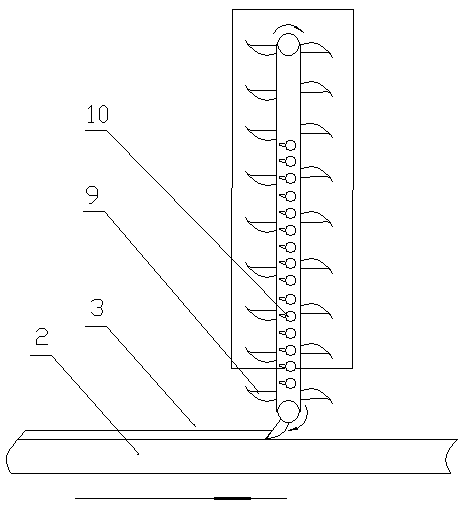

Drying and calcining method for bulk material and device thereof

InactiveCN108793791ASignificant energy savingSignificant emission reductionCharge treatment typeFurnace typesProduct gasRotary kiln

The invention discloses a drying and calcining method for a bulk material and a device thereof. The method comprises the following steps: enabling a bulk material layer with a certain thickness to perform continuous horizontal movement, repeatedly turning over the material by using a material overturning device which is fixed above the material and inserted in the material layer, enabling the material to rapidly and uniformly perform heat exchange with an outside heat source or cold source, thereby achieving a purpose of drying and calcining the material and cooling; enabling the material to be laid on a carrier which can be continuously and circularly operated, and fixedly installing the material overturning device, a heating and cooling device, a feeding and discharging device and a smoke and cooling gas outlet above the carrier. The above carrier which can be continuously and circularly operated is a rotary-operated annular kiln car or an annular floating body which is rotatably operated in an annular liquid tank, and a closed annular kiln cavity is installed above the carrier. The material overturning device, the heating and cooling device, the feeding and discharging device and the smoke outlet and the like are installed on a fixed kiln wall or kiln top, so that an annular horizontal rotary kiln is formed.

