Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35 results about "Brake specific fuel consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Brake-specific fuel consumption (BSFC) is a measure of the fuel efficiency of any prime mover that burns fuel and produces rotational, or shaft power. It is typically used for comparing the efficiency of internal combustion engines with a shaft output.

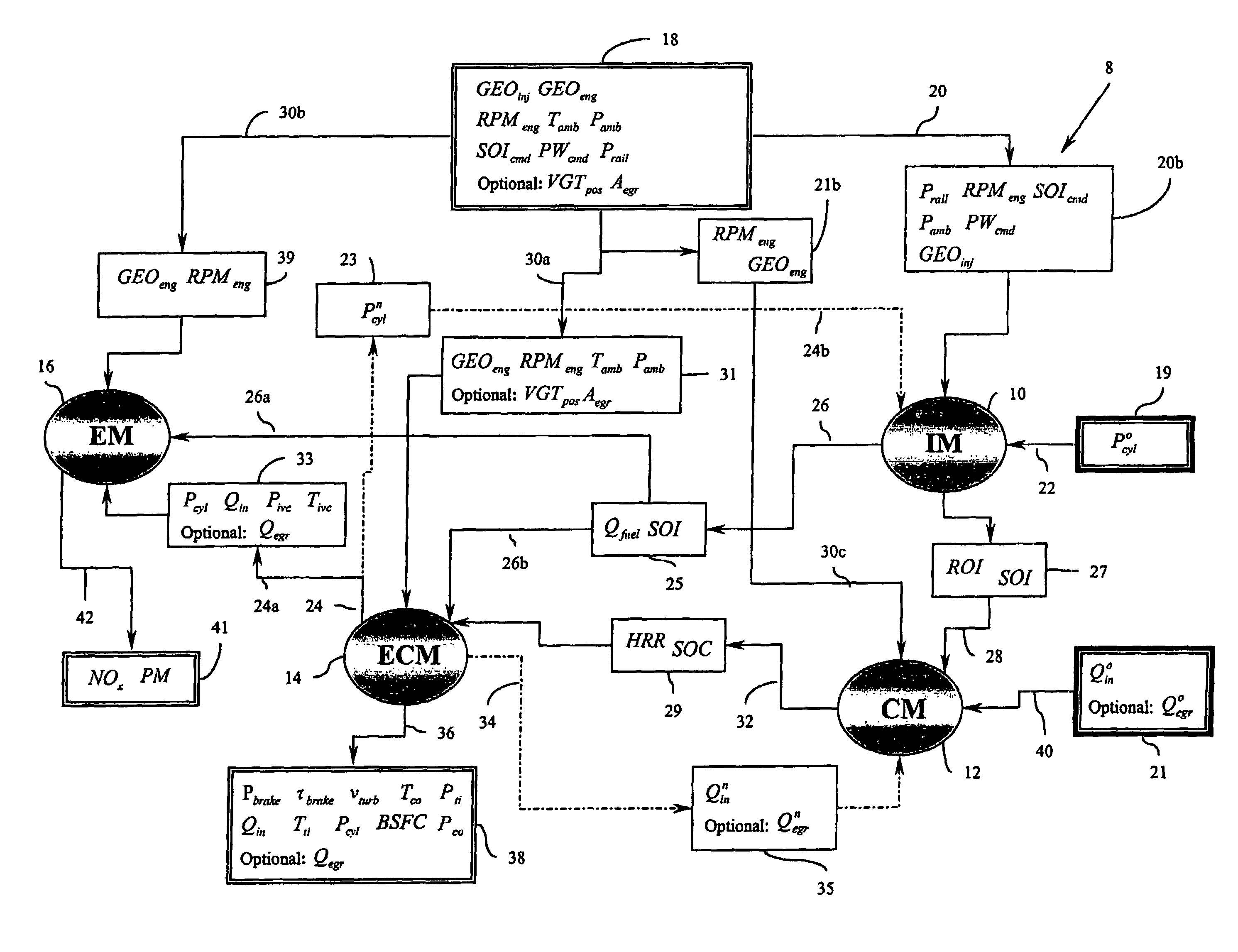

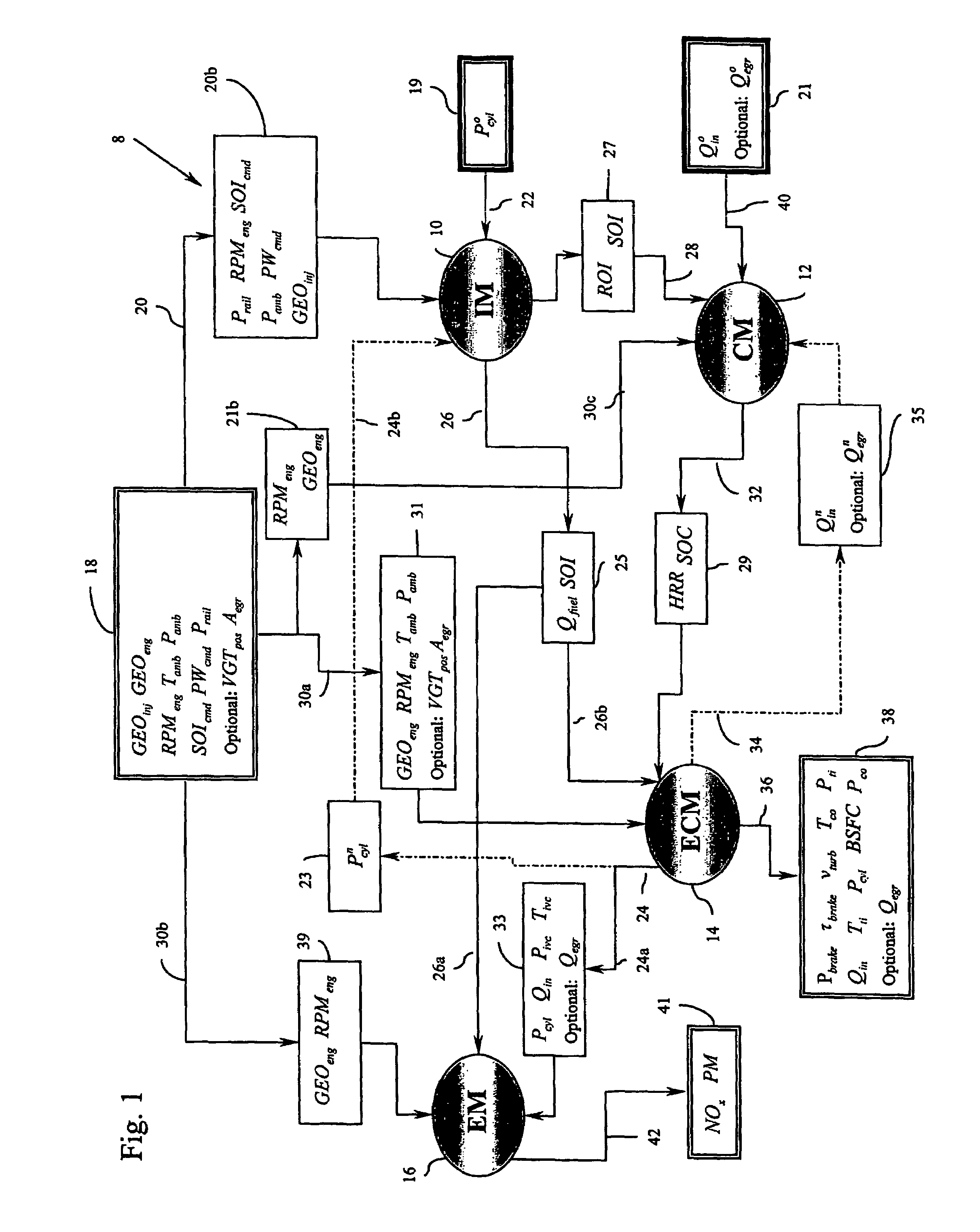

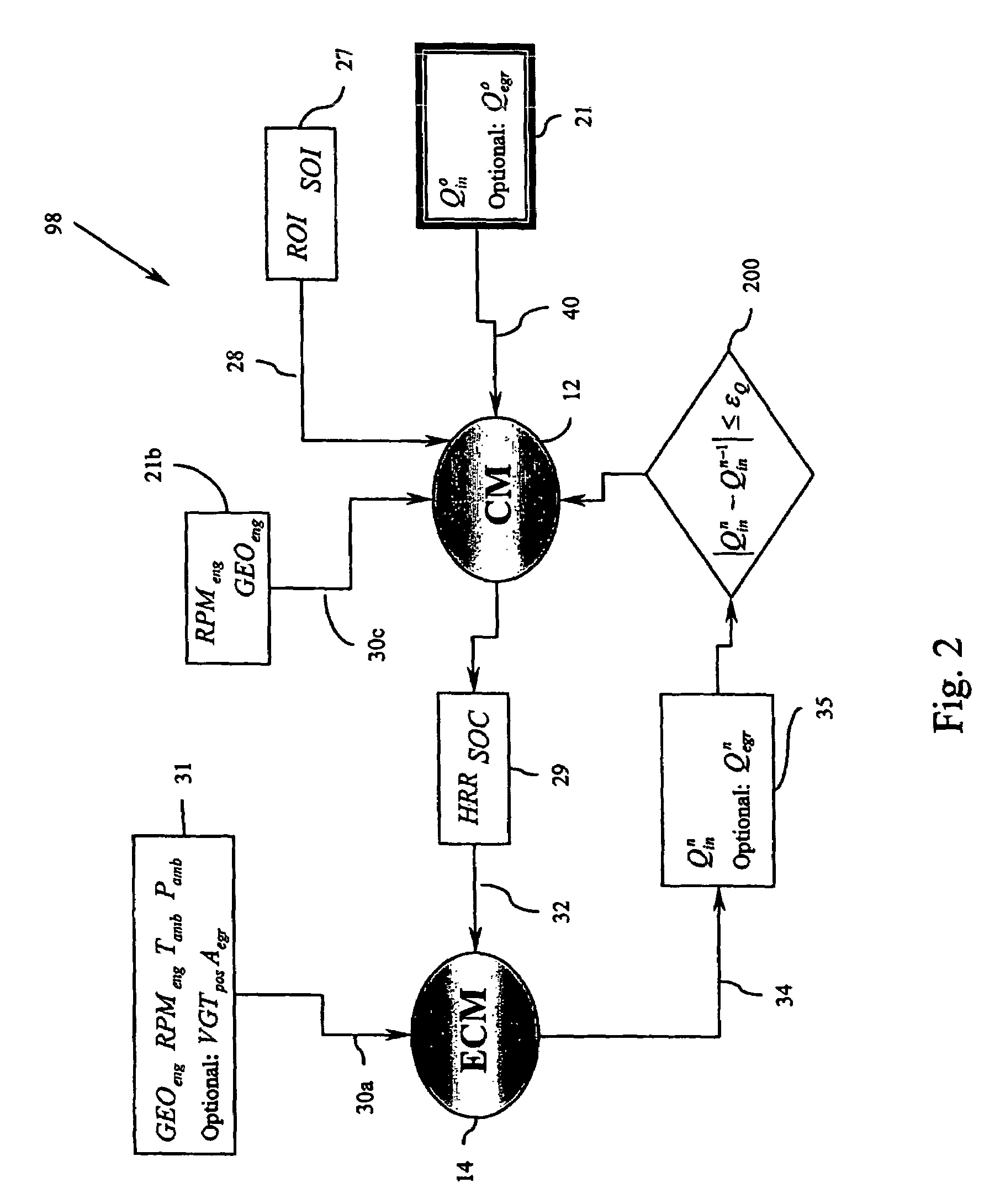

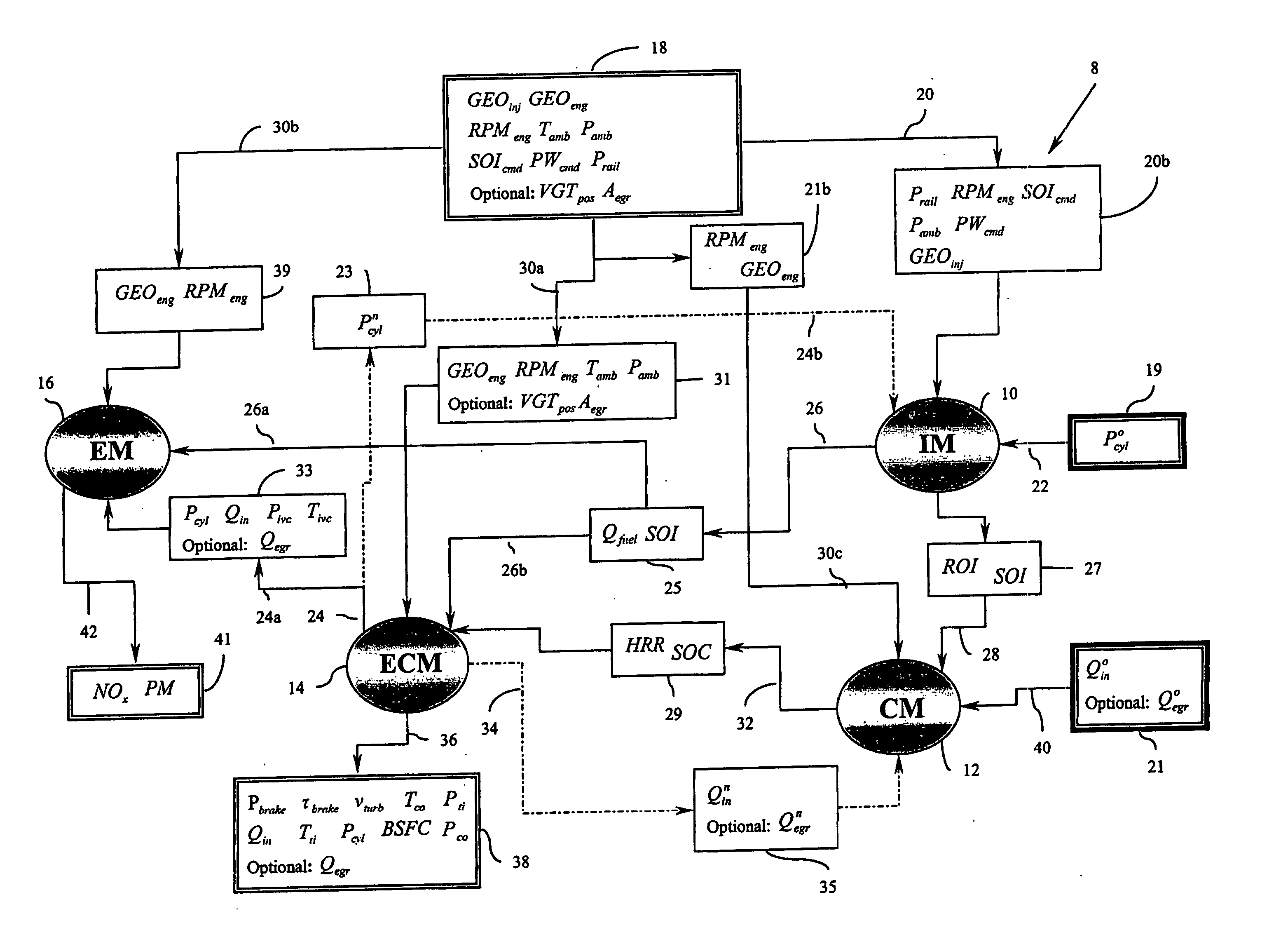

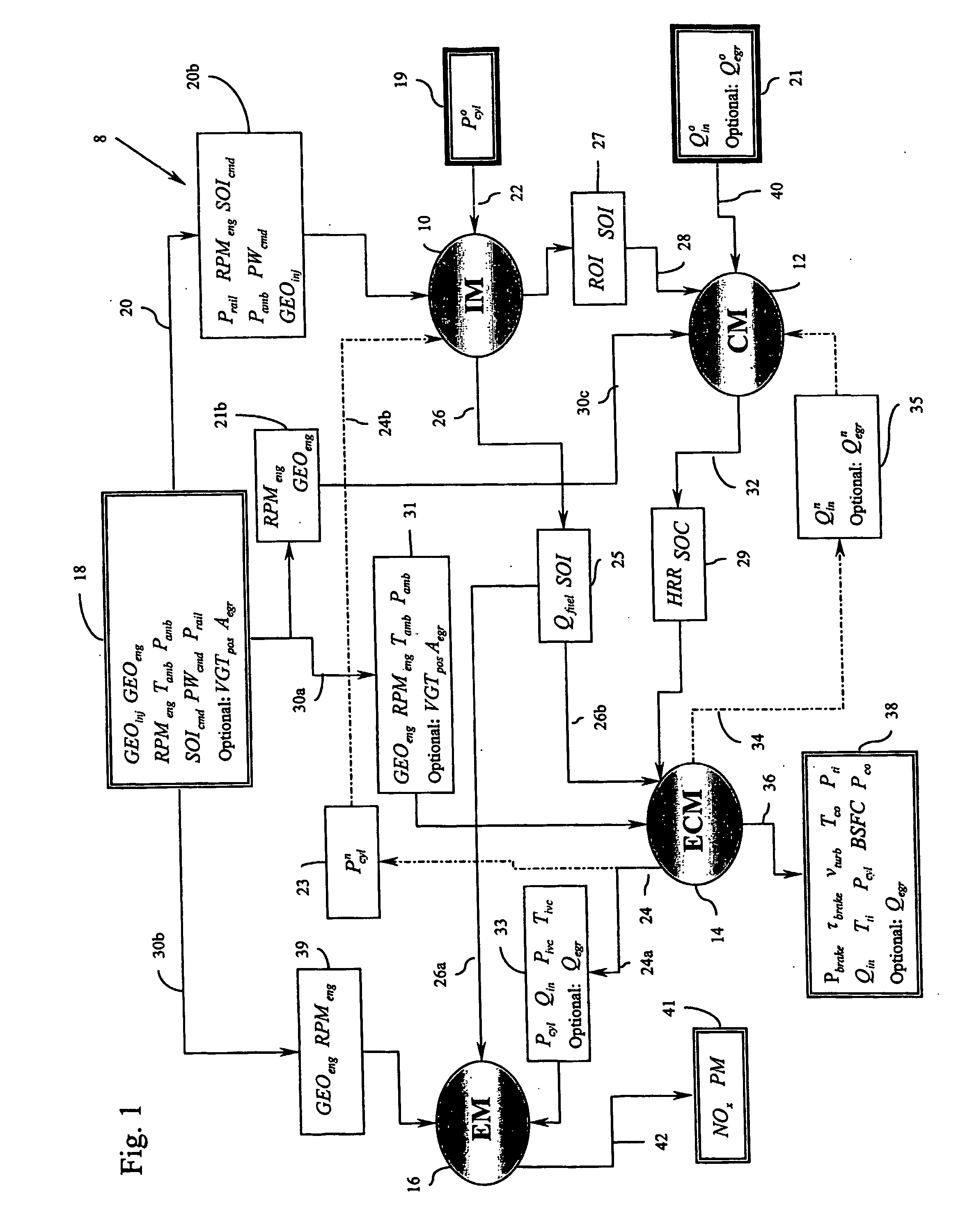

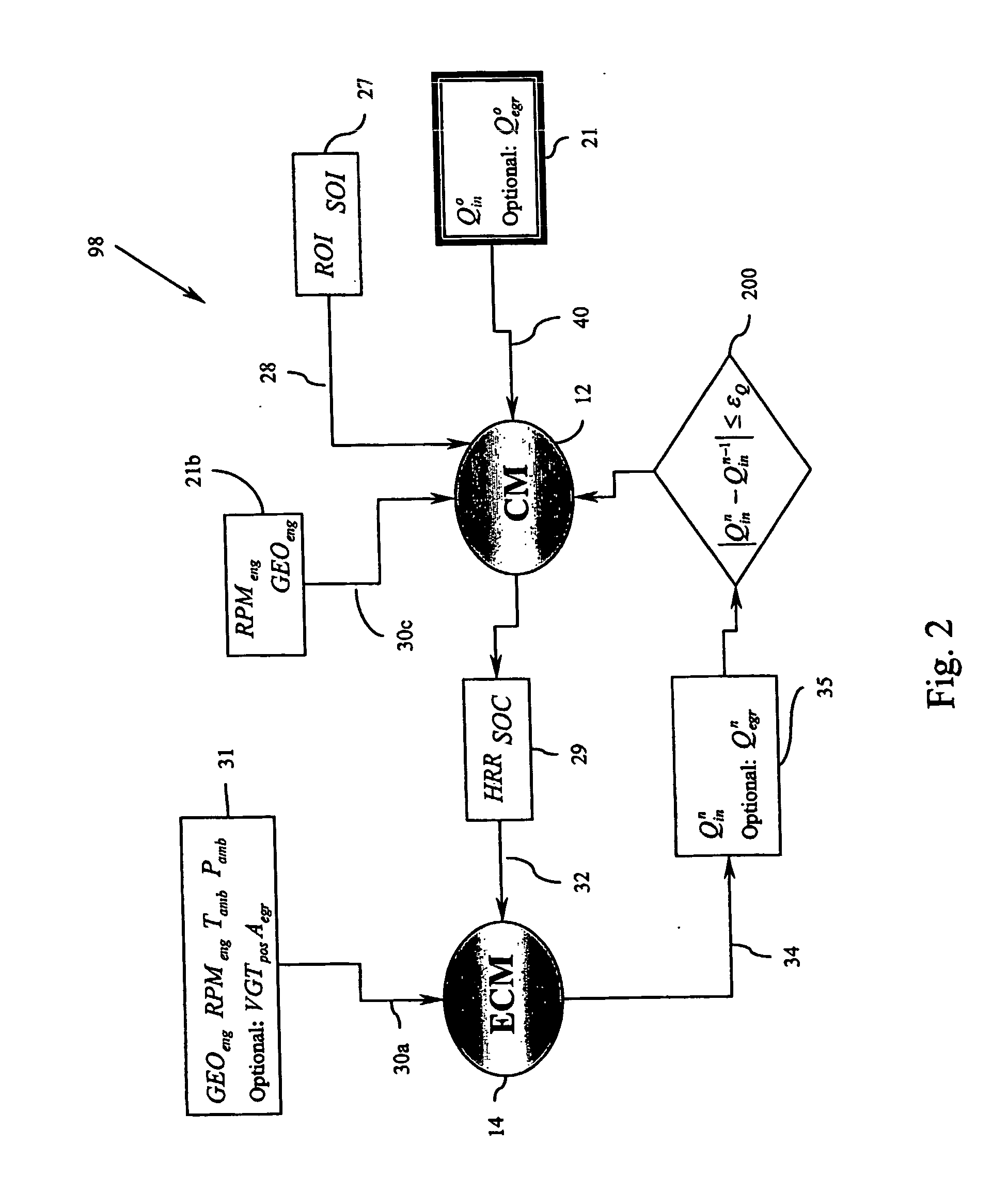

Method for controlling combustion in an internal combustion engine and predicting performance and emissions

InactiveUS7392129B2Electrical controlInternal combustion piston enginesBrake torqueBrake specific fuel consumption

Owner:WESTPORT POWER

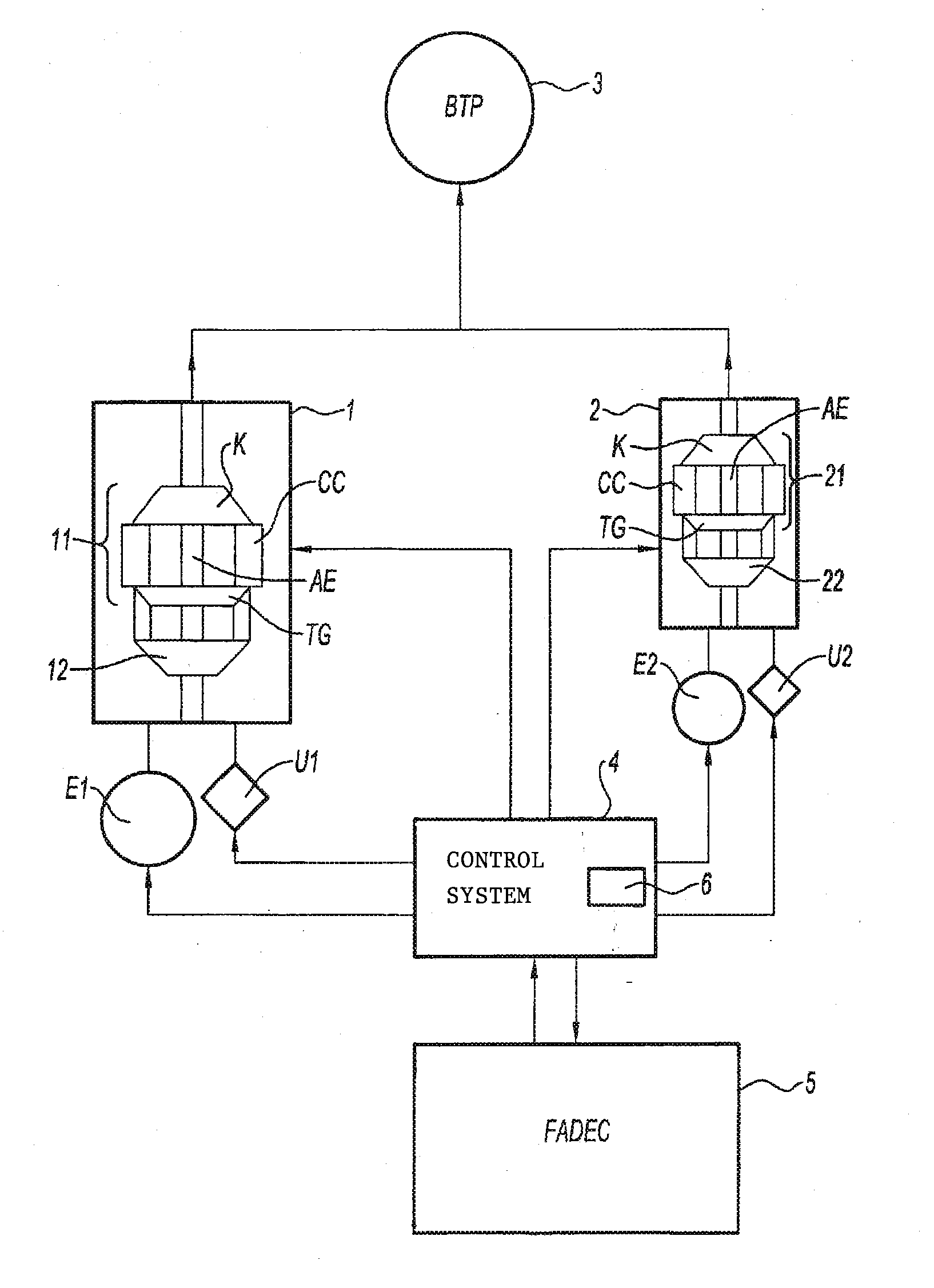

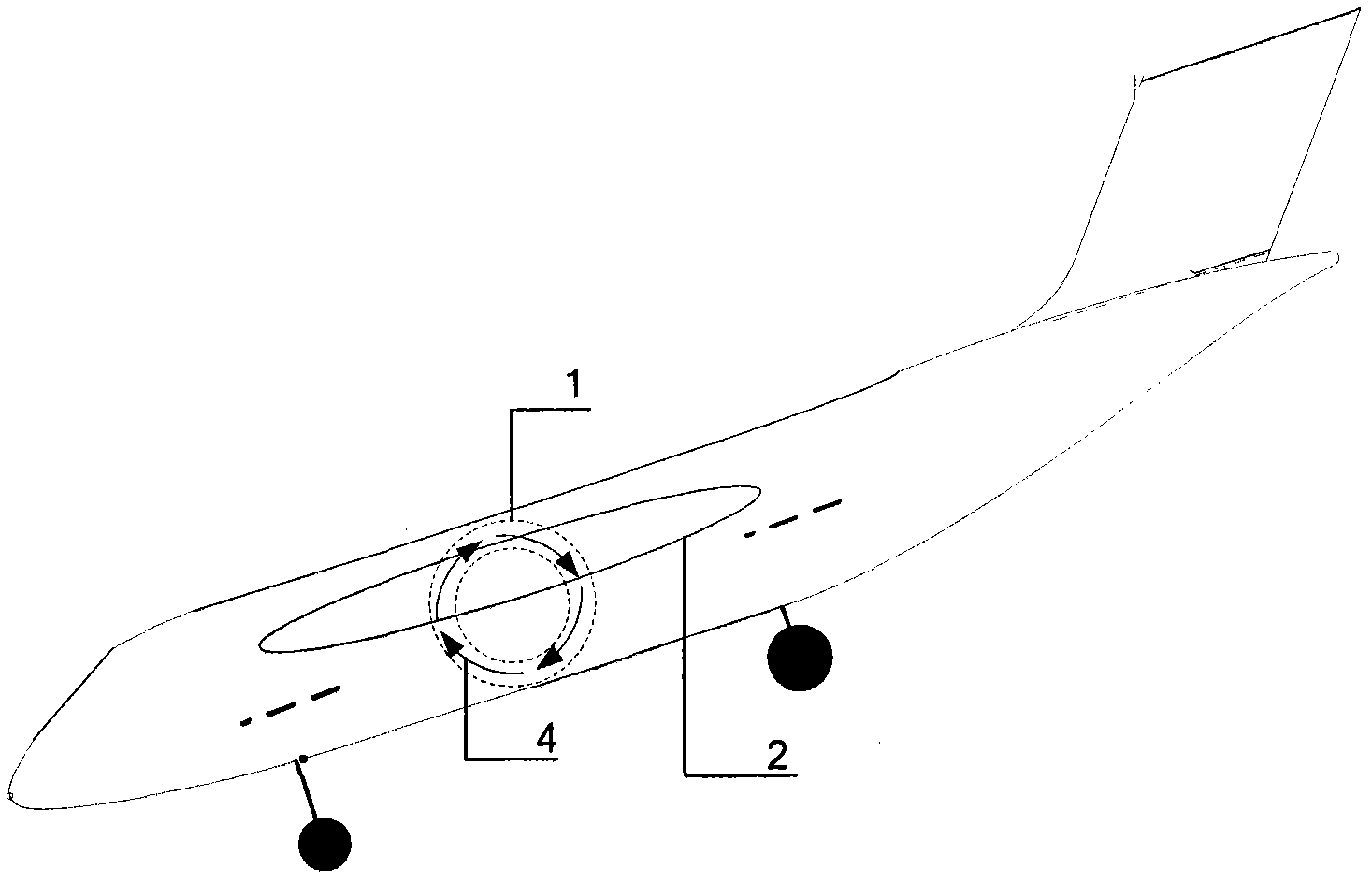

Method of optimizing the specific fuel consumption of a twin engine helicopter and twin engine architecture with control system for implementing it

InactiveUS20130219905A1Reduce decreaseCombustion enginesGas turbine plantsBrake specific fuel consumptionCombustion chamber

