Method for screening aroma-producing yeast and preparing ingredient from aroma-producing yeast

A technology of aroma-producing yeast and yeast, which is applied in the field of microorganisms and fermentation and brewing engineering, can solve the problems of long fermentation time, weak fermentation power of yeast, consumption, etc., and achieve the effect of simple process, sufficient fermentation aroma and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

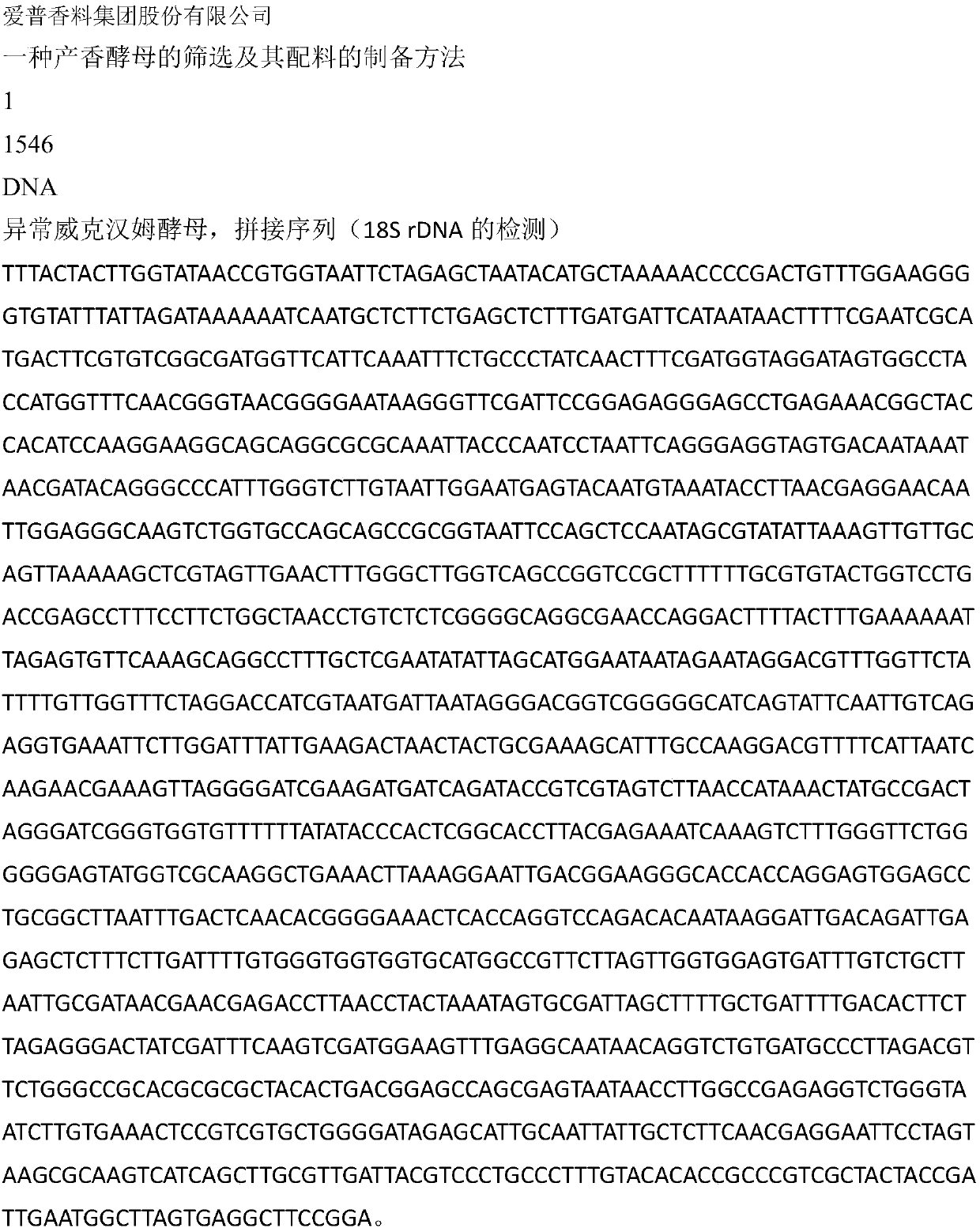

[0014] The first part is the screening and fermentation of yeast: take the yeast, use the rose bengal sodium agar medium to screen out the yeast with good fermentation aroma, and detect the 18S rDNA of the screened yeast, and the yeast is abnormal Klebham yeast, its splicing sequence is as described above.

[0015] The yeast is activated and cultivated in a sucrose solution with a mass percentage of 2 to 6%. The sucrose solution in this embodiment is 3% by mass, and the fermentation temperature is 25 to 35°C. The fermentation temperature in this embodiment is 27 to 35°C. 32°C, the fermentation time is 40-80 hours, and the number of yeasts detected reaches about 5.0×10 7 When the gelatinized starch solution is 9% by mass, add the gelatinized starch solution with a mass percentage of 9%, carry out aeration culture at 28°C, then add the gelatinized starch solution every 24 hours, repeat 6 times to obtain a culture solution, and the fermentation is over Afterwards, the culture so...

Embodiment 2

[0018] The same as Example 1, the difference is: the yeast is activated and cultured in a sucrose solution with a mass percentage of 5%, the fermentation temperature is 32-35°C, the fermentation time is 40-80h, and the number of yeasts detected reaches about 5.0 ×10 7 1 / mL, add gelatinized starch solution with a mass percentage of 10%, pass through clean air at 31°C for aerated culture, then add gelatinized starch solution every 24 hours, repeat 4 times to obtain a culture solution, and the fermentation is over Afterwards, the culture solution was concentrated to one-half of the volume of the original solution. Gelatinized starch is wheat starch.

[0019]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com