Efficient direct-heating dryer for powdery materials

A technology for powdery materials and dryers, applied in dryers, drying, drying of solid materials, etc., can solve the problems of low energy utilization rate, and achieve the effects of simple structure, saving coal consumption, and avoiding lowering of grades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

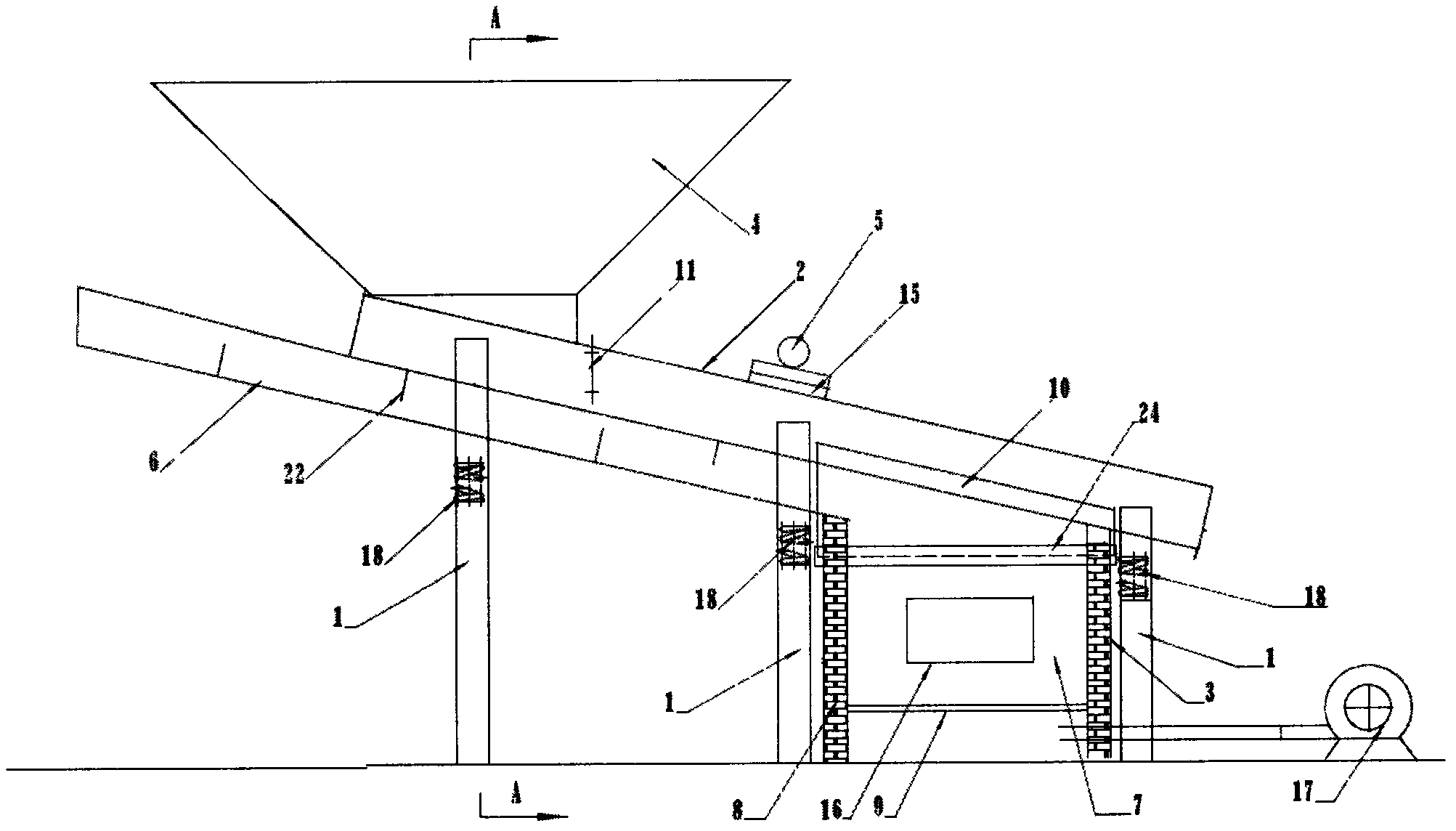

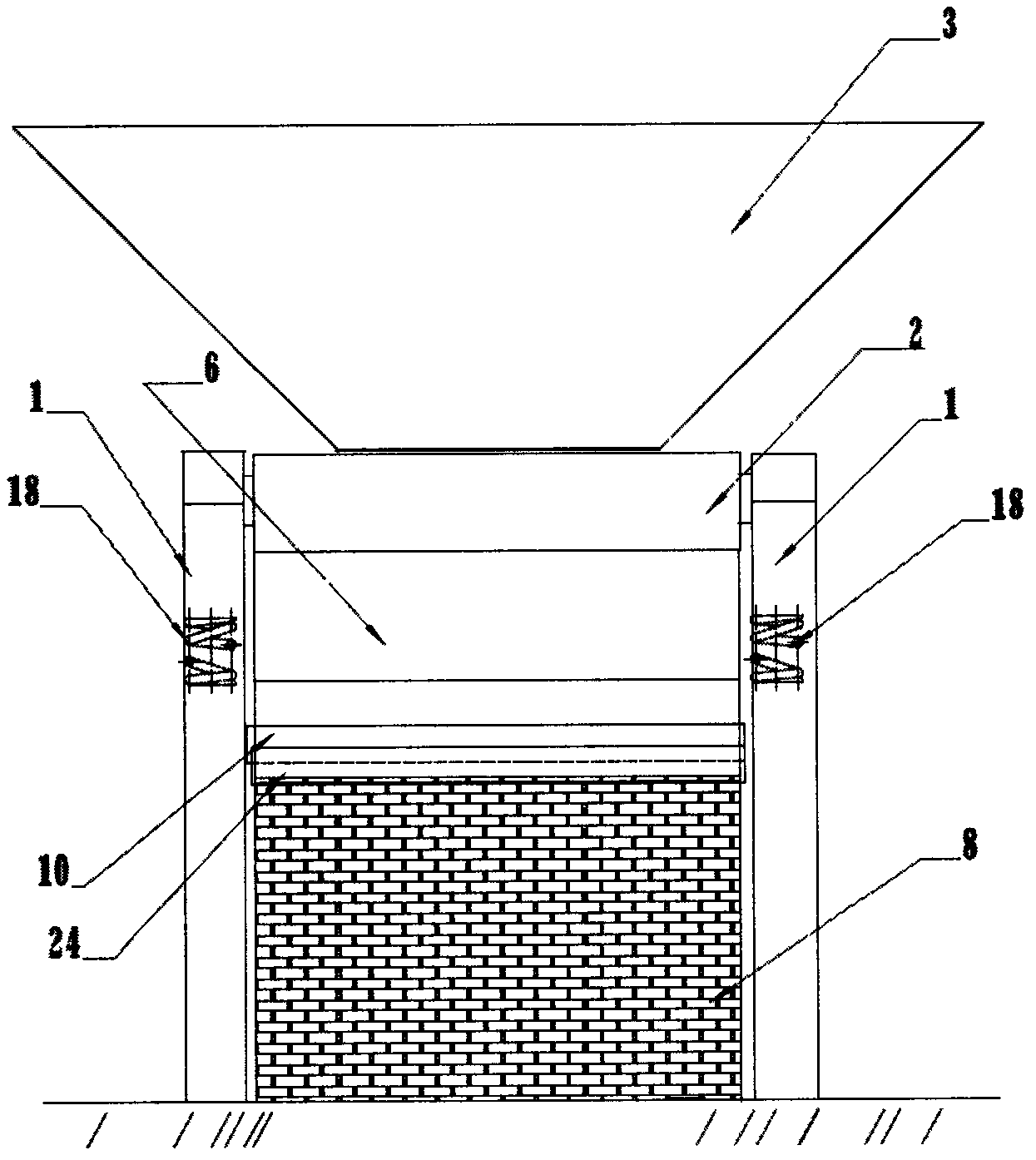

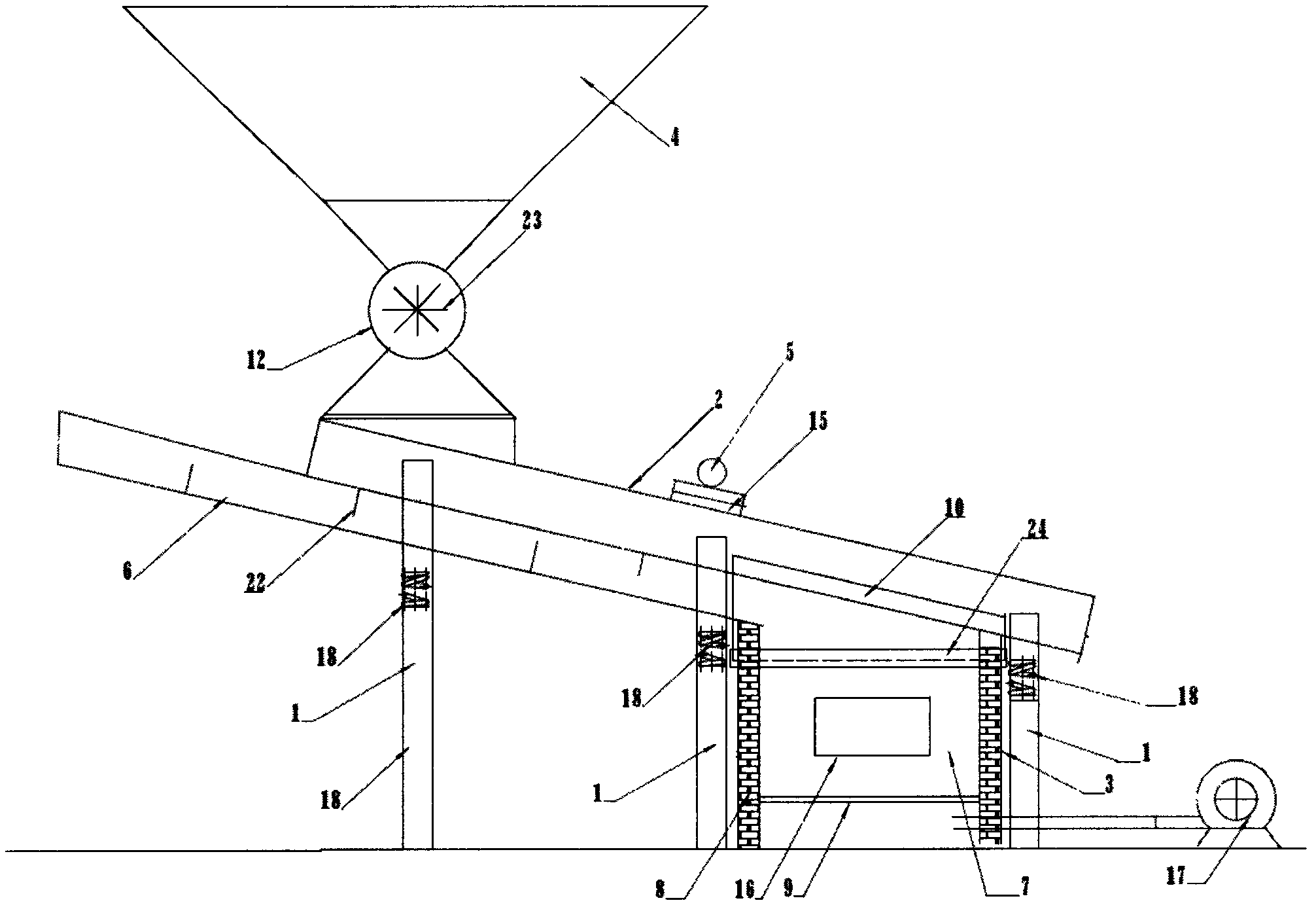

[0028] Such as figure 1 , figure 2 As shown, the powder material dryer includes a supporting column 1, on which a spring 18 is arranged, and on the supporting column 1, an inclined chute 2 is supported, and the inclined chute 2 is grooved, and the section of the inclined chute 2 is It is rectangular or U-shaped, and the inclined chute 2 is made of metal plate, which can be ordinary steel plate or stainless steel plate; the inclined chute 