Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

65 results about "Rheinheimera tangshanensis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

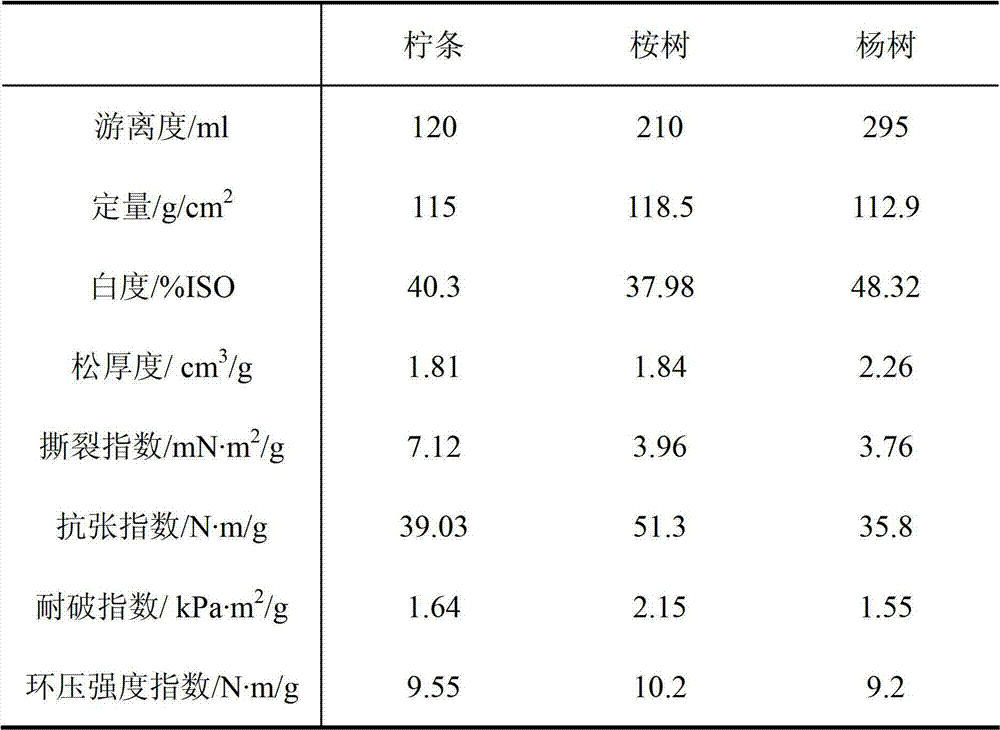

Biological ultrasonic pulping method for high-strength mechanical pulp

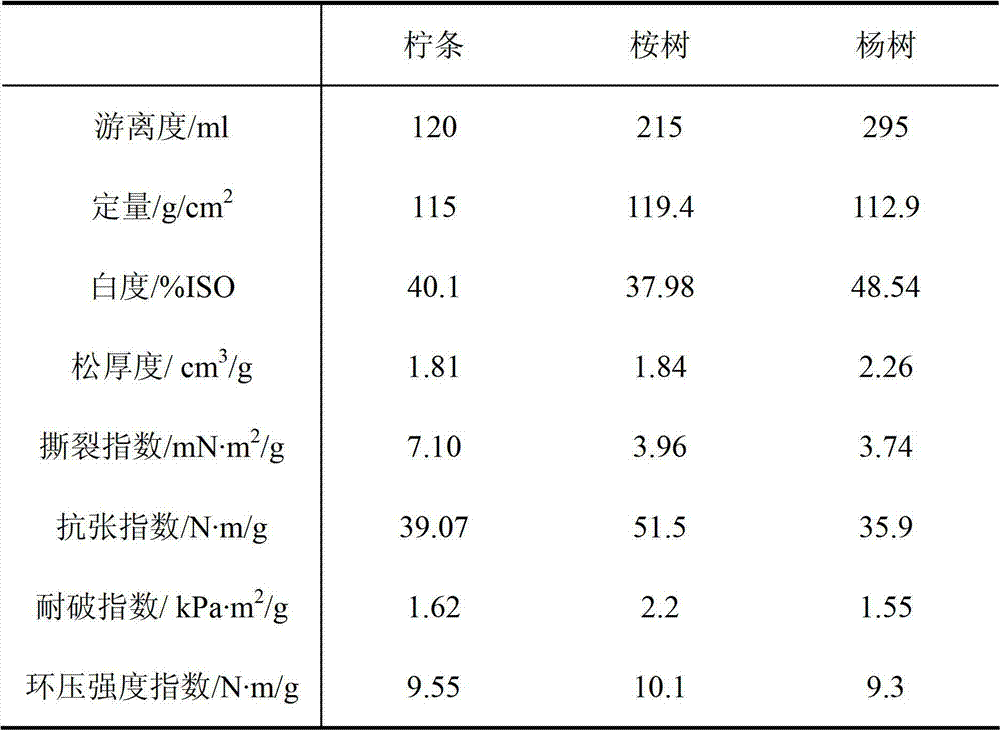

ActiveCN106400562AImprove pulping qualityNovel methodPretreatment with water/steamPretreatment with alkaline reacting compoundsRheinheimera tangshanensisHigh intensity

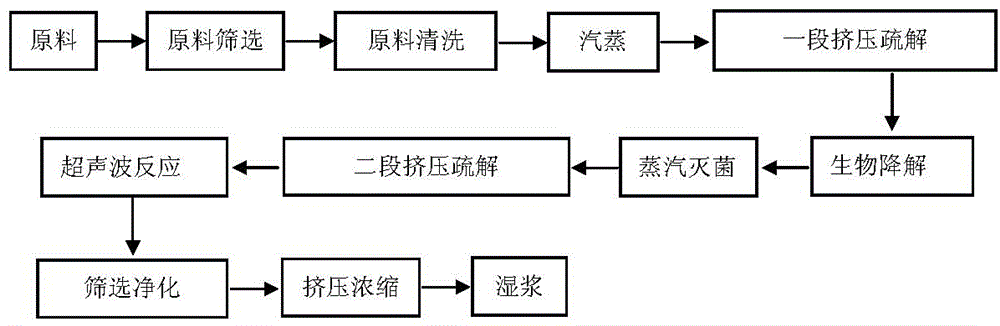

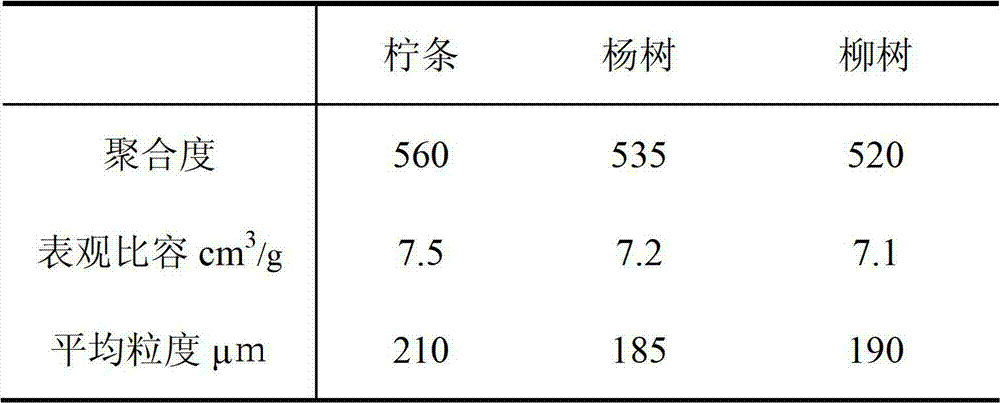

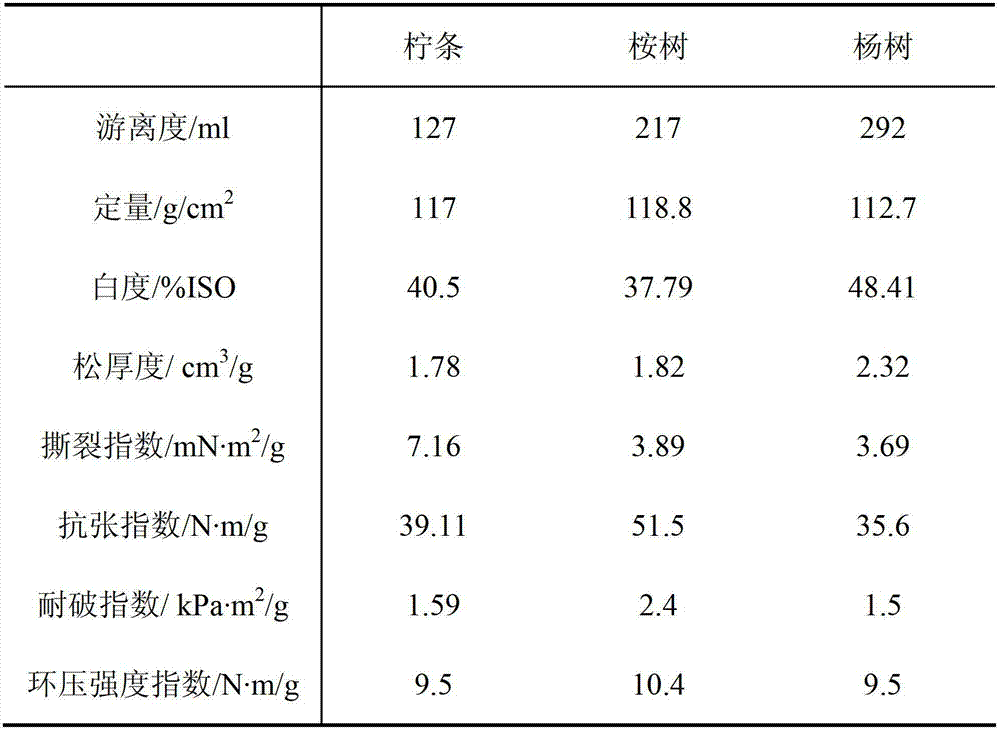

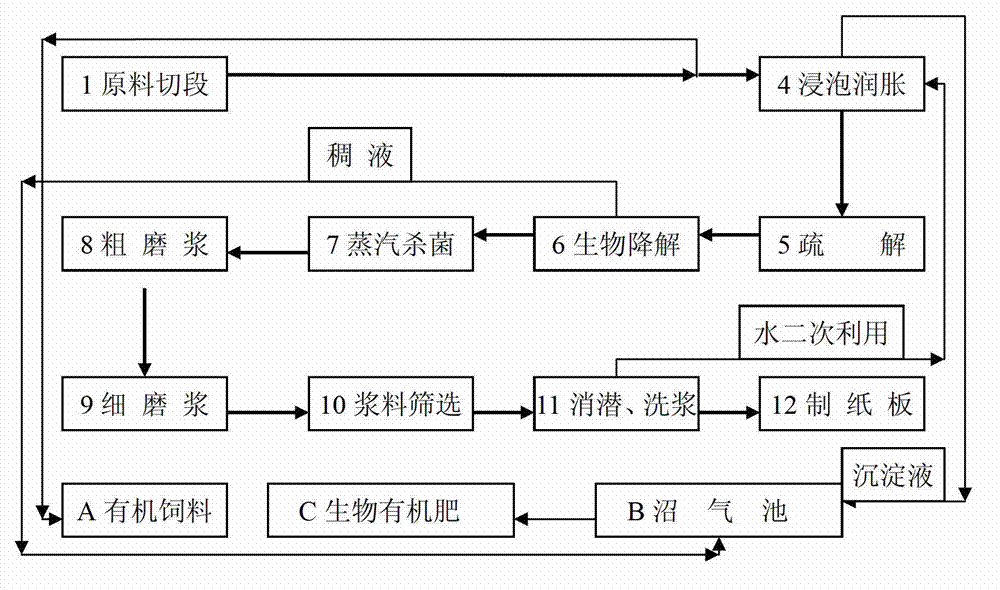

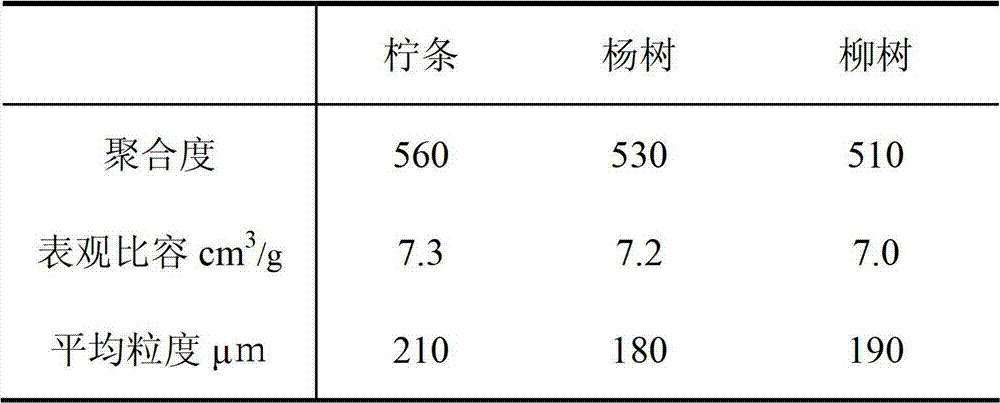

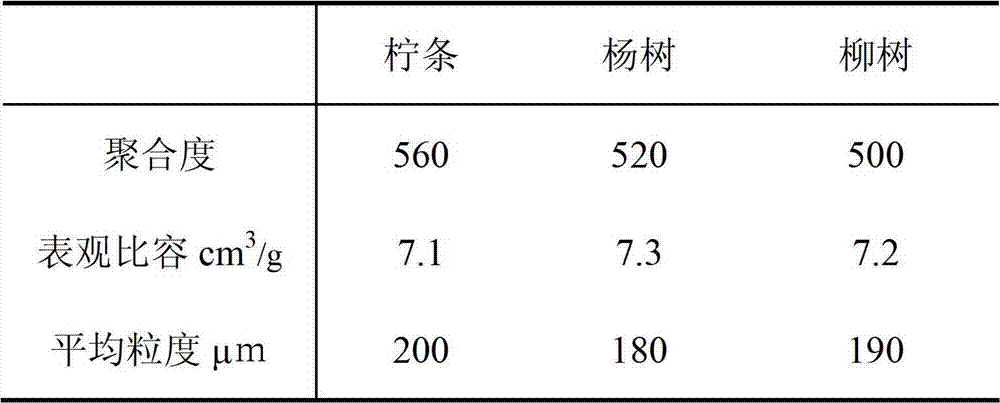

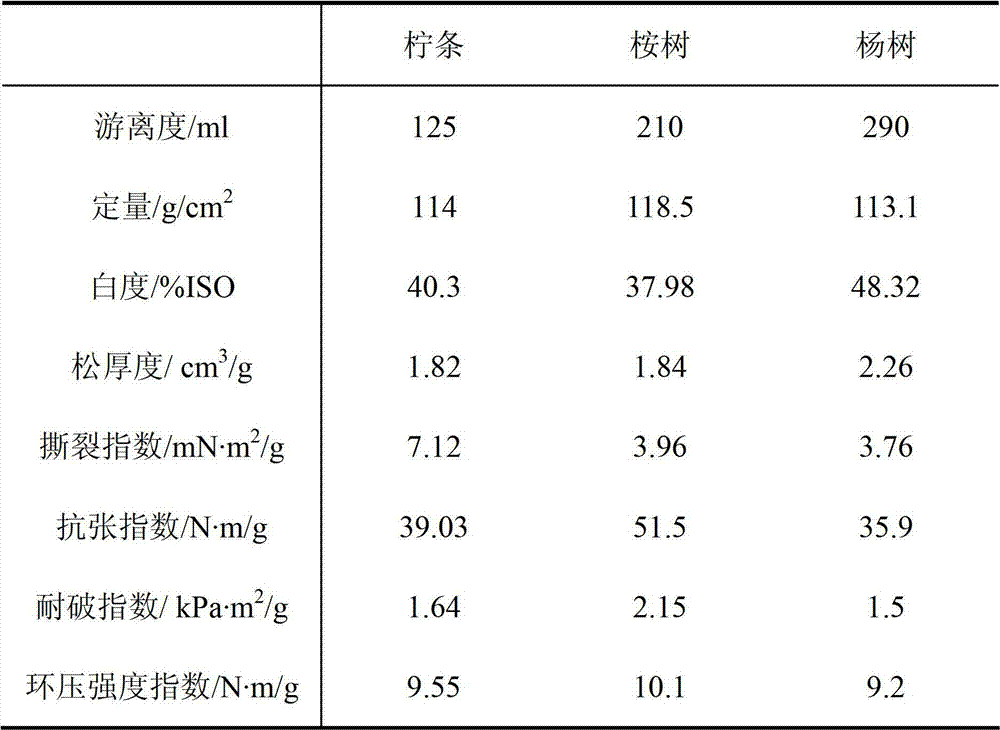

The invention relates to a biological ultrasonic pulping method for a high-strength mechanical pulp. The aims of improving the quality of a chemi-mechanical pulp, reducing the production cost and improving the production efficiency can be effectively achieved. The biological ultrasonic pulping method includes the steps that water is added into white rot fungi, rheinheimera tangshanensis, acinetobacter lwoffii and pseudomonas fluorescens to prepare composite bacterium liquid with the flora density larger than 6*10<7> per ml; a woody raw material is cut into wood chips with the length of 3 cm to 4 cm or a herbaceous plant raw material is cut to have the length of 4 cm to 5 cm, washing, steaming and dehydration are carried out, the obtained product is soaked in first-stage squeezing extrusion liquid for first-stage squeezing extrusion, and then the obtained product is placed into the composite bacterium liquid for biodegradation, bailed out, drained, sterilized with steam at the normal pressure, subjected to second-stage squeezing extrusion, ultrasonically reacted, washed, screened, filtered, squeezed and concentrated into a wet pulp. The method is novel, unique, scientific, easy to operate and good in effect, the quality of the chemi-mechanical pulp can be effectively improved, the production cost can be reduced, the production efficiency can be improved, and the biological ultrasonic pulping method saves energy and is environmentally friendly.

