Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

121results about How to "Save coal consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for incinerating sludge by using kiln tail system of cement plant

InactiveCN104329675ALow investment costLow running costSludge treatment by de-watering/drying/thickeningClinker productionCombustionGas release

The invention discloses a method for incinerating sludge by using a kiln tail system of a cement plant. A sludge atomization nozzle mounted on the kiln tail system of the cement plant is used for spraying sludge with the moisture content being 70-85 percent; the sludge can be atomized in the kiln tail system; water in the sludge can be instantly evaporated to be a part of waste gas, and a combustible substance is used as fuel for combustion; combusted residues serving as a part of a cement raw material enters a rotary kiln and is calcined into a cement clinker. According to the method, the defects of an existing sludge dry incineration technology can be overcome; a high-temperature environment of a cement production system is used for performing dry incineration, and the sludge is also used; powder contained in the kiln tail system can effectively suppress and absorb harmful gas released in a sludge incineration process, and the cement production energy consumption and the production cost are effectively reduced; therefore the method is more practicable and has industrial utilization value.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

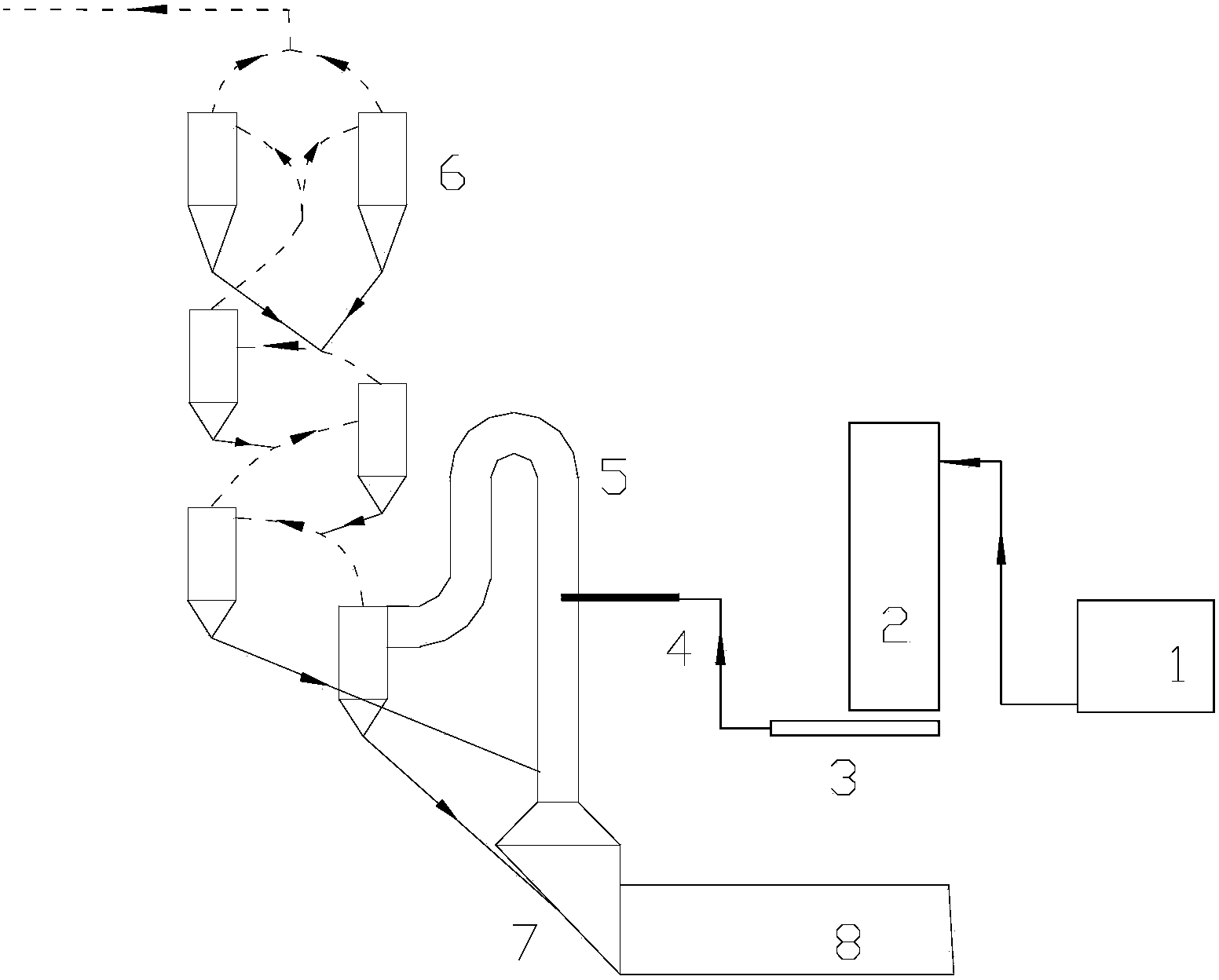

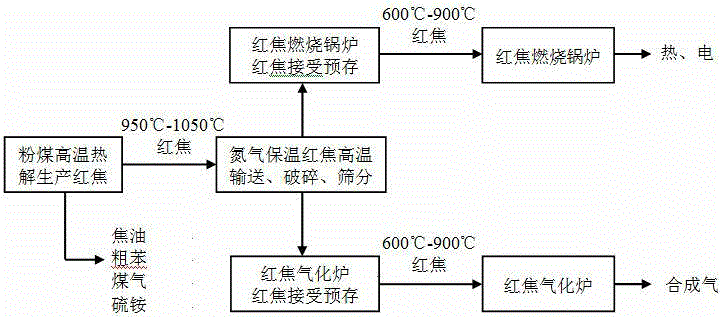

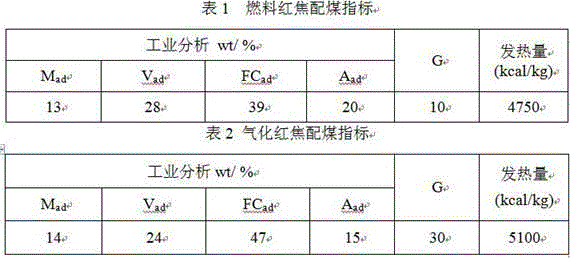

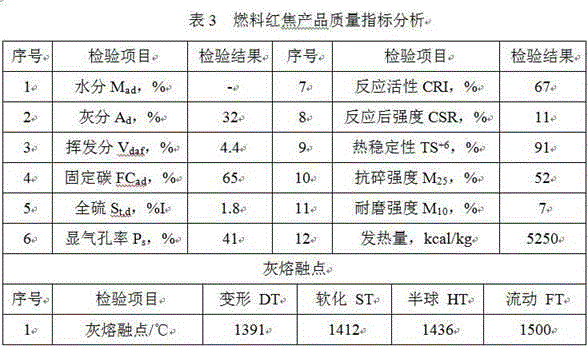

Method for directly using red coke obtained by high-temperature pyrolysis of pulverized coal

ActiveCN104449775AEasy to synthesizeInhibit synthesisChemical industryGasification processes detailsChemical industryRational use

The invention relates to a method for directly using red coke obtained by high-temperature pyrolysis of pulverized coal. The red coke, which is a product obtained by high-temperature pyrolysis of pulverized bituminous coal and lignite, is directly used as a clean cohesionless power fuel or a gasifying raw material at a starting temperature of 600 DEG C-900 DEG C and is respectively applied in a red coke combustion boiler and a red coke gasifying furnace for carrying out thermoelectric and gasification production processes. By the method, the domestic excess coking production capacity can be fully utilized and vitalized, the problems of irreversible heat loss and utilization of low-grade low-rank pulverized coal in the current conventional combustion of coal at home and abroad are solved, the purposes that the thermal efficiency of the power fuel is substantially increased and the carbon element in the gasifying raw material is efficiently utilized are achieved, the environmental pollution caused by water-quenching coke during the pyrolysis and upgrading of pulverized coal is avoided, multiple fields of power and chemical industry (smelting) are coordinated and taken into account, the coal-based polygeneration production process is further optimized, the entire system achieves the effect of rational use of energy and the method is in full compliance with the national requirements of the clean utilization of coal.

Owner:太原理工大学建筑设计研究院有限公司 +1

Coal slurry concentration increasing and industrial wastewater treating process and device

ActiveCN107312580AImprove liquidityReduce apparent viscosityLiquid carbonaceous fuelsGrain treatmentsIndustrial effluentEnergy consumption

The invention discloses a coal slurry concentration increasing and industrial wastewater treating process and device. The process comprises the following steps: (1) crushing coal, and then adding water and a dispersant for coarse grinding till the particle size is 50 microns or below, thus obtaining slurry 1; (2) performing shaping grinding on 25 to 35 weight percent of slurry 1 till the particle size is 20 to 30 microns, thus obtaining slurry 2, and pumping the residual slurry 1 serving as a water coal slurry product into a water coal slurry storage tank for gasification; (3) performing ultrafine grinding on 15 to 25 weight percent of the slurry 2 till the particle size is 5 to 10 microns, thus obtaining slurry 3, and conveying the residual slurry 2 and the newly obtained slurry 3 into the coarse grinding stage for coarse grinding, wherein after the coarse grinding in the step (1) and the steps (2) and (3) are repeatedly performed for multiple times, the aim of effectively increasing the concentration of the slurry 1 is fulfilled. In the concentration increasing process, used water can be replaced with industrial wastewater. According to the coal slurry concentration increasing and industrial wastewater treating process disclosed by the invention, the concentration of the coal slurry can be increased by at least 3 percent; the gasification energy consumption can be substantially reduced; the coal slurry concentration increasing and industrial wastewater treating process has the characteristics of safety, reliability, convenience in improvement and obvious economical benefits.

Owner:HUBEI YIHUA CHEMICAL INDUSTRY CO LTD

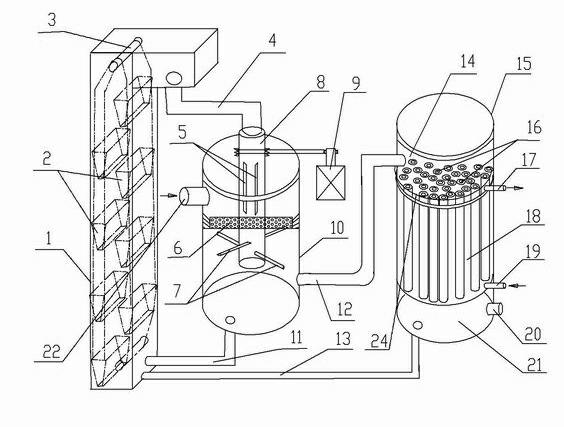

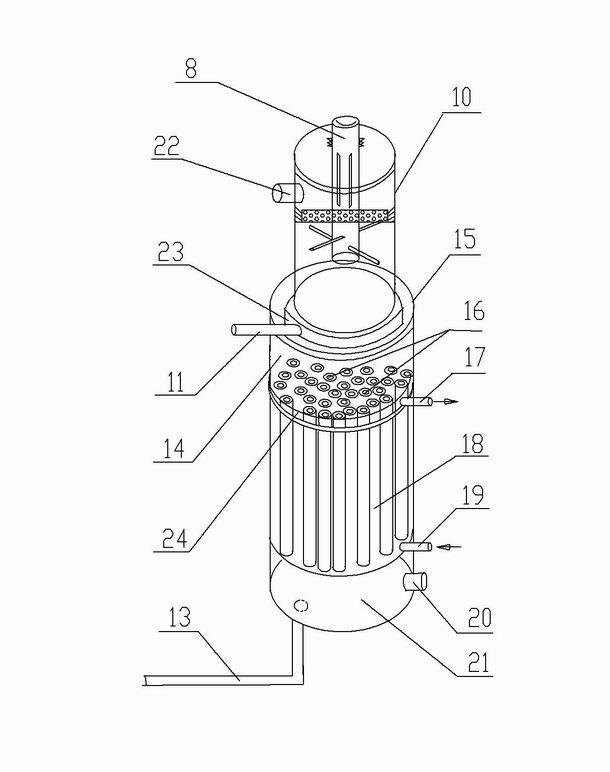

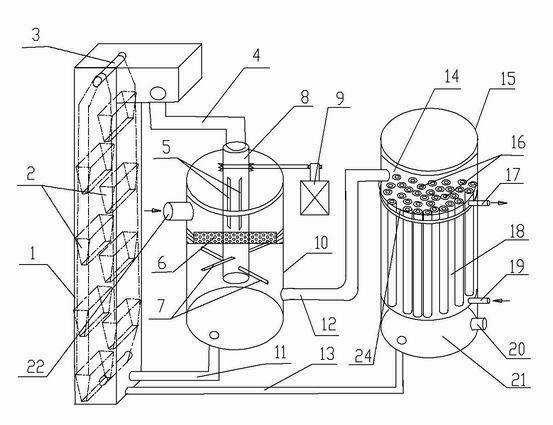

Boiler combustion smokeless zero-sewage sulfur-extraction energy-saving combining machine

InactiveCN102553385AReduce dosageSave coal consumptionCombination devicesUsing liquid separation agentCombustionDistillation

The invention relates to a boiler combustion smokeless zero-sewage sulfur-extraction energy-saving combining machine which comprises three parts including a sewage circulation elevator, a smoke comprehensive water processor and a distillation smoke cooler, wherein the sewage circulation elevator is internally provided with a lifting bucket; a smoke inlet pipe is arranged at the side of the smoke comprehensive water processor, and a backflow sewage pipe is arranged at the bottom of the smoke comprehensive water processor; a hollow shaft is inserted into the cavity of the smoke comprehensive water processor; a water inlet arranged at the upper end of the hollow shaft is connected with the sewage circulation elevator by a water pipe; a vertical groove is formed at the side of the hollow shaft; a stirring rod is arranged under the vertical groove; an opening at the side at the lower end of the stirring rod is connected with the side at the upper end of the distillation smoke cooler by a pipeline; a smoke cavity is arranged at the upper end of the distillation smoke cooler, a water cooler is arranged in the middle of the distillation smoke cooler, and a discharge cavity is arranged at the lower part of the distillation smoke cooler; the water cooler is internally provided with a cooling pipe; an opening at the bottom of the discharge cavity is connected with the lower end of the sewage circulation elevator by a pipe; and an opening at the side of the discharge cavity at the lower end of the sewage circulation elevator is connected with a boiler draught fan by a pipeline. The boiler combustion smokeless zero-sewage sulfur-extraction energy-saving combining machine has the advantages that no sewage is discharged, and energy is saved by 30%, and is environment-friendly and sanitary.

