Method for incinerating sludge by using kiln tail system of cement plant

A technology for incinerating sludge and cement plants, applied in combustion methods, dewatering/drying/concentrating sludge treatment, cement production, etc., can solve the problems of kiln tail temperature fluctuation, operation difficulty, equipment damage, etc., to reduce coal consumption , reduce investment and operating costs, the effect of fast burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

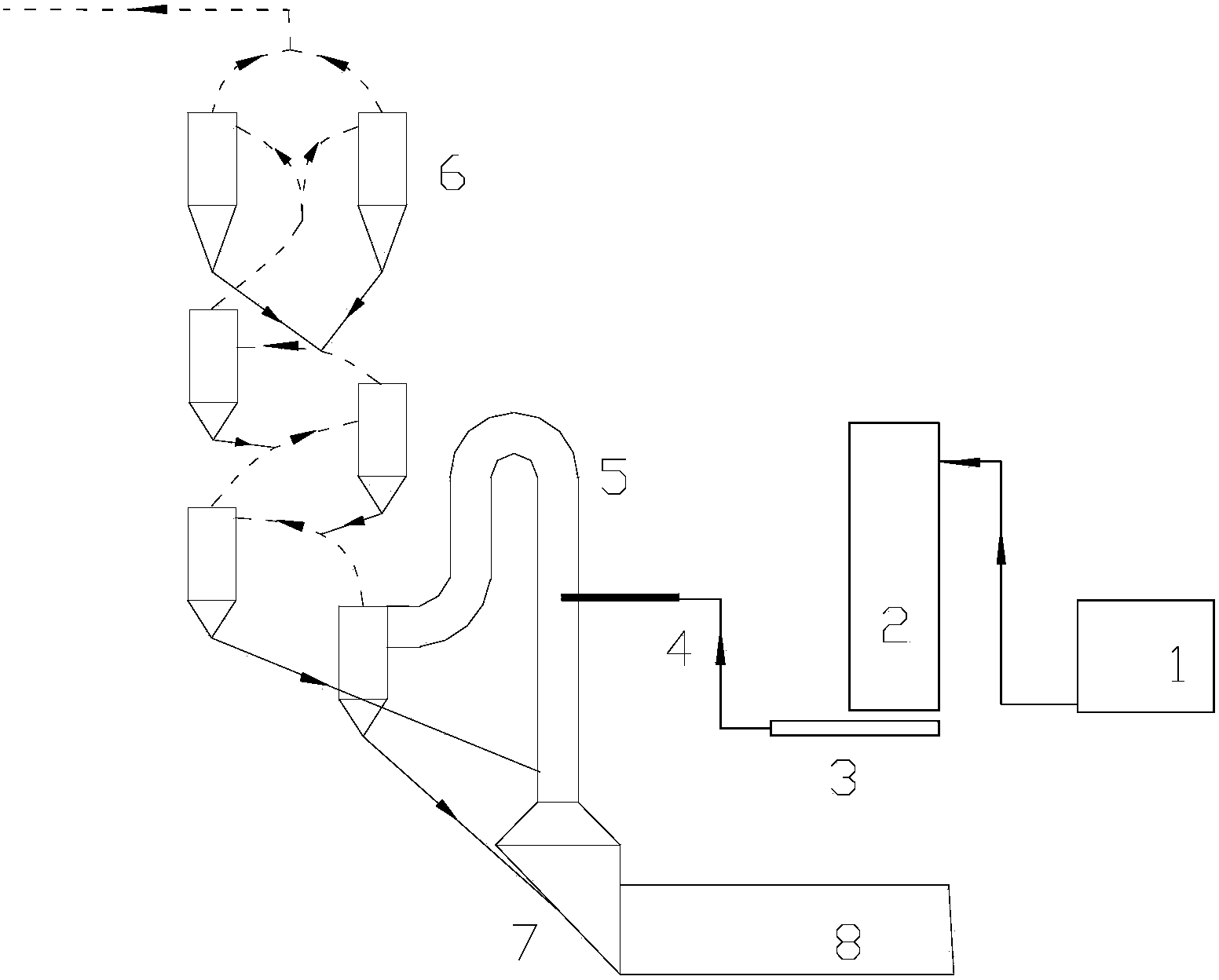

[0020] Such as figure 1 As shown, the present invention is a method for incinerating sludge using the kiln tail system of a cement plant. The system mainly includes: a sludge sealed tank car 1, a sludge bin 2, a sludge pump 3, a sludge nozzle 4, a decomposition furnace 5, a Heater 6, kiln tail smoke chamber 7, rotary kiln 8. Among them, the equipment used in the cement plant includes: calciner 5, preheater 6, kiln tail smoke chamber 7, and rotary kiln 8.

[0021] The dewatered sludge of the sewage treatment plant is transported to the cement plant by the sealed sludge tanker 1, and pumped to the sludge bin 2, wherein the moisture content of the sludge is between 70% and 85%.

[0022] The sludge in the sludge bin is pumped by the sludge pump 3 to the sludge inlet of the calciner 5 or the preheater 6 of the kiln tail system of the cement plant...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com