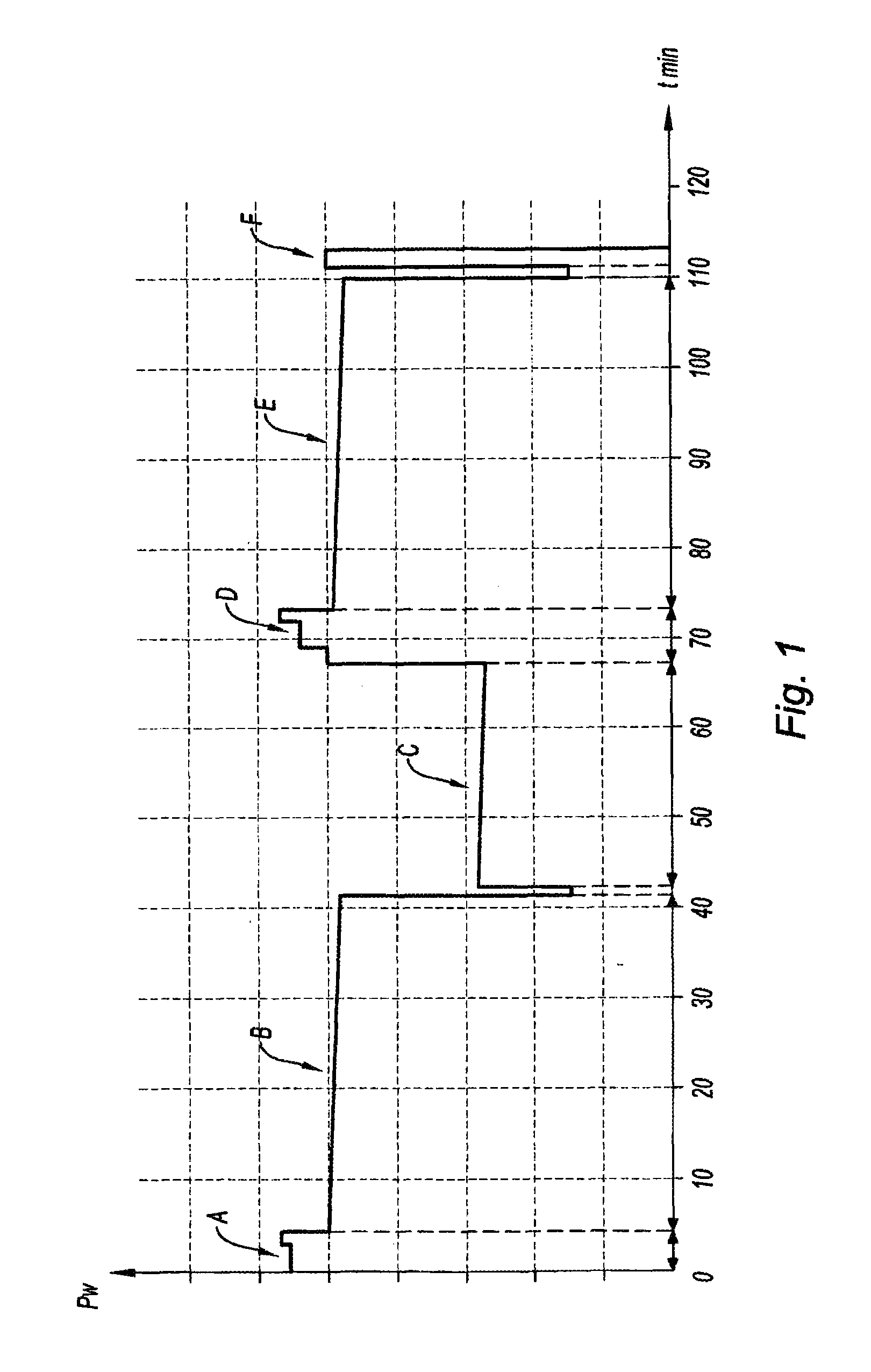

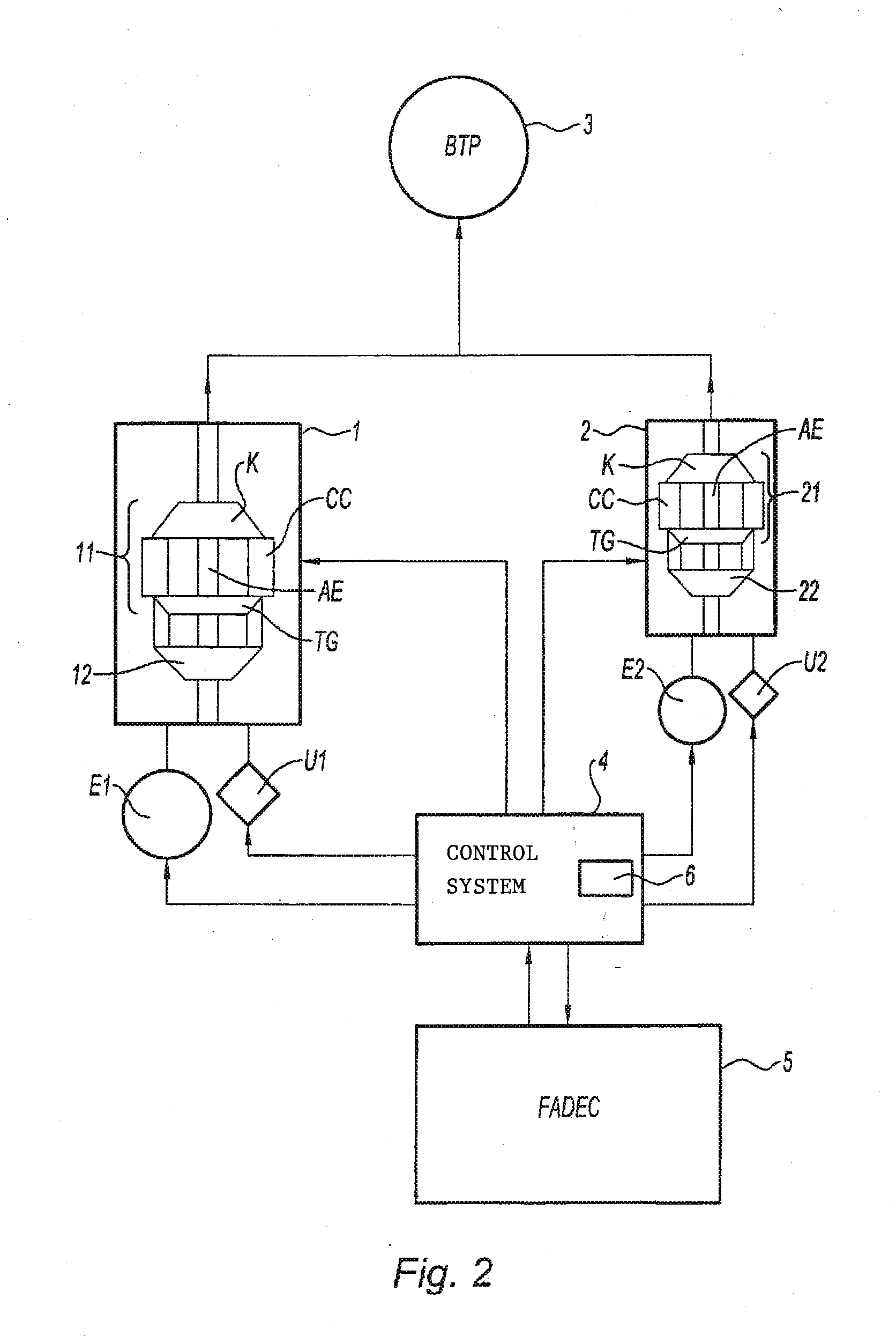

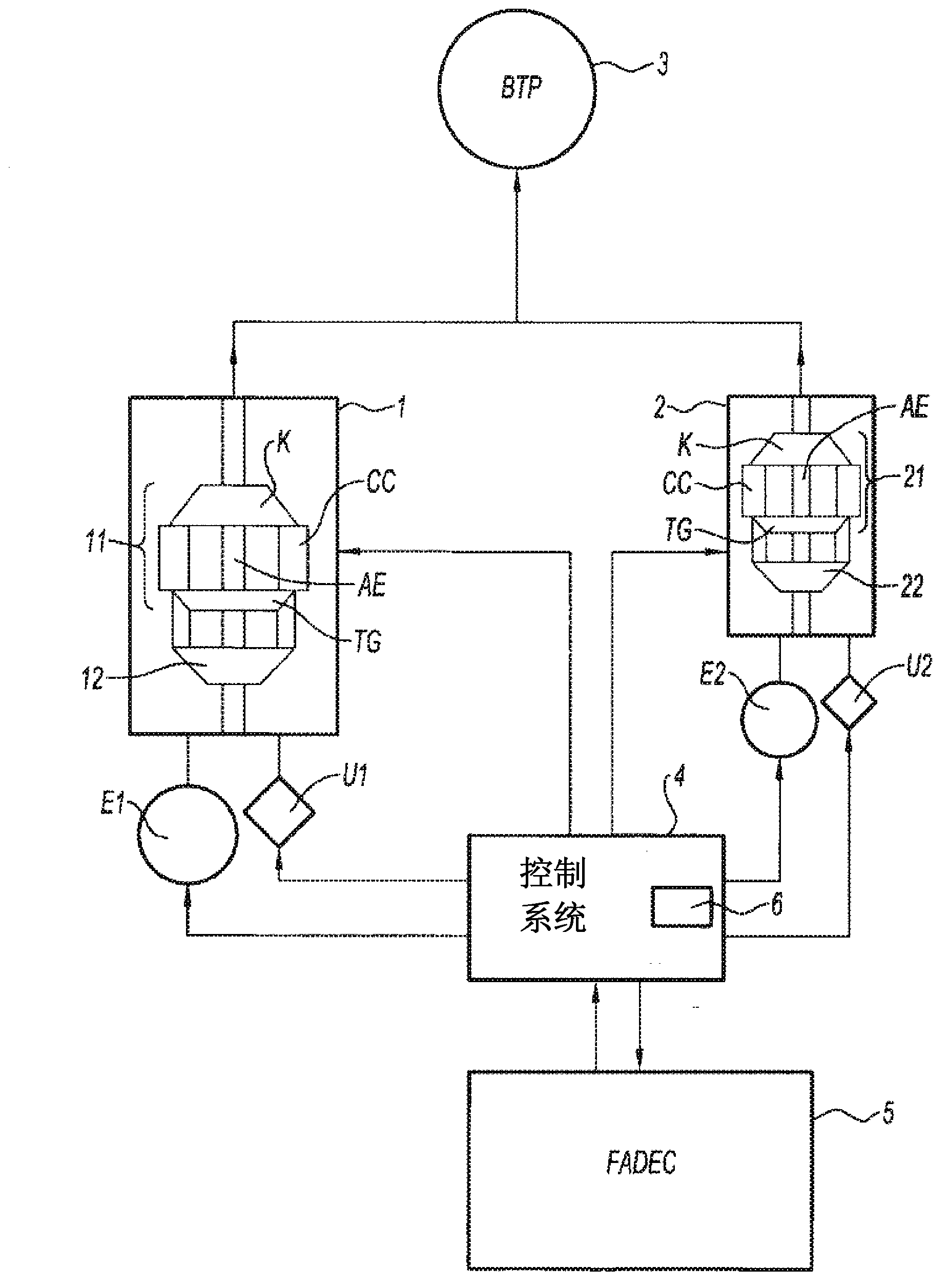

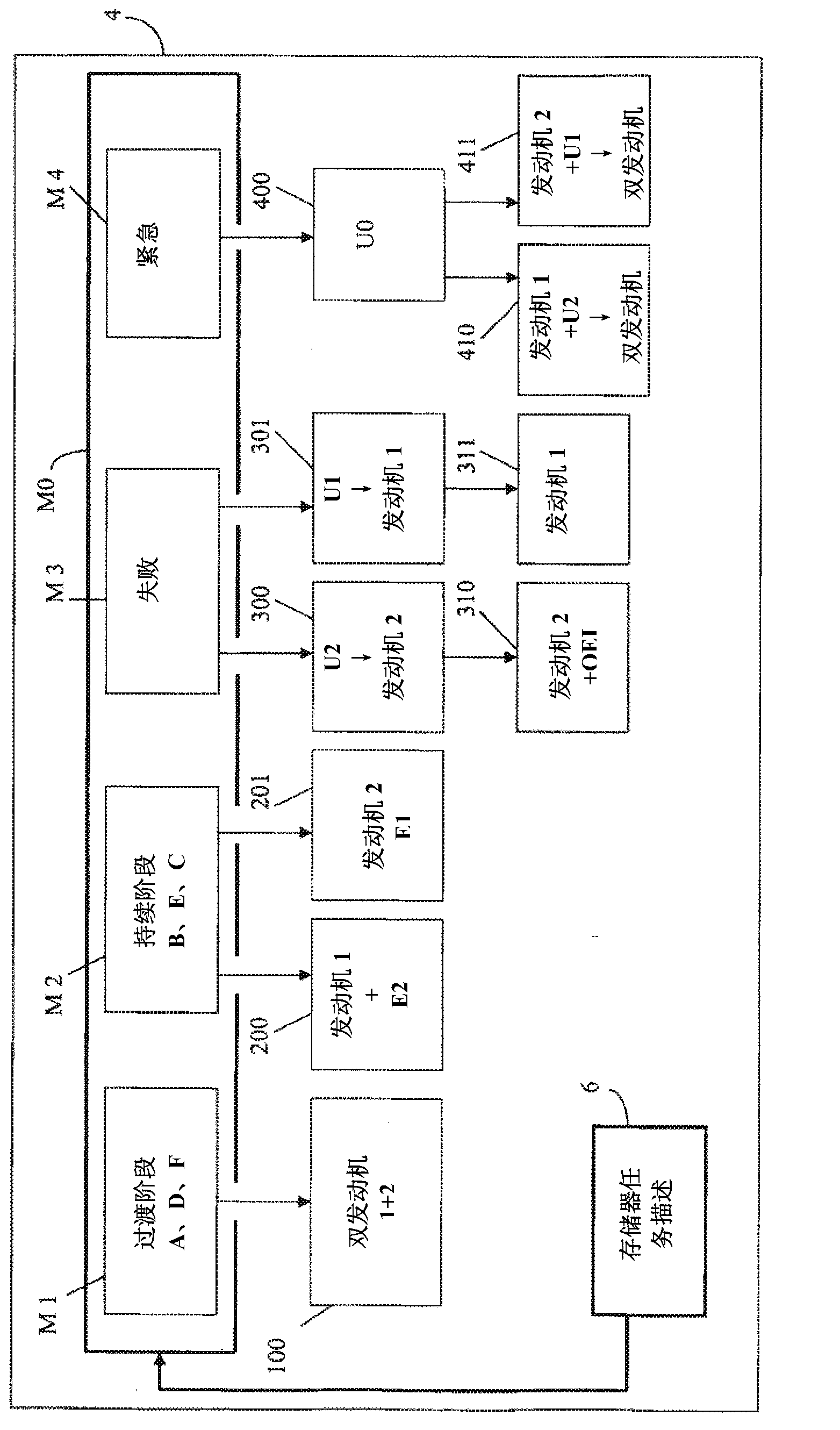

A method and architecture to reduce specific fuel consumption of a twin-engine helicopter without compromising safety conditions regarding minimum amount of power to be supplied, to provide reliable in-flight restarts. The architecture includes two turbine engines each including a gas generator and with a free turbine. Each gas generator includes an active drive mechanism keeping the gas generator rotating with a combustion chamber inactive, and an emergency assistance device including a near-instantaneous firing mechanism and mechanical mechanism for accelerating the gas generator. A control system controls the drive mechanism and emergency assistance devices for the gas generators according to the conditions and phases of flight of the helicopter following a mission profile logged beforehand in a memory of the system.

Owner:SAFRAN HELICOPTER ENGINES

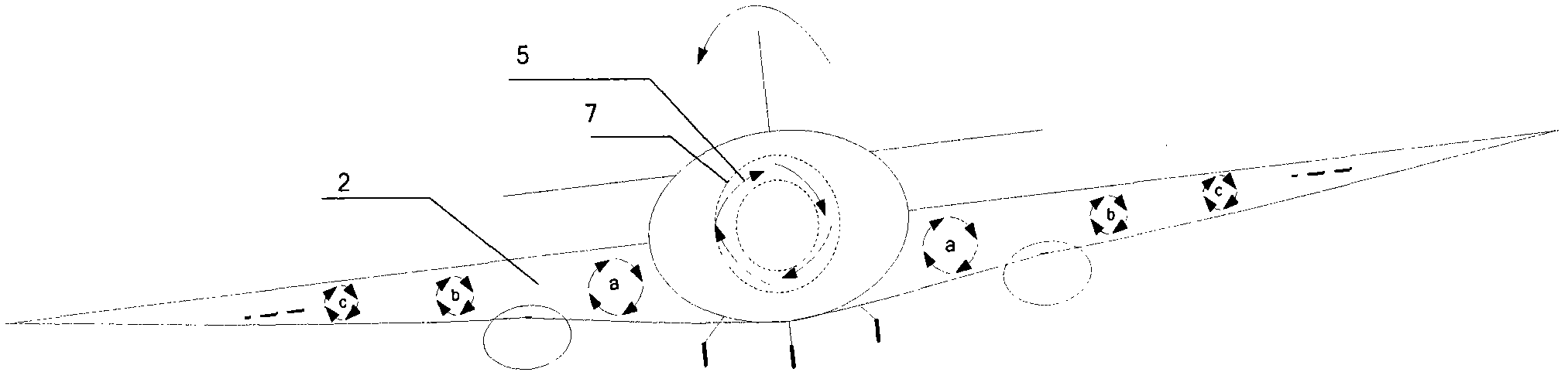

Method of optimizing the specific fuel consumption of a twin engine helicopter and twin engine architecture with control system for implementing it

ActiveCN103314198AGas turbine plantsEfficient propulsion technologiesBrake specific fuel consumptionCombustion chamber

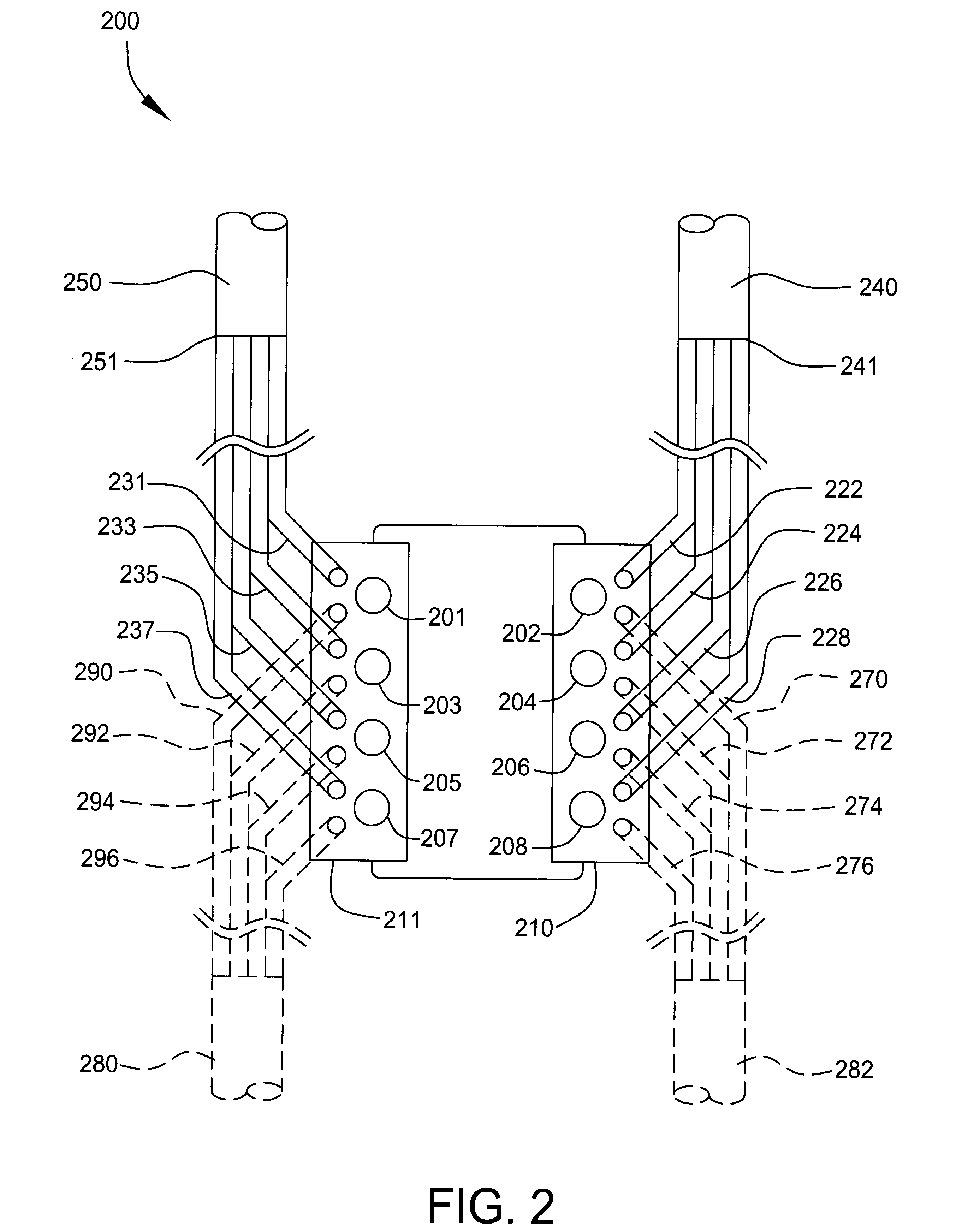

The invention seeks to reduce the specific fuel consumption Cs of a twin engine helicopter without compromising on the safety conditions regarding the minimum amount of power to be supplied for any kind of mission. To achieve this, the invention plans to make available special means capable of guaranteeing reliable in-flight restarts. One example of an architecture according to the invention involves two turbine engines (1, 2) each equipped with a gas generator (11, 21) and a with a free turbine (12, 22). Each gas generator (11, 21) is equipped with active drive means (E1, E2) capable of keeping the gas generator (1, 21) rotating with the combustion chamber inactive, and an emergency assistance device (U1, U2) comprising near-instantaneous firing means and mechanical means for accelerating the gas generator (11, 21).; The control system (4) controls the drive means (E1, E2) and the emergency assistance devices (U1, U2) for the gas generators (11, 21) according to the conditions and phases of flight of the helicopter following a mission profile logged beforehand in a memory (6) of this system (4).

Owner:TURBOMECA SA

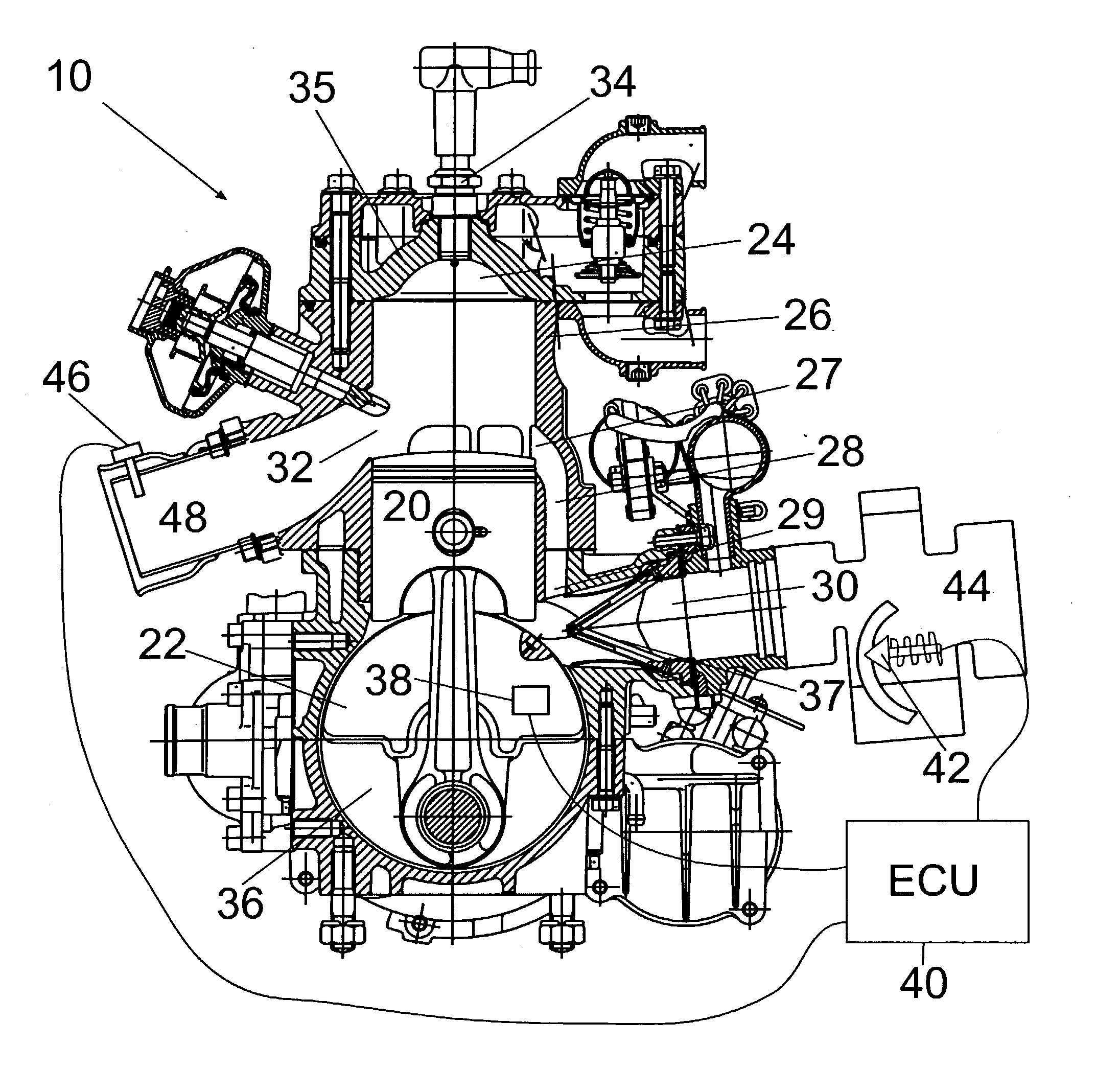

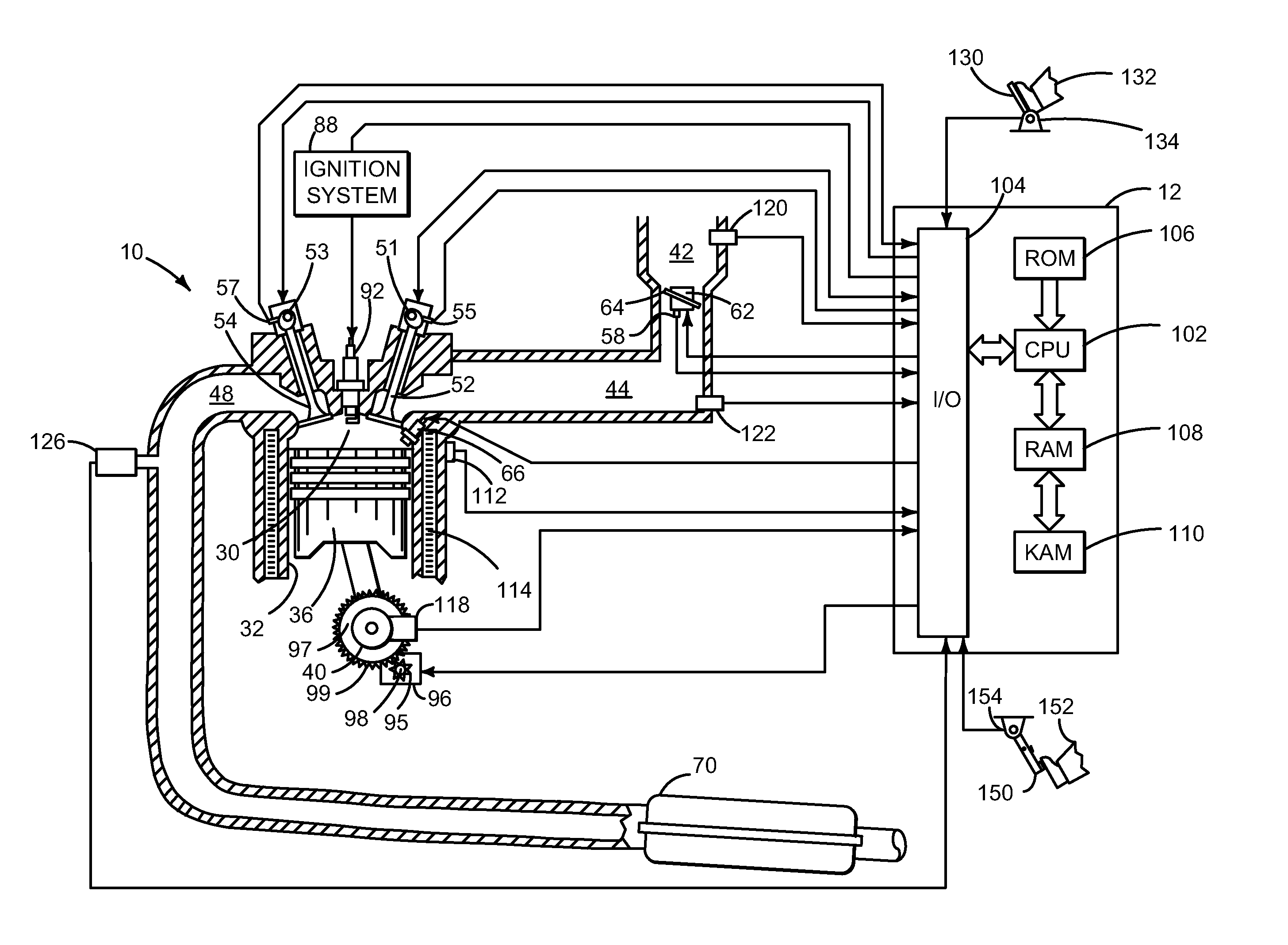

Method for controlling combustion in an internal combustion engine and predicting performance and emissions

InactiveUS20070073467A1Electrical controlInternal combustion piston enginesBrake torqueBrake specific fuel consumption

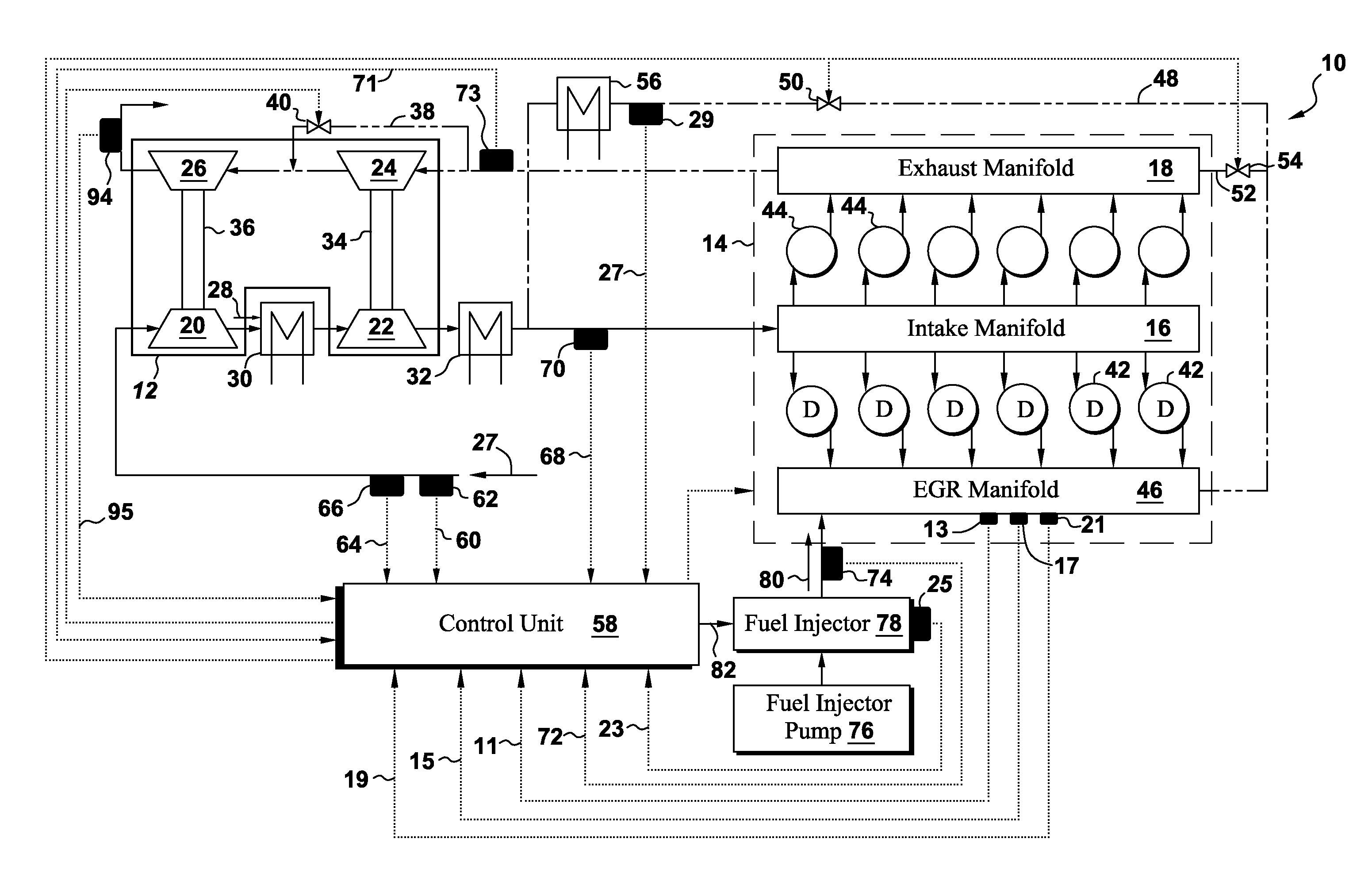

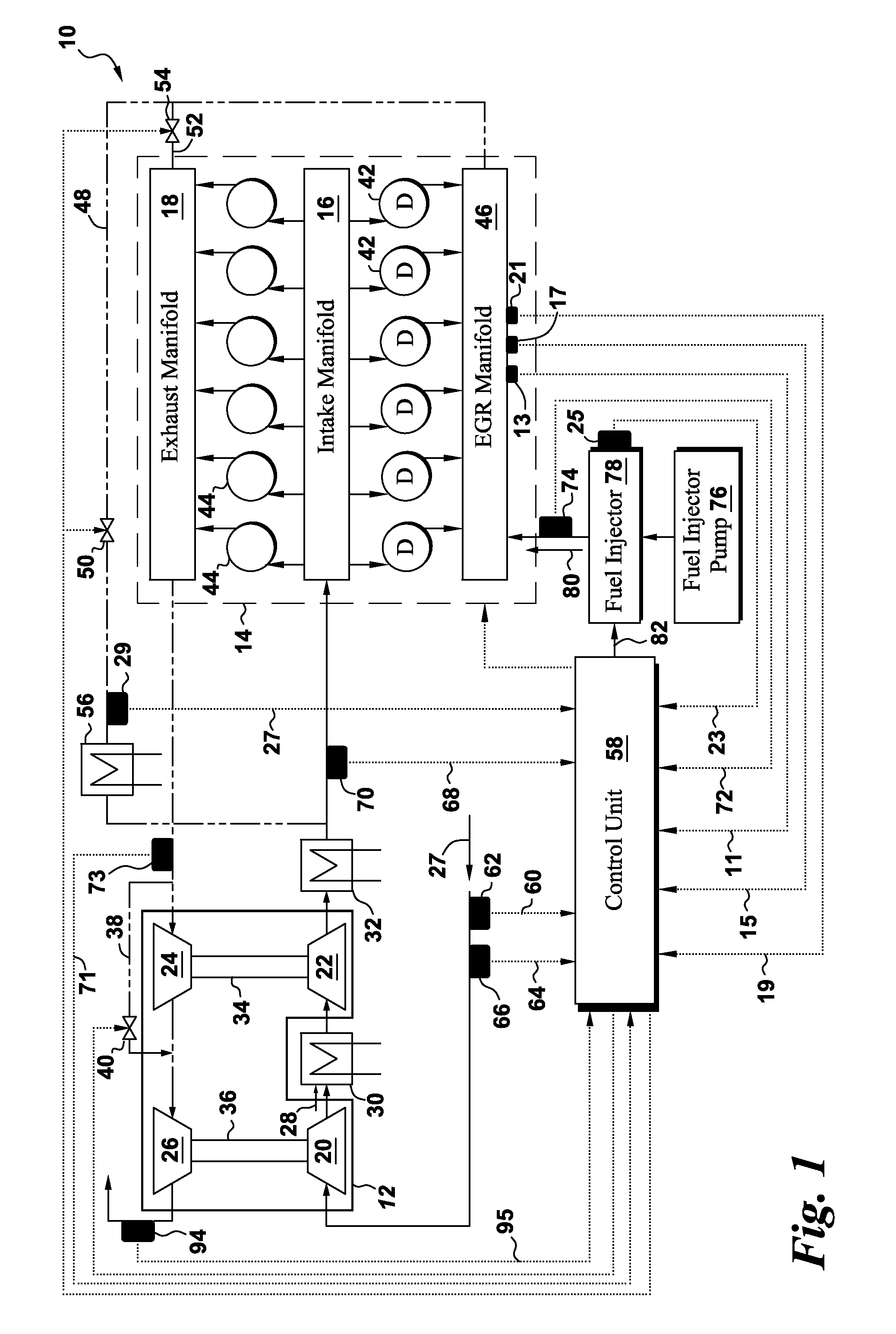

This disclosure teaches a method of controlling a direct injection internal combustion engine and predicting the behaviour of a direct injection internal combustion engine. An estimation of initial cylinder pressure, air flow and EGR flow (if applicable) is used to establish a system that provides engine behaviour by integrating an injection module, combustion module and engine control module to provide data indicative of engine behaviour such as brake torque and power, air flow, EGR flow, cylinder pressure, brake specific fuel consumption, start of combustion, heat release rate, turbo-charger speed and other variables. These values can then be used to adjust commanded variables such as start of injection, commanded pulse width, rail pressure to meet operator demand. Also the output data can be used as a tool to determine how a conceptualised engine design will behave. This is particularly useful for gaseous-fuelled internal combustion engines where cylinder pressure influences behaviour of injected gases in light of the fact that rail pressure and cylinder pressure are, generally, of a similar magnitude.

