Portland cement clinker with high compressive strength and preparation method thereof

A technology for Portland cement and Portland clinker, which is applied in cement production and other directions, can solve the problems of easy burning of raw meal entering the kiln, fluctuation of the raw meal rate value entering the kiln, etc., so as to save renewable resources and uniform materials. , the effect of solving serious overcapacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

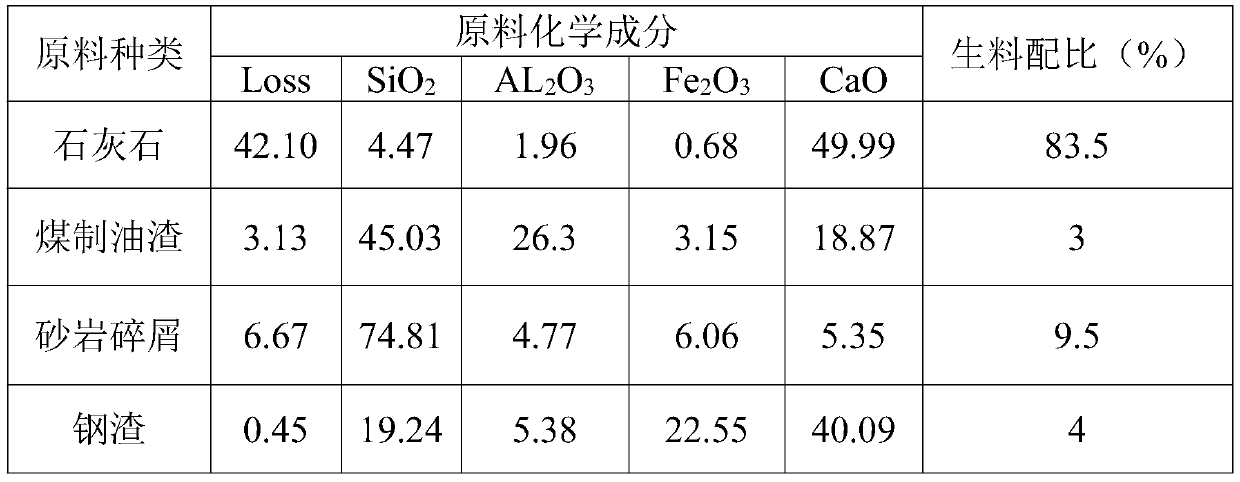

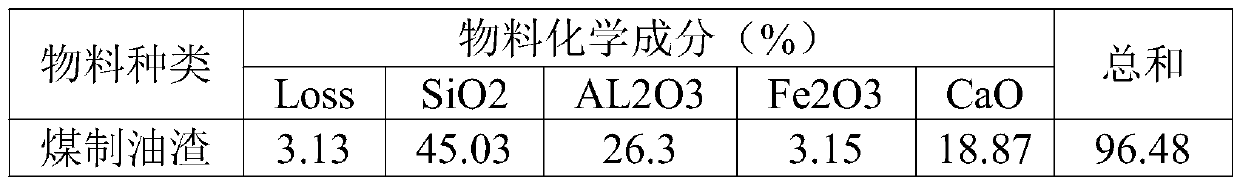

[0045] A kind of Portland cement clinker, the raw meal that is made by the limestone of 83.5 parts by weight, the sandstone debris of 9.5 parts by weight, the coal oil slag of 3 parts by weight, the steel slag grinding of 4 parts by weight, and mixes through It is formed by calcining 2.8 parts by weight of coal ash after burning.

Embodiment 2

[0047] A kind of Portland cement clinker, the raw meal that is made by the limestone of 80 weight parts, the sandstone debris of 7 weight parts, the coal oil residue of 4 weight parts, the steel slag batching grinding of 5 weight parts, and mixes It is formed by calcining 2.8 parts by weight of coal ash after burning.

Embodiment 3

[0049] A kind of Portland cement clinker, the raw material that is made by grinding of 85 parts by weight of limestone, 10 parts by weight of sandstone debris, 2 parts by weight of coal oil residue, and 6 parts by weight of steel slag, and mixed with It is obtained by calcining 2.8 parts by weight of coal ash after burning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com