Owner:徐林波

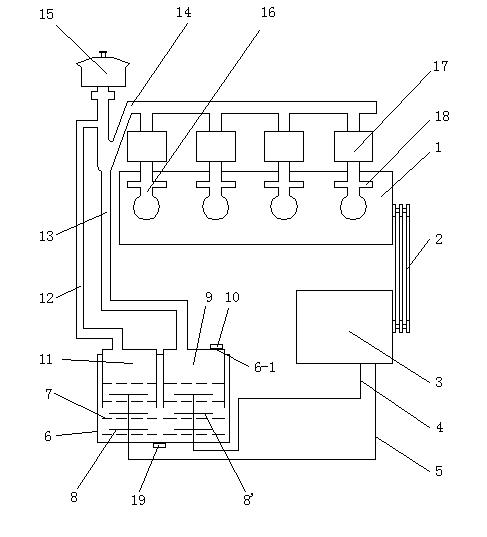

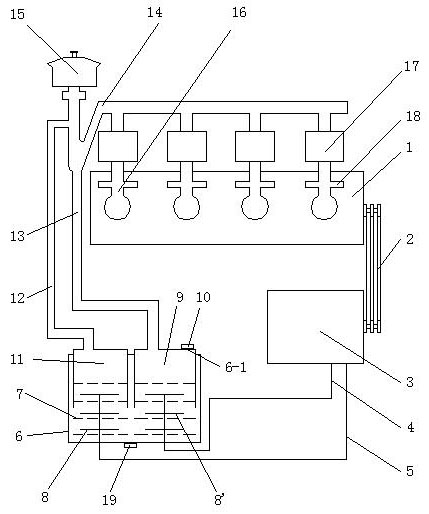

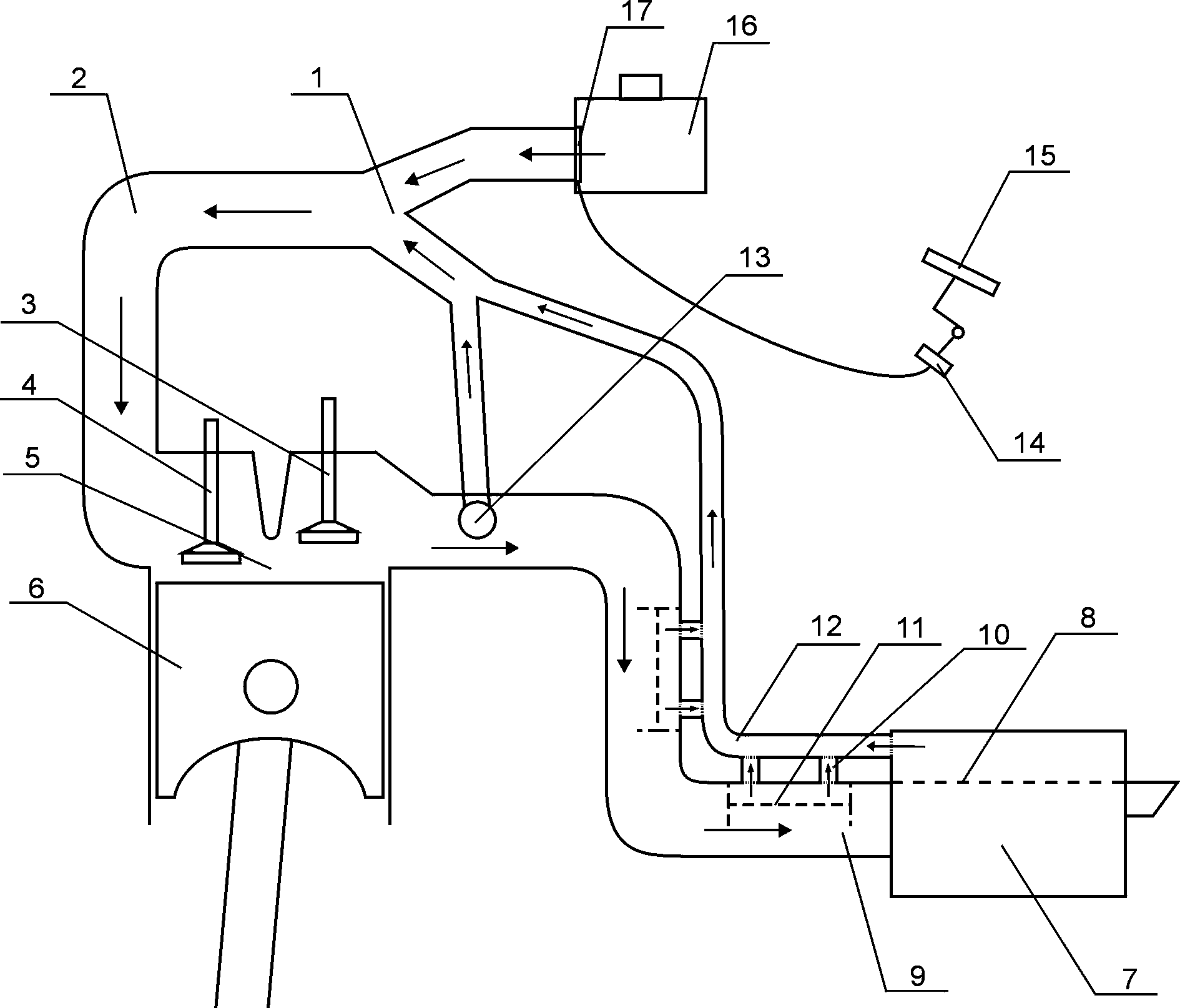

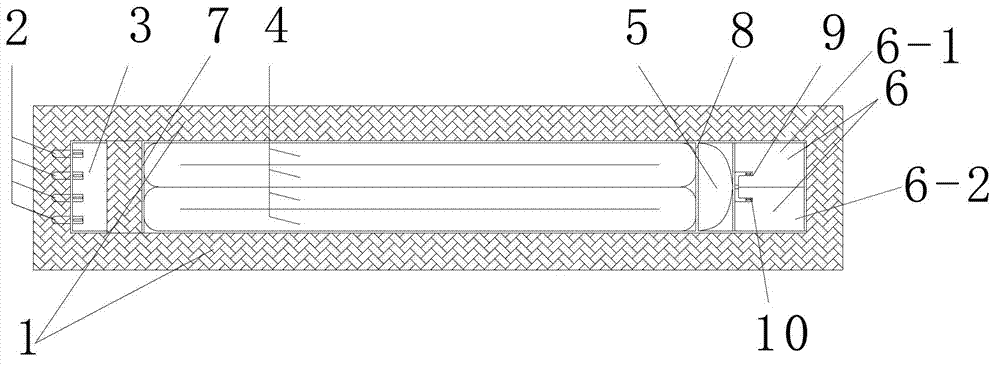

Engine vapor recycle and photolysis duplex combustion energy conservation and emission reduction method and device

InactiveCN103711614AReduce noiseEmission reductionNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberWater vapor

The invention relates to an engine vapor recycle and photolysis duplex combustion energy conservation and emission reduction method and device, and belongs to the field of engine energy conservation and environment protection. An existing engine exhaust system has the defects that energy consumption and emission are high, pollution to the environment is serious, and engine noise is large. According to the engine vapor recycle and photolysis duplex combustion energy conservation and emission reduction method and device, a heat absorber is arranged in an exhaust branch pipe, a Y-pipe is arranged on an air inlet pipe of an engine, and one port of the Y-pipe is connected with the heat absorber. When the engine exhausts air, vapor in tail gas is heated again by using the heat absorbing function of the heat absorber, the exhaust gas is driven to pass through the engine, enter a combustion chamber and be combusted again in a photolysis mode together, the vapor and the heat energy can be utilized in a duplex mode, and thus energy consumption of the engine is reduced effectively. Meanwhile, tail gas emission is reduced greatly, the emission of the engine can reach the national standard VI and the national standard VII, emission reduction reaches more than 80% when the engine is in an idle mode, and the effects of energy conservation, consumption reduction and emission reduction are truly achieved.

Owner:俞志毅

Intelligent forming, stacking and coking production method

ActiveCN111187634ASignificant energy savingSignificant emission reductionStacking articlesSpecial form destructive distillationCoal briquetteCoal

The invention relates to an intelligent forming, stacking and coking production method, which specifically comprises the steps of coal sample pretreatment, forming, stacking, coal charging and coke quenching, wherein the forming and stacking processes are intelligent, the forming in the intelligent forming specifically comprises the steps of raw material metering feeding, homogenizing, mold filling, forming and demolding to form a set of intelligent control system, the length, the width and the height of the formed coal briquettes are 500-1000 mm, 400-600 mm and 400-650 mm respectively, the precision of the size of the formed coal briquettes is within + / -2 mm, the intelligent stacking adopts gantry type stacking, the gantry type stacking is composed of a stacking bracket, a stacking lifting table and plural sets of stacking grippers, and the length, the width and the height of the stacked coal walls are 12000-2500 mm, 400-3400 mm and 1000-10000 mm. The method has the characteristics ofsimple process flow and high automation degree, and has advantages of remarkable energy saving, environment protection, emission reducing, yield increasing and social and economic benefits.