Owner:WESTPORT POWER

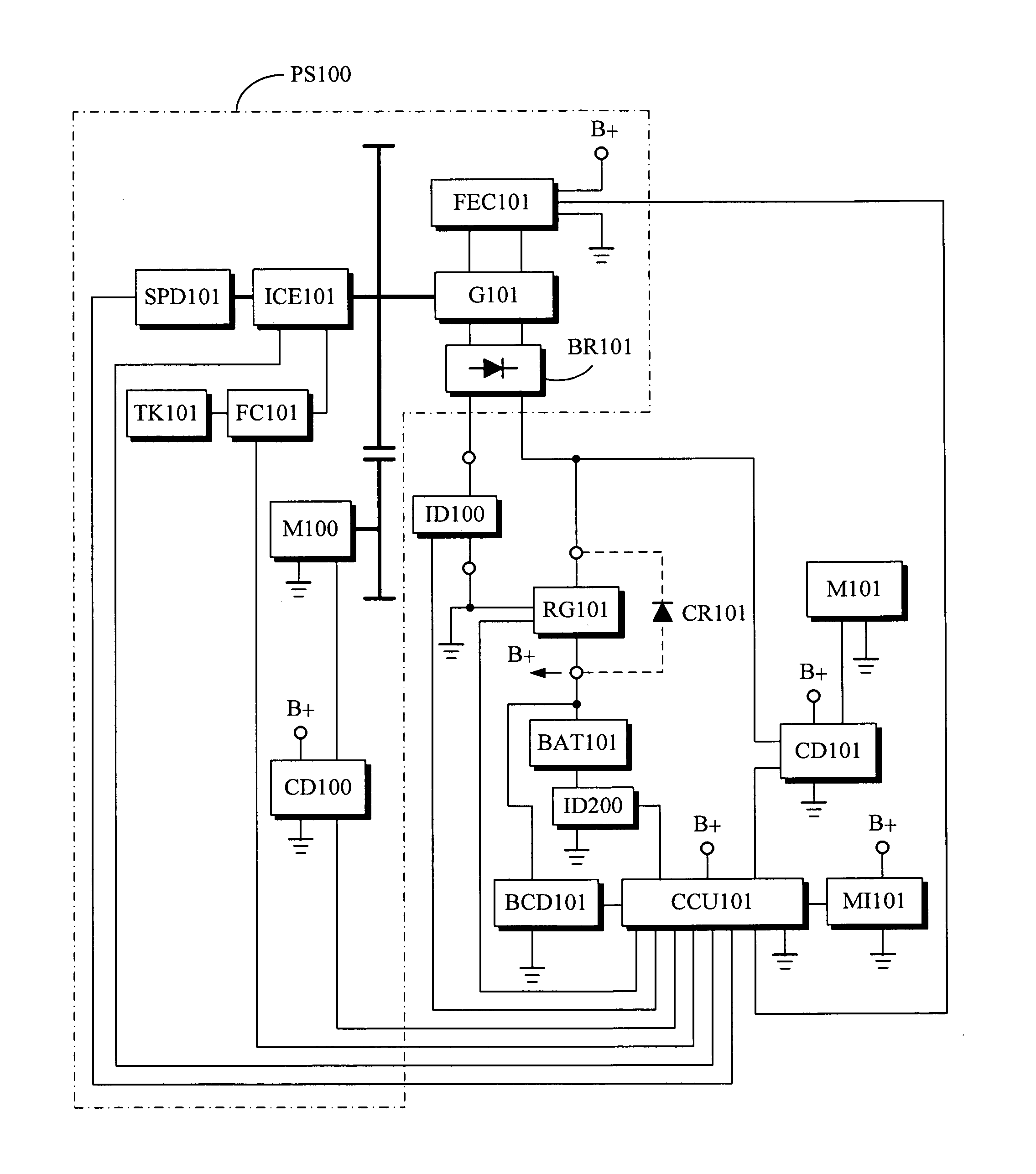

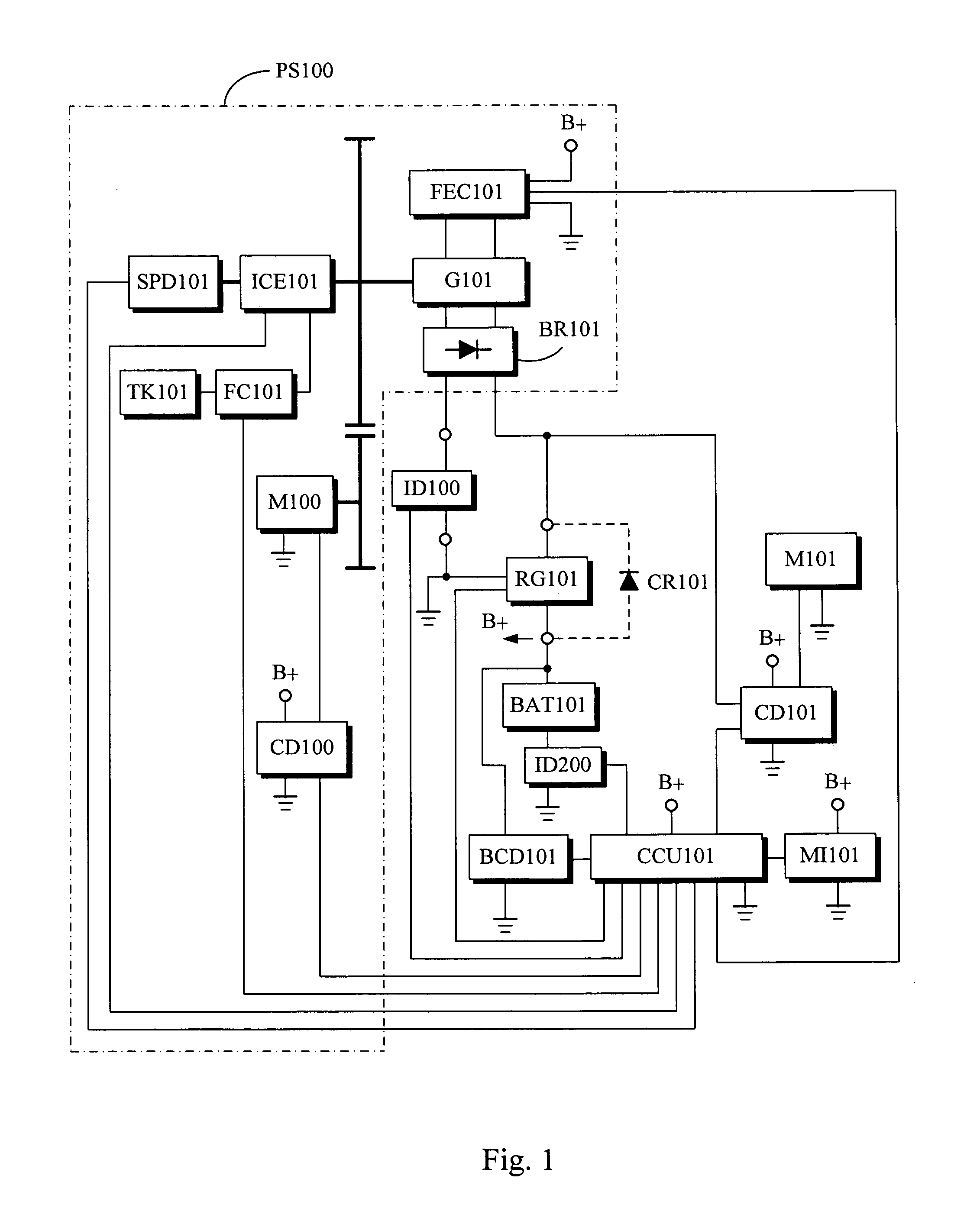

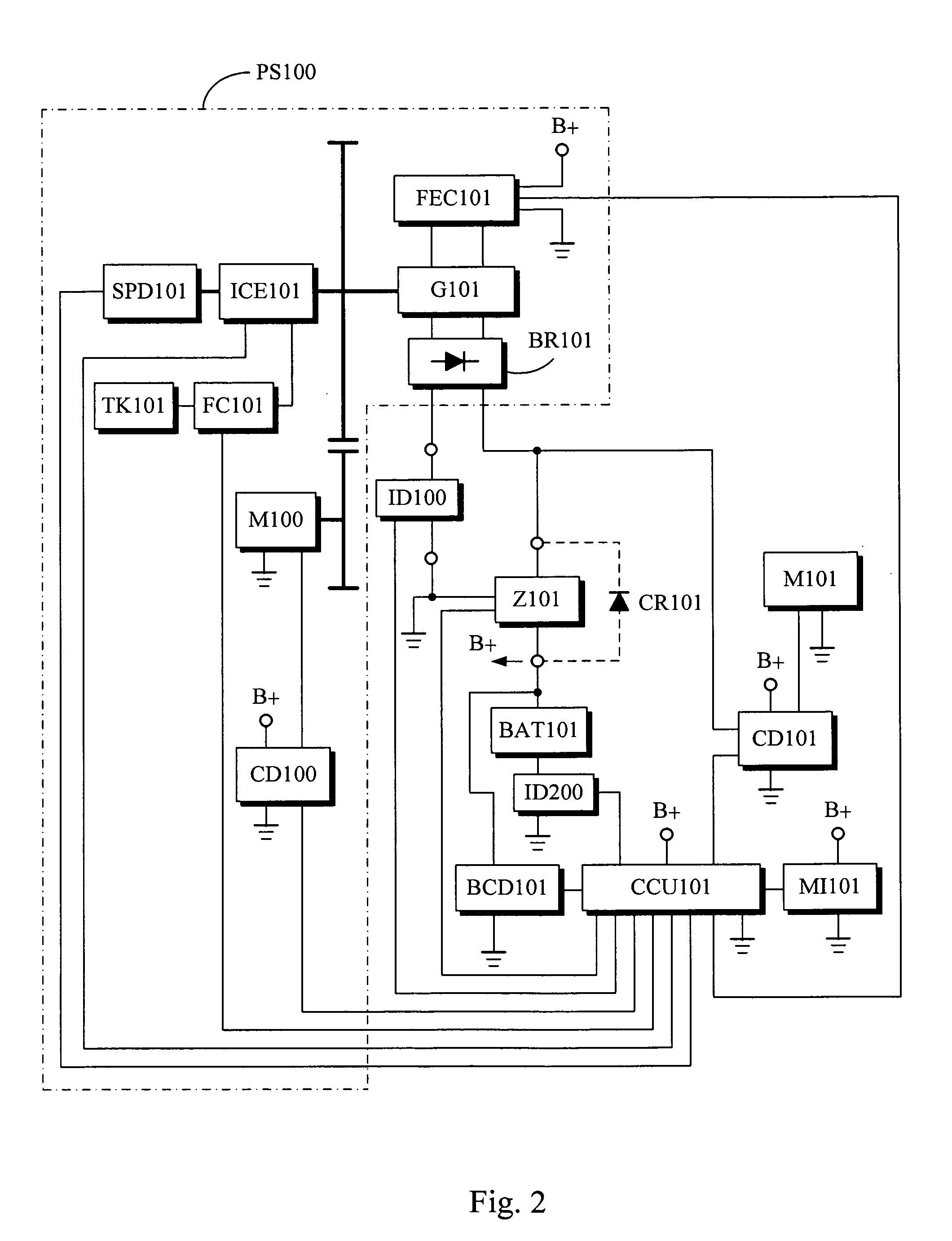

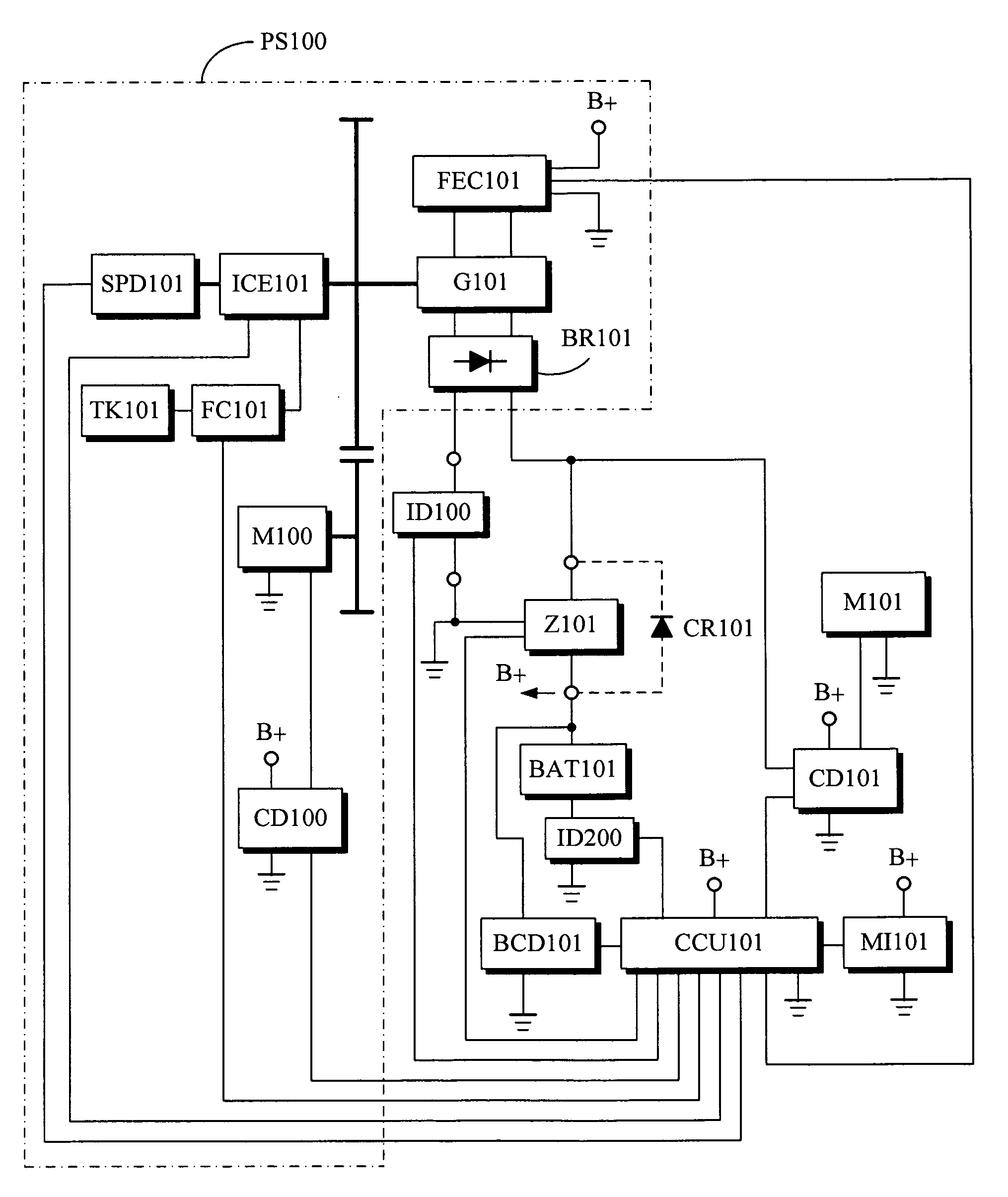

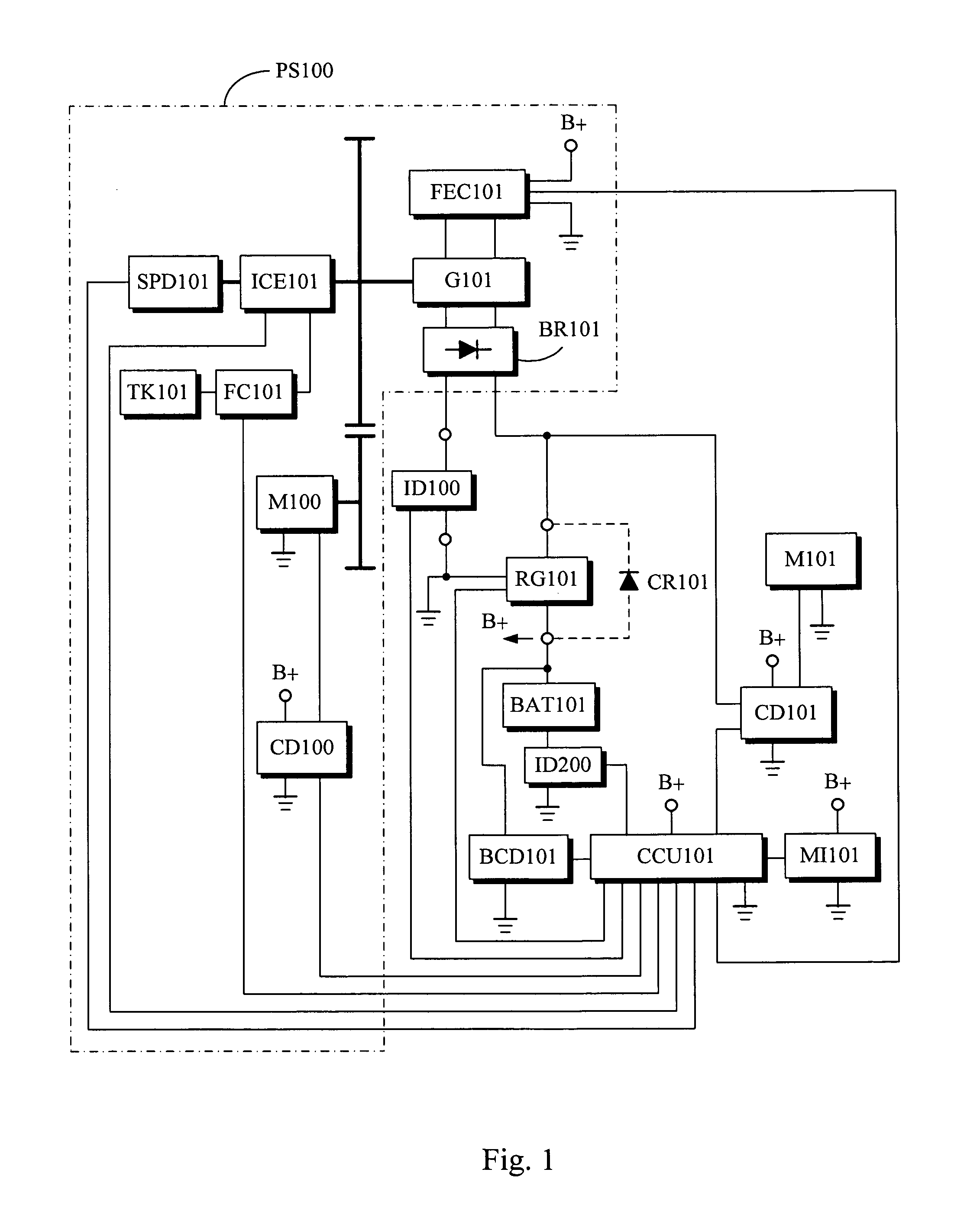

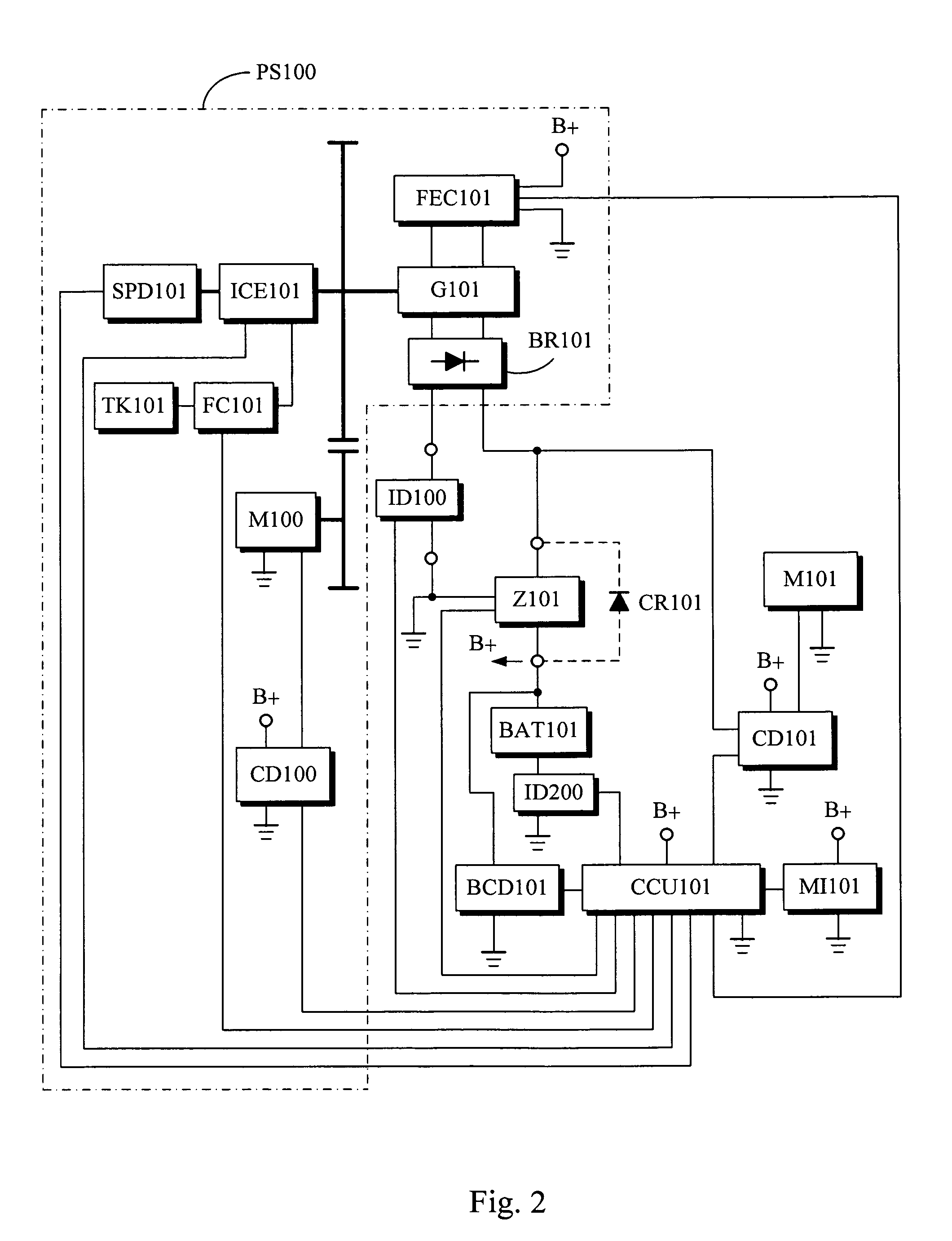

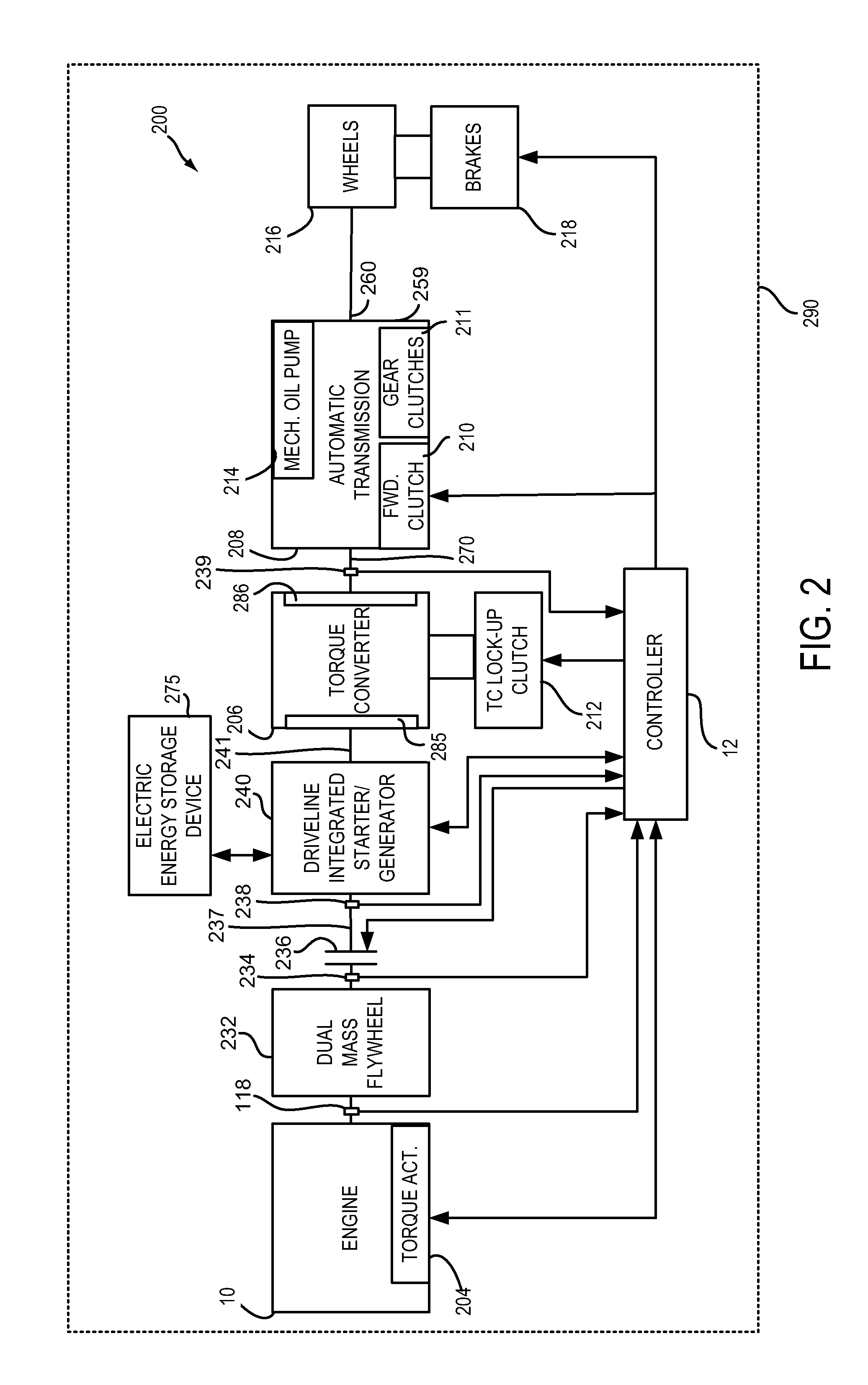

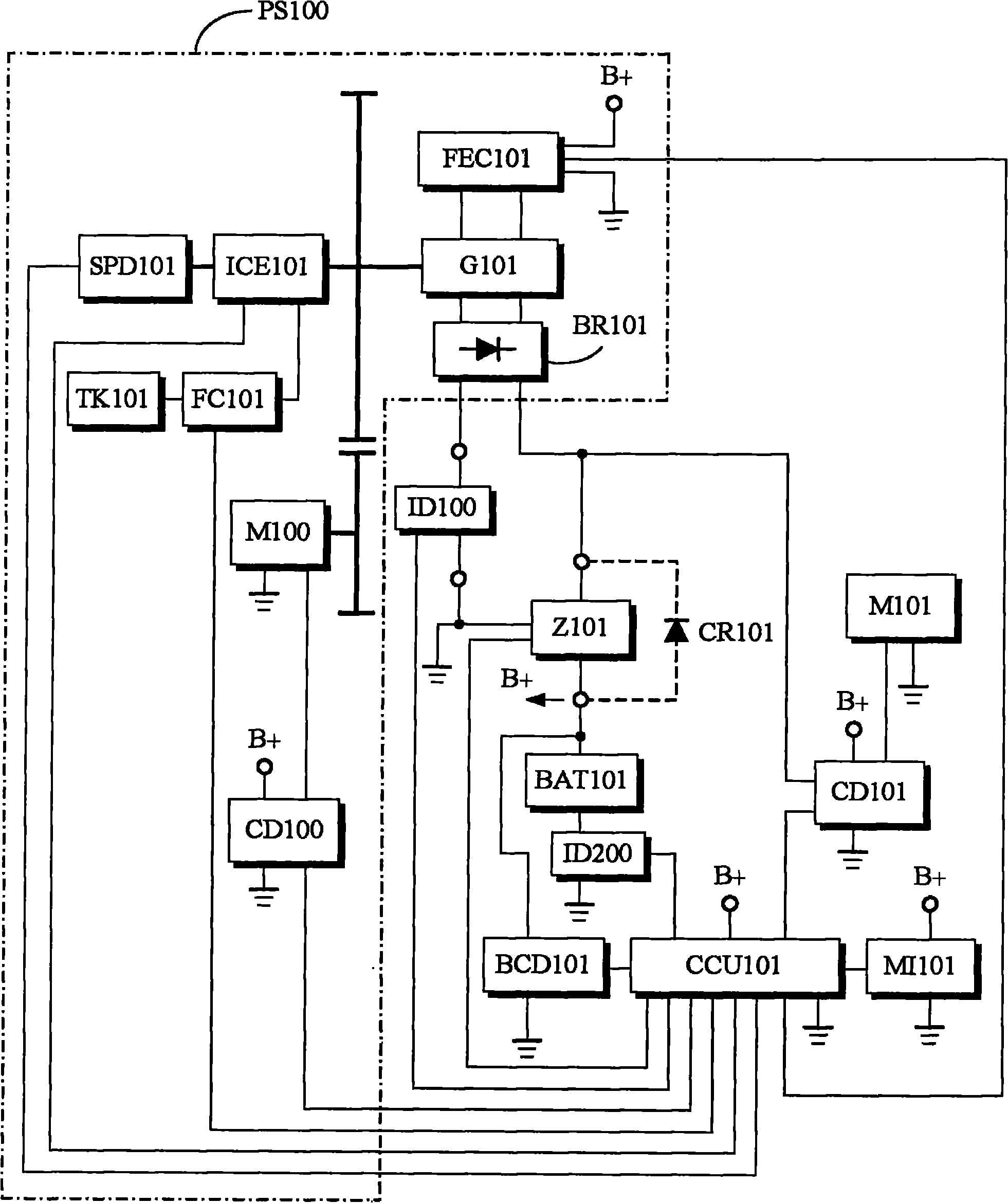

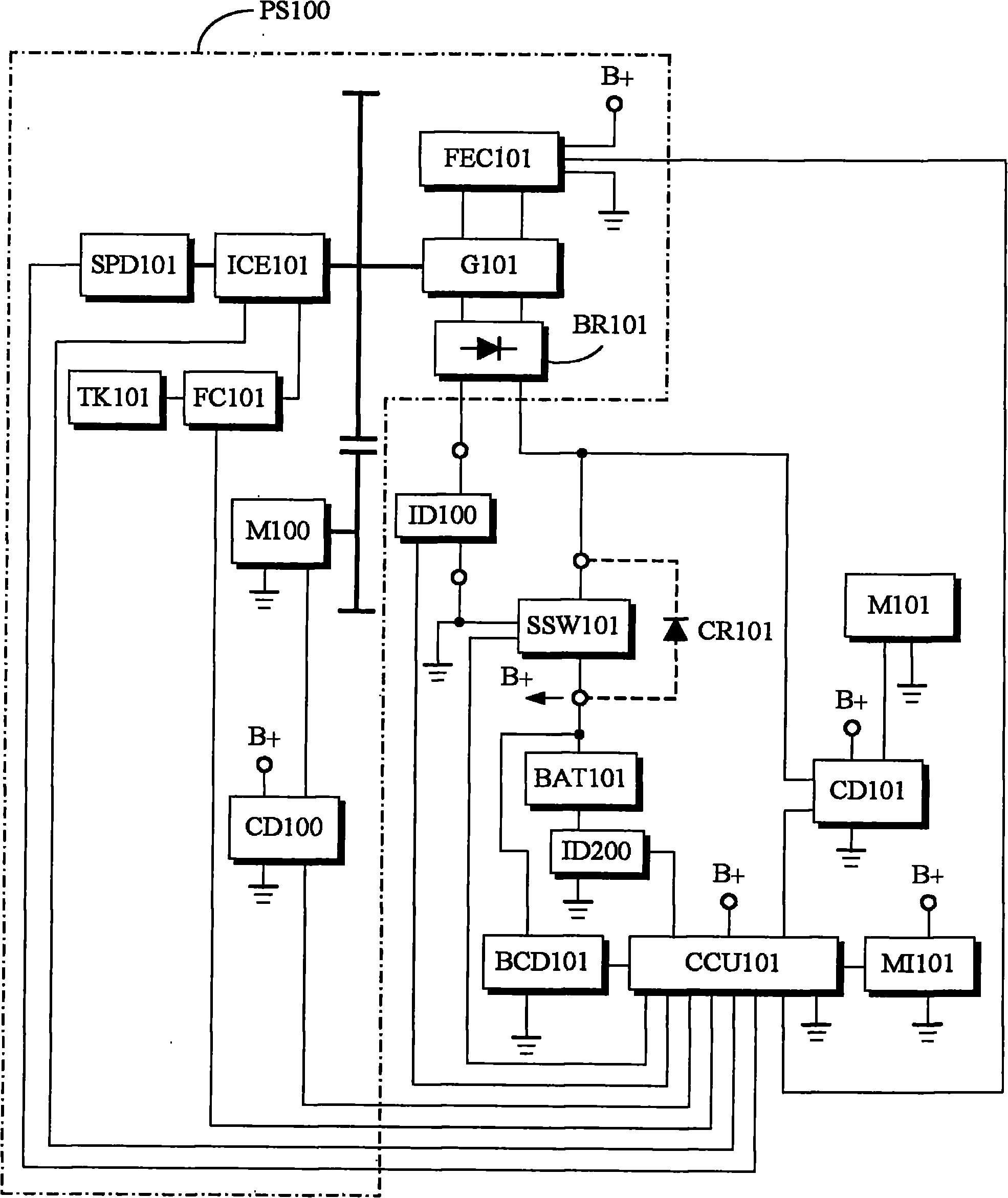

Battery charging coaction and output system with current limit supply

ActiveUS20110101778A1Improve energy savingReduce consumptionMaterial analysis by electric/magnetic meansSingle network parallel feeding arrangementsCurrent limitingBattery charge

The present invention relates to a power system utilizing an engine generator or public power with AC source, wherein the power system particularly has the characteristics that the maximum output current thereof is limited by electromagnetic effects, and / or constant current or nearly constant current output thereof is set to be lower than the maximum output current, for powering a load, and charging a battery, or jointly powering a load with a battery; when an engine generator set is utilized to be power supply, during operation, the engine operates with the best brake specific fuel consumption and / or the range of revolutions and torque for better energy saving.

Owner:YANG TAI HER

Method for tuning internal combustion engine manifolds

InactiveUS6564767B1Maximize wave pulse scavengingInternal combustion piston enginesExhaust apparatusBrake specific fuel consumptionExternal combustion engine

A method for tuning input / exhaust primaries in a multi-chamber spark ignition internal combustion engine. This method improves engine performance by correlating the timing of wave pulses in the input or exhaust system to combustion events in the combustion chambers. This has the effect of increasing the volumetric efficiency of the engine, resulting in increased brake specific fuel consumption and increased specific volume output.

