High efficiency low pollution hybrid Brayton cycle combustor

a combustor and high efficiency technology, applied in the direction of engines, machines/engines, mechanical equipment, etc., can solve the problems of limited general adoption, inability of such engines to meet sudden demand and/or maintain a constant working temperature or pressure, and inability to control such engines inefficiently, so as to achieve clean, efficient, pollution-free power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

A. Basic Configuration Of The Present System

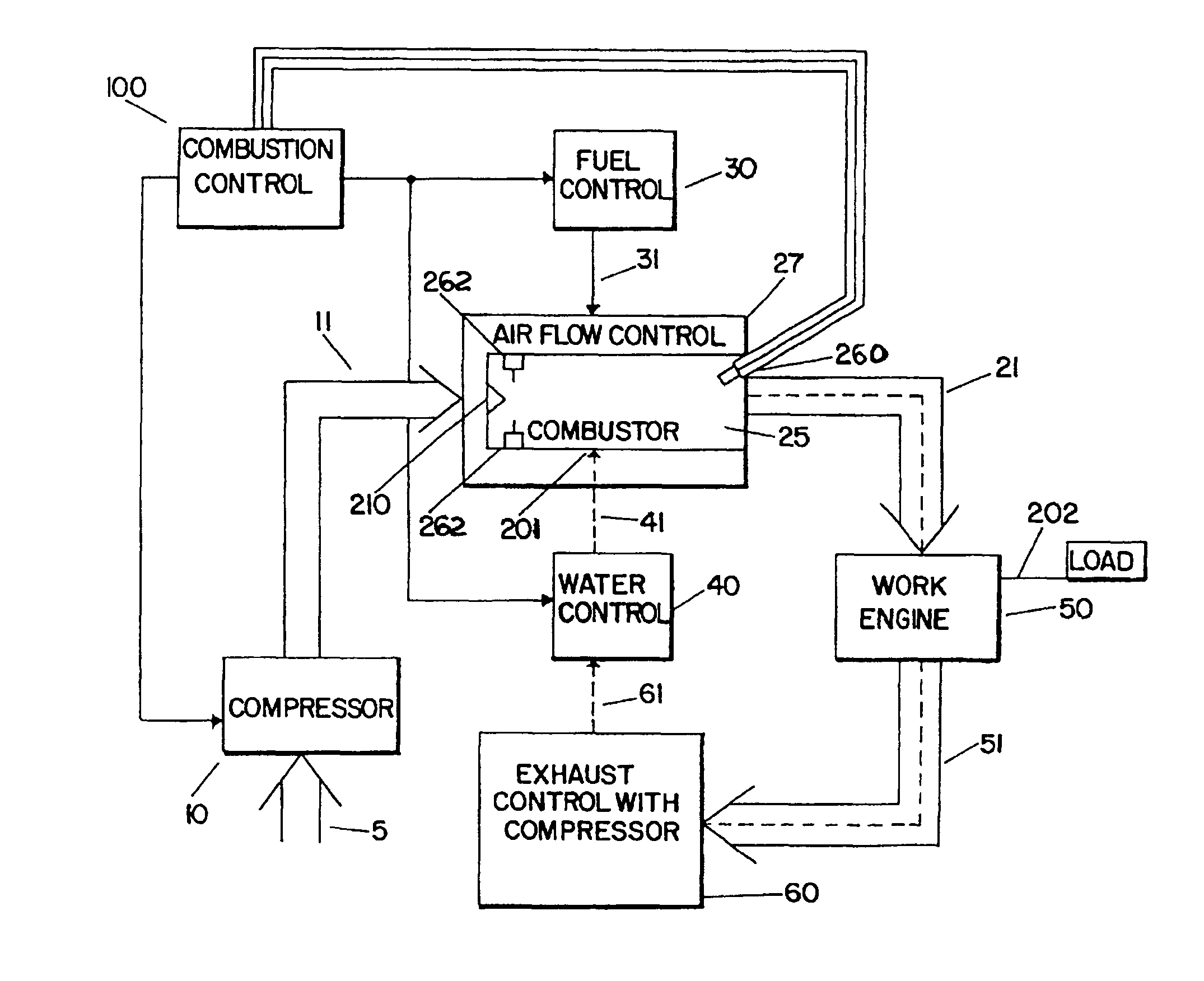

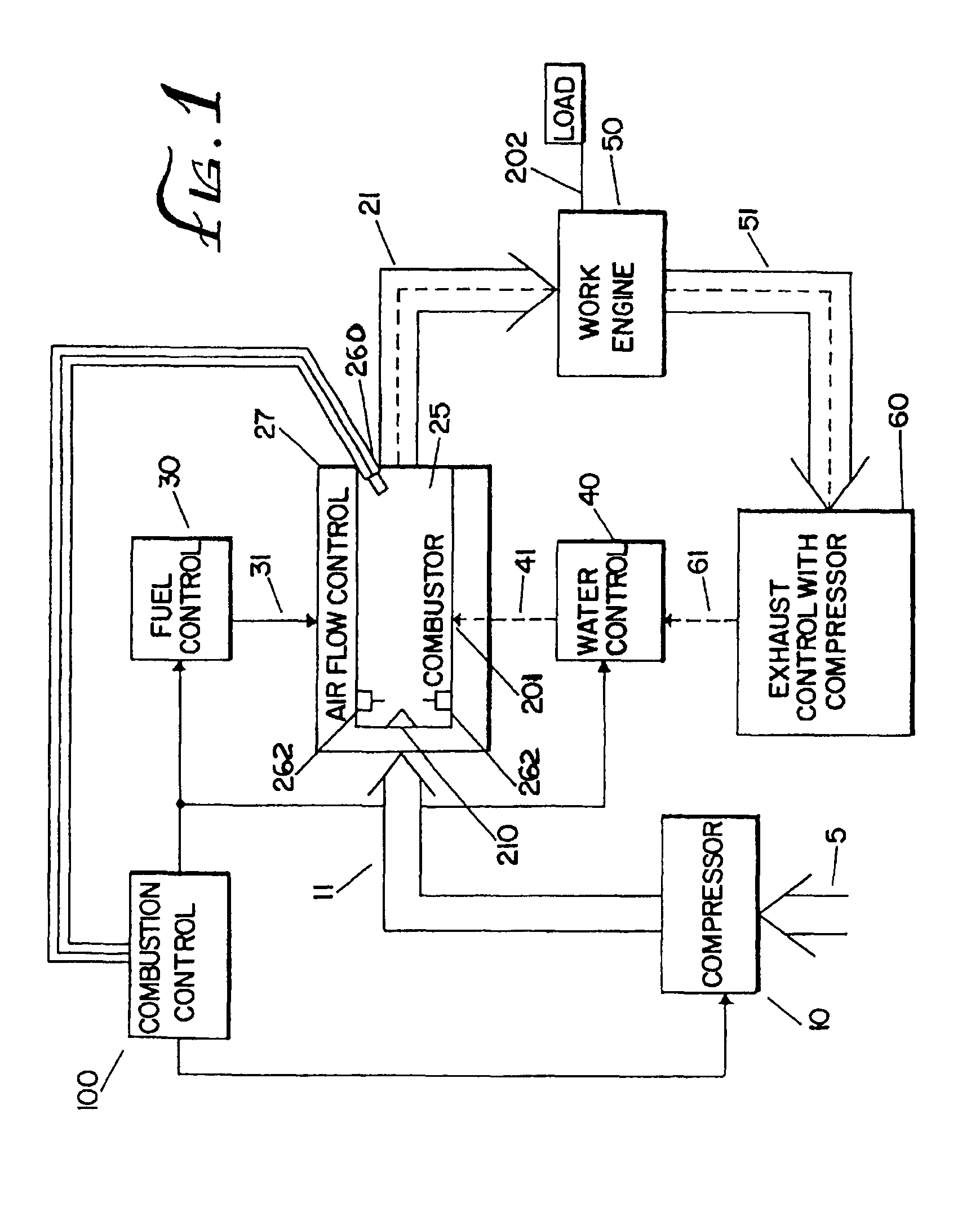

[0054]Referring now to FIG. 1, there is shown schematically a gas turbine engine embodying the teachings of the present invention. Ambient air 5 is compressed by compressor to a desired pressure resulting in compressed air 11. In a preferred embodiment, compressor 10 is a typical well-known two or three stage compressor, and the ambient air is compressed to a pressure greater than about four (4) atmospheres, and preferably 10 to 30 atmospheres. The temperature of the compressed air depends on the compression ratio. Al a compression ratio of 30:1 the compressed air temperature is approximately 1424° R (964° F.).

