Method for producing low-alkali Portland cement by using industrial solid waste

A Portland cement and solid waste technology, applied in the direction of cement production, etc., can solve the problem of high alkali content, and achieve the effects of saving the use of iron powder, reducing production costs, and reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

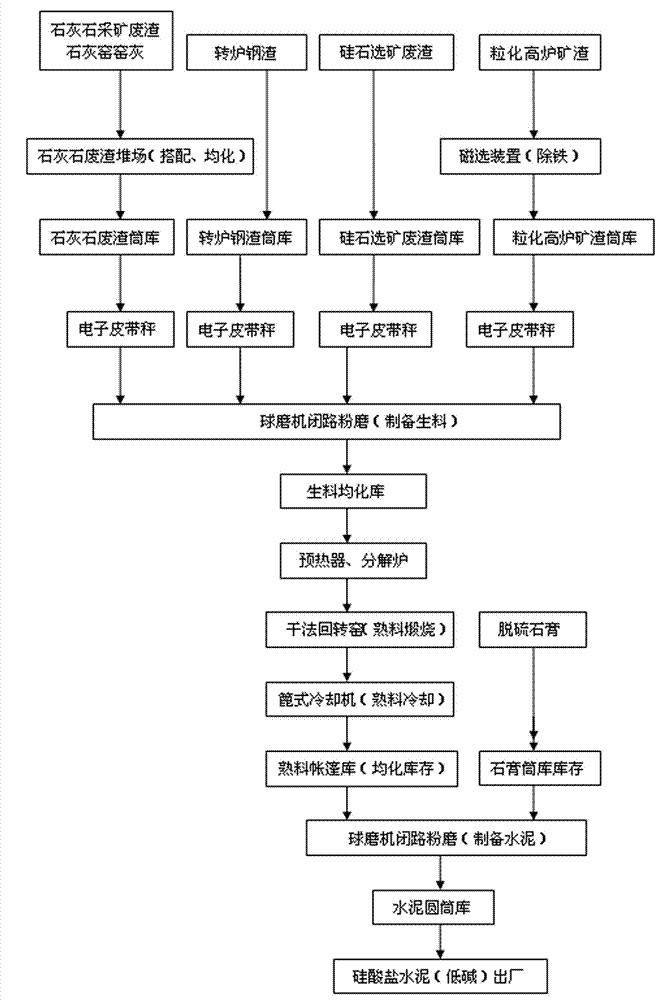

Method used

Image

Examples

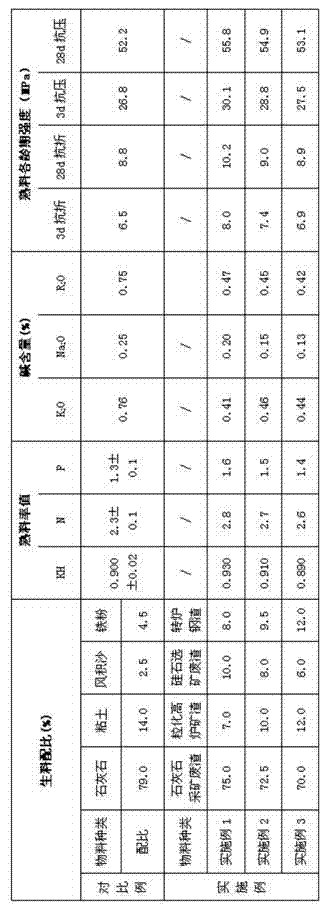

Embodiment 1

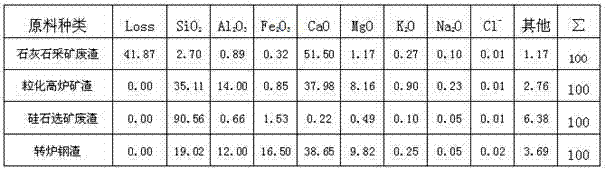

[0034] A. Raw ingredients

[0035] Limestone mining waste slag 75.0% (including 10.0% lime kiln dust), granulated blast furnace slag 7.0%, silica mineral processing waste slag 10.0%, converter steel slag 8.0%.

[0036] B. Clinker calcination

[0037] Determine the three ratios of clinker: KH: 0.930; N: 2.8, P: 1.60; the raw meal powder is preheated and calcined in a dry-process cement rotary kiln, and fired at a high temperature of 1400°C until it is partially melted. Calcium acid as the main mineral hydraulic gelling substance - Portland cement clinker.

[0039] Add 6.0% coagulant (industrial by-product desulfurization gypsum) to the clinker of low-alkali Portland cement, and grind it into low-alkali Portland cement 。

Embodiment 2

[0041] A. Raw ingredients

[0042] Limestone mining waste residue is 72.5% (including 10.0% lime kiln dust), granulated blast furnace slag is 10.0%, silica mineral processing waste residue is 8.0%, and converter steel slag is 9.5%.

[0043] B. Clinker calcination

[0044] Determine the three rate values of clinker: KH: 0.910, N: 2.7, P: 1.50. In the dry cement rotary kiln, the raw meal powder is preheated, calcined, and burned at a high temperature of 1400 ° C until it is partially melted to obtain a hydraulic gelling substance with calcium silicate as the main mineral - Portland cement clinker.

[0046] Add 6.0% coagulant (industrial by-product desulfurization gypsum) to low-alkali Portland cement clinker, and grind it into low-alkali Portland cement with alkali content 。

Embodiment 3

[0048] A. Raw ingredients

[0049] Limestone mining waste slag 70.0% (including 10.0% lime kiln dust), granulated blast furnace slag 12.0%, silica mineral processing waste slag 6.0%, converter steel slag 12.0%.

[0050] B. Clinker calcination

[0051]Determine the clinker three-rate value: clinker three-rate value: KH: 0.890, N: 2.6, P: 1.40. In the dry cement rotary kiln, the raw meal powder is preheated, calcined, and fired at a high temperature of 1400°C until it is partially melted to obtain a hydraulic gelling substance with calcium silicate as the main mineral----Portland cement clinker.

[0052] C. Cement grinding

[0053] Add 6.0% coagulant (industrial by-product desulfurization gypsum) to the clinker of low-alkali Portland cement, and grind it to make low-alkali Portland cement (low-alkali) with an alkali content of less than 0.50%. 。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com