Starting method of sulfur recovery process

A sulfur recovery and process technology, which is applied in the start-up process of the sulfur recovery process, and the field of sulfur recovery and start-up with low acid gas concentration at the initial stage of the start-up, can solve the problem of high organic sulfur content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

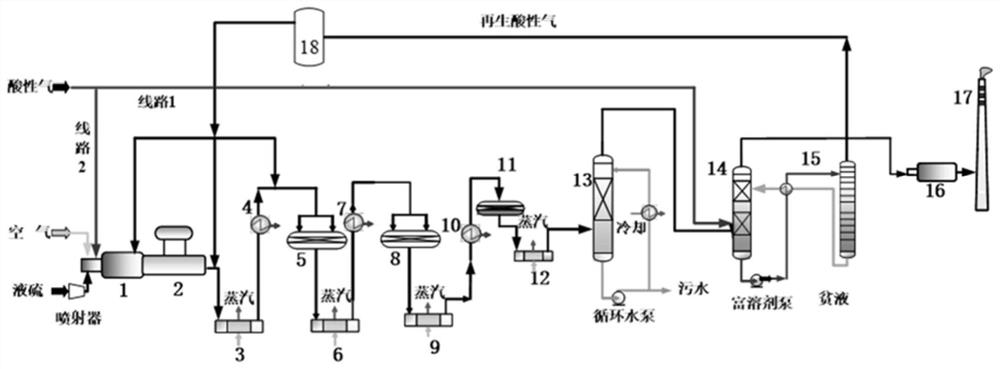

[0064] A 150,000-ton / year sulfur plant starts construction, and the start-up method is as follows: the acid gas generated by the upstream device is directly introduced into the absorption tower 14, that is, the line 1 is opened, the line 2 is closed, the temperature at the top of the absorption tower 14 is controlled to 35°C, and the incinerator 16 is ignited. , the incinerator adopts natural gas combustion to heat up, and the heating rate is 15°C / h. 2 When the S concentration reaches 6g / L, establish an amine liquid circulation regeneration system, control the temperature at the top of the regeneration tower 15 to 112°C, and the temperature at the bottom of the tower at 117°C, and the regenerated acid gas enters the acid gas buffer tank 18; when the buffer tank pressure reaches 20Kpa , start the liquid sulfur injector, the inert gas is used as power to carry the liquid sulfur into the sulfur furnace 1, and the air is distributed according to the complete combustion of the liqui...

Embodiment 2

[0079] A certain 80,000 tons / year sulfur plant starts construction, and the start-up method is as follows: after the upstream device produces acid gas, it is directly introduced into the absorption tower, the stage opens line 1 and closes line 2, the temperature at the top of the absorption tower is controlled at 25°C, the incinerator is ignited, and the incinerator The temperature is raised by natural gas combustion, and the heating rate is 10°C / h. When detecting and absorbing H in the tower amine liquid 2 When the S concentration reaches 8g / L, establish an amine liquid circulation regeneration system, control the temperature at the top of the regeneration tower to 115°C, and the temperature at the bottom of the tower at 120°C, and the regenerated acid gas enters the acid gas buffer tank; when the pressure of the buffer tank reaches 40Kpa, start Liquid sulfur injector, the inert gas is used as power to carry liquid sulfur into the sulfur furnace, and the air is distributed acc...

Embodiment 3

[0086] A 100,000-ton / year sulfur plant is started, and the start-up method is as follows: after the upstream device produces acid gas, it is directly introduced into the absorption tower, that is, line 1 is opened, line 2 is closed, the temperature at the top of the absorption tower is controlled at 30°C, the incinerator is ignited, and the incinerator adopts The temperature is raised by natural gas combustion, and the heating rate is 25°C / h. When detecting the absorption of H in the tower amine liquid 2 When the S concentration reaches 5g / L, establish an amine liquid circulation regeneration system, control the temperature at the top of the regeneration tower to 110°C, and the temperature at the bottom of the tower at 115°C, and the regenerated acid gas enters the acid gas buffer tank; when the pressure of the buffer tank reaches 35Kpa, start Liquid sulfur injector, the inert gas is used as power to carry liquid sulfur into the sulfur furnace, and the air is distributed accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com