Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

47 results about "Wickerhamomyces" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A genus of yeasts in the family Phaffomycetaceae and phylum Ascomycota.

Uses of Wickerhamomyces anomalus T1 in flavoring of soy sauce, and flavoring process

ActiveCN108330074AGood for later fragranceSuitable for growthFungiMicroorganism based processesAdditive ingredientSalt free

The invention discloses uses of Wickerhamomyces anomalus T1 in flavoring of soy sauce, and a flavoring process, and belongs to the field of food engineering. According to the present invention, the screened Wickerhamomyces anomalus T1 is preserved in the China General Microbiological Culture Collection Center on September 22, 2017, and has the preservation number of CGMCC No:14662; the strain is beneficial to the late flavoring of soy sauce; whether in the low-salt solid-state fermentation process or in the salt-free liquid-state fermentation process, the types of the aroma components can be increased, especially alcohols and esters can be increased, the phenethyl alcohol content in the low-salt solid-state soy sauce is increased to 14.34% from 4.49%, the total content of the alcohol esterin the salt-free liquid-state fermentation is increased to 41.05% from 38.1%, and the content is increased by 7.7%; and under the action of the aroma-producing yeast, the alcohol aroma and the esteraroma blended with the soy sauce present the unique flavor of the soy sauce.

Owner:张晨

Method for preparing flavor protein feed from compound bacteria fermentation distiller's grains

PendingCN107296150AHigh protein contentImprove palatabilityFood processingFood preservationCelluloseFiber

The invention belongs to the technical field of animal food or feed processing and particularly relates to a method for preparing a flavor protein feed from compound bacteria fermentation distiller's grains. The method comprises the steps of carrying out gas explosion on distiller's grains and carrying out ultrasonic cooperative treatment on broken lignin and cellulose, and then inoculating phanerochaete chrysosporium and trichoderma viride; inoculating candida utilis and wickerhamomyces anomalus on the basis of a degradation product; and finally adding yellow water generated in white spirit production to the fermented feed to prepare a pellet feed. According to the method for preparing the flavor protein feed from the compound bacteria fermentation distillers' grains, the crude fiber content is reduced, the protein content is improved, the flavor is added, the palatability and the security are improved, the environmental pollution of the distiller's grains and the yellow water is reduced, wastes are changed into treasure and the method has significant environmental benefits.

Owner:XIHUA UNIV

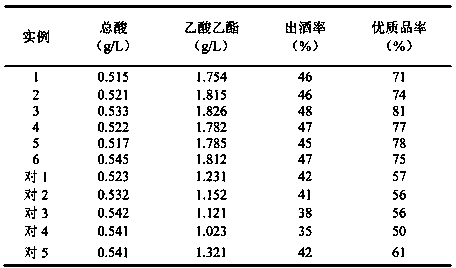

Microbial compound inoculant and preparation method and application thereof

ActiveCN111117901AIncrease the ester contentShorten fermentation timeFungiMicroorganism based processesHansenula anomalaAspergillus oryzae

The invention discloses a microbial compound inoculant and a preparation method and application thereof. The inoculant is prepared by mixing mould and yeast according to a weight ratio of (3-5):1. Themould is formed by mixing Aspergillus oryzae and Rhizopus oryzae according to a weight ratio of 1:(1-3); and the yeast is formed by mixing Saccharomyces cerevisiae, Hansenula anomala abnormal variant, Hansenula anomala and Wickerhamomyces anomalus according to a weight ratio of 1:(0.5-1.5):(0.5-1.5):(0.5-1.5). The fen-flavor liquor brewed by the microbial compound inoculant is pure in fen flavor,mellow, sweet, soft, natural, harmonious, refreshing in aftertaste, and high in liquor yield and high-quality liquor yield.

Owner:HENAN YANGSHAO LIQUOR IND CO LTD

Wickerhamomyces anomalus for feeding and application thereof

ActiveCN109609393AReduce diarrhea rateImprove conversion rateFungiAntinoxious agentsAcetic acidMycotoxin

The present invention discloses a wickerhamomyces anomalus for feeding and an application thereof. The wickerhamomyces anomalus Y4 has a preservation number of CGMCC NO.16540, the wickerhamomyces anomalus can withstand a high temperature of 100 DEG C, can grow in an acidic environment with a pH of 1.0 or higher, has strong bile salt resistance, has a function of degrading mycotoxins, and at the same time has a function of producing ethyl acetate. After the wickerhamomyces anomalus Y4 is prepared into a feed additive, the wickerhamomyces anomalus is safe and reliable in animal feeding effects,and has positive functions of promoting nutrient digestion and absorption, reducing diarrhea rate, improving feed conversion efficiency and promoting growth.

