Method for directly using red coke obtained by high-temperature pyrolysis of pulverized coal

A high-temperature pyrolysis and high-pulverized coal technology, which is applied in steam generation methods using heat carriers, steam generation methods, and coke ovens, etc., can solve the problems of the overall operation of the coking industry being difficult to improve, and the overcapacity of independent coking enterprises. The effect of saving coal logistics cost, improving energy utilization efficiency and high content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

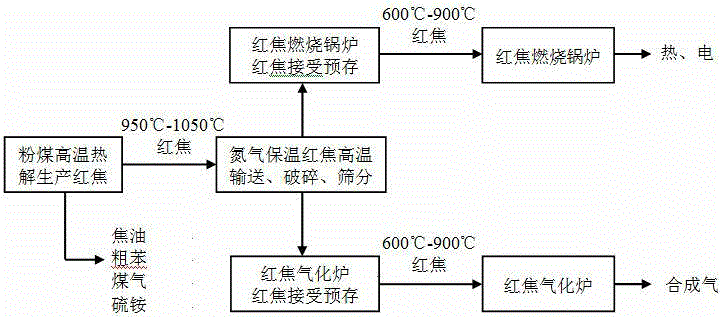

[0044] Below with annual production capacity 1,000,000 tons coking production unit as benchmark, according to the technical scheme provided above-mentioned of the present invention, the method for the red coke-electricity-gasification multi-generation of concrete implementation of this process is as follows:

[0045] (1) Determine the annual working days based on the red coke production capacity to be calculated as 300 days, the annual power generation is 1.44 billion kW·h, and the annual gasification gas production is 1.251 billion m 3 It is the main target product and by-products tar, crude benzene, etc.

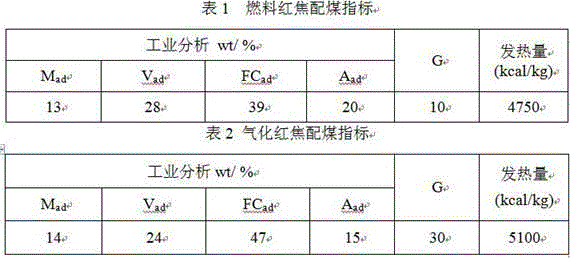

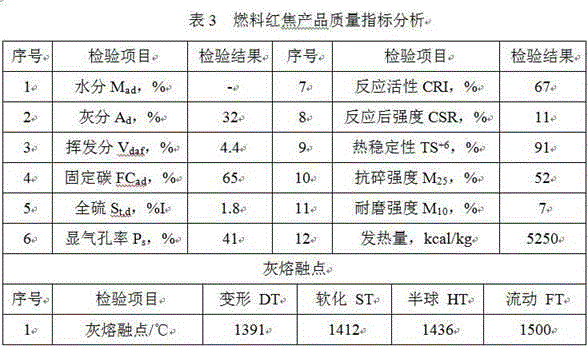

[0046] (2) According to the red coke coal blending index of tamping coke oven, see Table 1 and Table 2, complete the coal blending process of fuel red coke and gasification red coke.

[0047]

[0048] (3) Fuel red coke coal blending and gasification red coke coal blending according to the requirements of high-density tamping bulk density (≥1.17t / m 3 ) is stamped and sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com