Boiler combustion smokeless zero-sewage sulfur-extraction energy-saving combining machine

A technology of boiler combustion and combination machine, which is applied in the direction of combination device, use of liquid separation agent, and separation of dispersed particles, which can solve the problems of exhausted flue gas not up to standard, low sulfur removal rate, unstable gas and energy saving, etc., and achieve energy saving The effect of coal consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

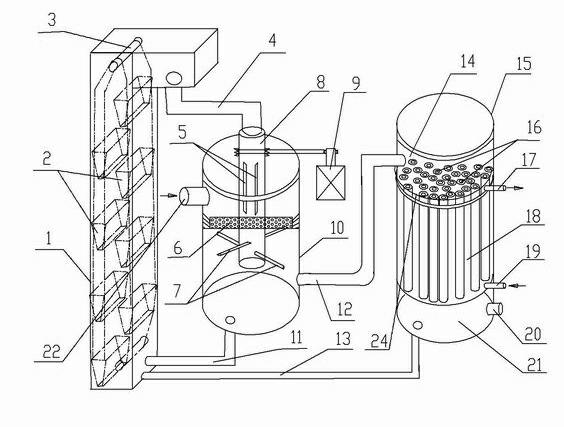

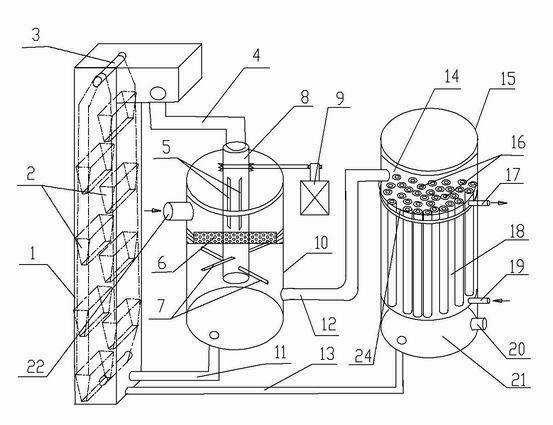

[0013] Embodiment 1: A combination machine for boiler burning smokeless zero-discharge sewage to extract sulfur and save energy, including three major components: sewage circulation hoist 1, flue gas comprehensive water processor 10, distillation flue gas cooler 15, and sewage circulation hoist 1 Equipped with evenly arranged lifting buckets 2, the lifting buckets 2 are connected in series through chains and connected with the sprockets on the upper and lower transmission shafts 3 in the sewage circulation hoist, and the transmission shaft 3 is driven by the motor through the transmission parts; the integrated flue gas water processor 10 It is a cylindrical cavity sealed up and down, with a smoke inlet pipe 22 on the side of the upper end, which is connected to the boiler exhaust pipe, and a backflow sewage pipe 11 is installed at the bottom, and the other end of the backflow sewage pipe 11 is connected to the lower end of the sewage circulation hoist 1; the hollow shaft 8, wit...

Embodiment 2

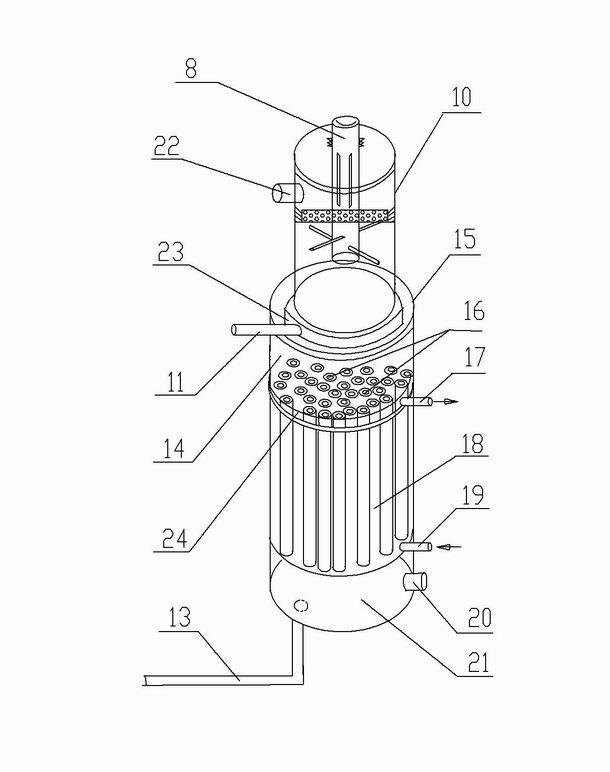

[0014] Embodiment 2: In order to reduce the floor space, the integrated flue gas water processor 10 and the distillation flue gas cooler 15 are connected in a superimposed structure (such as figure 2 ). At this time, the lower end of the integrated flue gas water processor 10 is open and placed on the distillation flue gas cooler 15. A sewage collection bucket 23 is set in 14, and the sewage collection bucket 23 is connected to the lower end of the sewage circulation hoist 1 through the return pipe connection 11, and other structures are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com