Owner:沃丰德(南阳)生物科技有限公司

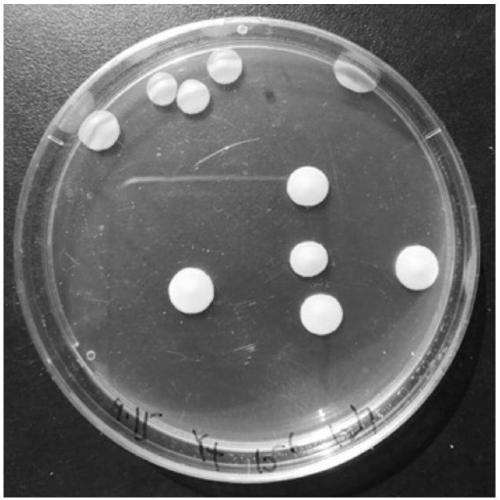

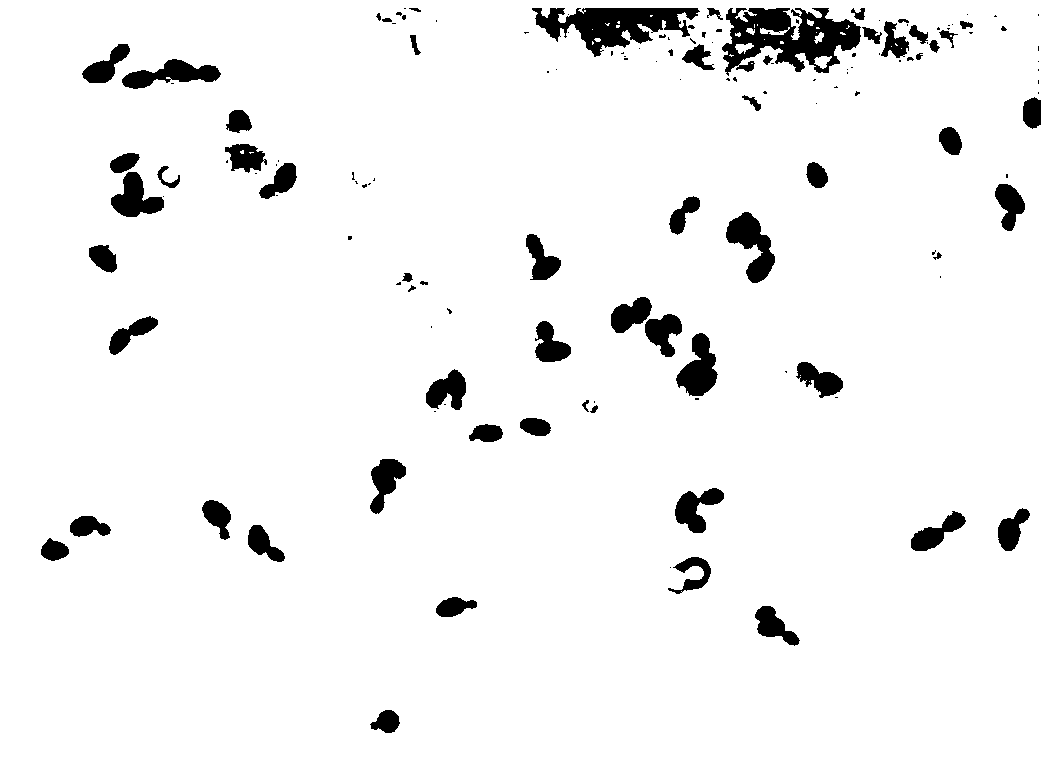

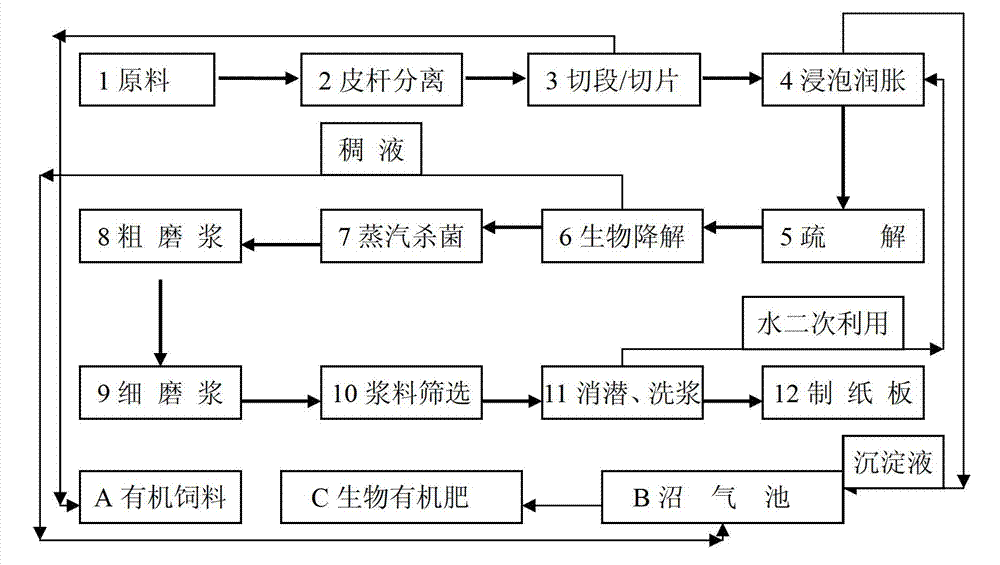

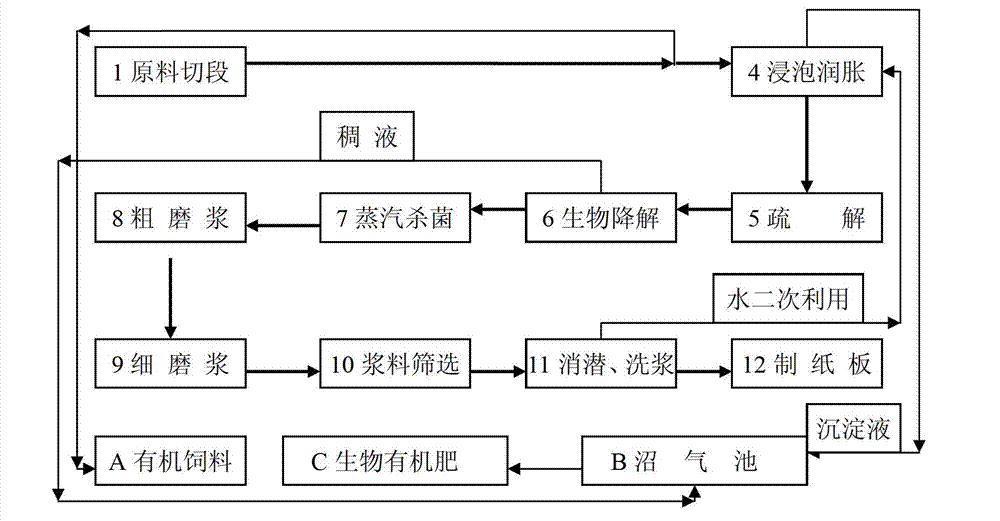

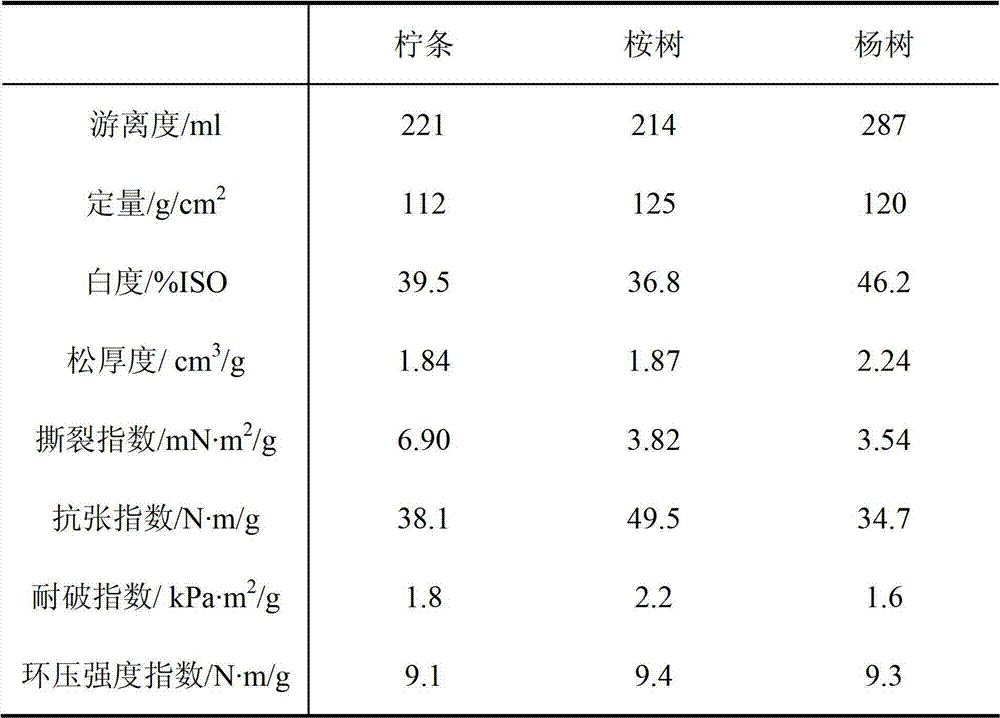

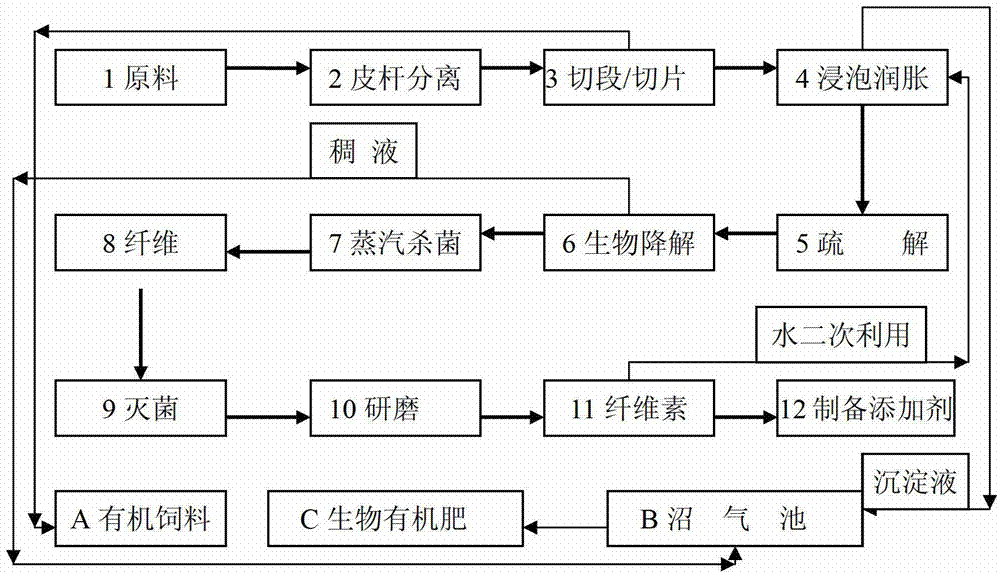

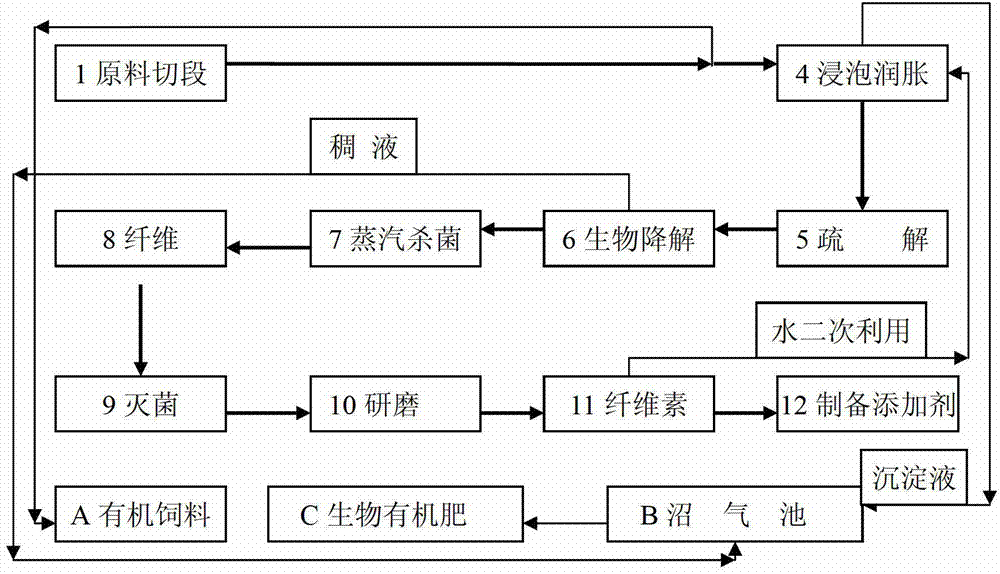

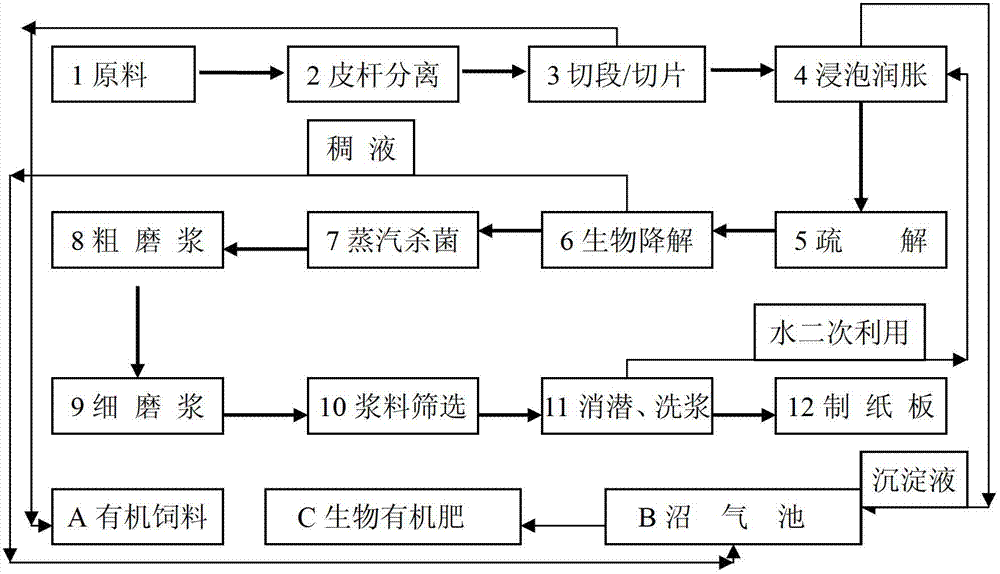

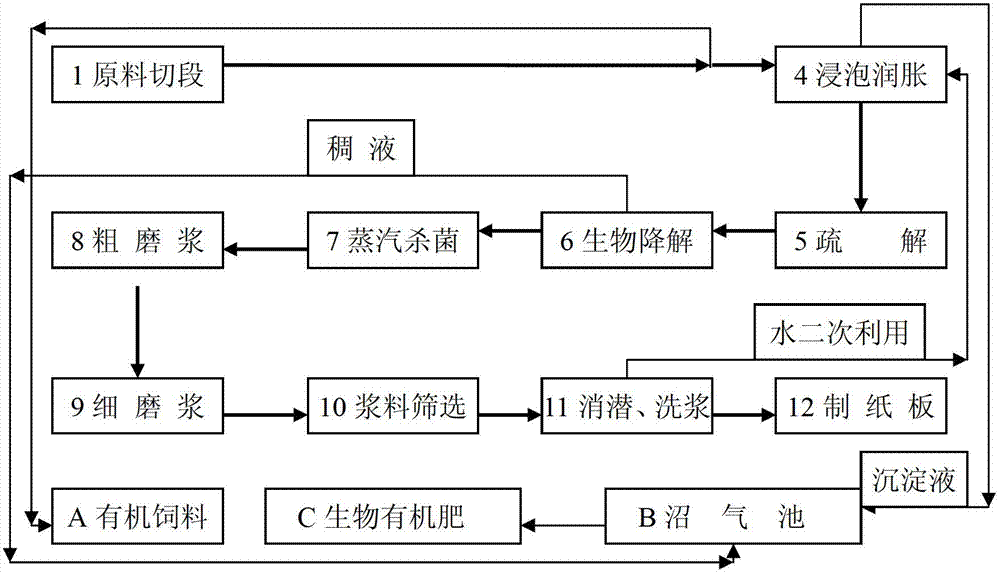

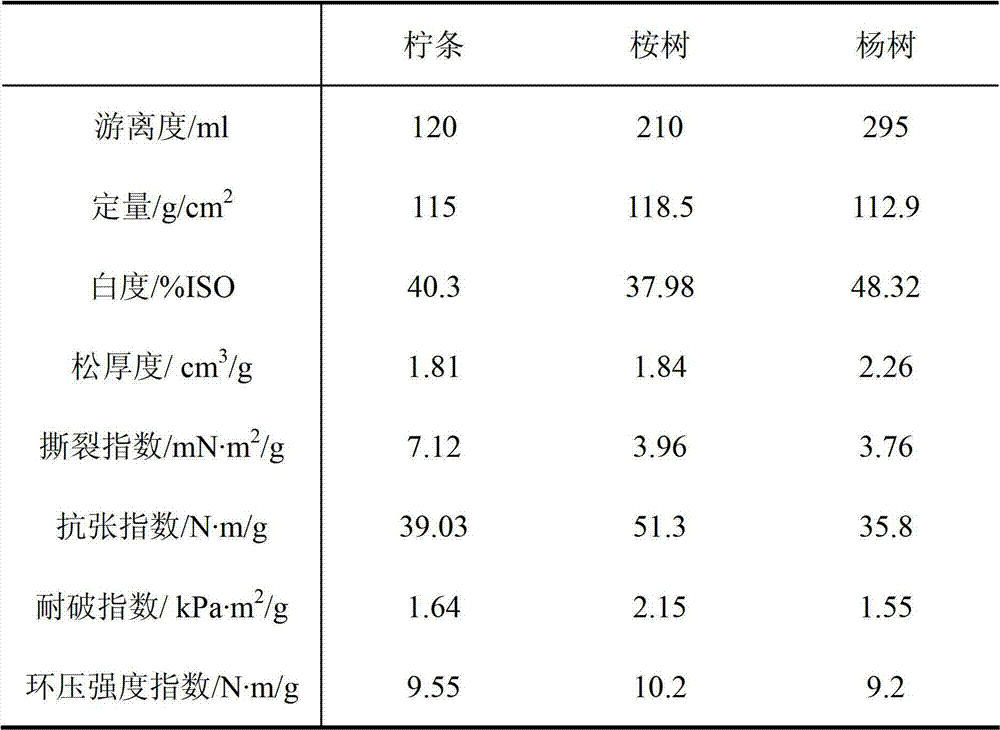

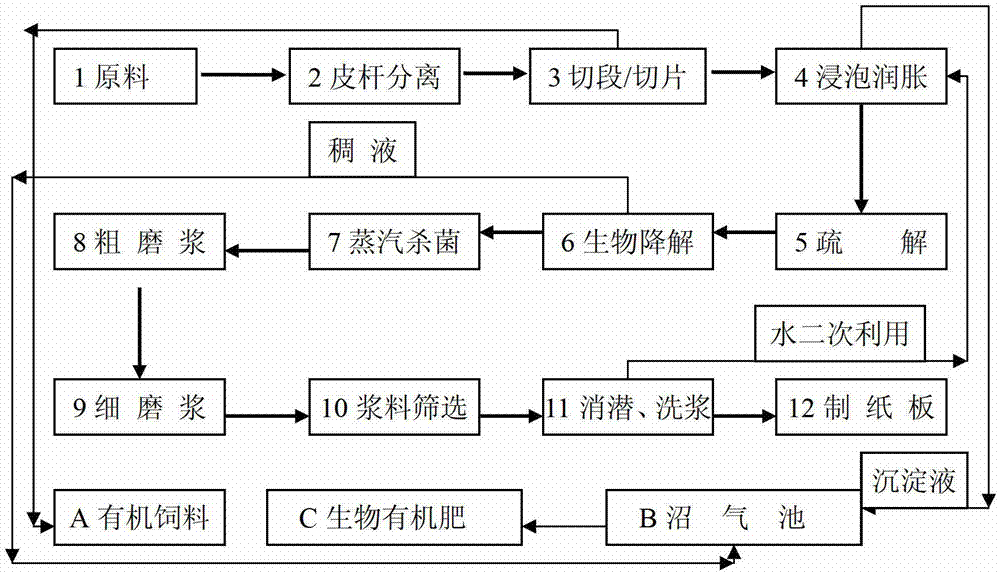

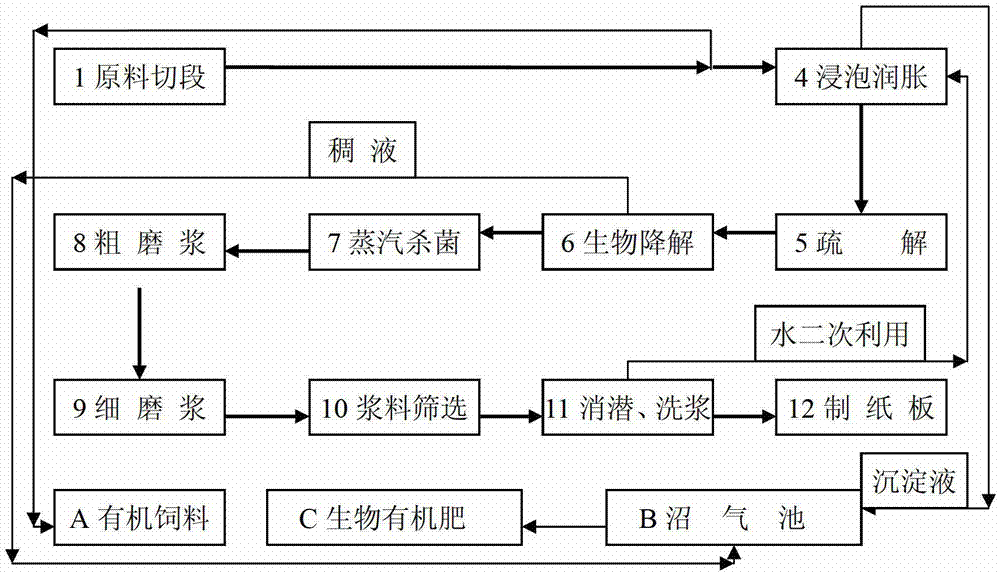

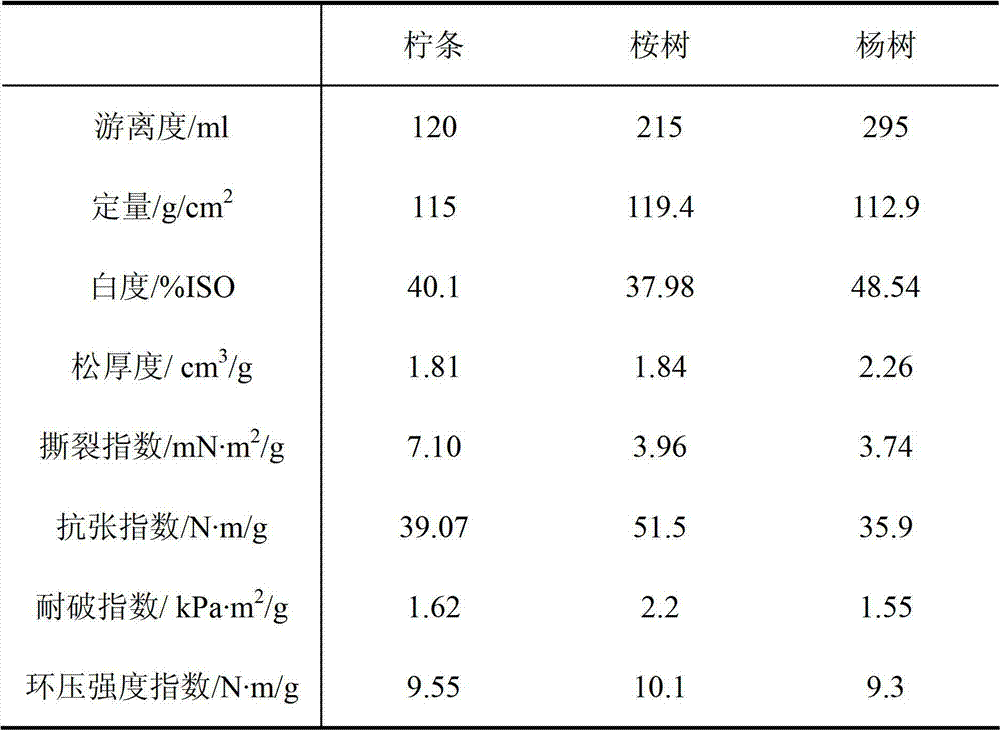

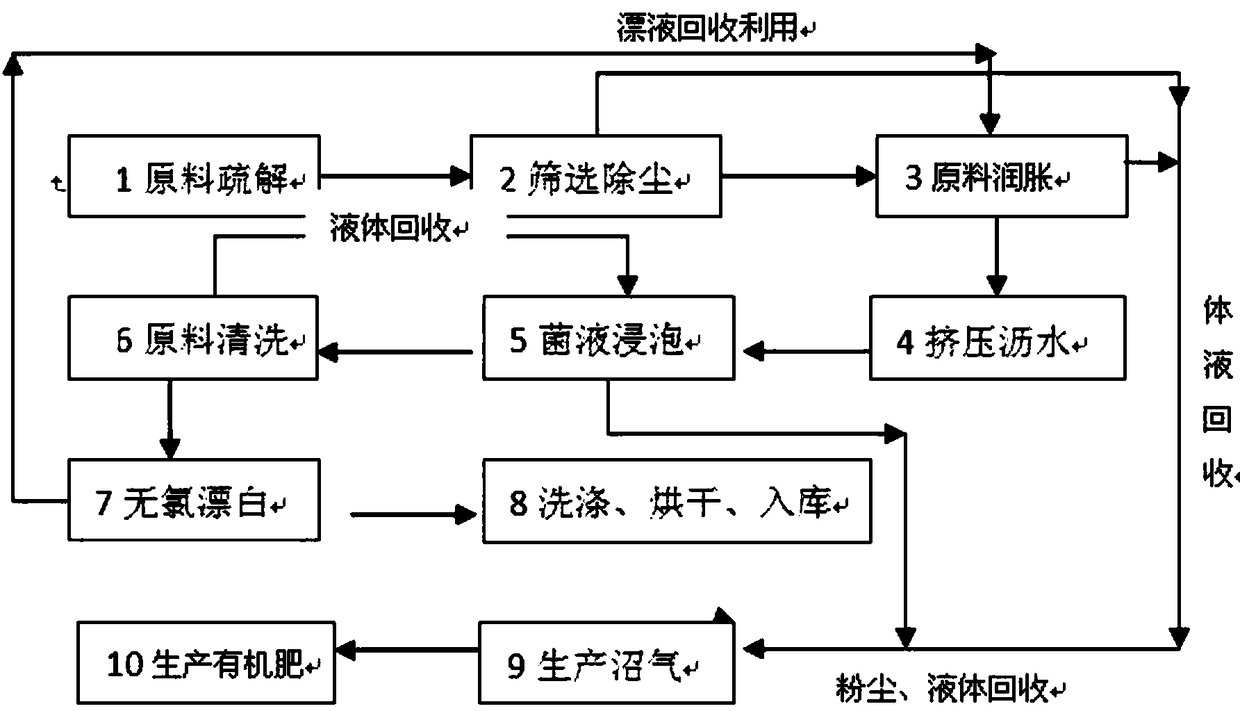

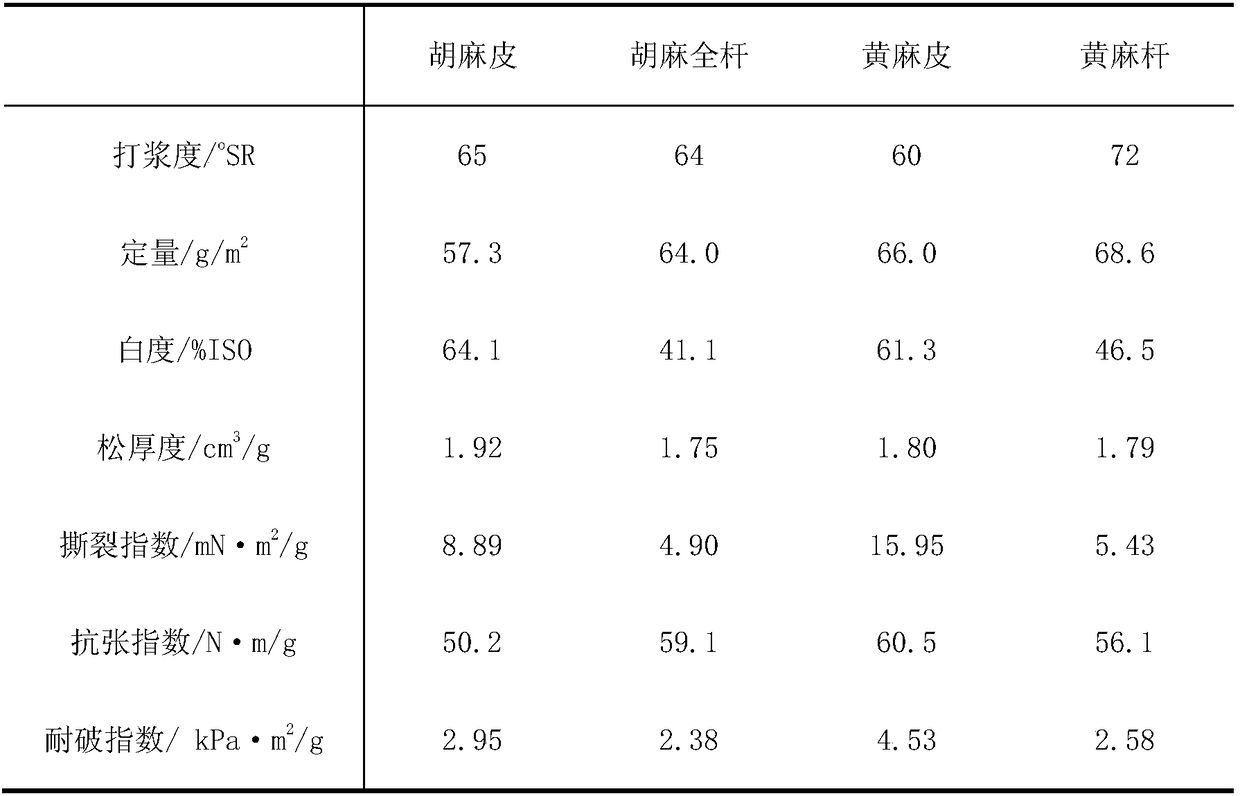

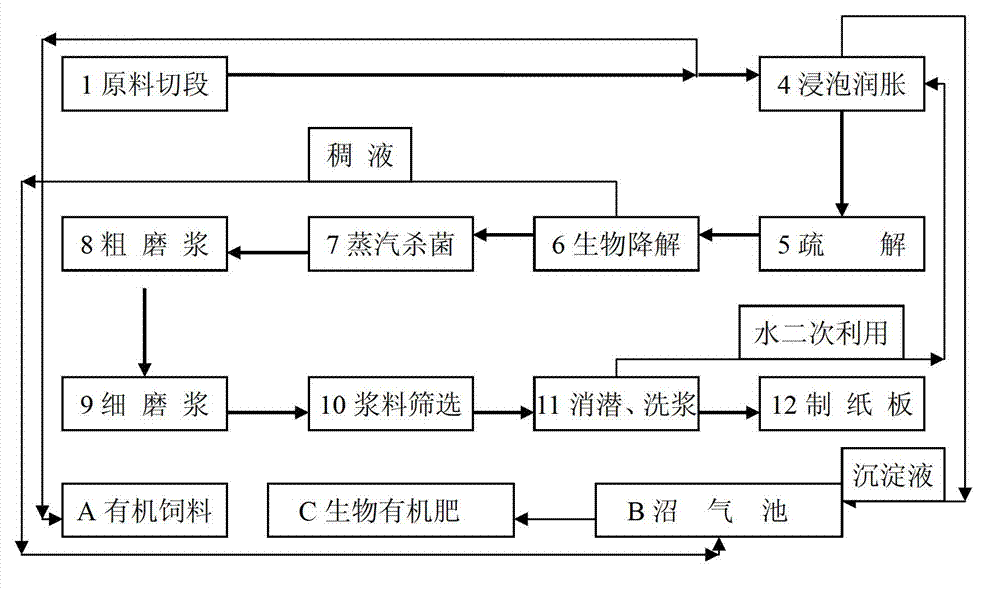

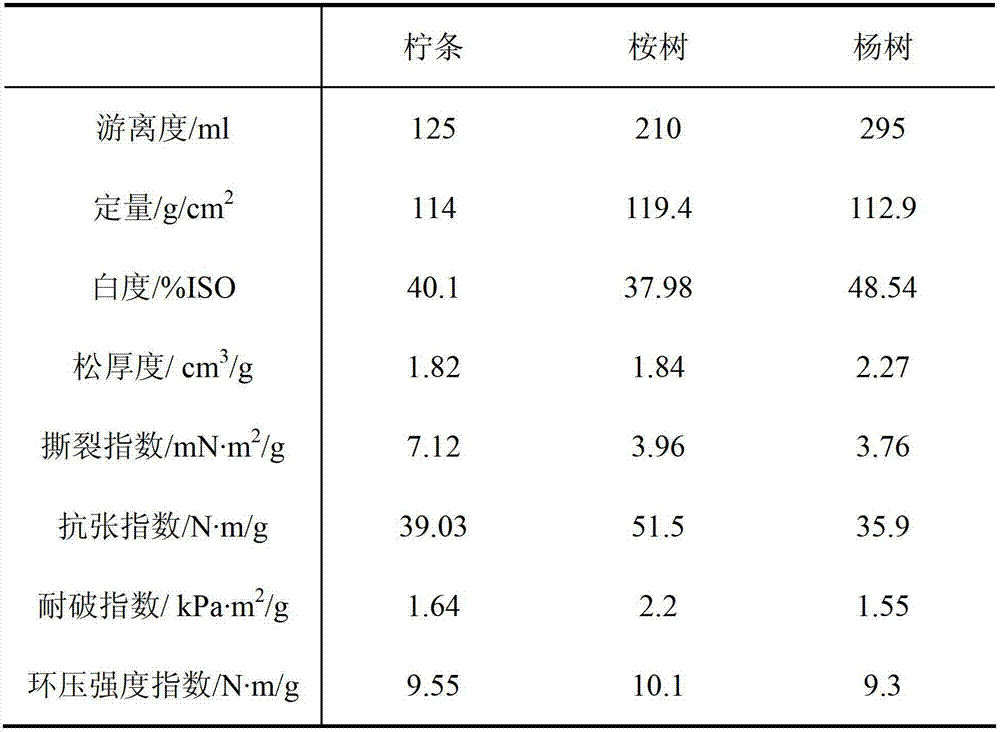

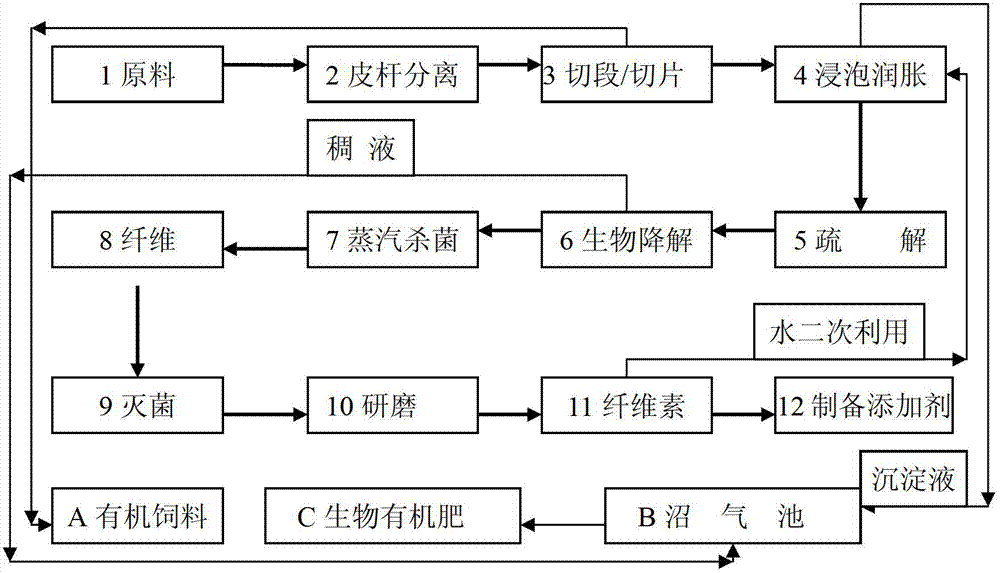