Owner:四川熊猫新材料科技有限公司

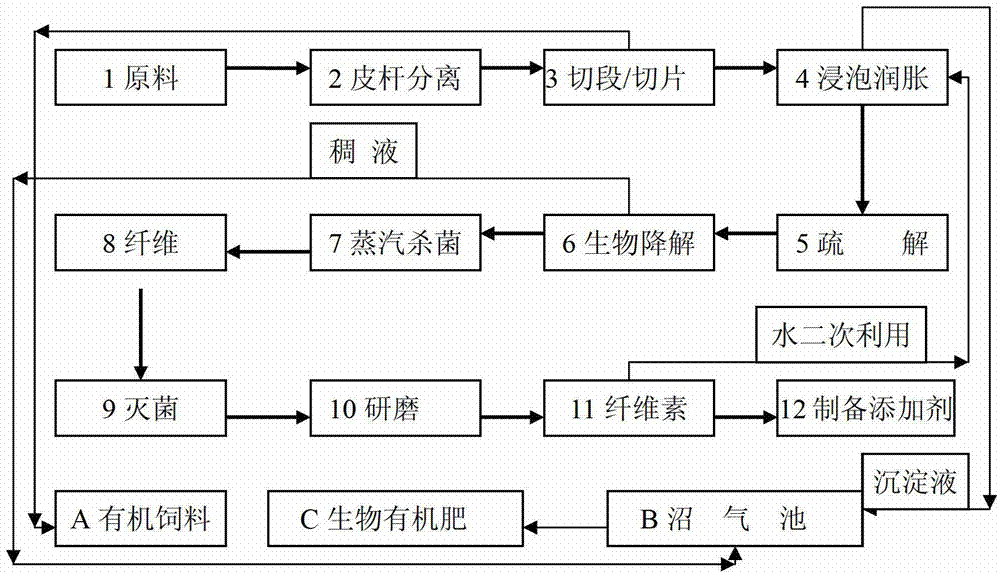

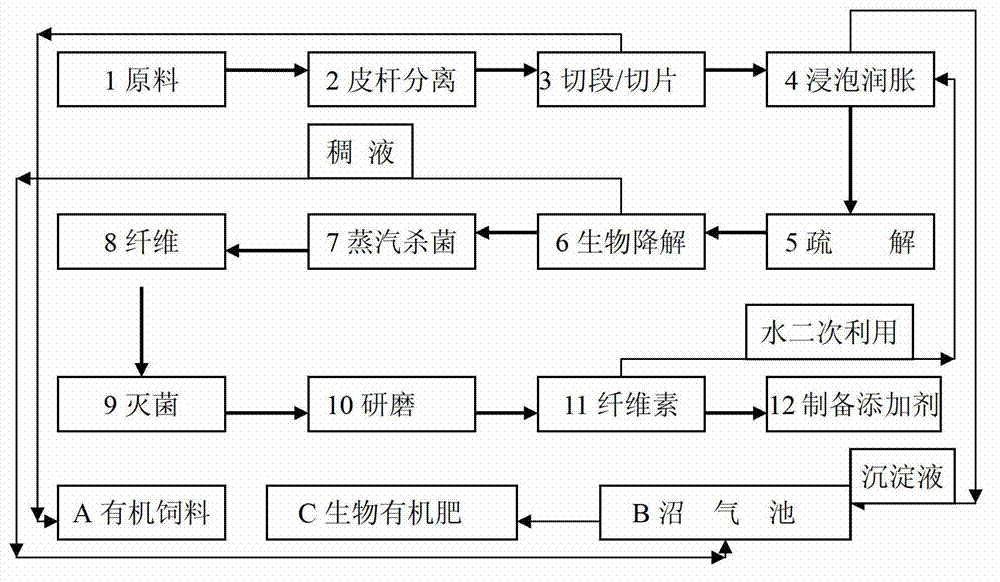

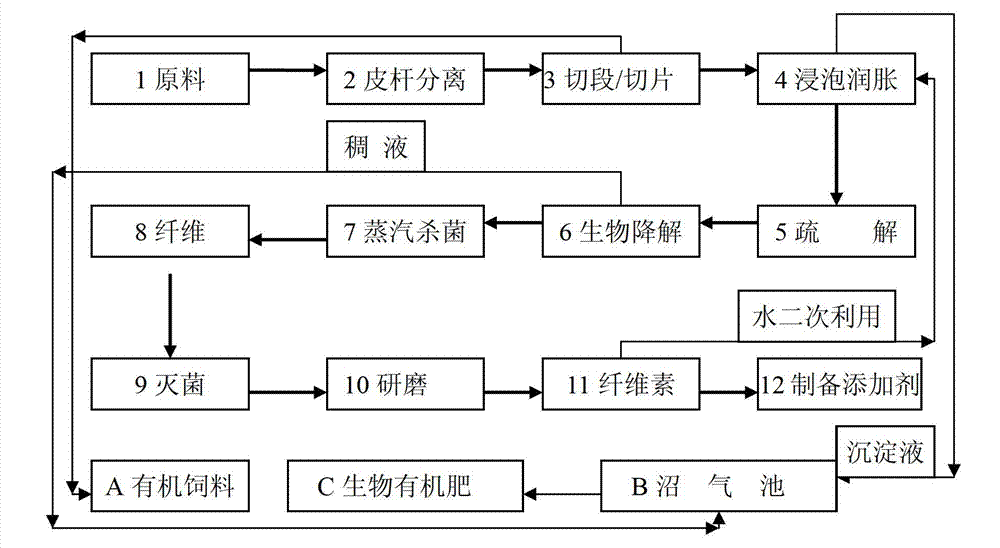

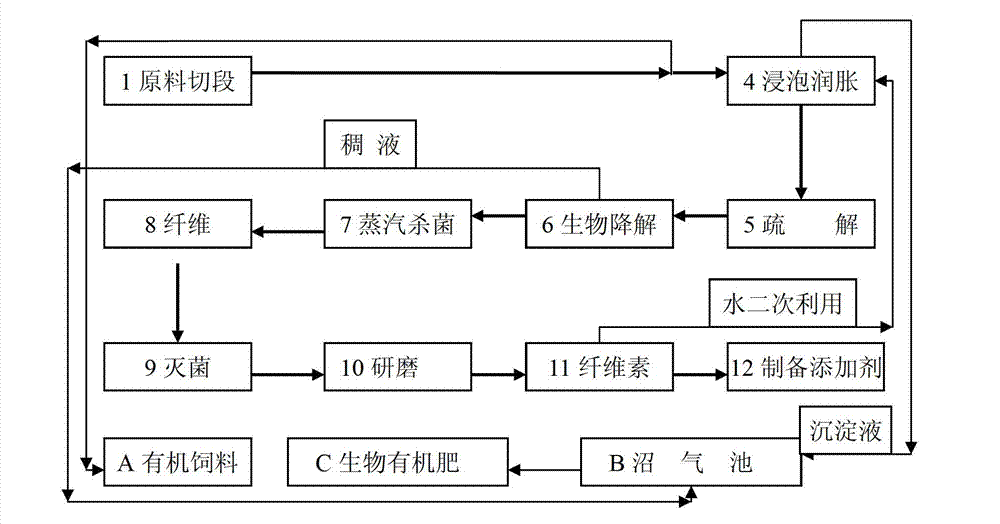

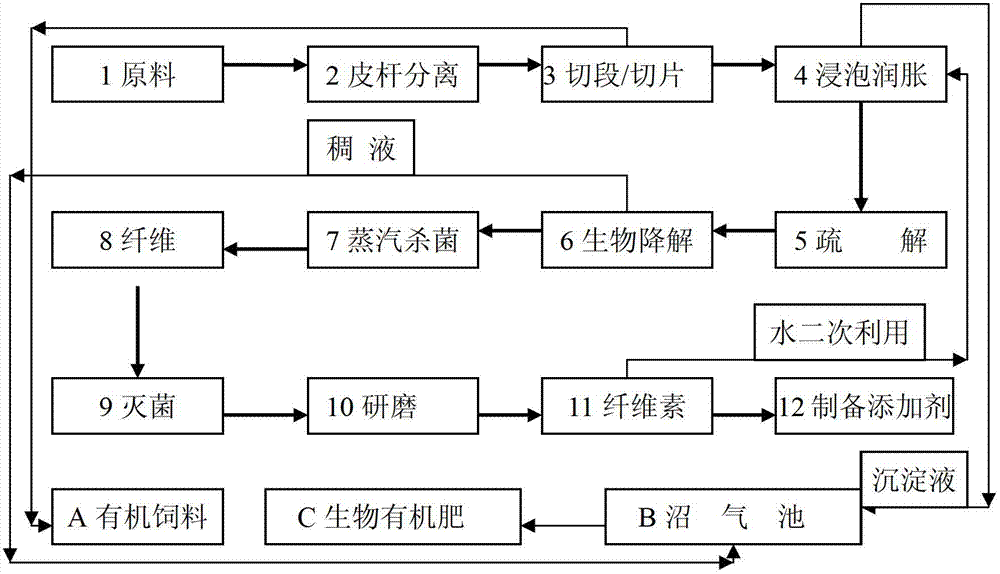

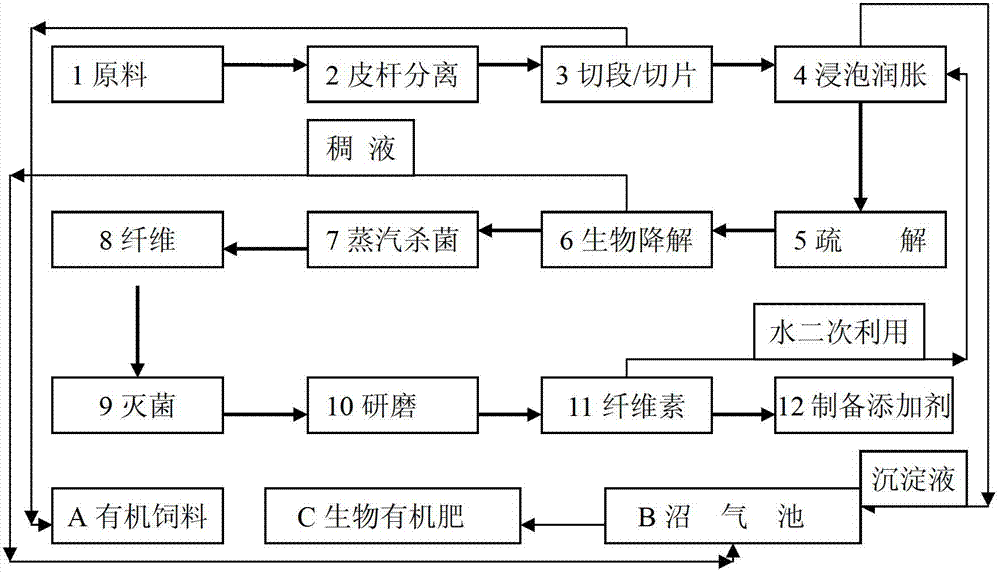

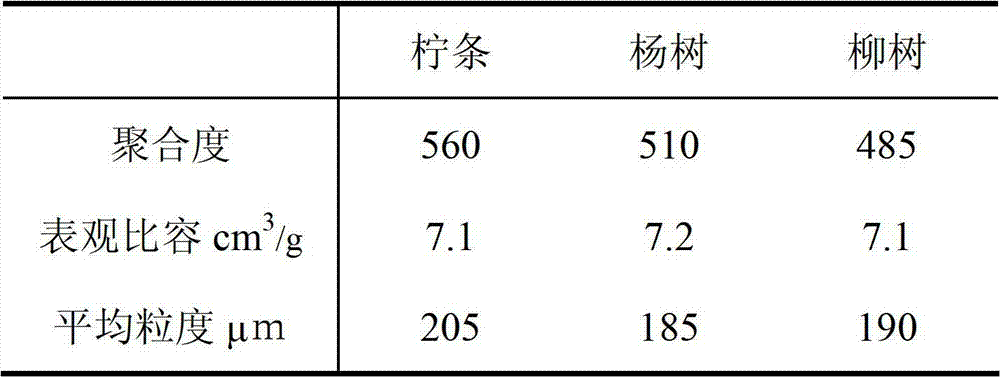

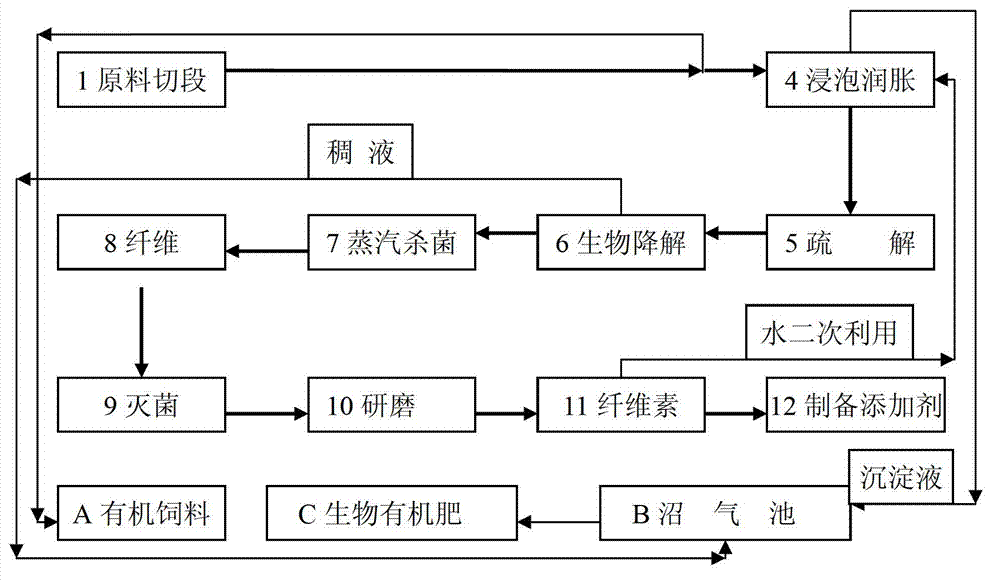

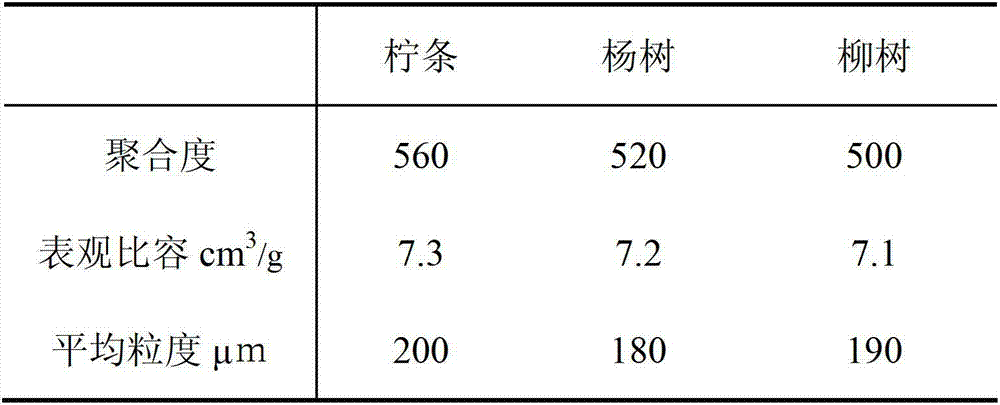

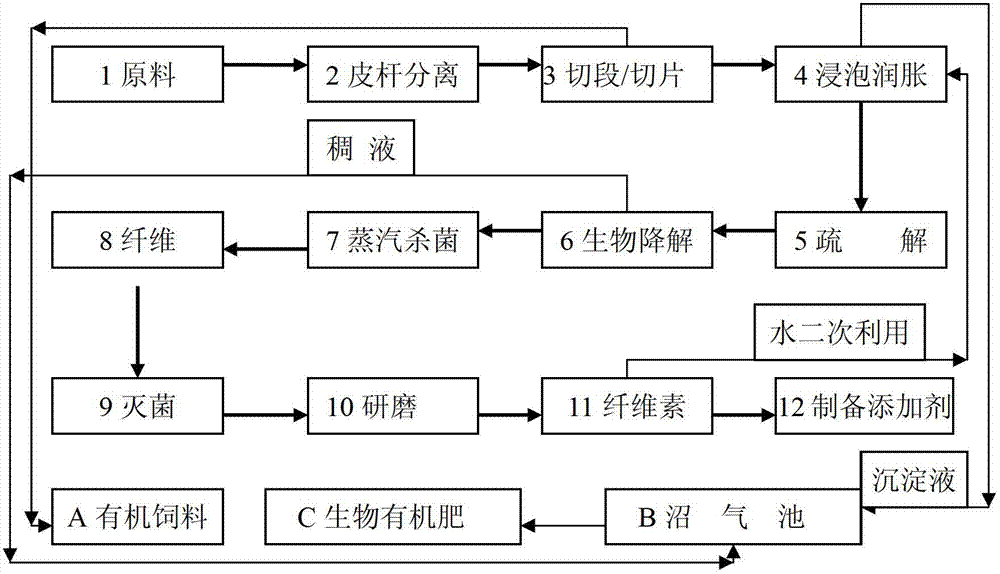

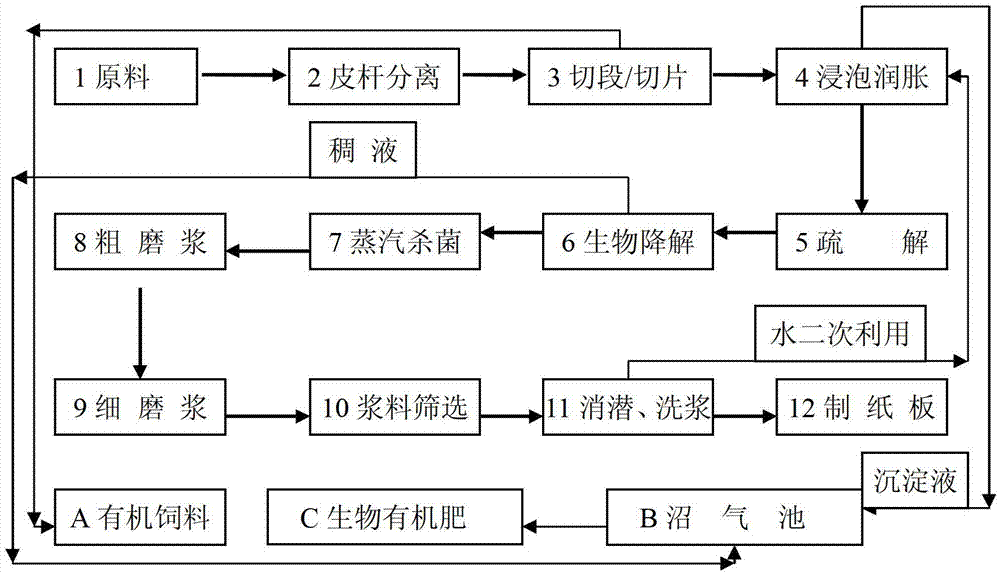

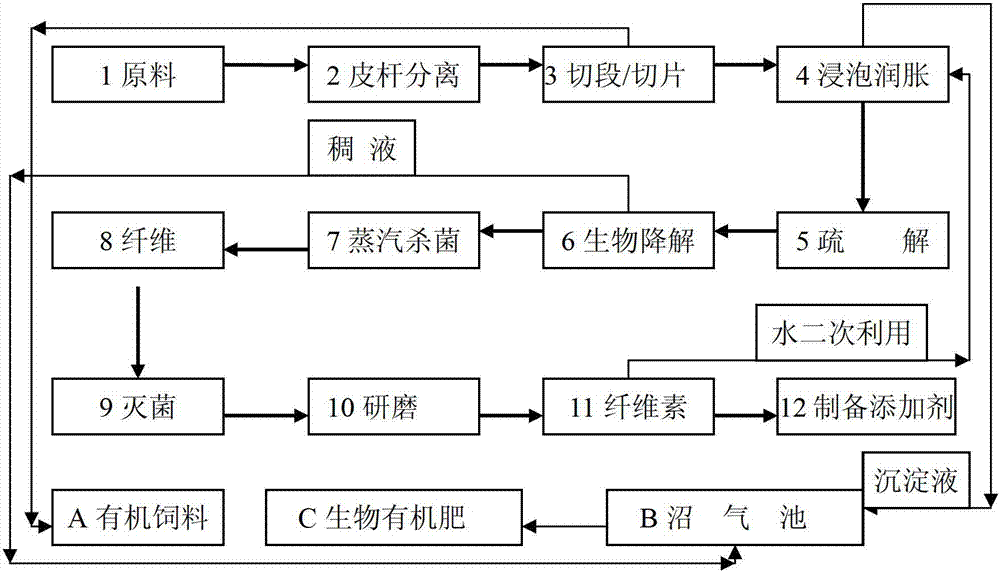

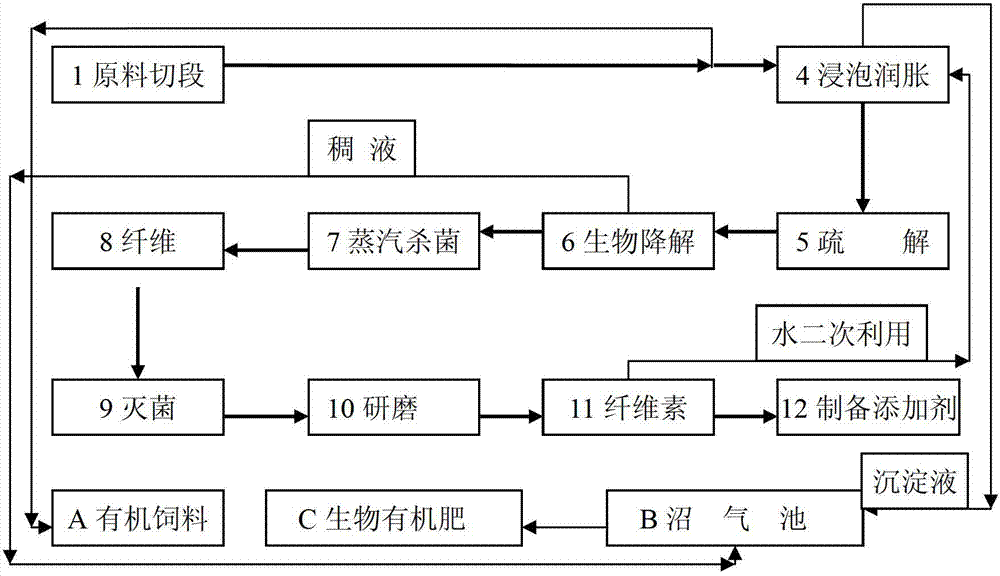

Biological flora and method for preparing cellulose for additive through same

InactiveCN102888338APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberCellulose

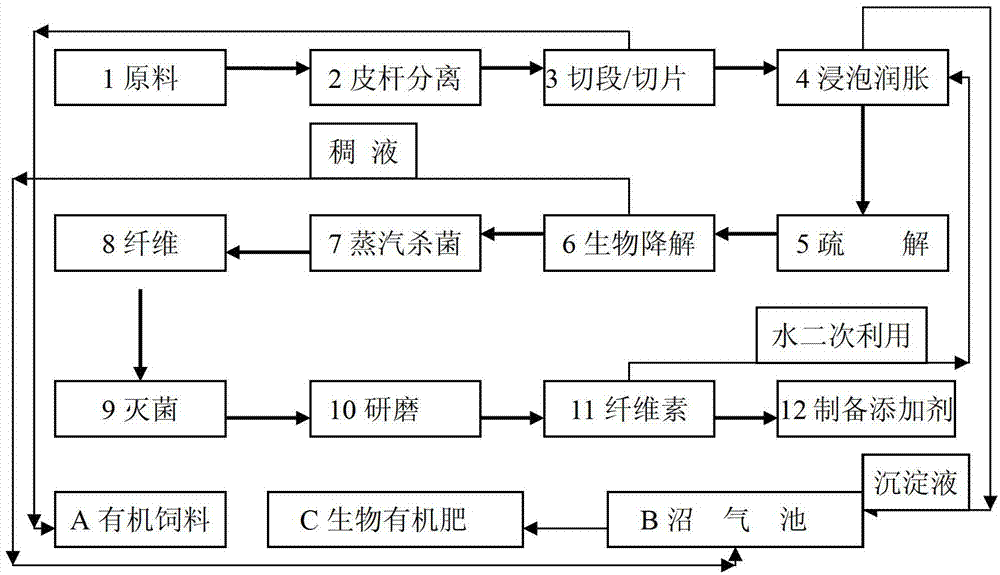

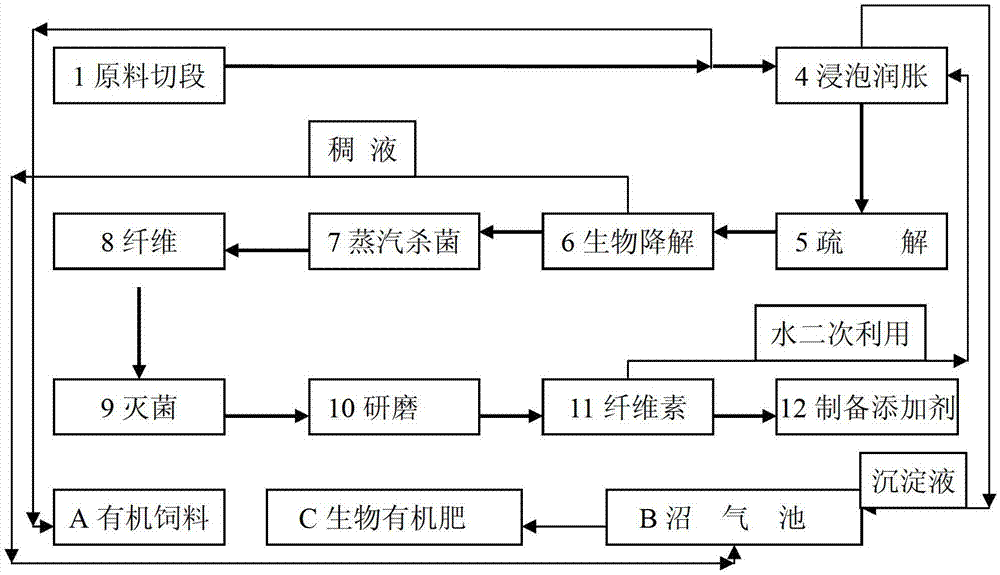

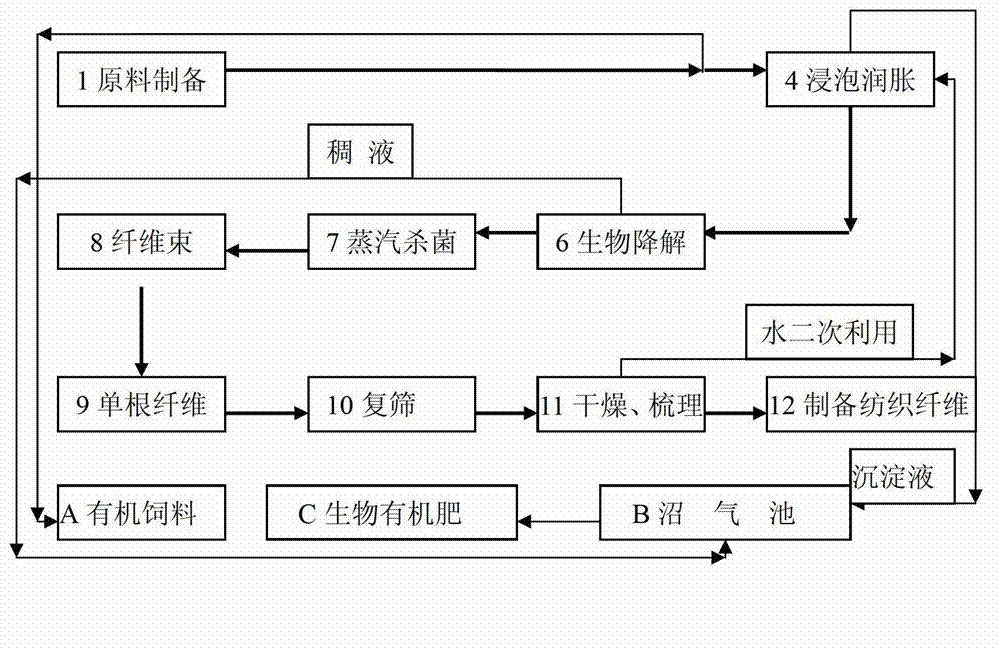

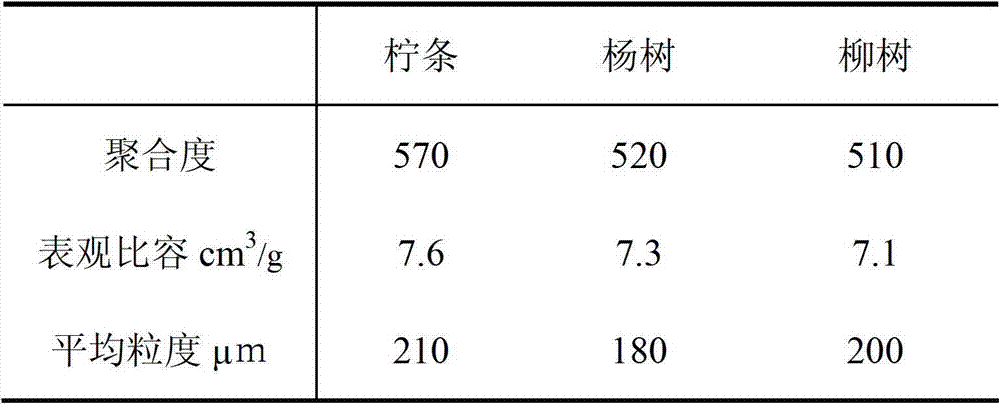

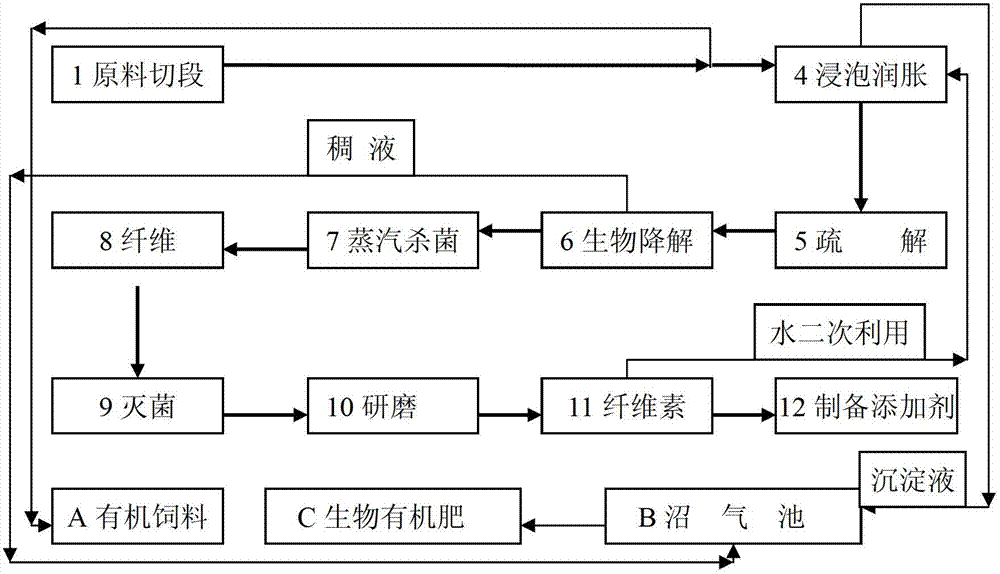

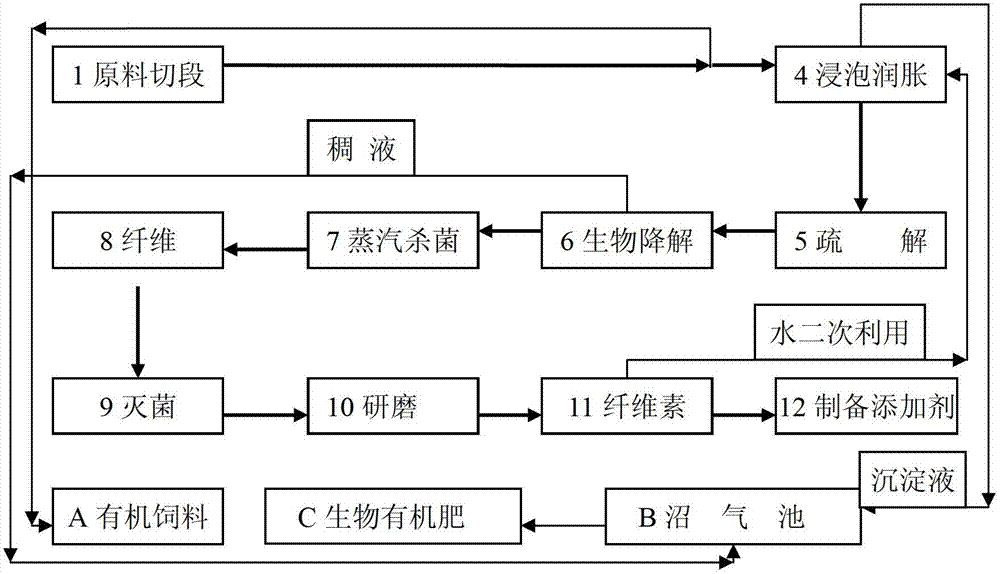

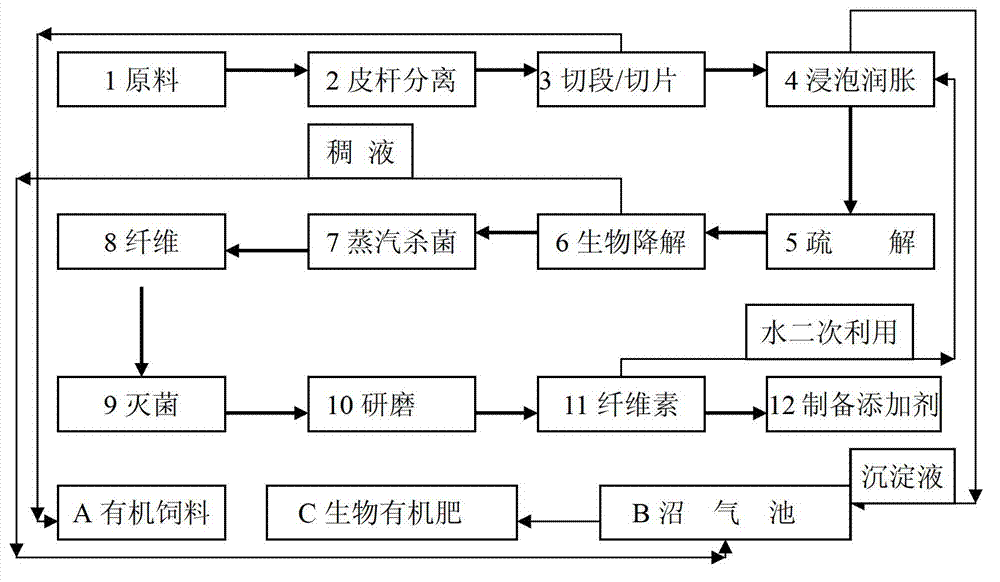

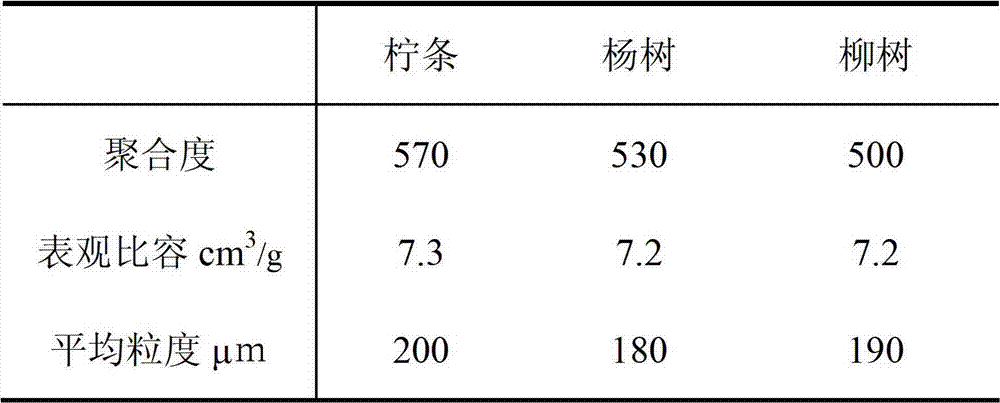

The invention relates to biological flora and a method for preparing cellulose for an additive through the biological flora. The composite flora comprises bacillus stored with the number of CGMCC (China General Microbiological Culture Collection Center) No. 5971, rheinheimera tangshanensis stored with the number of CGMCC No.5972, acinetobacter lwoffii stored with the number of CGMCC No. 5973, pseudomonas fluorescens stored with the number of CGMCC No. 5974 and Wickerhamomyces anomalus stored with the number of CGMCC No. 5975. The method comprises the steps as follows: preparing bacteria liquid; processing raw materials; and preparing fibers: difibering, biologically degrading, sterilizing through steam, obtaining fibers, sterilizing and grinding. The method provided by the invention is environment-friendly; and the waste liquid is directly transformed into organic fertilizer, therefore, zero release and zero pollution are achieved. The biological process performs protection to the fibers. Compared with traditional chemical method, the method provided by the invention has the advantages of low producing cost, high economic benefit, and capabilities of saving the energy and protecting the environment.