Owner:SLP PERFORMANCE PARTS

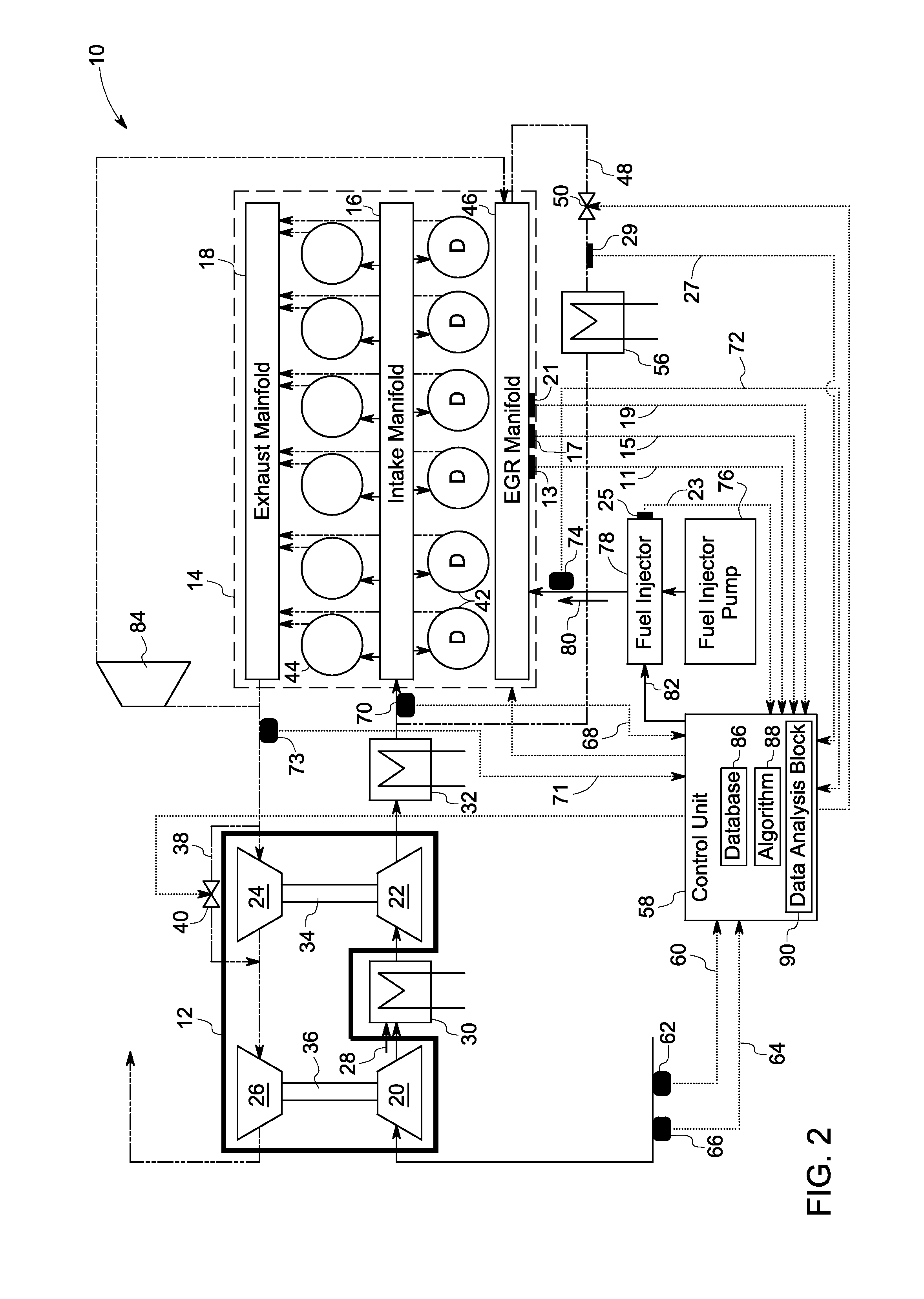

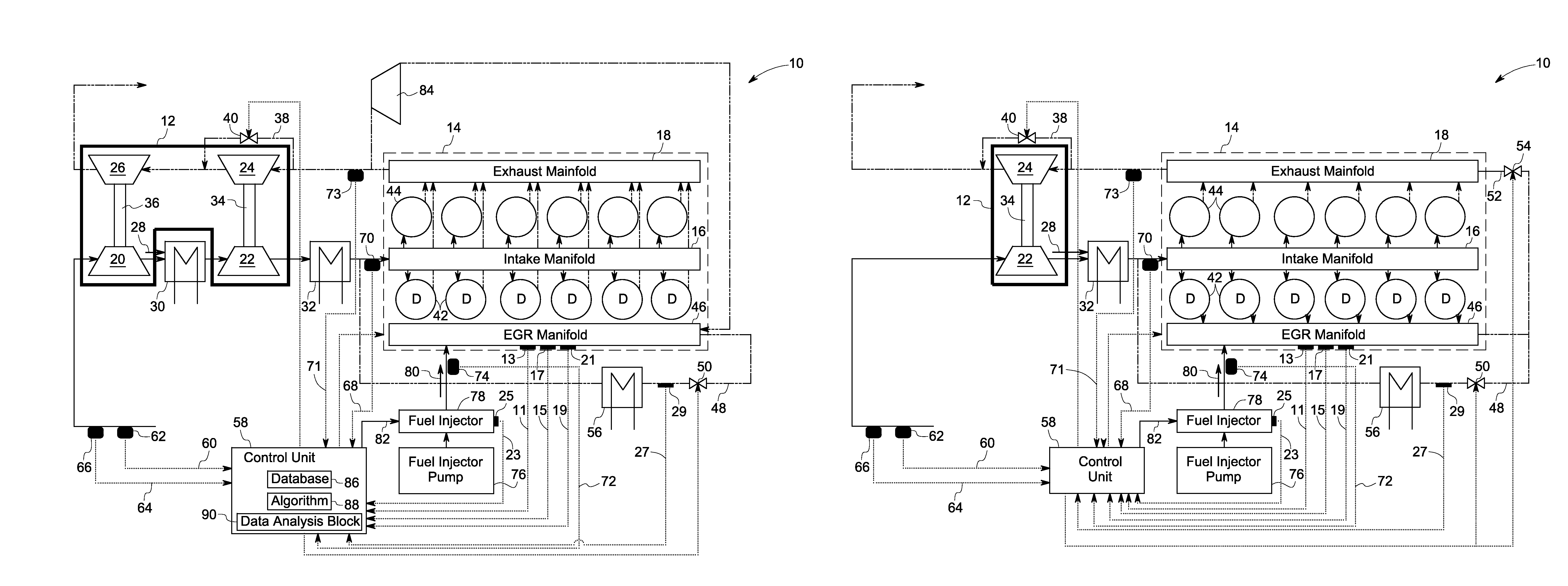

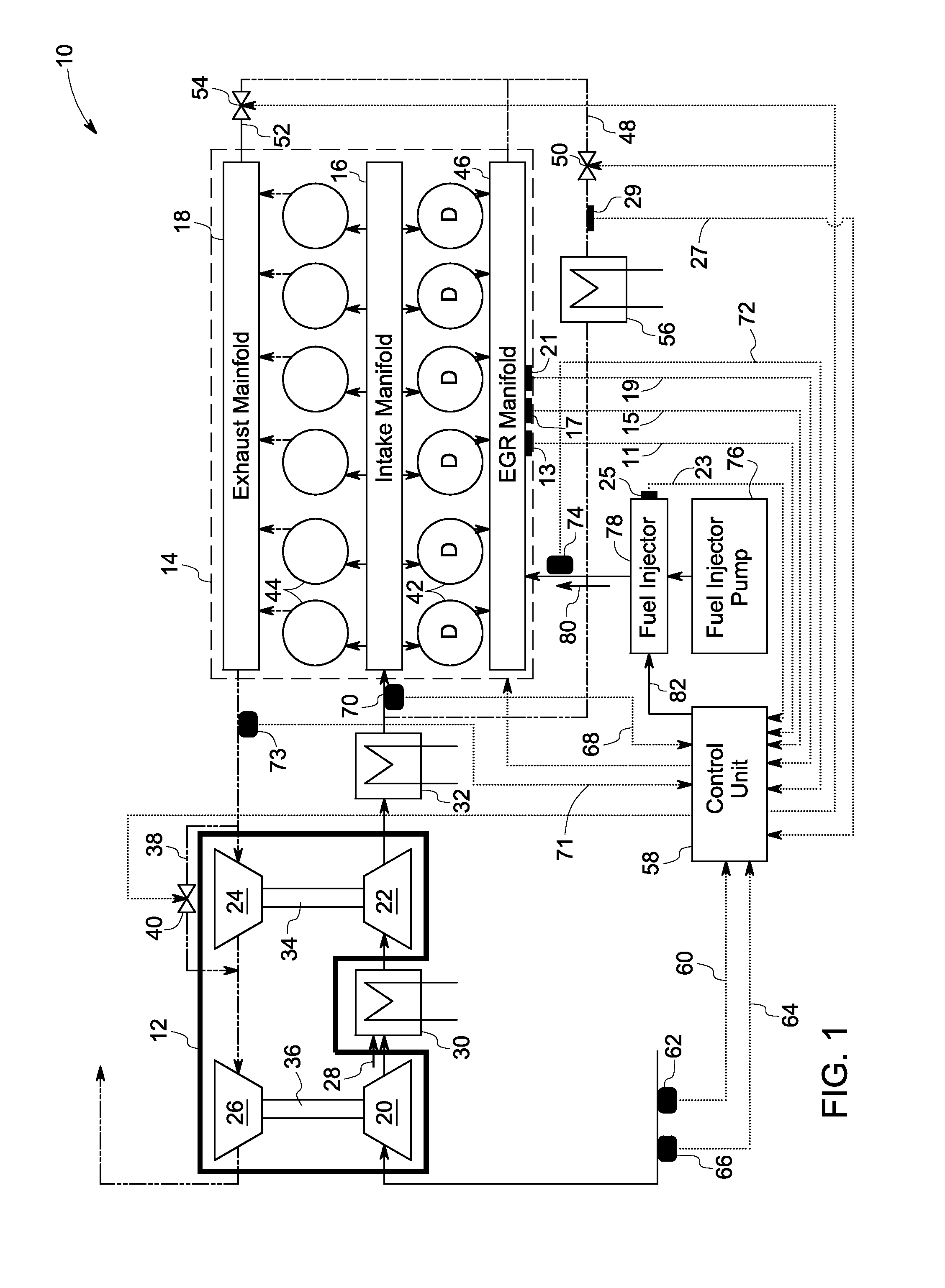

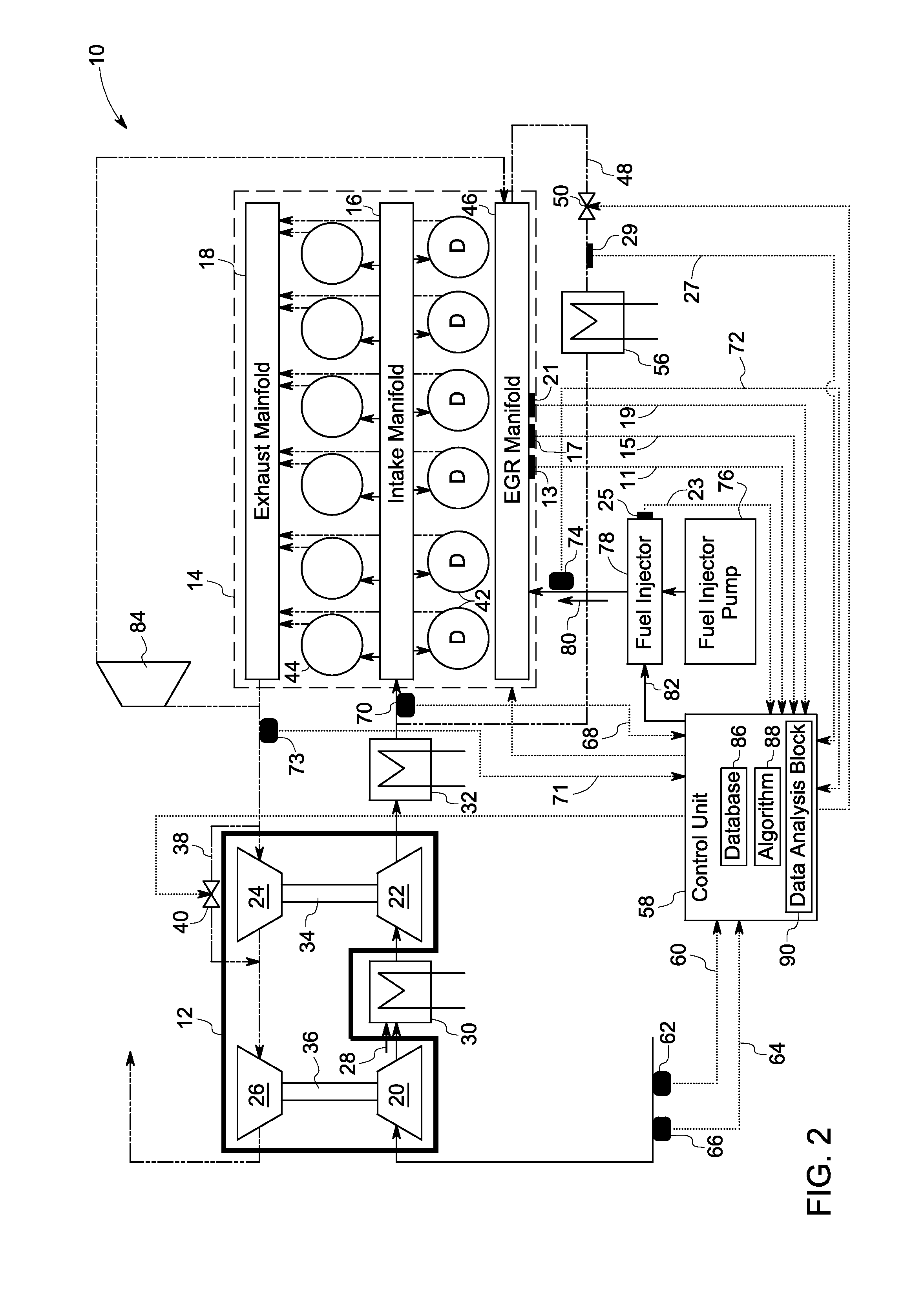

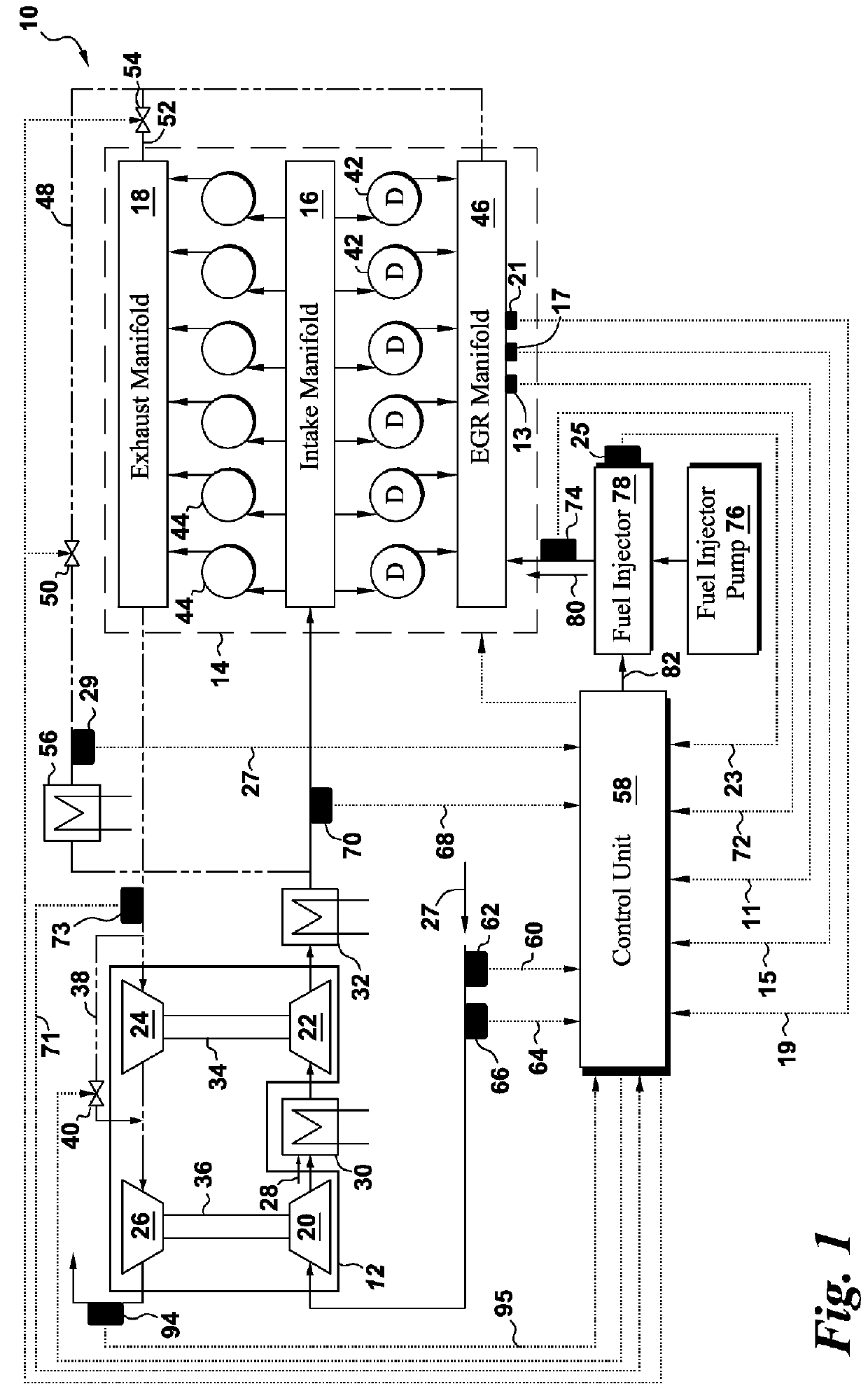

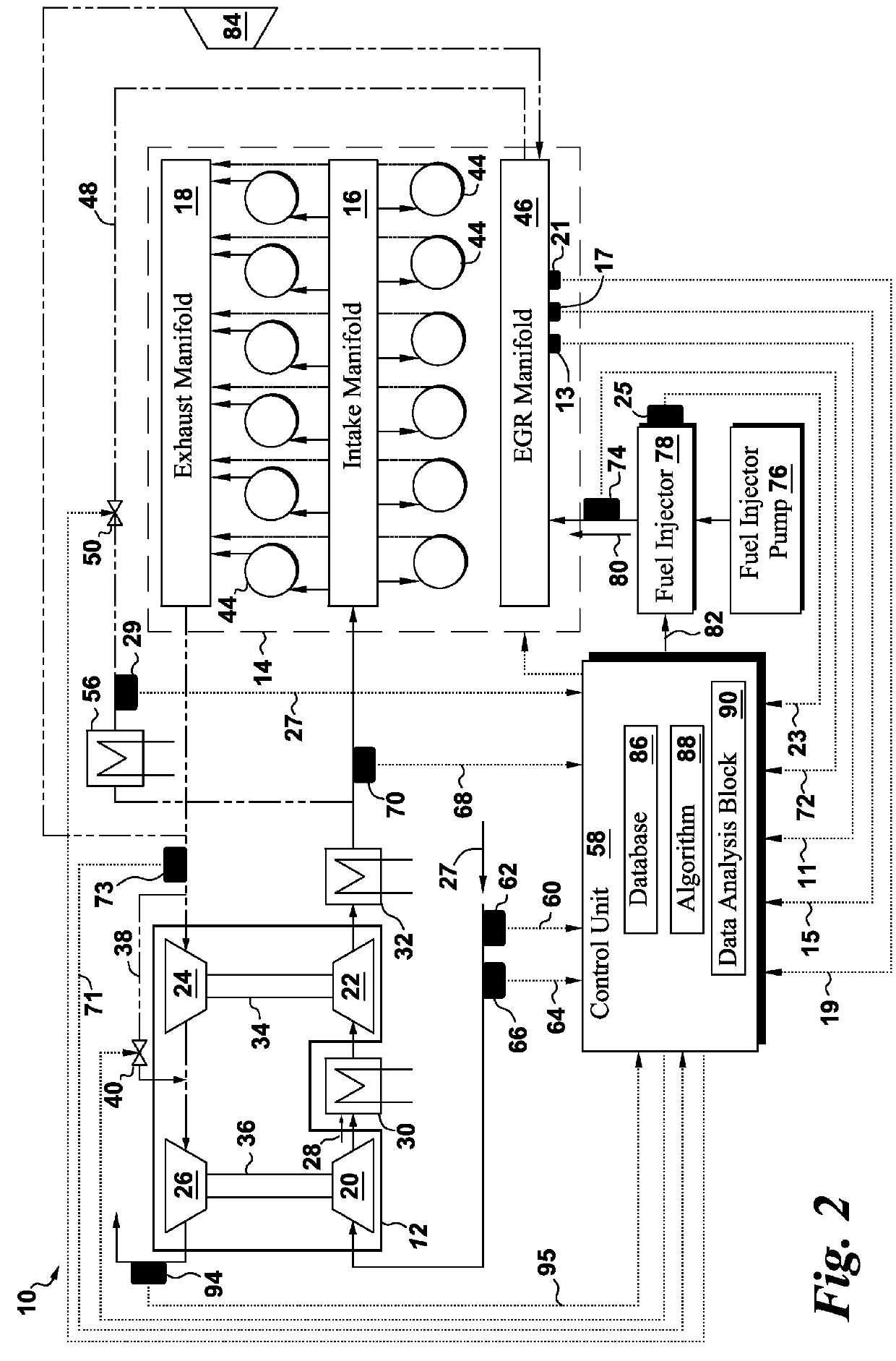

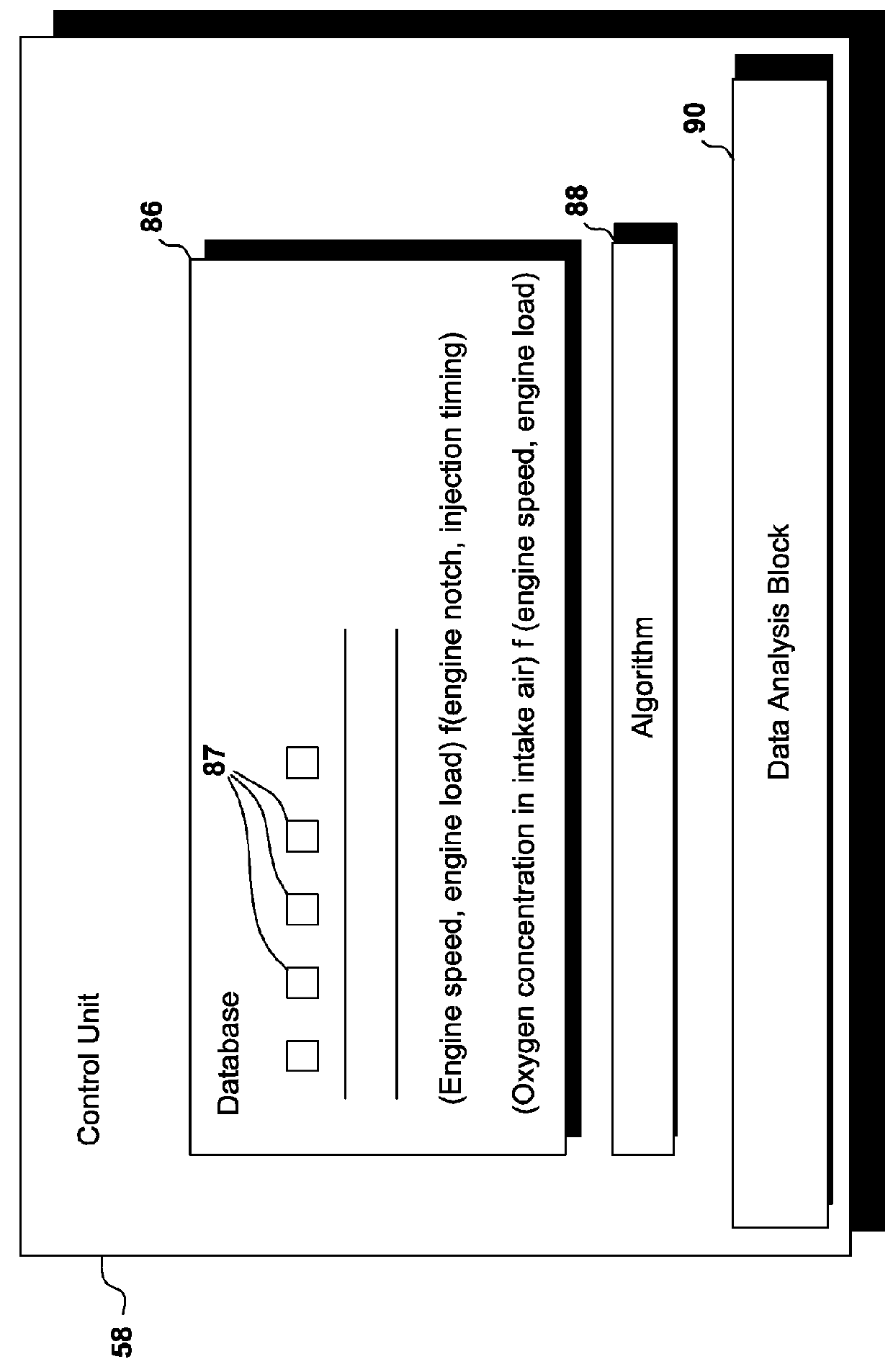

System and method for controlling exhaust emissions and specific fuel consumption of an engine

ActiveUS20160010576A1Fuel consumptionElectrical controlInternal combustion piston enginesBrake specific fuel consumptionEngineering

Owner:GE GLOBAL SOURCING LLC

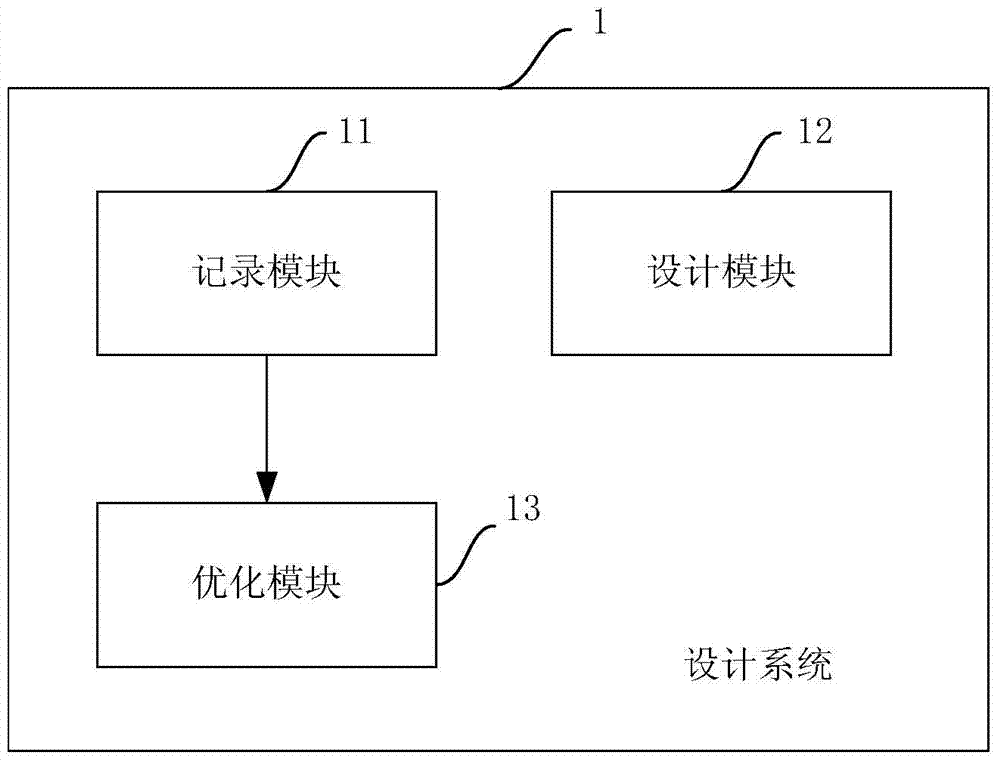

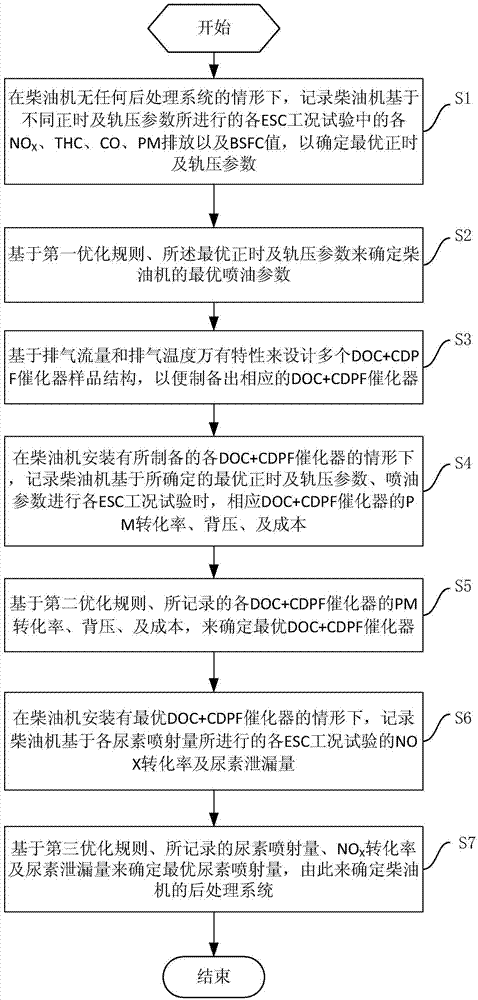

Method and system for designing diesel engine aftertreatment system

The invention provides a method and a system for designing a diesel engine aftertreatment system. The method includes: recording NOX, THC, CO and PM discharge and BSFC (brake specific fuel consumption) values under different injection combinations of diesel engine working condition test, when a diesel engine does not have any aftertreatment systems, so as to determine optimal timing and rail pressure parameters and determining optimal injection parameters based of a first optimization rule; designing multiple DOC (diesel oxidation catalyst) + CDPF (coated diesel particulate filter) catalyst sample structures based on universal characteristics of extraction flow and discharge temperature to prepare the corresponding catalysts, mounting the prepared catalysts on the diesel engine, recording PM conversion rate, backpressure and cost of the corresponding catalysts, and determining relevant information of the optimal catalyst based on a second optimization rule so as to prepare the optimal catalyst; mounting the optimal catalyst on the diesel engine with an optimized fuel system, recording NOX conversion rate and urea leakage rate of SCR (selective catalytic reduction), and determining optimal urea leakage rate based on a third optimization rule to have the aftertreatment system designed.

Owner:TONGJI UNIV

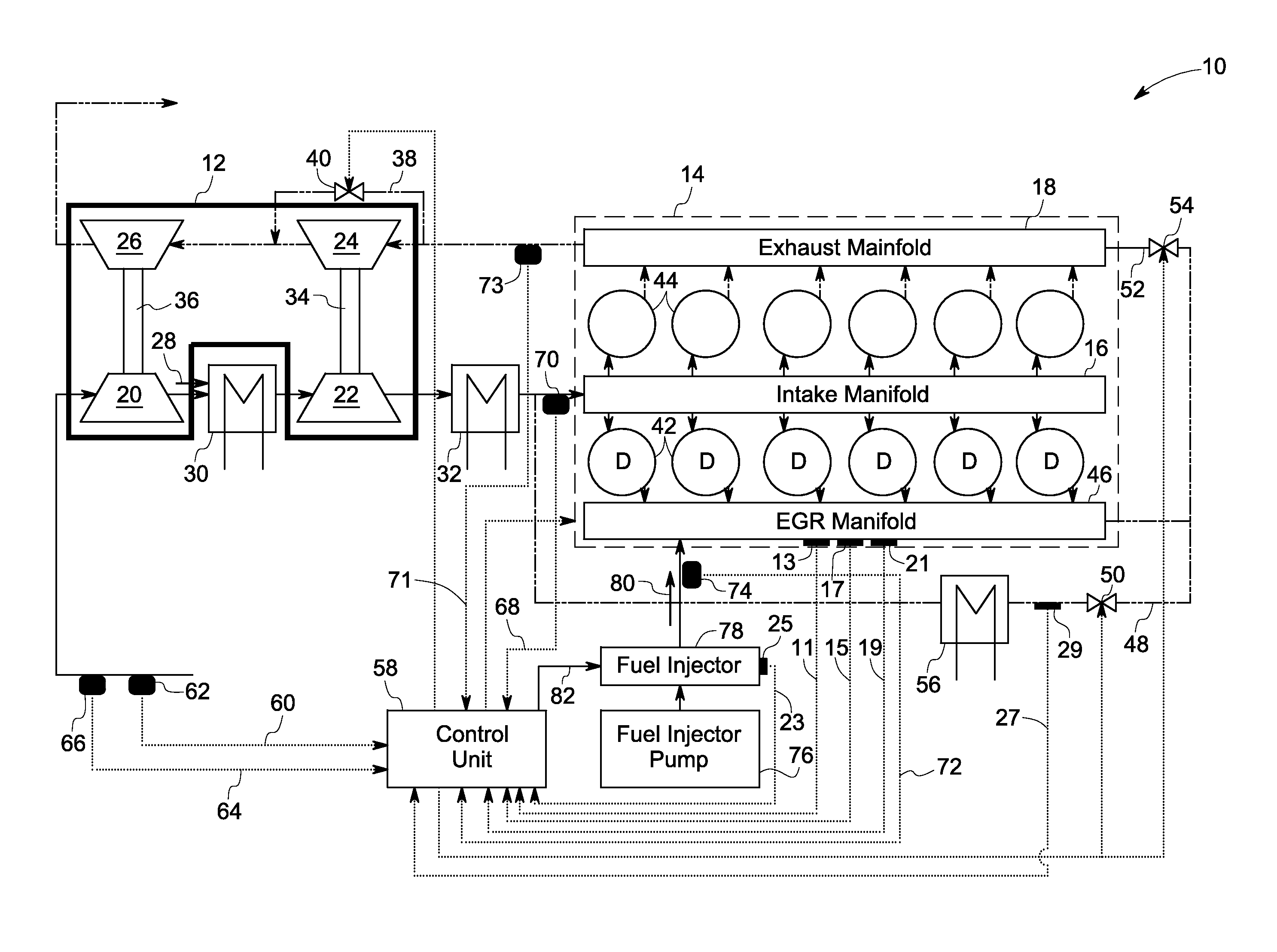

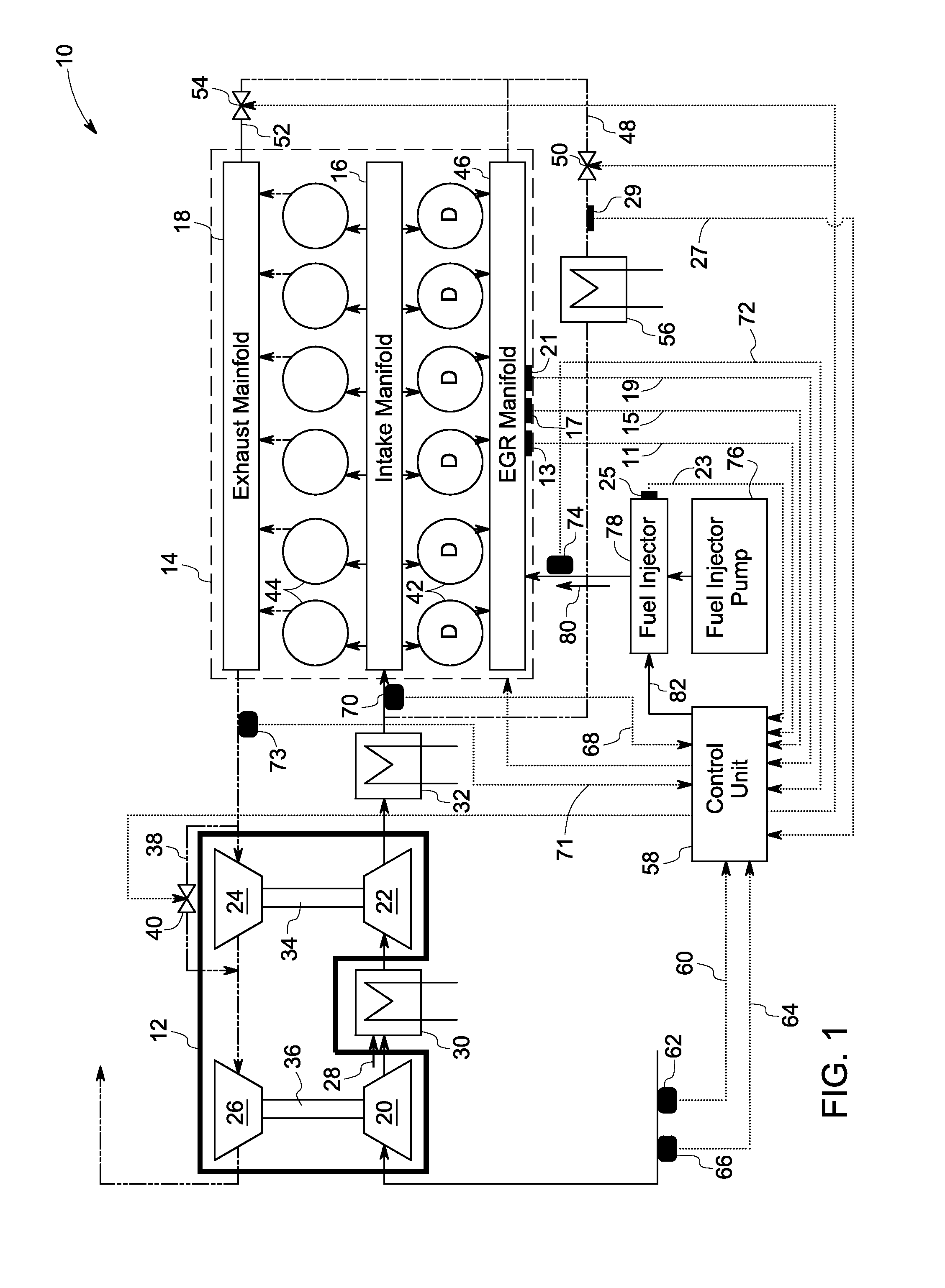

System and method for controlling exhaust emissions and specific fuel consumption of an engiine

ActiveUS20140109571A1Electrical controlInternal combustion piston enginesBrake specific fuel consumptionEngineering

A method includes combusting air within a plurality of cylinders of an internal combustion engine by injecting a fuel into the plurality of cylinders. The method further includes expanding a first portion of an exhaust gas generated from the plurality of combustion cylinders via a turbine. The method further includes controlling at least one of feeding a second portion of the exhaust gas via an exhaust channel bypassing the turbine; and recirculating a third portion of the exhaust gas to the plurality of combustion cylinders via a recirculation channel, as a function of an intake manifold air temperature and pressure at which the engine is operated.