Owner:WUHAN UNIV OF SCI & TECH

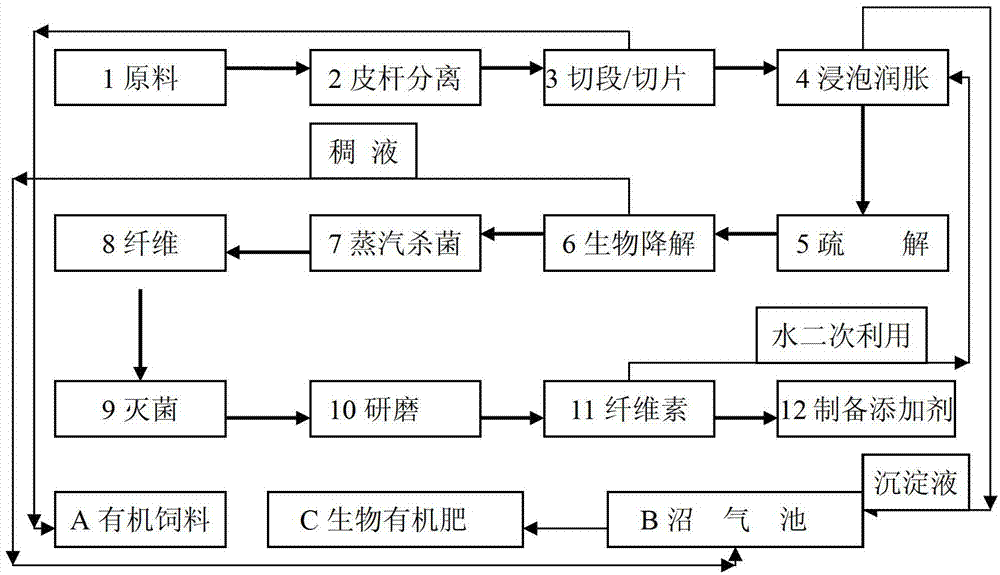

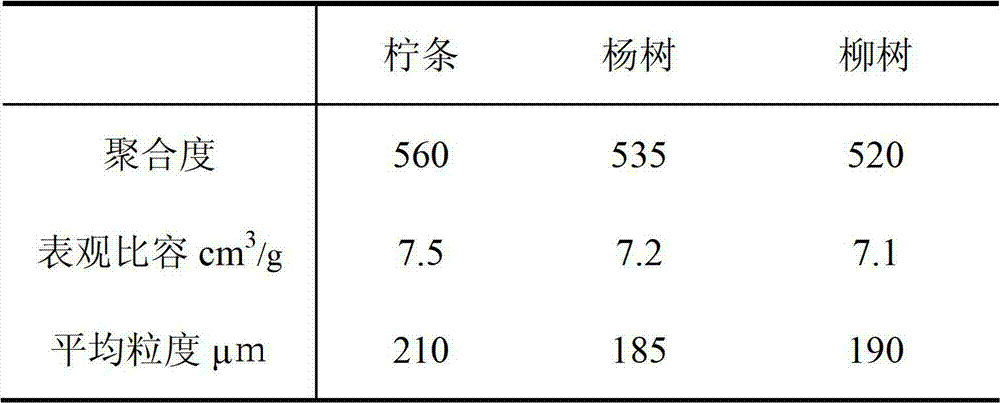

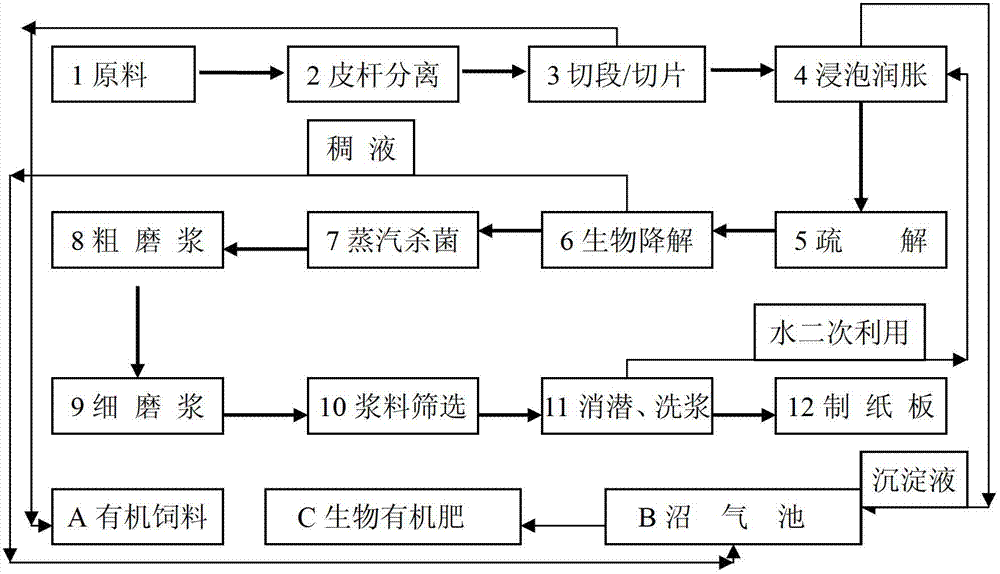

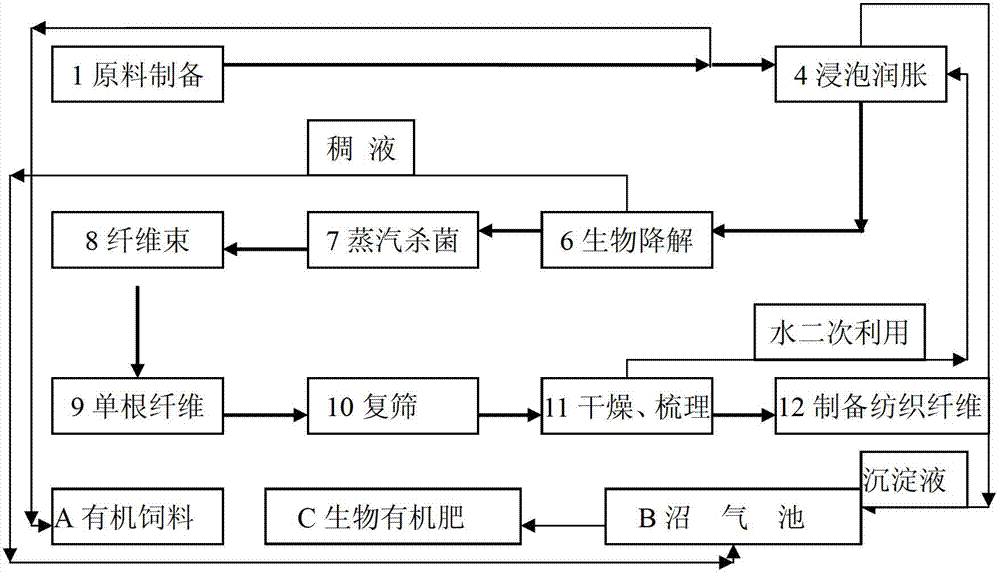

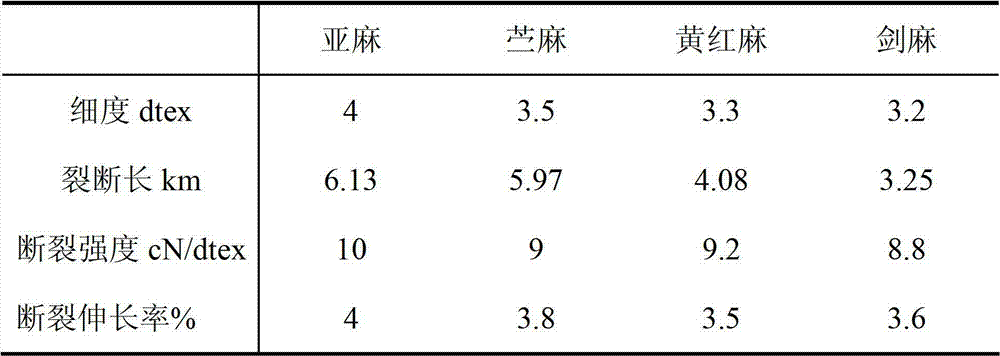

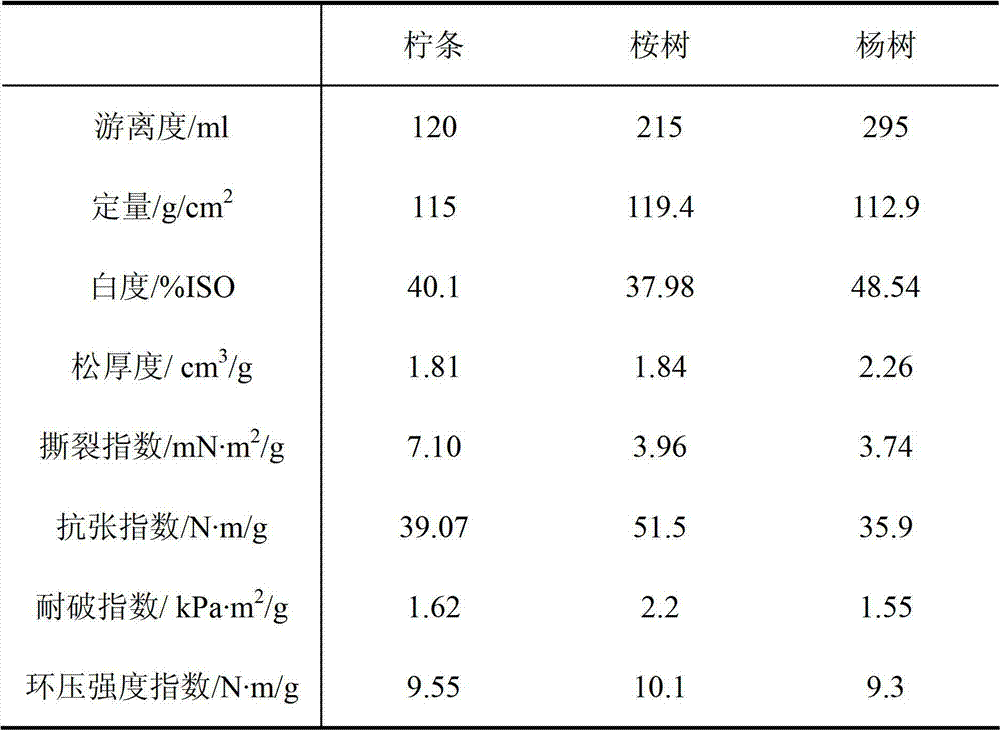

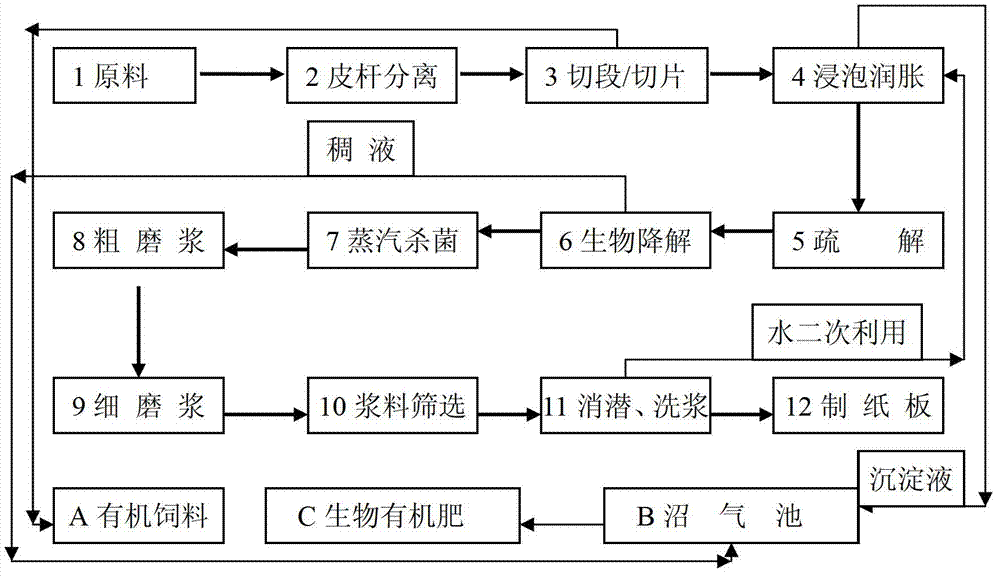

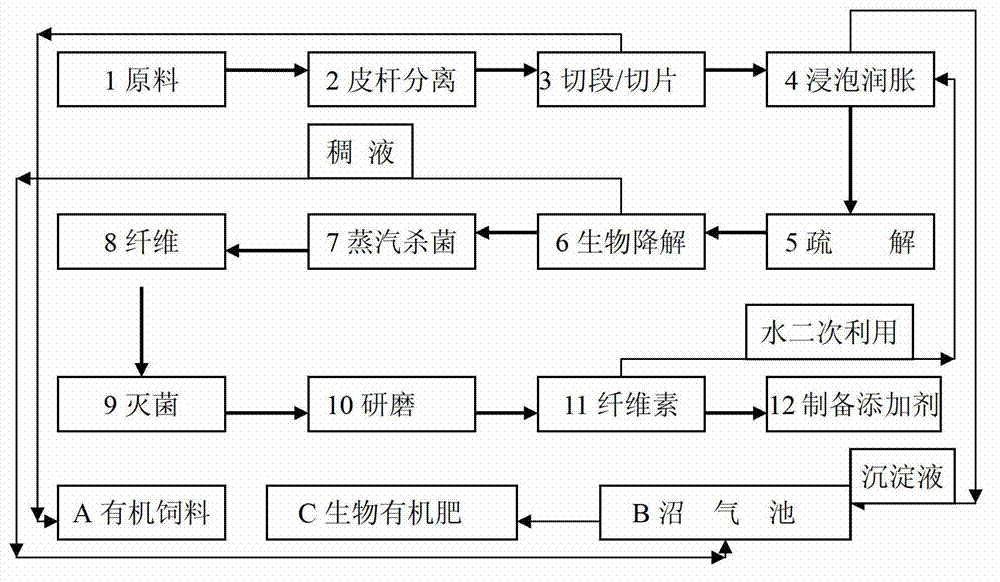

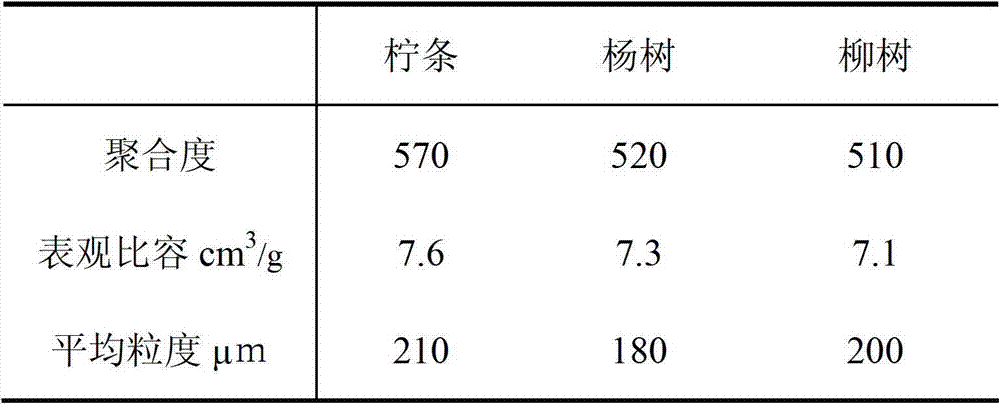

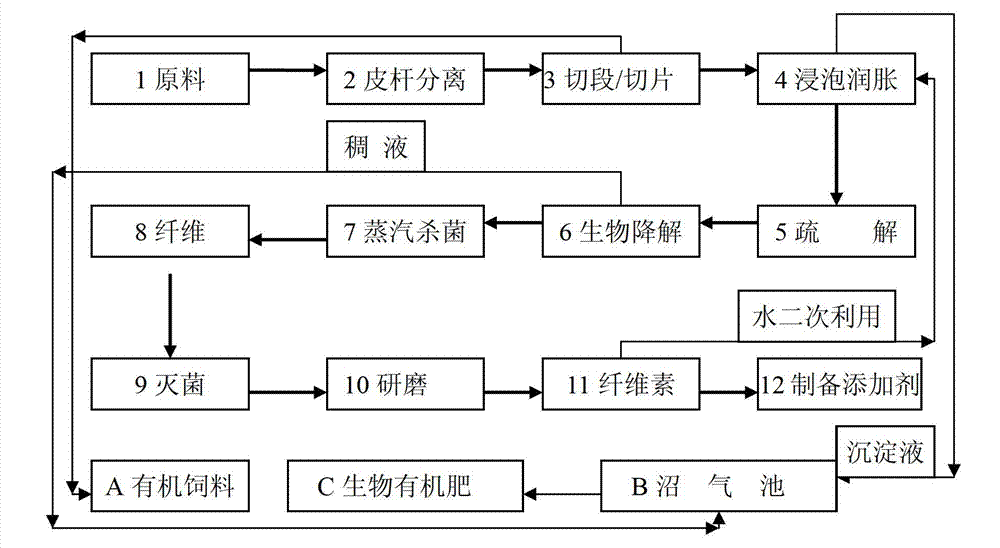

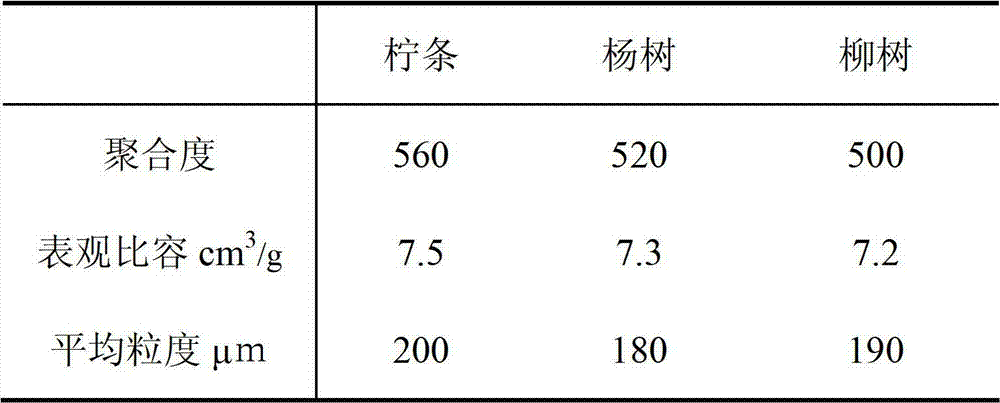

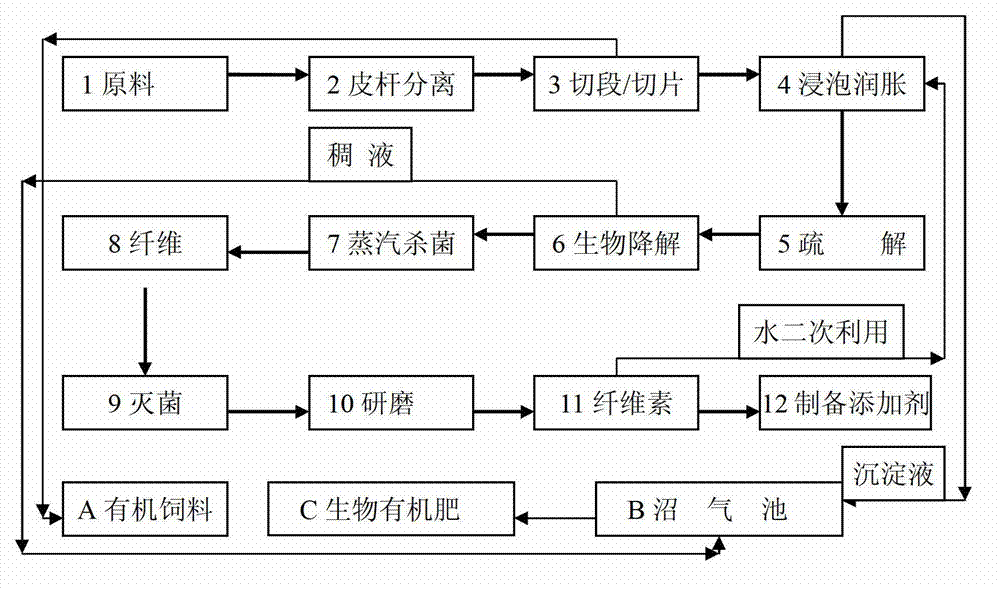

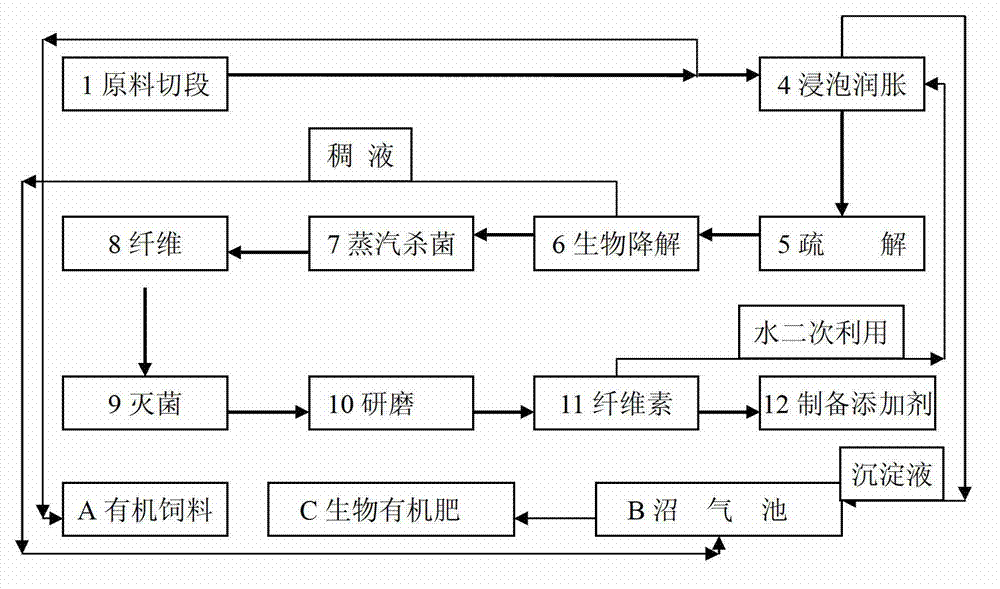

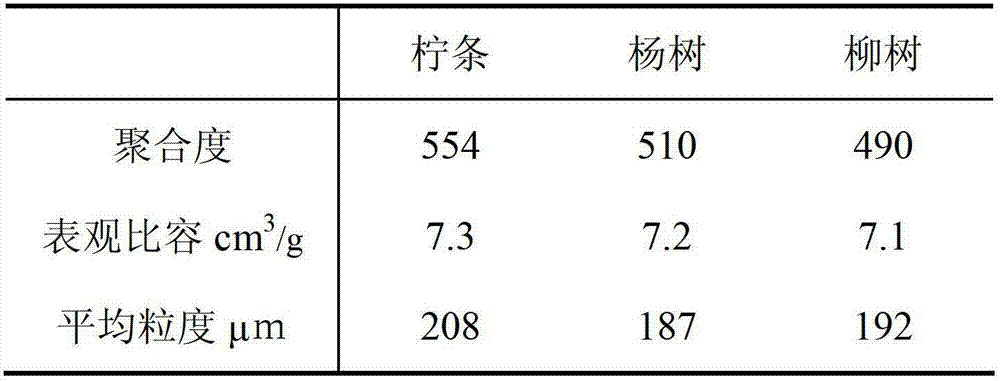

Biological flora and method for preparing cellulose for additive through same

InactiveCN102888338APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberCellulose

The invention relates to biological flora and a method for preparing cellulose for an additive through the biological flora. The composite flora comprises bacillus stored with the number of CGMCC (China General Microbiological Culture Collection Center) No. 5971, rheinheimera tangshanensis stored with the number of CGMCC No.5972, acinetobacter lwoffii stored with the number of CGMCC No. 5973, pseudomonas fluorescens stored with the number of CGMCC No. 5974 and Wickerhamomyces anomalus stored with the number of CGMCC No. 5975. The method comprises the steps as follows: preparing bacteria liquid; processing raw materials; and preparing fibers: difibering, biologically degrading, sterilizing through steam, obtaining fibers, sterilizing and grinding. The method provided by the invention is environment-friendly; and the waste liquid is directly transformed into organic fertilizer, therefore, zero release and zero pollution are achieved. The biological process performs protection to the fibers. Compared with traditional chemical method, the method provided by the invention has the advantages of low producing cost, high economic benefit, and capabilities of saving the energy and protecting the environment.