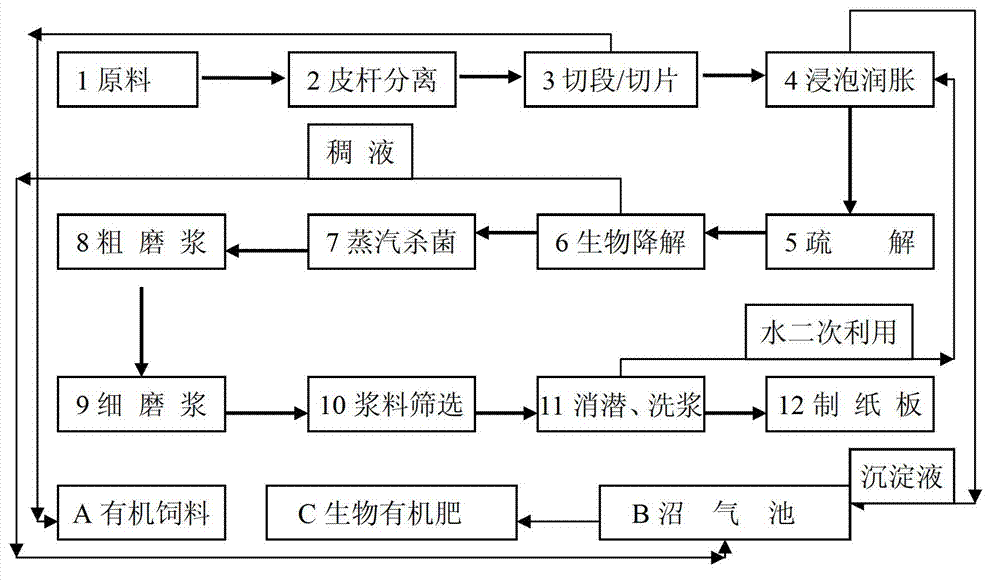

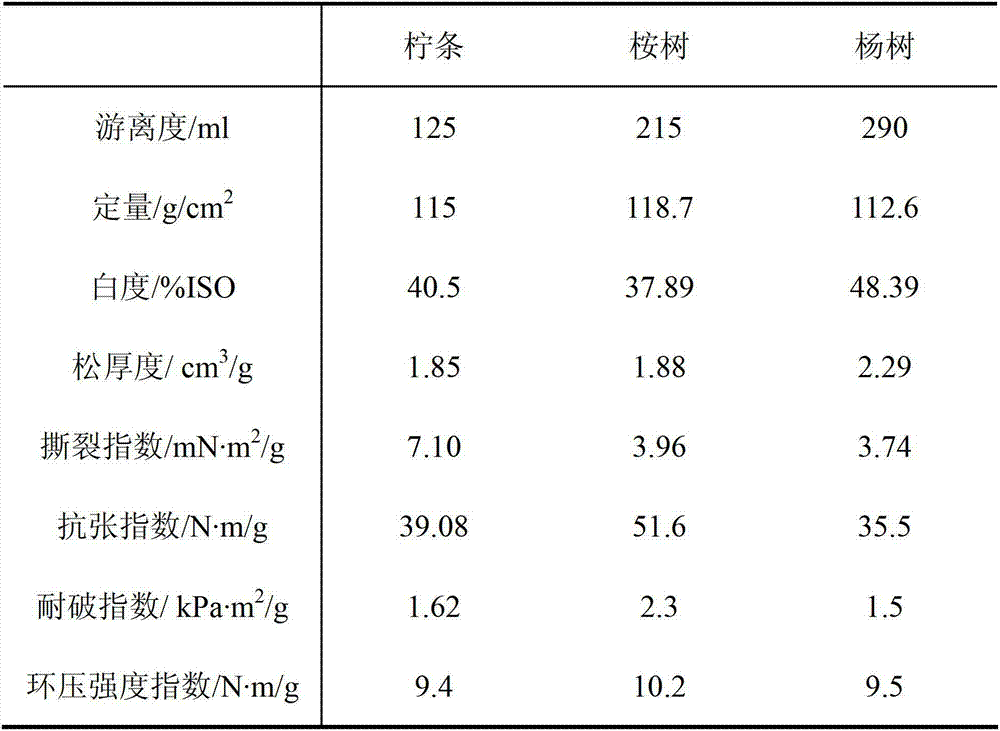

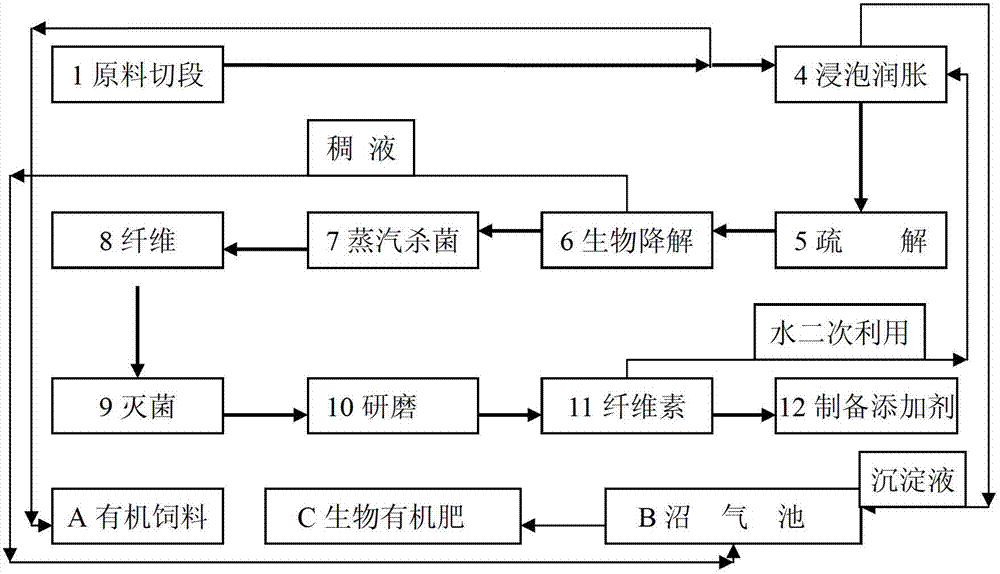

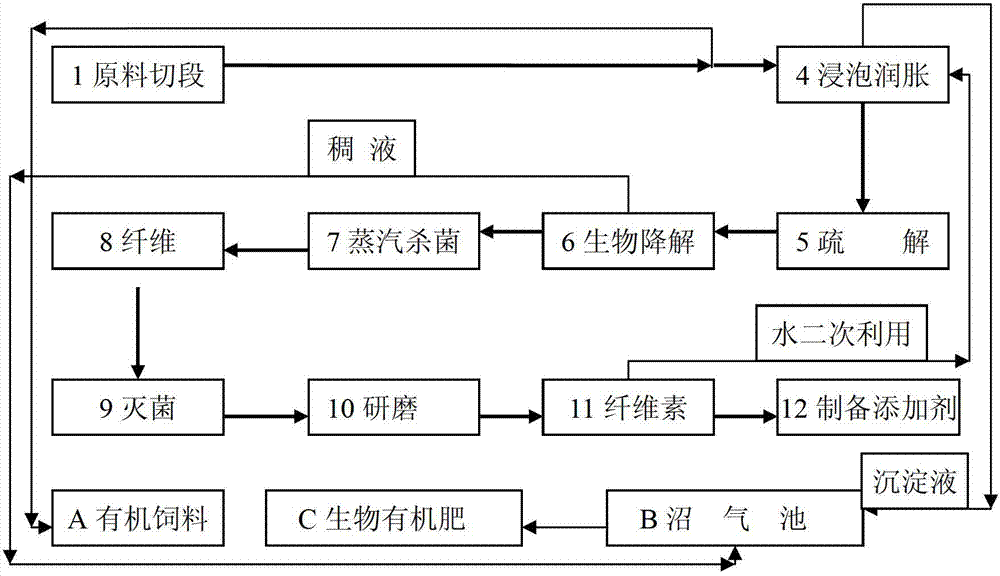

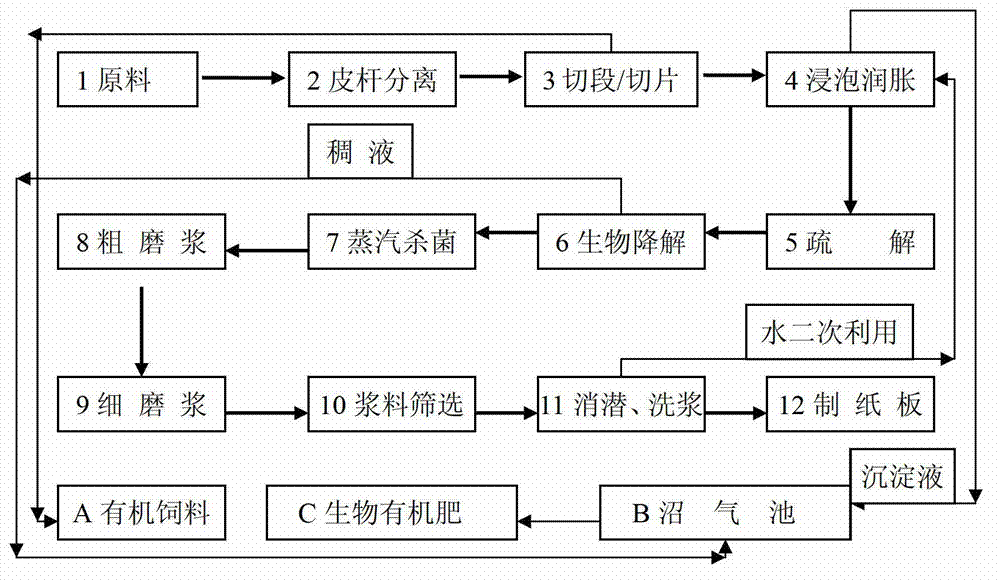

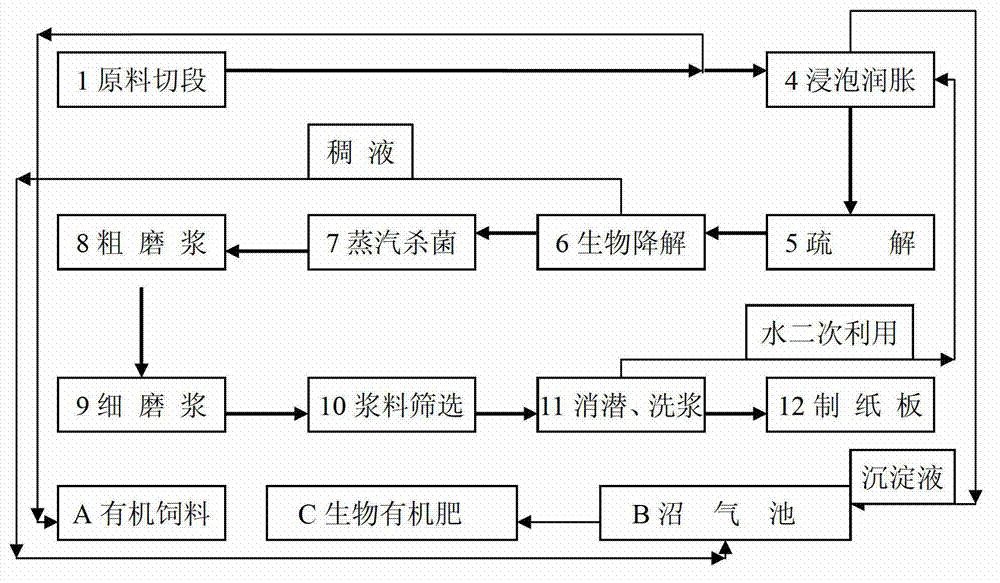

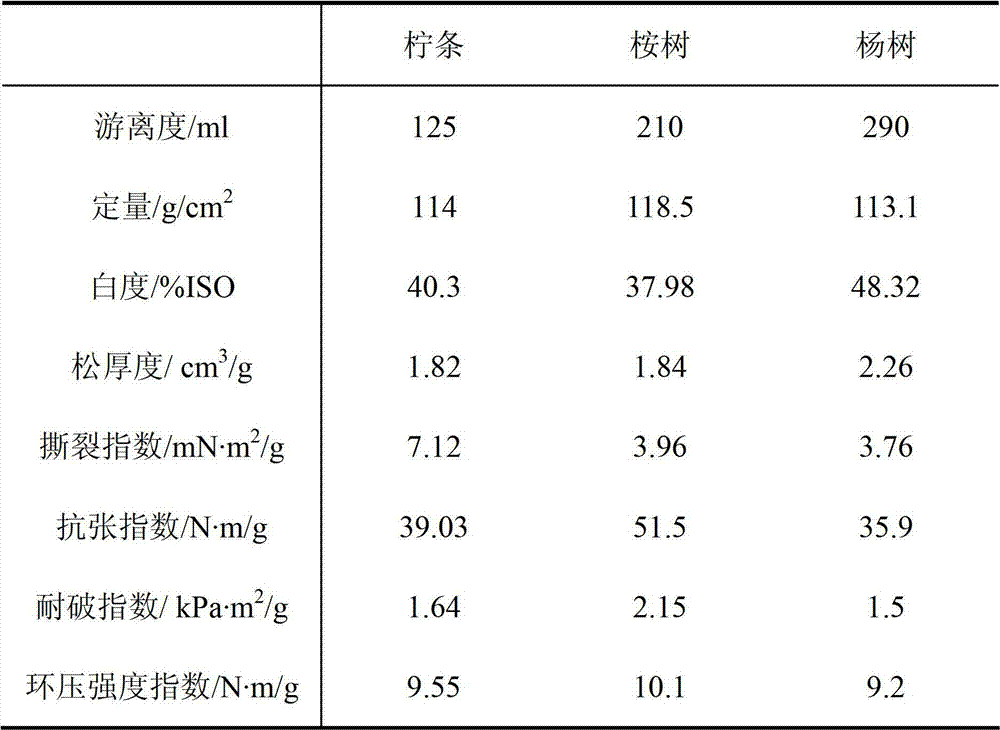

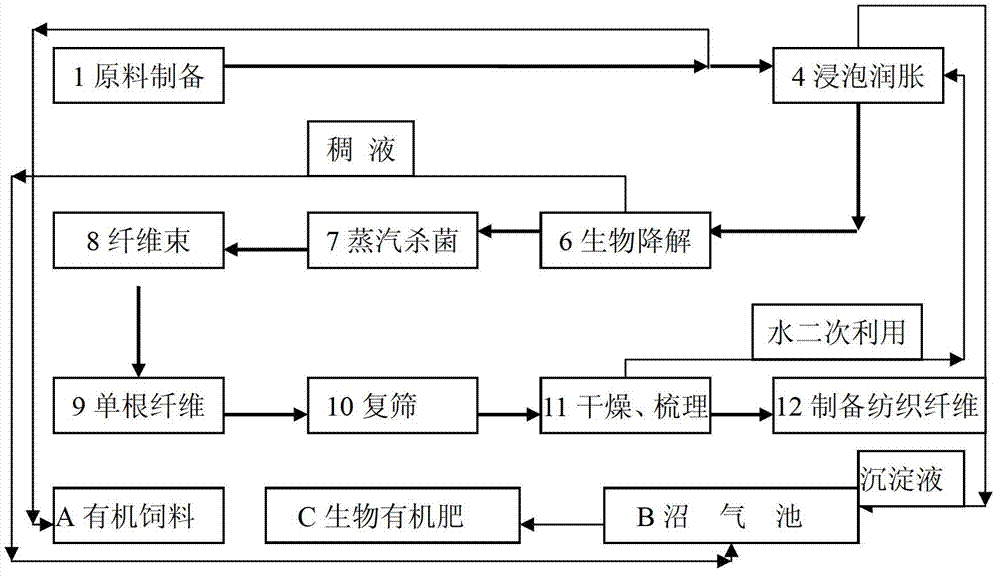

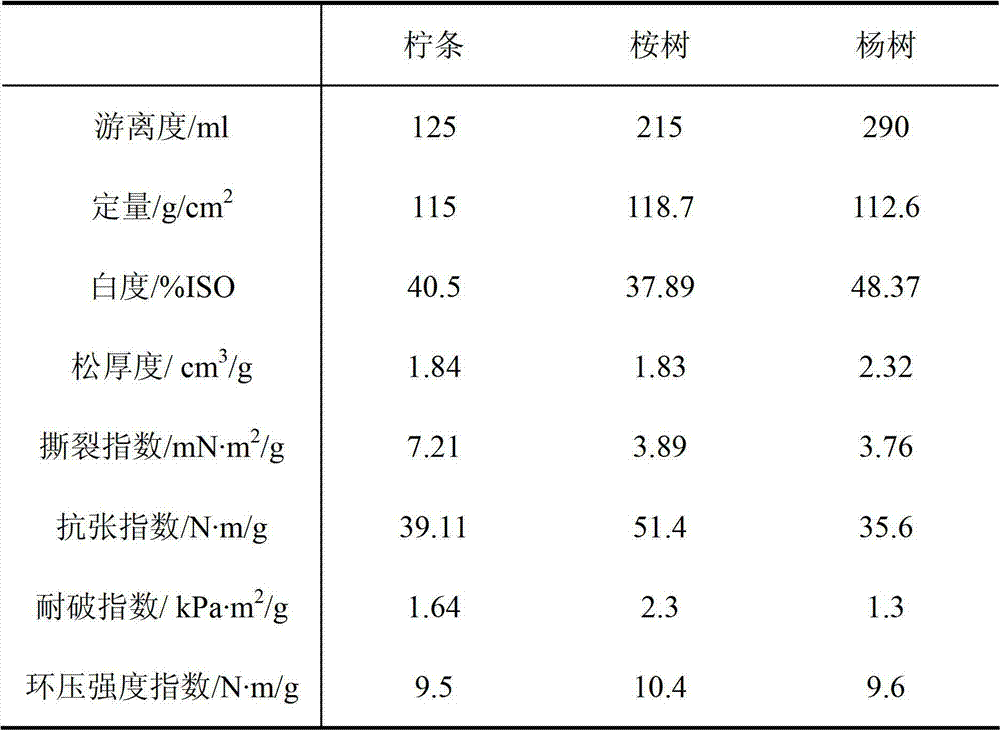

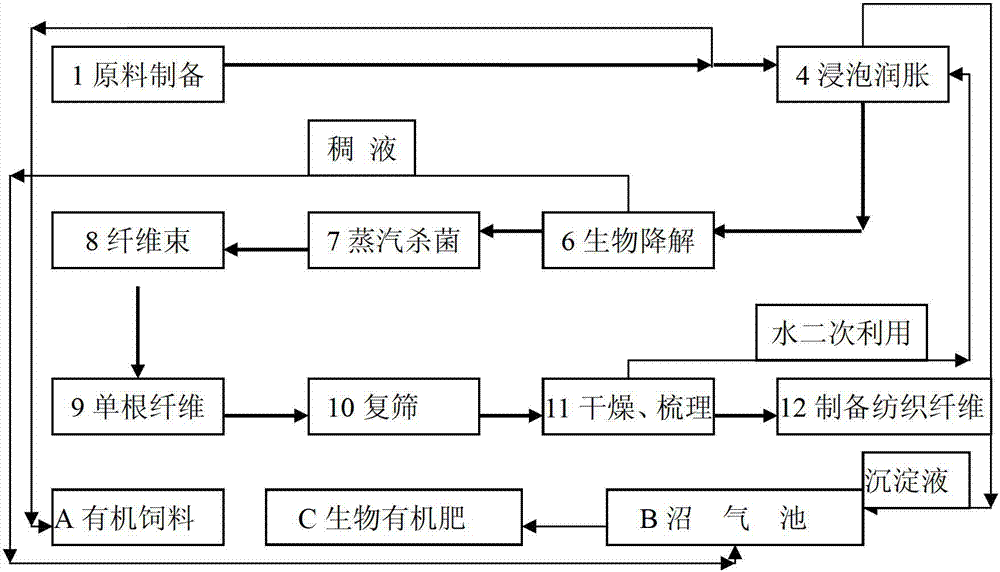

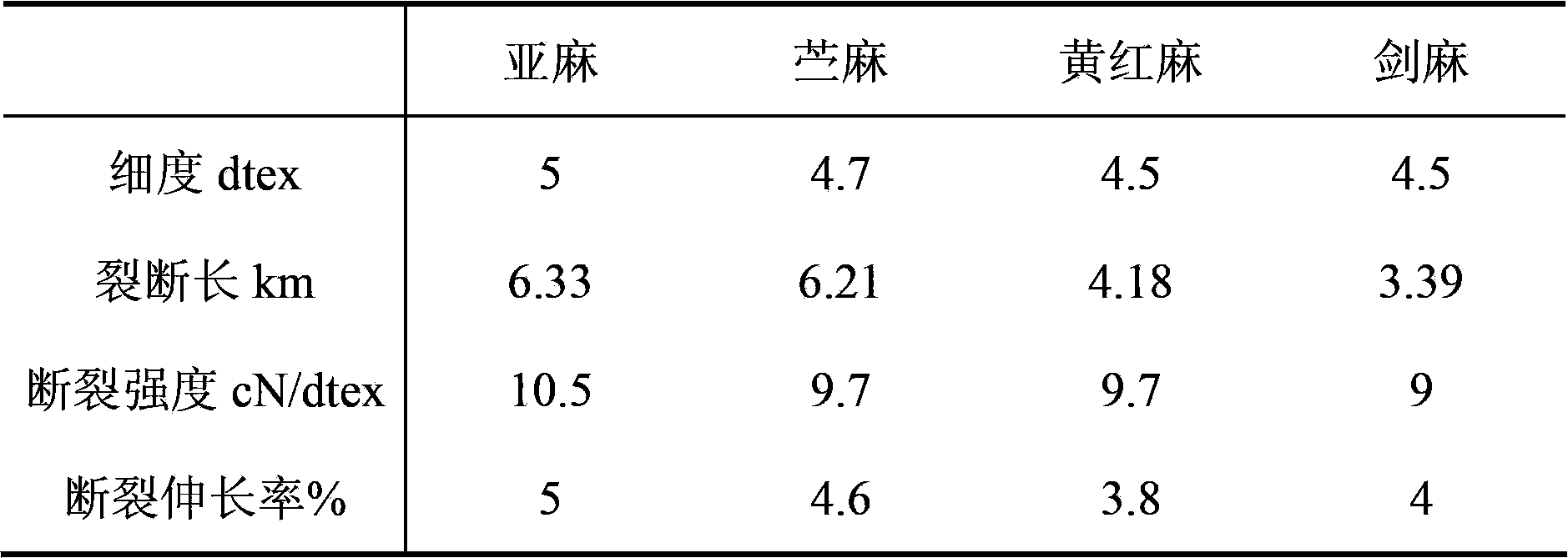

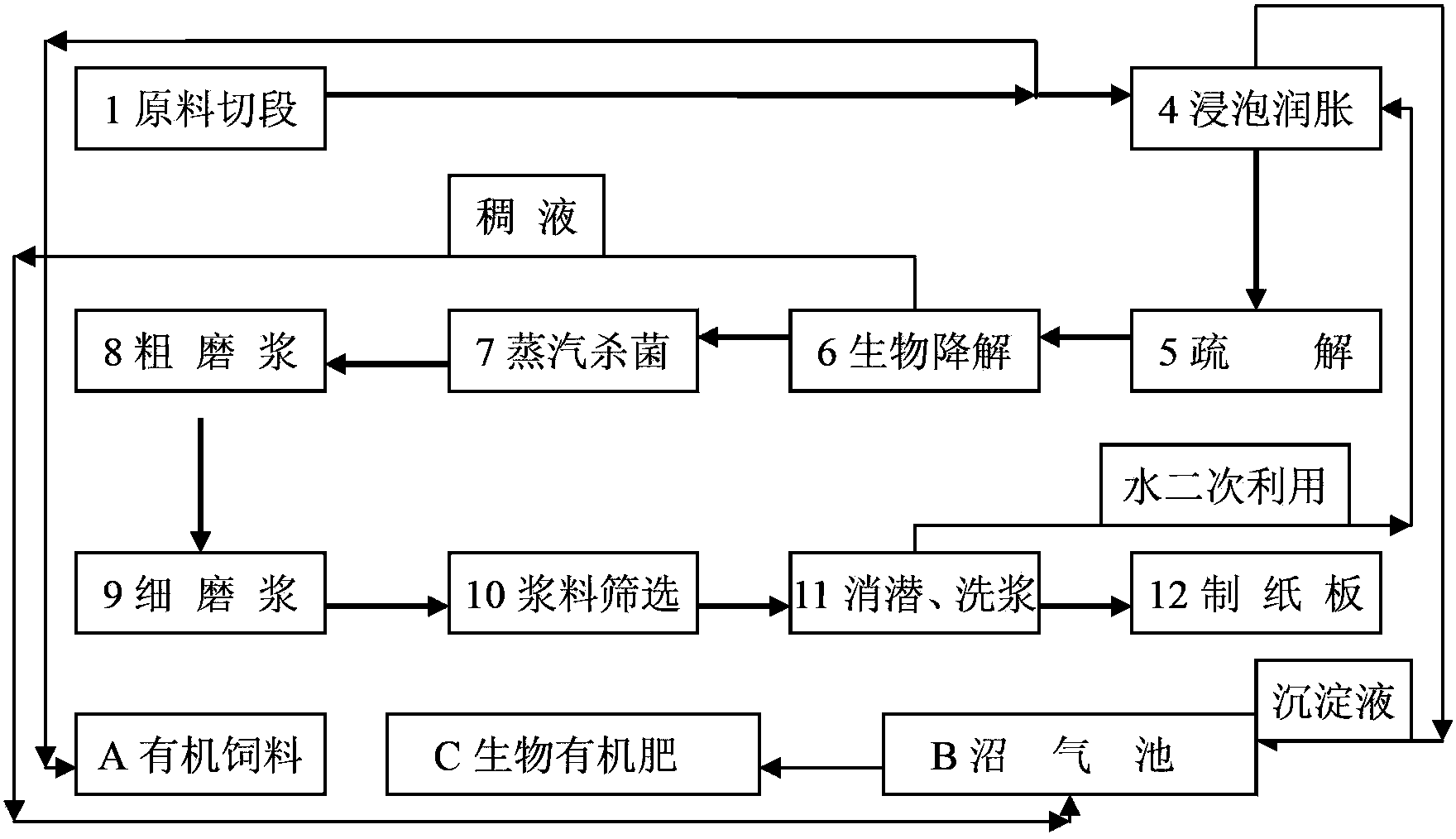

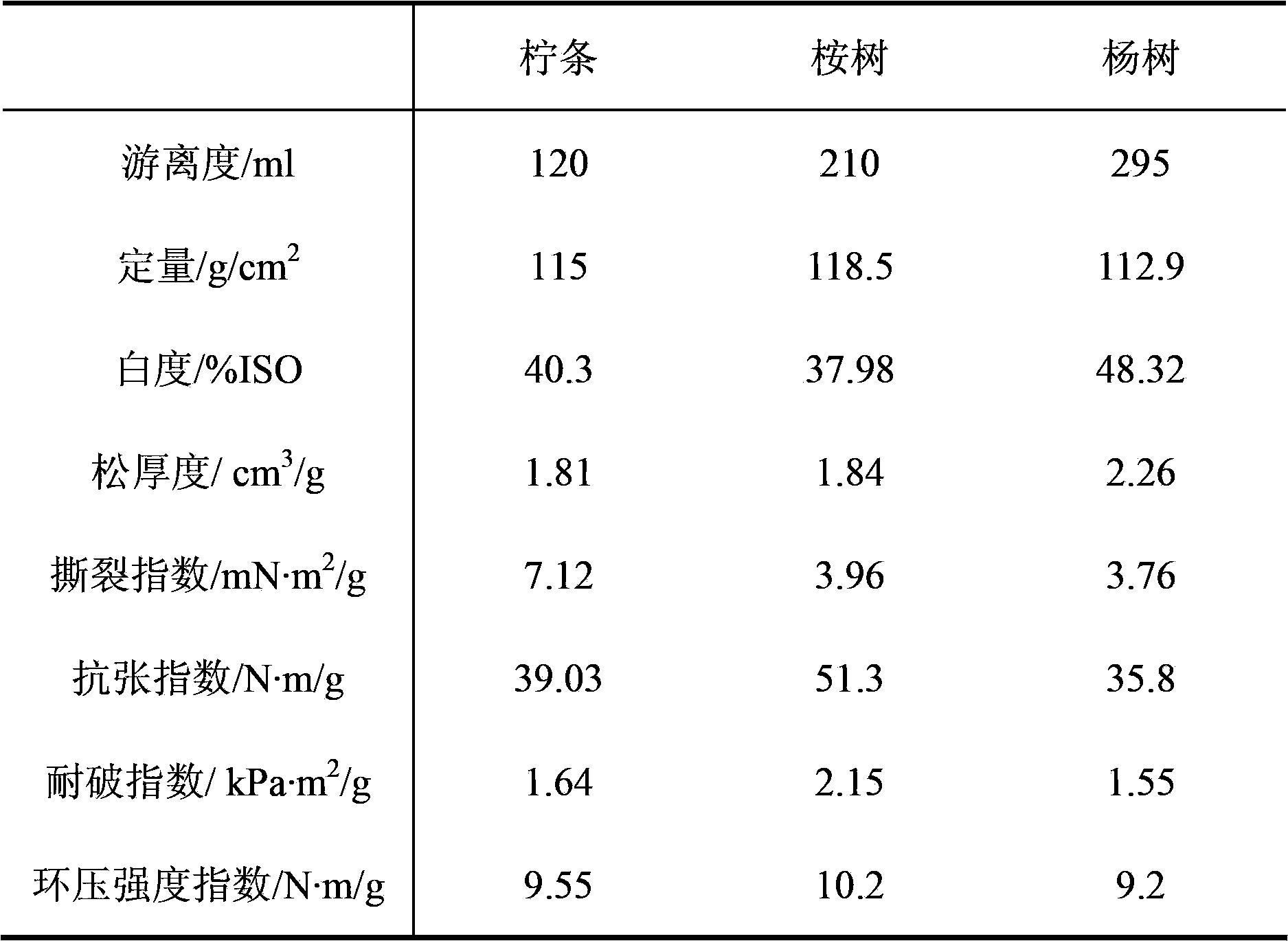

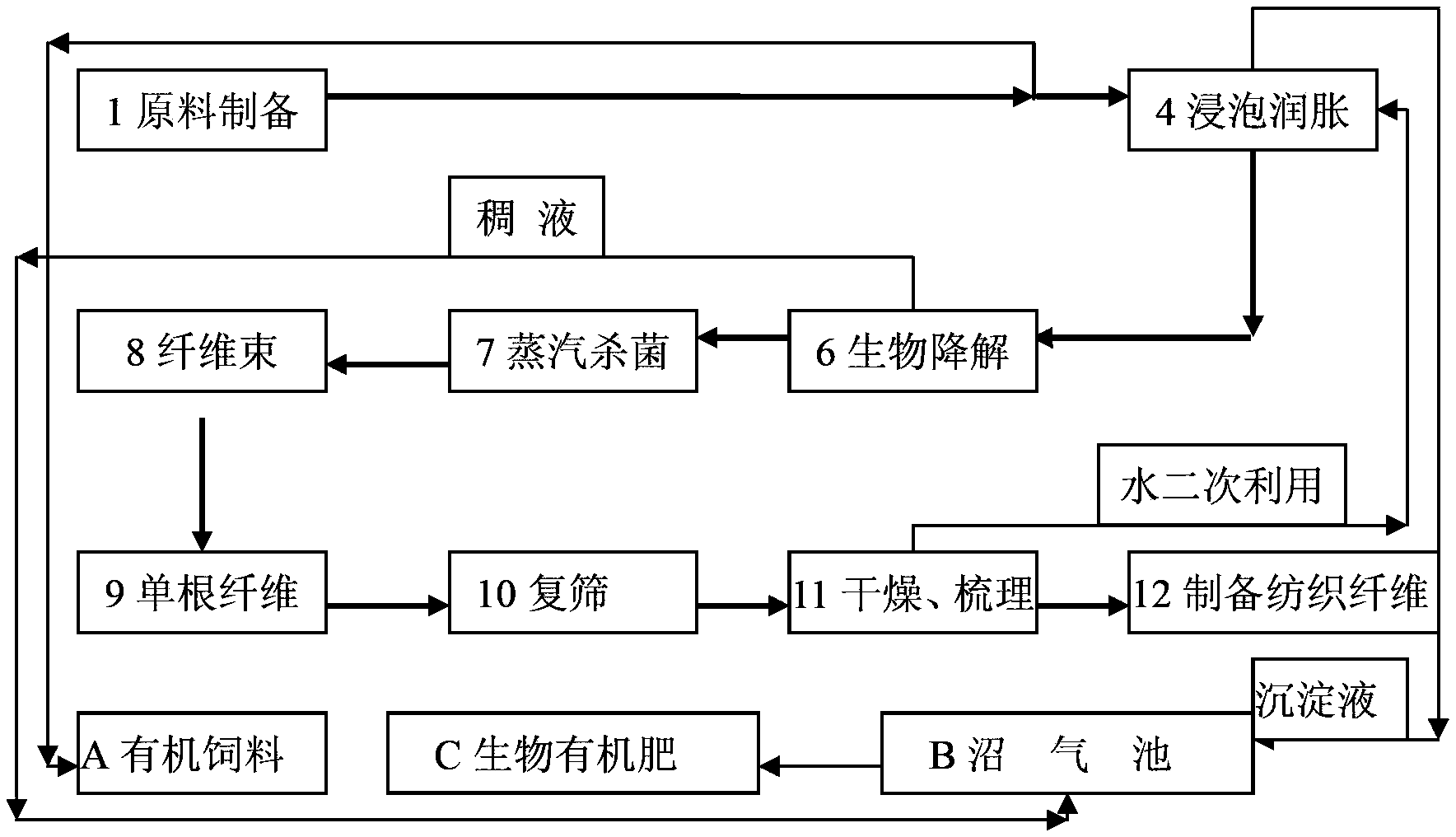

Bio-bacteria and bio-bacterial solution pulping method

InactiveCN102888360APlay a protective effectZero emissionBio-organic fraction processingBacteriaPaperboardOrganic fertilizer

The invention relates to bio-bacteria and a bio-bacterial solution pulping method. The bio-bacteria are wickerhamomyces anomalus with a collection number of CGMCC No.5975. The bio-bacterial solution pulping method mainly comprises the following steps of: preparing a bacterial solution; processing raw materials; and pulping, namely defibering, biodegradation, steam sterilization, coarse grinding, finely grinding, pulp screening, latency, and pulp washing. The paperboards made by the bio-bacterial solution pulping method reach AA or above level; and the waste liquid produced in pulp making can be recycled or changed into methane which is a kind of energy or organic fertilizers, so energy can be saved and environment pollution is avoided.

