Preparation method of ginkgo rice wine through synergistic fermentation of Wickerhamomyces anomalous and saccharomyces cerevisiae

A technology of Wickham and Saccharomyces cerevisiae is applied in the field of synergistic fermentation of Ginkgo biloba rice wine by abnormal Wickham yeast and Saccharomyces cerevisiae, which can solve the problems of unseen Wickham yeast and unfermented ginkgo rice wine, etc., and achieve rich varieties. , the effect of shortening the fermentation cycle and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

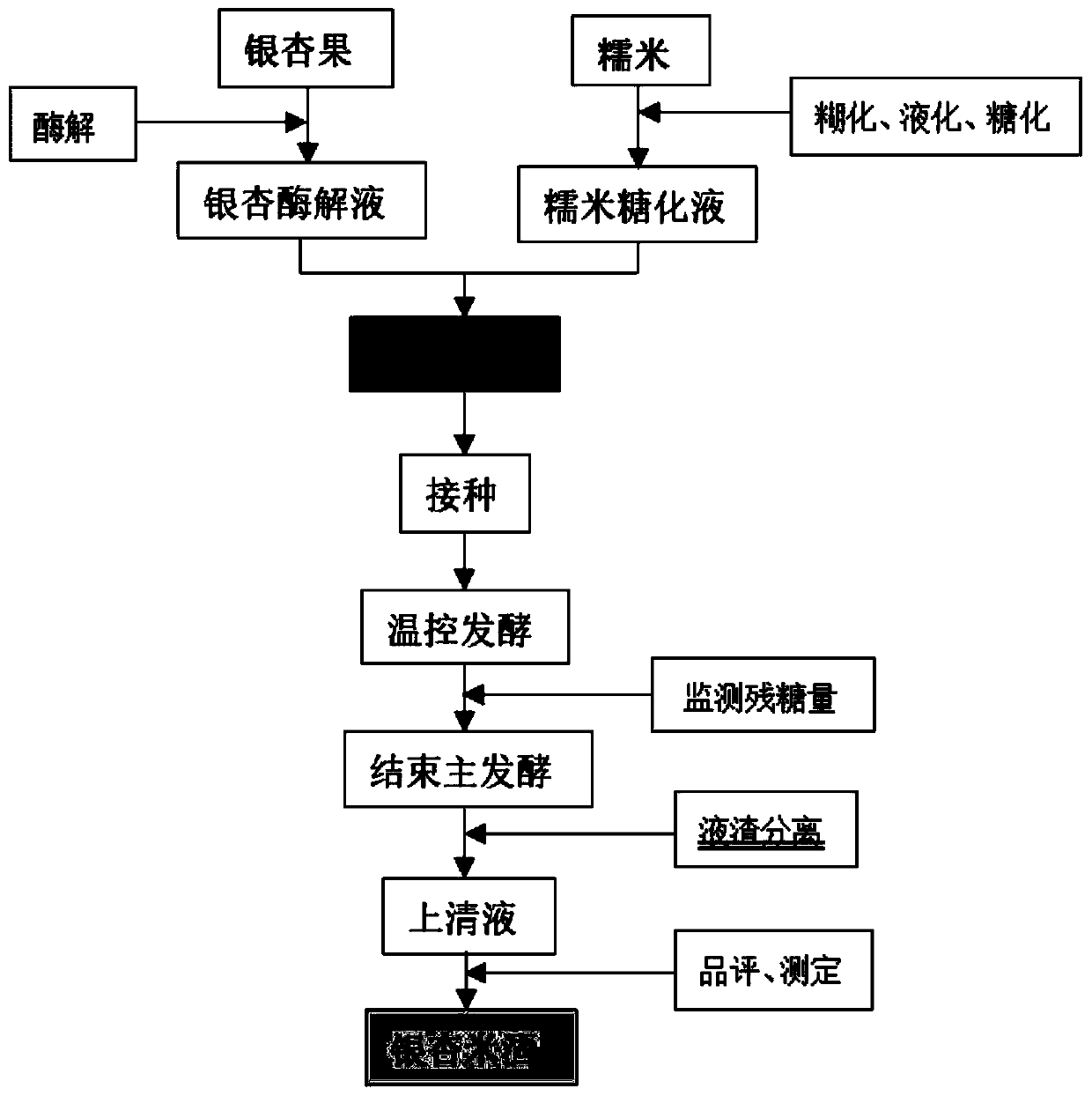

[0025] like figure 1 As shown, the present embodiment provides a method for making ginkgo rice wine co-fermented by abnormal Wickham yeast and saccharomyces, and the specific steps are:

