Drying and calcining method for bulk material and device thereof

A material and calcination technology, applied in lighting and heating equipment, furnace materials, furnaces, etc., can solve the problems of serious wear of lining materials, low thermal efficiency, increased heat dissipation and power consumption investment and operating costs, etc., to achieve fast heating of materials, The effect of huge social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

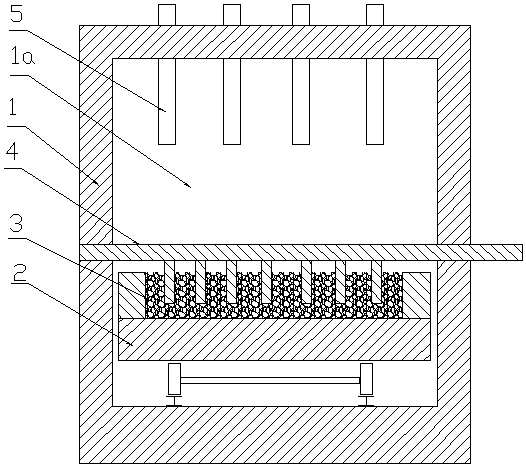

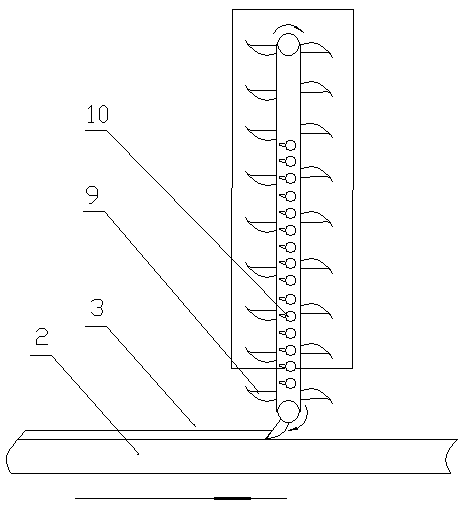

[0019] figure 1 In the process, the bulk material 3 with a certain thickness is continuously moved horizontally, and the bulk material 3 is repeatedly turned by a turning device (such as a plow) 4 fixed above it and inserted into the bulk material 3, so that the bulk material 3. It can quickly and evenly exchange heat with the external heat source or cold source, so as to achieve the purpose of drying, calcining and cooling the bulk material 3; On the kiln car 2, above it is a closed annular kiln cavity 1a; its material turning device 4, heating device 5, feeding and unloading device and flue gas outlet, etc. are installed on the fixed kiln wall or kiln roof, Thereby constitute a kind of annular horizontal rotary kiln.

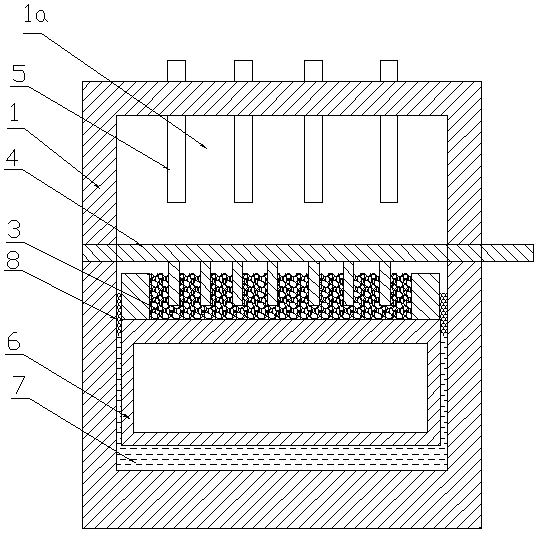

[0020] figure 2 In the process, the bulk material 3 with a certain thickness is continuously moved horizontally, and the bulk material 3 is repeatedly turned by a turning device (such as a plow) 4 fixed above it and inserted into the bulk material 3, so tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com