Owner:BEIJING TIANAN BIOSCI & TECH

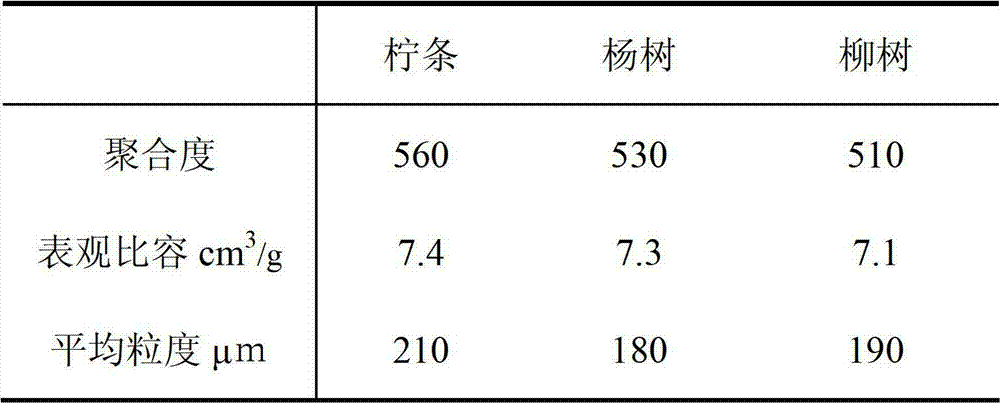

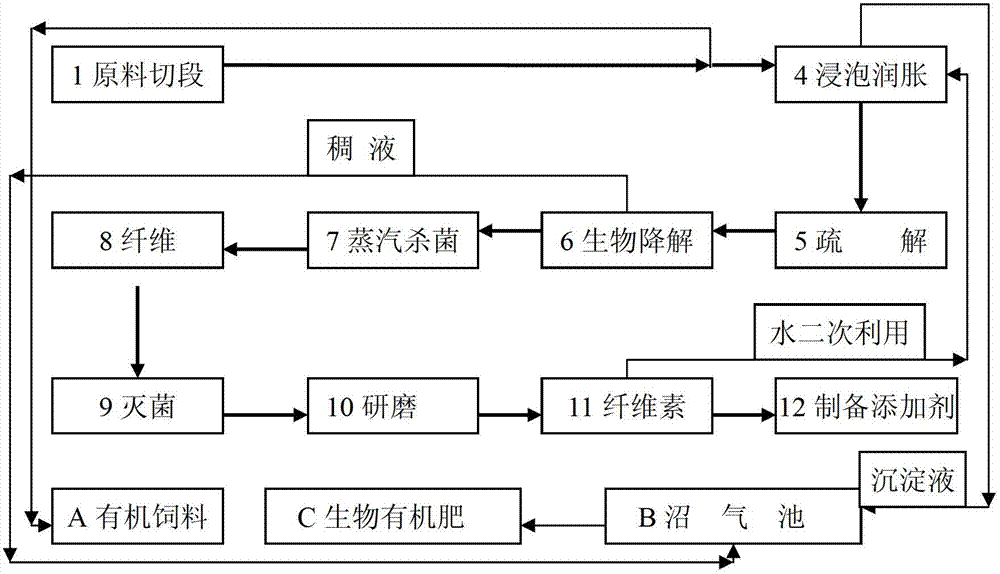

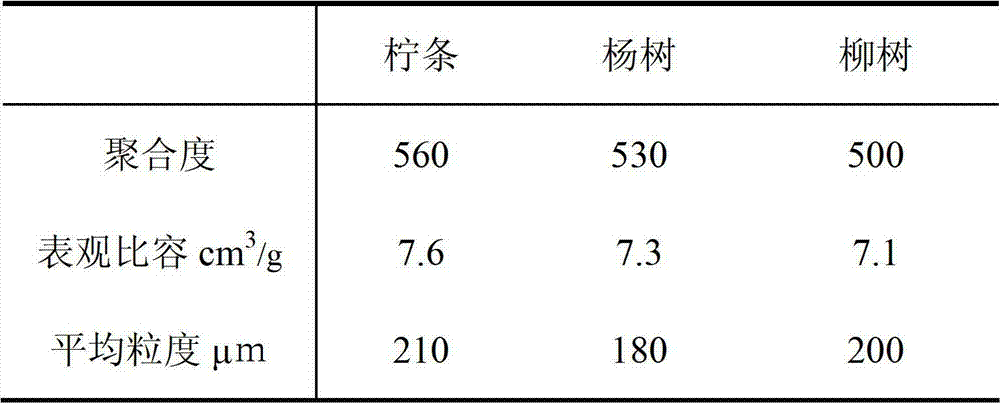

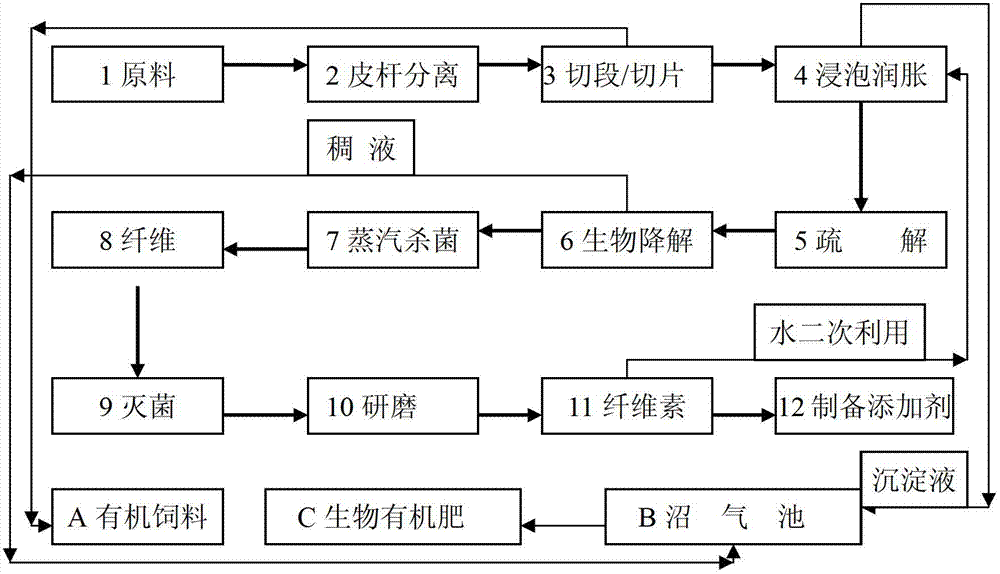

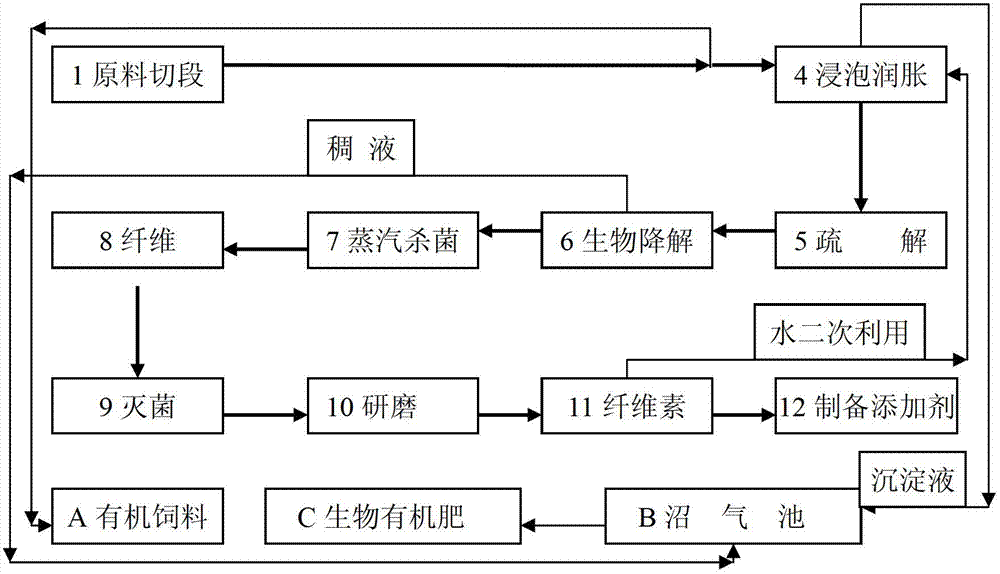

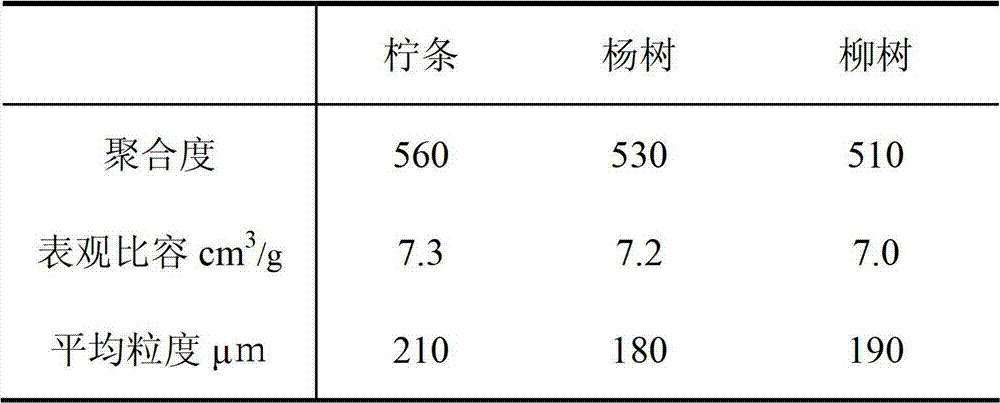

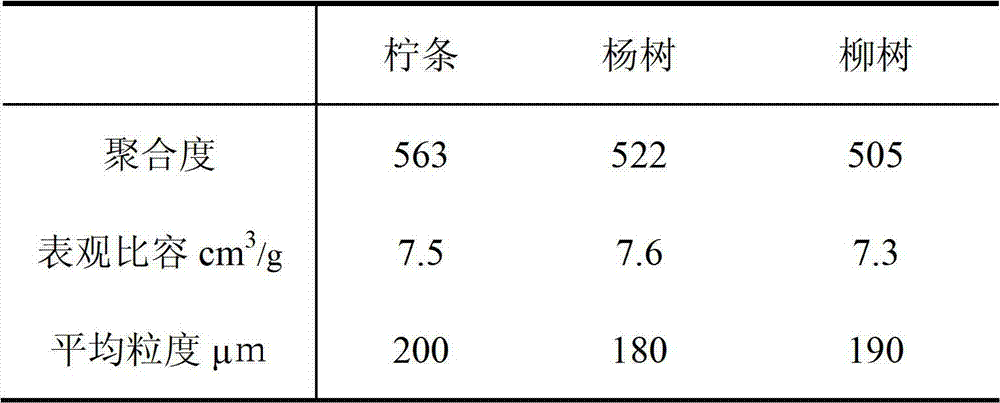

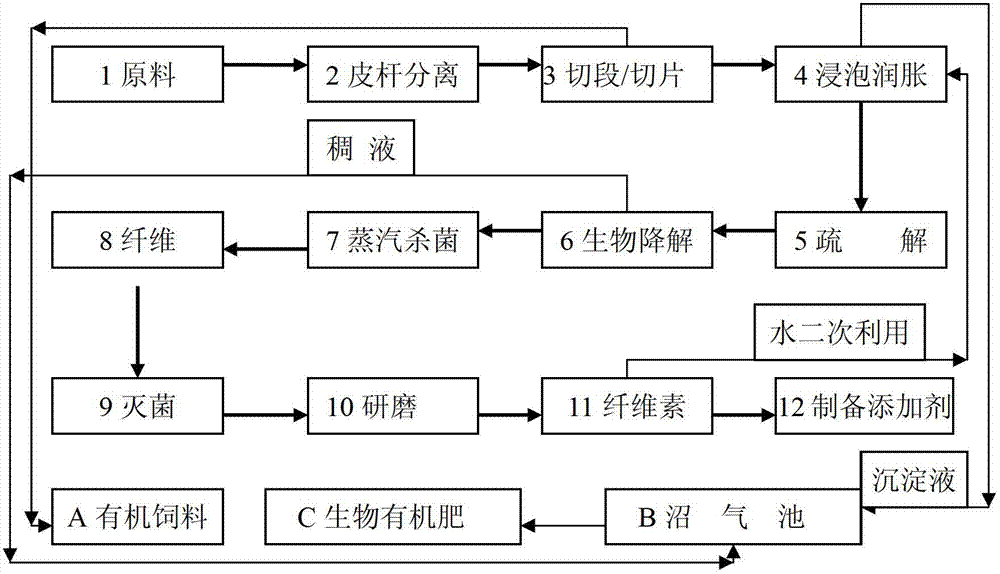

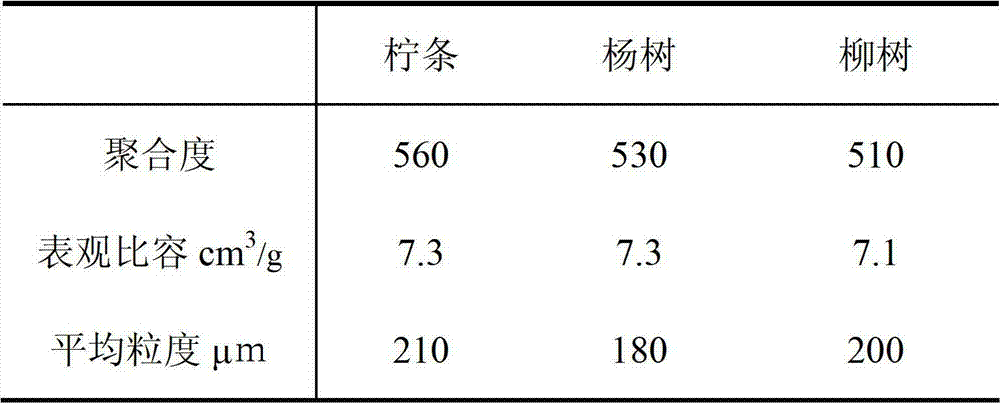

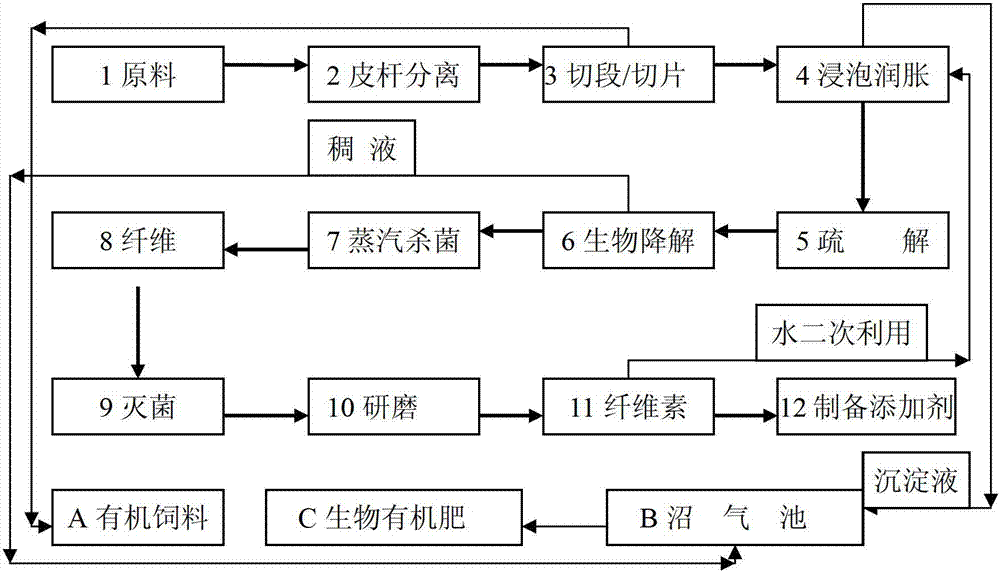

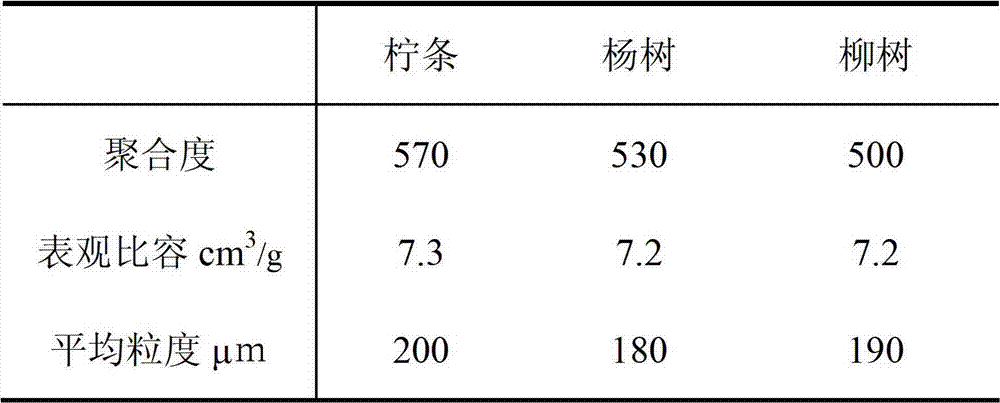

Composite flora and additive cellulose preparation method by using the same

InactiveCN103074219APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberPollution