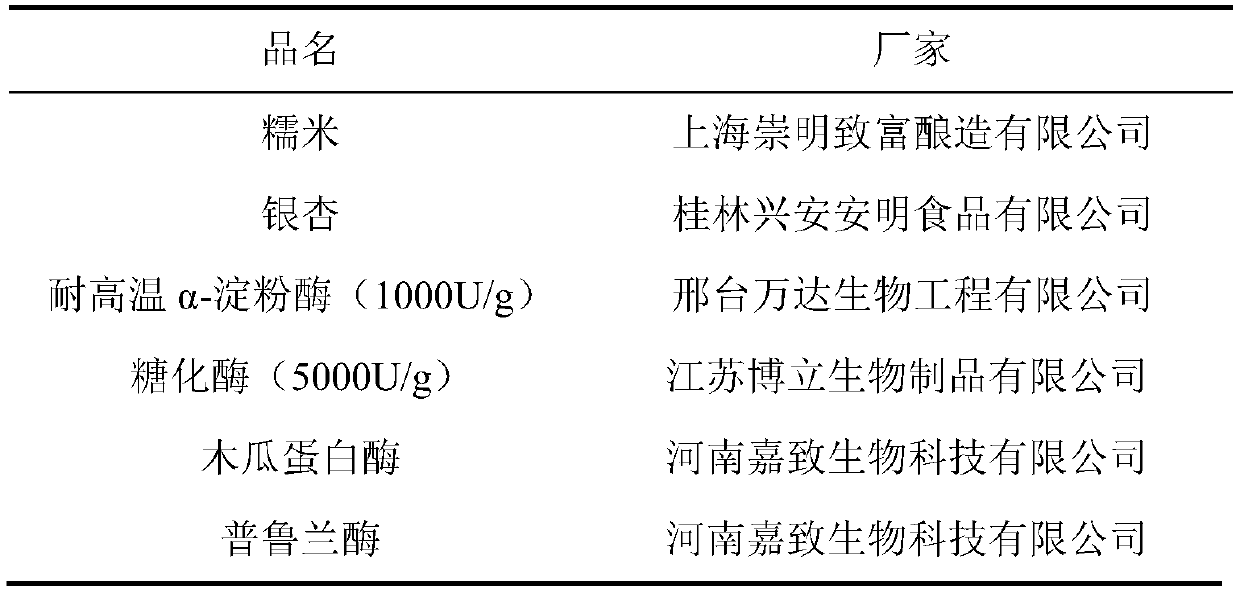

[0026] (1) Crush the broken glutinous rice and pass it through a 80-mesh sieve to obtain glutinous rice flour; take glutinous rice flour and water at a mass ratio of 1:8, gelatinize at a temperature of 90°C for 20 minutes, cool to room temperature (20°C) and add mass concentration 0.16% α-amylase (1000U / g, calculated as glutinous rice flour), liquefied at a temperature of 80°C for 45 minutes, cooled to 60°C, and added with a mass concentration of 4.8% glucoamylase (5000U / g, calculated as glutinous rice flour), Saccharify at a temperature of 60°C for 6 hours, boil at 100°C for 5.0 minutes to inactivate the enzyme, and obtain a glutinous rice saccharification solution, which is stored at -4°C for use;

[0027] (2) Remove the outer shell and inner testa of ginkgo, put it in a cooking pot and bo...

Embodiment 2

[0031] like figure 1 As shown, the present embodiment provides a method for making ginkgo rice wine co-fermented by abnormal Wickham yeast and saccharomyces, and the specific steps are:

[0032] (1) Grind the glutinous rice and pass it through a 80-mesh sieve to obtain glutinous rice flour; take glutinous rice flour and water at a mass ratio of 1:8, gelatinize at a temperature of 90°C for 20 minutes, cool to room temperature (20°C), and add a mass concentration of 0.16% α-amylase (1000U / g, calculated as broken rice flour), liquefied at a temperature of 80°C for 45min, cooled to 60°C, and added with a mass concentration of 4.8% glucoamylase (5000U / g, calculated as broken rice flour), in Insulate and saccharify at 60°C for 6 hours, boil at 100°C for 5.0 minutes to inactivate the enzyme, and obtain glutinous rice saccharification liquid, which is stored at -4°C for later use;

[0033] (2) Ginkgo biloba is removed from the shell and inner testa, placed in a cooking pot and boiled...

Embodiment 3

[0037] like figure 1 As shown, the present embodiment provides a method for making ginkgo beverage co-fermented by abnormal Wickham yeast and saccharomyces, and the specific steps are:

[0038] (1) Grind the glutinous rice and pass it through a 80-mesh sieve to obtain glutinous rice flour; take glutinous rice flour and water at a mass ratio of 1:8, gelatinize at a temperature of 90°C for 20 minutes, cool to room temperature (20°C), and add a mass concentration of 0.16% α-amylase (1000U / g, calculated as broken rice flour), liquefied at a temperature of 80°C for 45min, cooled to 60°C, and added with a mass concentration of 4.8% glucoamylase (5000U / g, calculated as broken rice flour), in Saccharify at 60°C for 6 hours, boil at 100°C for 5.0 minutes to inactivate the enzyme, and obtain glutinous rice saccharification liquid, which is stored at -4°C for later use;

[0039] (2) Remove the shell and inner testa of ginkgo, put it in a cooking pot and boil it for 2 hours to detoxify, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com