Method for controlling motion of cylinder piston of piston engine and device for implementing method

A technology of piston engine and engine cylinder, applied in the direction of internal combustion piston engine, engine cooling, mechanical equipment, etc., can solve the problems of engine consumption, easy wear, and large fuel loss, achieve high-efficiency, high-temperature and high-pressure combustion air, and prolong engine life. , significant effect of energy saving and emission reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

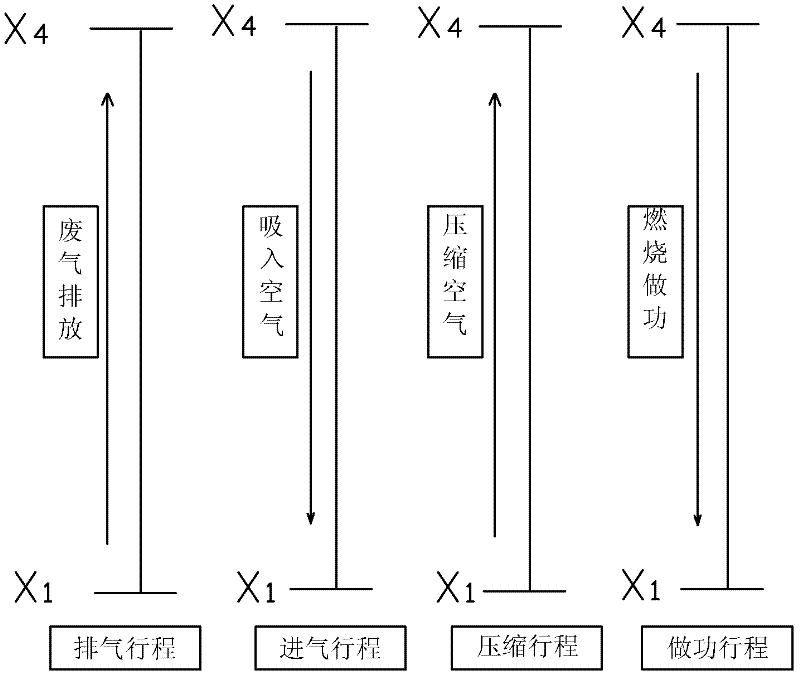

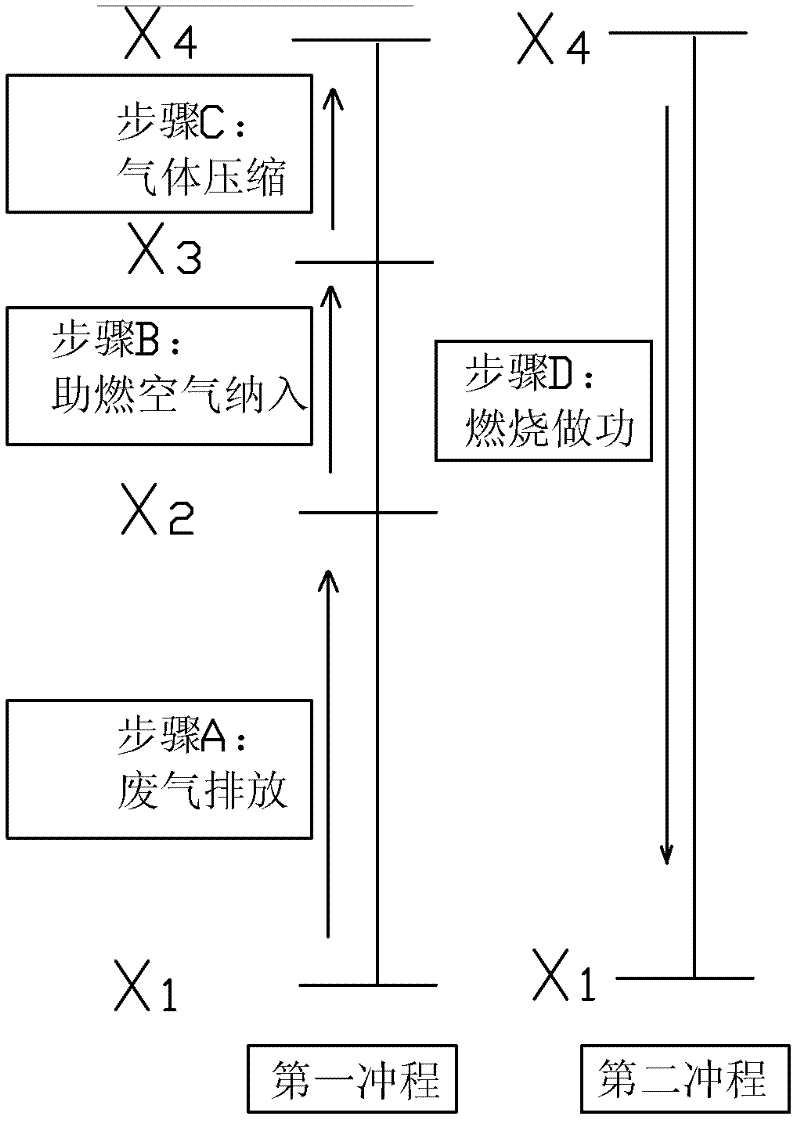

[0034] This embodiment provides a method for controlling the motion of the cylinder piston of a piston engine. The process is as follows: image 3 As shown, the engine cylinder has an intake valve, an exhaust valve and a combustion chamber, and the piston moves up and down driven by the crankshaft (the piston drives the crankshaft to rotate during the working stroke), and the piston runs in the cylinder with a bottom dead center X1 and a top dead center X4 , the intake valve is connected to the high-temperature and high-pressure combustion air source through the intake pipe, and two dead centers are added between the bottom dead center X1 and the top dead center X4, which are divided into the first dead point X2 and the second dead point X3, and the second The stop point X3 is above the first stop point X2, and the piston movement is controlled according to the following steps:

[0035] Step A, the exhaust valve is opened, the intake valve is closed, the piston moves upward fr...

Embodiment 2

[0045] This embodiment provides another device for obtaining high-temperature and high-pressure combustion-supporting air. The structure of this embodiment is the same as that of Embodiment 1, except that the specific height (distance perpendicular to the ground) of some parts is limited, specifically: the same pressure pipe 15 has a first steam flow port 13 located on the high temperature and high pressure steam generator 2 and a second steam flow port 16 located on the liquid storage and infusion tank 20; vertically speaking, the first steam flow port 13 is located on the high temperature and high pressure steam generator 2 The highest point of the internal space, the second steam circulation port 16 is located at the highest point of the internal space of the liquid storage and infusion tank 20, the highest point of the internal space of the high-temperature and high-pressure steam generator 2 is higher than the highest point of the internal space of the liquid storage and in...

Embodiment 3

[0047] This embodiment is a method for controlling the movement of the cylinder piston of a piston engine. The control process is the same as that of Embodiment 1. The high temperature and high pressure combustion air of this embodiment is obtained by using an existing turbocharger or supercharger. The high-pressure air delivery pipe 8 communicates with the turbocharger or supercharger and the high-temperature and high-pressure air storage tank 5, and then guides it into each combustion chamber of the engine through the intake branch pipe 6, thereby omitting other components.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com