The present invention relates to a composite flora and an additive cellulose preparation method by using the composite flora. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

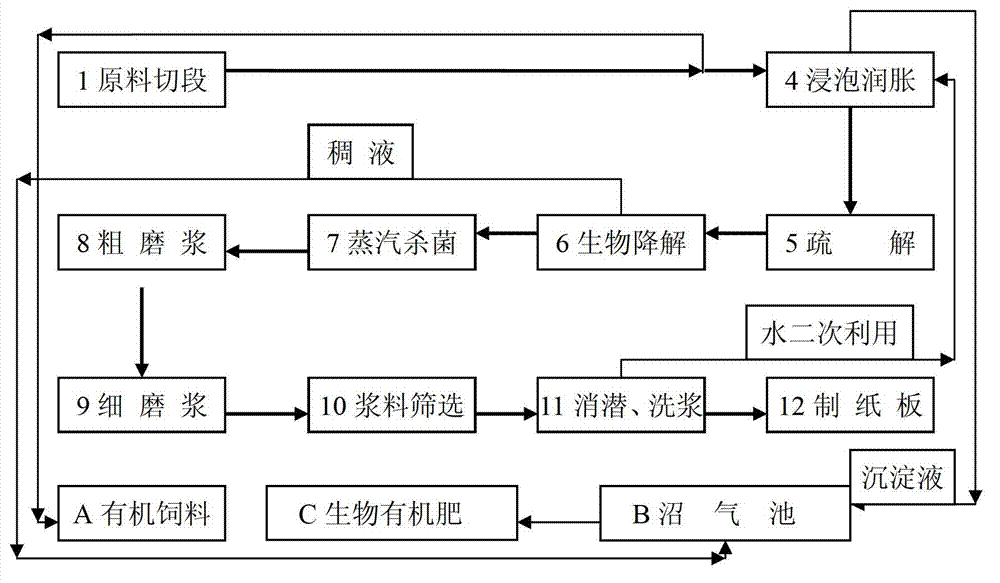

Composite flora and pulping method by using biological bacterial liquid of composite flora

InactiveCN103074250AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaCardboardFiber

The present invention relates to a composite flora and a pulping method by using a biological bacterial liquid of the composite flora. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and application of the same in biological bacterial liquid pulping process

InactiveCN103074249AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaCardboardFiber

The present invention relates to a composite flora and an application of the composite flora in a biological bacterial liquid pulping process. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and application of the same in additive cellulose preparation

InactiveCN103074254APlay a protective effectNo pollutionBio-organic fraction processingBacteriaEnvironmental resistanceFiber

The present invention relates to a composite flora and an application of the composite flora in additive cellulose preparation. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The process for preparing the additive cellulose comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Compound bacteria, compound bacterial agent containing same, preparation method of compound bacterial agent containing same, and application of compound bacteria and compound bacterial agent containing same

InactiveCN108220181ANo pollutionRemarkable effect on degrading ligninFungiBacteriaMicrobiologyChrysosporium species

The invention provides compound bacteria, a compound bacterial agent containing the same, a preparation method of the compound bacterial agent containing the same, and application of the compound bacteria and the compound bacterial agent containing the same. The compound bacteria comprise acinetobacter lwoffii with the preservation number of CGMCC No.5973, wickerhamomyces anomalus with the preservation number of CGMCC No.5975, phanerochaete chrysosporium and pleurotus ostreatus; through synergistic interaction of various bacteria in the compound bacteria, the compound bacteria have a remarkable effect in the aspect of degrading lignin, particularly the lignin in a hemp rod; the problems of overlong time in bio-pulping, low fibre degree and low yield in the prior art are solved; remarkabletechnical effects of high fibre degree, high yield, short working hours, low cost and no environmental pollution are achieved.

Owner:康盛时代(北京)生物技术有限公司

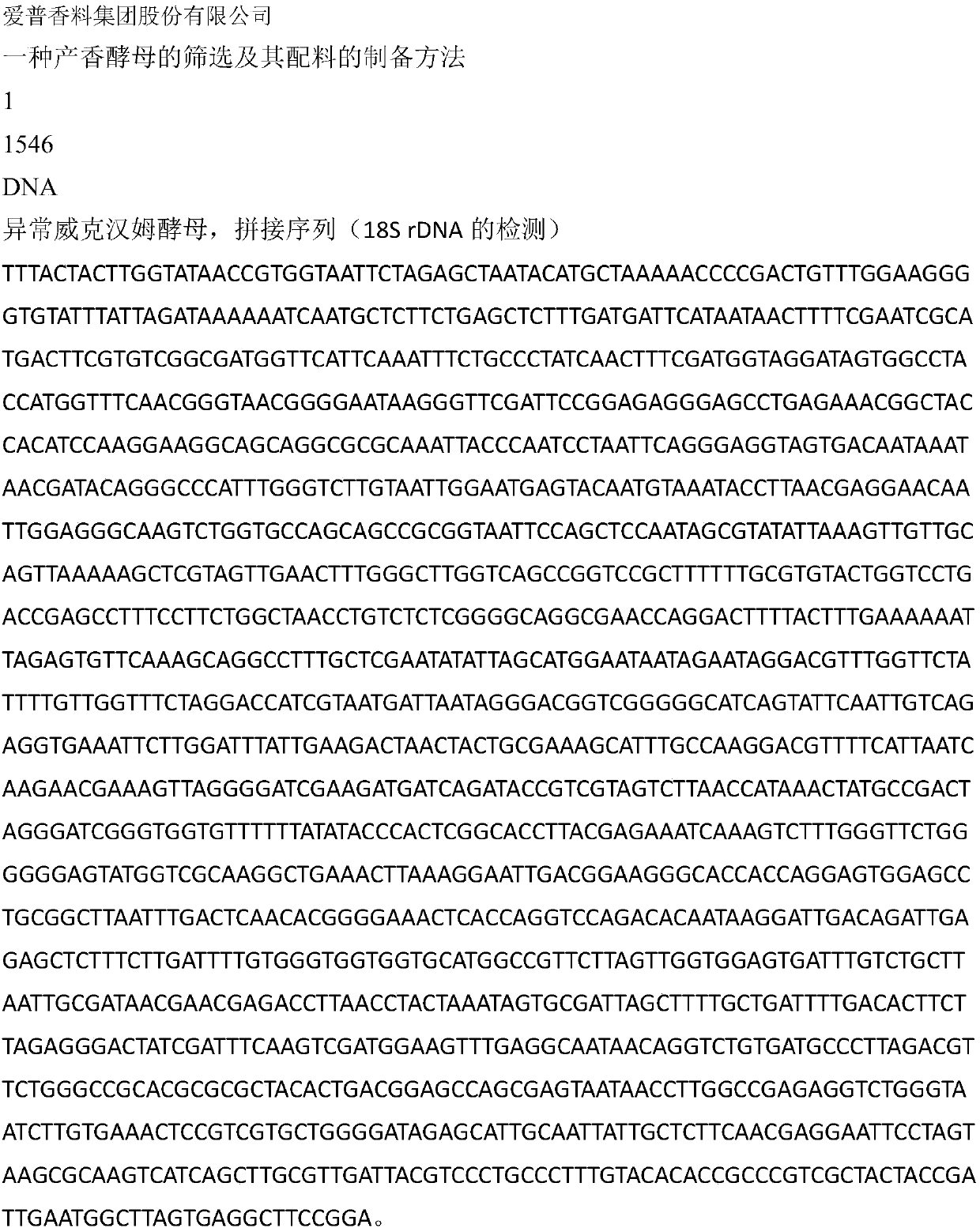

Method for screening aroma-producing yeast and preparing ingredient from aroma-producing yeast

InactiveCN107815422AReduce manufacturing costSimple processFungiPre-baking dough treatmentBiotechnologyAdditive ingredient

The invention discloses a method for screening aroma-producing yeast and preparing an ingredient from the aroma-producing yeast. A food ingredient which can be directly added into flour for producingfermented dough can be produced through fermentation of the yeast. The aroma-producing yeast is the yeast with a relatively outstanding aroma-producing effect separated from leaven and is determined as Wickerhamomyces anomalus through 18S rDNA detection. The yeast is used for preparing the food ingredient, and a brewing process utilizing gelatinized starch as the raw material and the aroma-producing yeast as the fermentation yeast is adopted, so that the problem that a fermented flour product does not have sufficient aroma is solved, and the industrial production efficiency of the fermented flour product is improved. The method is simple in complete process, high in production efficiency, low in production cost, free of pollution, suitable for industrial production, simple and convenient.The method has important significance to the improvement of fermentation aroma of the fermented flour product and the mechanization progress of the fermented flour product in China.

Owner:APPLE FLAVOR & FRAGRANCE GRP

Composite flora and additive cellulose preparation method by using the same

InactiveCN103074251APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberEnvironmental resistance

The present invention relates to a composite flora and an additive cellulose preparation method by using the composite flora. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and application of the same in biological bacterial liquid pulping process

InactiveCN103074255AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaCardboardFiber

The present invention relates to a composite flora and an application of the composite flora in a biological bacterial liquid pulping process. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

Mixed bacteria and use thereof in cellulose used for preparing additives

InactiveCN102888342APlay a protective effectNo pollutionBio-organic fraction processingBacteriaCelluloseFiber

The invention relates to mixed bacteria and use thereof in cellulose used for preparing additives. The mixed bacteria comprise acinetobacter lwoffii with a collection number of CGMCC No.5973, pseudomonas fluorescens with a collection number of CGMCC No.5974, and wickerhamomyces anomalus with a collection number of CGMCC No.5975. A process for preparing the cellulose used for preparing additives comprises the following steps of: preparing a bacterial solution; processing raw materials; preparing fibers by defibering, biodegradation, steam sterilization and fiber collection; and sterilizing, and grinding. The method is environment-friendly, because waste liquid is changed into organic fertilizers directly rather than being discharged. In the biological treatment process, the fibers are protected. Compared with the conventional chemical methods, the process has the advantages that the production cost is low, the economic benefit is high, energy can be saved and pollution is avoided.

