Bio-bacteria and bio-bacterial solution pulping method

A technology for biological bacteria and pulping, which is applied in fertilizers made from biological waste, microorganism-based methods, biochemical equipment and methods, etc. The effect of low production cost, reduced reaction time, improved purity and yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Configuration of bacterial liquid

[0031] The biological bacteria used in the present invention have been deposited in the General Microbiology Center of China Microbial Culture Collection Management Committee (CGMCC, No. 3, No. 1, Beichen West Road, Chaoyang District, Beijing) on April 6, 2012, and its deposit number is CGMCC No. 5975 biological bacteria (Wickerhamomyces anomalus).

[0032] The above-mentioned biological bacteria are mixed with water to form a bacterial liquid, and the density of the formed bacterial liquid is 60 million bacteria / ml or more for use.

Embodiment 2

[0033] Example 2 Biological bacterial liquid pulping of woody raw materials

[0034] Using Caragana korshinskii as the raw material, the biological bacteria liquid pulping method when using woody raw materials is specified. The biological pulping method of other woody materials, such as poplar and eucalyptus, can refer to this process.

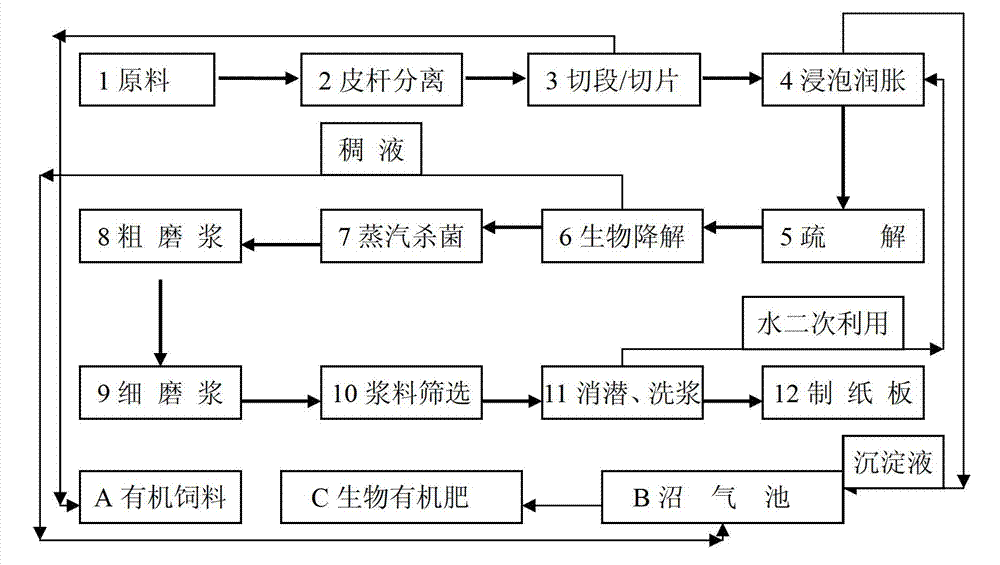

[0035] Please refer to figure 1 , The process of biological bacterial liquid pulping method is divided into three stages: preparation stage, pulping section and by-product section.

[0036] (1) Preparation stage: 1-4

[0037] 1)-2): Separate the harvested Caragana. It can be separated by a winnowing machine or other mechanical separation. After the skin rods are separated, the skins are input into the organic feed workshop for processing feed, and the peeled rods are input to the next program.

[0038] 3) Cut the rod into sections on the cutting machine, the length is 3-4cm, and the oblique opening is better to increase the penetration area.

[0039] ...

Embodiment 3

[0057] Example 3 Biological bacterial liquid pulping of herbal raw materials

[0058] Using wheat straw as the raw material, the biological bacteria liquid pulping method when using herbal raw materials is specified. The biological pulping method of other herbal raw materials, such as wheat straw, rice straw, and corn stover, can be carried out with reference to this process.

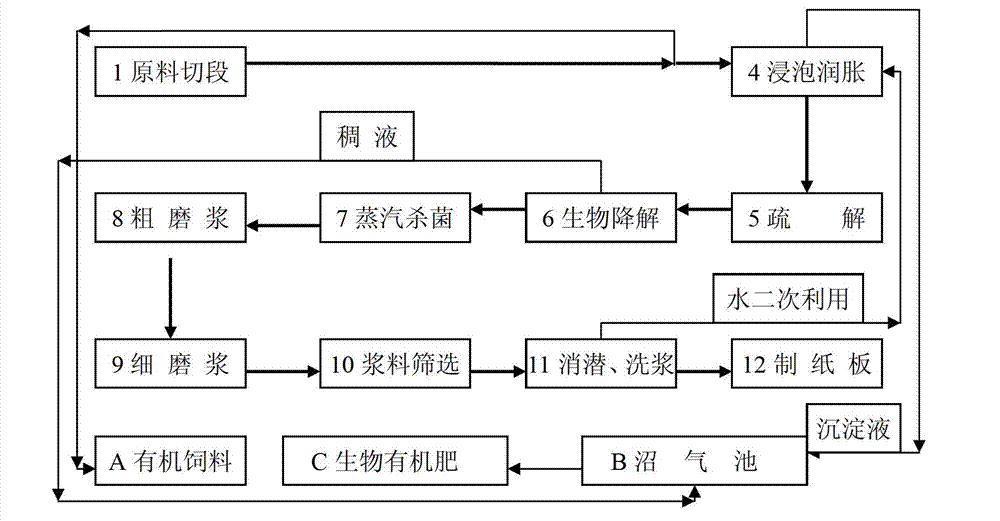

[0059] Please refer to figure 2 , The process of biological bacterial liquid pulping method is divided into three stages: preparation stage, pulping section and by-product section.

[0060] (1) Preparation stage: 1, 4

[0061] Cut the wheat straw into 4-5cm sections, and enter the soaking bin or soaking tank for washing and cold soaking. First, wash away the dirt and other debris on the surface of the raw material and soak at the same time. The water temperature is natural temperature and the time is soaked and swelled. Whichever is 10-12h. After the turbidity of the liquid after multiple soaking, the super...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com