Owner:山西博嘉慧科技有限公司

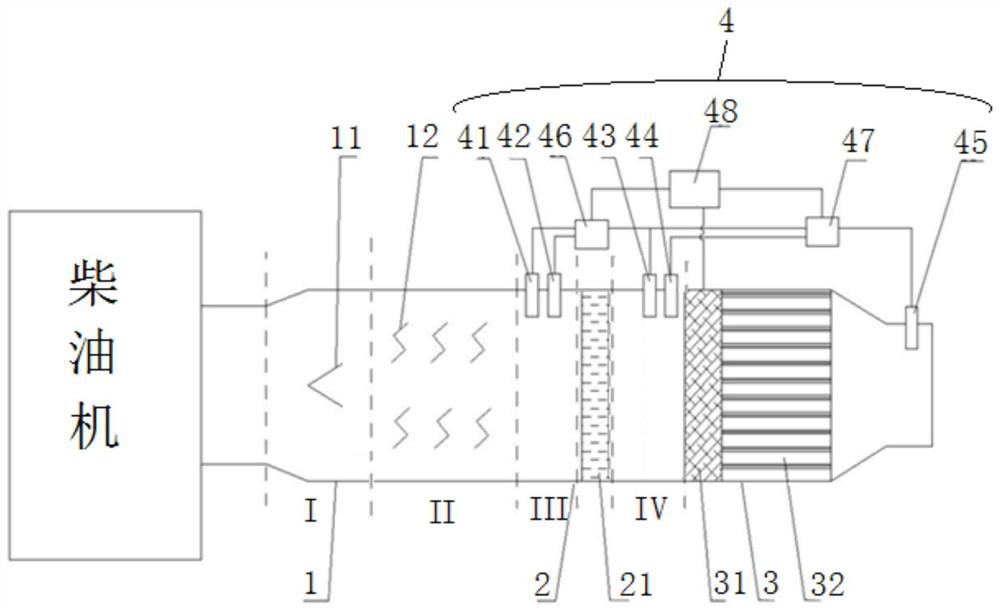

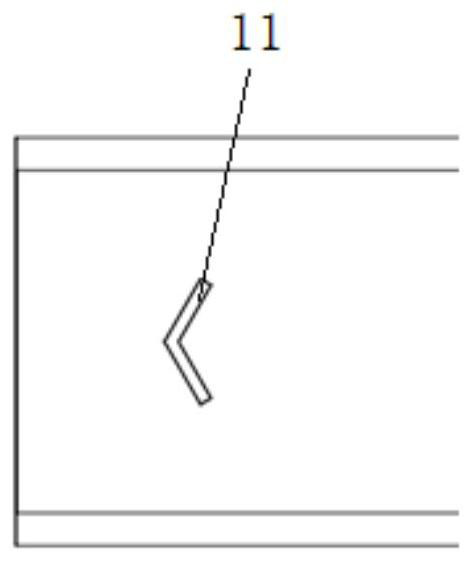

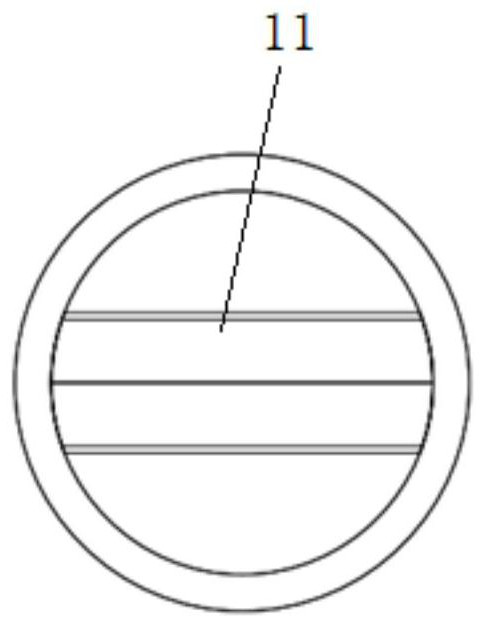

Particulate matter trapping and regenerating system applying turbulent agglomeration as pretreatment and control method

ActiveCN112901323AIncreased chance of collisionLarge particle sizeInternal combustion piston enginesExhaust apparatusParticulatesDieseling

The invention discloses a particulate matter trapping and regenerating system applying turbulence agglomeration as pretreatment and a control method. The particulate matter trapping and regenerating system applying turbulent agglomeration as pretreatment and the control method aim to reduce the emission of particulate matters in the tail gas of a diesel engine. According to the particulate matter trapping and regenerating system applying the turbulent agglomeration as pretreatment and the control method, the particulate matters are captured by applying a turbulent agglomeration method, and meanwhile, whether particulate matter regeneration is started or not is judged by monitoring the pressure difference in real time. According to the particulate matter trapping and regenerating system applying the turbulent agglomeration as pretreatment and the control method, the particulate matters can be well discharged, and meanwhile, the back pressure of the engine is reduced.