Owner:GE GLOBAL SOURCING LLC

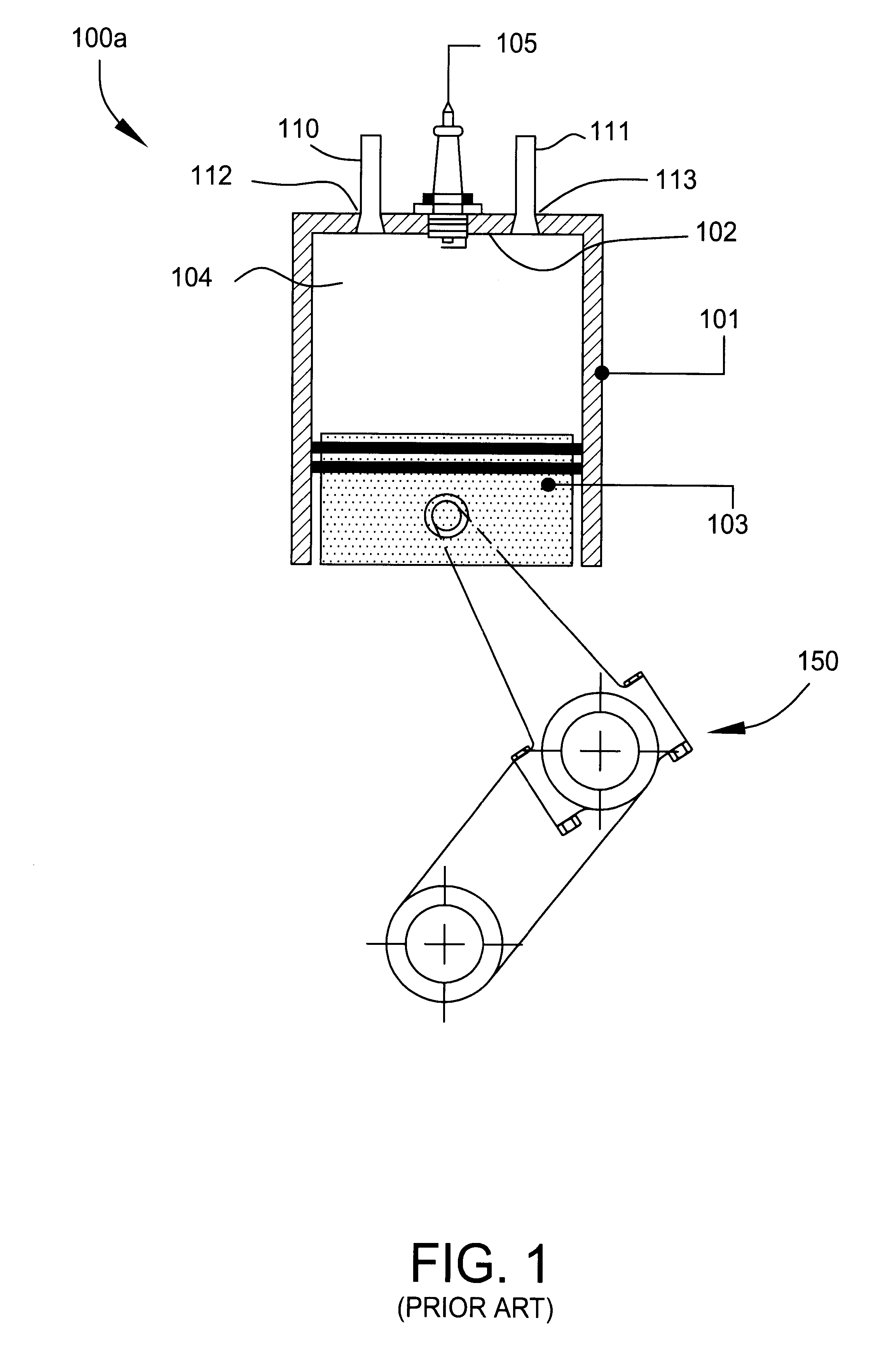

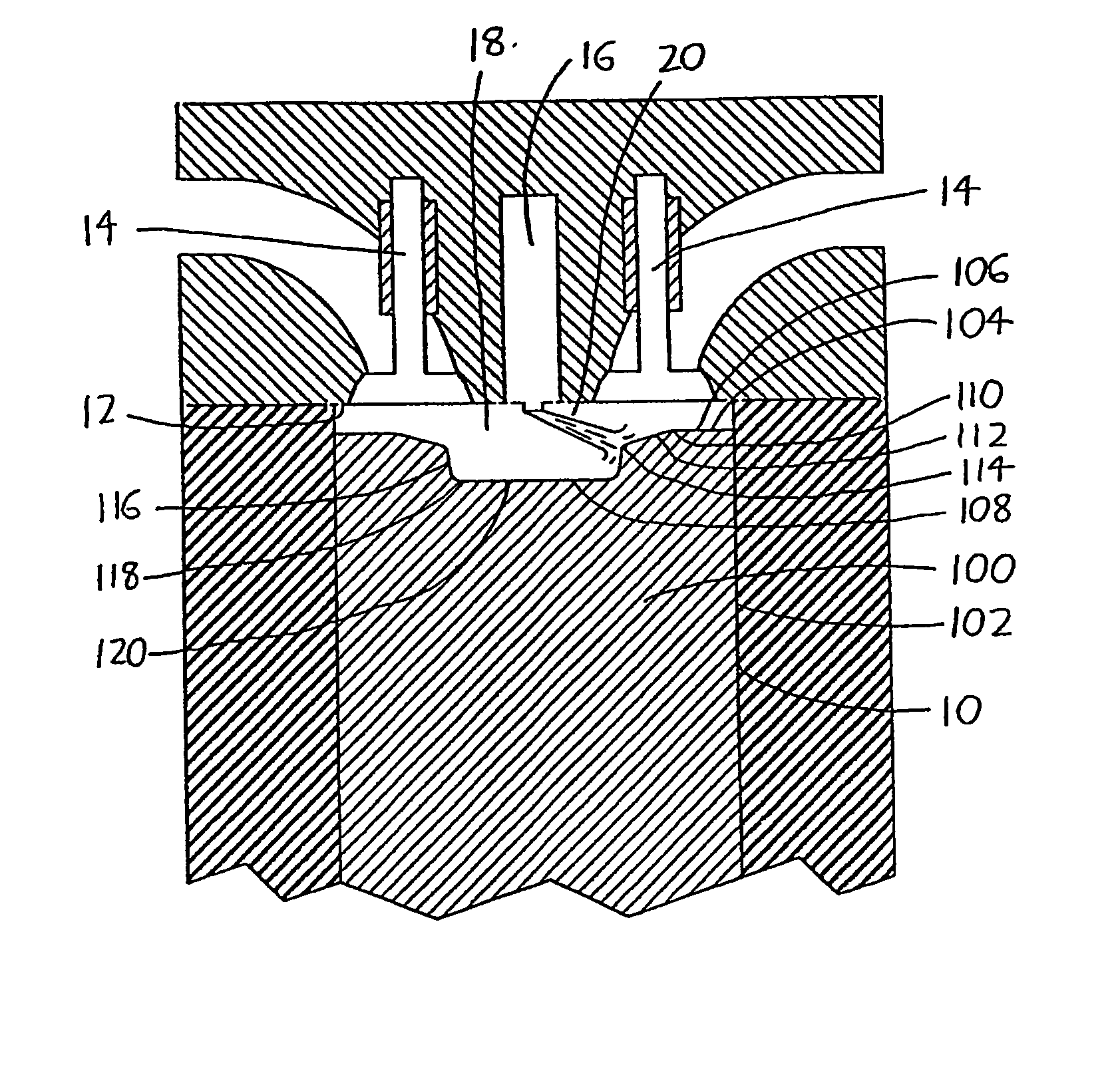

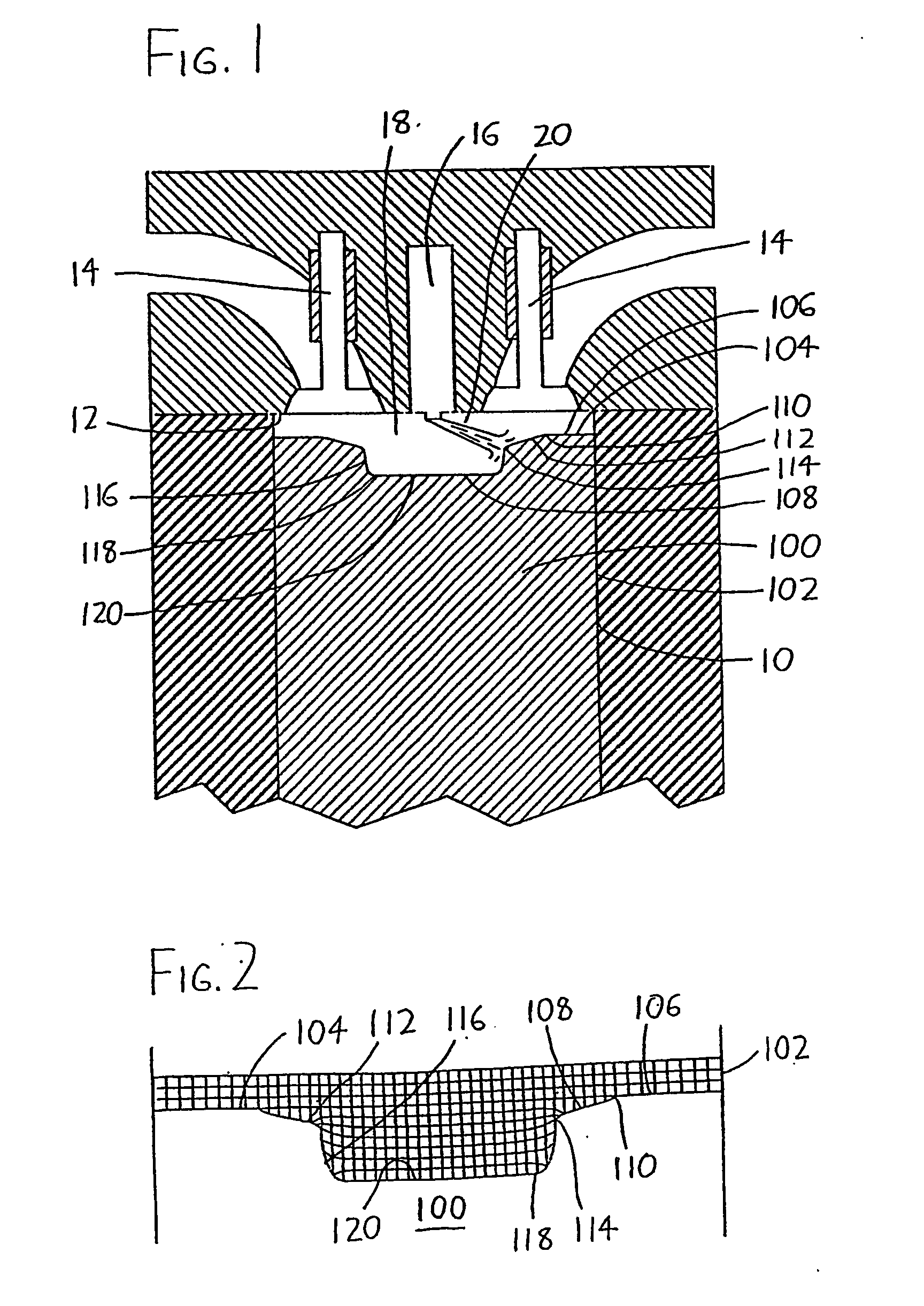

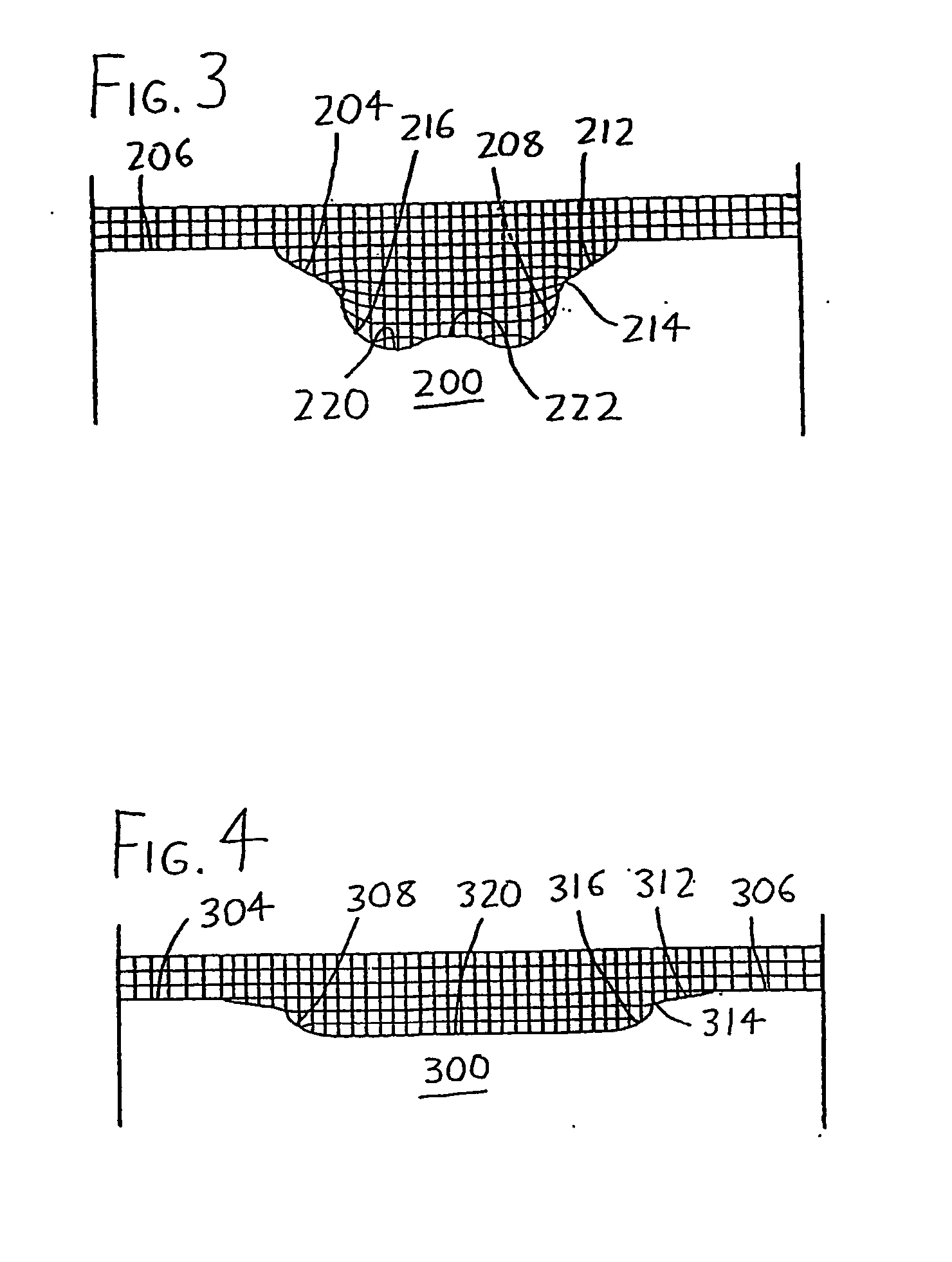

Piston/combustion chamber configurations for enhanced ci engine performace

InactiveUS20050166890A1Significant emission reductionLarge regionInternal combustion piston enginesCylinder headsBrake specific fuel consumptionCombustion chamber

Piston face (104, 204, 304) and combustion chamber (18) designs for use particularly in HSDI (high speed direct injection) diesel engines include an open bowl (108 208, 308) characterized by a large face perimeter region (106, 206, 306) on the piston face (104, 204, 304), and a bowl (18) defined by a first depressed region (112, 212, 312) gently sloping radially inwardly from the face perimeter region (106, 206, 306) and a second depressed region (116, 216, 316) sharply sloping radially inwardly from the first depressed region (112, 212, 312) to the bowl floor (120, 220, 320). Injection is preferably directed towards an intermediate edge which is well-defined between the first and second depressed regions, resulting in portions of the injected fuel plume being directed to both the squish regions and the portion of the bowl situated below the intermediate edge. The designs promote premixed or MK (Modulated Kinetics) combustion, with a concomitant reduction in soot and nitrous oxides (NOx) emissions while maintaining or enhancing brake specific fuel consumption.

Owner:WISCONSIN ALUMNI RES FOUND

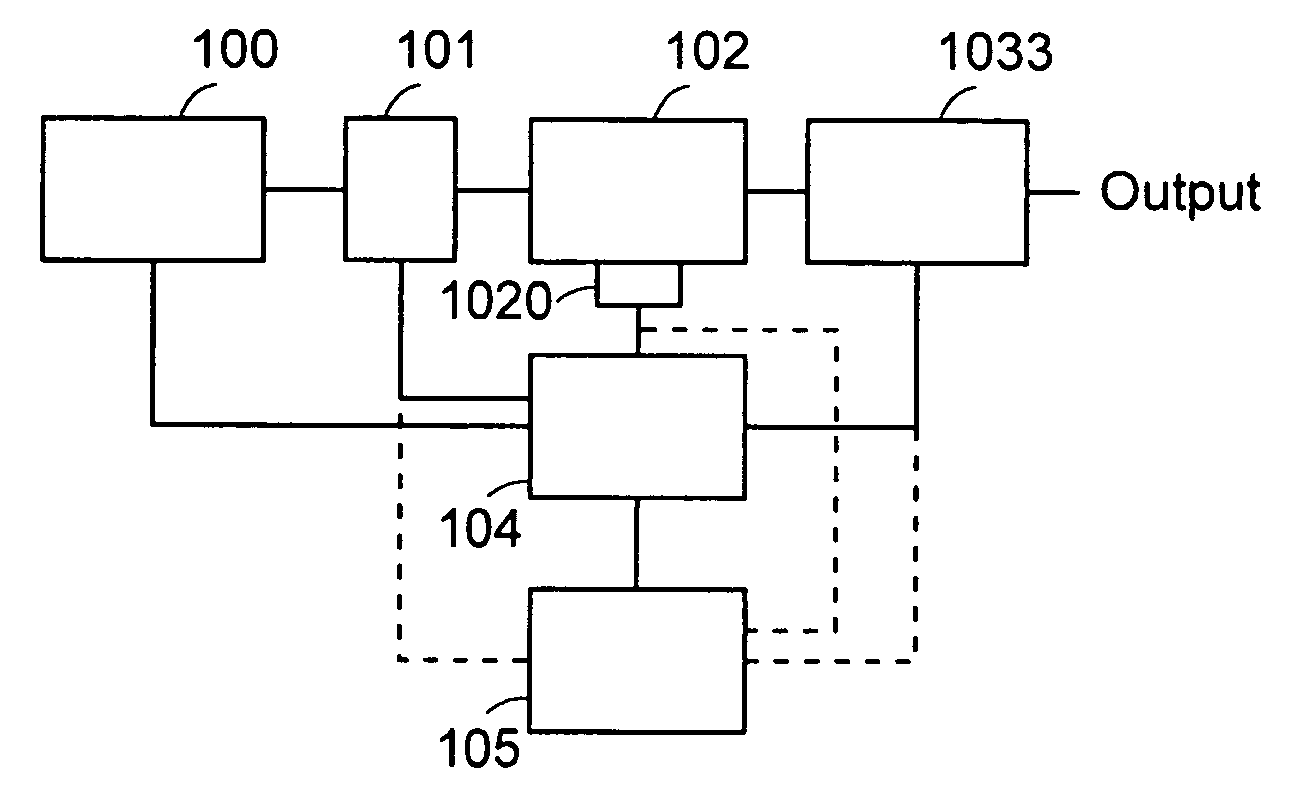

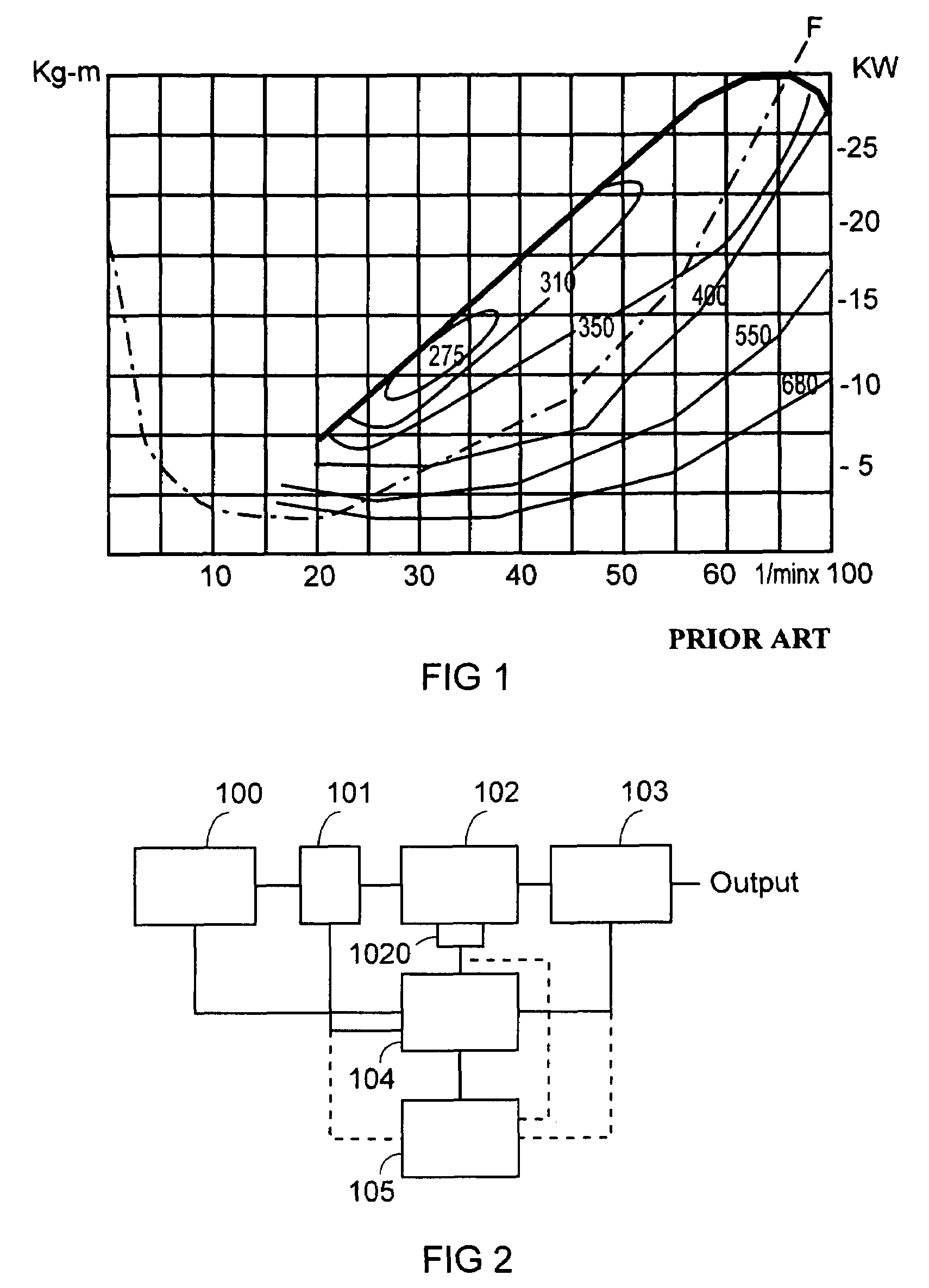

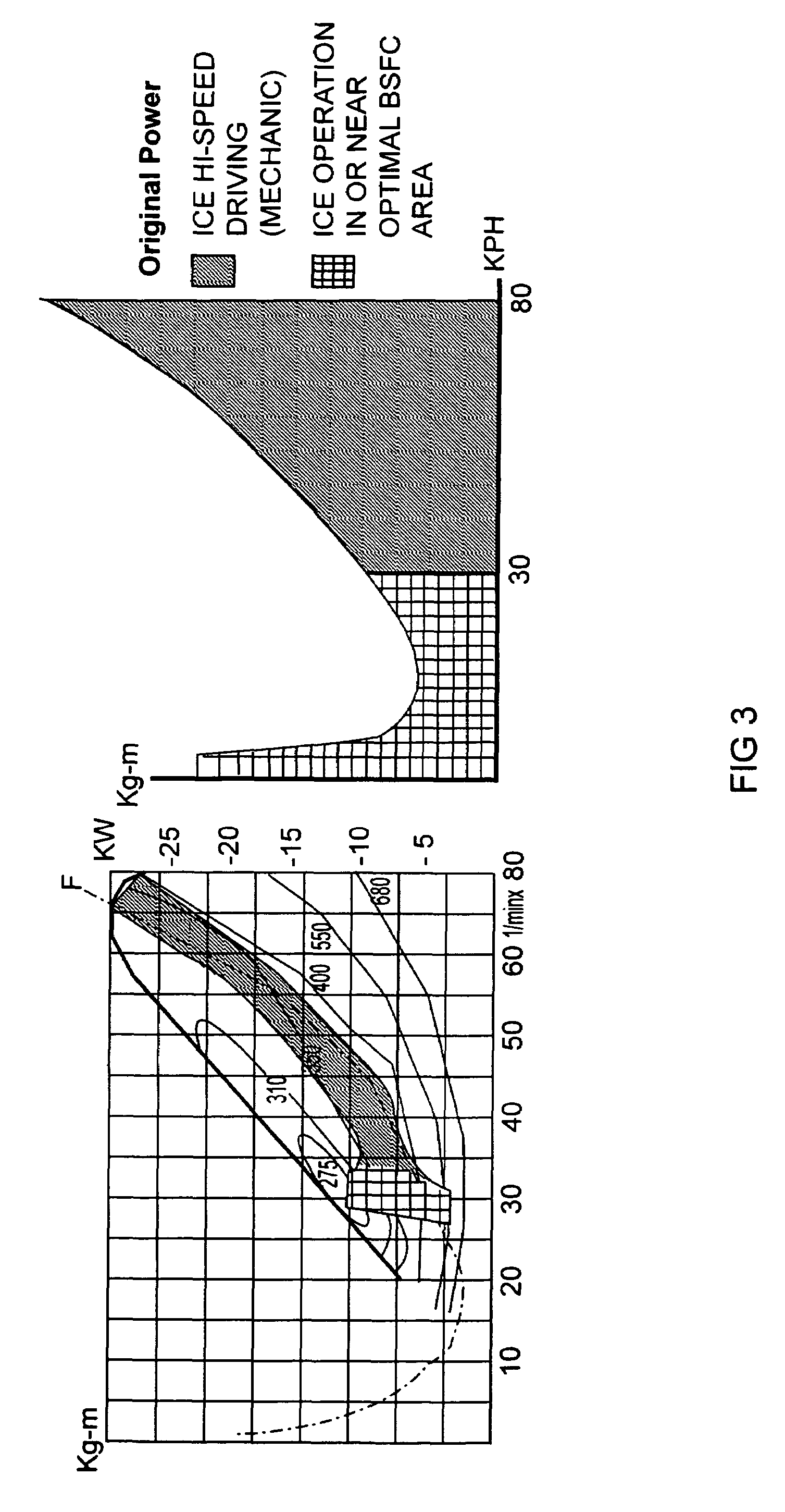

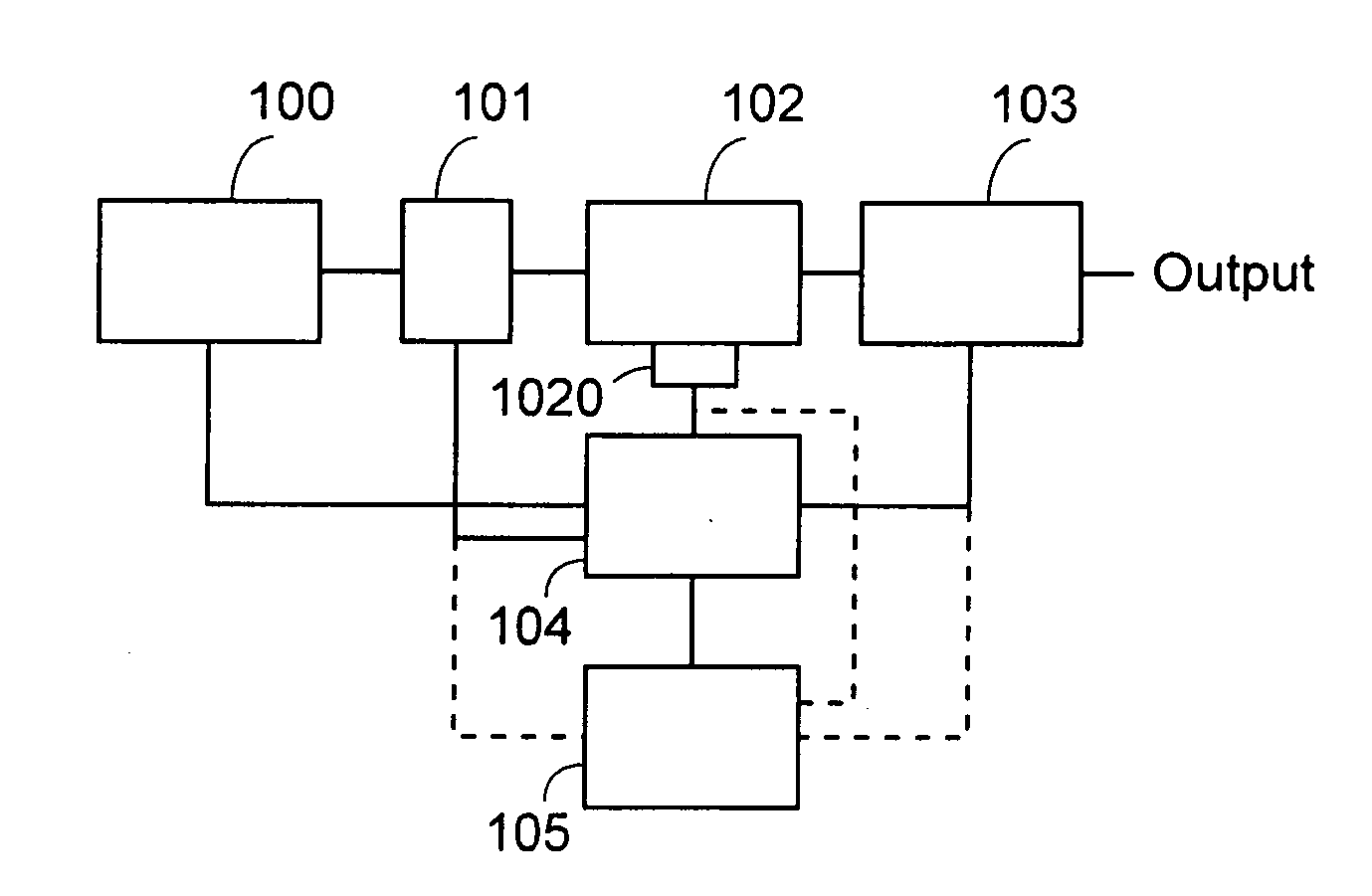

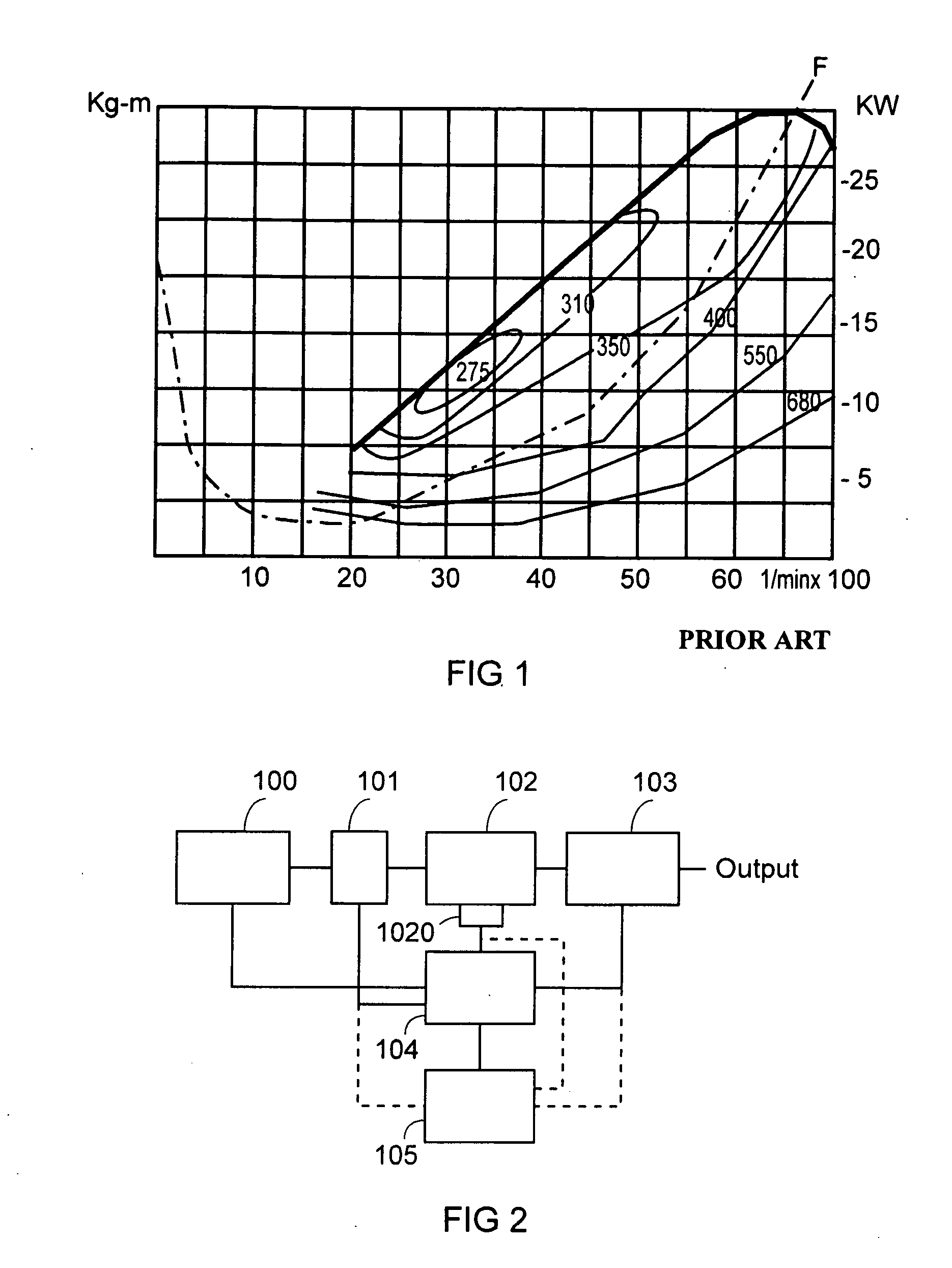

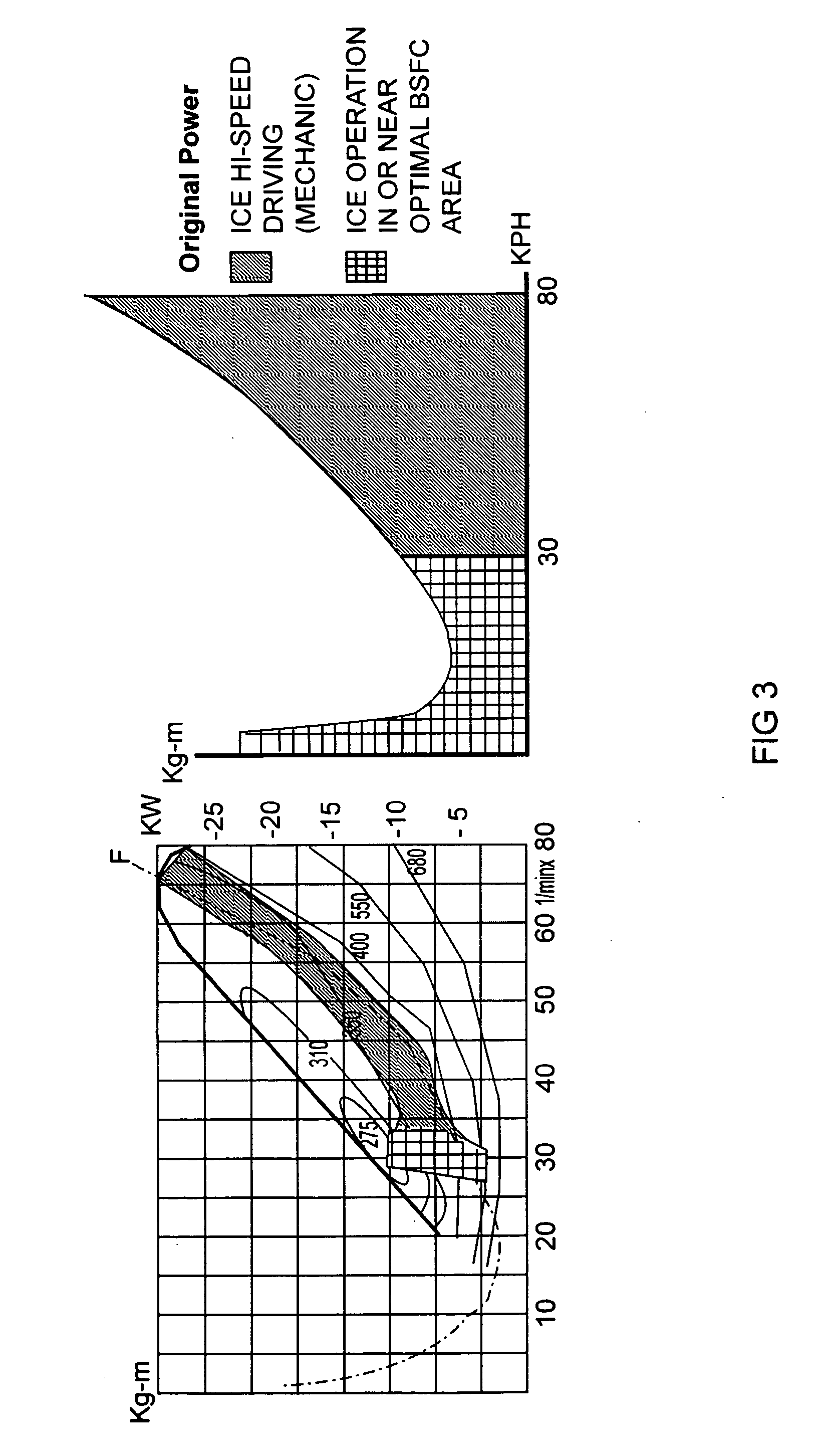

Engine running at fixed speed incorporated controllable transmission power system

InactiveUS7479091B2Improve efficiencySave fuelVehicle fittingsInternal combustion piston enginesFuel conservationBrake specific fuel consumption

A power system of controllable transmission incorporated with an engine running at fixed speed that controls the engine to run at a fixed speed or approaching a fixed speed within an rpm range with higher BSFC (braking specific fuel consumption) when the engine is started up from static status and in the accelerated drive from low rpm, the output end of the engine drives to achieve active control of the controllable front-end gearbox that is capable of executing variable or invariable gear shift so to activate the output end to execute accelerated drive output from low to high rpm; meanwhile, in the course of start-up and acceleration from lower to high rpm and in driving operation, the engine runs in an rpm range with higher BSFC for saving fuel.

