Uses of Wickerhamomyces anomalus T1 in flavoring of soy sauce, and flavoring process

A Wickham and yeast technology is applied in the soy sauce flavoring process. The abnormal Wickham yeast T1 can solve the problems of insufficient soy sauce flavor and no flavoring process in the field of soy sauce flavoring, so as to save resources. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

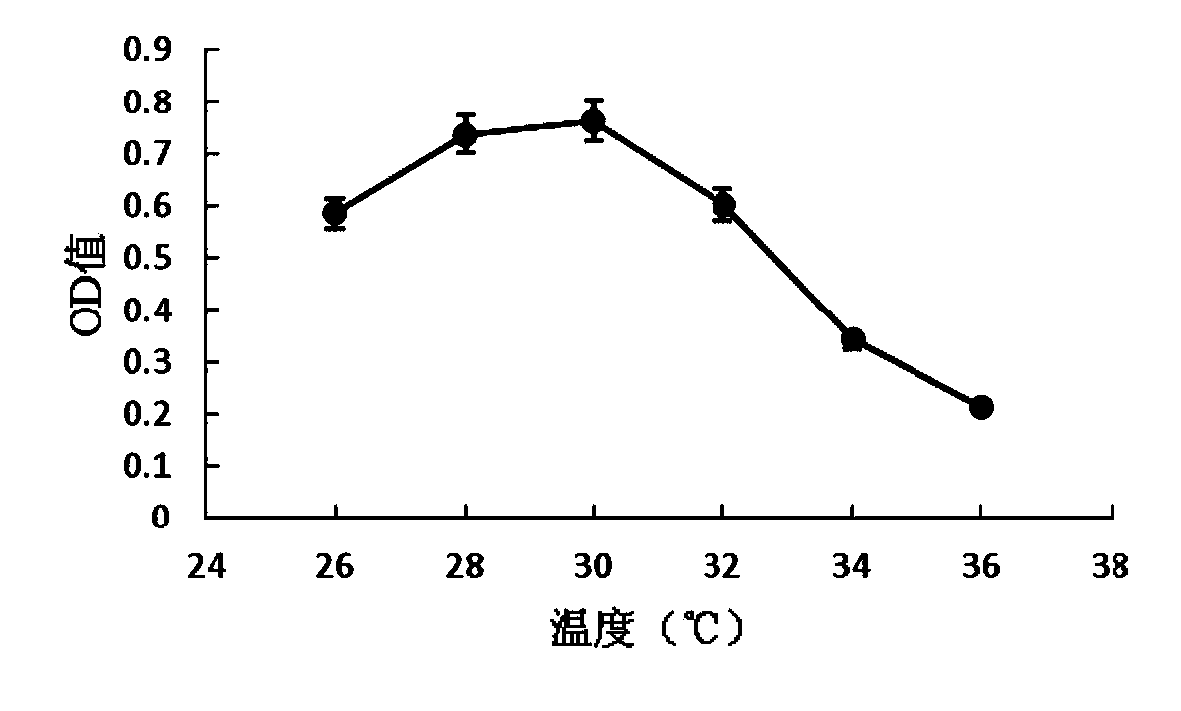

[0041] Example 1 Screening and Growth Characteristics of Abnormal Wickham Saccharomyces T1 Strain

[0042] 1. The screening steps for abnormal Wickham yeast T1 strain are as follows:

[0043] Under sterile conditions, mince the Parma ham sample, transfer it to sterile water, vortex and mix it, let it stand for a few minutes, and take the supernatant for separation and screening by streaking method, coating method, and dilution pouring plate method According to the color, size, luster, and transparency of the colony, a single colony was picked and separated and purified by streaking. During multiple isolation and purification processes, a strain T1 that could produce a pleasant aroma was obtained. By extracting the sample genome DNA, 16SrDNA sequence was amplified by PCR, and homologous comparison was performed to prove that the strain was Wickham anomaly, and the strain screened in the present invention was named Wickham anomaly T1.

[0044] The 16S rDNA sequence of Saccharom...

Embodiment 2

[0074] The preparation process of the low-salt solid moromi in A fermentation is as follows:

[0075] 1) Mix soybean meal, bean dregs, and bran at a weight ratio of 5:3:2 to obtain a dry material, add yellow pulp water 1.5 times the weight of the dry material to fully infiltrate, sterilize and steam the material at 121°C for 35 minutes, and the obtained clinker is yellow. The brown color is not dark brown, and the water is suitable for dry and wet to pinch without a hard core and not sticky. At room temperature, koji is planted in an aseptic environment with an amount of 3% of the dry weight of clinker, and then statically cultivated at 27-30° C. for 48 hours to obtain soy sauce koji.

[0076] When the process conditions of this step are determined, in order to improve the activity of protease in soy sauce koji, the four factors of bean dregs content, moistening amount, steaming time and koji making time are selected as the regression model. After testing and analysis, the mod...

Embodiment 3

[0091] The production method of the salt-free liquid moromi in A fermentation is as follows:

[0092] 1) Soybean meal, bean dregs, and bran are mixed in a weight ratio of 5:3:2 to obtain a dry material. The dry material and salt-free yellow syrup are sterilized separately. After sterilization, the dry material and salt-free yellow syrup are 1:4 The mass ratio was fully mixed, inoculated with 3% soy sauce koji essence, sealed with gauze, and cultured on a shaking table at 32° C. and 140 r / min for 48 hours to obtain liquid soy sauce koji. ; add salt-free yellow pulp water equal to the volume of the raw material, adjust the pH to 5.3, ferment for 5-8 days, and sterilize.

[0093] 2) Take the liquid soy sauce koji, add salt-free yellow pulp water equivalent to the liquid soy sauce koji to the liquid soy sauce koji, adjust the pH to 4.8-5.5, and culture it on a shaker at 43°C and 140r / min for 6-7 days to obtain fermentation Salt-free liquid moromi.

[0094] Take the salt-free liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com