Owner:RES INST OF HIGHWAY MINIST OF TRANSPORT

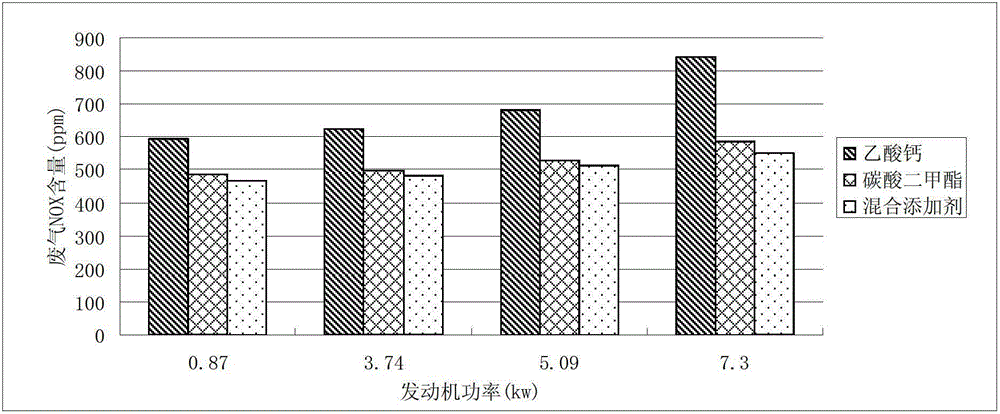

Additive for reducing emission of charcoal smoke and harmful gas of diesel engine and preparation method thereof

InactiveCN103113942BSignificant emission reductionEmission reduction effect is obviousLiquid carbonaceous fuelsFuel additivesEngineeringSolvent

The invention discloses an additive for reducing the emission of the charcoal smoke and harmful gas of a diesel engine and a preparation method thereof. The additive comprises a solute and a solvent, wherein the solute comprises the mixture of dimethyl carbonate and calcium acetate, and the solvent is ethanol or a mixture containing ethanol. With the adoption of the additive capable of reducing the emission of the waste gas harmful ingredients and charcoal smoke of a diesel engine and the preparation method for the same provided by the invention, the burning environment of burning diesel oil is improved from different aspects relative to the prior art, the limitation of the traditional single improvement means is broken, and cost can be reduced while combustion-supporting efficiency is ensured; simultaneously, a certain effect can be generated on the emission reduction of harmful ingredients in tail gas.

Owner:SOUTHEAST UNIV

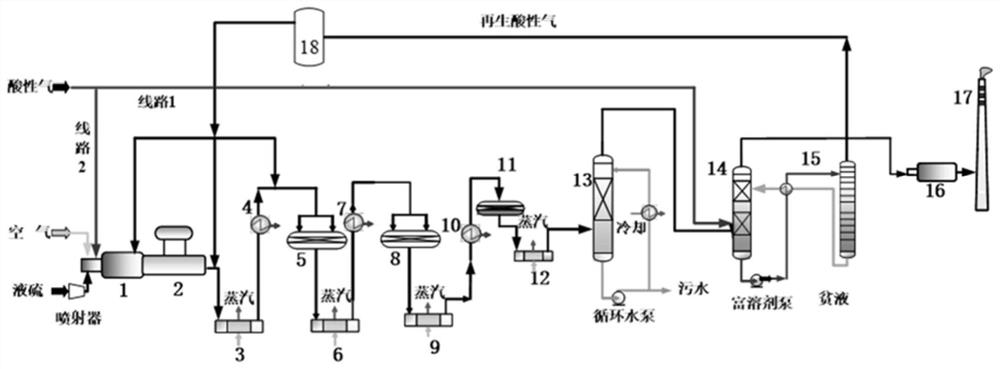

Starting method of sulfur recovery process

ActiveCN113860266AGuaranteed emission standardsEasy to operateGas treatmentDispersed particle separationFlue gasProcess engineering

The invention belongs to the technical field of sulfur recovery, and particularly relates to a starting method of a sulfur recovery process. According to the starting method of the sulfur recovery process, during starting, acid gas is introduced into an absorption tower for enrichment, absorption and regeneration, and liquid sulfur is introduced into a sulfur production furnace for reaction; the regenerated acid gas can be mixed with SO2 generated by the reaction at any position, such as behind the sulfur production furnace, behind a waste heat boiler, in front of a first-stage heater and in front of a first-stage reactor, for subsequent reaction; and when the acid gas is stable and the system load meets the requirement, introduction of the liquid sulfur is stopped, and the acid gas is directly introduced into the sulfur production furnace for direct reaction, so that the device can perform normal production. The method can solve the problem that the emission of flue gas SO2 is influenced by high organic sulfur content caused by the fact that low-concentration acid gas cannot be treated and is directly combusted through a torch or is introduced into a sulfur production furnace of a sulfur recovery device in the initial starting stage, and ensures that emission of the sulfur recovery device reaches the standard in the whole starting process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Overwater unpowered microalgae culture method and floating island system

ActiveCN102766567BReduce water consumptionReduce the cost of trainingBioreactor/fermenter combinationsBiological substance pretreatmentsTreatment pondSettling basin

Disclosed are an overwater unpowered microalgae culture method and a floating island system. The floating island system comprises a circular floating bed which is provided with a treatment tank, a culture tank, a sedimentation tank and a collection tank. The collection tank comprises a water collection tank and an algae collection tank. The treatment tank is connected with a water inlet pipe. A first partition is arranged between the treatment tank and the culture tank. A second partition is arranged between the culture tank and the sedimentation tank. The upper portion of the sedimentation tank is communicated with the water collection tank through a water outlet pipe. The bottom of the sedimentation tank is communicated with the algae collection tank through an algae discharge pipe. Polluted water can be pumped into the floating island culture tank for microalgae culture by atmospheric pressure, algae absorb nutrient salts in the water and carbon dioxide in air, and the water and the algae are primarily separated by sedimentation. Therefore, unpowered microalgae culture, polluted water purification, emission reduction, carbon sequestration, water-algae separation and the like are achieved, and cost in microalgae culture is reduced greatly.

