Coupling technology of thermoelectric methanol from coals

A methanol and process technology, which is applied in the combined process field of coal multi-generation, can solve the problems of energy consumption, water consumption, sensible heat cannot be effectively used, and low-load operation efficiency of thermal power plants, so as to improve efficiency, increase load, and save energy. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific implementation of the present invention will be further described below.

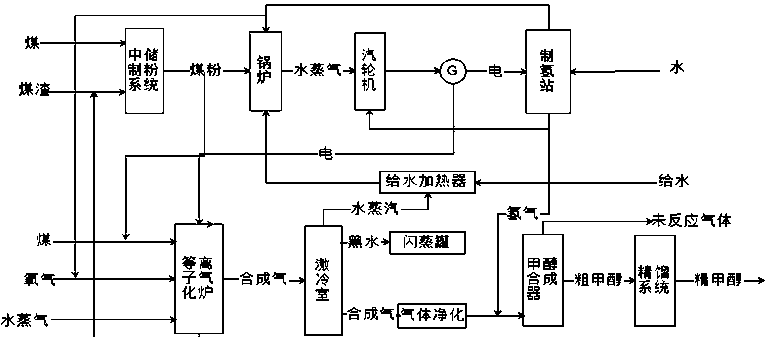

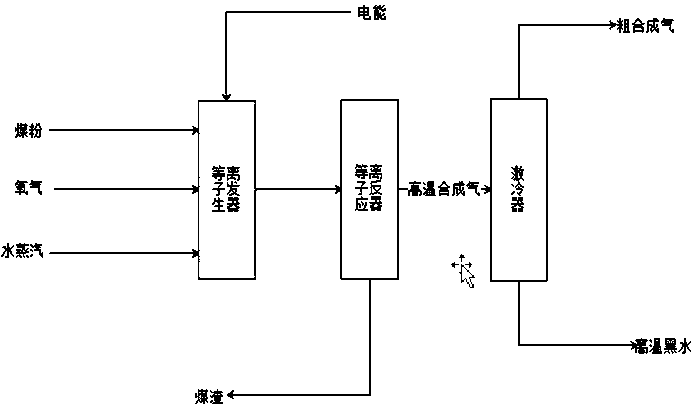

[0017] To implement the above-mentioned coal-to-thermal-electric methanol coupling process provided by the present invention is a production process in which a plasma gasifier-based coal-to-methanol system is coupled with a thermal power plant. The main purpose is to deal with gasified coal slag. A large amount of sensible heat cannot be effectively used, low-load operation efficiency of thermal power plants, and water consumption in the conversion process; the use of plasma can instantaneously reach high temperatures. Under such high temperatures, coal can be quickly gasified to produce plasma A large amount of electricity is needed, and the power plant can provide it with the required electricity, which can increase the load of the unit, thereby avoiding low efficiency caused by low load. At the same time, the pulverizing system of the power plant can provide pulverized coal for the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com