Owner:BEIJING TIANAN BIOSCI & TECH

Method for drying and burning sludge via cement plant kiln tail system

InactiveCN104315523ALow investment costLow running costSludge treatment by de-watering/drying/thickeningNature of treatment waterSludgeEngineering

The invention discloses a method for drying and burning sludge via cement plant kiln tail system, the method comprises the steps as follows: firstly spraying the sludge, the water content of which is 70-85% into the cement plant kiln tail humidifier tower through the atomizing nozzle, the smoke of the temperature of 250-400 degrees centigrade discharged from the cement plant kiln tail gets into the humidifier tower from the top; the sludge is dried by the high temperature smoke in the kiln tail humidifier tower and transmitted to the kiln tail burning system as the fuel of the cement producing system, the burned residue is used as the cement raw material and transmitted to the rotary kiln to be burned into the cement clinker; the method for drying and burning sludge via cement plant kiln tail system can overcome the defect of the prior sludge drying and burning technology, the dust in the waste gas can effectively absorb the harmful gas generated by the sludge drying process, the high temperature environment of the cement producing system for drying and burning and the sludge is used, the cement producing energy consumption and producing cost can be effectively reduced, the method is practical and has industrial use value.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

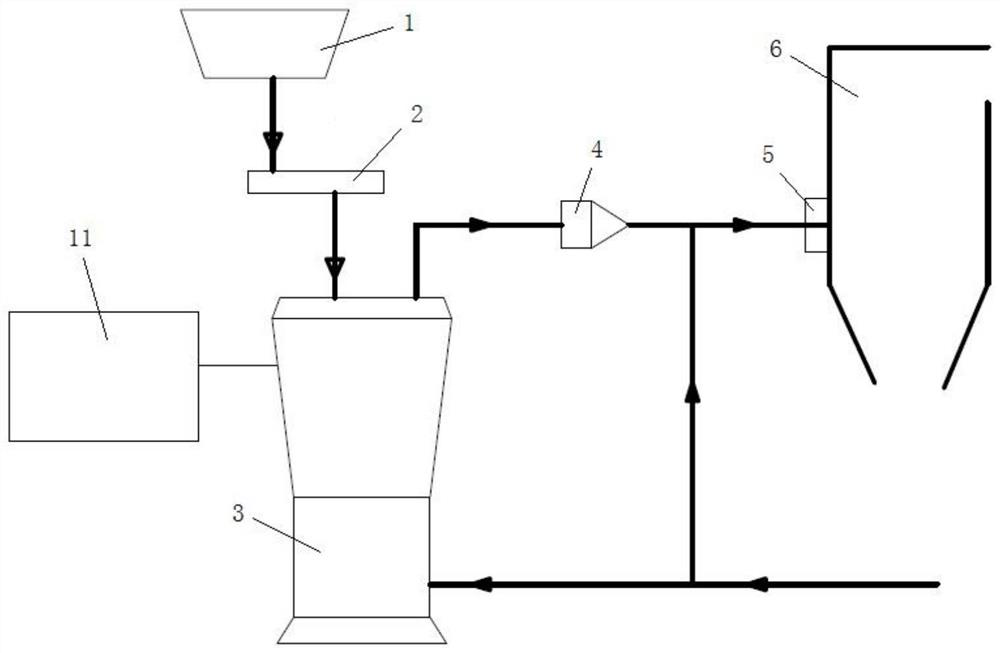

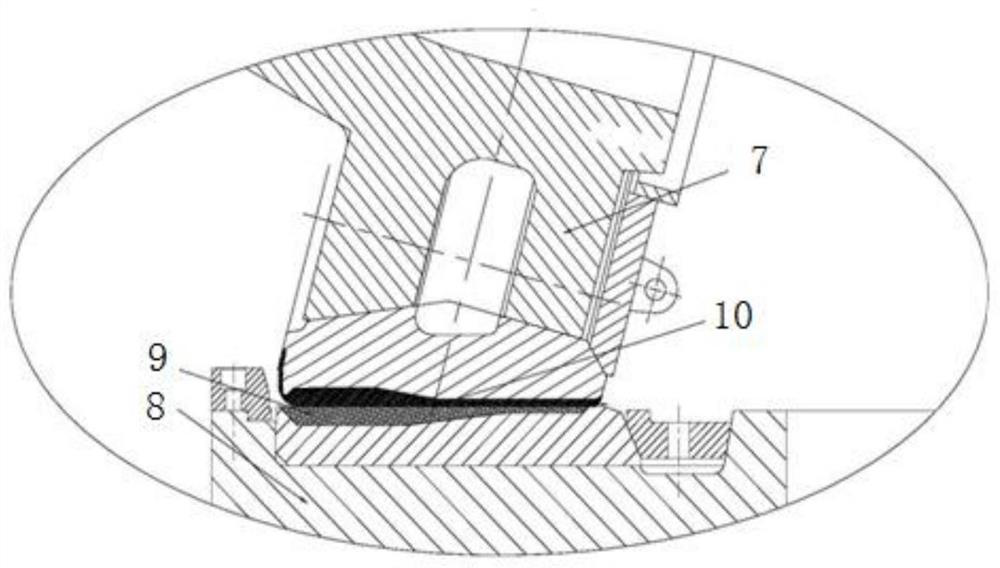

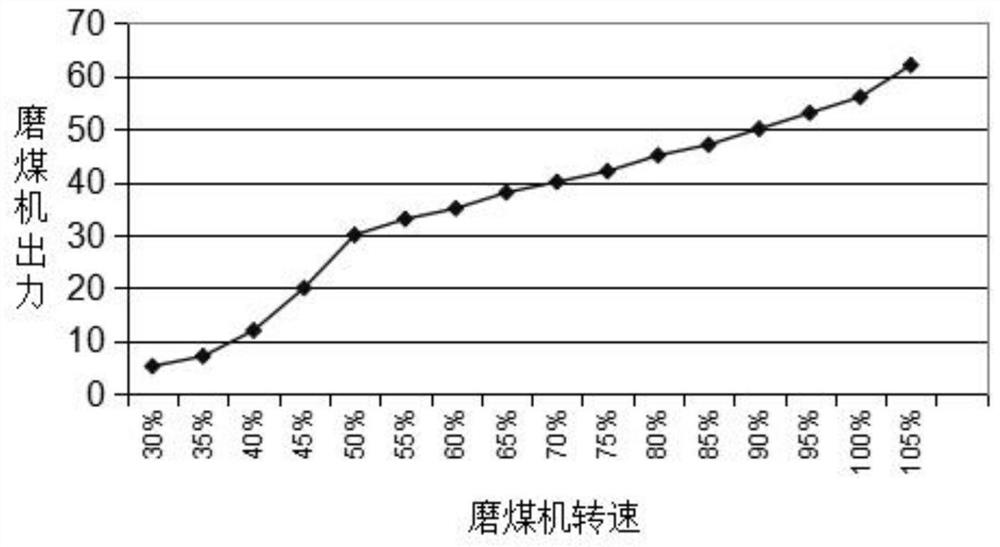

Method for controlling output of coal mill in ignition process of boiler

ActiveCN112354672AControl speedHas the ability to restoreSolid fuel pretreatmentGrain treatmentsCombustorPower station

The invention discloses a method for controlling the output of a coal mill in the ignition process of a boiler. According to the method, in the starting ignition process of the boiler of a power station, a raw coal hopper supplies raw coal to a coal feeder, the coal feeder quantitatively supplies the raw coal to the coal mill, the coal mill grinds the raw coal into pulverized coal which is carriedinto a separator by primary air, qualified pulverized coal is screened by the separator, is brought into a combustor by the primary air, and enters a boiler hearth through a nozzle of the combustor to be combusted; the output of the coal mill can be adjusted through adjustment of the rotating speed of the coal mill according to the positive correlation between the rotating speed of the coal milland the output; a high-voltage variable-frequency speed regulation device is used for controlling the rotating speed of the coal mill, so that the rotating speed can be continuously increased and decreased in the one-time ignition process, and the rotating speed of the coal mill is controlled to be changed according to different stages of ignition. According to the method, the high-voltage variable-frequency speed regulation device is used for controlling the rotating speed of the coal mill, continuous change of the rotating speed of the coal mill can be controlled without modifying the interior of the coal mill, and the reduction capacity and the regulation capacity are achieved.

Owner:INNER MONGOLIA JINGNENG KANGBASHI THERMAL POWER CO LTD +1

Multiple circular fume tube type energy-saving furnace for heating and cooking

InactiveCN101126511ATake advantage ofIncrease the heating areaLighting and heating apparatusStove/ranges for heating waterHeating effectHearth

The invention discloses an energy-saving heating furnace which has a plurality of round flue tubes and consists of a furnace shaft and a heat booster; the heat booster comprises an outer layer, a plurality of round flue tubes, a top cover and a sealing door; the outer layer takes a shape a cylinder, the round flue tubes are arranged inside the outer layer and a heat booster water jacket is formed between the round flue tubes and the outer layer; the furnace shaft comprises a pedestal, a top tray, a furnace shaft water jacket and a thin curving water pipe which is wrapped in a hearth; the thin curving water pipe is communicated with the furnace shaft water jacket which is communicated with the heat booster water jacket. The invention can make full use of the energy source and has large heating area, good heating effect, the coal consumption is low, thus energy can be saved by 70 percent at least; the invention has long service life owing to the adoption of the stainless steel.

Owner:王德玉

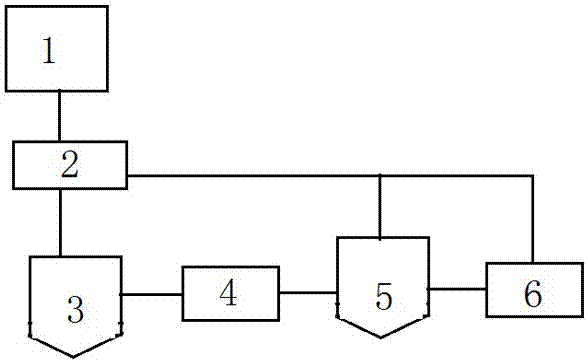

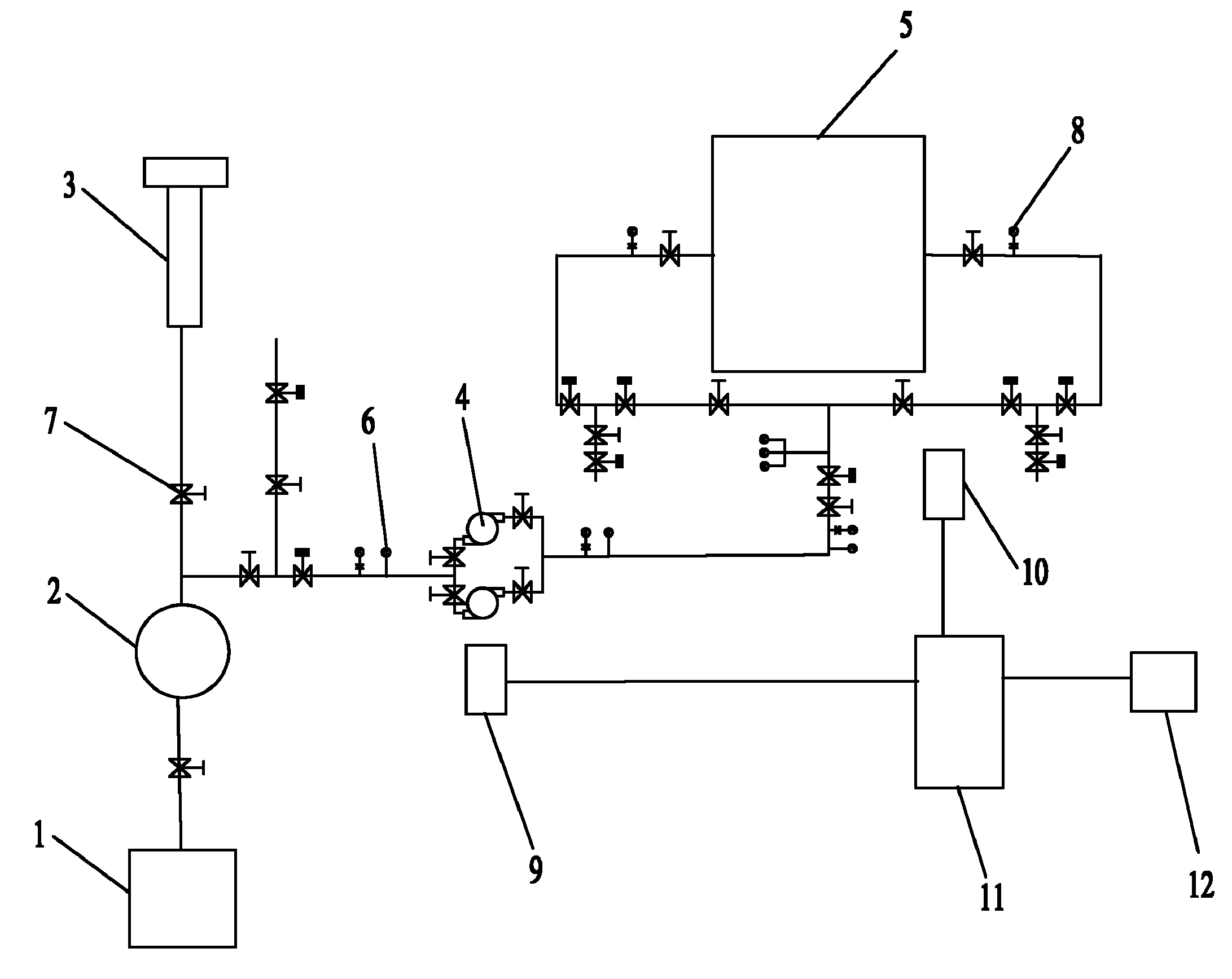

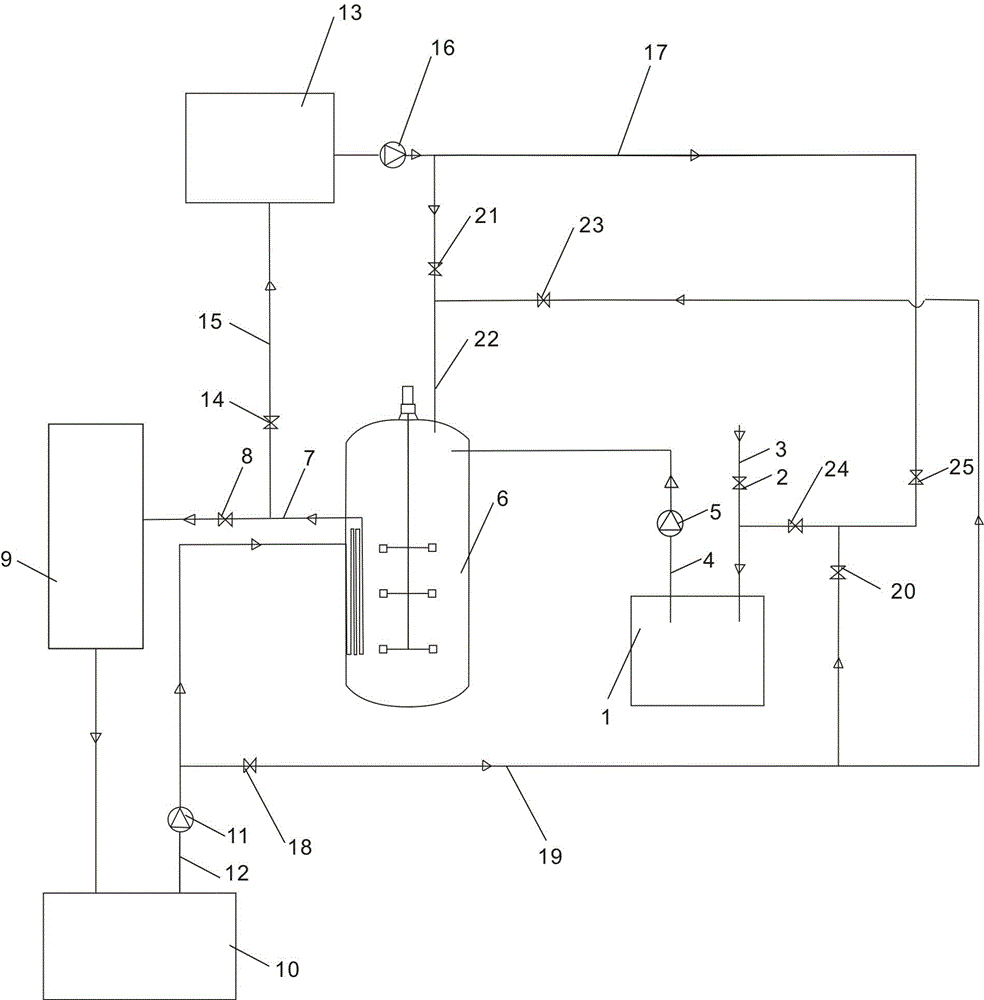

System for recycling biogas

InactiveCN102153193AImprove securitySave coal consumptionWaste based fuelTreatment with anaerobic digestion processesSulfur dioxideCoal

The invention relates to the technical field of biogas recovery, in particular to a system for recycling biogas. The system for recycling the biogas comprises a sewage station anaerobic treatment system, a biogas storage tank, a torch, a roots blower and a boiler, wherein an outlet of the sewage station anaerobic treatment system is communicated to an inlet of the biogas storage tank through a pipeline; an outlet of the biogas storage tank is communicated to an inlet of the torch through a pipeline; the outlet of the biogas storage tank is communicated to an inlet of the roots blower through a pipeline; and an outlet of the roots blower is communicated to the boiler through a pipeline. In the invention, biogas generated by the sewage station anaerobic treatment system is pressurized by the roots blower and then is inducted into the boiler to be burnt, so that not only can the explosion phenomenon caused by the biogas discharged into air be avoided and the safety of biogas utilization be improved, but also the value that the biogas is used as energy is sufficiently utilized and the coal using amount of the boiler is reduced. Moreover, sulfur dioxide generated when the biogas is burnt can be desulfurized through a desulfurization system of the boiler, so as to fulfill the aim of reducing emission.