Owner:CHINA THREE GORGES UNIV

A production method of intelligent forming, palletizing and coking

ActiveCN111187634BSignificant energy savingSignificant emission reductionStacking articlesSpecial form destructive distillationCokeEconomic benefits

Owner:山西博嘉慧科技有限公司

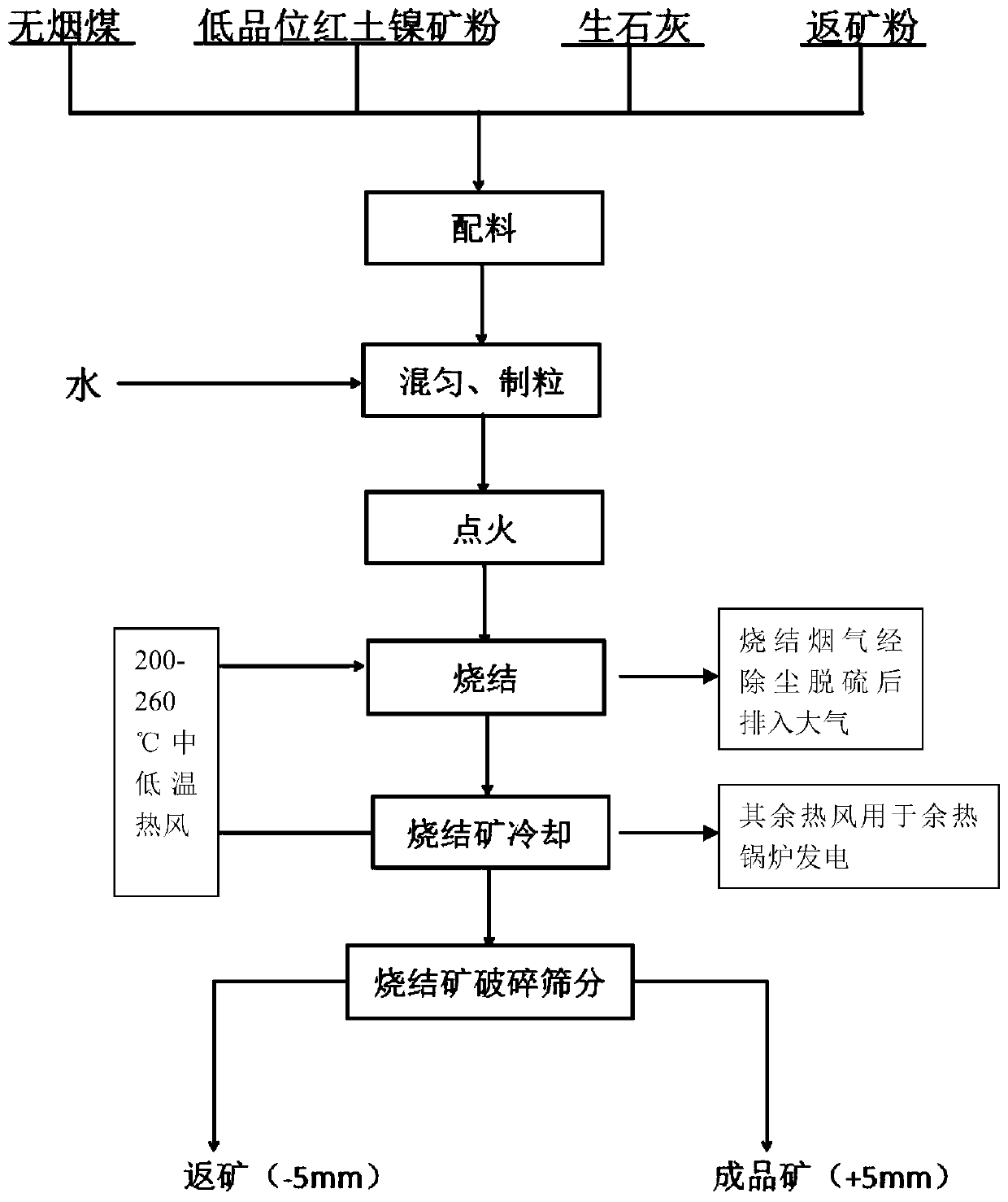

A kind of sintering method of laterite nickel ore

The invention discloses a laterite-nickel ore sintering method based on medium and low temperature cooling hot-blast air. The sintering method comprises the following steps: mixing laterite-nickel ore, ore returning powder, fuel and quicklime to obtain a mixture; adjusting the moisture of the mixture to be 16wt%-18wt%, and pelletizing the mixture in a mixed manner to obtain sintered material; igniting and sintering the sintered material to obtain hot sinter; during the sintering process, feeding hot-blast air lower than 300 DEG C into a sintering machine burden surface fume hood; carrying outheat exchange on cold-blast air and hot sinter to obtain hot-blast air and cold sinter; and crushing and screening the cold sinter to obtain sinter of finished product. According to the method, the medium and low temperature hot-blast air below 300 DEG C is returned to the sintering machine, so that the minerogenetic condition of the sinter is improved and the laterite-nickel ore sintering strength is improved; and in addition, the effective utilization of cooled hot exhaust gas of the sinter is realized, solid burnup is reduced, and emission of CO2 is reduced.

