Process for preparing cement clinker from bauxite converter slag

A cement clinker and converter slag technology, applied in the field of building materials, can solve the problems of low utilization rate, limited recycling process and capacity, etc., to reduce environmental load, reduce kiln firing system temperature, and improve clinker quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further explained below in conjunction with specific embodiments.

[0026] The present invention relates to a process for preparing cement clinker from bauxite converter slag. The cement clinker is composed of raw materials in the following parts by weight ratio:

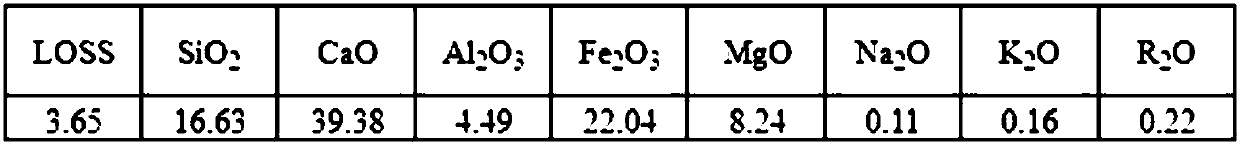

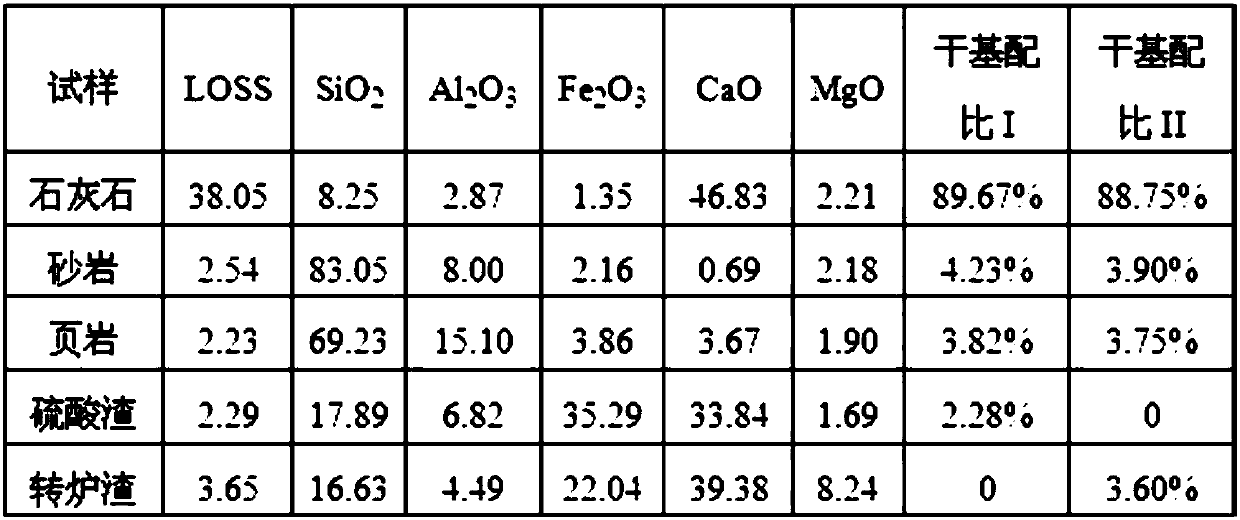

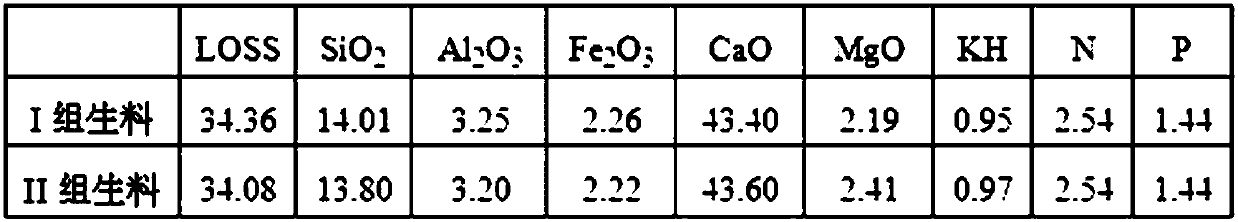

[0027] Composition of raw meal: 88.75 parts of limestone, 3.9 parts of sandstone, 3.75 parts of shale, 3.6 parts of converter slag, which are produced after raw meal grinding, slurry dehydration, filter cake drying and crushing, clinker firing and clinker cooling and crushing processes ;

[0028] Raw meal grinding: The raw meal is weighed according to the following weight fraction ratios, 88.75 parts of limestone, 3.9 parts of sandstone, 3.75 parts of shale, 3.6 parts of converter slag, add water, grind, stir evenly, make a slurry, make the material The water content in the slurry is 35%;

[0029] Slurry dehydration: the slurry is dehydrated under the condition of vacuum degree 0.02~0.0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com