Owner:LEE & MAN PAPER MFG

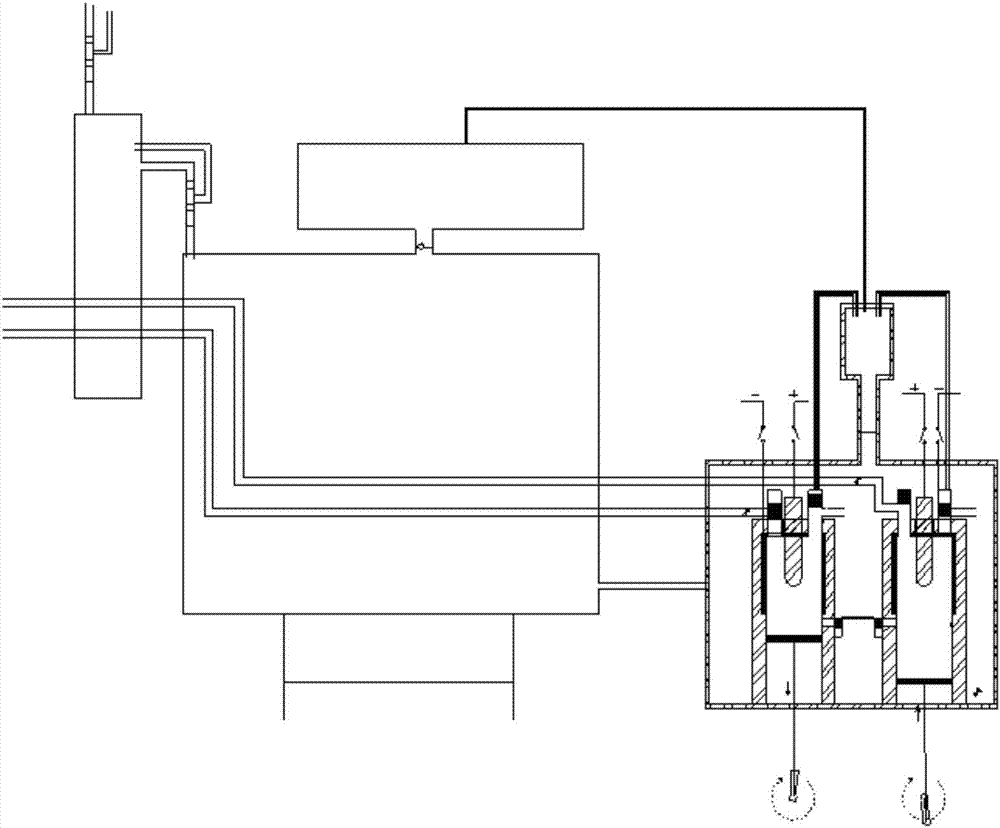

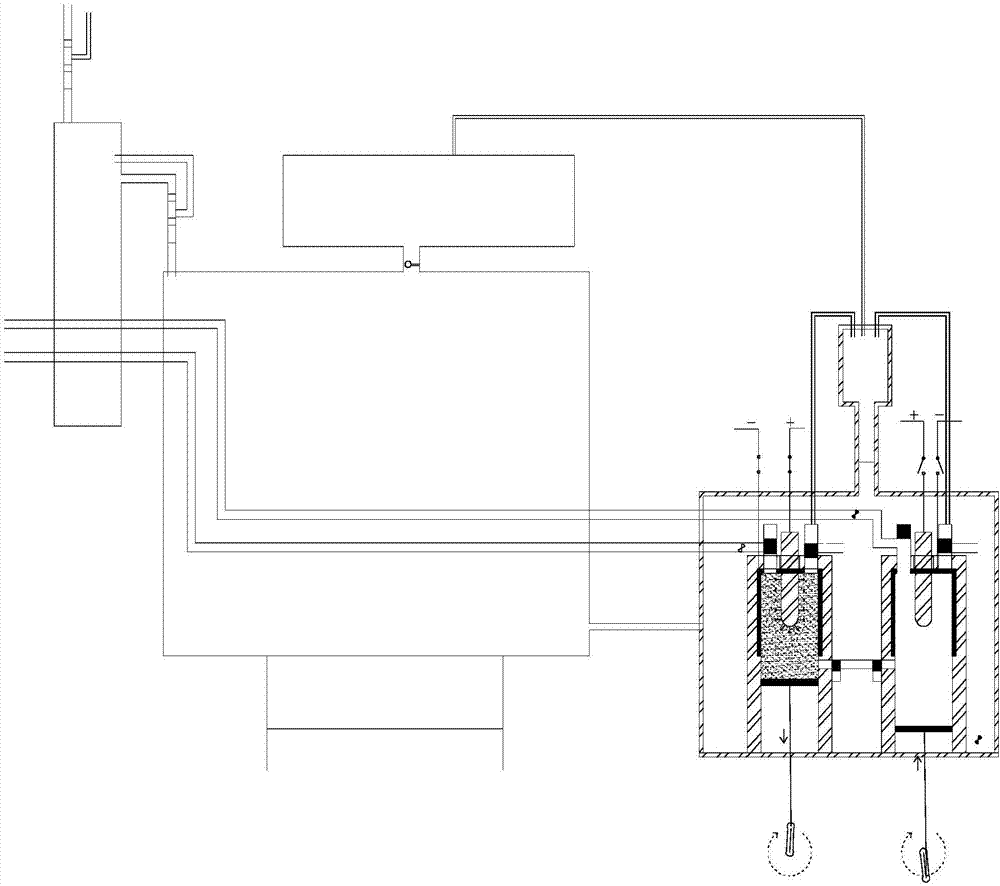

Coal-fired power generation system of coal-fired power plant

PendingCN107313810AEfficient use ofIncrease profitEngine componentsEngines characterised by uniflow principleSprinkler systemEngineering

The invention discloses a coal-fired power generation system of a coal-fired power plant. The coal-fired power generation system of the coal-fired power plant comprises a water replenishing tank, a water heating tank, a high-pressure water tank, a boiler, an electricity storage and supply system, ionization chambers, pistons which are arranged in the ionization chambers, power output mechanisms which are in transmission connection with the pistons, a power generator which is connected with the power output mechanisms, water spraying systems which are used for spraying the water in the water tank into the ionization chambers, and a controller which is used for controlling the electricity storage and supply system and the water spraying systems; both the two ionization chambers are arranged in the high-pressure water tank; a first high-pressure air cylinder is arranged at the upper end of the high-pressure water tank; the two ionization chambers are communicated with each other through a second high-pressure gas pipe and a first high-pressure gas pipe respectively; high-pressure high-temperature ionization gas in the two ionization chambers provides pressure for the high-pressure water tank through the first high-pressure air cylinder. Through the arrangement, the coal-fired power generation system of the coal-fired power plant provided by the invention has the advantages that the coal-fired power generation system of the coal-fired power plant is energy-saving and environment-friendly, and the energy resource utilization rate is effectively improved.

Owner:杨甫在

Efficient direct-heating dryer for powdery materials

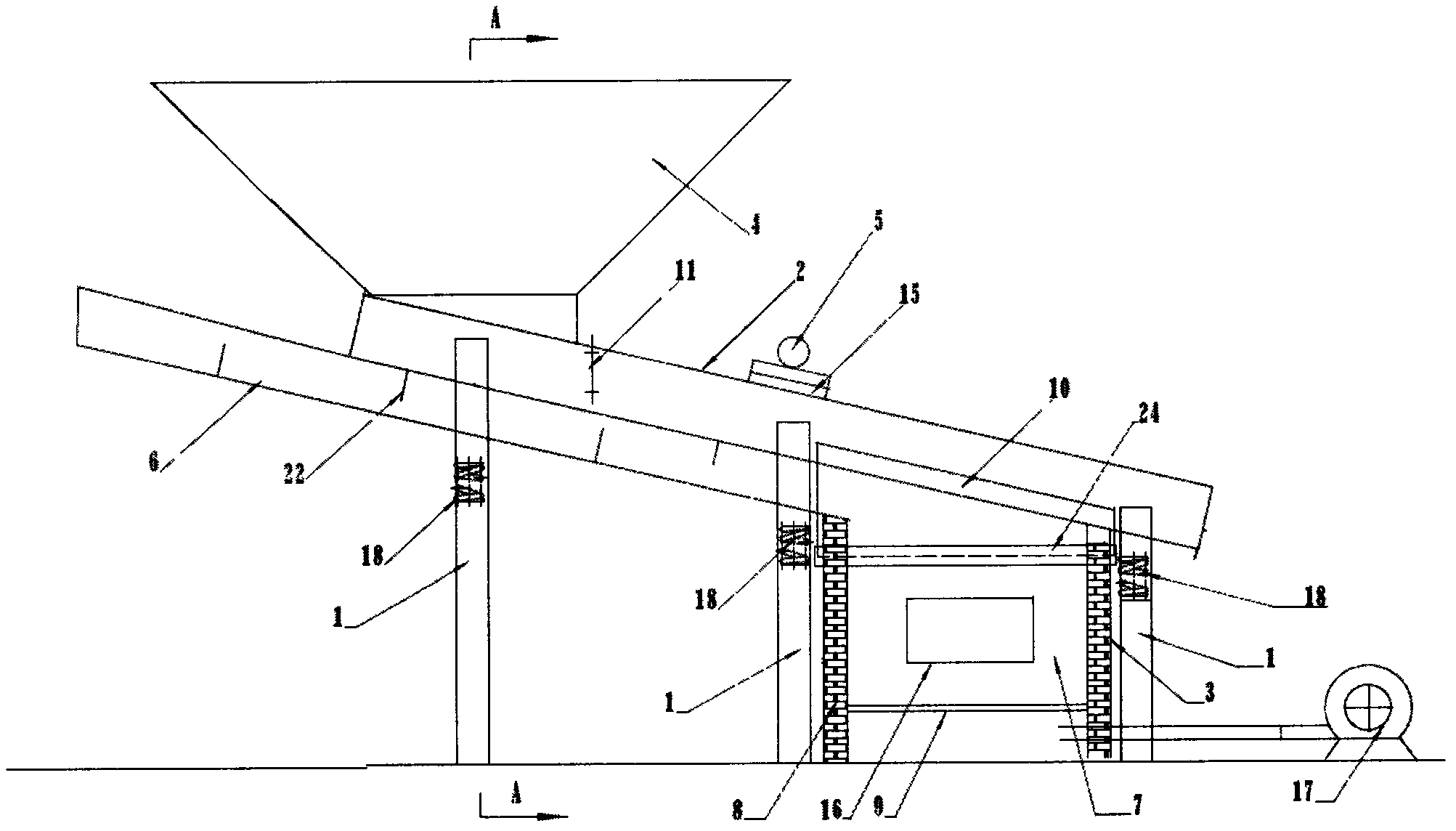

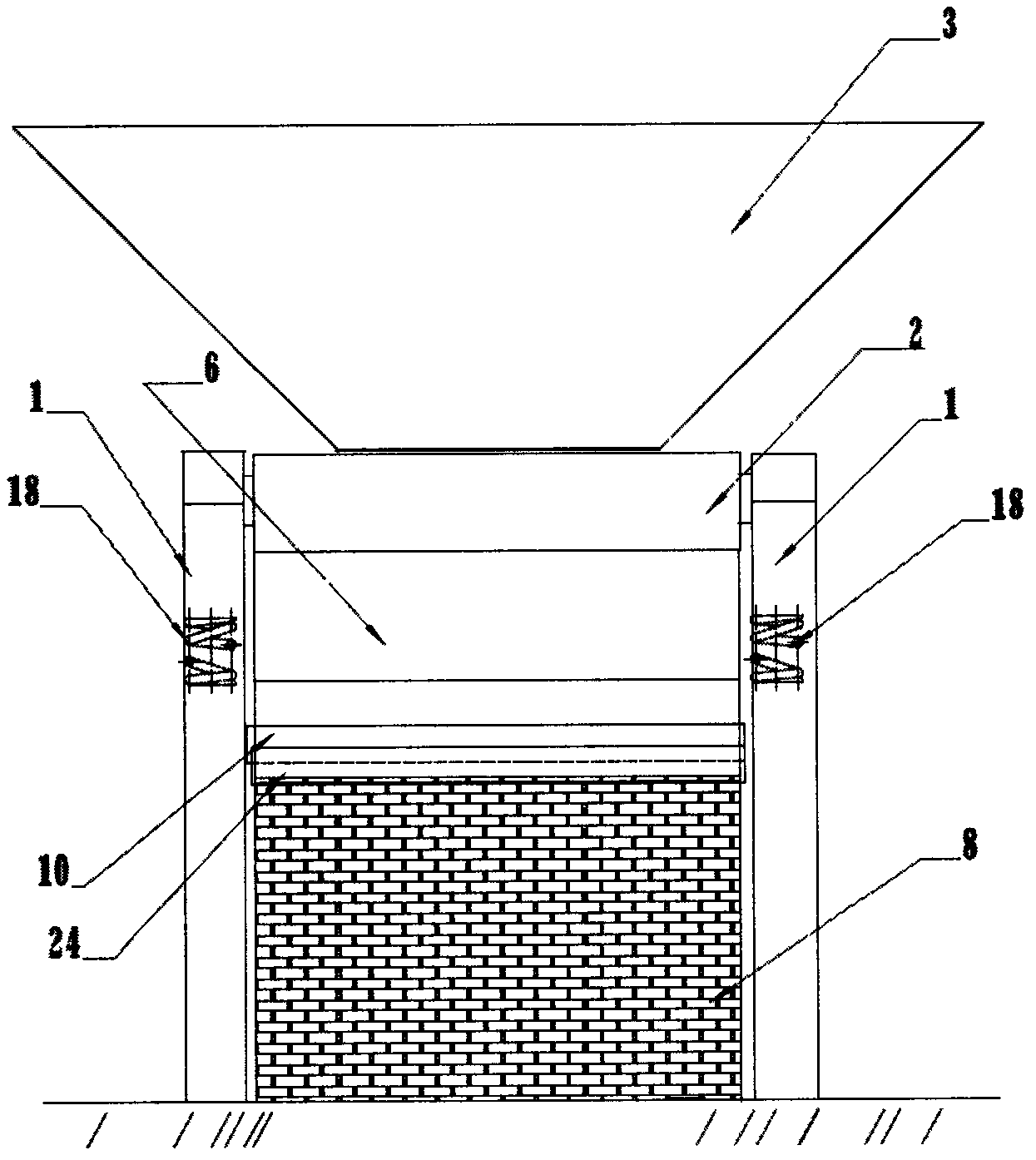

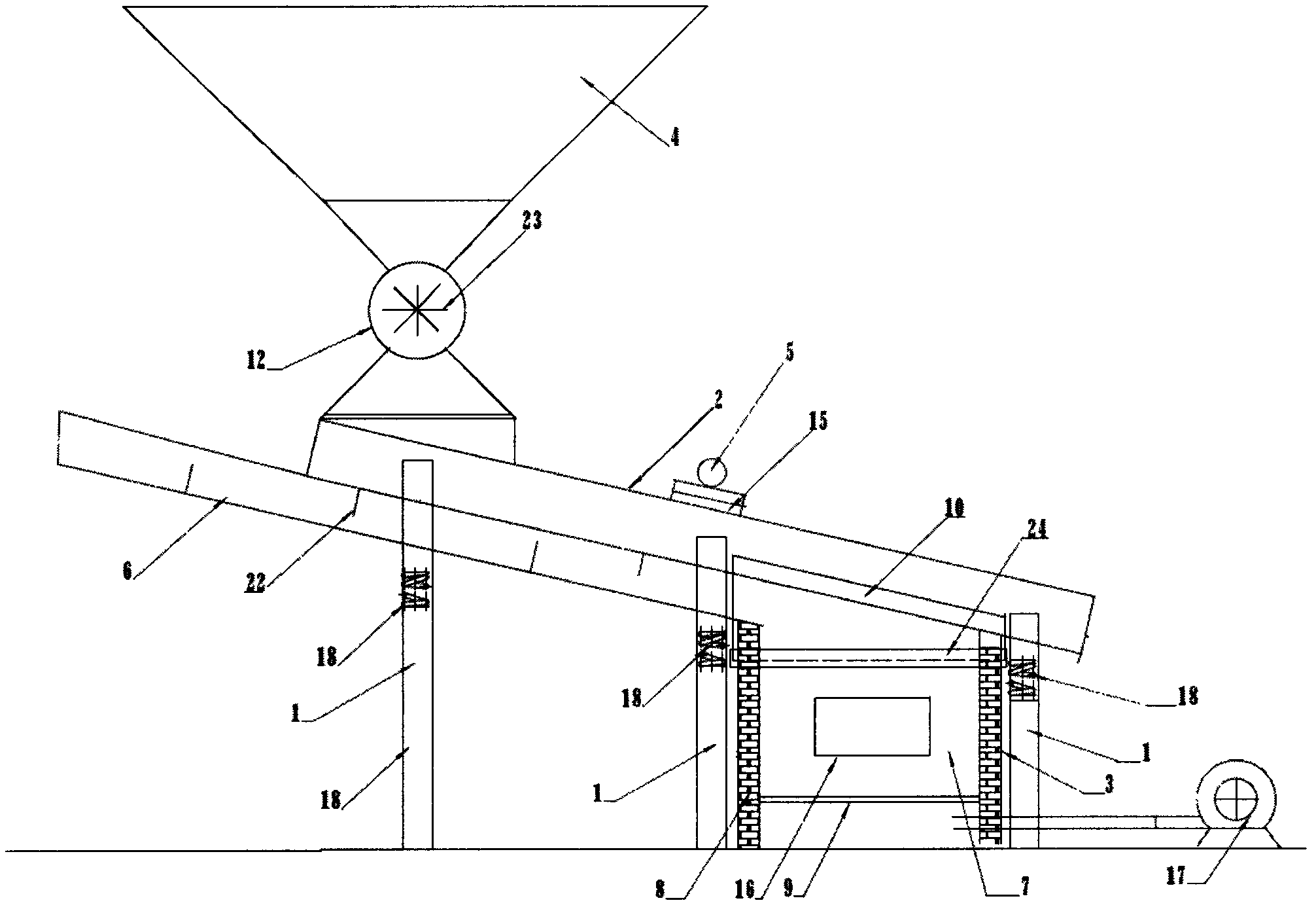

ActiveCN103234338ASimple structureFully evaporatedDrying solid materialsHeating arrangementEngineeringRadiant heat