Owner:YANG TAI HER

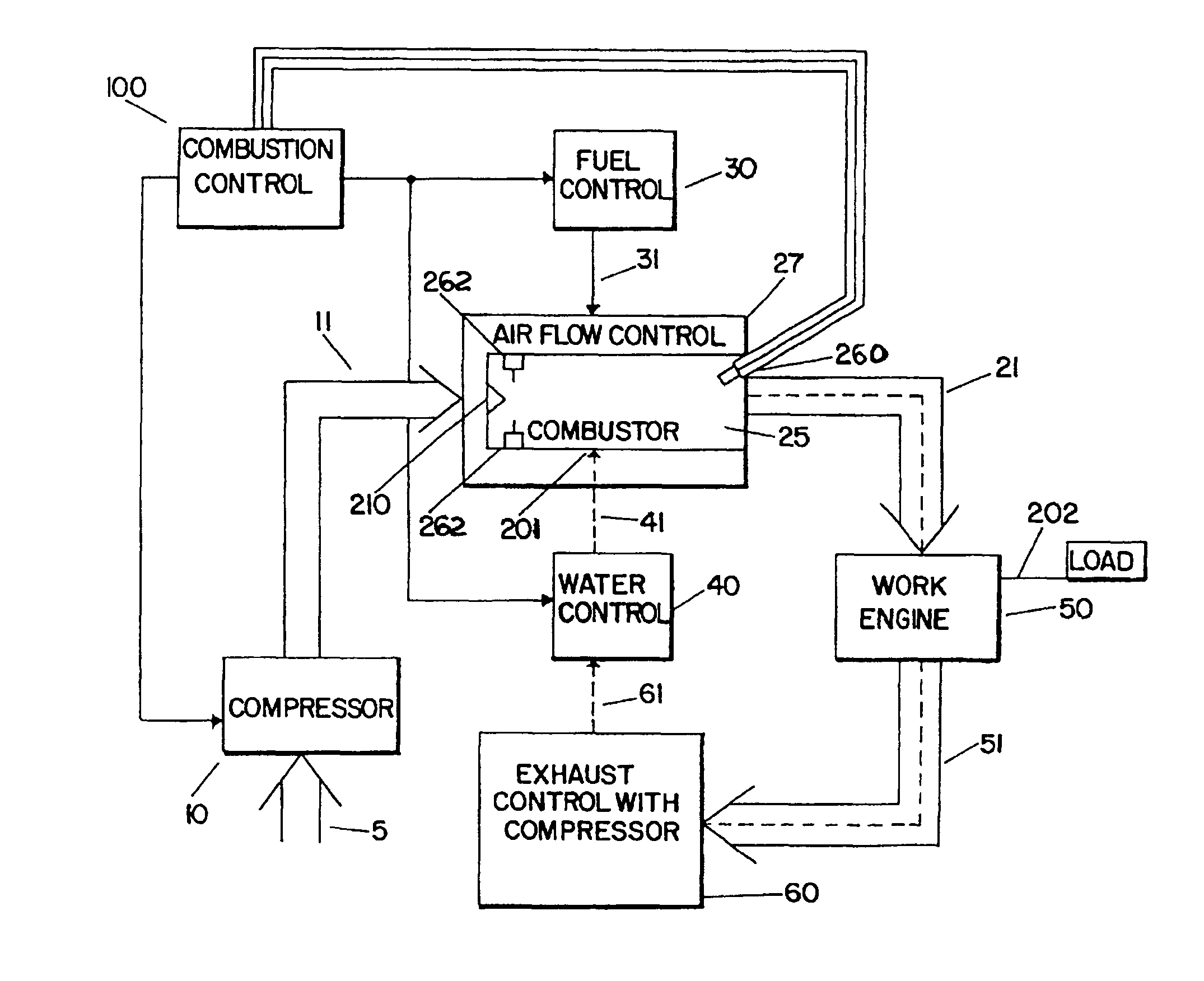

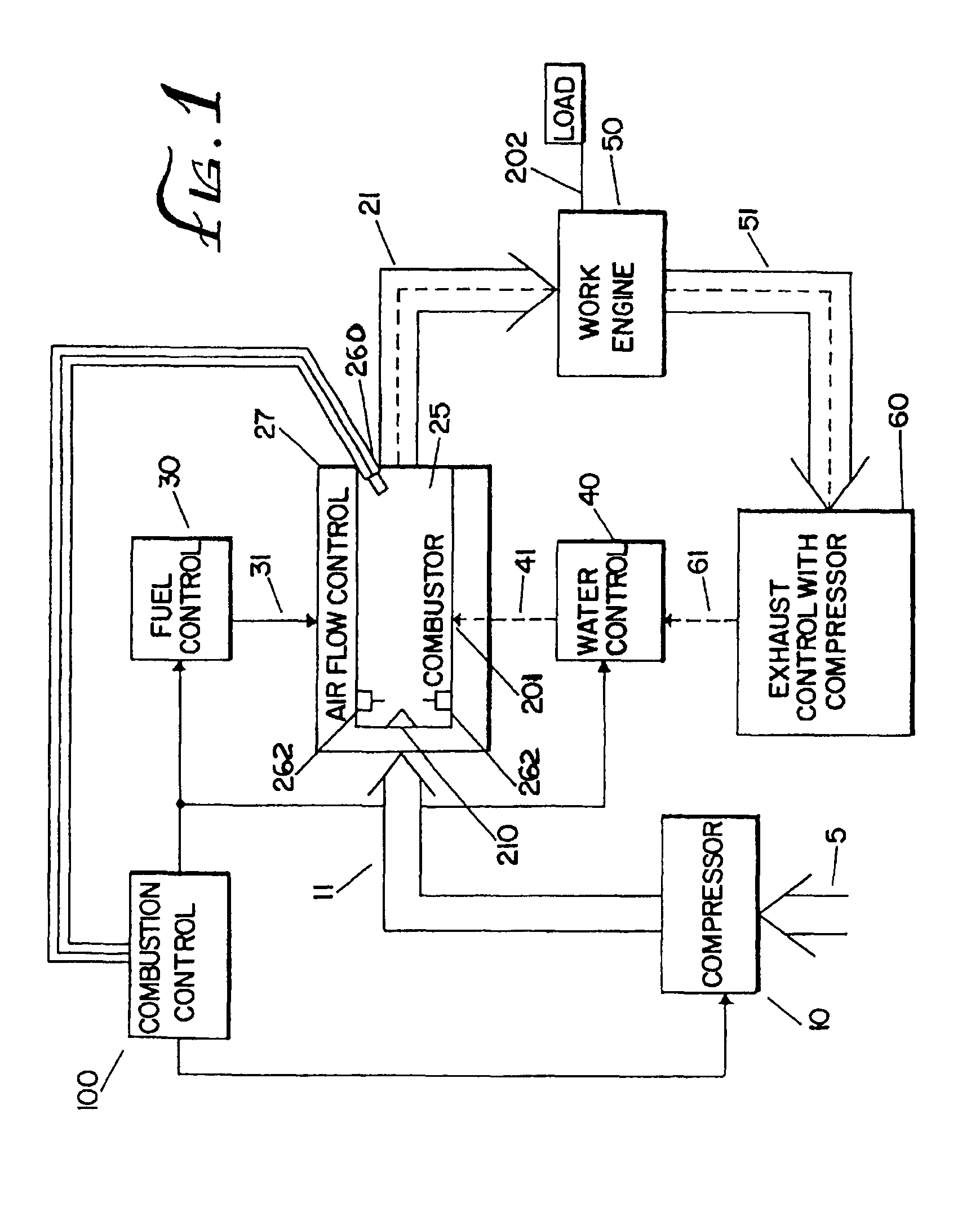

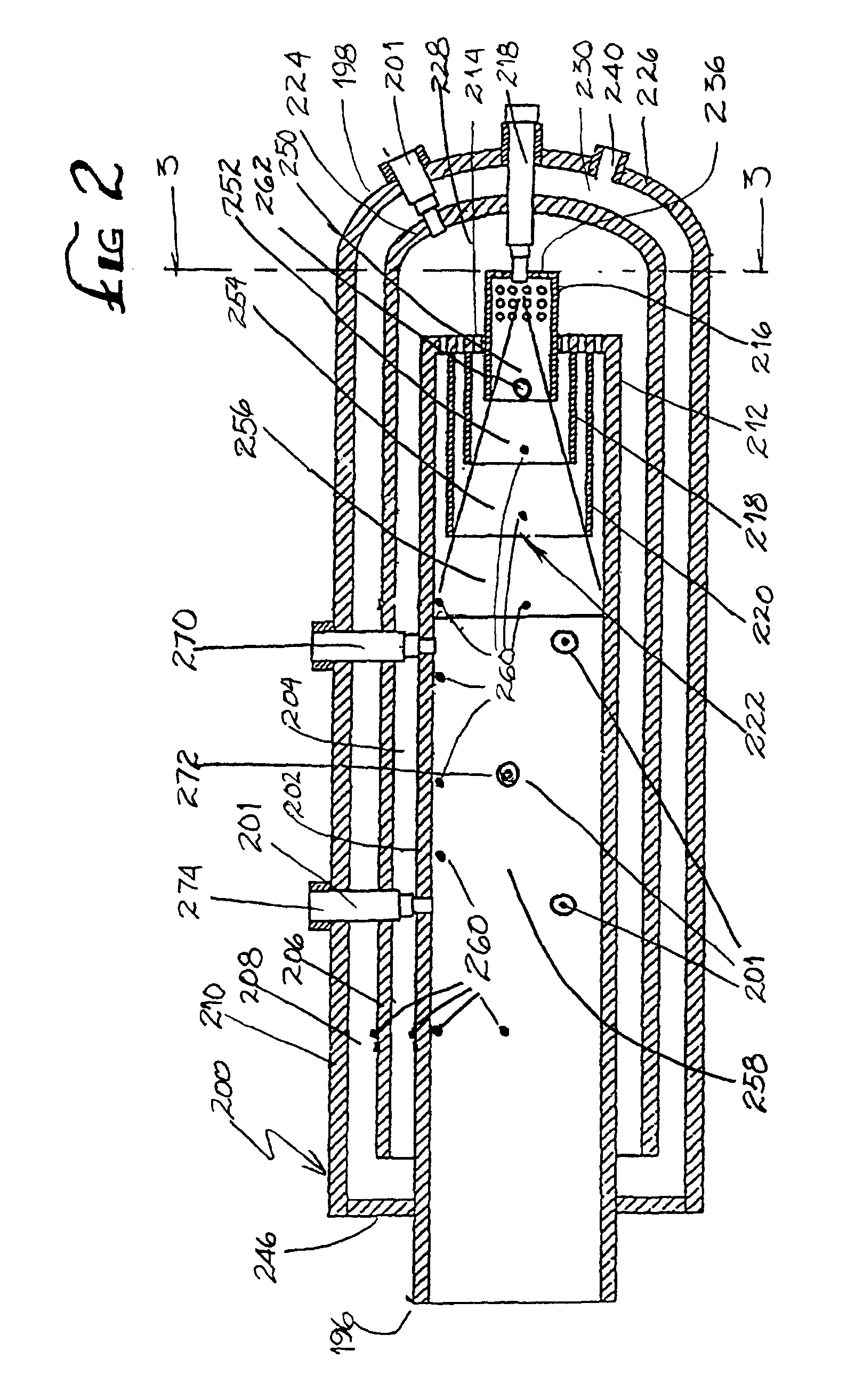

High efficiency low pollution hybrid Brayton cycle combustor

InactiveUSRE43252E1Efficient and clean and pollution free powerIncrease horsepowerGas turbine plantsTurbine/propulsion fuel controlCombustion chamberWorking fluid

A power generating system is described which operates at high pressure and utilizes a working fluid consisting of a mixture of compressed non-flammable air components, fuel combustion products and steam. The working fluid exiting the power generating system is substantially free of NOx and CO.Working fluid is provided at constant pressure and temperature. Combustion air is supplied by one or more stages of compression. Fuel is injected at pressure as needed. At least about 40% of the oxygen in the compressed air is consumed when the fuel is burned. Inert liquid is injected at high pressure to produce working an inert mass of high specific heat diluent vapor for use for internal cooling of the combustion chamber.The use of non-flammable liquid injection inhibits the formation of pollutants, increases the efficiency and available horsepower from the system, and reduces specific fuel consumption. Control systems allow the independent control of the quantity, temperature and pressure of the air, fuel and non-flammable liquid introduced in the combustion chamber allowing control of the maximum temperature and average temperature within the combustion temperature as well as the temperature of the exhaust from the combustion chamber.

Owner:VAST POWER PORTFOLIO

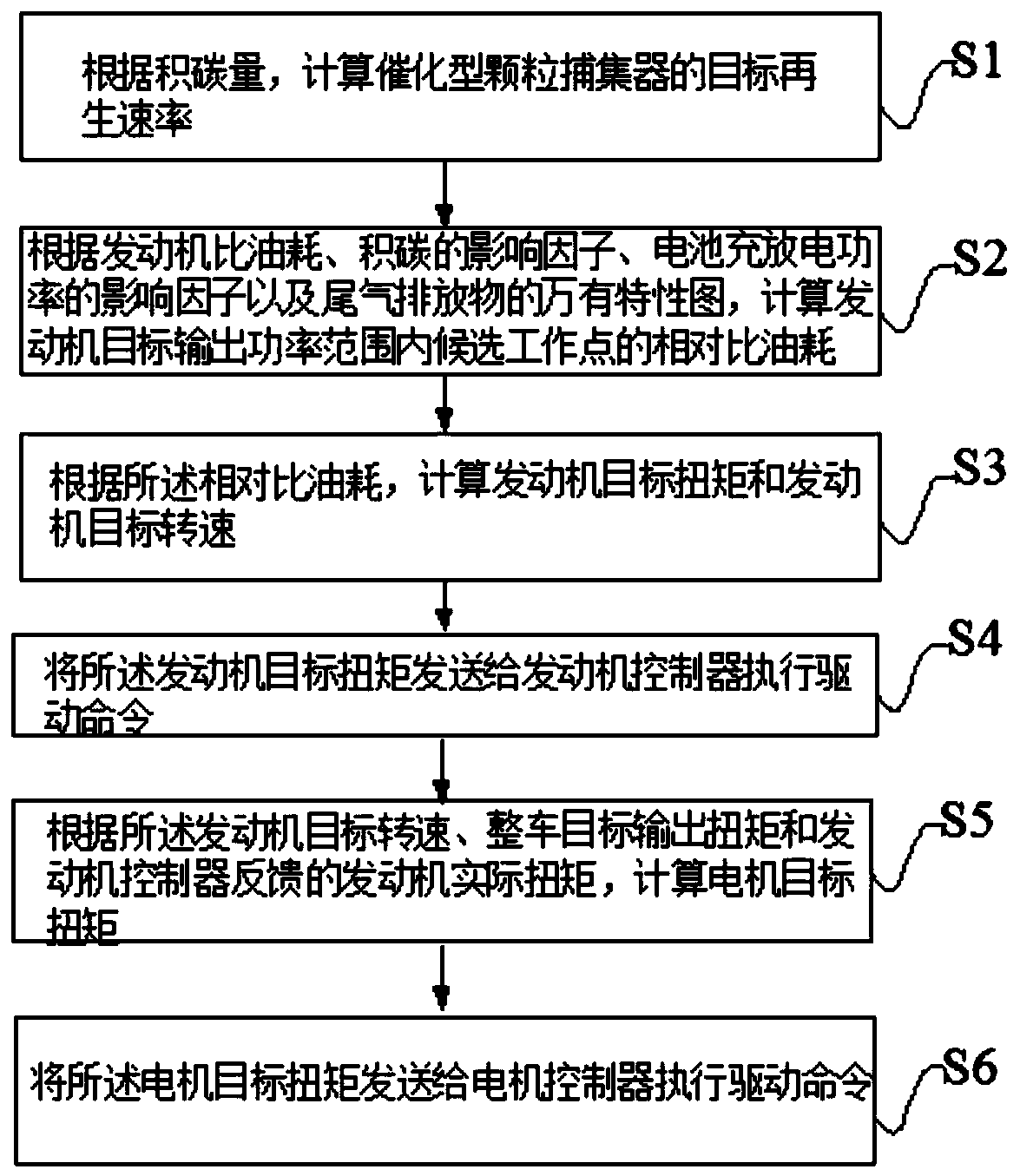

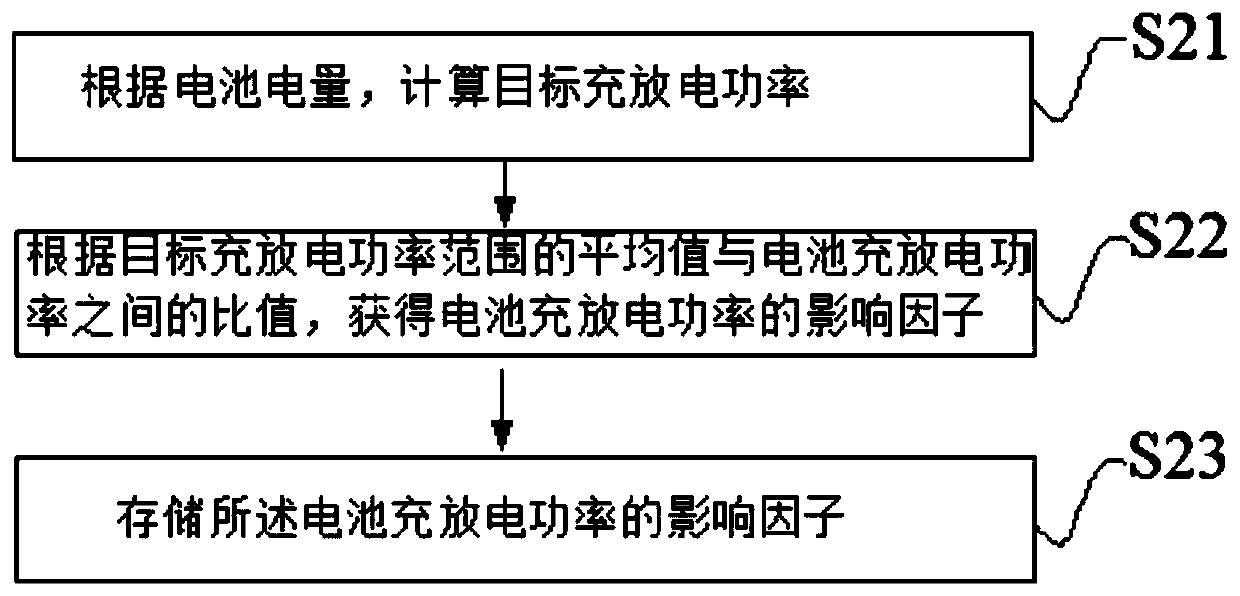

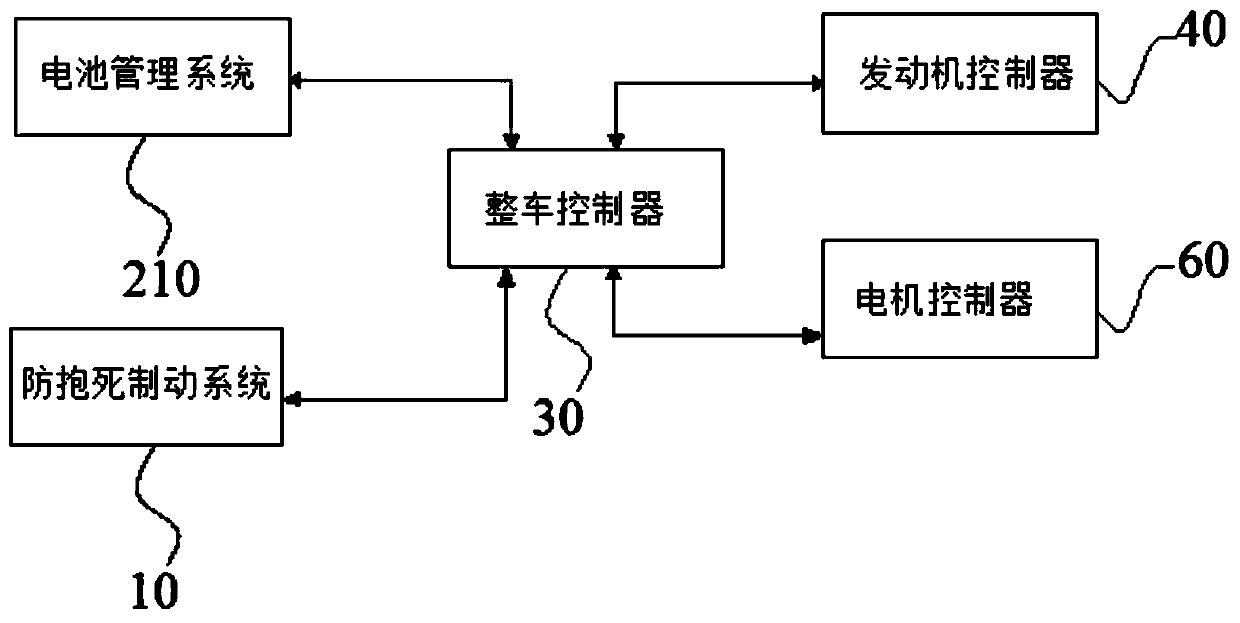

Fuel consumption control method for considering emission of hybrid vehicle

ActiveCN110435632AIncrease speedIncrease opportunitiesHybrid vehiclesSpeed controllerBattery chargeBrake specific fuel consumption

The invention provides a fuel consumption control method for considering emission of a hybrid vehicle. The control method comprises at least the steps: calculating the target regeneration rate of a catalytic particle catcher according to the carbon deposition amount; calculating the relative specific fuel consumption of the candidate working points in the target output power range of an engine according to the specific fuel consumption of the engine, the influence factors of carbon deposition, the influence factors of battery charging and discharging power and the universal characteristic diagram of tail gas emission; calculating the target torque and target rotating speed of the engine according to the relative specific fuel consumption; sending the target torque of the engine to an engine controller to execute a driving command; calculating the target torque of a motor according to the target rotating speed of the engine, the target output torque of the whole vehicle and the actual torque of the engine fed back by the engine controller; and sending the target torque of the motor to a motor controller to execute a driving command. According to the control method, the carbon deposition amount in a particle catcher or the catalytic particle catcher is reduced while the energy conversion loss is reasonably controlled.

Owner:TONGJI UNIV

Engine running at fixed speed incorporated controllable transmission power system

InactiveUS20070037661A1Save fuelImprove efficiencyVehicle fittingsInternal combustion piston enginesBrake specific fuel consumptionStart up

A power system of controllable transmission incorporated with an engine running at fixed speed that controls the engine to run at a fixed speed or approaching a fixed speed within an rpm range with higher BSFC (braking specific fuel consumption) when the engine is started up from static status and in the accelerated drive from low rpm, the output end of the engine drives to achieve active control of the controllable front-end gearbox that is capable of executing variable or invariable gear shift so to activate the output end to execute accelerated drive output from low to high rpm; meanwhile, in the course of start-up and acceleration from lower to high rpm and in driving operation, the engine runs in an rpm range with higher BSFC for saving fuel.