Owner:BEIJING TIANAN BIOSCI & TECH

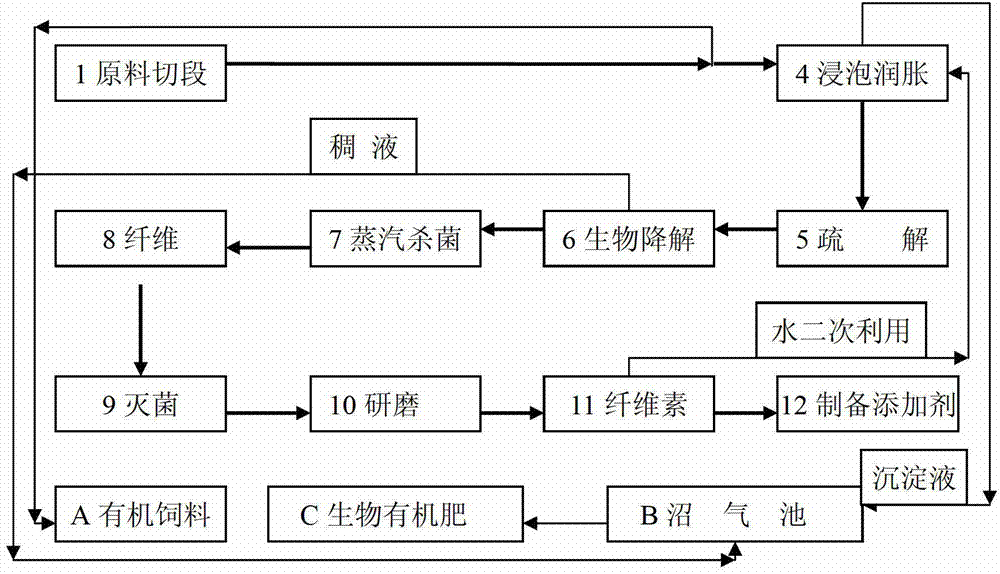

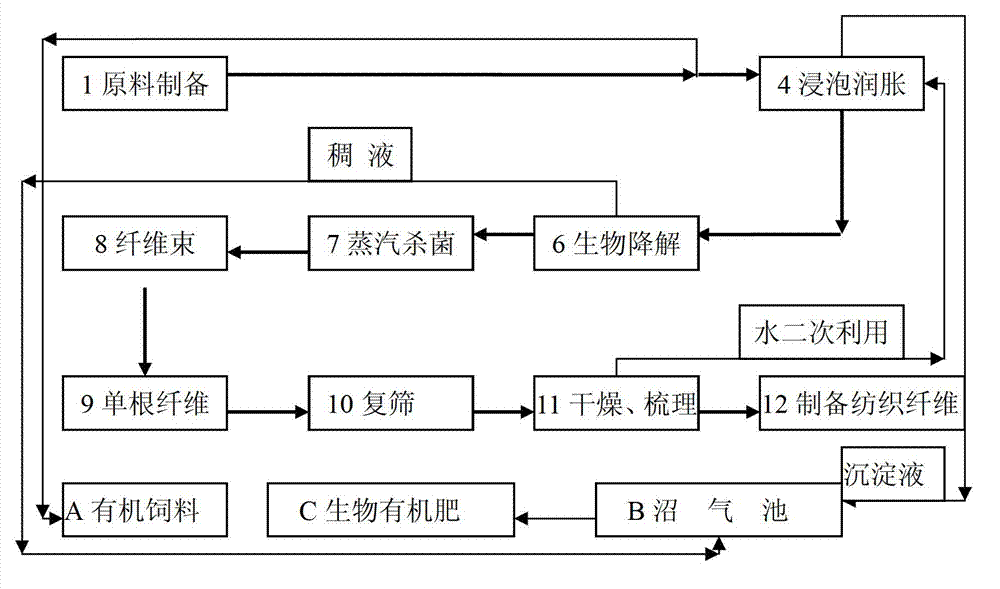

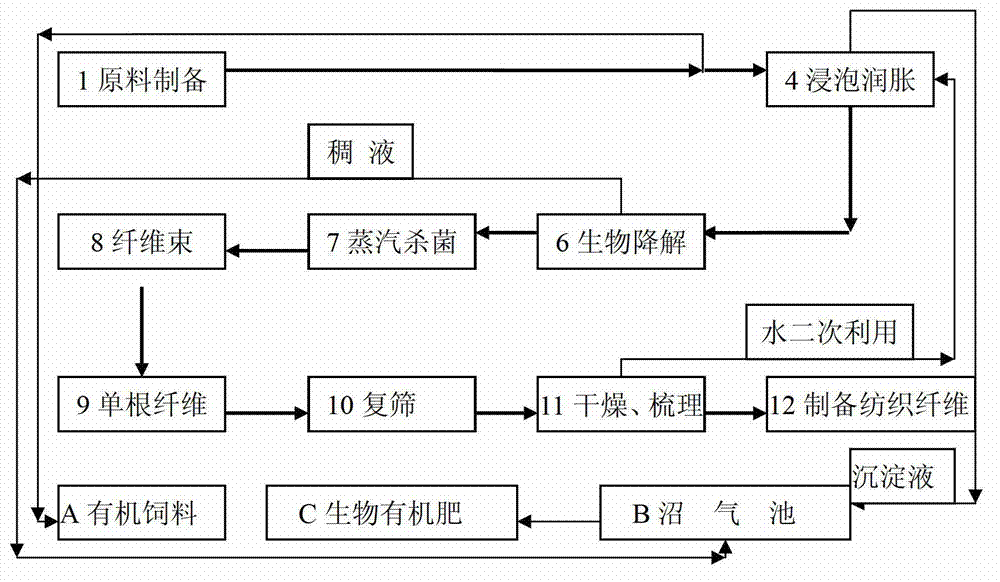

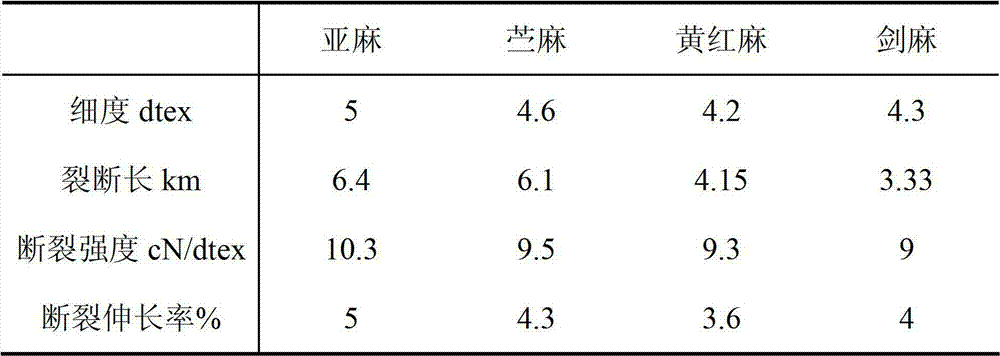

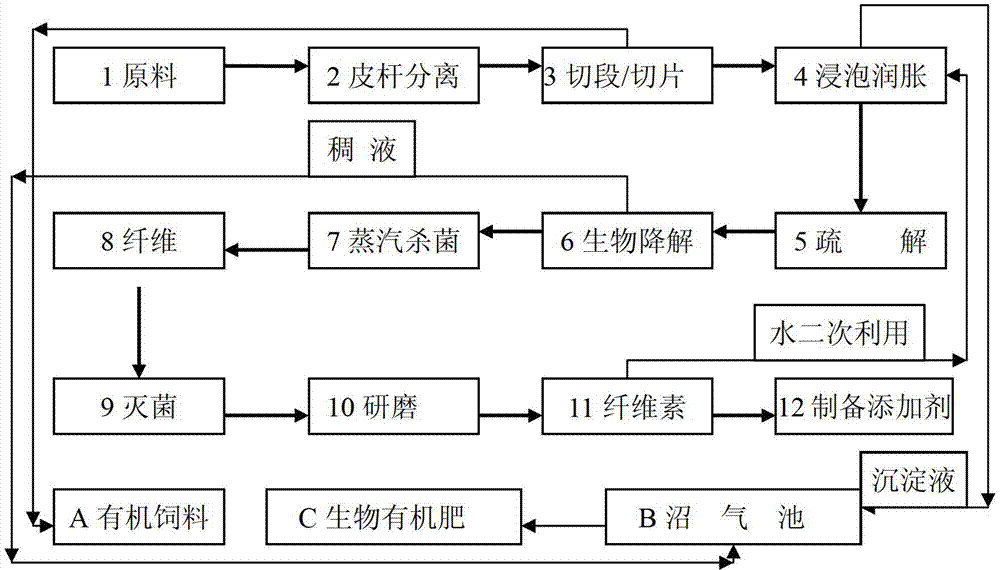

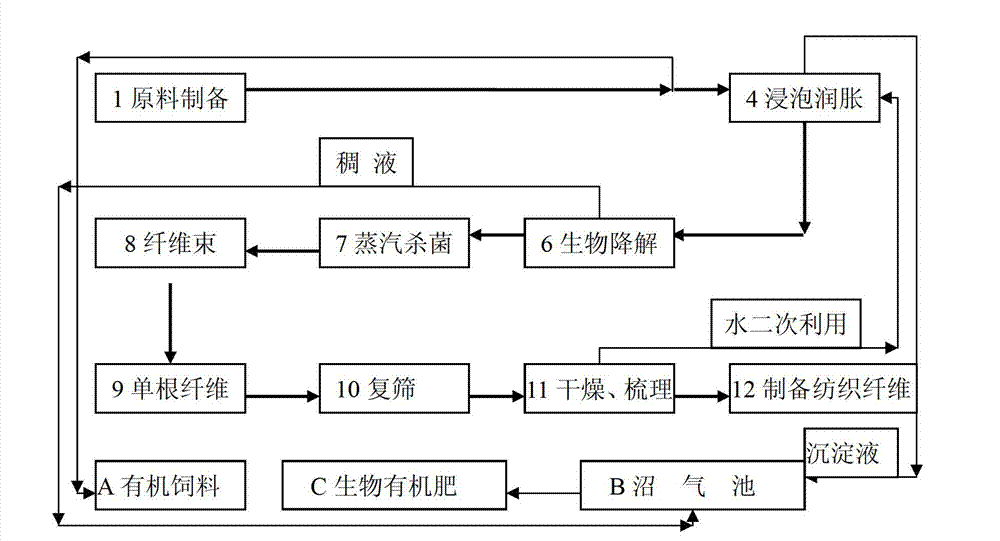

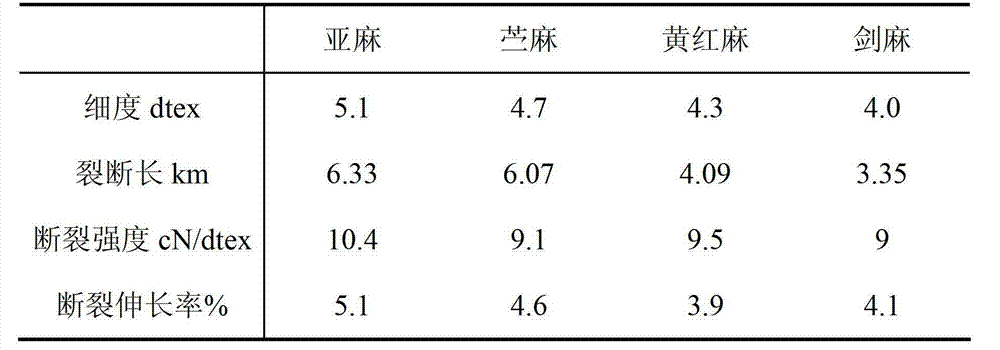

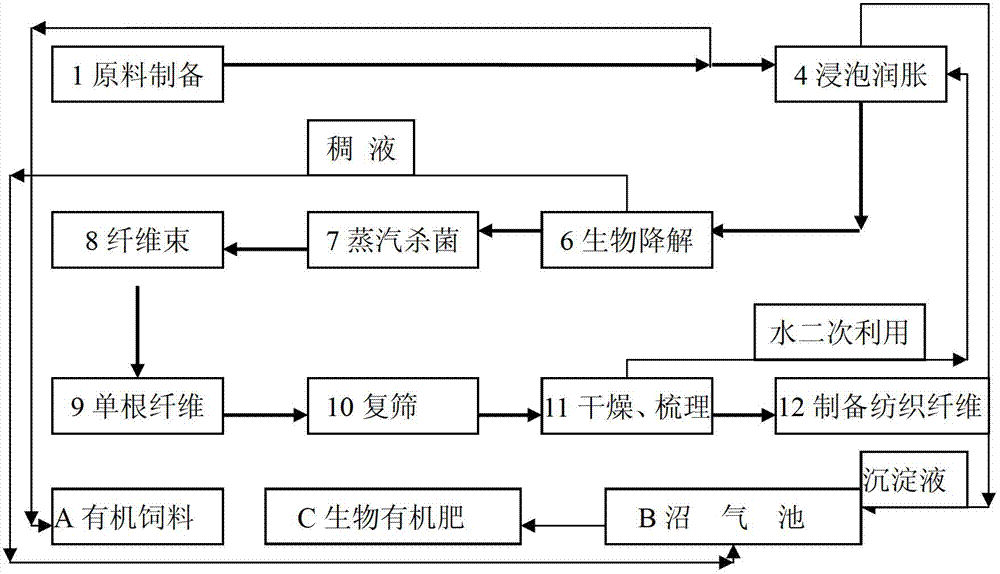

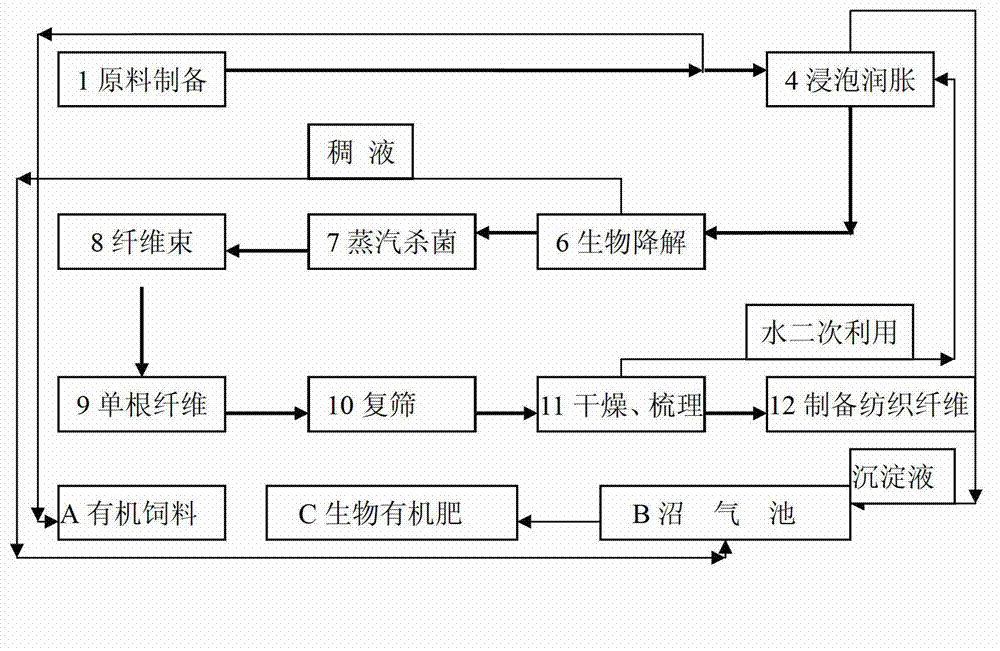

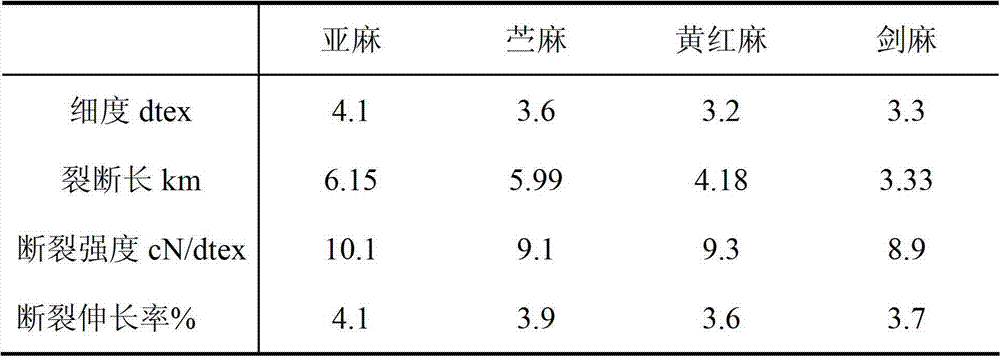

Composite flora and application of the same in textile fiber preparation

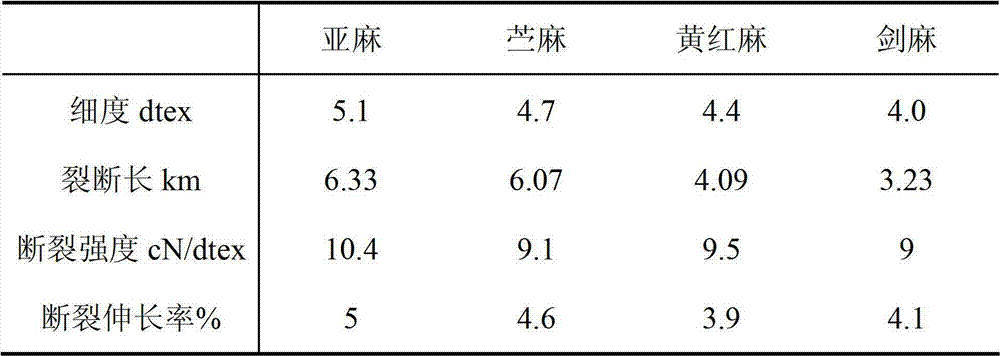

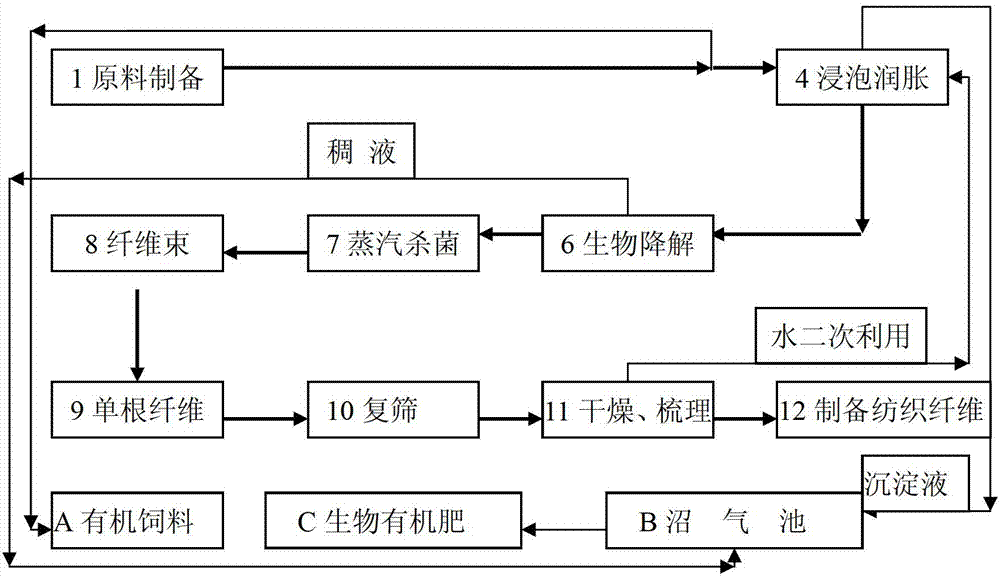

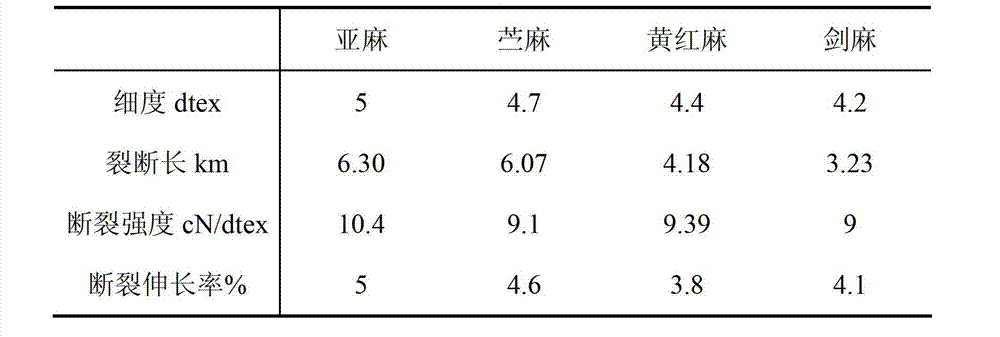

InactiveCN103074216APlay a protective effectZero pollutionBio-organic fraction processingBacteriaEnvironmental resistanceTextile fiber

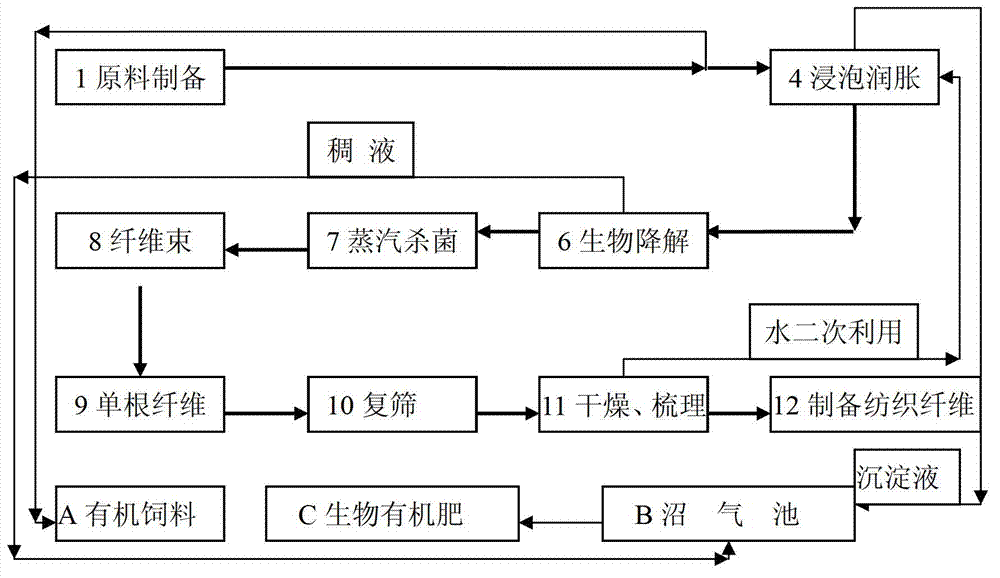

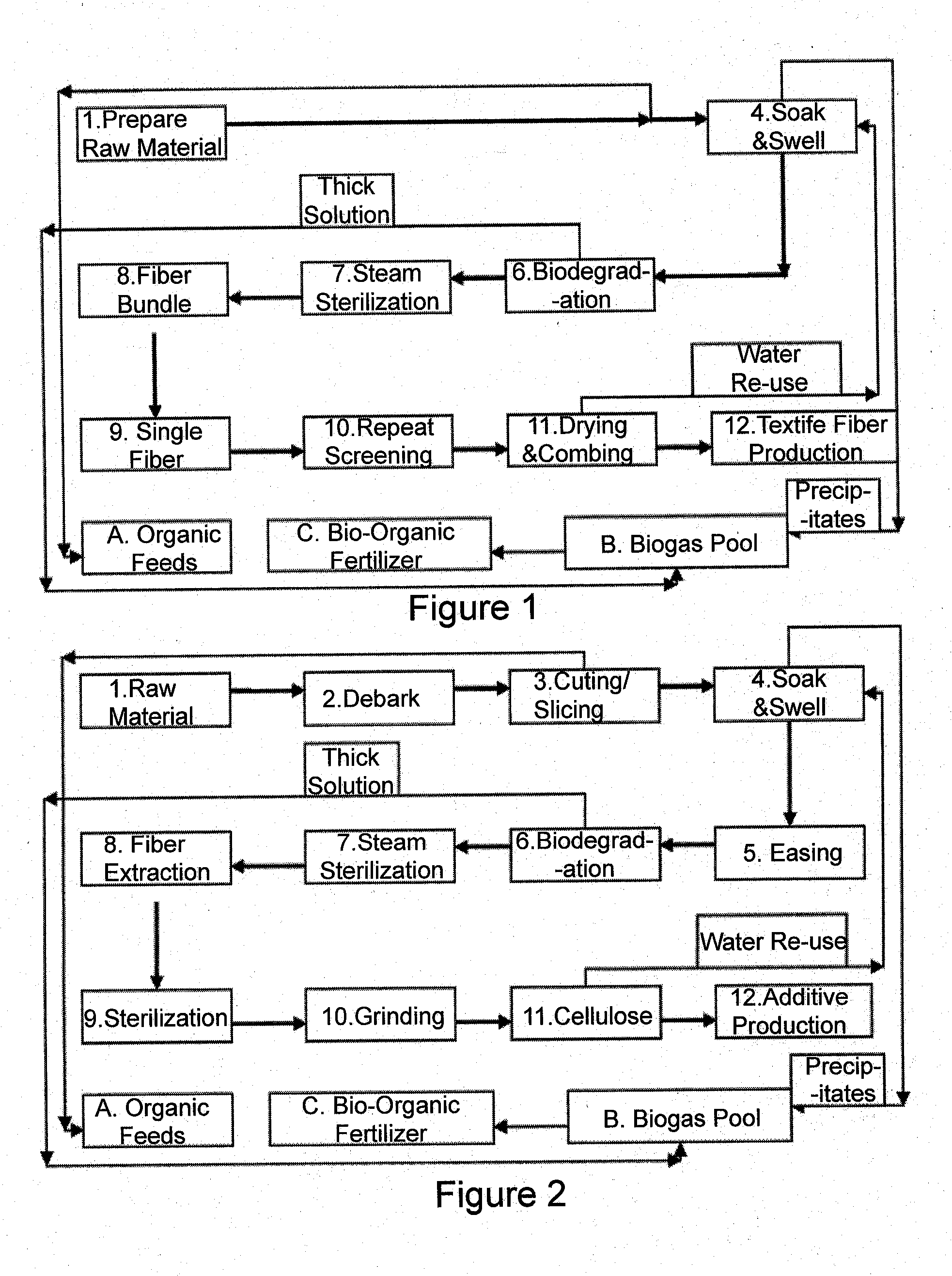

The present invention relates to a composite flora and an application of the composite flora in textile fiber preparation. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Compound bacteria and method for preparing textile fiber using same

InactiveCN102888366APlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberEnvironmental resistance

