Water-based fluorocarbon finish paint and preparation method and application thereof

A water-based fluorocarbon and topcoat technology, applied in the field of coatings, can solve problems such as affecting the use effect, low VOC content, and easy foaming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Example 1 Preparation of water-based fluorocarbon topcoat.

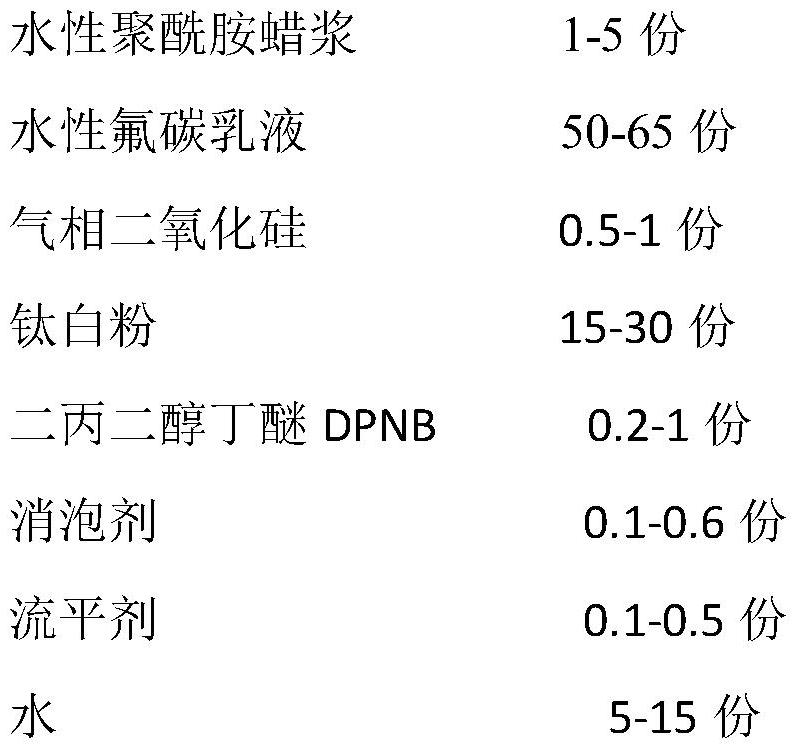

[0020] Component A:

[0021] Table 1

[0022]

[0023] Put components 1-7 into the tank, stir at 800 rpm for 20 minutes, then grind all the materials through a grinder to a fineness below 30 μm, add components 8-11 in turn, stir at 800 rpm for 30 minutes, and Filter and pack with a 200-mesh filter to obtain component A of water-based fluorocarbon coatings.

[0024] B component:

[0025] The water-based isocyanate curing agent is selected from United Curing Chemicals 3598T.

[0026] When in use, mix A and B evenly at a mass ratio of 5:1, then add a small amount of water (8-10wt%) to spray.

[0027] The performance test results of the prepared waterborne fluorocarbon topcoat are shown in Table 1.

Embodiment 2

[0028] Example 2 Preparation of water-based fluorocarbon topcoat.

[0029] Component A:

[0030] Table 2

[0031]

[0032] Put components 1-7 into the tank, stir at 800 rpm for 20 minutes, then grind all the materials through a grinder to a fineness below 30 μm, add components 8-11 in turn, stir at 800 rpm for 30 minutes, and Filter and pack with a 200-mesh filter to obtain component A of water-based fluorocarbon coatings.

[0033] B component:

[0034] Water-based isocyanate curing agent combined curing chemistry 3598T

[0035] When in use, mix A and B evenly at a mass ratio of 5:1 and then add 8-10% of water for spraying.

Embodiment 3

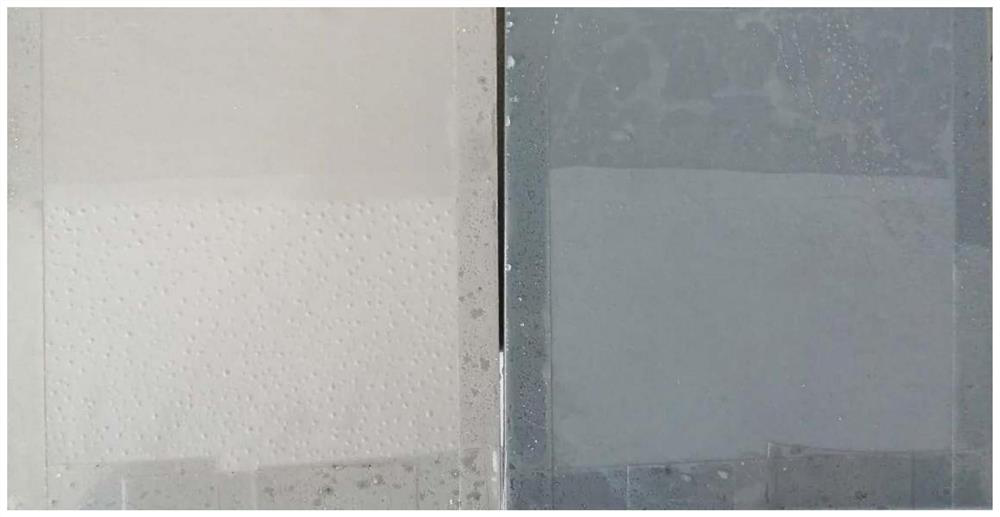

[0046] Example 3 Application of water-based fluorocarbon topcoat.

[0047] The water-based fluorocarbon topcoat prepared in Example 1 is used in conjunction with the water-based cold-sprayed zinc and water-based epoxy mica iron of Wuxi Huadong Zinc Shield, wherein the water-based cold-sprayed zinc is used as a primer, and the water-based epoxy mica iron intermediate paint is used as an intermediate Paint, water-based fluorocarbon topcoat is sprayed as a topcoat for corrosion protection of steel structures. Wherein, the water-based fluorocarbon topcoat in comparative example 1 is Baotashan paint.

[0048] The specific implementation steps are as follows:

[0049] table 5

[0050]

[0051] Table 6

[0052] Test items example 1 Example 2 Contrast 1 Adhesion (MPa) 12 10 12 Impact resistance (g*cm) 50 50 50 water resistant 3500 3300 2000 Salt spray resistance 5000 5500 2000 Resistant to 5% sulfuric acid 7 days pass 7 da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com