Owner:BEIJING TIANAN BIOSCI & TECH

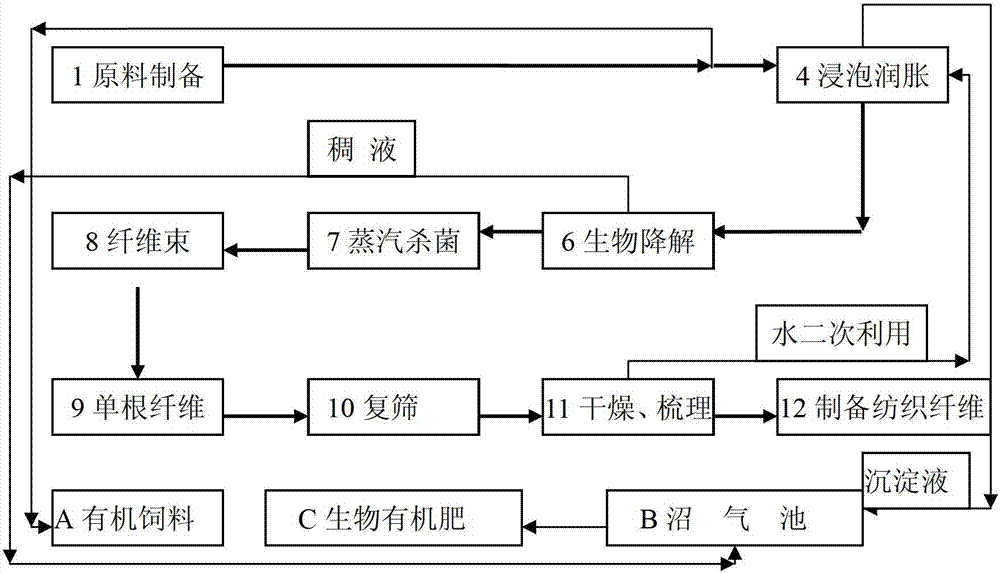

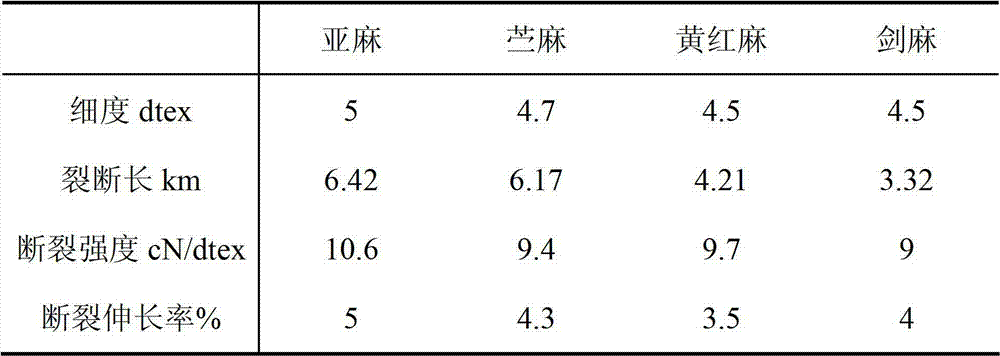

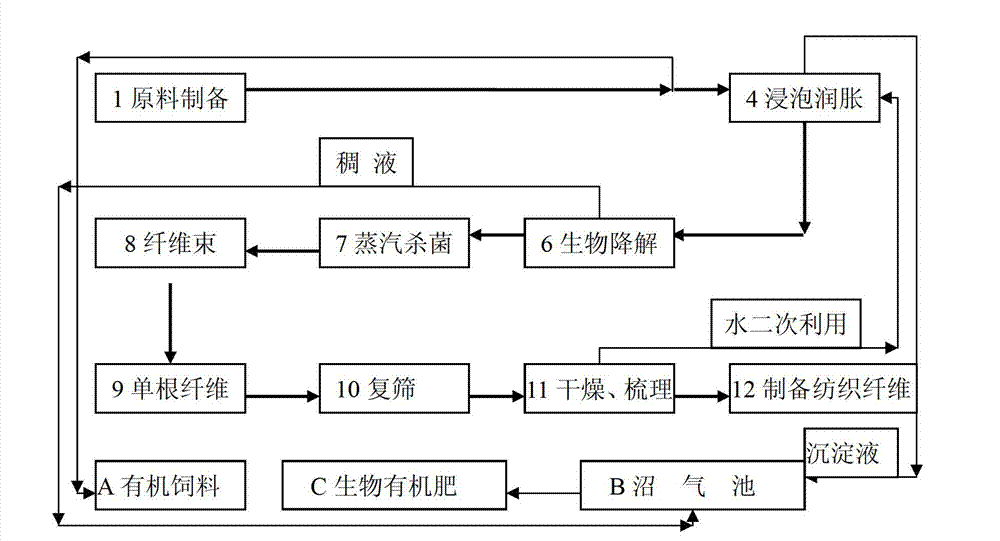

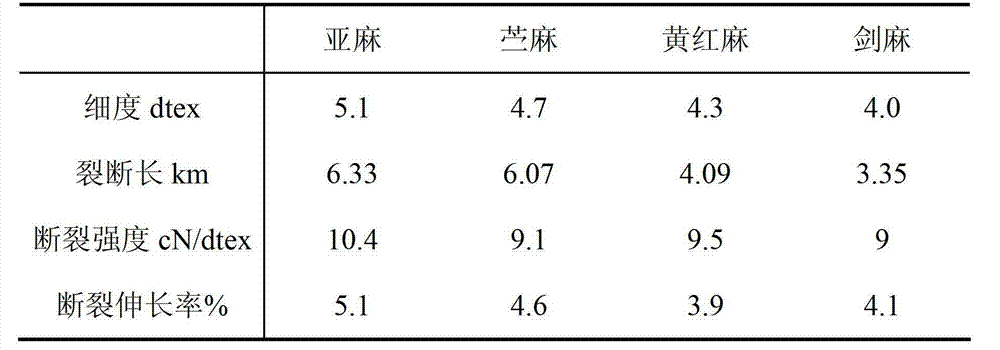

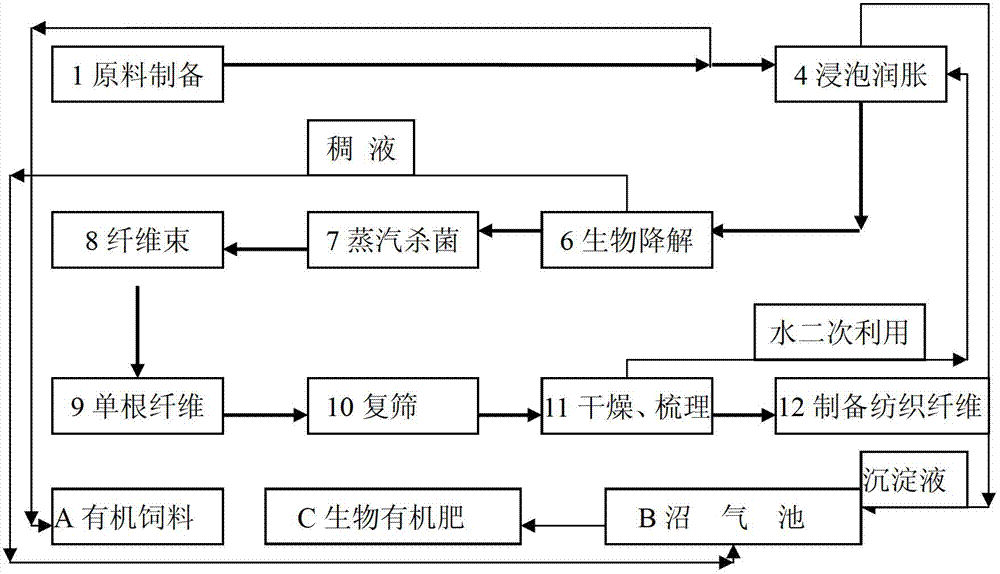

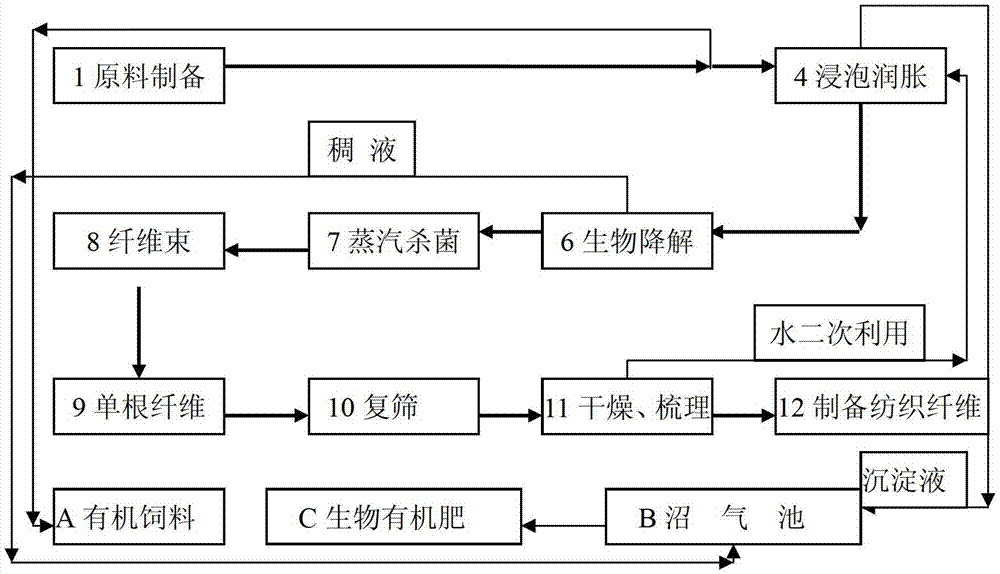

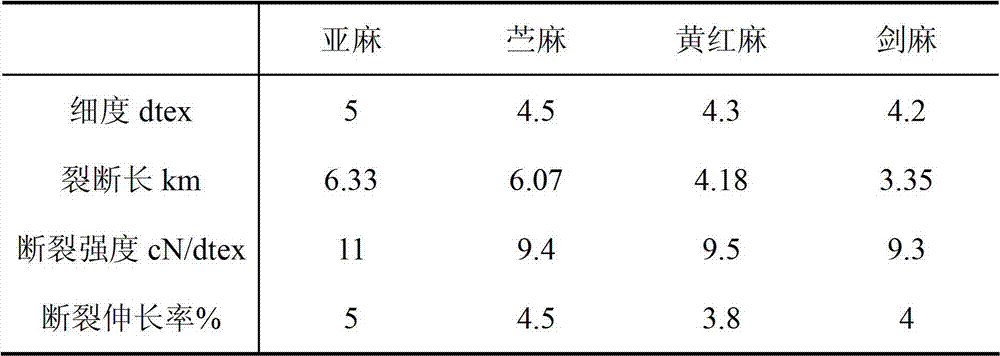

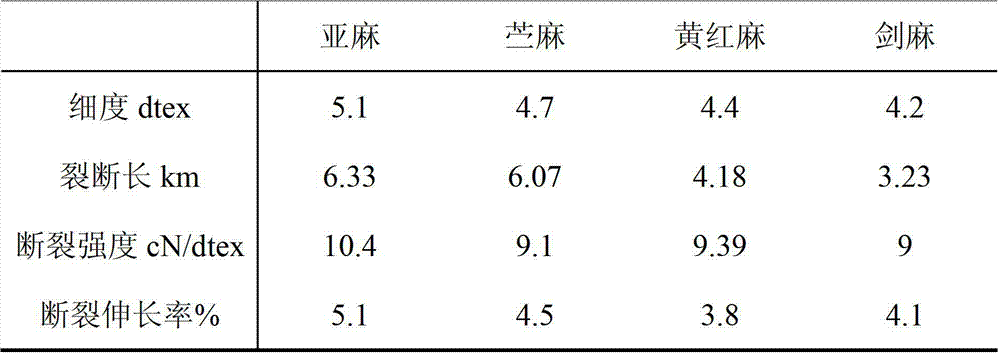

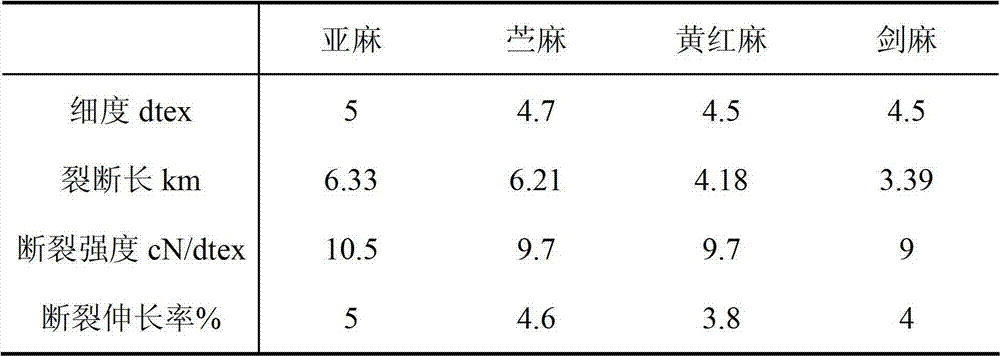

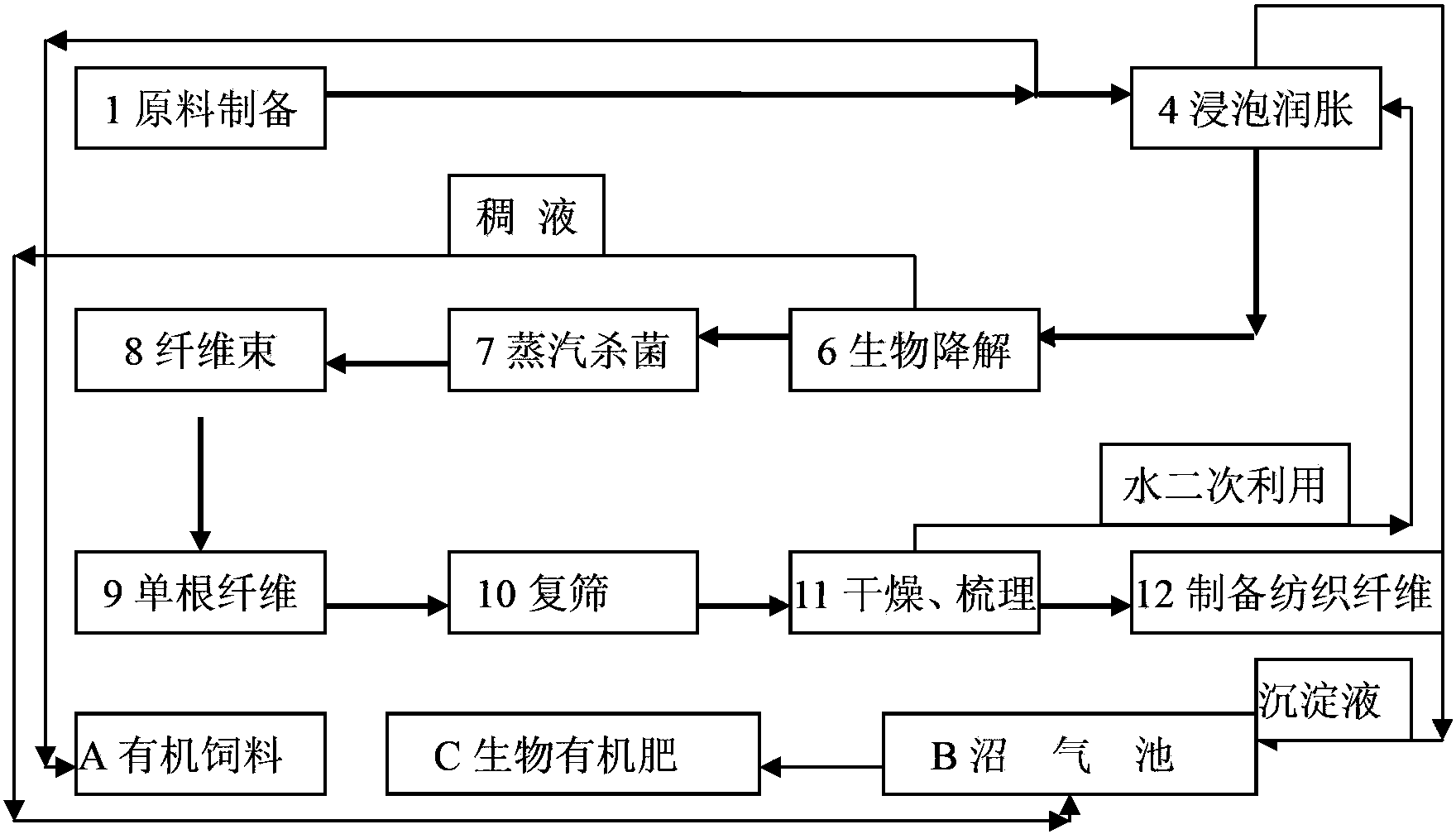

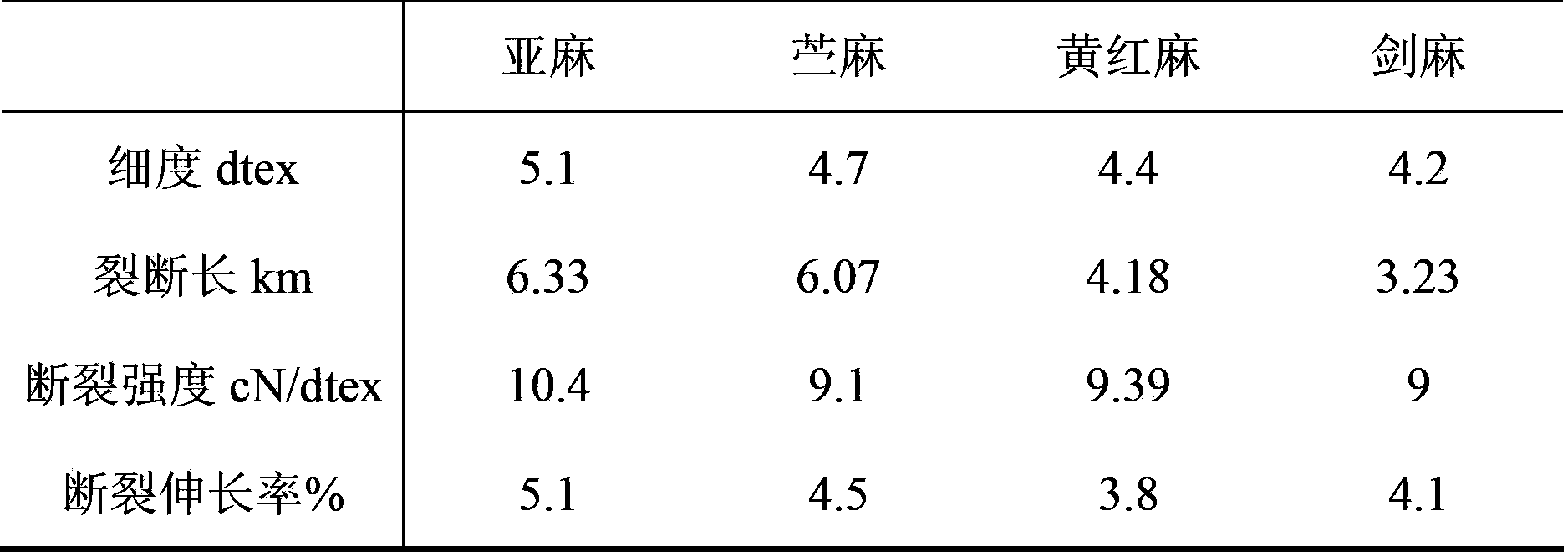

Composite flora and application of the same in textile fiber preparation

InactiveCN103074267APlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberPseudomonas fluorescens

The present invention relates to a composite flora and an application of the composite flora in textile fiber preparation. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and pulping method by using biological bacterial liquid of composite flora

InactiveCN103074263AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaFiberPseudomonas fluorescens

The present invention relates to a composite flora and a pulping method by using a biological bacterial liquid of the composite flora. The composite flora comprises acinetobacter lwoffii with a preservation number of CGMCC No.5973, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and application of the same in textile fiber preparation

InactiveCN103074214APlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberPseudomonas fluorescens

The present invention relates to a composite flora and an application of the composite flora in textile fiber preparation. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and application of the same in additive cellulose preparation

InactiveCN103074252APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberFlora

The present invention relates to a composite flora and an application of the composite flora in additive cellulose preparation. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The process for preparing the additive cellulose comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and textile fiber preparation method by using the same

InactiveCN103074220APlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberEnvironmental resistance

The present invention relates to a composite flora and a textile fiber preparation method by using the composite flora. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and additive cellulose preparation method by using the same

InactiveCN103074253APlay a protective effectNo pollutionBio-organic fraction processingBacteriaFiberPseudomonas fluorescens

The present invention relates to a composite flora and an additive cellulose preparation method by using the composite flora. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises fiber kneading or squeezing rolling, biodegradation, steam sterilization, fiber obtaining, sterilization and grinding. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

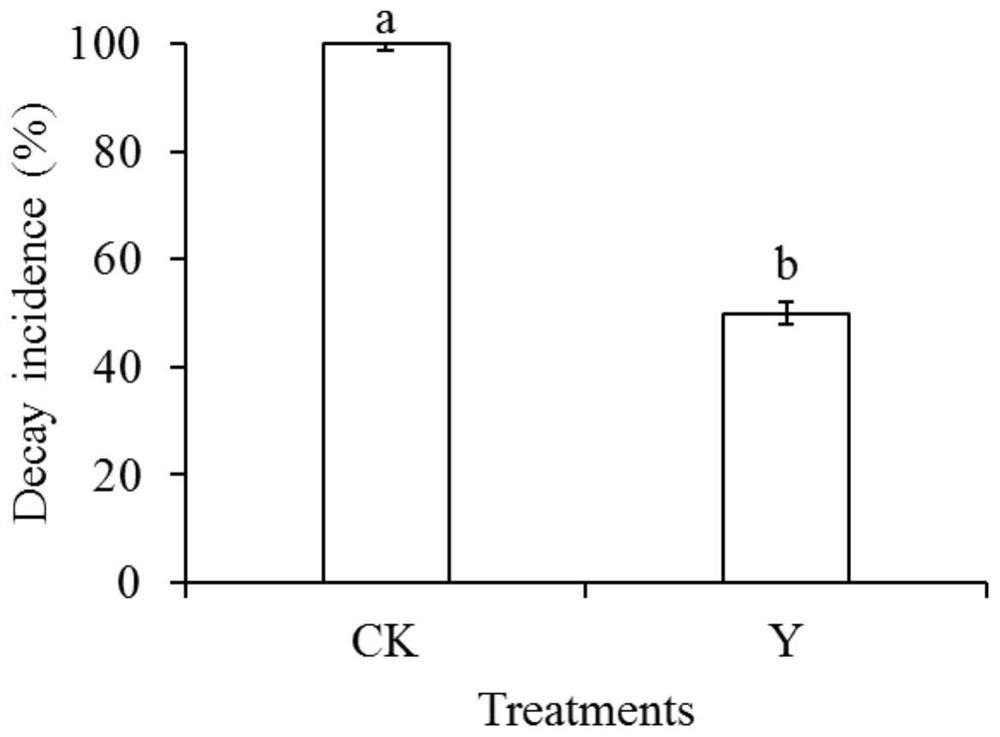

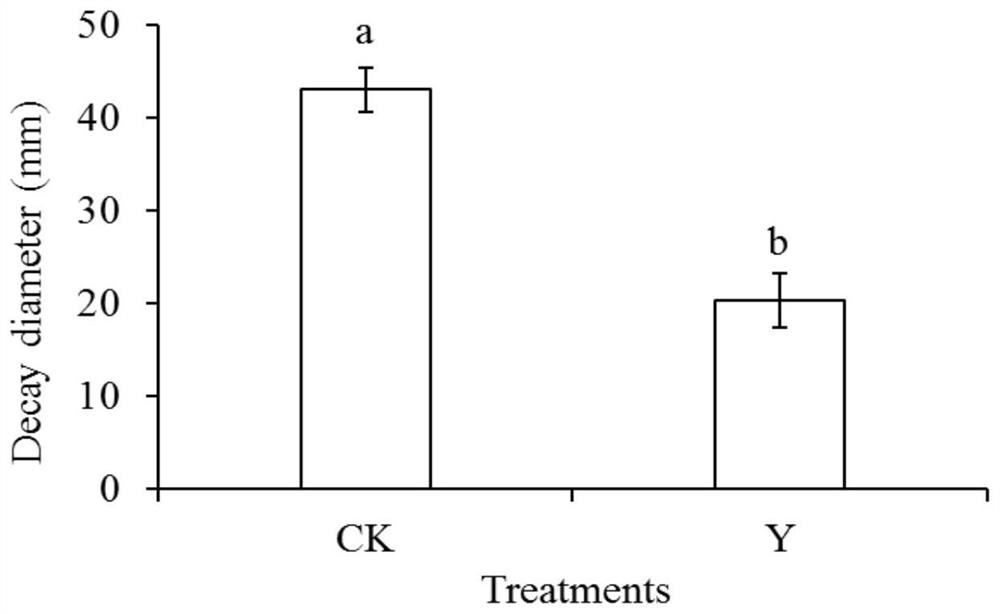

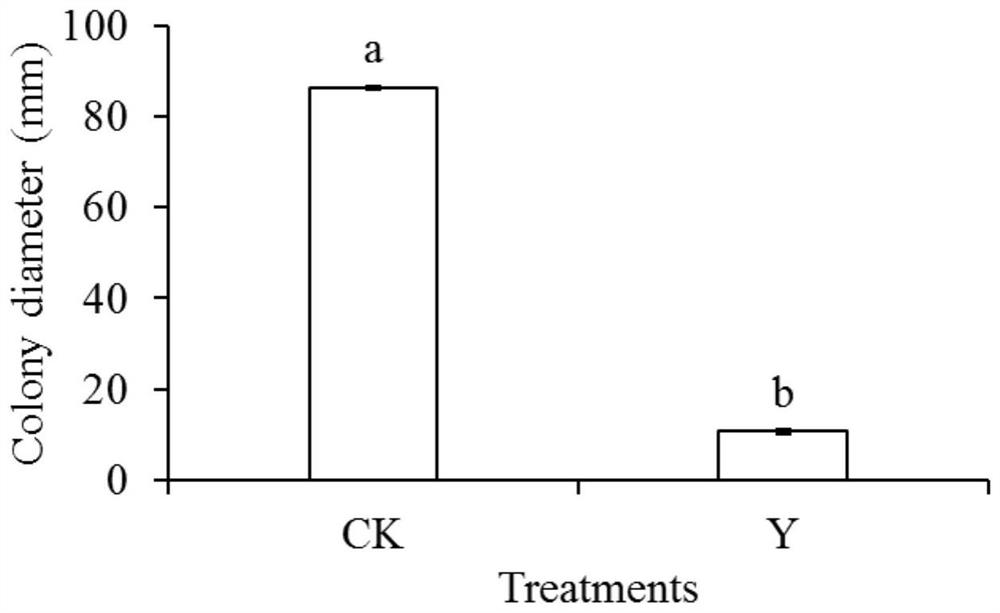

Application of Wickerhamomyces anomalus in postharvest disease control, storage and fresh-keeping of tomatoes

PendingCN113273604AHas broad-spectrum antibacterial propertiesInhibit BotrytisFungiFruit and vegetables preservationWickerhamomycesSporeling

The invention belongs to the technical field of biological control, and relates to application of Wickerhamomyces anomalus in postharvest disease control, storage and fresh-keeping of tomatoes. A method comprises the following steps of: activating and culturing Wickerhamomyces anomalus, performing centrifuging to obtain thalli, diluting the thalli with sterile water to obtain a yeast suspension with the concentration of 1*10<8> cells / mL, punching the surfaces of the tomatoes, injecting the yeast suspension, and injecting an isopyknic botrytis cinerea spore suspension with the concentration of 1*10<5> spores / mL after 2 hours, so as to effectively control the gray mold, or directly and uniformly spraying the yeast suspension on the surfaces of the tomatoes, and performing natural air-drying. The purposes of preventing and treating the postharvest gray mold of the tomatoes, storing and fresh-keeping can be realized; according to the invention, postharvest gray mold and natural rot of the tomatoes can be effectively controlled, so that the loss caused by postharvest diseases of the tomatoes is reduced; meanwhile, operation is convenient, safe and environment-friendly; and remarkable economic benefits and social benefits are achieved.