The invention relates to compound bacteria and a method for preparing textile fiber using the same. The compound bacteria comprise bacillus stored with a number of CGMCC No. 5971, rheinheimera tangshanensis stored with a number of CGMCC No. 5972, pseudomonas fluorescens stored with a number of CGMCC No. 5974, and Wickerhamomyces anomalus stored with a number of CGMCC No. 5975. The method comprises the following steps of: preparing bacteria liquid; processing raw materials; and preparing fibers, wherein fiber preparing steps comprise the following steps of: degrading, biologically degrading, sterilizing through steam, and obtaining the fibers; drying; and carding. The method provided by the invention is environment-friendly; waste liquid is directly transformed into organic fertilizer, and therefore, zero emission and zero pollution are achieved. A biological treating process performs protection to the fibers. Compared with a traditional chemical method, the method provided by the invention has the advantages of being low in producing cost, high in economic benefit, and is capable of saving an energy resource and protecting an environment.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and additive cellulose preparation method by using the same

InactiveCN103074219APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberPollution

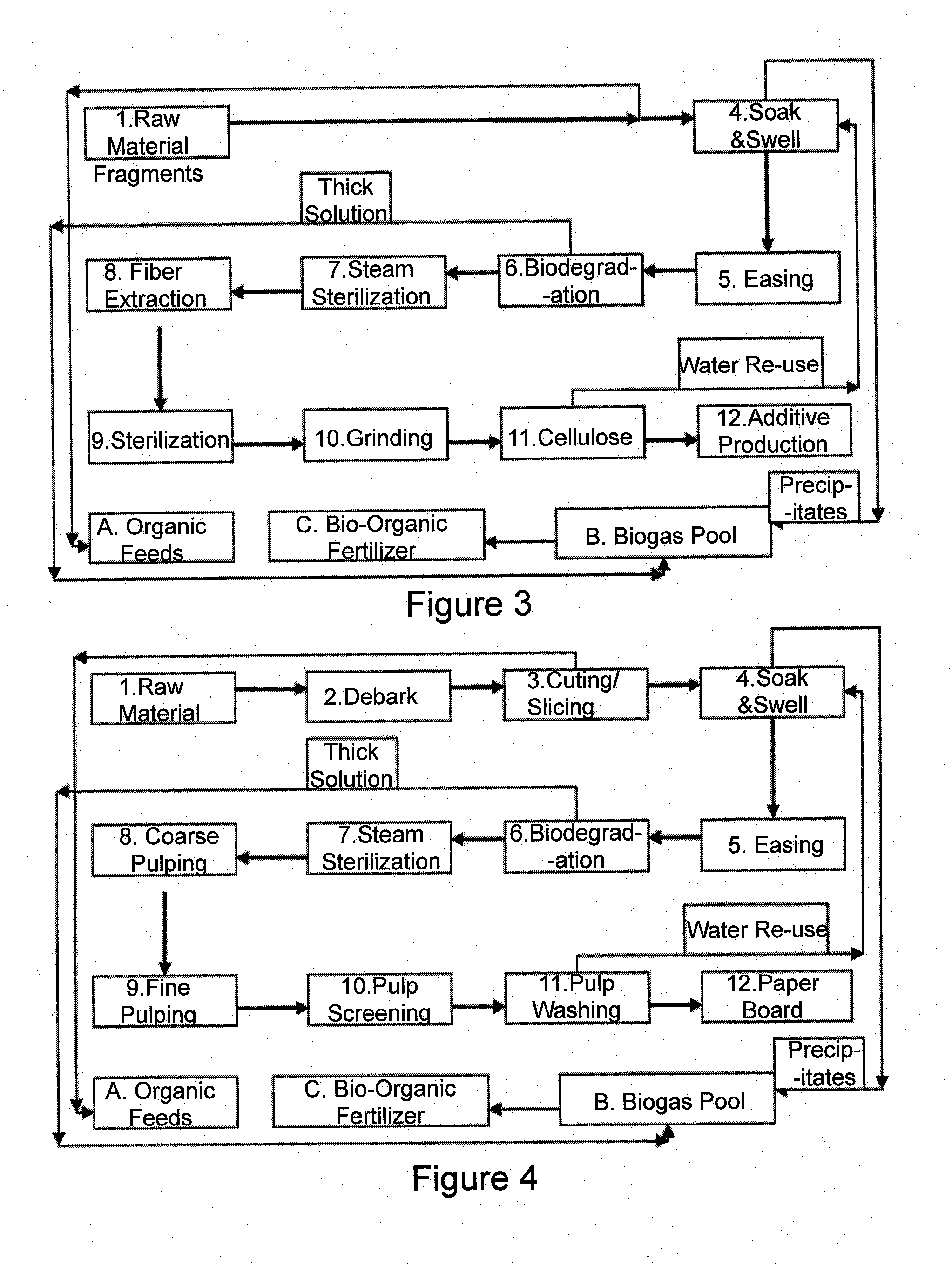

The present invention relates to a composite flora and an additive cellulose preparation method by using the composite flora. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

