One-bath process of scouring and dyeing cotton fabric with reactive dyes and soap

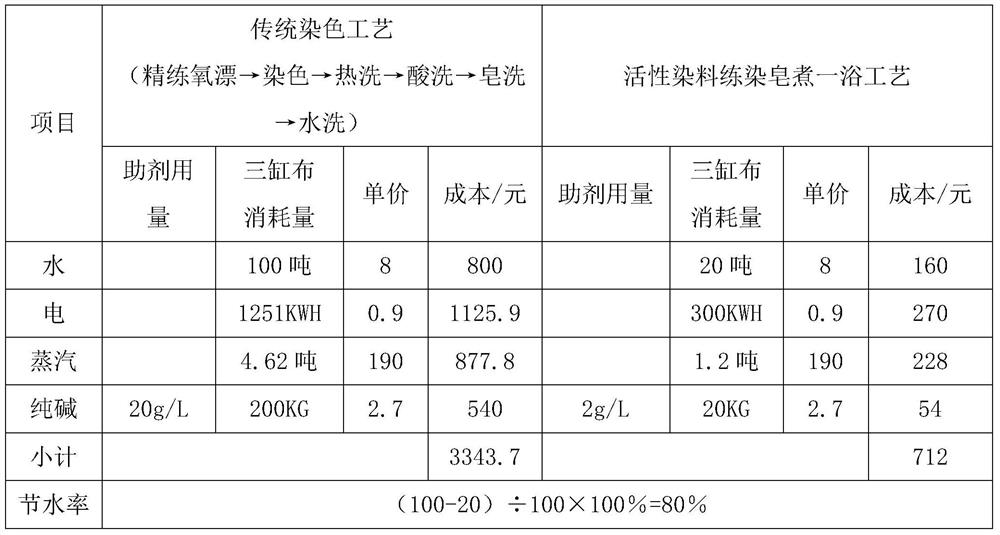

A technology for reactive dyes and cotton fabrics, applied in the field of dyeing and finishing, can solve the problems of time-consuming sewage treatment, and achieve the effects of overcoming adverse effects, reducing resource consumption, and improving color yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] This embodiment provides a one-bath process for scouring and dyeing of dark blue cotton fabrics with reactive dyes and soaping. Specifically, the cotton gray cloth to be treated and water are added in the main tank of the normal temperature and pressure dyeing machine, and the bath ratio is 1:10. Then add the low-temperature scouring agent of 2.0g / L, the reactive red LA-BN of 0.9% (o.w.f), the reactive yellow LA-RN of 0.57% (o.w.f), the reactive green LA-DB of 3.3% (o.w.f), 70g / L of anthracite and 2.0g / L soda ash, heated up to 80°C at a heating rate of 1°C / min and kept warm for 35min, scouring and dyeing in the same bath; after dyeing, directly add 2.0g / L without draining Use low-temperature soaping agent for soaping, and heat preservation treatment at 80°C for 20-50 minutes. When the color of the dyeing solution turns light yellow to light brown, it is the end point of soaping. At this time, the pH value of the dyeing solution drops to 3-6; then drain liquid, into col...

Embodiment 2

[0026] The present embodiment provides a kind of one-bath process of scouring and dyeing soaping of dark gray cotton fabric reactive dyes, specifically adding the cotton gray cloth to be treated and water in the main vat of the normal temperature and pressure dyeing machine, the bath ratio is 1:10, and then Add 1.0g / L low-temperature scouring agent, 0.27% (o.w.f) reactive red LA-BN, 0.35% (o.w.f) reactive yellow LA-RN, 0.69% (o.w.f) reactive dark blue LA-GN, 50g / L Soda ash of 1.5g / L and 1.5g / L soda ash are heated up to 85°C at a heating rate of 1.5°C / min and kept warm for 25min, then scouring and dyeing are carried out in the same bath; after dyeing, 0.5g / L of Soaping with low-temperature soaping agent, heat preservation treatment at 85°C for 20-50 minutes, until the color of the dyeing solution turns light yellow to light brown, which is the end point of soaping. At this time, the pH value of the dyeing solution drops to 3-6; then drain 1. Wash once in cold water at room temp...

Embodiment 3

[0030] This embodiment provides a black cotton fabric reactive dyeing and soaping one-bath process. Specifically, the cotton gray cloth to be treated and water are first added to the master vat of a dyeing machine at normal temperature and pressure. The bath ratio is 1:15, and then added 3.0g / L low temperature scouring agent, 0.05% (o.w.f) reactive deep red LA-DB, 0.04% (o.w.f) reactive yellow brown LA-DR, 4.5% (o.w.f) reactive black LA-G, 80g / L Soda ash of 2.0g / L and 2.0g / L soda ash are heated up to 65°C at a heating rate of 1°C / min and kept warm for 50min, then scouring and dyeing are carried out in the same bath; after dyeing, 3.0g / L soda ash is directly added Soaping with low-temperature soaping agent, heat preservation treatment at 65°C for 20-50 minutes, until the color of the dyeing solution turns light yellow to light brown, which is the end point of soaping. At this time, the pH value of the dyeing solution drops to 3-6; then drain 1. Wash once in cold water at room t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com