Owner:JIANGSU UNIV

Composite flora and pulping method by using biological bacterial liquid of composite flora

InactiveCN103074257AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaFiberCardboard

The present invention relates to a composite flora and a pulping method by using a biological bacterial liquid of the composite flora. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and textile fiber preparation method by using the same

InactiveCN103074247APlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberPseudomonas

The present invention relates to a composite flora and a textile fiber preparation method by using the composite flora. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and textile fiber preparation method by using the same

InactiveCN103074248APlay a protective effectZero pollutionBio-organic fraction processingBacteriaEnvironmental resistanceTextile fiber

The present invention relates to a composite flora and a textile fiber preparation method by using the composite flora. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and pulping method by using biological bacterial liquid of composite flora

InactiveCN103074261AZero pollutionPlay a protective effectBio-organic fraction processingBacteriaCardboardFiber

The present invention relates to a composite flora and a pulping method by using a biological bacterial liquid of the composite flora. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, pseudomonas fluorescens with a preservation number of CGMCC No.5974, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora for biological preparation of textile fibers, and applications thereof

InactiveCN103074221APlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberEnvironmental resistance

The present invention relates to a composite flora for biological preparation of textile fibers, and applications thereof. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora for biological preparation of textile fibers, and applications thereof

InactiveCN103074221BPlay a protective effectZero pollutionBio-organic fraction processingBacteriaTextile fiberEnvironmental resistance

The present invention relates to a composite flora for biological preparation of textile fibers, and applications thereof. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and pulping method by using biological bacterial liquid of composite flora

InactiveCN103074250BZero pollutionPlay a protective effectBio-organic fraction processingBacteriaFiberRheinheimera tangshanensis

The present invention relates to a composite flora and a pulping method by using a biological bacterial liquid of the composite flora. The composite flora comprises rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method mainly comprises: preparing a bacterial liquid; treating raw materials; and pulping, wherein pulping comprises: fiber kneading or squeezing rolling, biodegradation, steam sterilization, crude pulp grinding, fine pulp grinding, pulp material screening, soaking, and pulp washing. The paper board prepared by using the pulping method can achieve a level of more than an AA grade. In addition, waste liquid generated during a pulping process can be recycled or converted into biogas or an organic fertilizer adopted as an energy source so as to provide advantages of energy source saving and environment protection.

Owner:BEIJING TIANAN BIOSCI & TECH

Composite flora and textile fiber preparation method by using the same

InactiveCN103074248BPlay a protective effectZero pollutionBio-organic fraction processingBacteriaEnvironmental resistanceTextile fiber

The present invention relates to a composite flora and a textile fiber preparation method by using the composite flora. The composite flora comprises bacillus sp. with a preservation number of CGMCC No.5971, rheinheimera tangshanensis with a preservation number of CGMCC No.5972, acinetobacter lwoffii with a preservation number of CGMCC No.5973, and Wickerhamomyces anomalus with a preservation number of CGMCC No.5975. The method comprises the following steps: preparing a bacterial liquid; treating raw materials; and preparing fibers, wherein fiber preparation comprises biodegradation, steam sterilization, fiber obtaining, drying, and combing. According to the present invention, the method does not pollute the environment, a waste liquid is directly converted into an organic fertilizer so as to achieve zero emission and zero pollution, the biological treatment process provides a protection effect for fibers, advantages of low production cost and high economic benefits are provided compared with the traditional chemical method, and characteristics of energy source saving and environmental protection are provided.

Owner:BEIJING TIANAN BIOSCI & TECH

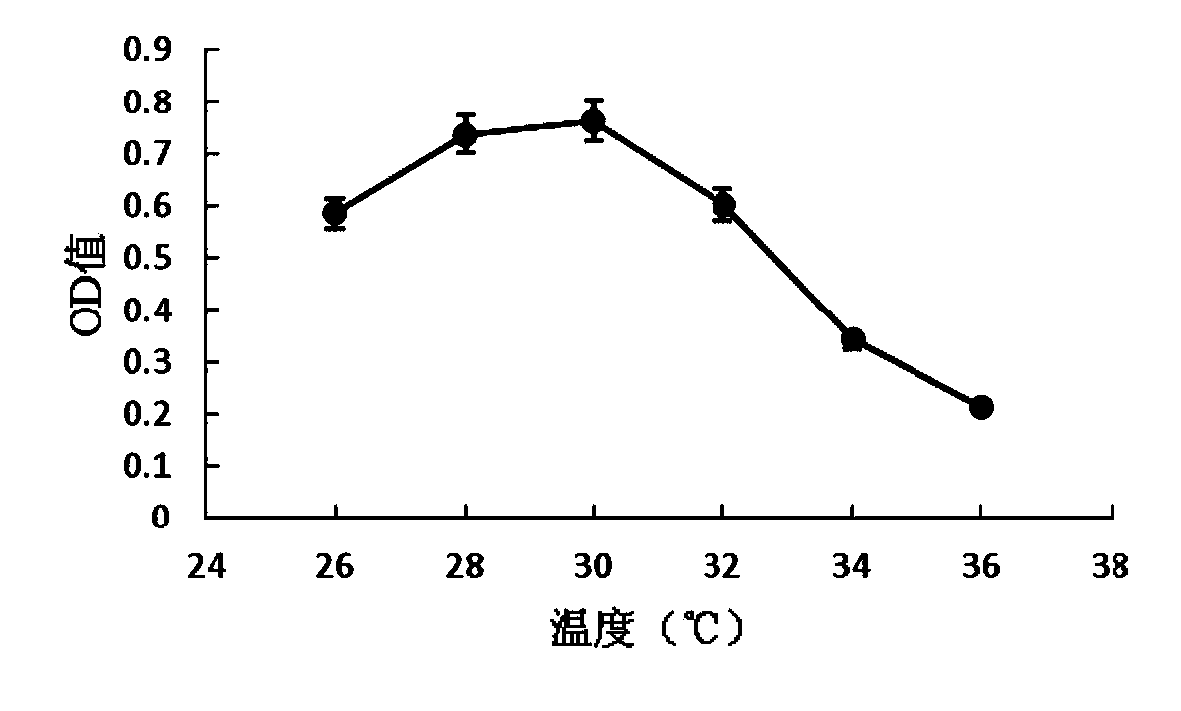

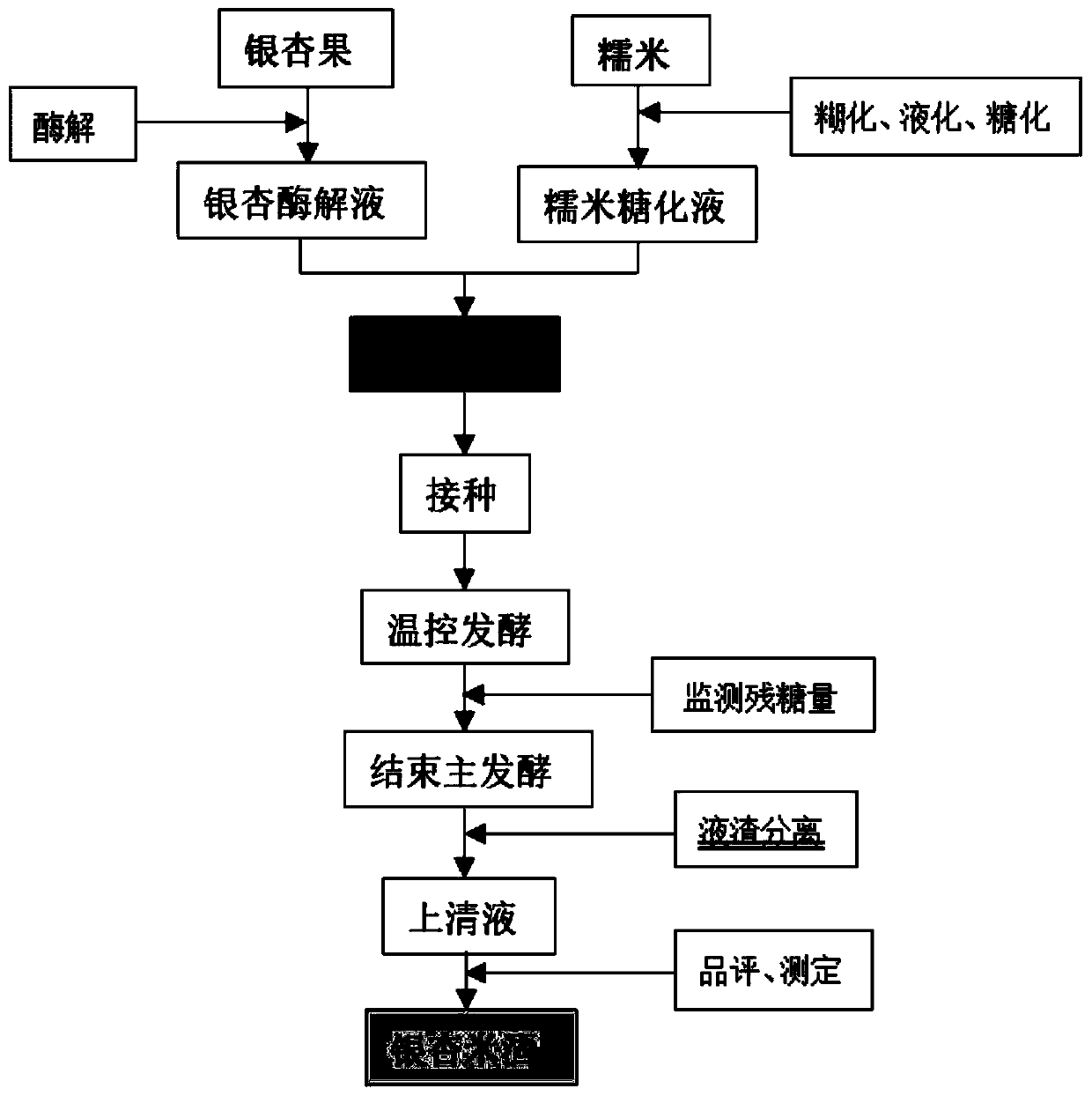

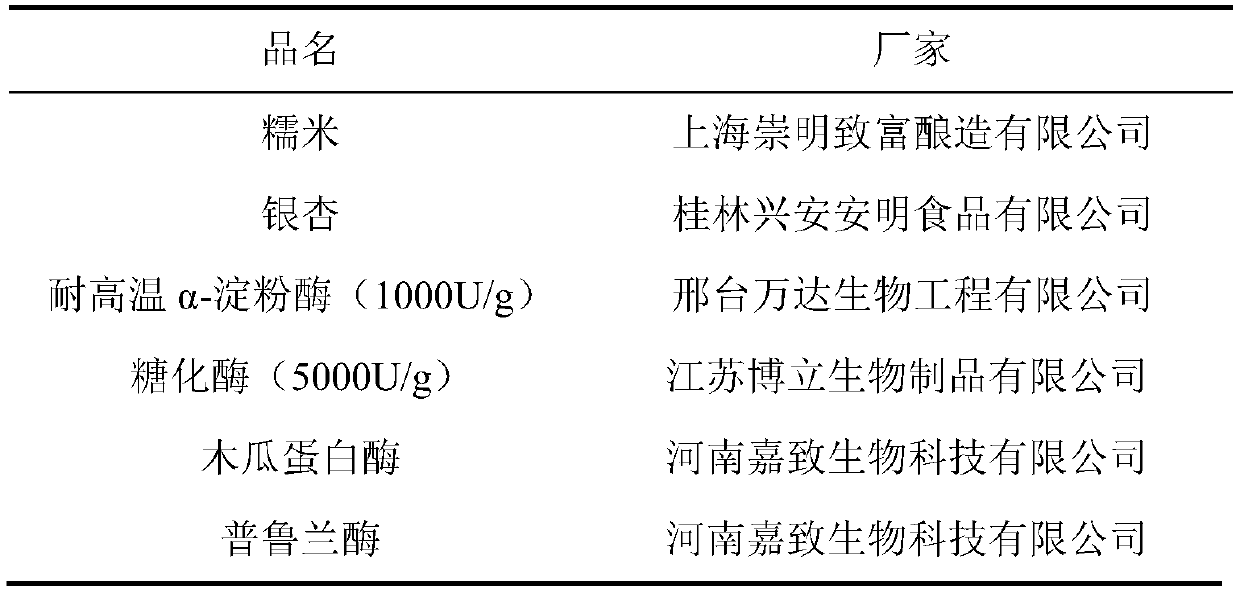

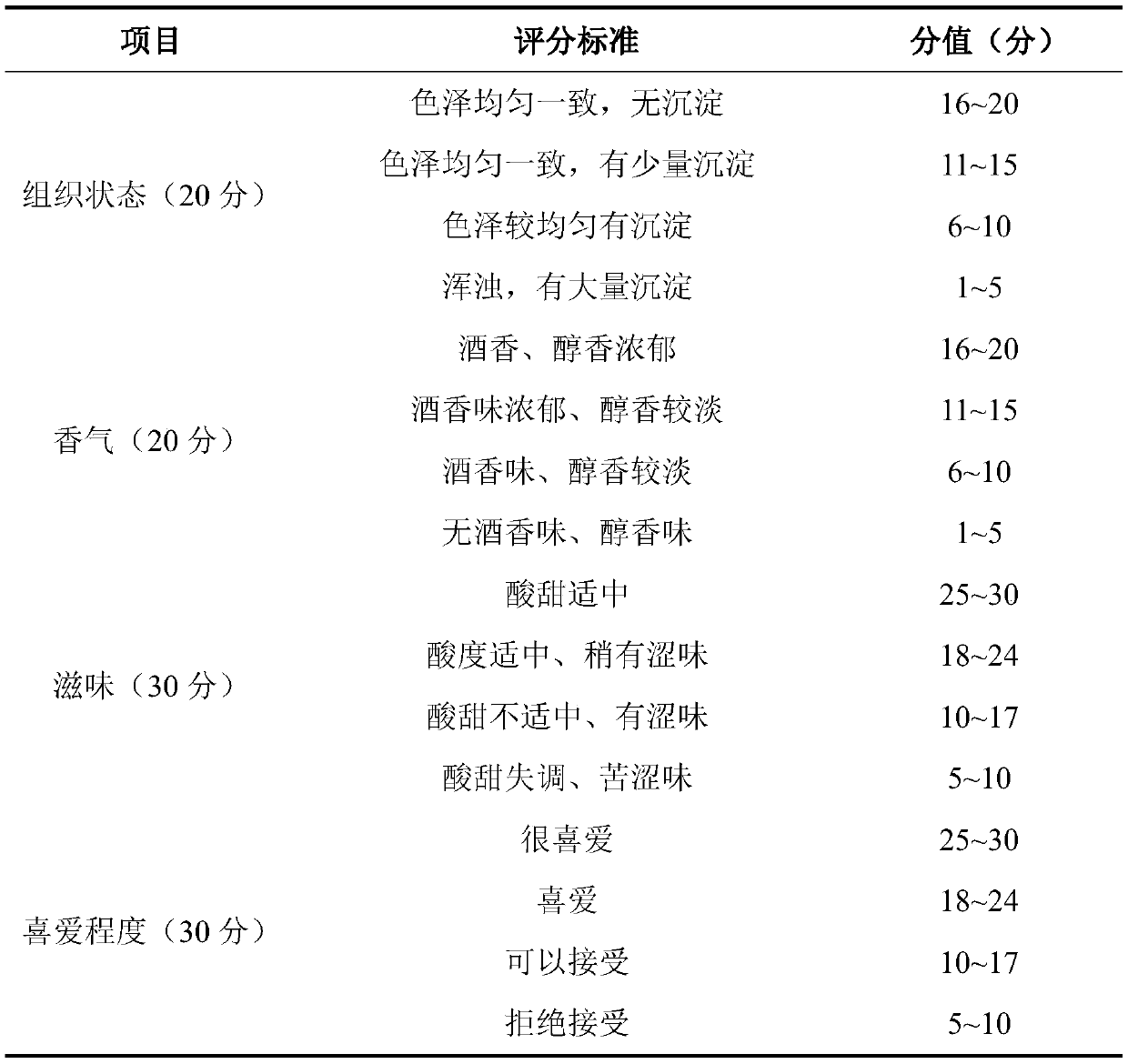

Preparation method of ginkgo rice wine through synergistic fermentation of Wickerhamomyces anomalous and saccharomyces cerevisiae

InactiveCN111534407ASolve outputSolve quality problemsMicroorganism based processesAlcoholic beverage preparationBiotechnologyHydrolysate

The invention provides a preparation method of ginkgo rice wine through synergistic fermentation of Wickerhamomyces anomalous and saccharomyces cerevisiae, which comprises the following steps: respectively saccharifying glutinous rice and ginkgo, adding 0-80% of ginkgo enzymatic hydrolysate into the glutinous rice saccharified liquid, inoculating Wickerhamomyces anomalous (the preservation numberis CGMCC No.6983) and saccharomyces cerevisiae (the preservation number is CCTCCM2014463) according to the ratio of (1-1000): 1 (the unit inoculum size is 5 * 10<4>CFU / mL), fermenting at 24-36 DEG C for 48-96 hours, and centrifuging to obtain supernate, namely the gingko rice wine. Starch and other functional components in gingko are utilized to the maximum extent, the high-quality gingko rice wine is brewed, the traditional diet theory of homology of food and medicine in China is developed, the rice wine with Chinese national characteristics and long history is produced and embodied, the national development strategy of industrial production of traditional food is met. The consumption requirements of consumers on low alcoholic strength, high nutrition, obvious health care function, uniquefragrance and the like of the wine product are met.

Owner:SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com