2 forms an angle of 12-15 degrees with the horizontal line; the inclined chute is supported by the two side walls A support frame 15, the vibrator 5 is arranged on the support frame 15, so that only one vibrator is needed to achieve a uniform vibration balance, and a vibrator can be respectively set on the two side walls, and when the vibration force of one vibrator is not enough, use The two vibrators achieve the purpose of increasing the vibration force;

[0029] A heating chamber 3 is provided below the inclined chute 2, specifically arr...

Embodiment 2

[0035] In the case that the dryer is different except for the heating chamber and other settings are the same, it is mainly realized by burning natural gas or coal gas in the heating chamber. In this case, the furnace wall of the heating chamber can also adopt the structure of embodiment 1 , the refractory brick and insulation layer structure can be used as the furnace wall, and only the nozzle and ignition device for burning natural gas or gas are installed in the furnace, and the drying temperature is controlled by controlling the size of the natural gas. When this method is adopted, the impact on the environment is small, especially the natural gas itself has no environmental pollution.

Embodiment 3

[0037] Electric heating equipment can also be set in the heating chamber of the dryer for heating the inclined chute. By arranging resistance wires in the heating chamber, generally several groups of resistance wires are arranged along the bottom of the inclined chute in the heating chamber. By controlling different groups of resistance wires, the load can be controlled and the drying temperature can be precisely controlled. When this method is used, there is no impact on the environment, but the electricity cost is relatively high.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com