Sodium-potassium ratio adjusting device of device for recovering mixed alkali from indigo products

A product recovery and adjustment device technology, applied in indigo dyes, organic dyes, chemical instruments and methods, etc., can solve the problems of high processing costs and production costs, waste of alkali resources, environmental pollution, etc., and achieve significant emission reduction and reduction of The use of tap water, the effect of huge benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with drawings and embodiments.

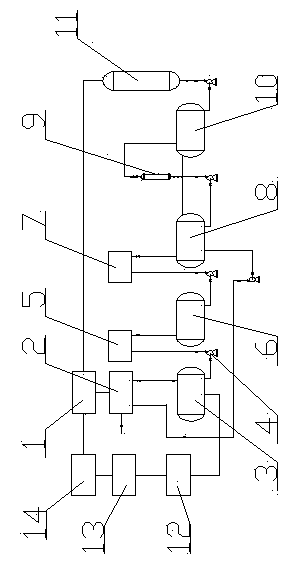

[0022] figure 1 As shown, a device for recovering mixed lye from the indigo post-treatment washing process includes a washing lye tank 3, a pump 4, a suspended matter filter 5, a suspended matter filter lye tank 6, an organic matter filter 7, and an organic matter filter alkali Water tank 8, cooling tower 9, cooling alkaline water storage tank 10, cooling alkaline water supply tank 11, concentrating device 12, sodium-potassium ratio adjusting device 13 and dehydration device 14. The water outlet of the indigo post-treatment filter press 2 is connected to the sodium-potassium ratio adjustment device 13 through the concentration device 12, the sodium-potassium ratio adjustment device 13 is connected to the dehydration device 14, and the dehydration device 14 is connected to the indigo oxidation reactor 1; the water inlet of the washing alkali water tank 3 Connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com