Method for controlling output of coal mill in ignition process of boiler

A boiler ignition and control method technology, which is applied in the field of coal mill control, can solve the problems of reducing the minimum output, complicated construction process, and expanding the output range of coal mills, etc., to achieve the effects of reducing thermal shock, protecting life, and reducing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

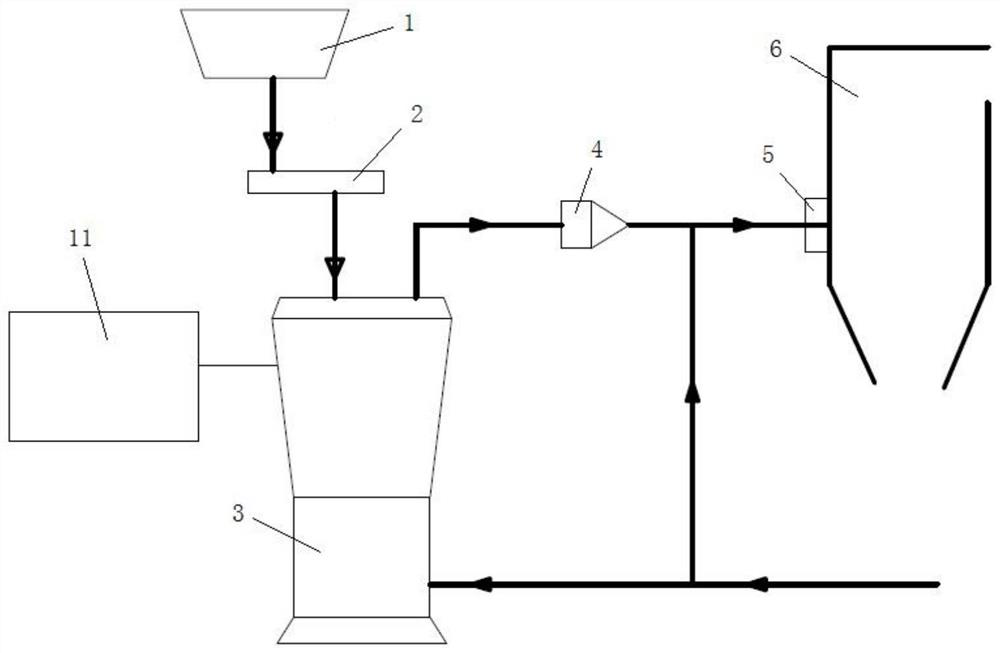

[0030] Such as figure 1 As shown, in the present invention, the direct blowing type pulverizing system provides raw coal from the raw coal hopper 1 to the coal feeder 2, and the coal feeder 2 supplies the raw coal to the coal mill 3 quantitatively. The present invention applies a coal mill of ZGM113K-II model, After the coal mill grinds the raw coal into coal powder, it is brought into the separator 4 by the primary air, and the qualified coal powder is screened by the separator and brought into the burner 5 by the primary air, and enters the furnace of the boiler 6 through the burner nozzle for combustion.

[0031] In order to make the rotating speed of the coal mill adjustable, a high-voltage frequency conversion speed regulating device 11 is installed for the coal mill. The coal mill in the present invention is different from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com