A dryer for powdery materials is particularly suitable for drying moisture-containing mineral aggregates after mineral dressing. The dryer comprises a bearing column, a groove-shaped inclined chute is arranged on a column support, and an included angle formed by the inclined chute and the horizontal line is in a range of 7-30 degrees; a heating cavity is positioned below the inclined chute and capable of providing heat to heat the inclined chute, and the heated inclined chute dries mineral aggregates; and the heating cavity is provided with a chimney, and the top of the inclined chute is connected with a feeding hopper. The dryer is simple in structure and can be disassembled easily, the heat source is fully utilized, and radiant heat can be fully utilized when combustible substances are used for heating the inclined chute.

Owner:滨州市科创孵化器有限公司

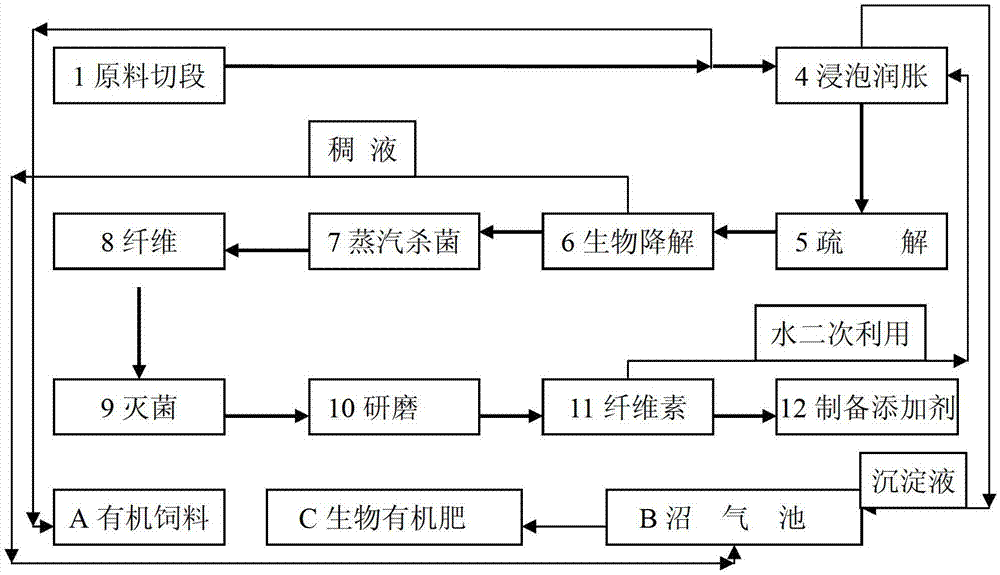

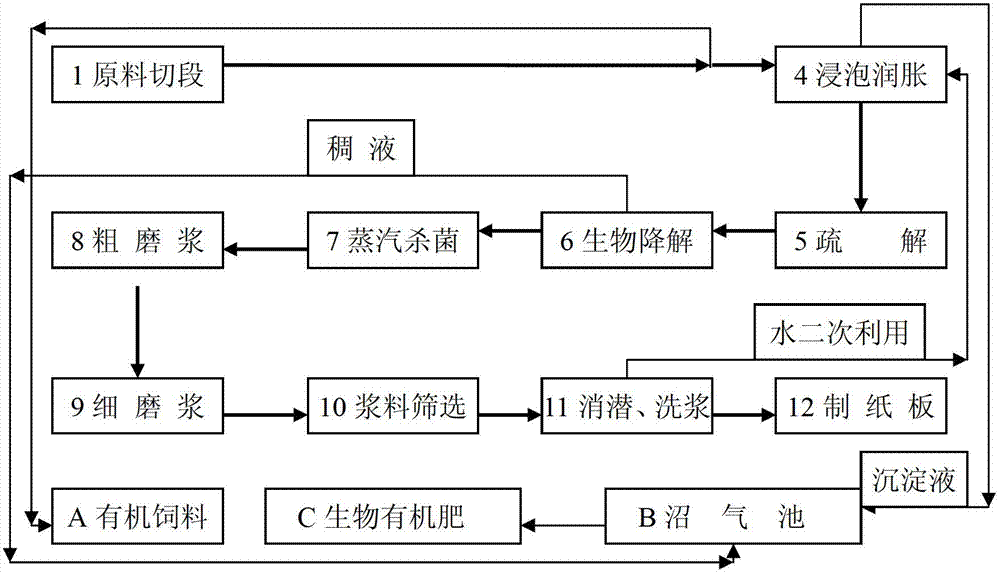

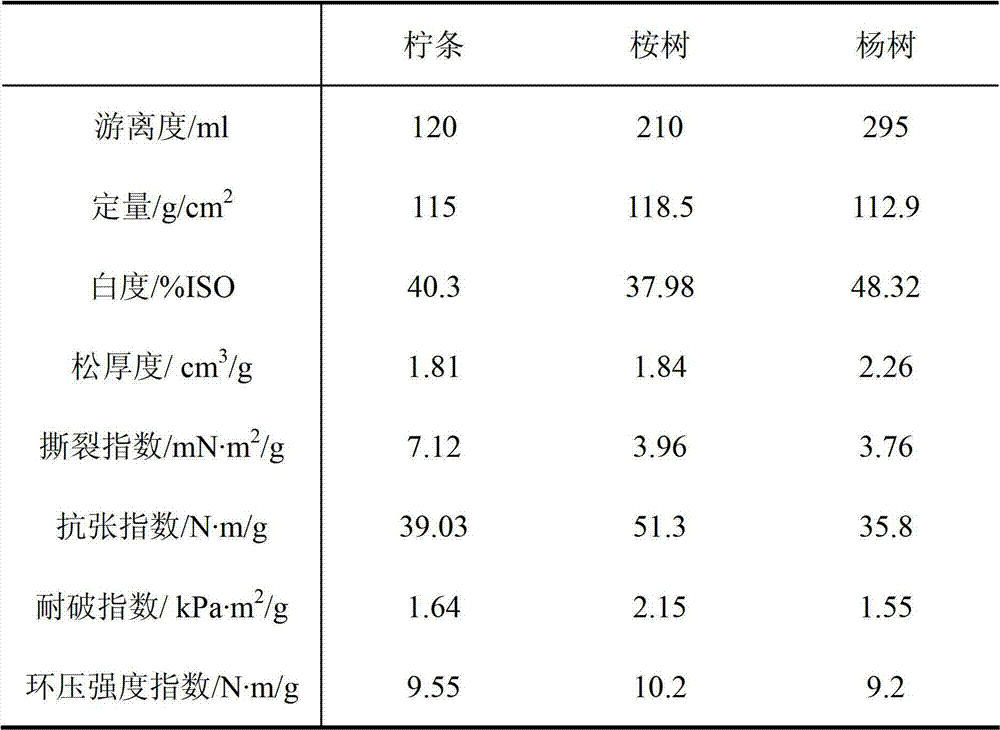

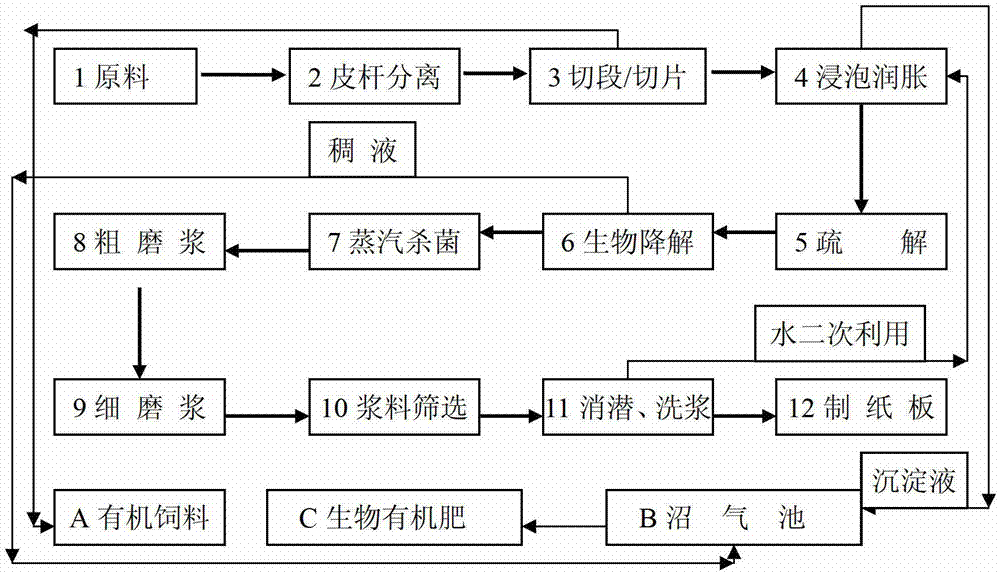

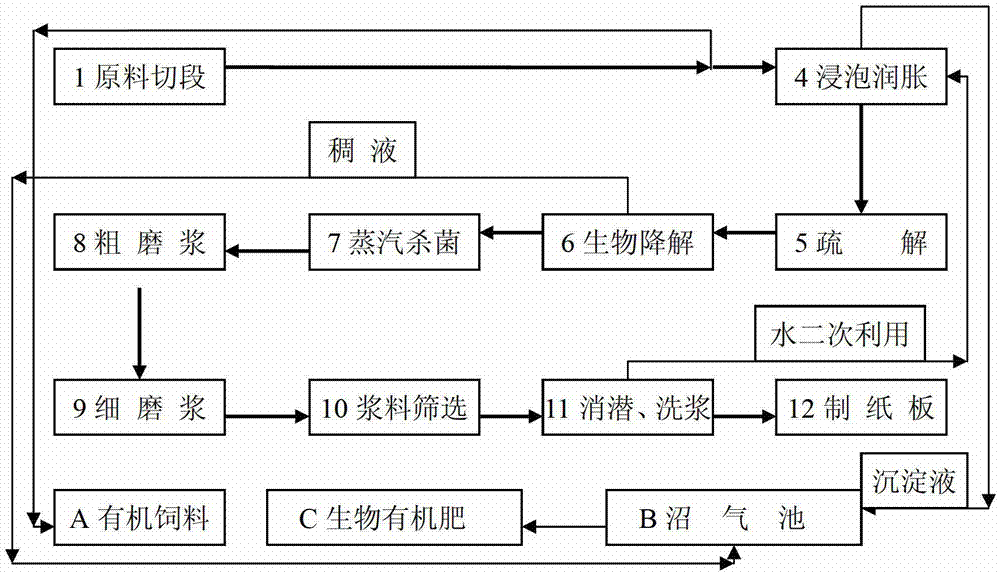

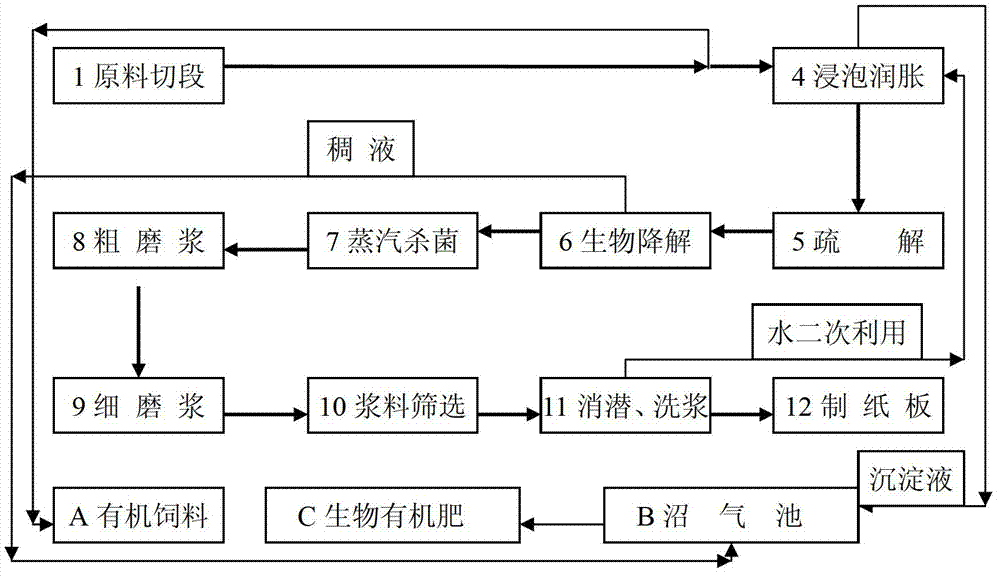

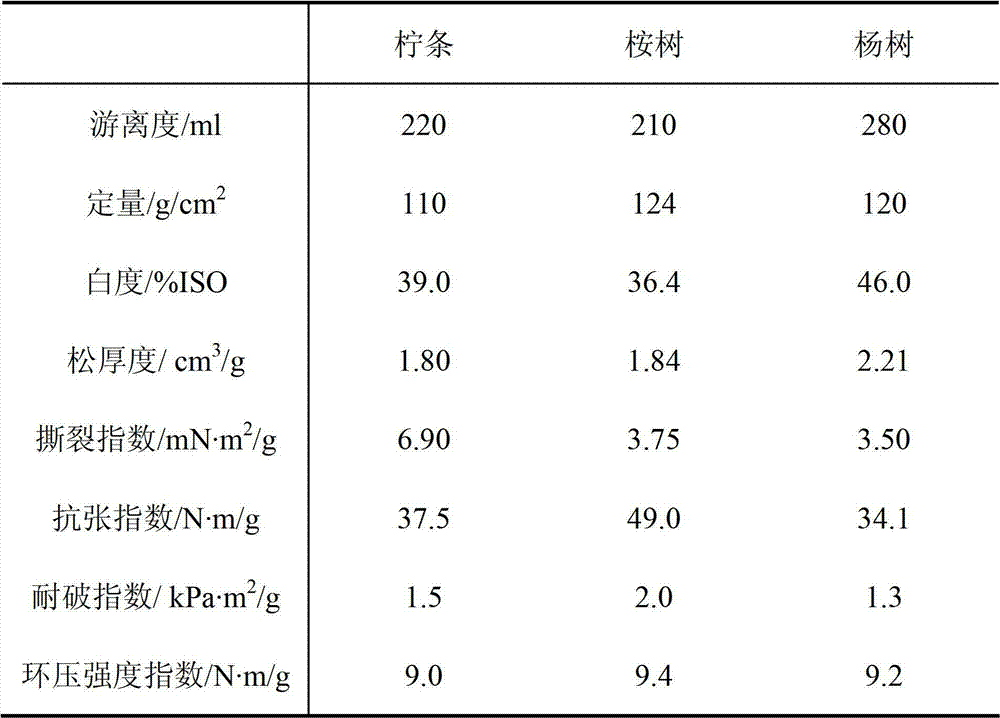

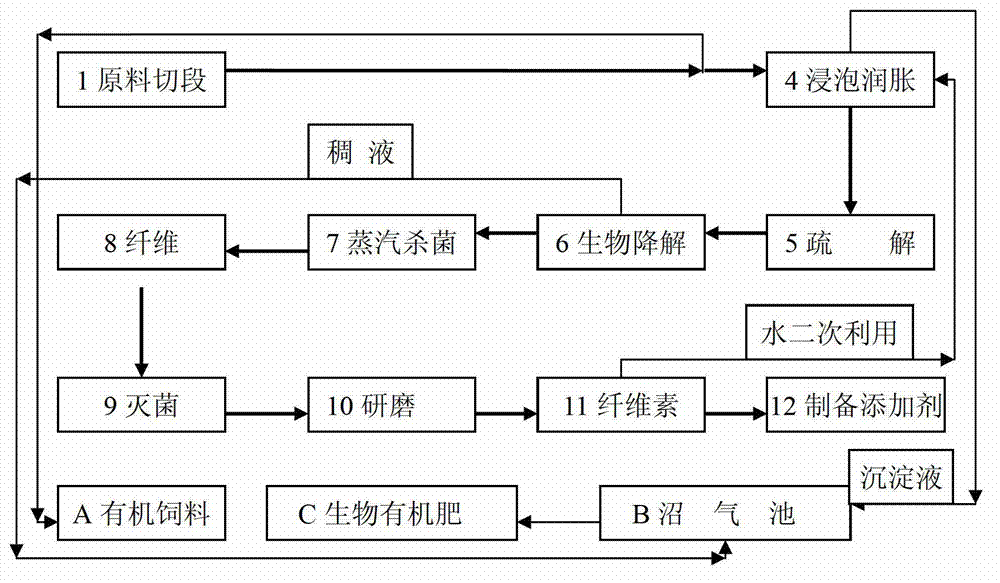

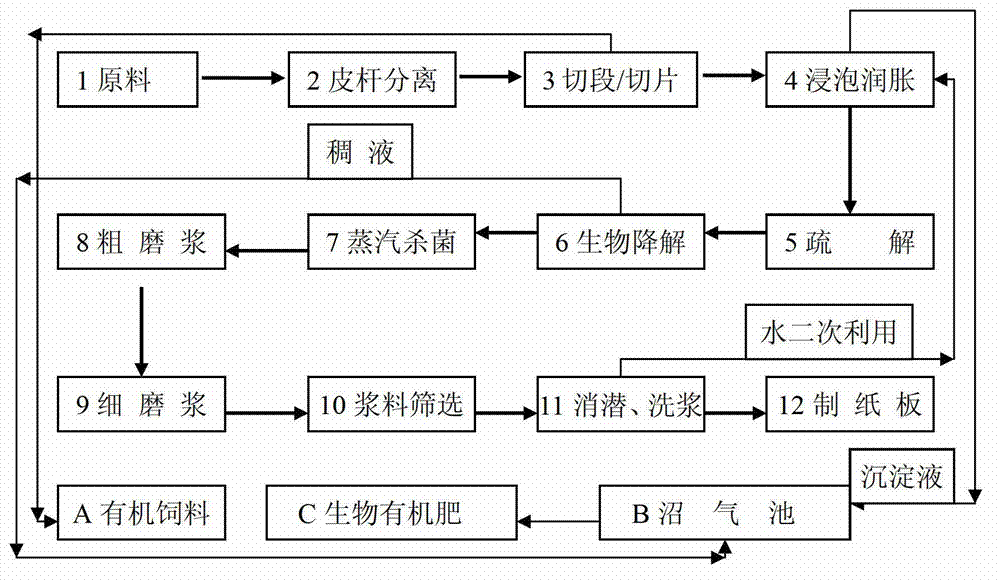

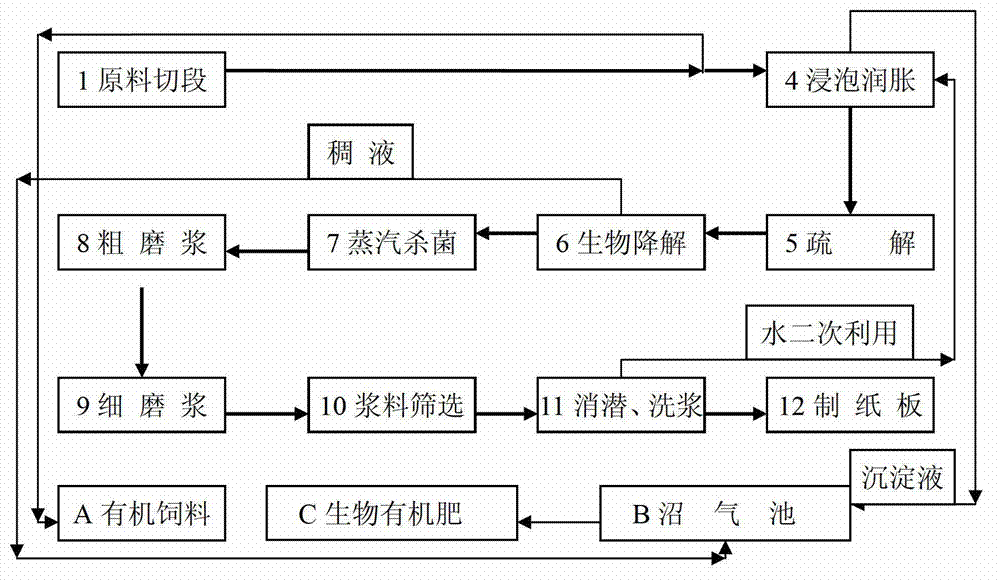

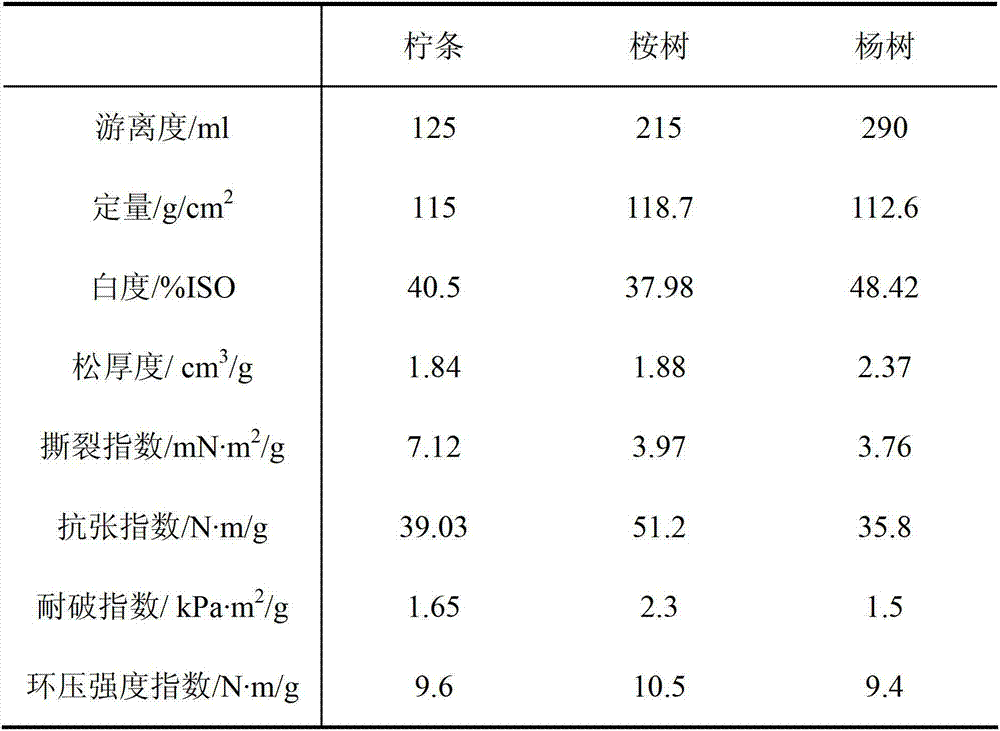

Bio-bacteria and bio-bacterial solution pulping method

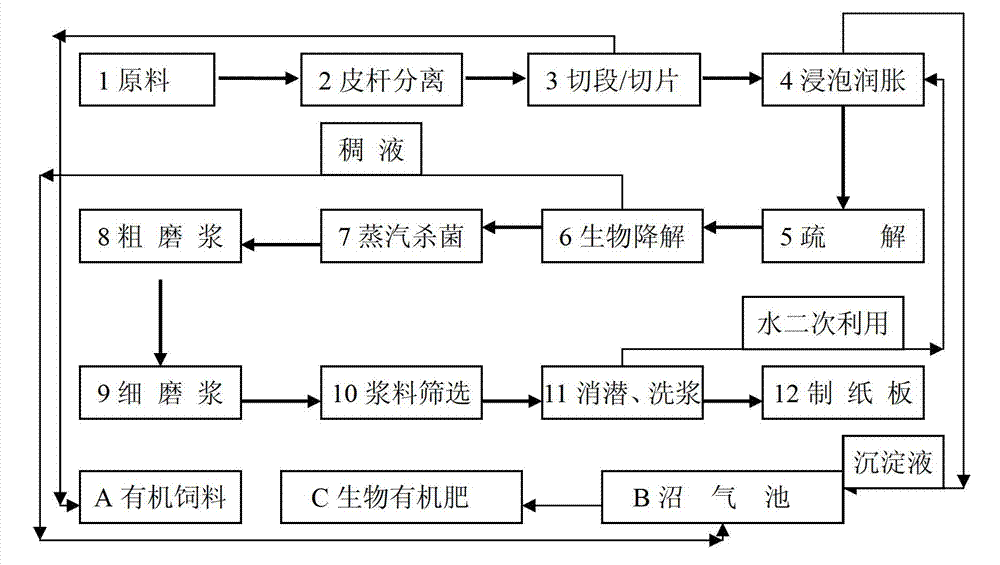

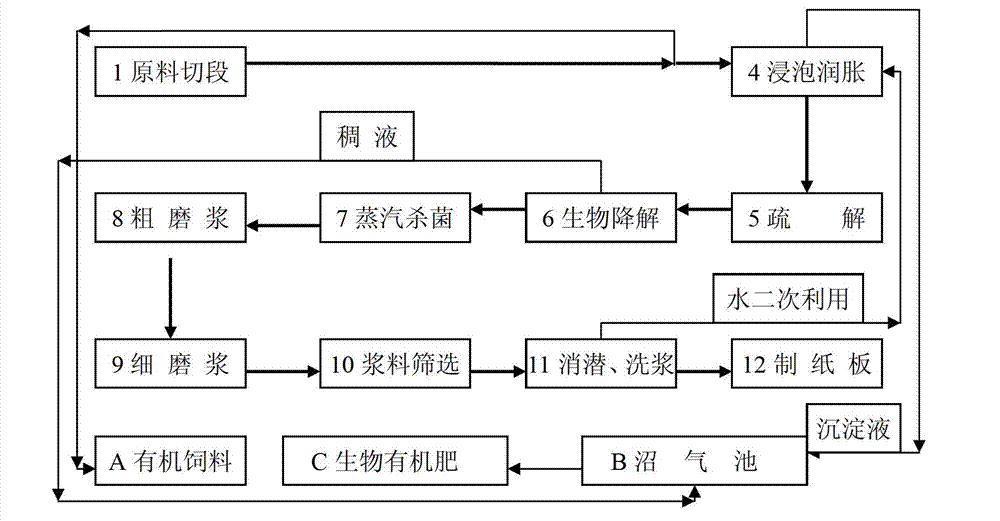

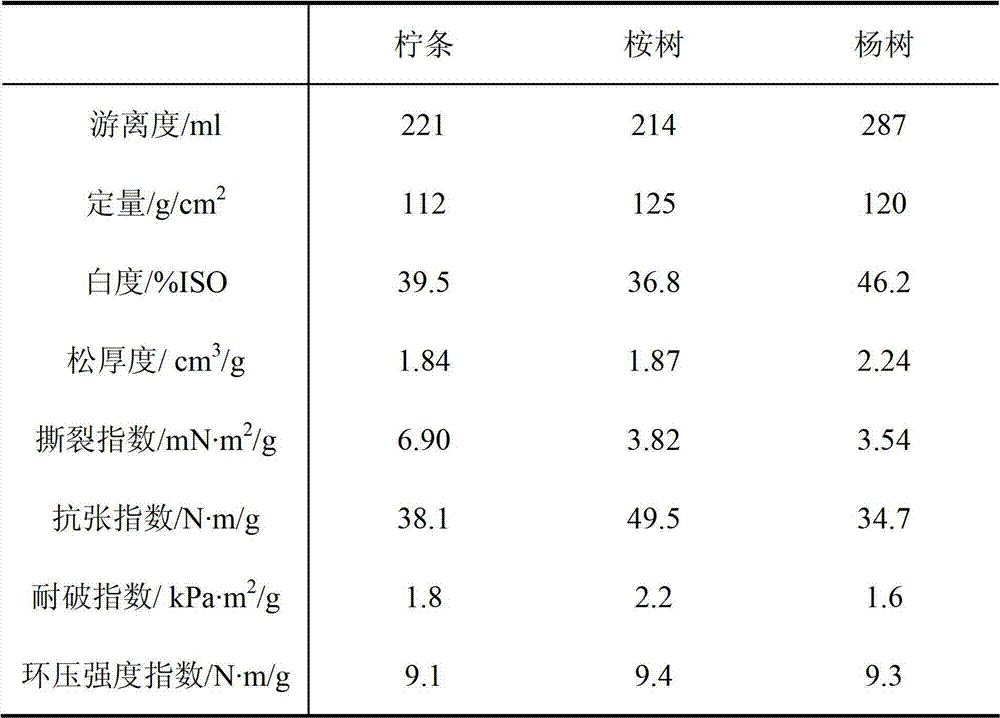

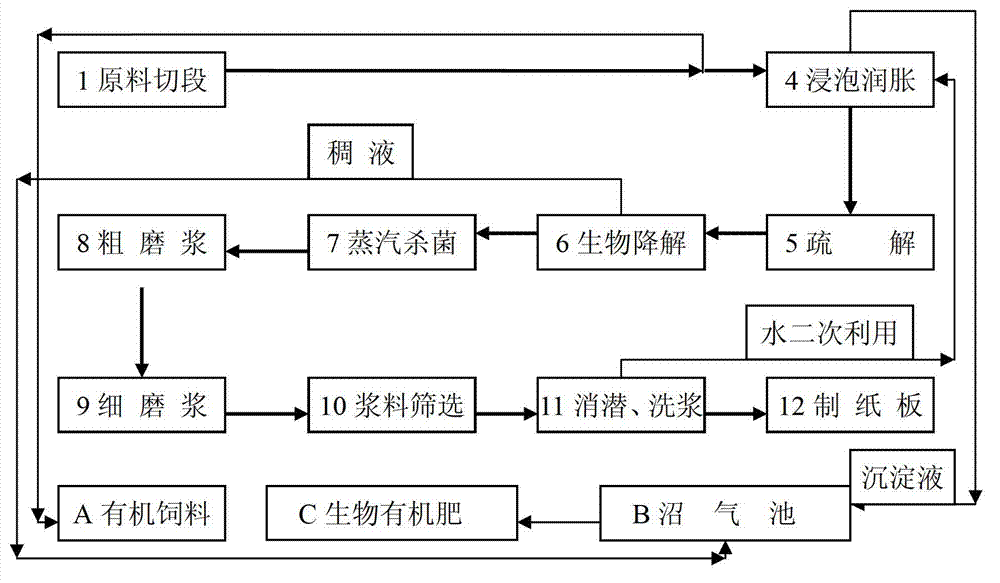

InactiveCN102888360APlay a protective effectZero emissionBio-organic fraction processingBacteriaPaperboardOrganic fertilizer

The invention relates to bio-bacteria and a bio-bacterial solution pulping method. The bio-bacteria are wickerhamomyces anomalus with a collection number of CGMCC No.5975. The bio-bacterial solution pulping method mainly comprises the following steps of: preparing a bacterial solution; processing raw materials; and pulping, namely defibering, biodegradation, steam sterilization, coarse grinding, finely grinding, pulp screening, latency, and pulp washing. The paperboards made by the bio-bacterial solution pulping method reach AA or above level; and the waste liquid produced in pulp making can be recycled or changed into methane which is a kind of energy or organic fertilizers, so energy can be saved and environment pollution is avoided.