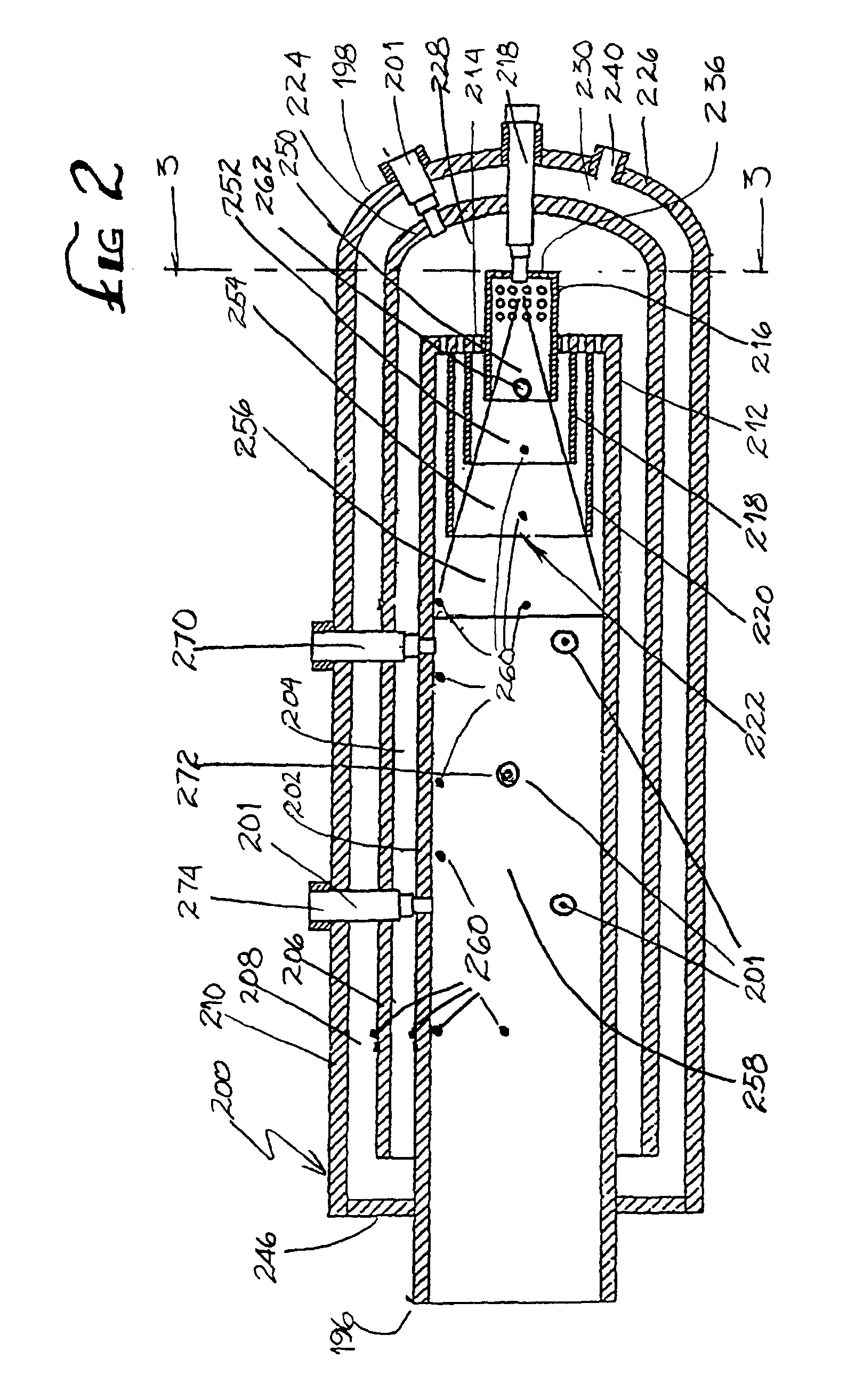

[0055]The flow of the compressed air 11 is controlled by an air flow controller 27 to a combustor 25. Combustors are well-known in the art. However, in the present invention, the compressed air 11 is supplied in a staged, circumferential manner by air flow control 27 to the combustor 200 shown in FIG. 2 and more fully described below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com