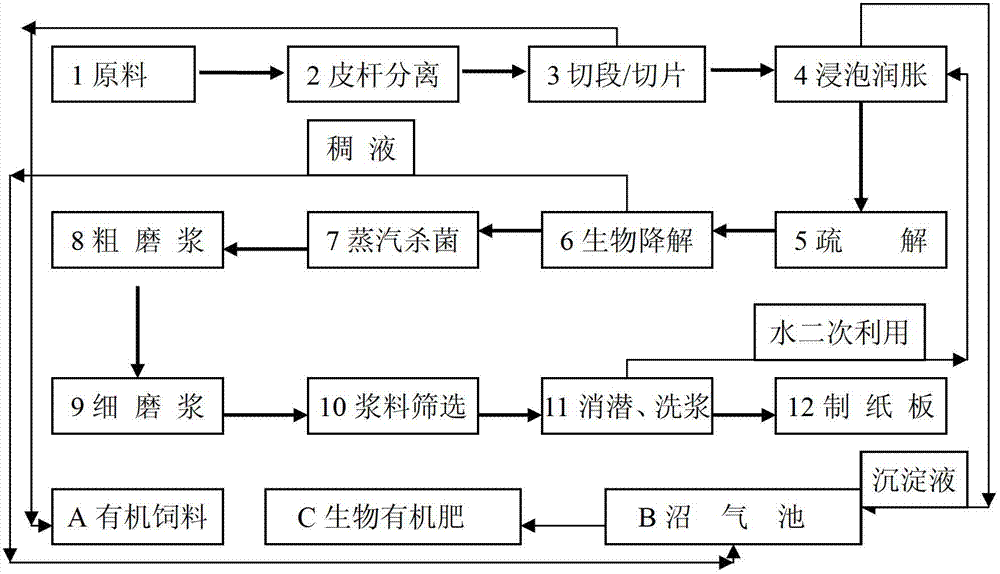

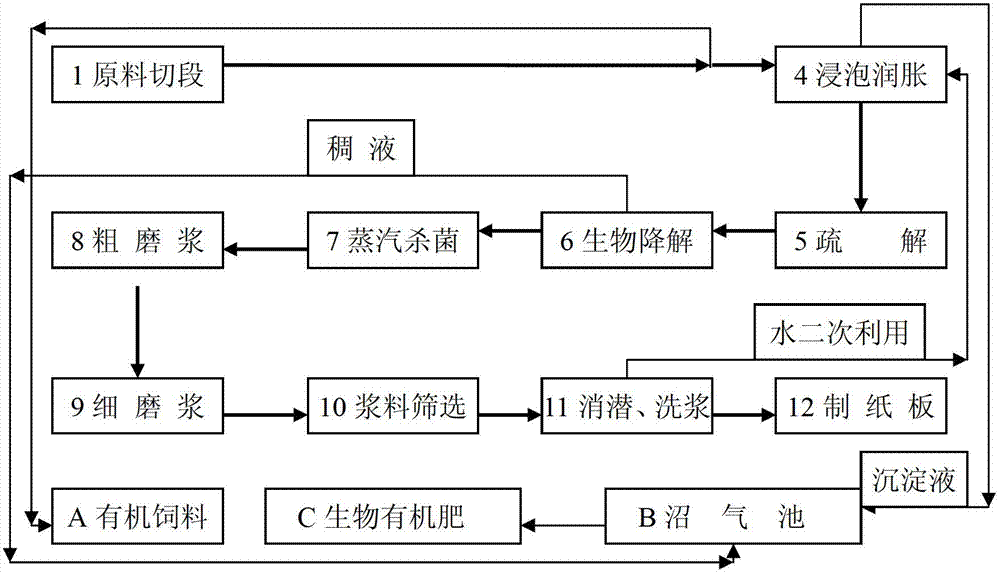

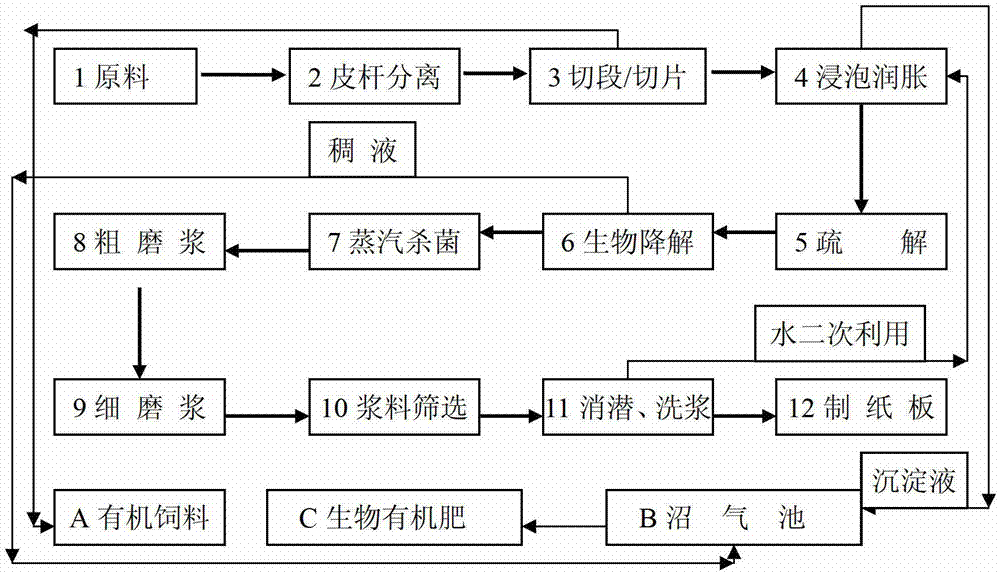

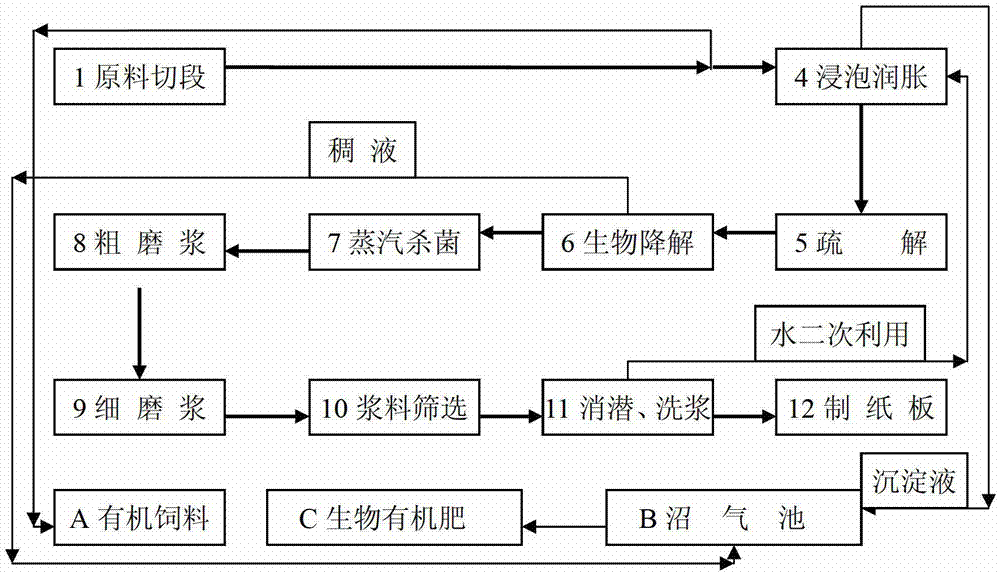

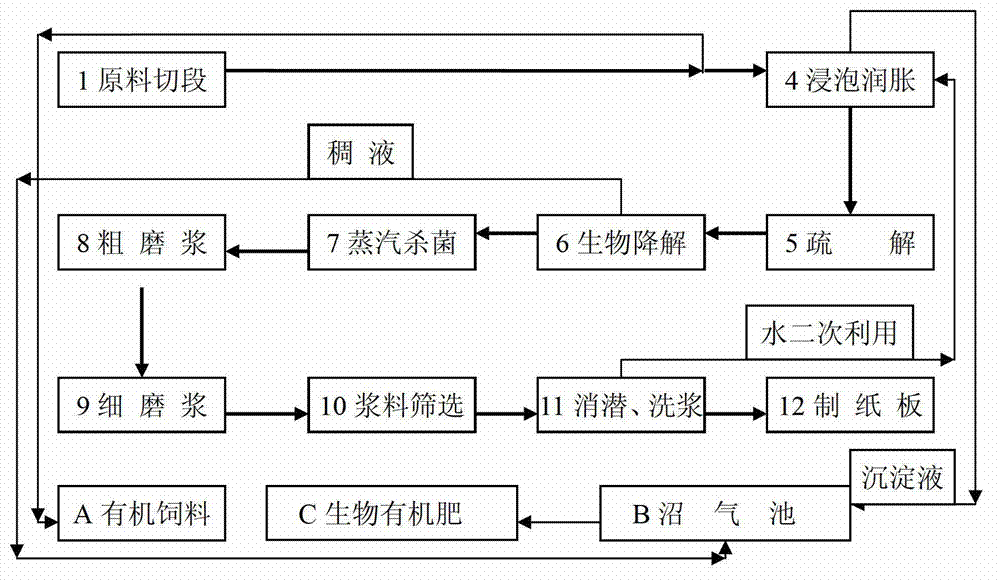

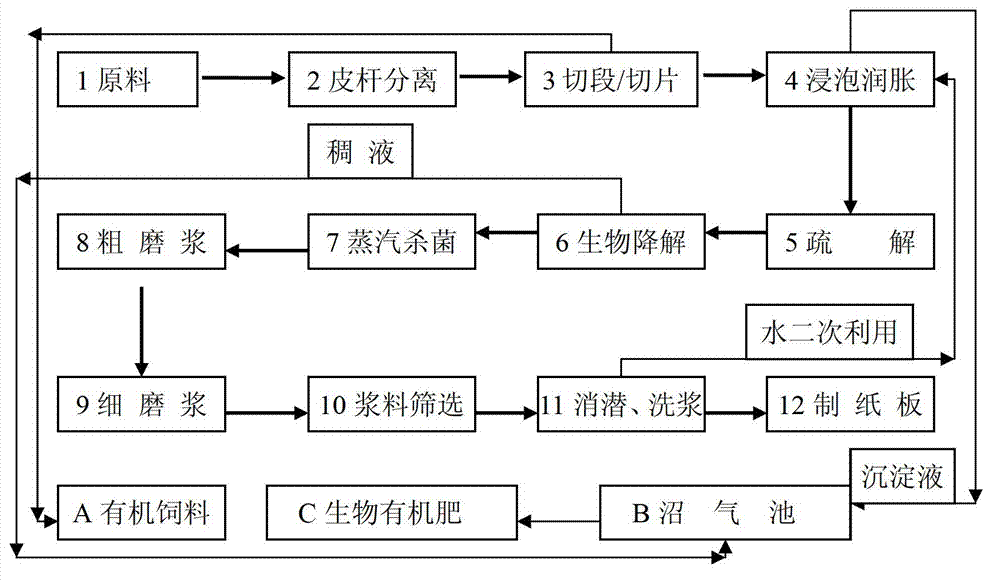

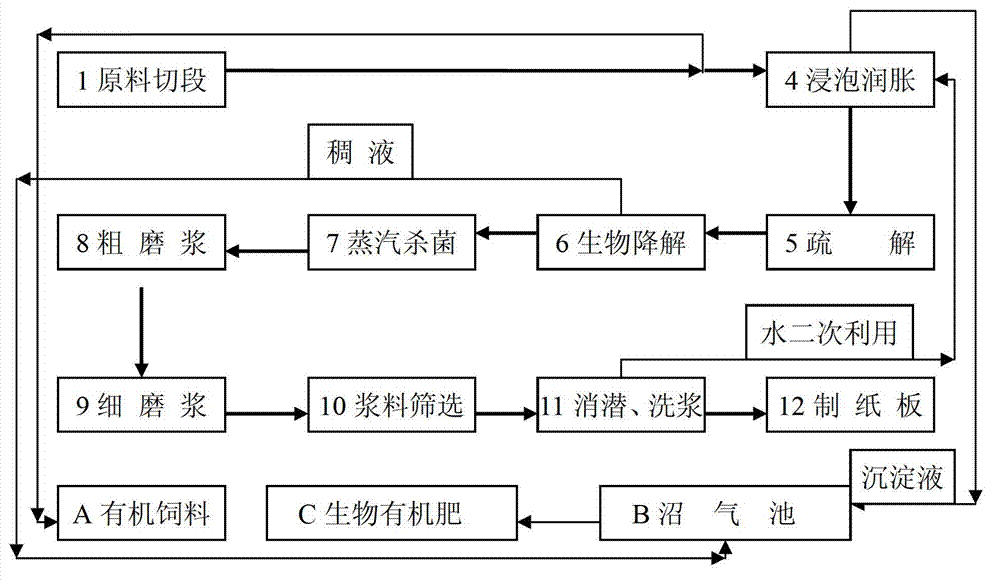

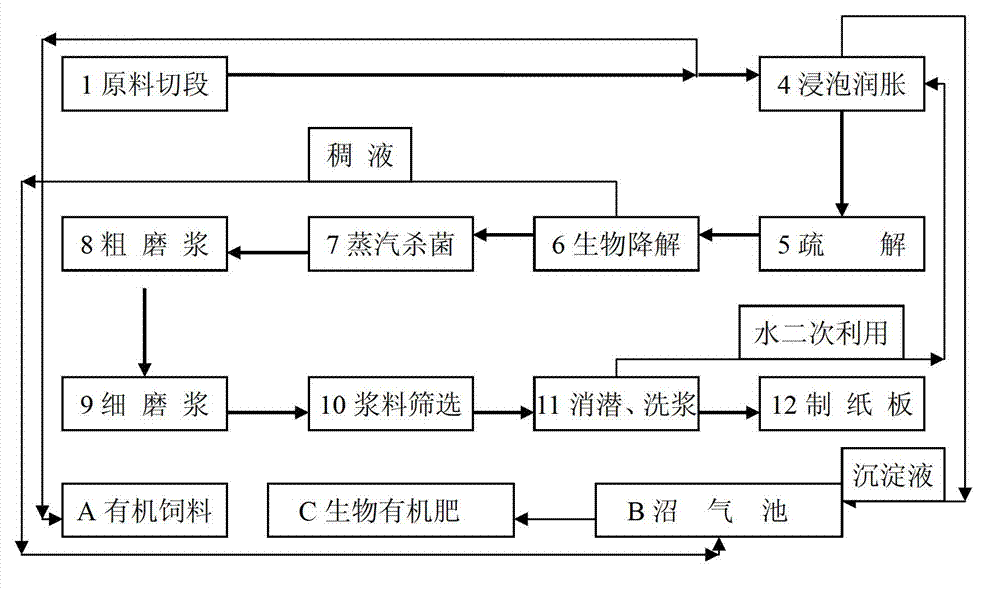

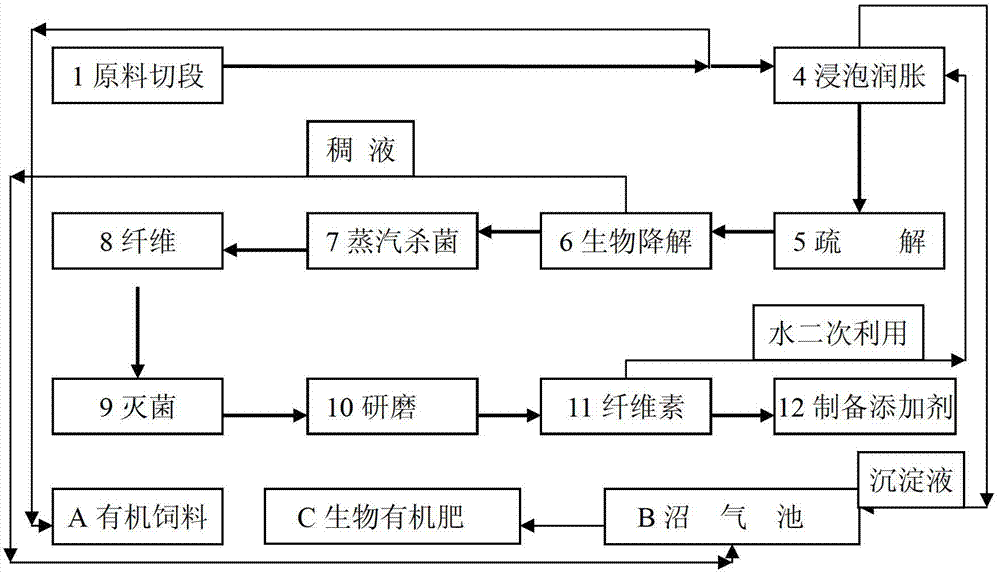

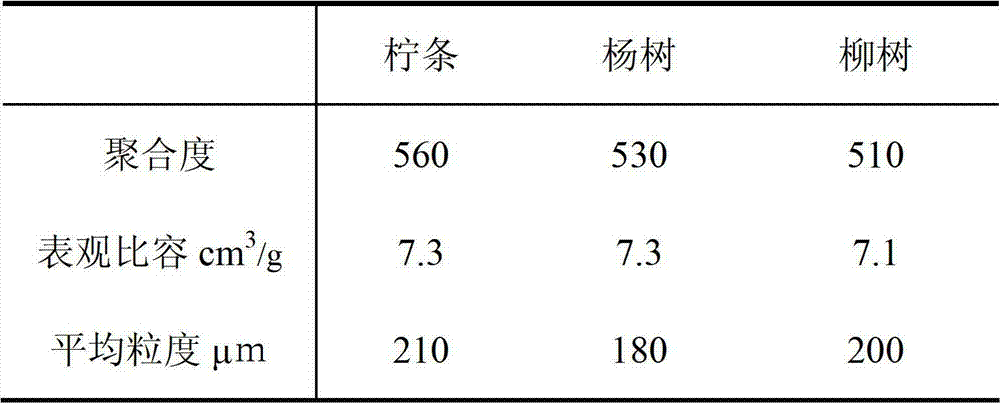

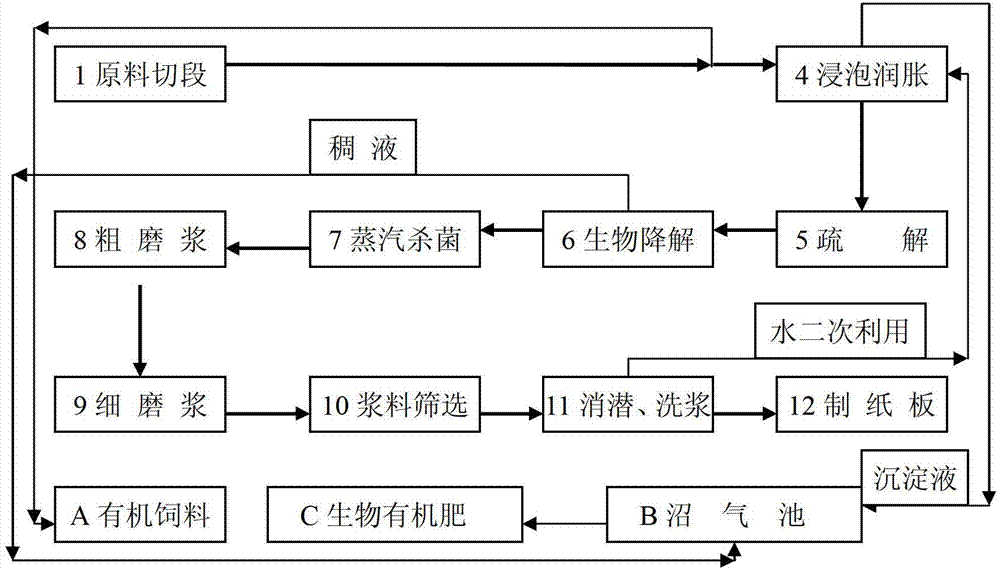

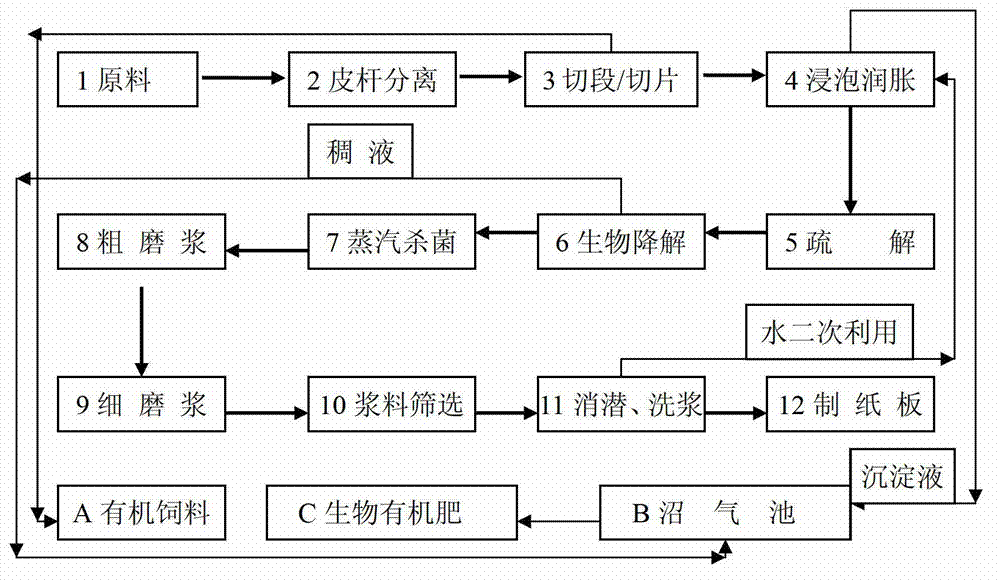

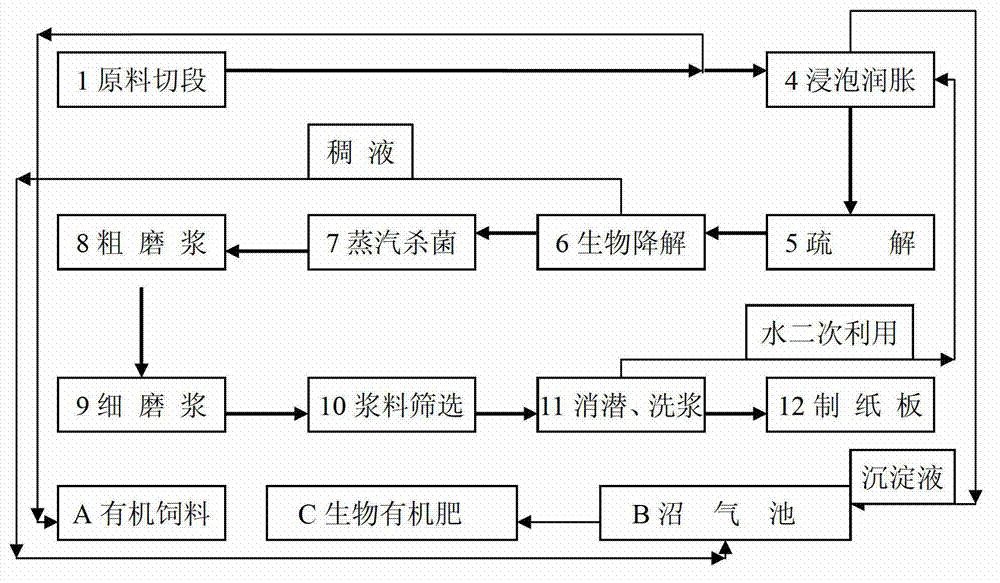

Composite flora and pulping method by using biological bacterial liquid of composite flora