Owner:CENT SOUTH UNIV

Structure ceramic metal abrasion reduction material

The invention relates to a structure ceramic metal abrasion reduction material which comprises lubricating oil or lubricating grease used as a carrier; natural ore powder with the fineness specification of 100 to 500 nanometers is uniformly added into the lubricating oil or the lubricating grease; the content of the ore powder in the lubricating oil or the lubricating grease is 0.1% to 1%; the core powder comprises elementary components: 5% to 20% of silicon, 5% to 20% of aluminium, 5% to 10% of calcium, 5% to 20% of magnesium, 5% to 10% of carbon, 1% to 10% of iron, 1 to 10% of sodium and 0.01% to 1% of scandium; the structure ceramic metal abrasion is prepared by the steps of: selecting the ore powder, adding the ore powder into the lubricating oil or the lubricating grease according toa certain proportion and carrying out emulsification and diffusion treatment; a right amount of reduction material is added into machine oil of an engine; in the running process of mechanical equipment, the reduction material is combined with engine body elements on the frictional negative surface by virtue of the heat energy generated by the high temperature gas and the friction of the engine toform a smooth and hard structure ceramic protective layer, thereby achieving the purpose that frictional factors of the machine elements are decreased, the abrasion is reduced, the service life of the machine elements is prolonged and the oil is saved.

Owner:中科宝鹿新材料(辽宁)有限公司

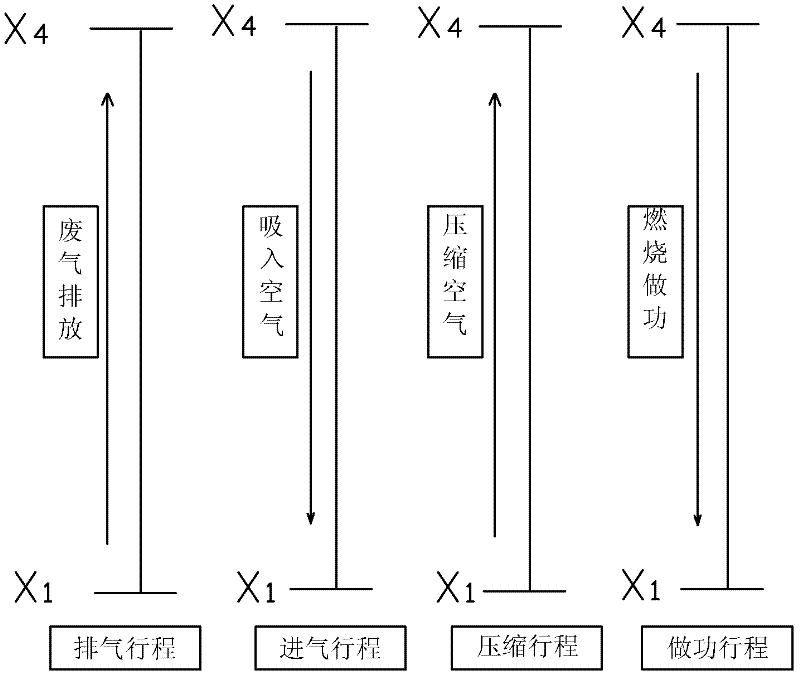

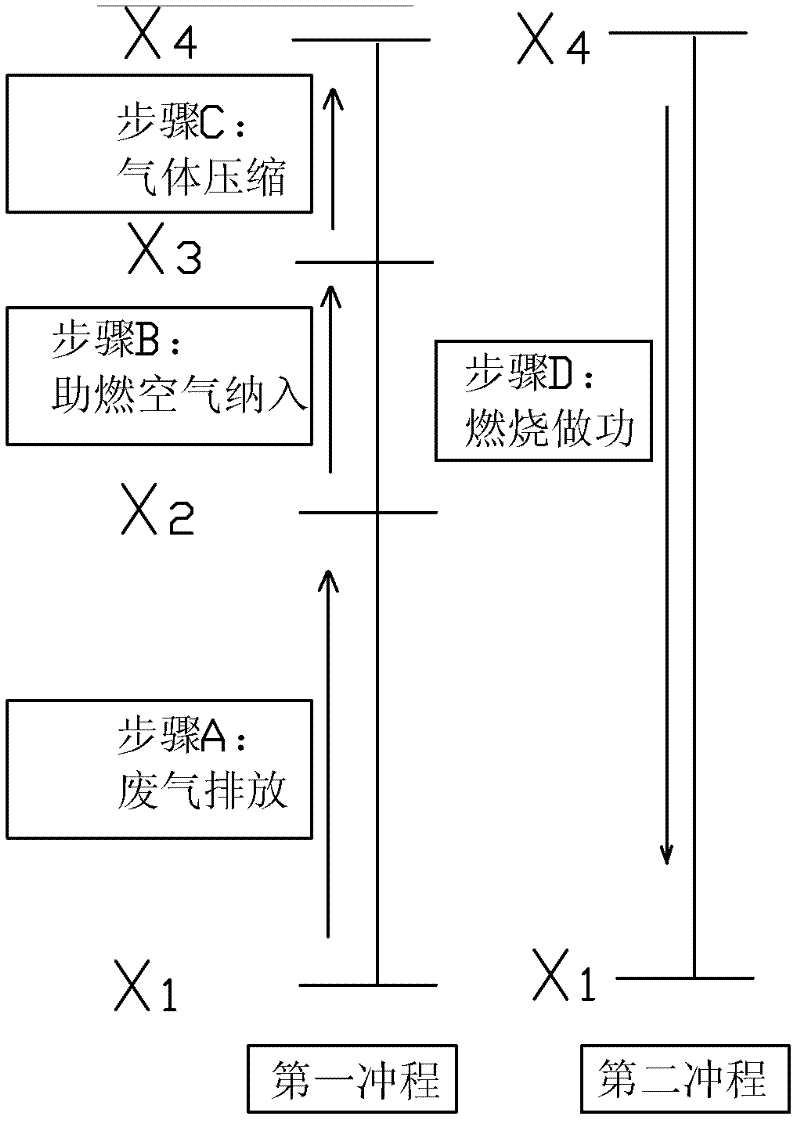

Method for controlling motion of cylinder piston of piston engine and device for implementing method

