Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Reduced compound center" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

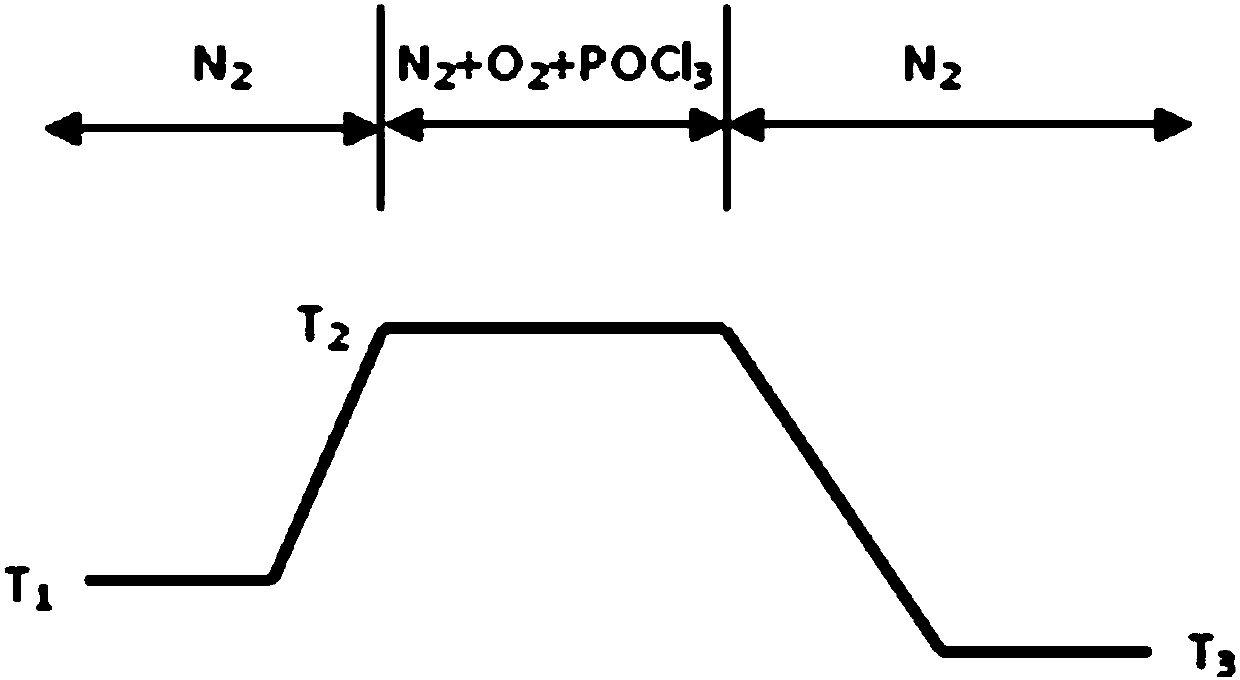

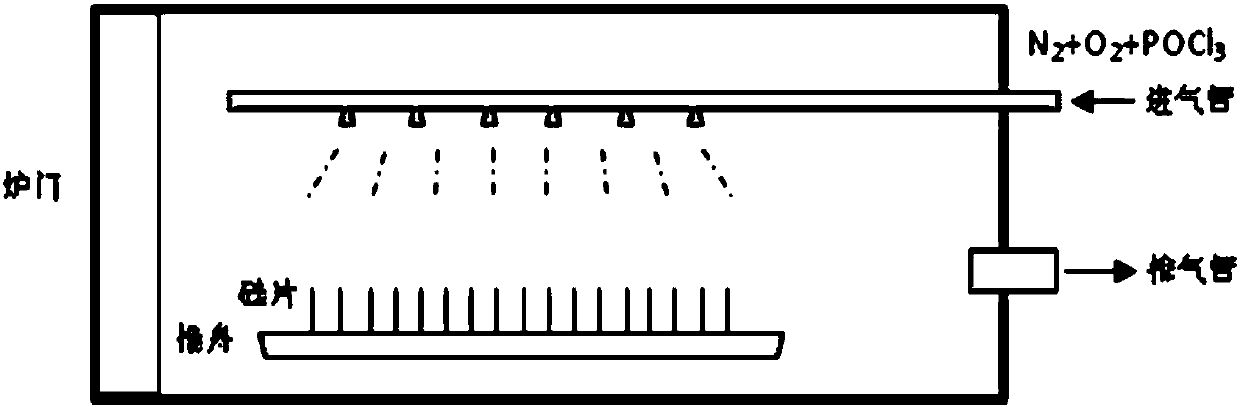