InactiveCN103074250AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaCardboardFiber

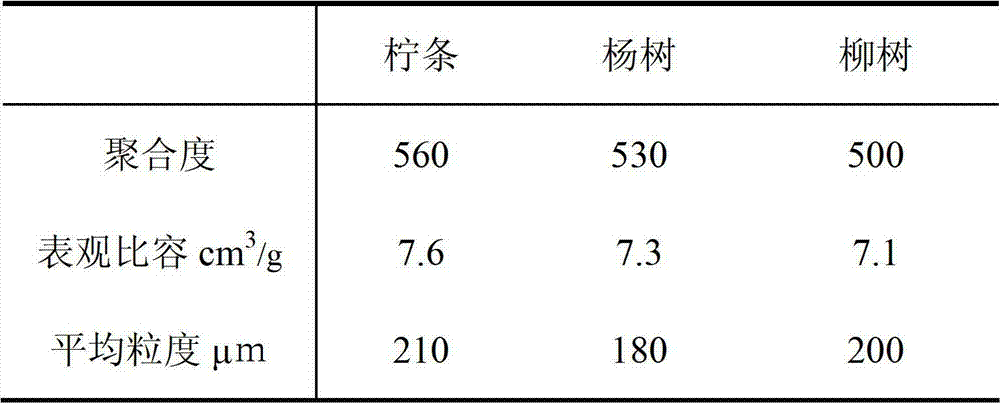

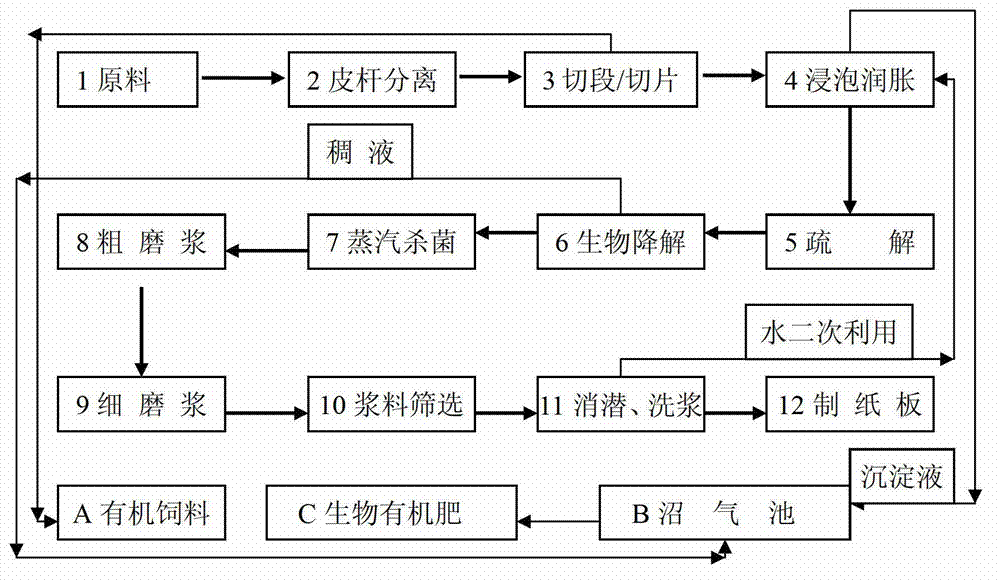

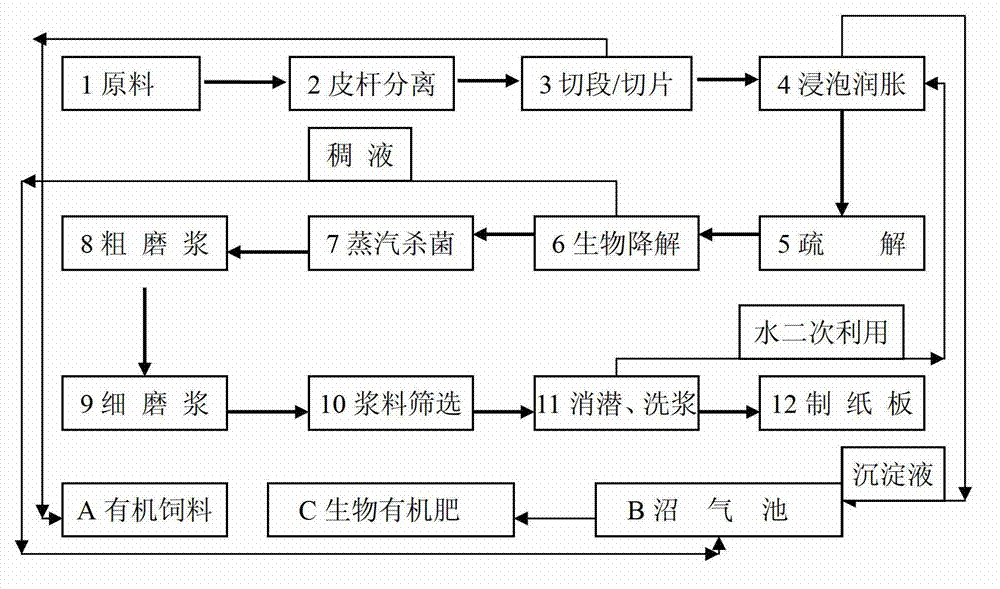

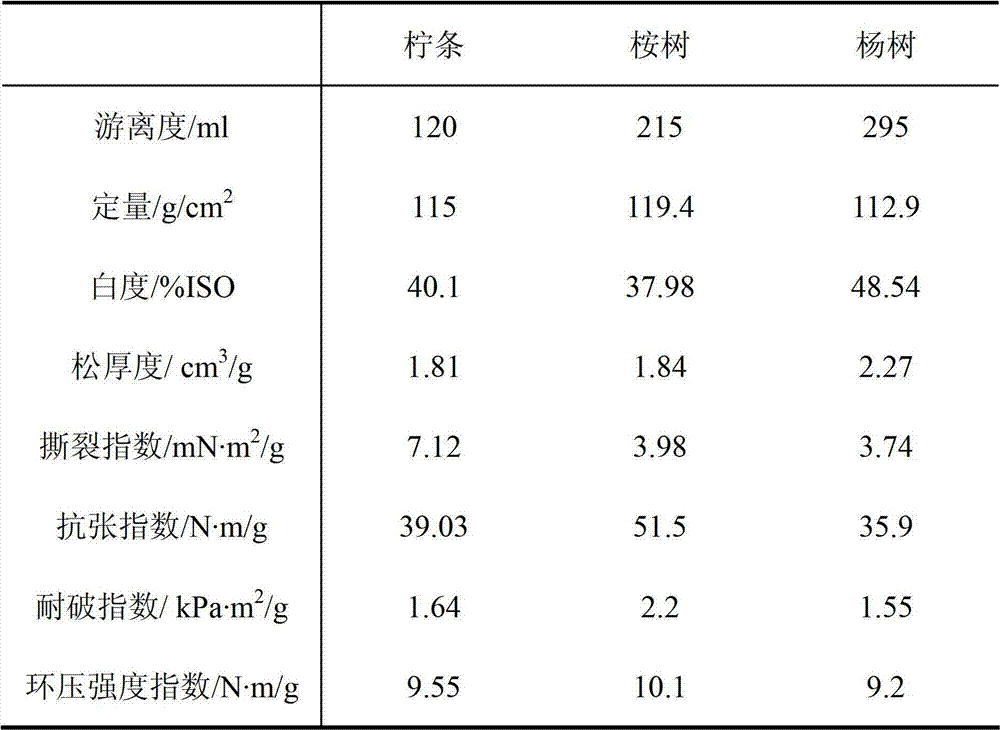

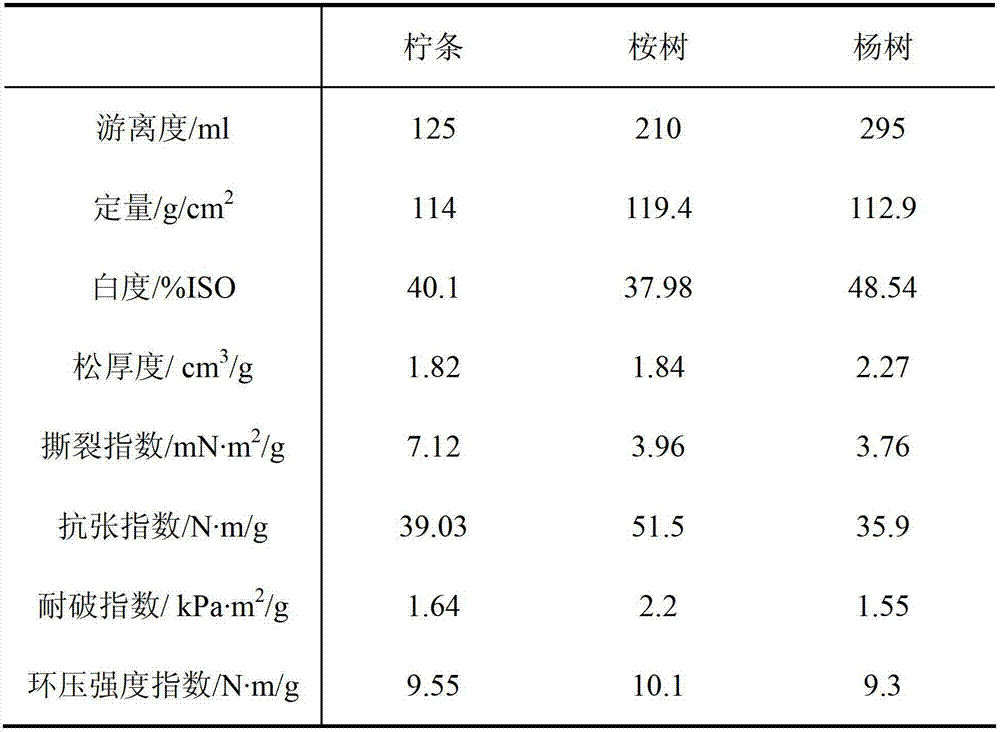

The present invention relates to a composite flora and a pulping method by using a biological bacterial liquid of the composite flora. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and application of the same in biological bacterial liquid pulping process

InactiveCN103074249AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaCardboardFiber

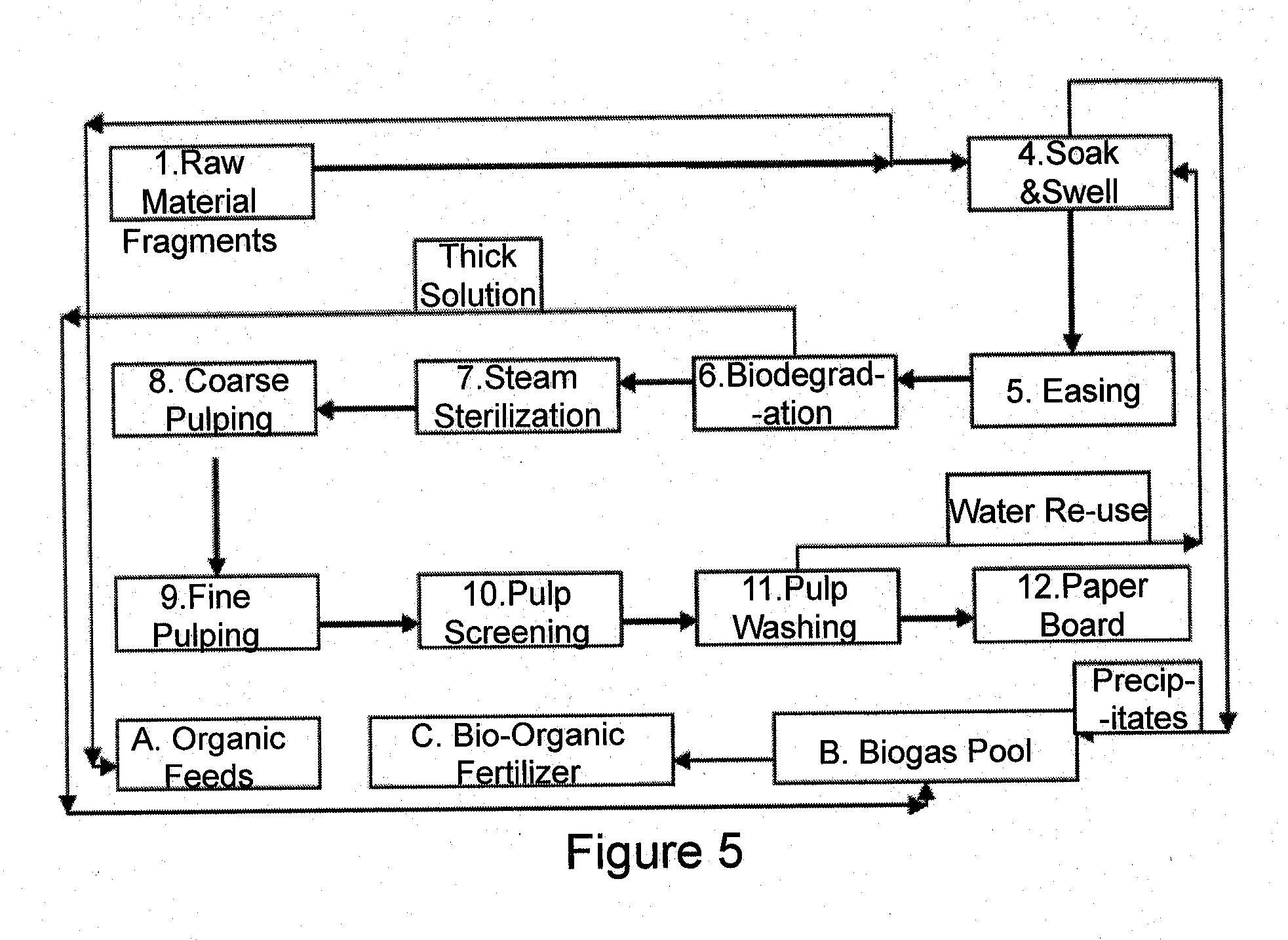

The present invention relates to a composite flora and an application of the composite flora in a biological bacterial liquid pulping process. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

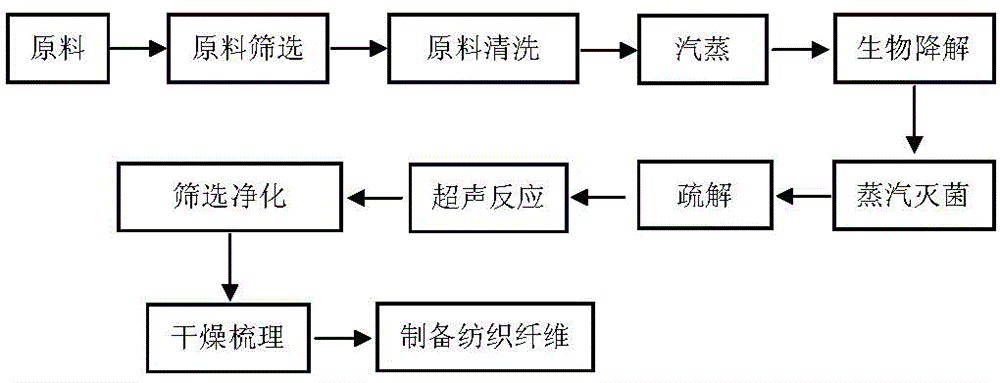

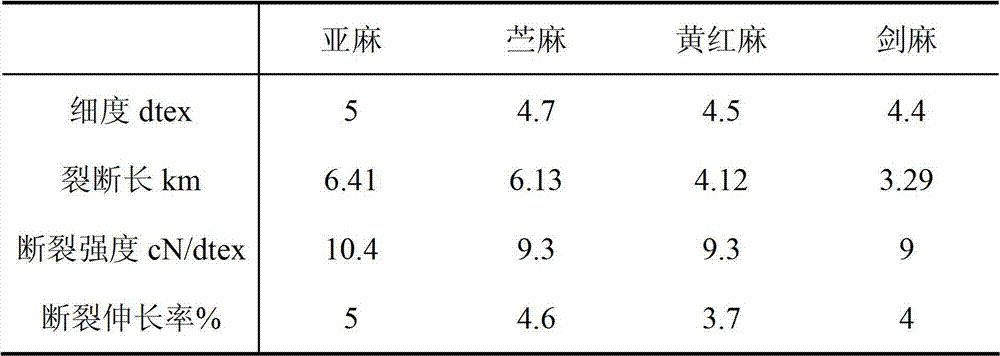

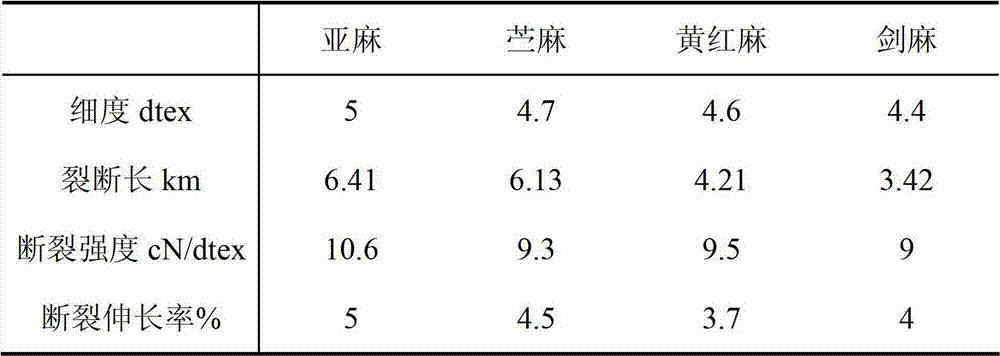

Method for biologically and ultrasonically preparing textile fibers

The invention relates to a method for biologically and ultrasonically preparing textile fibers, which effectively solves the problem of pollution and the problem on how to save energy and water, reduce emission, reduce production cost and increase the utilization rate of materials. The method includes the following steps: brown-rot fungi, acinetobacter lwoffii, pseudomonas fluorescens and rheinheimera tangshanensis are mixed together and added with water, so that a compound bacteria liquid is prepared; a material is cut up, washed with water, steamed to be softened, dehydrated and added with the compound bacteria liquid for biodegradation, the material is then bailed out, drained and sterilized by steam under normal pressure, defibering agent is then added to defiber the material into fiber bundles, the fiber bundles are ultrasonically processed, so that the fiber bundles become single fibers, pulp in the form of the single fibers is sent into a pulp washer, washed, purified, then screened and filtered, so that purified single fibers are obtained, and the purified single fibers are soaked in warm water, then dried, carded and drawn, so that the fibers are further straightened into textile fibers. The method disclosed by the invention is advanced, easy to operate, high in production efficiency, energy-saving, environment-friendly, low in cost and easy to popularize and apply.