Owner:YANG TAI HER

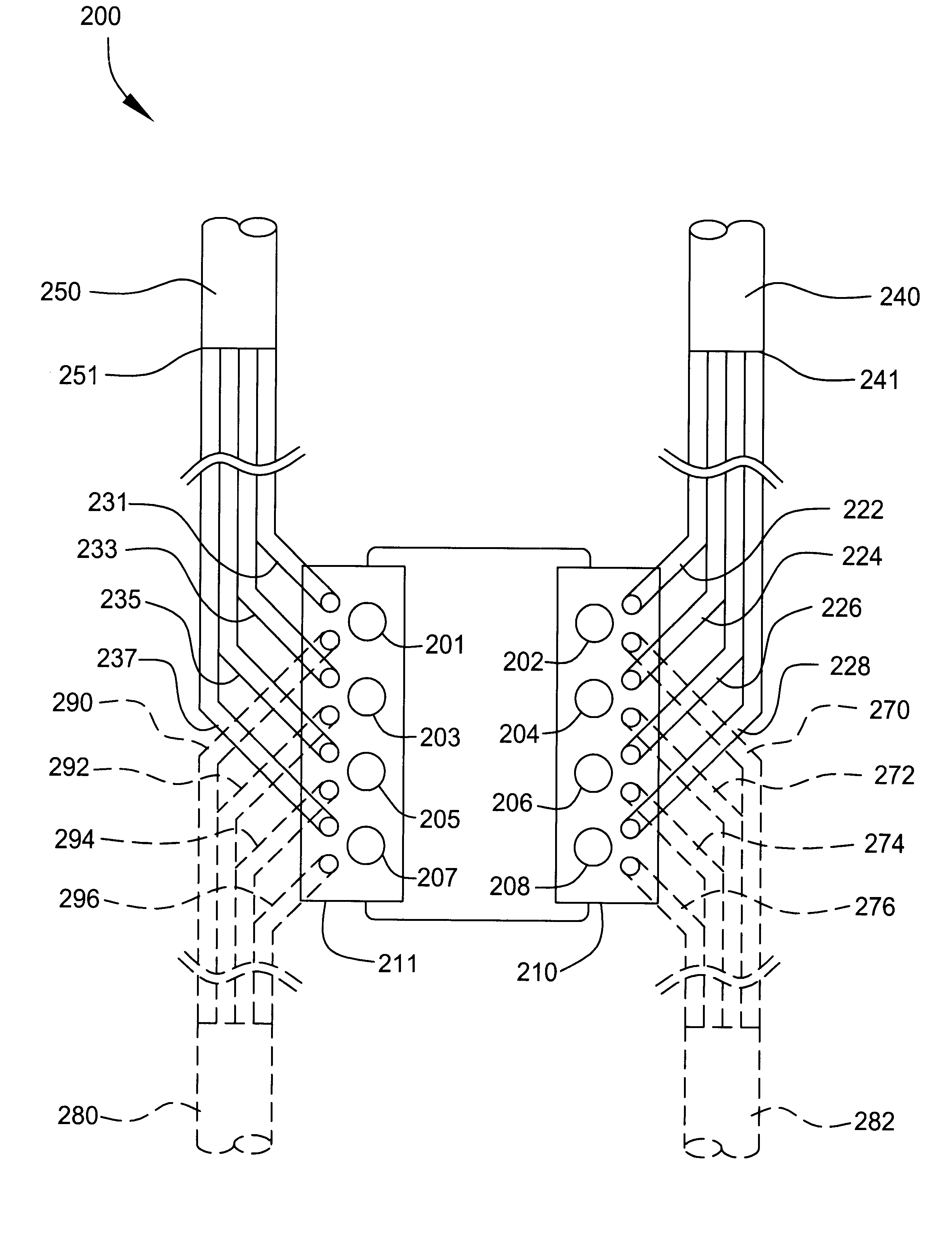

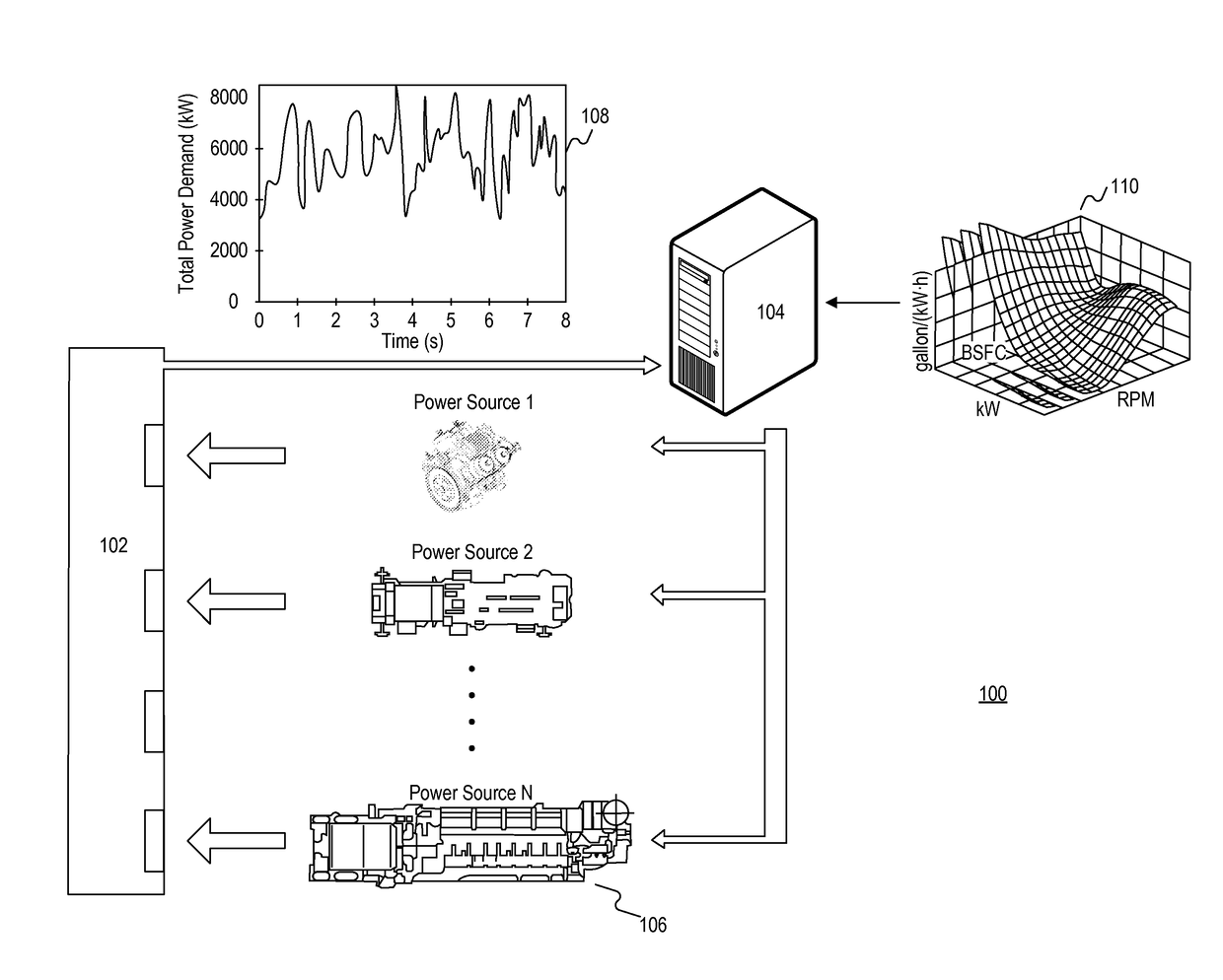

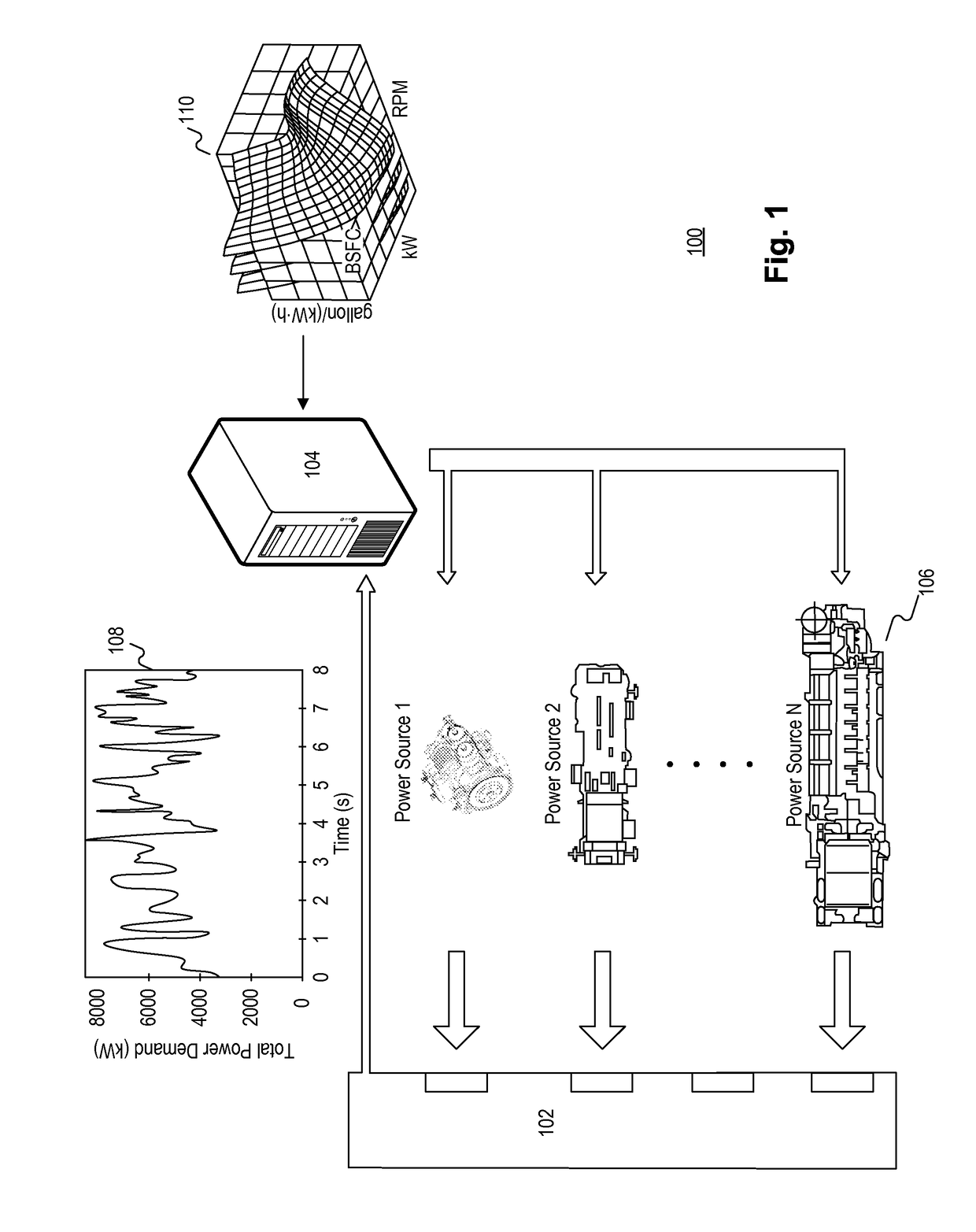

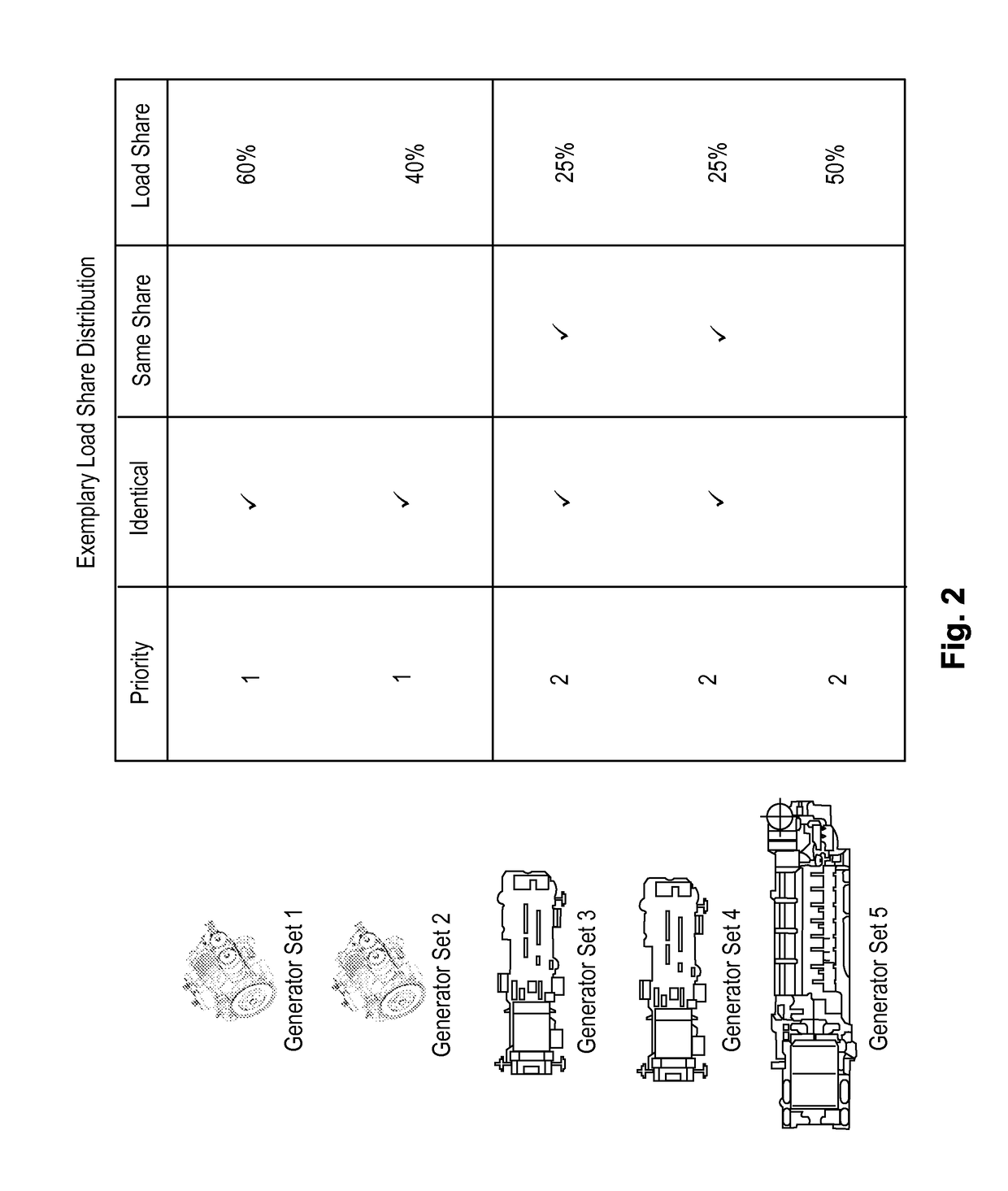

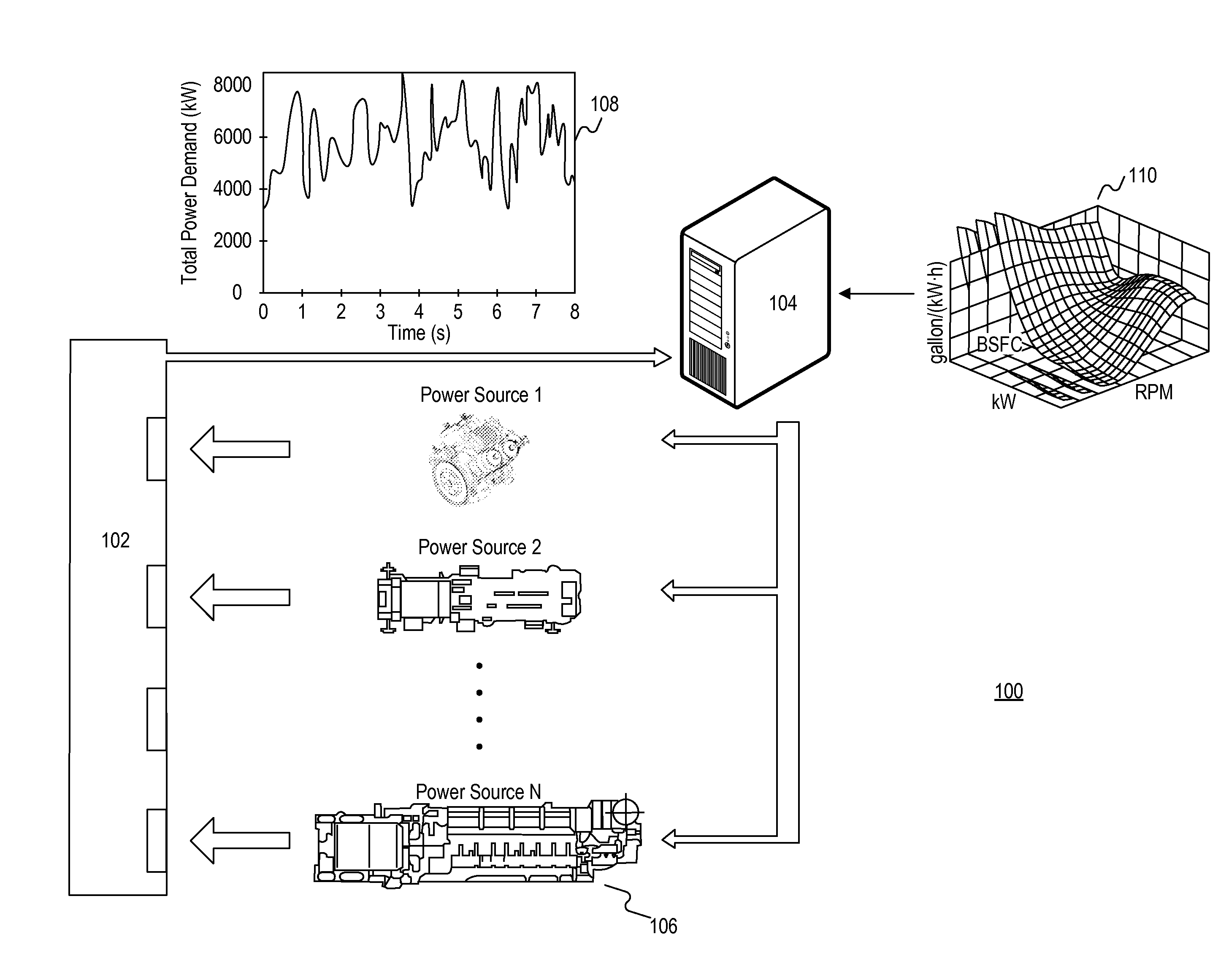

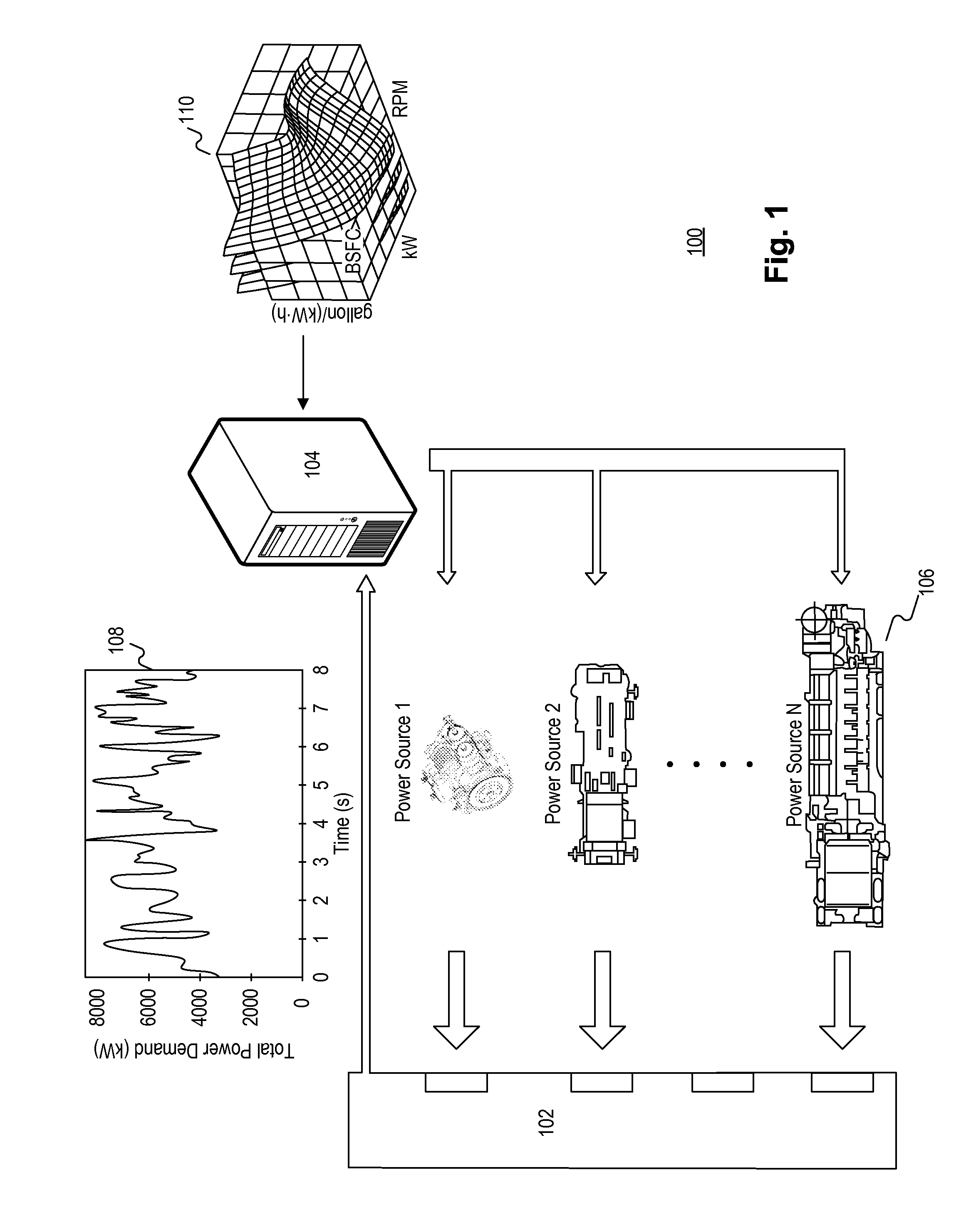

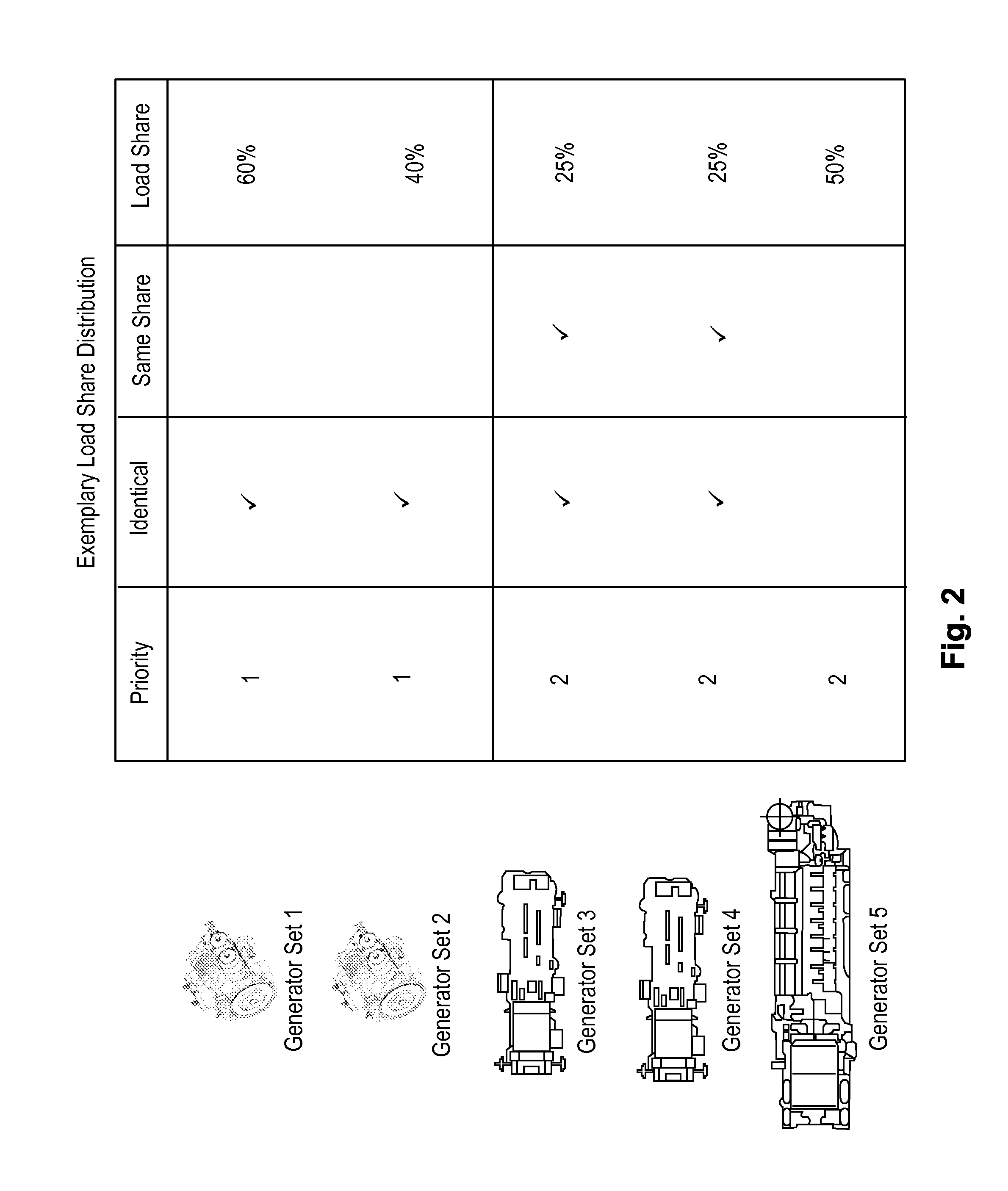

Managing load sharing among multiple engines

A method and a system of managing load sharing among a plurality of power sources are disclosed. According to certain embodiments, the method includes determining a total power output to be directed from the plurality of power sources to at least one power consumer. The method also includes retrieving a Brake Specific Fuel Consumption (BSFC) curve associated with each of the plurality of power sources. The method further includes determining an operating priority for each of the plurality of power sources based on operating constraints associated with the respective power source. The method further includes determining a load share for each of the plurality of power sources based on at least the total power output, the BSFC curves, and the operating priorities.

Owner:CATERPILLAR INC

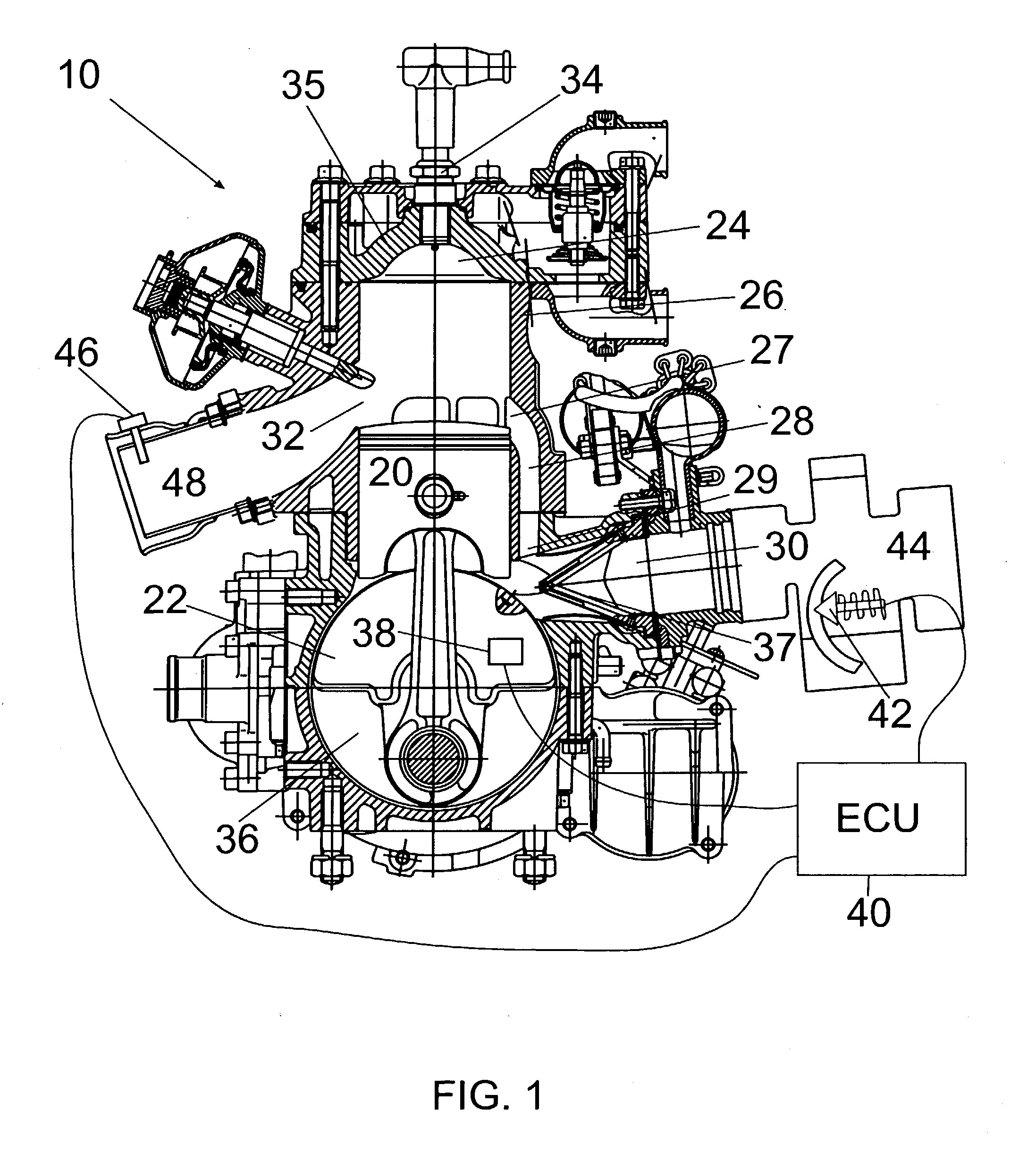

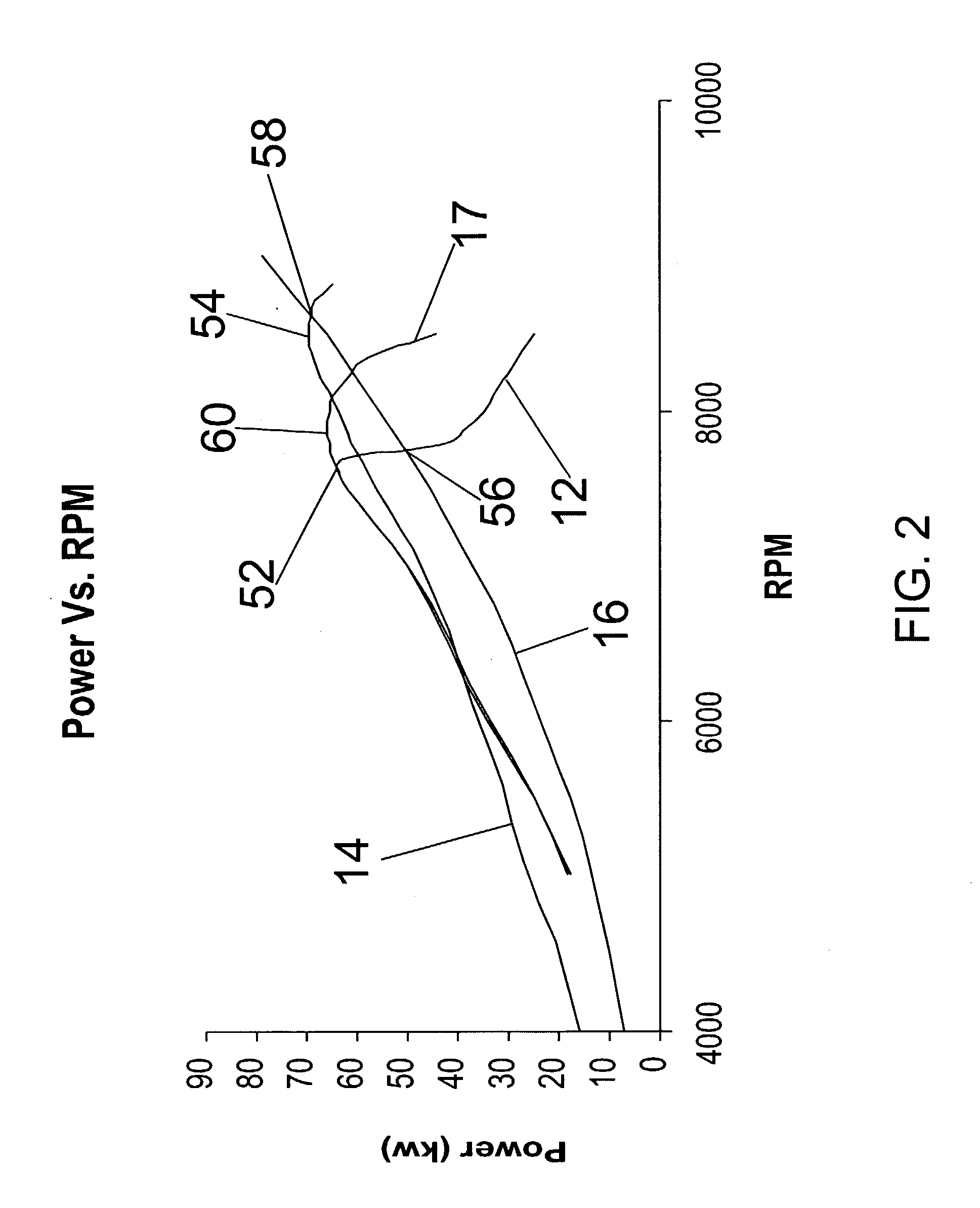

Engine control

InactiveUS20030121496A1Reducing engine 's performanceIncrease temperatureElectrical controlInternal combustion piston enginesMoving averageBrake specific fuel consumption

An engine control system utilizes the brake specific fuel consumption (BSFC) to increase the temperature of the exhaust gas present in the exhaust pipe and determines a moving average engine speed from at least two actual engine speeds determined from a speed sensor located on the crankshaft of the engine. The control system also includes a map that uses the moving average engine speed and the actual engine speed to retrieve a solenoid duty cycle to alter the BSFC of the engine at certain RPM to increase the maximum power output of the engine.

Owner:BOMBARDIER RECREATIONAL PROD INC

Managing load sharing among multiple engines

A method and a system of managing load sharing among a plurality of power sources are disclosed. According to certain embodiments, the method includes determining a total power output to be directed from the plurality of power sources to at least one power consumer. The method also includes retrieving a Brake Specific Fuel Consumption (BSFC) curve associated with each of the plurality of power sources. The method further includes determining an operating priority for each of the plurality of power sources based on operating constraints associated with the respective power source. The method further includes determining a load share for each of the plurality of power sources based on at least the total power output, the BSFC curves, and the operating priorities.

Owner:CATERPILLAR INC

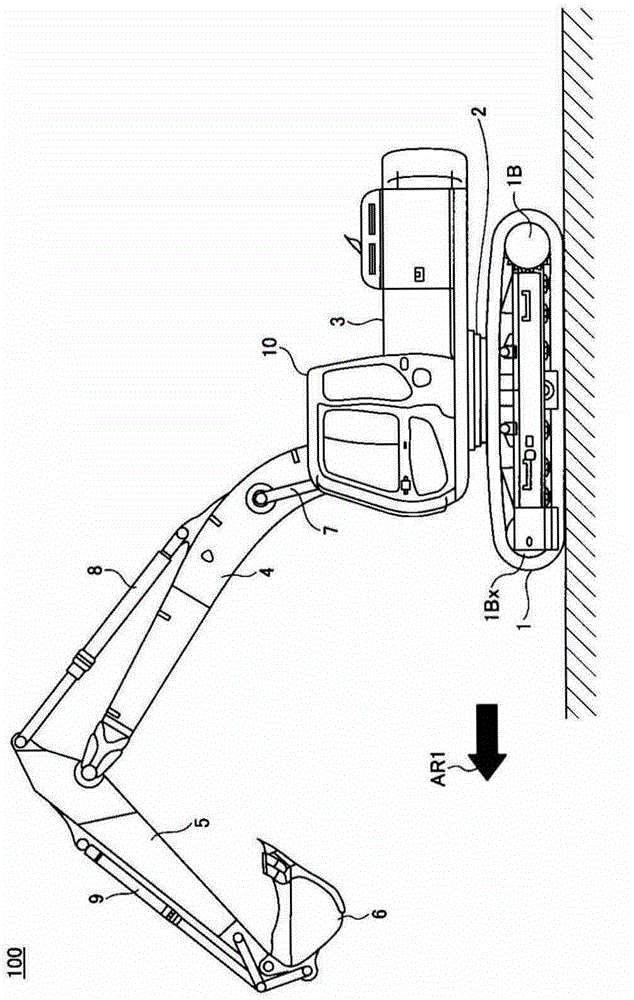

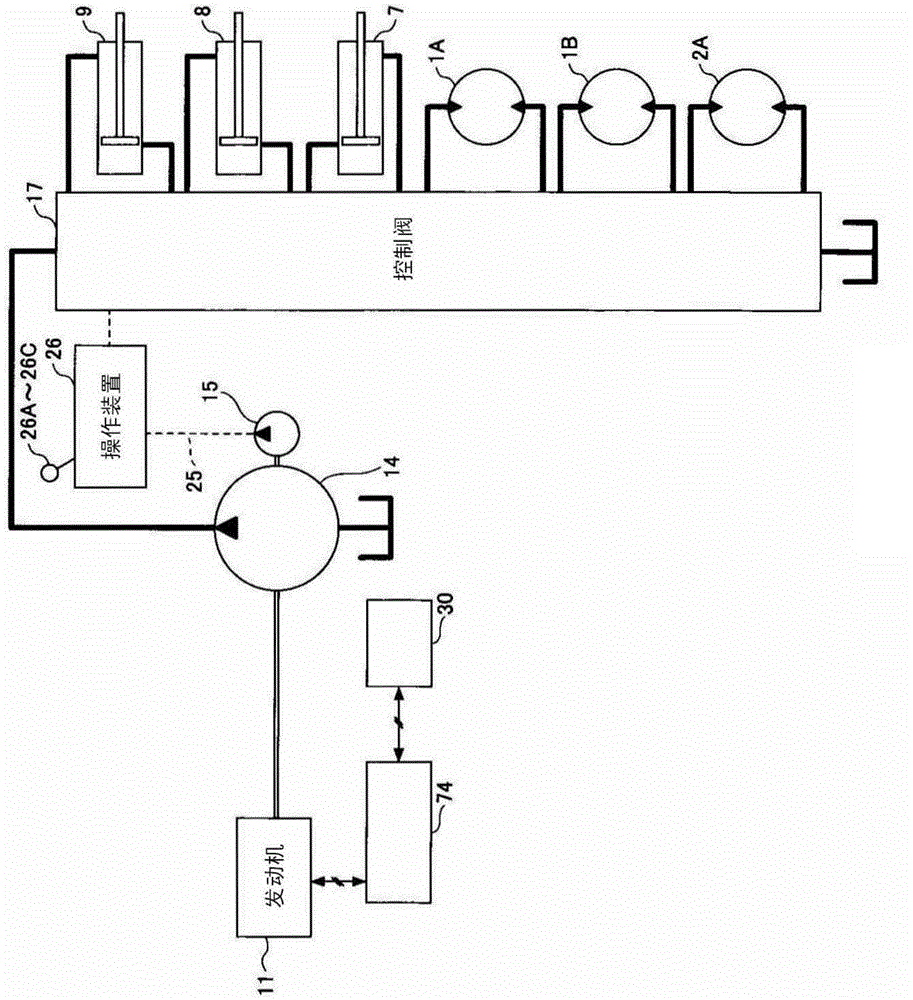

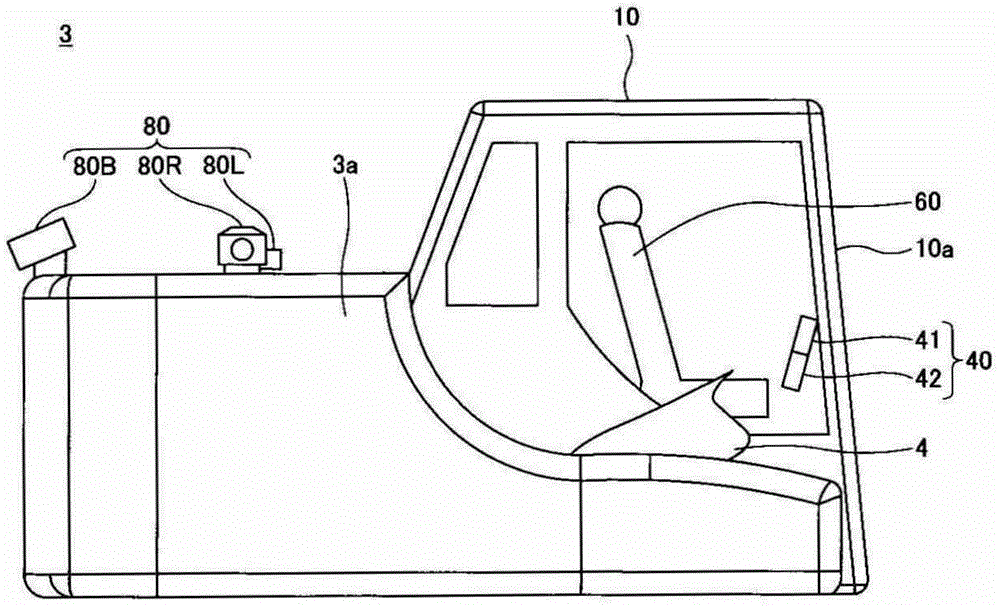

Building machinery

The present invention provides building machinery, which is used for switching displaying grand average specific fuel consumption and section average specific fuel consumption in a display device. The building machinery comprises: a lower portion walking body configured to perform walking movement; an upper portion solid of revolution configured to carry the lower portion walking body with rotation freely; a cab configured to carry the upper portion solid of revolution; a specific fuel consumption calculating device configured to calculate the specific fuel consumption based on the duration of runs and the consumption of fuel; and a display device configured to carry the cab and capable of switching displaying at least one of the grand average specific fuel consumption and the section average specific fuel consumption.

Owner:SUMITOMO CONSTRUCTION MACHINERY

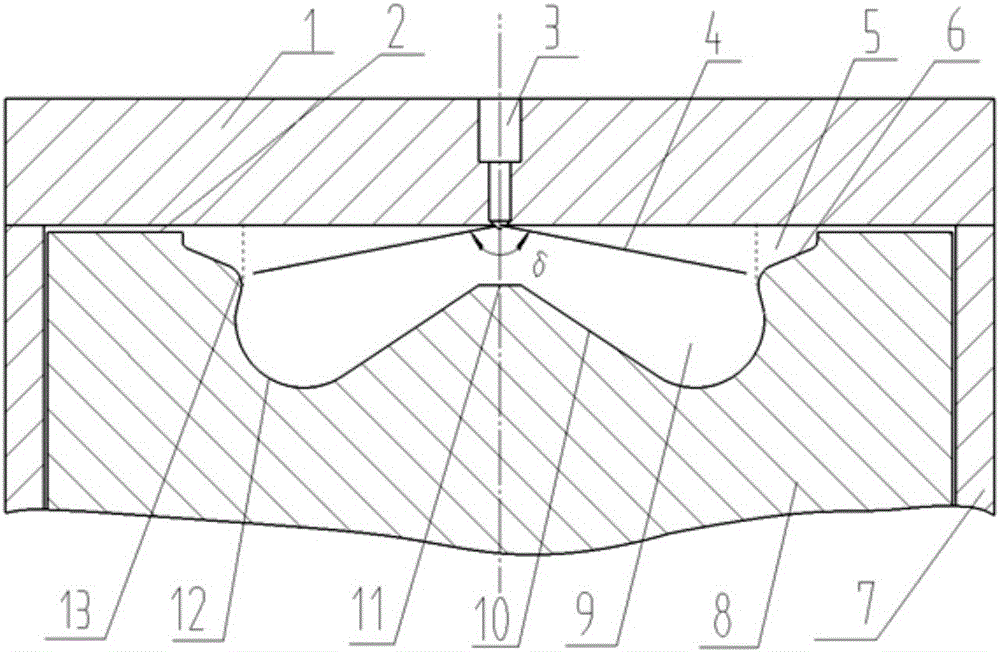

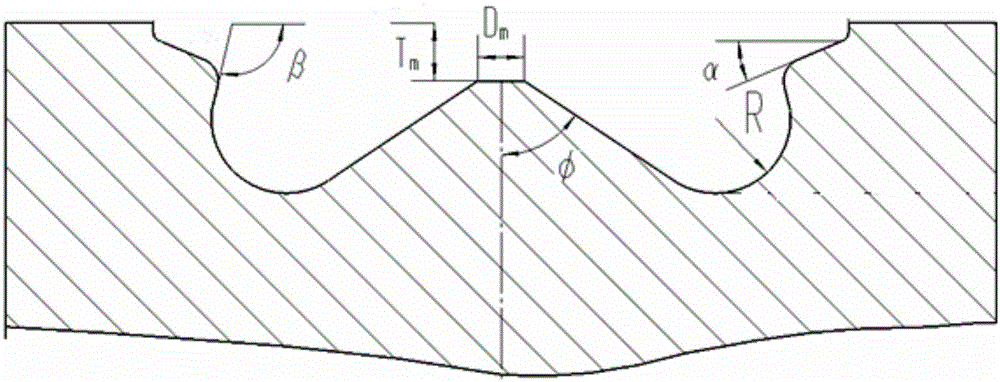

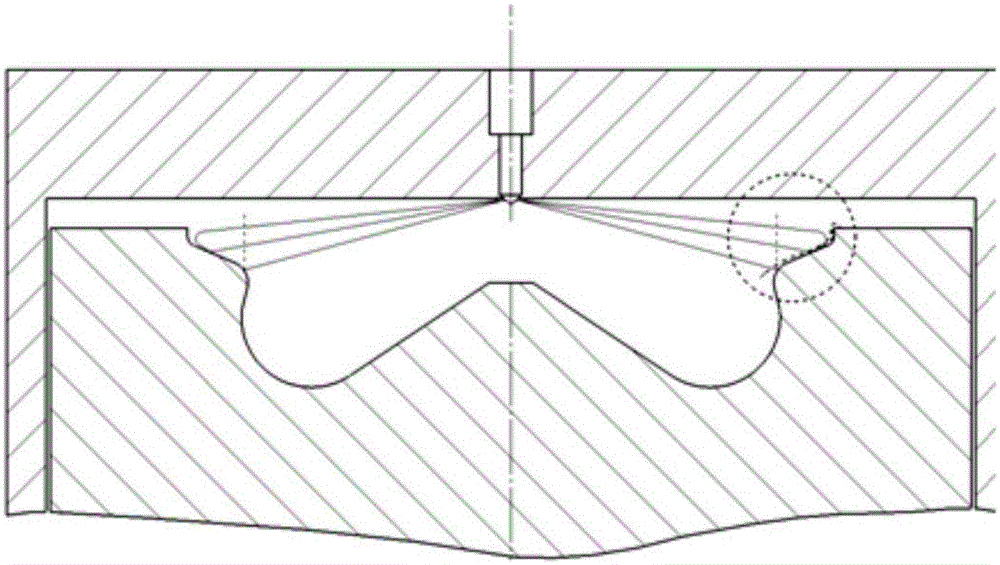

Aviation diesel engine piston combustion chamber and combustion system

InactiveCN105736170AAvoid serious problemsBalanced fuel consumptionMachines/enginesPistonsCombustion systemAviation

The invention discloses an aviation diesel engine piston combustion chamber and a combustion system. The aviation diesel engine piston combustion chamber comprises a cylinder cover and a cylinder barrel, wherein a piston is arranged in the cylinder barrel; a cavity of the combustion chamber is formed between the top of the piston and the cylinder cover; a combustion chamber concave pit is formed in the top of the piston; a groove is formed in the top of the piston and is located around the combustion chamber; and the groove is located on the outer side of the combustion chamber pit. The requirements of high power per liter, relatively low explosion pressure, engine weight and low effective brake specific fuel consumption during high-speed high-load operation of an aviation diesel engine can be met.

Owner:CHERY AUTOMOBILE CO LTD

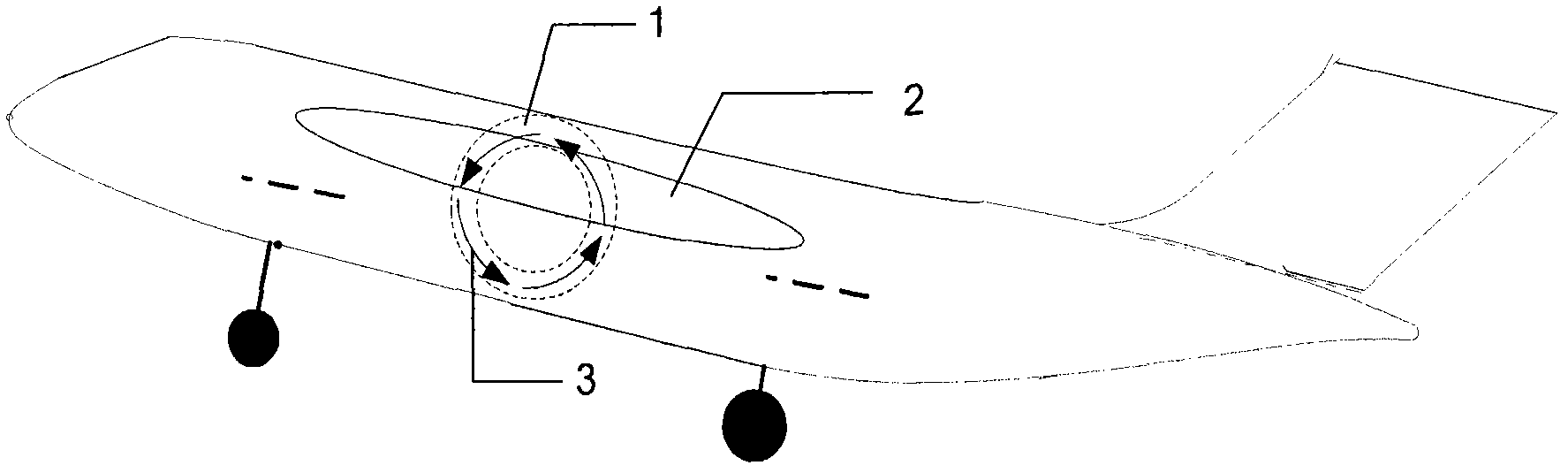

Flight control method

InactiveCN102642622ASolve problems that cannot be manipulatedImprove survivabilityFuel tank safety measuresBrake specific fuel consumptionFlight control modes

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

Unleaded fuel compositions

ActiveUS20150184095A1Reduce contentReduce the amount of solutionNon-fuel substance addition to fuelCombustion enginesAlkaneBrake specific fuel consumption

Unleaded fuel compositions is provided which comprise:15 to 20 volume % of one or more alkanols having from 2 to 4 carbon atoms;20 to 75 volume % of one or more branched paraffins having from 5 to 10 carbon atoms;0 to 25 volume % of one or more linear or branched olefins;0 to 35 volume % of one or more mono-alkylated benzenes,The unleaded fuel composition increase engine efficiency or the brake specific fuel consumption of an engine when used.

