Preparing method for calcium aluminate powder for water purifying agent

A technology of calcium aluminate powder and water purifying agent, which is applied in the direction of preparation of calcium aluminate, alkaline earth metal aluminate/aluminum oxide/aluminum hydroxide, chemical instruments and methods, etc., which can solve adverse effects on human health, large energy consumption, The problem of high content, to achieve a significant effect of saving coal, the effect of saving coal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

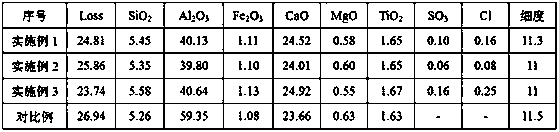

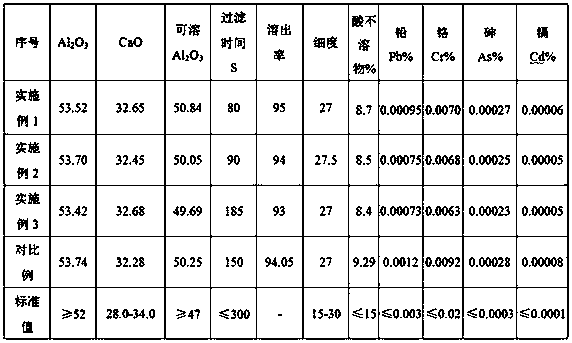

Embodiment 1

[0027] A preparation method of calcium aluminate powder for water purifying agent, comprising the following steps:

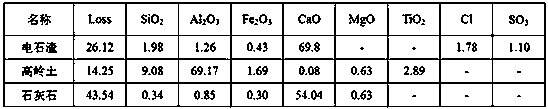

[0028] 1) In terms of mass percentage, 32.4% of limestone, 57.6% of kaolin and 10% of carbide slag are mixed and ground, and then homogenized; before limestone, kaolin and carbide slag are mixed, limestone and kaolin are crushed to a particle size smaller than 2.5cm, the calcium carbide slag is directly mixed and proportioned; use a φ3.6×11m raw material mill to grind until the fineness (0.08mm square hole sieve residue) is less than 11.5%;

[0029] 2) Transfer the mixture obtained in step 1) to a five-stage cyclone preheater for preheating, the preheating temperature is 270-950°C, and the preheating time is 15 minutes, and then sent to a φ3.4×45m rotary kiln for calcination, calcined The conditions include: the rotation speed of the rotary kiln is 3 rpm, the calcination temperature is 1350°C, the calcination time is 40min, the burned clinker is cooled in a grat...

Embodiment 2

[0032] Same as Example 1, the difference is: 38% limestone, 57% kaolin and 5% carbide slag are mixed and ground.

Embodiment 3

[0034] Same as Example 1, the difference is: 26.7% limestone, 58.3% kaolin and 15% carbide slag are mixed and ground.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com