Owner:BEIJING TIANAN BIOSCI & TECH

Environmental protection dyeing technology

The invention relates to an environmental protection dyeing technology, which comprises the following steps: 1) a fabric paint pad dyeing novel process flow is characterized by comprising steps of preparing a semi-finished product, performing cation modification, drying, performing pad dyeing on the paint, predrying and baking; and 2)a yarn paint continuous annular pad dyeing technology which is characterized in that the technology employs a continuous pad dyeing innovation technology of yarn pre-treatment and after-treatment of paint dyeing, so that a traditional yarn intermittent dyeing mode such as reeled yarn and cheese dyeing is changed. The process flow comprises the steps of warping yarn, unwinding a warp beam, pre-treating, drying, dyeing the paint, predrying, baking, (sizing), and doffing the beam. The technology changes a traditional desizing / dyeing two bath process to a desizing / dyeing one bath process, technology flow is greatly shortened, printing and dyeing treatment time is shortened by about 50%, water consumption and sewage discharge capacity are reduced by about 50%, power consumption is reduced by about 50%, coal amount is reduced by about 40%, and comprehensive cost is saved by about 45%.

Owner:QINGDAO XINYIFA IND & TRADE

Dust-proof and combustion-supporting additive of fired coal

A dustproof and combustion-supporting additive of coal fired consists of alcohol, ethyl ether, burnt lime, Tween, nitrate and water proportionally. The process is carried out by mixing nitrate solution with lime milk and Tween to become emulsion, adding into alcohol, blending, adding into ethyl ether, and blending to obtain the final product. It can improve full burning rate of coal by 10-15%, hearth temperature 40-50 Deg C. and save coal 22.2-32.1%. It achieves less solid smoke displacement, simple raw materials and process.