InactiveCN102392734AIncrease powerImprove stabilityLiquid coolingNon-fuel substance addition to fuelExhaust valveTop dead center

The invention belongs to the technical field of engine control, and relates to a method for controlling the motion of a cylinder piston of a piston engine and a device for implementing the method. The motion of the piston is controlled through the following steps that: A, a piston moves from a bottom dead center X1 to a position X2 upwards under the driving of a crankshaft, an exhaust valve is opened, an inlet valve is closed, and waste gas is discharged from a gas outlet; B, when the piston arrives at the position X2, the inlet valve is opened, the exhaust valve is closed, high-temperature and high-pressure combustion-supporting air is fed from the inlet valve, and the piston continues to move upwards to a position X3; C, when the piston arrives at the position X3, the inlet valve and the exhaust valve are both closed, and the piston continues to move to a top dead center X4; and D, the inlet valve and the exhaust valve are both closed, mixed gas is combusted so as to act on the piston, and the piston moves from the top dead center X4 to the bottom dead center X1. By using the method and device disclosed by the invention, under same conditions, compared with two-stroke engines and four-stroke engines, larger power, higher stability, lower noise and more significant energy saving and emission reduction can be obtained.

Owner:李永红

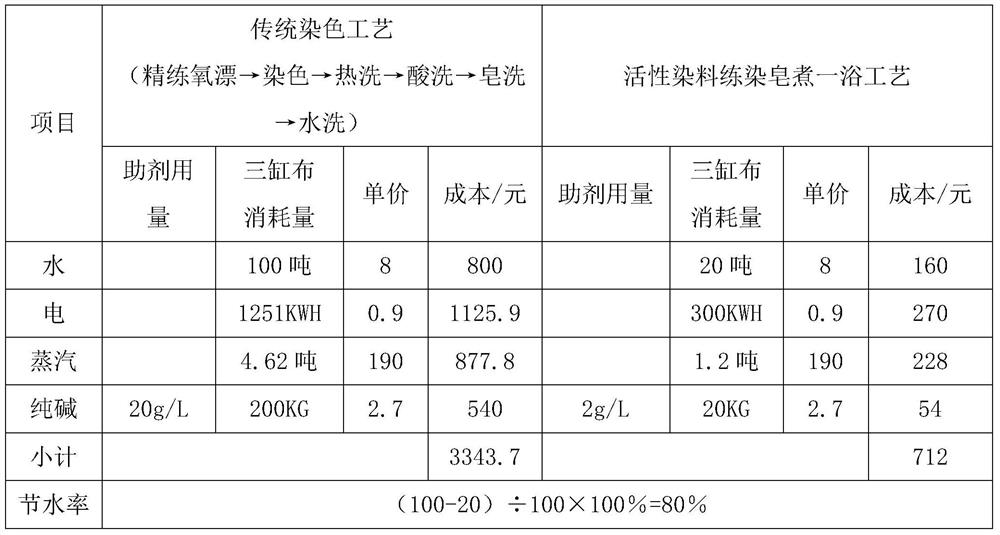

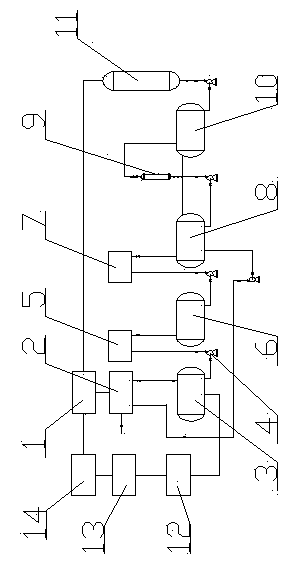

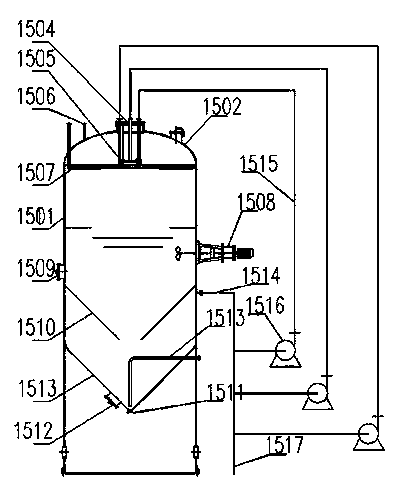

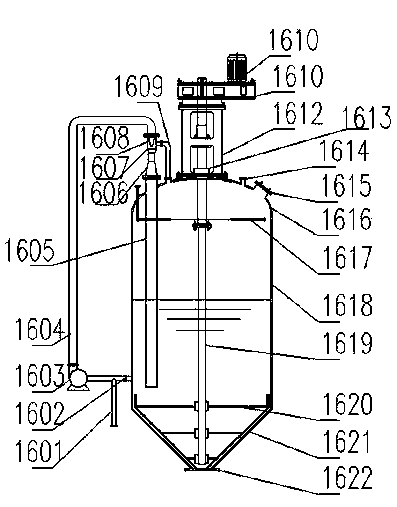

One-bath process of scouring and dyeing cotton fabric with reactive dyes and soap