Owner:SHELL USA INC

Battery charging coaction and output system with current limit supply

ActiveUS8552588B2Improve energy savingReduce consumptionMaterial analysis by electric/magnetic meansSingle network parallel feeding arrangementsCurrent limitingBattery charge

The present invention relates to a power system utilizing an engine generator or public power with AC source, wherein the power system particularly has the characteristics that the maximum output current thereof is limited by electromagnetic effects, and / or constant current or nearly constant current output thereof is set to be lower than the maximum output current, for powering a load, and charging a battery, or jointly powering a load with a battery; when an engine generator set is utilized to be power supply, during operation, the engine operates with the best brake specific fuel consumption and / or the range of revolutions and torque for better energy saving.

Owner:YANG TAI HER

System and method for controlling exhaust emissions and specific fuel consumption of an engine

ActiveUS9140179B2Electrical controlInternal combustion piston enginesBrake specific fuel consumptionTurbine

A method includes combusting air within a plurality of cylinders of an internal combustion engine by injecting a fuel into the plurality of cylinders. The method further includes expanding a first portion of an exhaust gas generated from the plurality of combustion cylinders via a turbine. The method further includes controlling at least one of feeding a second portion of the exhaust gas via an exhaust channel bypassing the turbine; and recirculating a third portion of the exhaust gas to the plurality of combustion cylinders via a recirculation channel, as a function of an intake manifold air temperature and pressure at which the engine is operated.

Owner:GE GLOBAL SOURCING LLC

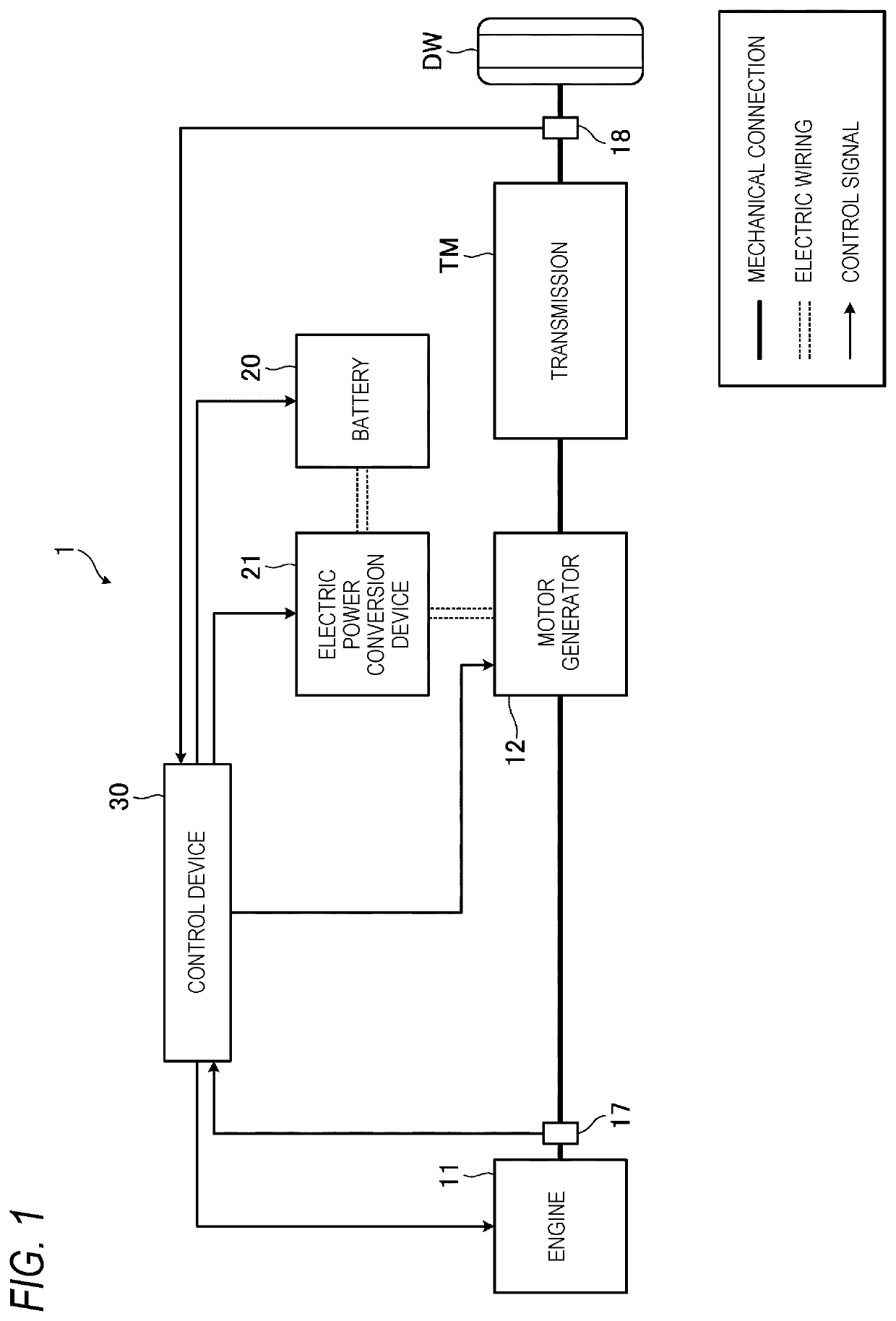

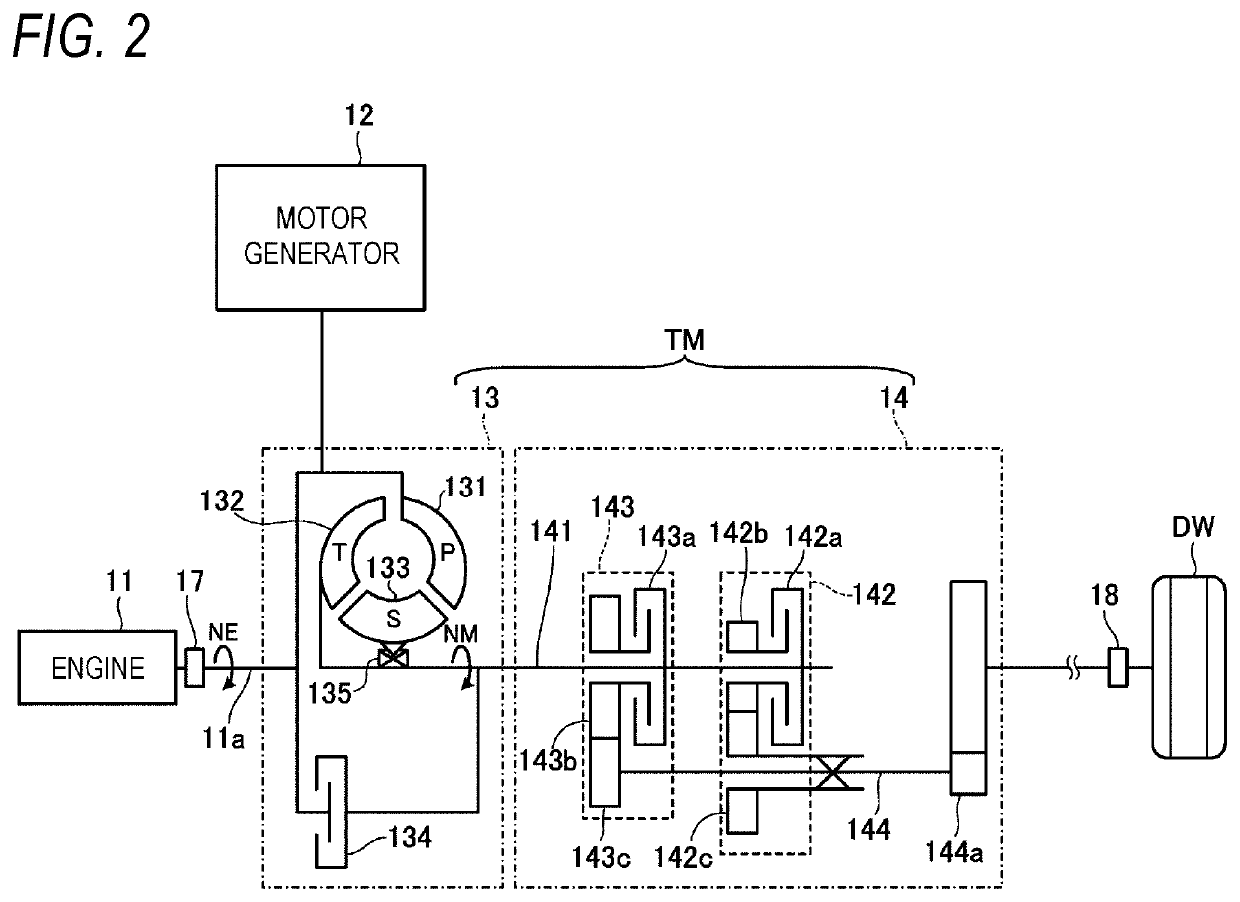

Vehicle control device

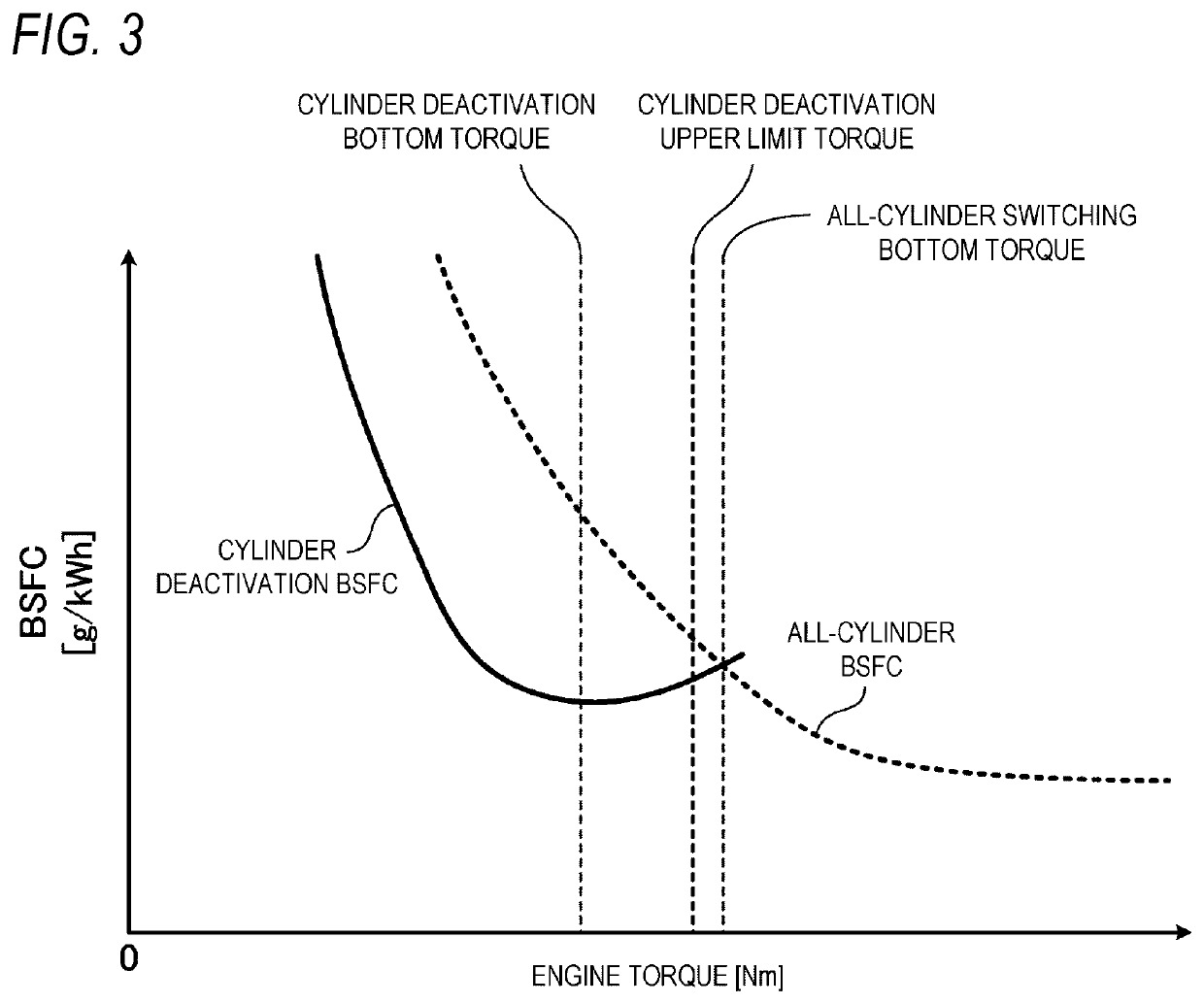

PendingUS20220306079A1Increase fuel consumptionPreventing decrease in drivabilityHybrid vehiclesInstruments for road network navigationBrake specific fuel consumptionDrive wheel

A vehicle control device controls a vehicle including an internal combustion engine, an electric motor, and a drive wheel driven by an output of at least one of the internal combustion engine and the electric motor. When the internal combustion engine is in a cylinder deactivation operation, if a target torque reaches a cylinder deactivation bottom torque at which a value of a cylinder deactivation brake specific fuel consumption, which is a brake specific fuel consumption when the internal combustion engine is in the cylinder deactivation operation, is minimized, the vehicle control device executes cylinder deactivation bottom assist control for increasing a motor torque output from the electric motor in accordance with an increase in the target torque while maintaining an engine torque output from the internal combustion engine at the cylinder deactivation bottom torque.

Owner:HONDA MOTOR CO LTD

Calibration method and device for gasoline hydrogenated engine

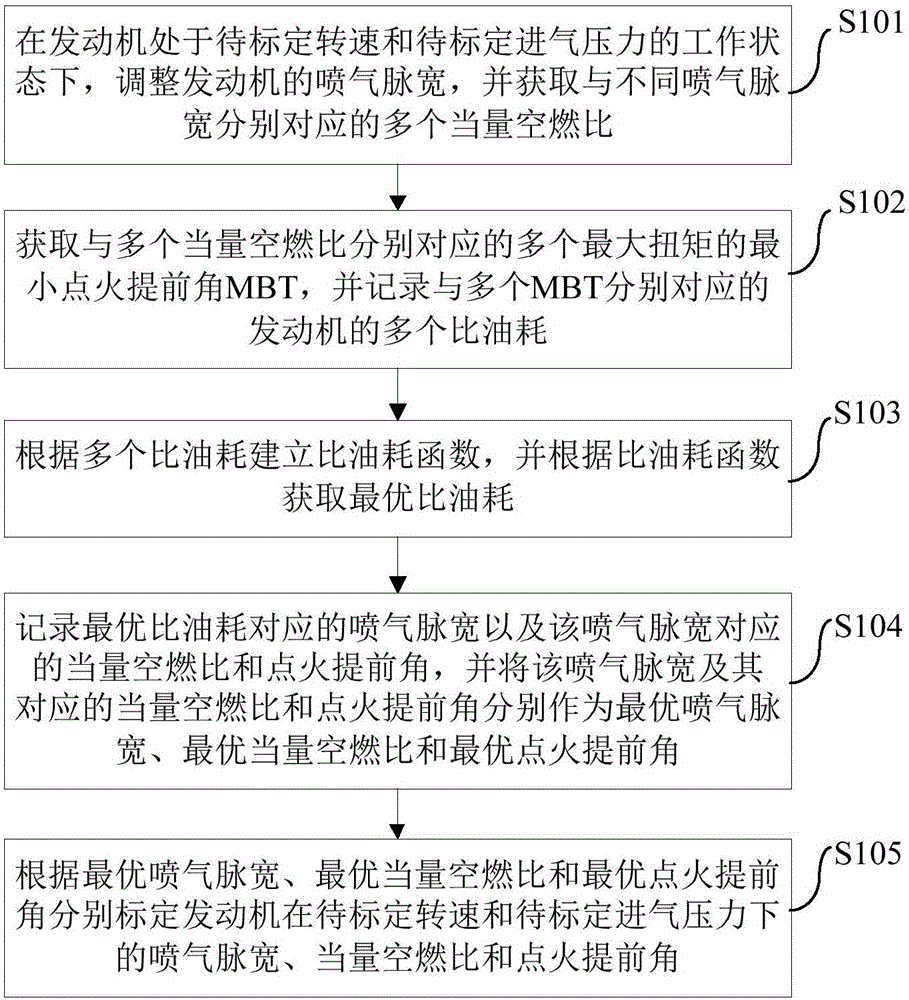

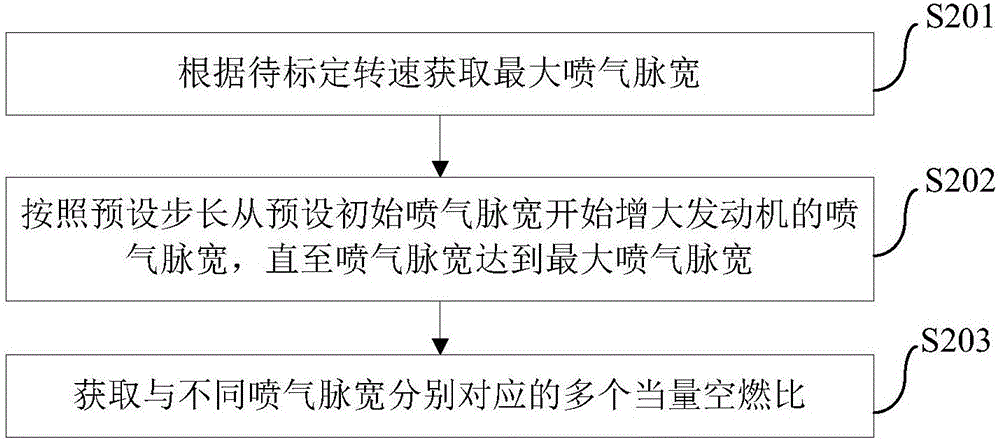

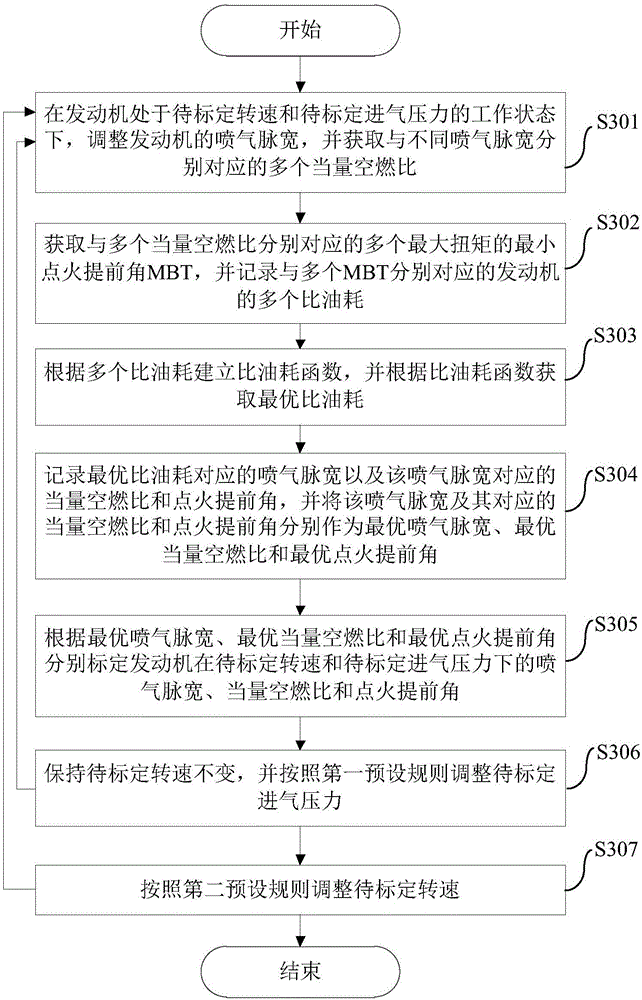

ActiveCN104653309BEasy dischargeMeet emission requirementsEngine controllersMachines/enginesMaximum torqueBrake specific fuel consumption

The invention discloses a calibration method and calibration device for a gasoline-hydrogen fueled engine. The calibration method comprises the following steps: regulating gas-jetting pulse width of an engine and obtaining multiple corresponding equivalent air-fuel ratios; obtaining minimum-ignition advance angles MBT of maximum torques corresponding to the multiple equivalent air-fuel ratios, and recording multiple specific fuel consumptions of the engines; obtaining optimal specific fuel consumption and recording the gas-jetting pulse width corresponding to the optimal specific fuel consumption as well as equivalent air-fuel ratios and ignition advance angles under the gas-jetting pulse width, and respectively calibrating to-be-calibrated rotation speed and to-be-calibrated gas-jetting pulse width, the equivalent air-fuel ratios and ignition advance angles under the gas inlet pressure of the engine. The calibration method for the gasoline-hydrogen fueled engine of the embodiment of the invention can greatly improve the exhaustion of the gasoline-hydrogen fueled engine relative to the exhaustion of the same-displacement gasoline engine, so that the exhaustion requirements of national locomotive can be satisfied, and the engine reaches the best dynamic property and economical efficiency.

Owner:BYD CO LTD

System and method for controlling exhaust emissions and specific fuel consumption of an engine

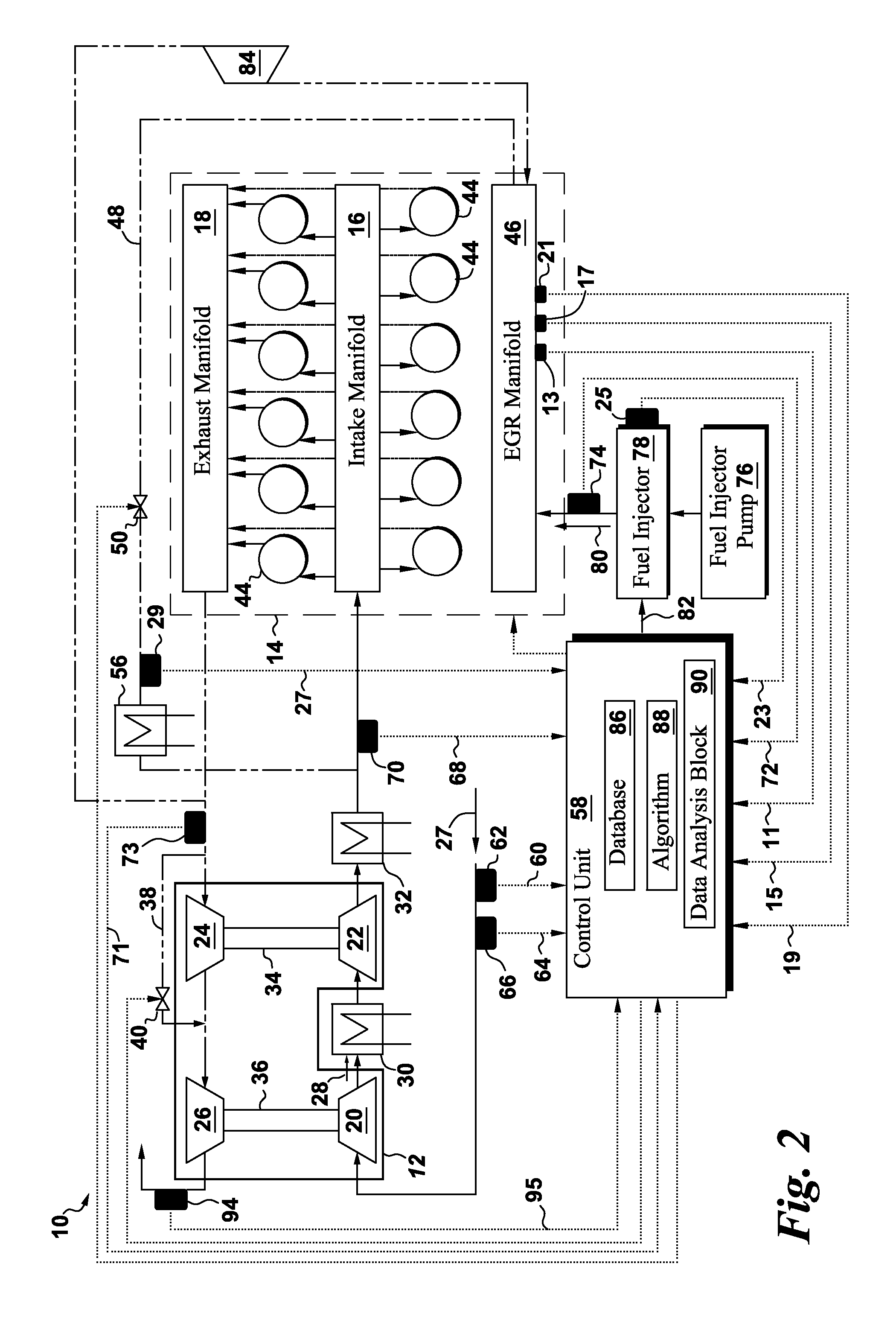

ActiveUS9964056B2Electrical controlInternal combustion piston enginesBrake specific fuel consumptionOxygen

A method includes controlling an engine speed based on: intake manifold air temperature and / or intake manifold pressure one, or more, of the following data parameters: an engine load as a function of a fuel level, a fuel injecting timing, an intake oxygen concentration, a constituent concentration from the exhaust gas flow, an engine power, and an engine torque. The method also recirculates a portion of the exhaust gas flow to the combustion cylinders of the engine via a recirculation channel, as a function of intake manifold temperature and / or intake manifold pressure at which the engine is operated. An engine system, other methods, and a non-transitory computer readable medium encoded with a program, to enable a processor-based control unit to control aspects of the engine are also disclosed.

Owner:GE GLOBAL SOURCING LLC

Unleaded fuel compositions

ActiveUS9862904B2Reduce contentReduce the amount of solutionCombustion enginesGaseous engine fuelsAlkaneEngine efficiency

Unleaded fuel compositions is provided which comprise:15 to 20 volume % of one or more alkanols having from 2 to 4 carbon atoms;20 to 75 volume % of one or more branched paraffins having from 5 to 10 carbon atoms;0 to 25 volume % of one or more linear or branched olefins;0 to 35 volume % of one or more mono-alkylated benzenes,The unleaded fuel composition increase engine efficiency or the brake specific fuel consumption of an engine when used.

Owner:SHELL USA INC

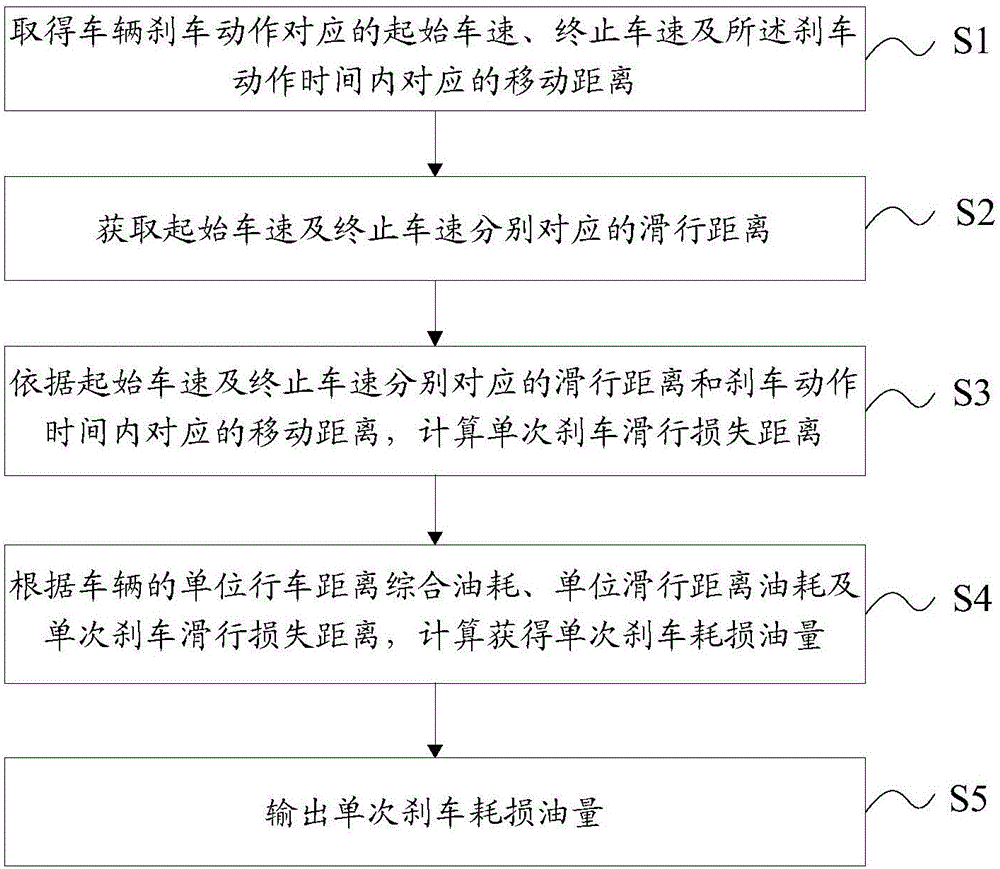

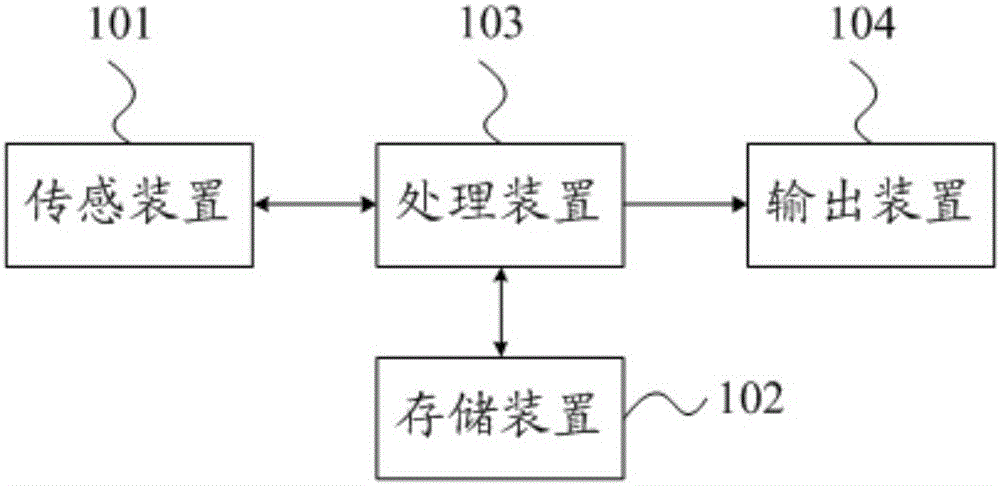

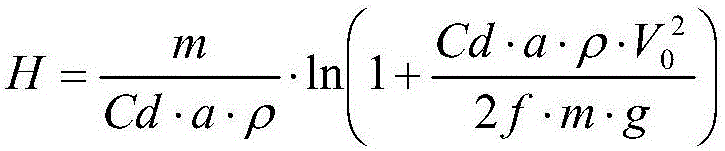

Vehicle braking oil consumption prompting method and system

InactiveCN106043270AReduce usageReduce brakingBrake safety systemsBrake specific fuel consumptionOil consumption

The invention discloses a vehicle braking oil consumption prompting method. The vehicle braking oil consumption prompting method comprises the steps that the initial braking speed and the termination braking speed which correspond to the vehicle braking action and the corresponding movement distance in the braking action time are obtained; the sliding distances which correspond to the initial braking speed and the termination braking speed are obtained; the single braking sliding loss distance is calculated according to the sliding distances corresponding to the initial braking speed and the termination braking speed and the corresponding movement distance in the braking action time; and the single braking oil consumption is calculated and obtained according to the unit driving distance comprehensive oil consumption, the unit sliding distance oil consumption and the single braking sliding loss distance of a vehicle and is output. By means of the vehicle braking oil consumption prompting method provided by the invention, the sliding distance loss caused by braking is converted into the oil consumption value to be calculated and quantitatively output, and thus a driver can be prompted and can reduce unnecessary braking behaviors as far as possible, so that oil consumption is reduced, and meanwhile, the driving safety is improved. The invention further discloses a vehicle braking oil consumption prompting system.

Owner:刘瑞洋

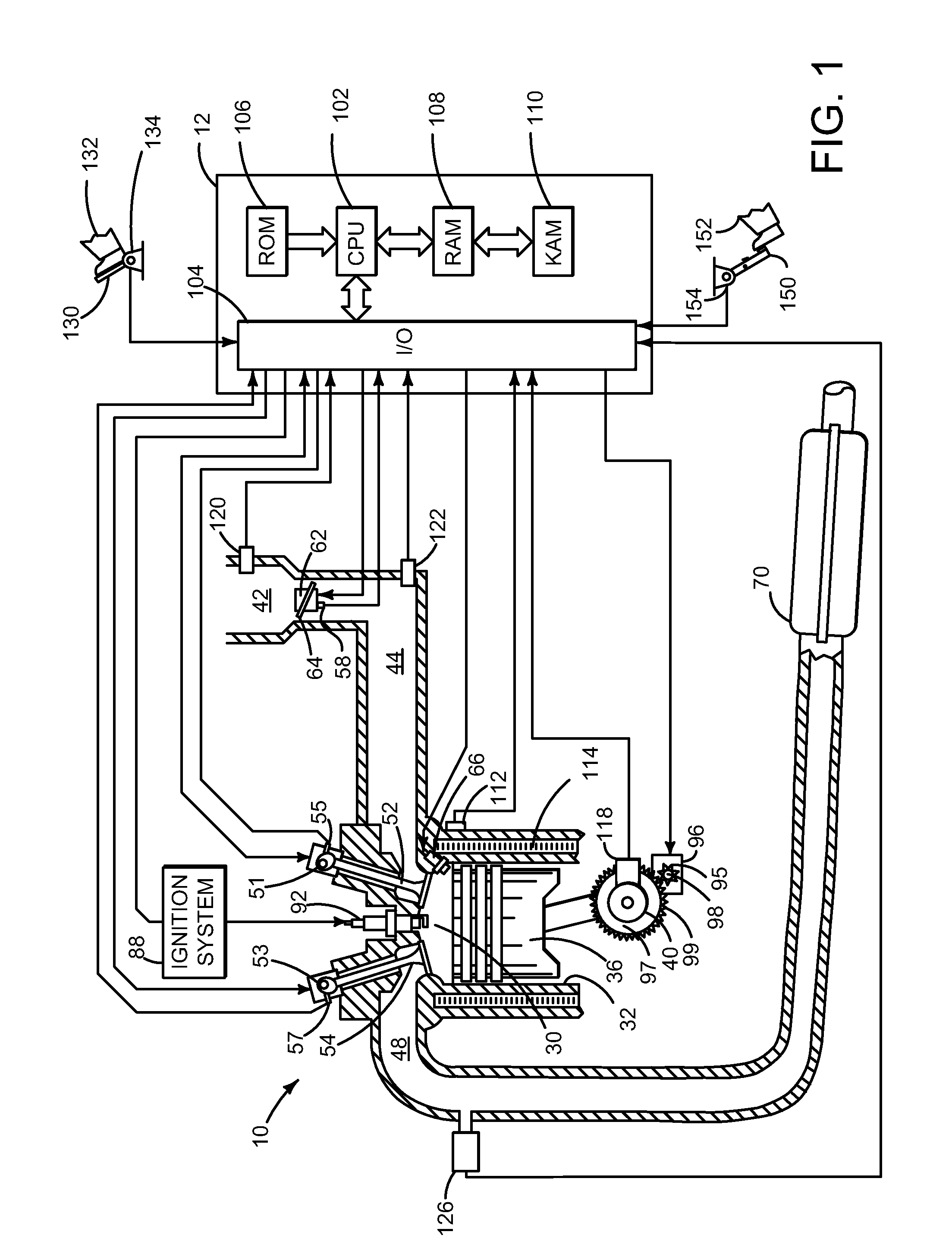

Methods and systems for operating an engine in a hybrid vehicle driveline

ActiveUS20160061121A1Improving hybrid driveline efficiencyImprove driveline efficiencyHybrid vehiclesAnalogue computers for vehiclesBrake specific fuel consumptionEngineering

Systems and methods for increasing hybrid driveline efficiency are disclosed. In one example, an efficient engine operating region is defined within an engine operating domain based on an engine's brake specific fuel consumption. The systems and methods may increase an amount of time a hybrid driveline operates at more efficient operating conditions.

Owner:FORD GLOBAL TECH LLC

Storage battery charging and jointly outputting system of current-limiting power supply

ActiveCN102055232AExtend your lifeDc network circuit arrangementsCurrent/voltage measurementBrake specific fuel consumptionControl engineering

The invention relates to a storage battery charging and jointly outputting system of a current-limiting power supply. In the invention, an engine generator or a mains alternating current power supply is used, and the system specifically has the characteristic of limiting the maximum output current via an electromagnetic effect and / or has the characteristic of setting constant current lower than the maximum output current or setting an output close to the constant current so as to supply power to a load and charge a storage battery or supply power to the load together with the storage battery; and when an engine generator set is used as a power supply, during running, the engine runs with an optimal and / or better energy-saving revolution in an optimal and / or better torque region in the Brake Specific Fuel Consumption.

Owner:杨泰和

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com