Owner:韩维国

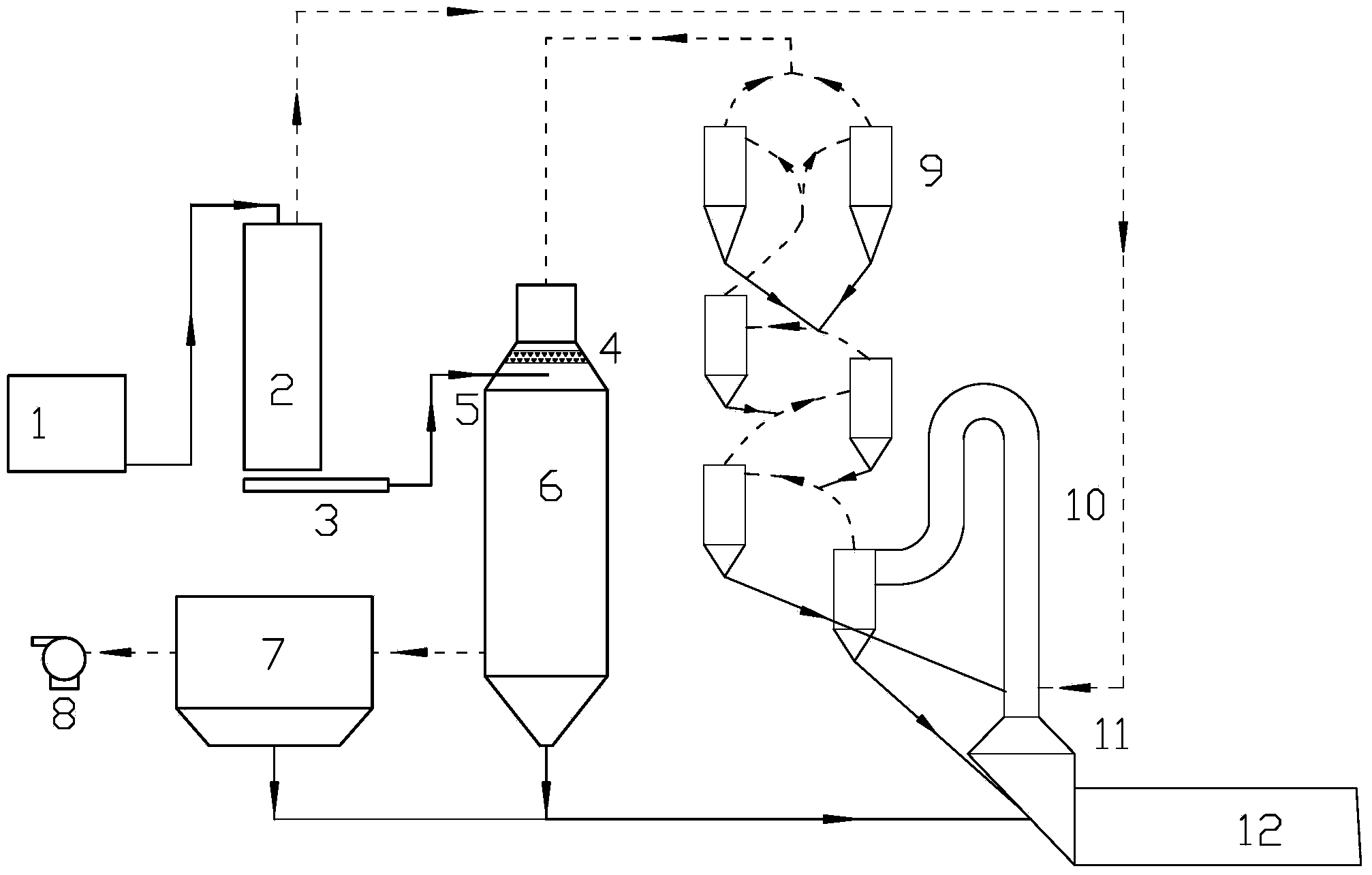

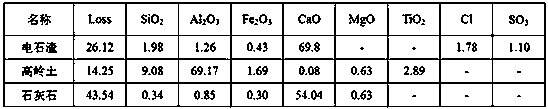

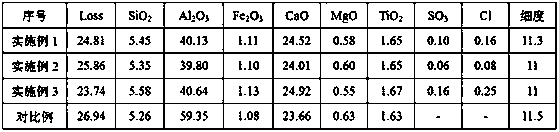

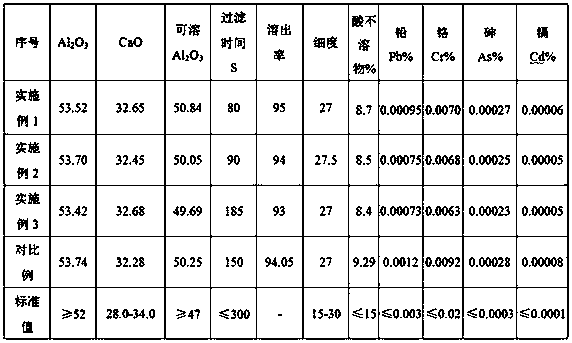

Preparing method for calcium aluminate powder for water purifying agent

InactiveCN109607586ASave coal consumptionSave coalCalcium aluminatesWater/sewage treatment by flocculation/precipitationCycloneSlag

The invention belongs to the technical field of water-purifying-agent raw material preparing, and discloses a preparing method for calcium aluminate powder for a water purifying agent. The method includes the following steps that 1) 25%-40% by mass of limestone, 55%-60% by mass of kaolin and 5%-15% by mass of carbide slags are mixed and ground, and then are homogenized; 2) the mixture obtained inthe step 1) is delivered to a five-stage cyclone preheater and preheated, and then is delivered to a rotary kiln and calcined, and burned clinker is put into a grate cooler and cooled; 3) the coolingclinker obtained in the step 2) is homogenized, and then is ground, and the calcium aluminate powder for the water purifying agent is obtained. According to the preparing method for the calcium aluminate powder for the water purifying agent, by adding the carbide slags, the using amount of the limestone can be decreased, discharging of smoke SO2 is reduced, coal can be saved, and energy consumption is reduced.

Owner:HENAN YISHUIYUAN WATER PURIFICATION MATERIAL TECH CO LTD

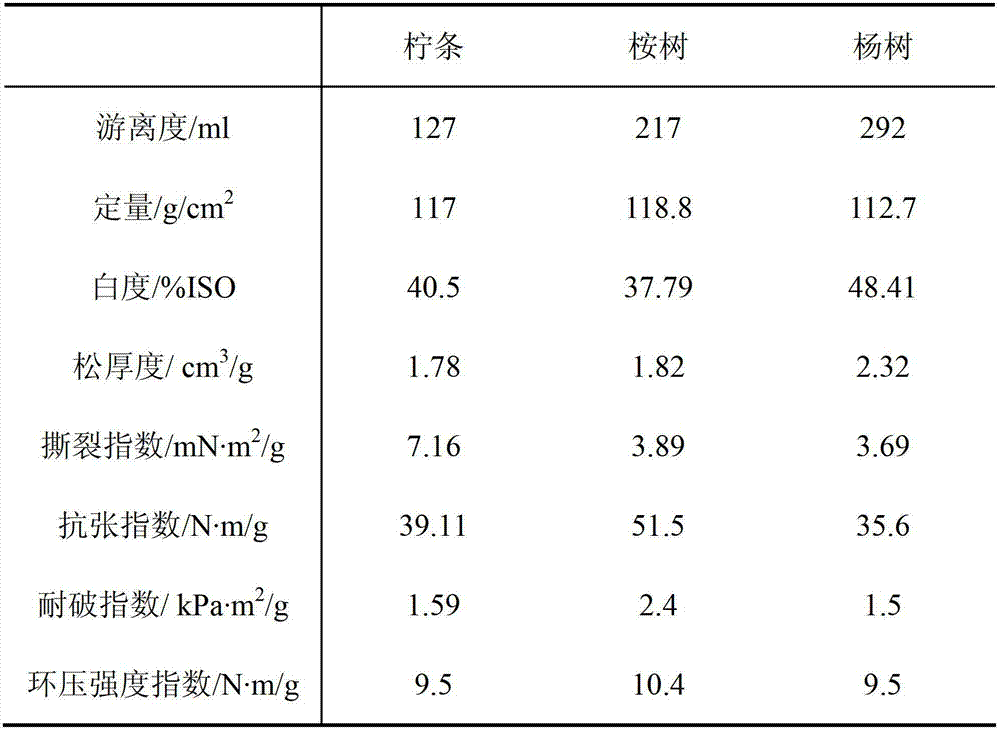

Composite flora and pulping method by using biological bacterial liquid of composite flora

InactiveCN103074250AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaCardboardFiber

The present invention relates to a composite flora and a pulping method by using a biological bacterial liquid of the composite flora. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

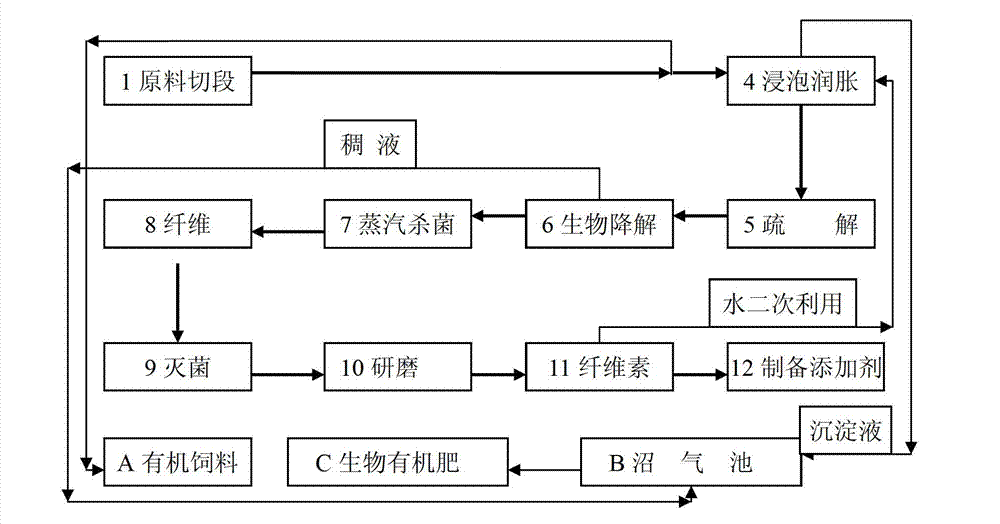

Bacillus and method for preparing textile fiber using same

InactiveCN102888372APlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberCarding

The invention relates to bacillus and a method for preparing textile fiber using the bacillus. The bacillus (bacillus sp.) is stored with a number of CGMCC No. 5971. The method comprises the following steps of: preparing bacteria liquid; processing raw materials; and preparing fibers, wherein fiber preparing steps comprise the following steps of: biologically degrading, sterilizing through steam, and obtaining the fibers; drying; and carding. The method provided by the invention is environment-friendly; waste liquid is directly transformed into organic fertilizer, therefore, zero emission and zero pollution are achieved. A biological treating process performs protection to the fibers. Compared with a traditional chemical method, the method provided by the invention has the advantages of being low in producing cost, high in economic benefit, and is capable of saving an energy resource and protecting an environment.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and application of the same in biological bacterial liquid pulping process

InactiveCN103074249AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaCardboardFiber

The present invention relates to a composite flora and an application of the composite flora in a biological bacterial liquid pulping process. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

Pseudomonas fluorescens and biological bacteria liquid pulping method

InactiveCN102888358APlay a protective effectZero emissionBio-organic fraction processingBacteriaPaperboardPseudomonas fluorescens

The invention relates to pseudomonas fluorescens and a biological bacteria liquid pulping method. The pseudomonas fluorescens is stored with a number of CGMCC No. 5974. The biological bacteria liquid pulping method mainly comprises the following steps of: preparing bacteria liquid; processing raw materials; and pulping, wherein pulping steps comprise the following steps of: defibering, biologically degrading, sterilizing through steam, carrying out rough pulping, carrying out fine pulping, screening a sizing agent, removing latency, and washing the sizing agent. A paperboard prepared by the biological bacteria liquid pulping method provided by the invention reaches a level over AA grade; waste liquid produced in a pulping process can be recycled or transformed into methane which can be served as an energy resource or organic fertilizer, and therefore, energy resources are saved, and environment protection is achieved.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and additive cellulose preparation method by using the same

InactiveCN103074256APlay a protective effectNo pollutionBio-organic fraction processingBacteriaEnvironmental resistanceFiber

The present invention relates to a composite flora and an additive cellulose preparation method by using the composite flora. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and pseudomonas fluorescens with a preservation number of CGMCC No.5974. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

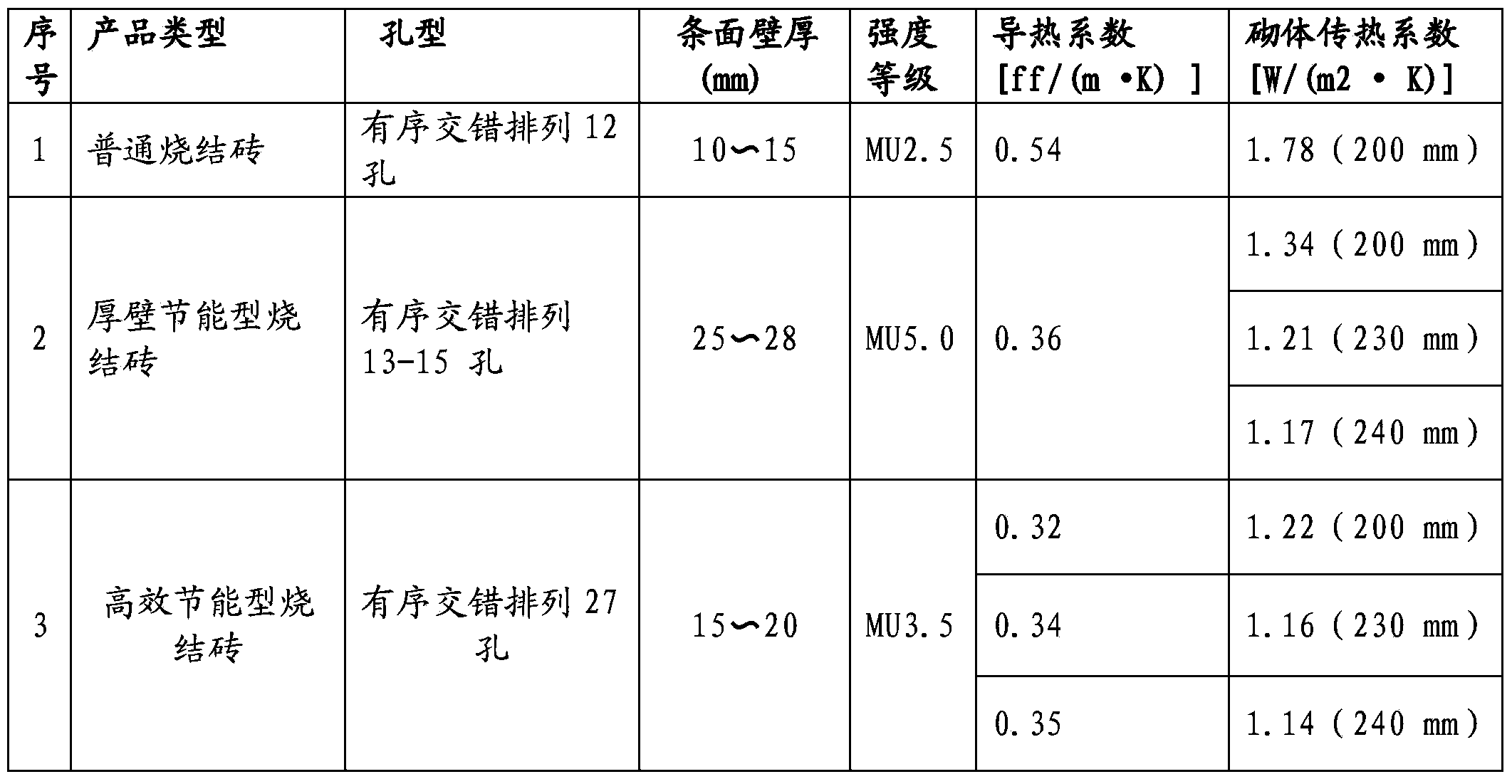

Self thermal insulation sintered brick and production method thereof

The invention belongs to the field of brick making, and specifically relates to a self thermal insulation sintered brick made of mushroom dregs. The sintered brick is prepared by the following steps: mixing mushroom dregs, coal powder, and shale together, taking the mixture as the raw material, and then subjecting the mixture to steps of moulding, drying, and burning so as to obtain the self thermal insulation sintered brick. The content of mushroom dregs in the raw materials can exceed 30% or even reach 40%. The provided method can reduce the coal using amount, increase the thermal resistance of sintered brick, and improve the thermal insulation performance of sintered brick. The building made of the sintered bricks can guarantee the thermal insulation effect without a thermal insulation layer, and can meet the requirements on building energy saving. Compared to the conventional thermal insulation construction, the construction cost is reduced by 20 to 32 yuan / m2. The provided self thermal insulation sintered brick has the advantages of stable quality, durability, user-friendliness, practicality, economy, and good thermal insulation property. Moreover, a large amount of agricultural wastes is processed and utilized, and the ecological environment is protected and improved.

Owner:彭强

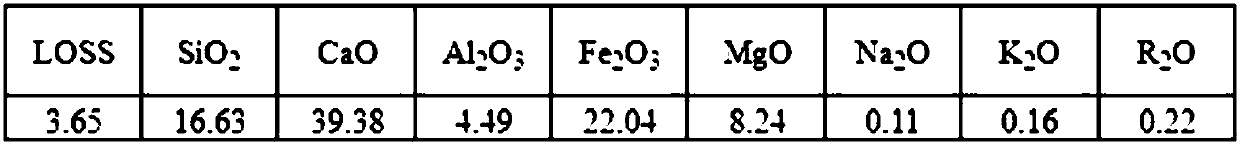

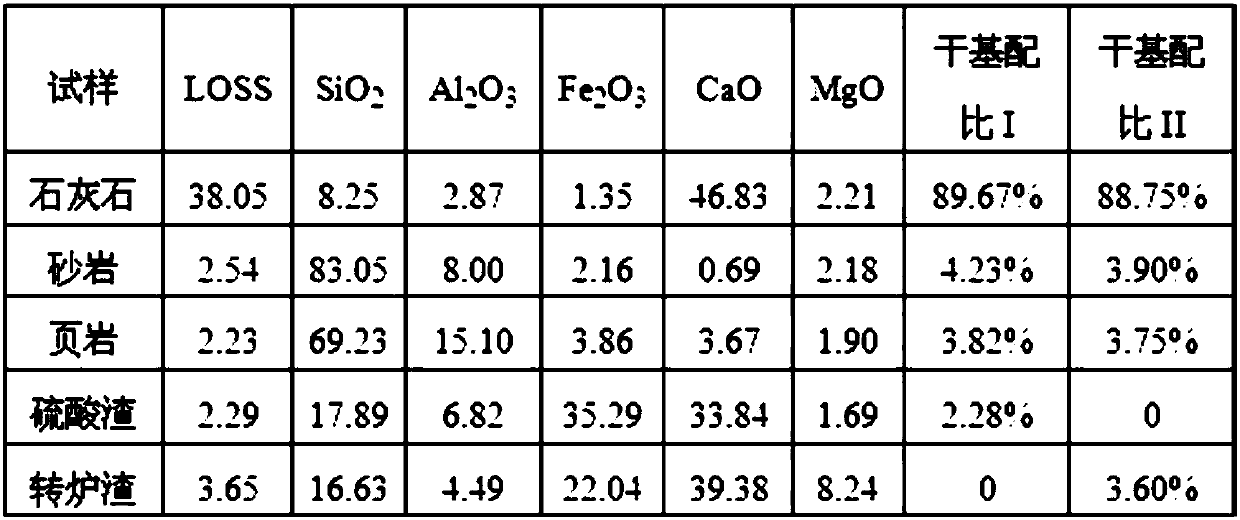

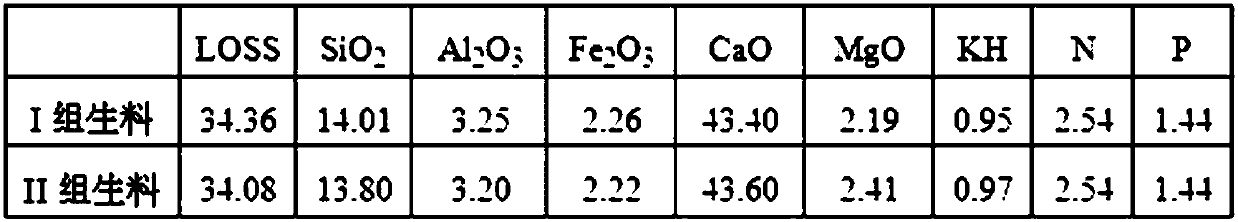

Process for preparing cement clinker from bauxite converter slag

The invention relates to the technical field of building materials and discloses a process for preparing cement clinker from bauxite converter slag. The raw materials of the cement clinker are composed of, in parts by weight, 87.75-89.75 parts of limestone, 2.9-4.9 parts of sandstone, 2.75-4.75 parts of shale and 2.6-4.6 parts of converter slag. The process comprises the following steps: subjecting the raw materials to grinding; subjecting slurry to dehydration; drying and crushing of a filter cake, sintering clinker; and cooling and crushing the clinker. According to the process for preparingcement clinker from bauxite converter slag in the invention, the converter slag is used instead of sulfuric acid slag, the heat consumption of the clinker is reduced in batching; and since the converter slag contains high content of CaO, the proportioning amount of limestone is reduced, and the amount of CaCO3 in the raw materials is reduced, so the heat supply for pre-decomposition is reduced, the burnability of the raw materials is improved, sintering temperature is lowered, and the quality of the clinker is enhanced.

