Biological ultrasonic pulping method for high-strength mechanical pulp

A technology of ultrasonic and mechanical pulping, applied in the field of paper pulping, to achieve novel and unique methods, good effect and the effect of improving pulp quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

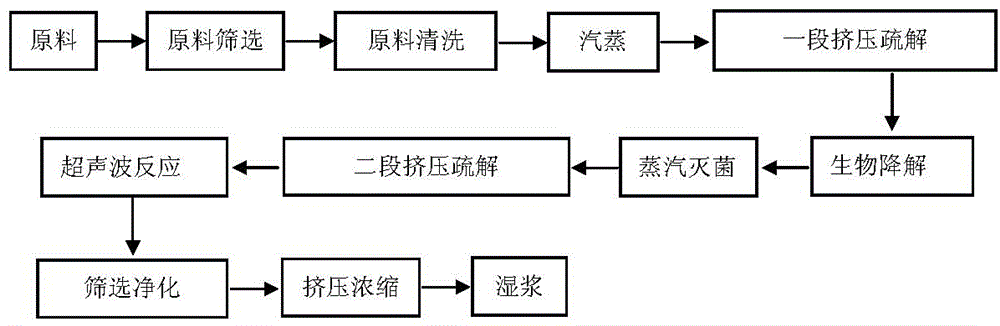

[0022] Depend on figure 1 Shown, the present invention in concrete implementation, comprises the following steps:

[0023] (1), preparation of compound bacteria liquid:

[0024] Compound white rot fungus, Rheinrichia tangshanensis, Acinetobacter ruckerii and Pseudomonas fluorescens in a mass ratio of 2~3︰1~3︰1~2︰1~2, add water to make bacteria The group density is 6×10 7 more than one / ml compound bacteria solution;

[0025] (2) Steaming raw materials: the raw materials are woody or herbaceous plants containing fibers, first cut the woody raw materials into wood chips with a length of 3-4cm, or cut the herbaceous plant raw materials into 4-5cm long, After washing with water for 2 to 3 times, it is sent to the steaming chamber, steamed with steam for 10 to 30 minutes to soften the raw materials, and then enters the helical spiral dehydrator for dehydration;

[0026] (3) One-stage extrusion defrosting: send the softened and dehydrated raw materials into a one-stage double-scr...

Embodiment 2

[0035] In the specific implementation of the present invention, the composite bacteria liquid is that white rot fungus, Rhinemeria tangshanensis, Acinetobacter ruckerii and Pseudomonas fluorescens are mixed in a mass ratio of 2.2~2.8︰1.5~2.5︰1.2 ~1.8︰1.2~1.5 compounded together, add water to make the colony density 6×10 7 more than one / ml compound bacteria solution;

[0036] The one-stage extruding solution is in mass percent: NaOH 1.2-1.8% and H 2 o 2 0.02~0.08% is made by adding water to 100%;

[0037] The mass ratio of the first-stage decomposed raw material to the composite bacterial solution is 1:7, the biodegradation temperature is kept at 36-38°C, and the time is 35-40 hours;

[0038] The two-stage extruding liquid is expressed in mass percent: NaOH 2.5-3.5%, H2 o 2 3.0~5.0%, Na 2 SiO 3 2~3.0% and DTPA 0.2~0.4% add water to 100%.

Embodiment 3

[0040] In the specific implementation of the present invention, the compound bacteria liquid is that white rot fungus, Rhinemeria tangshanensis, Acinetobacter ruckerii and Pseudomonas fluorescens are compounded in a mass ratio of 2.5: 2: 1.5: 1.5 together, add water to make a colony density of 6 x 10 7 more than one / ml compound bacteria solution;

[0041] The one-stage extruding and defibrating solution is in mass percent: NaOH 1.5% and H 2 o 2 Made by adding water to 0.06% to 100%;

[0042] The mass ratio of the raw material and the composite bacterial liquid after the first stage of decompression is 1:7, the biodegradation temperature is kept at 37°C, and the time is 36 to 38 hours;

[0043] Described two-stage extruding defibrate liquid is in mass percent: NaOH 3%, H 2 o 2 4%, Na 2 SiO 3 2.5% and DTPA0.3% are made by adding water to 100%.

[0044] The method of the invention adopts biological pulping, reduces environmental pollution from the source of pulping, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile index | aaaaa | aaaaa |

| Tear index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com