The invention relates to a one-bath process for scouring and dyeing cotton fabrics with reactive dyes and soaps. Specifically, low-temperature scouring agents, sodium sulfate and low-alkali reactive dyes are used to scouring and dye cotton fabrics in a dyeing machine at normal temperature and pressure. Add low-temperature soaping agent for soaping, then drain, enter cold water and wash once at room temperature, and then release the cloth; low-temperature scouring agent consists of fatty alcohol polyoxyethylene ether and polyaspartic acid in a weight ratio of 1: (0.3-2) It is prepared by mixing, and the low-temperature soaping agent is prepared by mixing laccase, ammonium acid polymer and active oxygen preparation in a weight ratio of 2:1:1. The whole process of the invention only needs two cylinders of water, and does not involve the secondary steam heating process, reduces resource consumption, reduces costs, and also achieves high-efficiency production, water and energy saving, emission reduction and pollution reduction, and has good dyeing Fastness and color reproducibility.

Owner:JINJIANG CITY LONGSHENG KNITTING PRINTING & DYEING CO LTD

Sewage treatment system in cane sugar manufacture

InactiveCN104743741ADrainage water quality is stableSignificant emission reductionMultistage water/sewage treatmentHigh concentrationWater discharge

The invention discloses a sewage treatment system in cane sugar manufacture. The discharged water of the traditional sewage treatment system in cane sugar manufacture cannot reach the standard. According to the sewage treatment system, a pipeline is connected with an adjusting tank; a pipeline is connected with an anaerobic tank; a pump body is connected with an active sludge oxidation pond; a 1# oxidation pond, a 2# oxidation pond and a 3# oxidation pond are connected in series by pipelines; 1-6# sludge settling tanks are connected in parallel by pipelines. All the above facilities constitute a complete treatment system. The sewage treatment system treats sewage in the following sequence: the high-concentration wastewater and the sugar manufacture circulation surplus wastewater discharged by pipelines enter the adjusting tank and serially flow to the anaerobic tank through the pipelines; the anaerobically treated wastewater is pumped into the active sludge oxidation pond to be treated with active sludge, then enters into the 1# oxidation pond, the 2# oxidation pond and the 3# oxidation pond in sequence to be oxidized, and then enters into the 1-6# parallel sludge settling tanks for settling sludge, and finally the supernate is discharged. The COD index concentration of water discharged by the treatment system is 15-30mg / L and reaches the discharging standard.

Owner:广西糖业集团星星制糖有限公司

A method for producing pure silver and co-producing metallic aluminum from a waste silver catalyst whose carrier is alumina

ActiveCN111364060BNo emissionsIncrease added valueProcess efficiency improvementMetallic aluminumPtru catalyst

The invention discloses a method for producing pure silver from a waste silver catalyst whose carrier is alumina to co-produce metallic aluminum. In the method, the waste silver catalyst whose carrier is alumina is mixed with a flux, placed in an aluminum electrolytic cell for electrolysis, and respectively Obtain crude aluminum, crude silver and residual electrolyte, break the residual electrolyte and return to the electrolysis process; heat the crude aluminum above the melting point by melting method and stir, and precipitate as silver-aluminum intermetallic compound in solid state to form infusible residue, and the rest is liquid metal Aluminum, remove the residue and send it to the condensate process; use the condensate method to raise the temperature of the crude silver above the melting point, and then slowly cool it down to 960 ° C, the silver solidifies into a solid, and the aluminum floats on the surface of the solid silver in liquid form, then remove Liquid aluminum is returned to the smelting process; adopting this method to produce pure silver and metal aluminum, the recovery rates of silver and aluminum are greater than 98.0% and 95% respectively, and the purity of pure silver and aluminum products are respectively 98.5% and 98.0%, with high silver recovery rate , short process, green environmental protection, high resource utilization, low cost, and mature equipment.

Owner:KUNMING BOREN PRECIOUS METALS

Sodium-potassium ratio adjusting device of device for recovering mixed alkali from indigo products

InactiveCN104177862AReduce usageSignificant emission reductionOrganic chemistryIndigoid dyesCooling towerFull recovery

The invention relates to a device for recovering mixed alkali from indigo products. The device comprises a filter pressing recovery device and a washing water recovery device and is characterized in that a concentrating device is connected with a water outlet of an indigo aftertreatment filter press and a sodium-potassium ratio adjusting device respectively; the sodium-potassium ratio adjusting device is connected with a dehydration device; the dehydration device is connected to an indigo oxidation reactor; a water inlet of a washing alkaline water tank is communicated with the water outlet of the indigo aftertreatment filter press; a water outlet of the washing alkaline water tank is communicated with a water inlet of a suspended matter filtration alkaline water tank via a suspended matter filter; a water outlet of the suspended matter filtration alkaline water tank is communicated with a water inlet of an organic matter filtration alkaline water tank via an organic matter filter; a water outlet of the organic matter filtration alkaline water tank is communicated with a cooling alkaline water tank via a cooling tower; and the cooling alkaline water tank is connected to the indigo oxidation reactor. In combination with the requirements of an indigo oxidation process, the filter pressing filtrate is concentrated and the sodium-potassium ratio is adjusted to be reused in the indigo oxidation process, the low-concentration mixed alkali liquor after filter pressing and washing is collected and indiscriminately used as the water for washing and the water for diluting alkali fused materials and full recovery and surplus utilization of low-concentration mixed alkali are achieved through recovery and indiscriminate use, thus achieving the aims of reducing emission and reducing the consumption of fresh tap water.

Owner:JIANGSU TAIFENG CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com