Owner:遵义兴正业矿业有限公司

Composite flora and pulping method by using biological bacterial liquid of composite flora

InactiveCN103074264AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaCardboardFiber

The present invention relates to a composite flora and a pulping method by using a biological bacterial liquid of the composite flora. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and pseudomonas fluorescens with a preservation number of CGMCC No.5974. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora for biological preparation of cellulose additive, and applications thereof

InactiveCN103074223APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberCellulose

The present invention relates to a composite flora for biological preparation of a cellulose additive, and applications thereof. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, and acinetobacter lwoffii with a preservation number of CGMCC No.5973. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

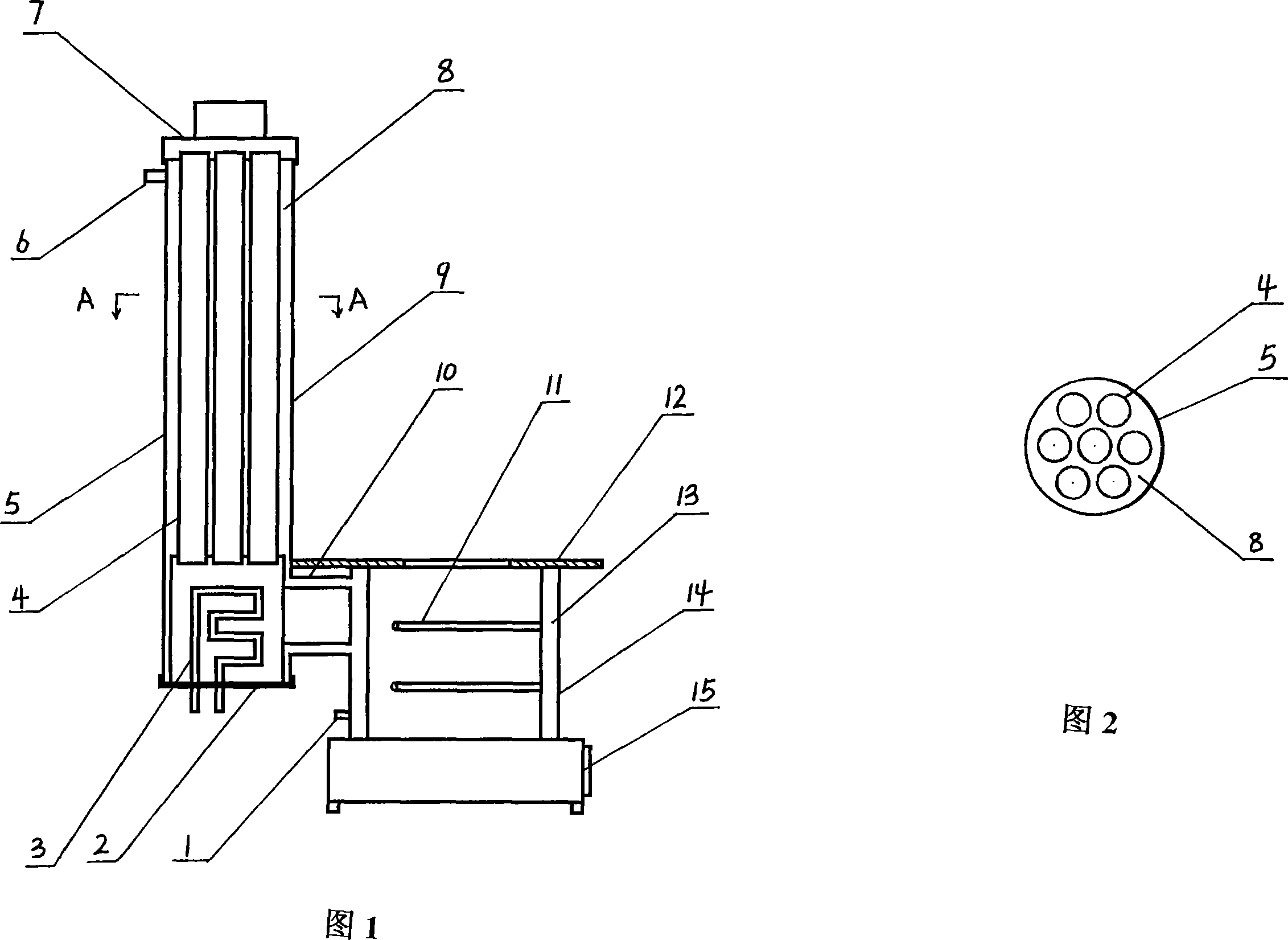

Combustor for efficiently and stably combusting anthracite coal in decomposition furnace

InactiveCN105864758AReduce the dosage ratioCalcination heat consumption reducedPulverulent fuel combustion burnersAutomatic controlCombustor

The invention relates to a combustor for efficiently and stably combusting anthracite coal in a decomposition furnace. The combustor consists of a center air passage, a clean air passage and an annular space, wherein the annular space is formed between the center air passage and the clean air passage; a plurality of coal air passages are uniformly distributed inside the annular space; a rotational porous annular partition is arranged at the outlet of the annular space; the outlet end of the center air passage and the outlet end of the clean air passage are each provided with a rotational flow generating device; the outlet of the center air passage adopts an external expansion design; the outlet of the clean air passage adopts an internal shrinkage design. The combustor disclosed by the invention is unique in structure and capable of making coal powder be completely coated and preheated by high-temperature tertiary air; meanwhile, clearances exist among a plurality of coal powder beams, so the contact area between high-temperature gas and the coal powder is greatly increased, the preheating speed of coal powder flow is remarkably increased, the anthracite coal is enabled to reach the ignition temperature after entering a high-oxygen-concentration region, the combustion efficiency is improved, and the amount of consumed coal is reduced; the amount of fed coal is automatically controlled, and the porous annular partition is rotationally regulated, so the rigidity of coal air is stabilized, the thermal load in a hearth is also effectively regulated, the combustion stability is guaranteed, the temperature in the decomposition furnace is uniformly distributed, and emission of NOx is reduced.

Owner:XIANGTAN UNIV

Acinetobacter lwoffii and method for preparing cellulose for additive using same

InactiveCN102888362APlay a protective effectZero pollutionBio-organic fraction processingBacteriaFiberCellulose

The invention relates to acinetobacter lwoffii and a method for preparing cellulose for an additive using the acinetobacter lwoffii. The acinetobacter lwoffii is stored with a number of CGMCC No. 5973. The method comprises the following steps of: preparing bacteria liquid; processing raw materials; and preparing fibers, wherein fiber preparing steps comprise the following steps of: defibering, biologically degrading, sterilizing through steam, and obtaining the fibers, sterilizing and grinding. The method provided by the invention is environment-friendly; waste liquid is directly transformed into organic fertilizer, therefore, zero emission and zero pollution are achieved. A biological treating process performs protection to the fibers. Compared with a traditional chemical method, the method provided by the invention has the advantages of being low in producing cost, high in economic benefit, and is capable of saving an energy resource and protecting an environment.

Owner:BEIJING TIANAN BIOSCI & TECH

Portland cement clinker with high compressive strength and preparation method thereof

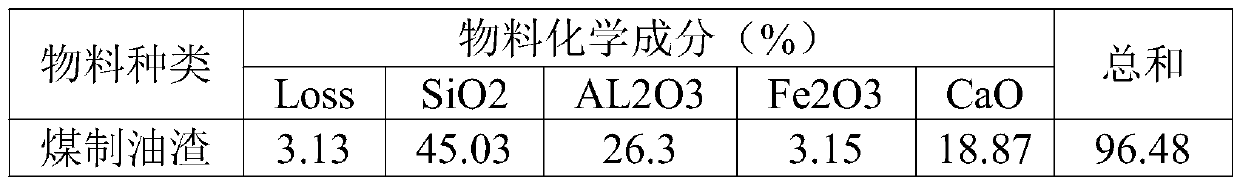

The invention provides a Portland cement clinker with high compressive strength. A raw meal adopts the following components in percent by weight: 80%-85% of limestone, 2-4% of coal-to-oil residue, 7-12% of sandstone, and 2-6% of steel slag ingredients. New industrial solid waste coal slag is adopted as a substitute for a clay raw material to participate in a raw meal formula, natural non-renewableresources are saved, and the pain point problem of waste producing enterprises and government is solved. The three-day compressive strength value of the clinker can be increased to 37 MPa or more. Bythe unique raw meal homogenization technology, large fluctuation of a raw meal rate into a kiln caused by cyclic enrichment of kiln ash in a homogenization silo when a rotary kiln is started and a raw meal mill is stopped is avoided, continuous uniformity of raw meal ingredients into the kiln is ensured, and thus reliable guarantees for improvement of clinker strength are provided.

Owner:SHANXI EXCELLENCE CEMENT CO LTD

Compound bacteria for biological bacteria liquid pulping and application of compound bacteria

InactiveCN102888373AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaPaperboardOrganic fertilizer

The invention relates to compound bacteria for biological bacteria liquid pulping and application of the compound bacteria. The invention also provides a biological bacteria liquid pulping method. The compound bacteria comprise bacillus stored with a number of CGMCC No. 5971, acinetobacter lwoffii stored with a number of CGMCC No. 5973, and Wickerhamomyces anomalus stored with a number of CGMCC No. 5975. The method mainly comprises the following steps of: preparing bacteria liquid; processing raw materials; and pulping, wherein pulping steps comprise the following steps of: defibering, biologically degrading, sterilizing through steam, carrying out rough pulping, carrying out fine pulping, screening a sizing agent, removing latency, and washing the sizing agent. A paperboard prepared by the biological bacteria liquid pulping method provided by the invention reaches a level over AA grade; waste liquid produced in a pulping process can be recycled or transformed into methane which can be served as an energy resource or organic fertilizer, and therefore, energy sources are saved, and environment protection is achieved.

Owner:BEIJING TIANAN BIOSCI & TECH

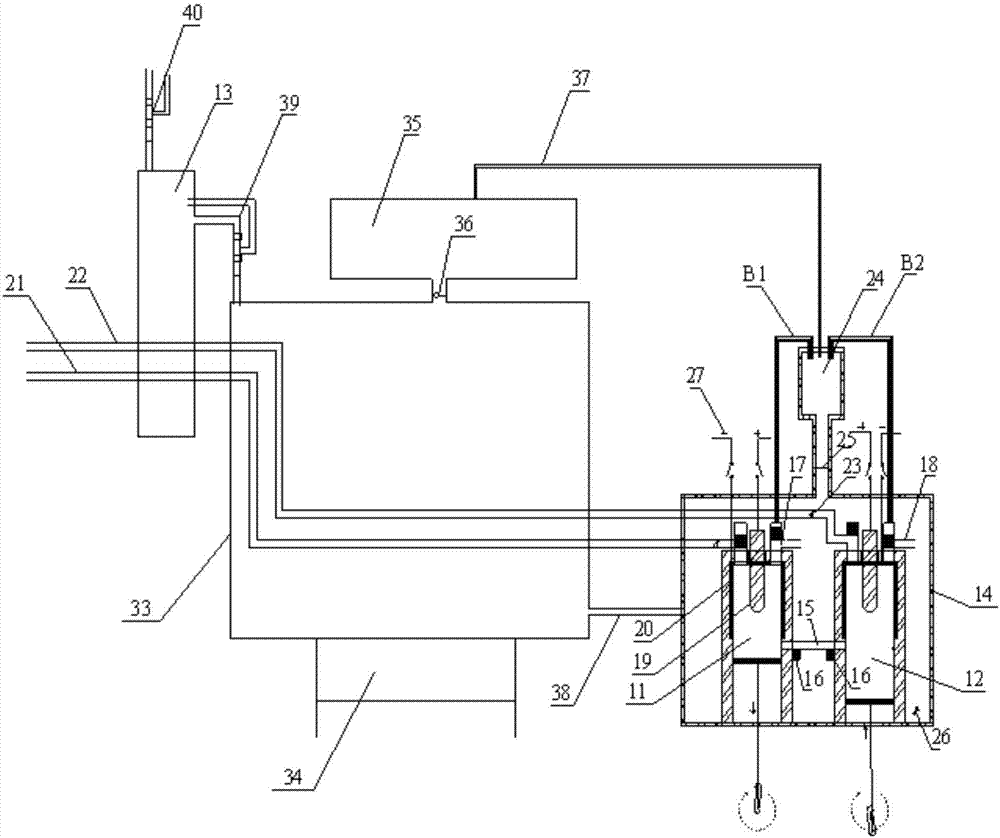

Batching and water filling system and method in neomycin sulfate fermentation production

ActiveCN104531505ASave coal consumptionSolve the problem of high proportion of water costBioreactor/fermenter combinationsBiological substance pretreatmentsWater useCooling tower

The invention discloses a batching and water filling system in neomycin sulfate fermentation production. The system comprises a batching tank, wherein the batching tank is communicated to a drinking water pipeline with a first valve; one end of a material liquid pipeline with a batching pump is communicated to the batching tank and the other end of the material liquid pipeline is communicated to a fermentation tank; one end of a fermented cooling water pipeline with a second valve is communicated to the fermentation tank and the other end of the fermented cooling water pipeline is communicated to a multistage cooling tower; and the multistage cooling tower is communicated to the fermentation tank by virtue of a pipeline with a check valve, a circulating water tank and a circulating water tank water outlet pipeline with a first water tank pump and a check valve. The batching and water filling system and method in neomycin sulfate fermentation production disclosed by the invention can be used for solving a problem of relatively high water cost proportion and improving repeated utilization rate of water, and by batching materials by virtue of hot water, water using cost and steam consumption are reduced, so that coal consumption of a boiler is reduced.

Owner:YICHANG SANXIA PHARMA

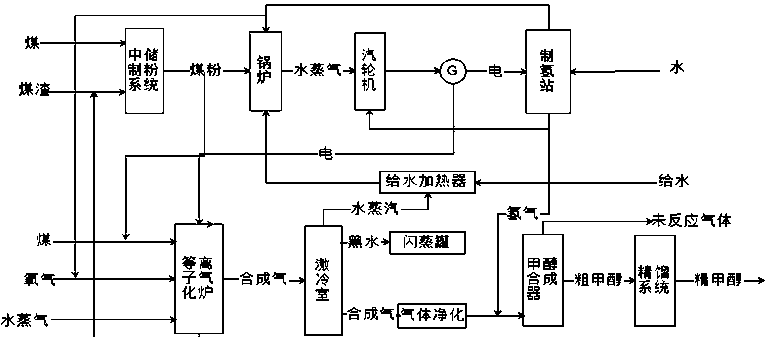

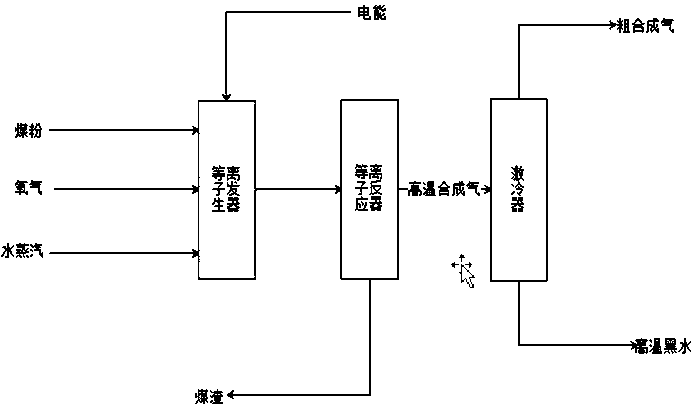

Coupling technology of thermoelectric methanol from coals

InactiveCN109054902AEasy loadingImprove efficiencyOrganic compound preparationChemical industryThermoelectric materialsWater vapor

The invention discloses a coupling technology of thermoelectric methanol from coals. In the coupling technology, a plasma gasifier is coupled with a thermal power plant system, the plasma gasifier isused to replace a traditional gasifier, the electric energy and coal powder required for the plasma gasifier can both be directly acquired from a power plant, a hydrogen generation station of a thermal power plant provides H2 to a methanol generation system, and the problem of energy and water consumption caused by using gas-water conversion device is avoided; expect being used for synthesizing methanol, unreacted synthesis gas after being gasified is introduced into a boiler of the thermal power plant to increase the quantity of heat production and save coals; discharge gas of the gasifier contains a great quantity of sensible heat, a part of the sensible heat is used for producing high-temperature and high-pressure vapour to be provided to the gasifier after being recovered or preheat feedwater of the boiler, and the air extraction quantity of a steam turbine is reduced; a gas purification system recovers CO2 produced in the process, and carbon emission is reduced; and according to the method, a gas-water reaction system is cancelled, the water consumption is reduced, the heat is recovered, the energy utilization ratio is improved, and the coal consumption is reduced.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com