Oxygen/carbon dioxide combustion technique applied to cement clinker production process

A technology for cement clinker and production process, applied in cement production, carbon capture, waste heat treatment, etc., can solve problems such as complete realization difficulties, strengthen heat exchange in furnace, solve low flue gas temperature, reduce investment and operation cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

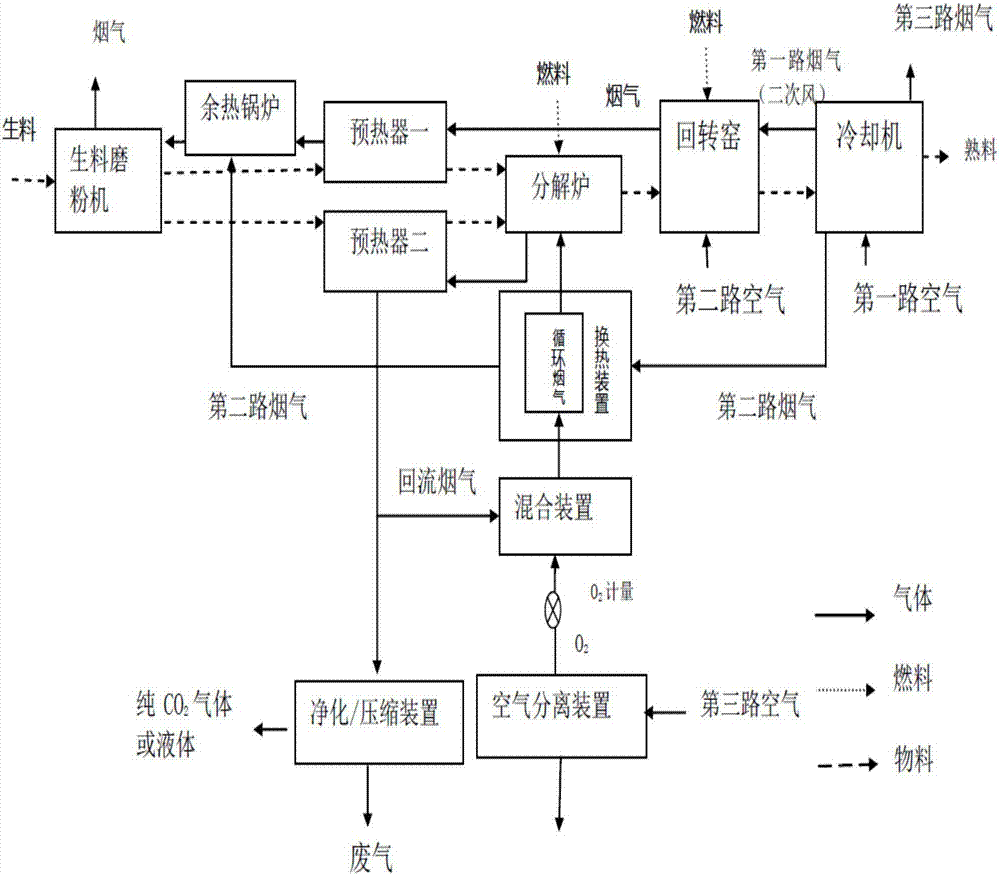

Embodiment 1

[0045] The humidity of the raw meal entering the raw meal mill is 10%, and the flue gas discharged from the waste heat boiler enters the raw meal mill to dry the raw meal. The humidity of the raw meal after drying is 0.5%, and the raw meal is homogenized. The homogenized raw meal enters the preheater 1 and the preheater 2 respectively for preheating, and the preheated raw meal enters the calciner in O 2 / CO 2 Atmosphere decomposition, the temperature of the decomposition furnace is 880-890°C, the decomposed raw material enters the rotary kiln for calcination, the fuel in the rotary kiln is burned in the air atmosphere, and is used for raw material calcination, and the calcined material enters the cooler for cooling, cooling Then get cement clinker. During this process, the air is divided into three paths into the kiln system. The first air blows into the cooler to cool the clinker. After cooling the clinker, the high-temperature flue gas discharged from the cooler includes t...

Embodiment 2

[0049] The humidity of the raw meal entering the raw meal mill is 12%, and the flue gas discharged from the waste heat boiler enters the raw meal mill to dry the raw meal. The humidity of the raw meal after drying is 0.8%, and the raw meal is homogenized. The homogenized raw meal enters the preheater 1 and the preheater 2 respectively for preheating, and the preheated raw meal enters the calciner in O 2 / CO 2 Atmosphere decomposition, the temperature of the decomposition furnace is 870-880°C, the decomposed raw material enters the rotary kiln for calcination, the fuel in the rotary kiln is burned in the air atmosphere, and is used for raw material calcination, and the calcined material enters the cooler to cool, and the Then get cement clinker. During this process, the air is divided into three paths into the kiln system. The first air blows into the cooler to cool the clinker. After cooling the clinker, the high-temperature flue gas discharged from the cooler includes the f...

Embodiment 3

[0053] The humidity of the raw meal entering the raw meal mill is 8%, and the flue gas discharged from the waste heat boiler enters the raw meal mill to dry the raw meal. The humidity of the raw meal after drying is 1%, and the raw meal is homogenized. The homogenized raw meal enters the preheater 1 and the preheater 2 respectively for preheating, and the preheated raw meal enters the calciner in O 2 / CO 2 Atmosphere decomposition, the temperature of the decomposition furnace is 850-860°C, the decomposed raw material enters the rotary kiln for calcination, the fuel in the rotary kiln is burned in the air atmosphere, and is used for raw material calcination, and the calcined material enters the cooler for cooling, cooling Then get cement clinker. During this process, the air is divided into three paths into the kiln system. The first air blows into the cooler to cool the clinker. After cooling the clinker, the high-temperature flue gas discharged from the cooler includes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com