Owner:BEIJING ZHONGKE AOBEI ULTRASONIC TECH RES INST

Composite flora and additive cellulose preparation method by using the same

InactiveCN103074256APlay a protective effectNo pollutionBio-organic fraction processingBacteriaEnvironmental resistanceFiber

The present invention relates to a composite flora and an additive cellulose preparation method by using the composite flora. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and pseudomonas fluorescens with a preservation number of CGMCC No.5974. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and application of the same in additive cellulose preparation

InactiveCN103074254APlay a protective effectNo pollutionBio-organic fraction processingBacteriaEnvironmental resistanceFiber

The present invention relates to a composite flora and an application of the composite flora in additive cellulose preparation. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The process for preparing the additive cellulose comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and pulping method by using biological bacterial liquid of composite flora

InactiveCN103074264AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaCardboardFiber

The present invention relates to a composite flora and a pulping method by using a biological bacterial liquid of the composite flora. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and pseudomonas fluorescens with a preservation number of CGMCC No.5974. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora for biological preparation of cellulose additive, and applications thereof

InactiveCN103074223APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberCellulose

The present invention relates to a composite flora for biological preparation of a cellulose additive, and applications thereof. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, and acinetobacter lwoffii with a preservation number of CGMCC No.5973. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Compound bacteria and application in biological bacteria liquid pulping technology of compound bacteria

InactiveCN102888341AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaRheinheimera tangshanensisPaperboard

The invention relates to compound bacteria and application of the compound bacteria in a biological bacteria liquid pulping technology. The compound bacteria comprise bacillus stored with a number of CGMCC No. 5971, rheinheimera tangshanensis stored with a number of CGMCC No.5972, acinetobacter lwoffii stored with a number of CGMCC No. 5973, and pseudomonas fluorescens stored with a number of CGMCC No. 5974. The method mainly comprises the folllowing steps of: preparing bacteria liquid; processing raw materials; and pulping, wherein pulping steps comprise the following steps of: defibering, carrying out biodegradation, sterilizing through steam, carrying out rough pulping, carrying out fine pulping, screening a sizing agent, removing latency, and washing the sizing agent. A paperboard prepared by a biological bacteria liquid pulping method provided by the invention reaches a level over AA grade; waste liquid produced in a pulping process can be recycled or transformed into methane which can be served as an energy resource or organic fertilizer, and therefore, energy sources are saved, and environment protection is achieved.

Owner:BEIJING TIANAN BIOSCI & TECH

Compound bacteria for biological bacteria liquid pulping and application of compound bacteria

InactiveCN102888343AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaRheinheimera tangshanensisPaperboard

The invention relates to compound bacteria for biological bacteria liquid pulping and application of the compound bacteria. The invention also provides a biological bacteria liquid pulping method. The compound bacteria comprise bacillus stored with a number of CGMCC No. 5971, rheinheimera tangshanensis stored with a number of CGMCC No.5972, and Wickerhamomyces anomalus stored with a number of CGMCC No. 5975. The method mainly comprises the following steps of: preparing bacteria liquid; processing raw materials; and pulping, wherein pulping steps comprise the following steps of: defibering, carrying out biodegradation, sterilizing through steam, carrying out rough pulping, carrying out fine pulping, screening a sizing agent, removing latency, and washing the sizing agent. A paperboard prepared by the biological bacteria liquid pulping method provided by the invention reaches a level over AA grade; waste liquid produced in a pulping process can be recycled or transformed into methane which can be served as an energy resource or organic fertilizer, and therefore, energy resources are saved, and environment protection is achieved.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora for biological preparation of textile fibers, and applications thereof

InactiveCN103074226APlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberRheinheimera tangshanensis

The present invention relates to a composite flora for biological preparation of textile fibers, and applications thereof. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora for biological preparation of textile fibers, and applications thereof

InactiveCN103074224APlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberRheinheimera tangshanensis

The present invention relates to a composite flora for biological preparation of textile fibers, and applications thereof. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, and acinetobacter lwoffii with a preservation number of CGMCC No.5973. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and additive cellulose preparation method by using the same

InactiveCN103074251APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberEnvironmental resistance

The present invention relates to a composite flora and an additive cellulose preparation method by using the composite flora. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and application of the same in biological bacterial liquid pulping process

InactiveCN103074255AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaCardboardFiber

The present invention relates to a composite flora and an application of the composite flora in a biological bacterial liquid pulping process. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

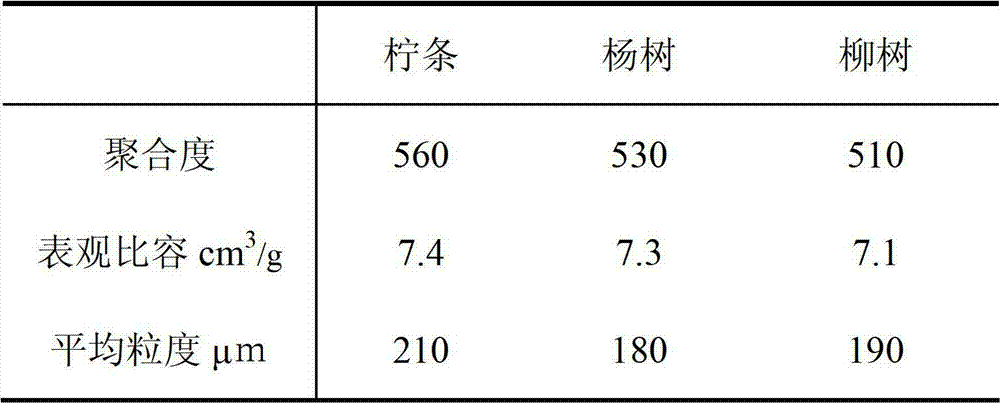

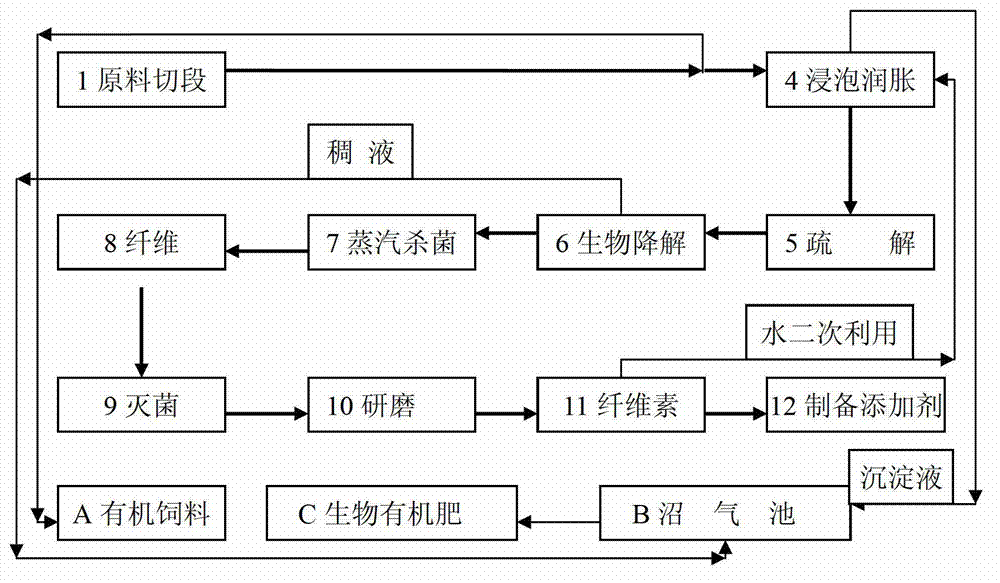

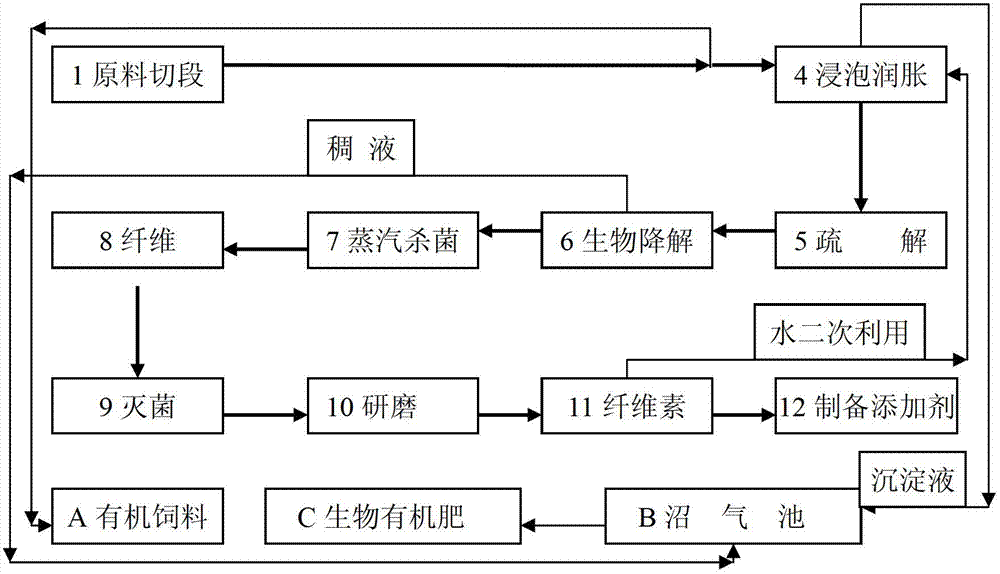

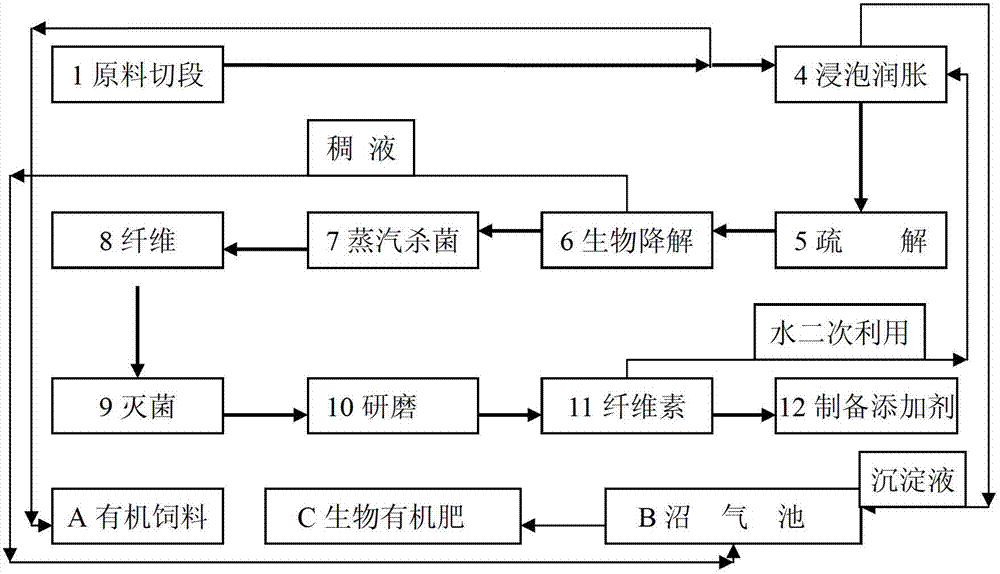

Rheinheimera tangshanensis and method for preparing cellulose for additive using same

InactiveCN102888369APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberCellulose

The invention relates to rheinheimera tangshanensis and a method for preparing cellulose for an additive using the rheinheimera tangshanensis. The rheinheimera tangshanensis is stored with a number of CGMCC No. 5972. The method comprises the following steps of: preparing bacteria liquid; processing raw materials; and preparing fibers, wherein fiber preparing steps comprise the following steps of: defibering, biologically degrading, sterilizing through steam, and obtaining the fibers, sterilizing and grinding. The method provided by the invention is environment-friendly; waste liquid is directly transformed into organic fertilizer, therefore, zero emission and zero pollution are achieved. A biological treating process performs protection to the fibers. Compared with a traditional chemical method, the method provided by the invention has the advantages of being low in producing cost, high in economic benefit, and is capable of saving an energy resource and protecting an environment.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and application of the same in additive cellulose preparation

InactiveCN103074260APlay a protective effectNo pollutionBio-organic fraction processingBacteriaEnvironmental resistanceFiber

The present invention relates to a composite flora and an application of the composite flora in additive cellulose preparation. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and pseudomonas fluorescens with a preservation number of CGMCC No.5974. The process for preparing the additive cellulose comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and application of the same in textile fiber preparation

InactiveCN103074259APlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberRheinheimera tangshanensis

The present invention relates to a composite flora and an application of the composite flora in textile fiber preparation. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and pseudomonas fluorescens with a preservation number of CGMCC No.5974. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora for biological preparation of cellulose additive, and applications thereof

InactiveCN103074266APlay a protective effectNo pollutionBio-organic fraction processingBacteriaCelluloseFiber

The present invention relates to a composite flora for biological preparation of a cellulose additive, and applications thereof. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, and pseudomonas fluorescens with a preservation number of CGMCC No.5974. The process for preparing a cellulose additive comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and application of the same in textile fiber preparation

InactiveCN103074214APlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberPseudomonas fluorescens

The present invention relates to a composite flora and an application of the composite flora in textile fiber preparation. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and application of the same in additive cellulose preparation

InactiveCN103074252APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberFlora

The present invention relates to a composite flora and an application of the composite flora in additive cellulose preparation. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The process for preparing the additive cellulose comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Rheinheimera tangshanensis and biological bacteria liquid pulping method thereof

InactiveCN102888361APlay a protective effectZero emissionBio-organic fraction processingBacteriaRheinheimera tangshanensisPaperboard

The invention relates to rheinheimera tangshanensis and a biological bacteria liquid pulping method of the rheinheimera tangshanensis. The rheinheimera tangshanensis is stored with a number of CGMCC No. 5972. The biological bacteria liquid pulping method mainly comprises the following steps of: preparing bacteria liquid; processing raw materials; and pulping, wherein pulping steps comprise the following steps of: defibering, biologically degrading, sterilizing through steam, carrying out rough pulping, carrying out fine pulping, screening a sizing agent, removing latency, and washing the sizing agent. A paperboard prepared by the biological bacteria liquid pulping method provided by the invention reaches a level over AA grade; waste liquid produced in a pulping process can be recycled or transformed into methane which can be served as an energy resource or organic fertilizer, and therefore, energy resources are saved, and environment protection is achieved.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and textile fiber preparation method by using the same

InactiveCN103074220APlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberEnvironmental resistance

The present invention relates to a composite flora and a textile fiber preparation method by using the composite flora. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and additive cellulose preparation method by using the same

InactiveCN103074253APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberPseudomonas fluorescens

The present invention relates to a composite flora and an additive cellulose preparation method by using the composite flora. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Wickerhamonyces anomalus CGMCC#5975 and Its Application Thereof

Provided are a complex microbial flora, an application thereof in preparing a textile fabric, a cellulose for use as an additive, and a biological bacterial solution pulp, and a method for using the complex microbial flora. The complex microbial flora comprises Bacillus sp. of deposit number CGMCC No. 5971, Rheinheimera tangshanensis of deposit number CGMCC No. 5972, Acinetobacter Iwoffii of deposit number CGMCC No. 5973, Pseudomonas fluorescens of deposit number CGMCC No. 5974, and Wickerhamomyces anomalus of deposit number CGMCC No. 5975. The method provided comprises: formulation of a bacterial solution, processing of raw materials, and preparation or pulping of the fiber. In one embodiment, the invention generally includes at least one Wickerhamomyces anomalus of deposit number CGMCC No. 5975, either alone or in the presence of other microorganisms as a complex microbial flora, and their applications thereof.

Owner:BEIJING TIANAN BIOSCI & TECH

Rheinheimera tangshanensis and method for preparing textile fiber by using same

InactiveCN102888368APlay a protective effectZero pollutionBio-organic fraction processingBacteriaFiberEnvironmental resistance

The invention relates to Rheinheimera tangshanensis and a method for preparing textile fibers by using the same. The collection number of the rheinheimera tangshanensis is CGMCC No.5972.The method comprises the following steps of: preparing a bacterial solution; processing raw material; and preparing fibers, namely biodegradation, steam sterilization, fiber collection, drying and carding. The method disclosed by the invention is completely environment-friendly, because all waste liquid can be directly converted into organic fertilizers. In a biological treatment process, fibers are protected. Compared with the conventional chemical methods, the method has the advantages that the production cost is low, the economic benefit is high, energy can be saved and pollution is avoided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and pulping method by using biological bacterial liquid of composite flora

InactiveCN103074257AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaFiberCardboard

The present invention relates to a composite flora and a pulping method by using a biological bacterial liquid of the composite flora. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com