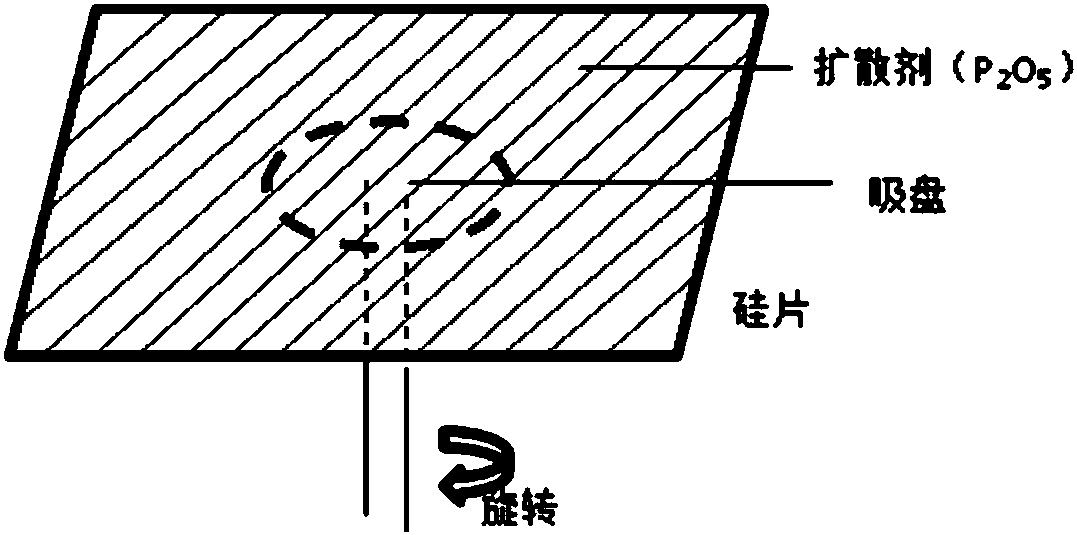

Heat treatment method for n-type silicon wafer

ActiveCN105624795AExtend your lifeImprove conversion efficiencyPolycrystalline material growthAfter-treatment detailsSilicon oxideSolar cell

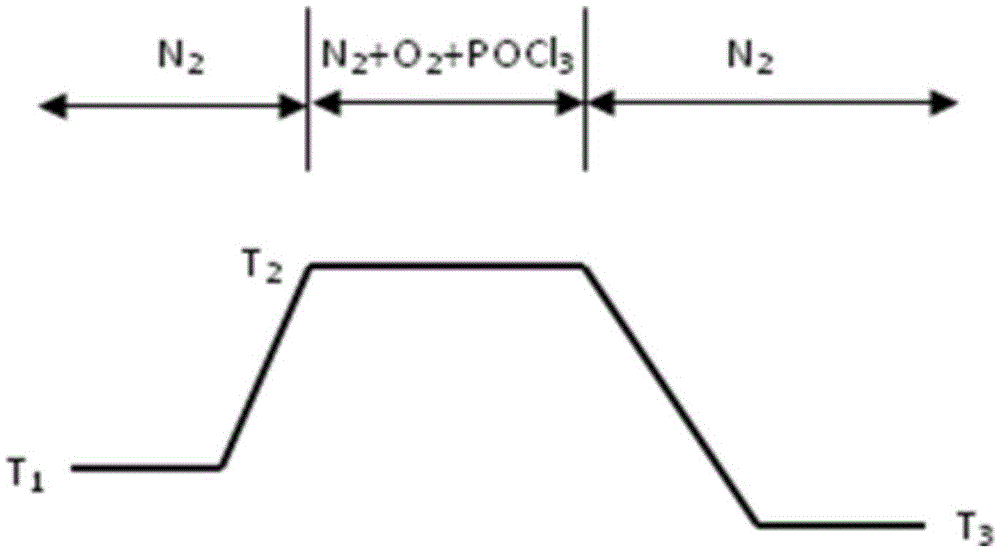

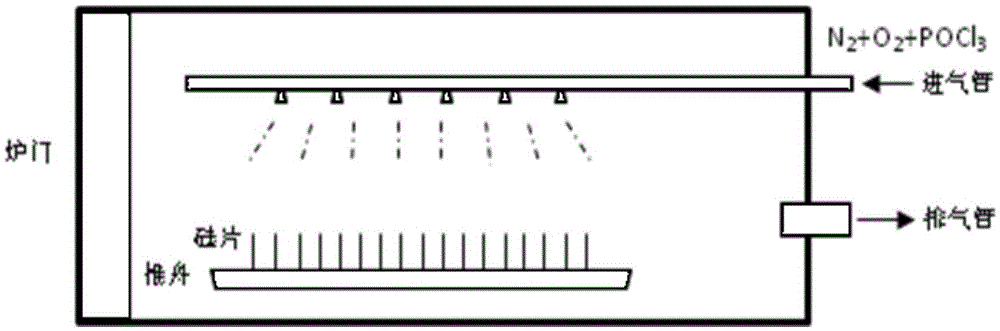

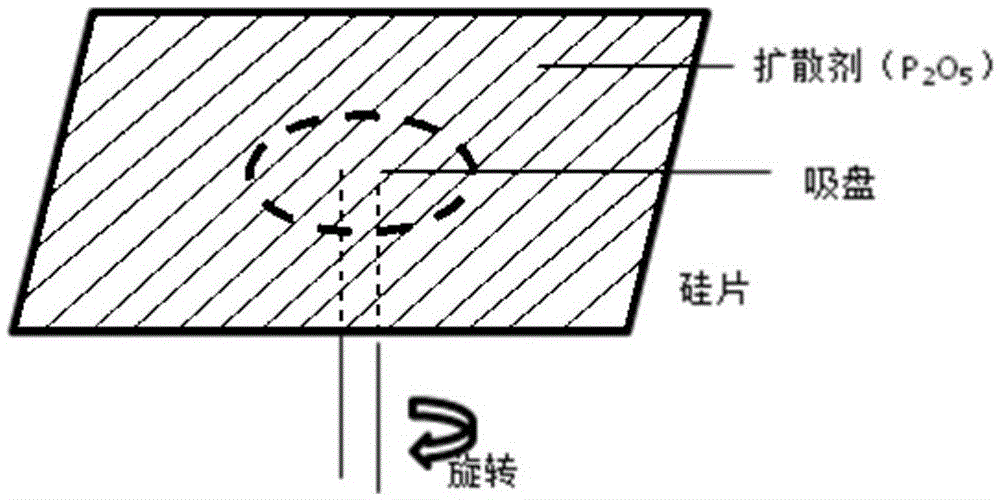

The invention provides a heat treatment method for an n-type silicon wafer. The heat treatment method at least includes the steps that the n-type silicon wafer to be treated is provided, the n-type silicon wafer is put into a heat treatment furnace with a certain temperature, and the temperature is increased to a certain value; oxygen is introduced into the heat treatment furnace; a dispersing agent containing n-type doping elements is supplied to the surface of the n-type silicon wafer so that a silicon oxide layer and an n-type doping layer can be formed on the surface of the n-type silicon wafer; the silicon oxide layer and the n-type doping layer are removed after heat treatment is completed. After the n-type silicon wafer is subjected to heat treatment, recombination centers, caused by the concentration of the doping elements and heat stress, in the n-type silicon wafer can be reduced, the quality and uniformity of the n-type silicon wafer can be improved, the service life of current carriers in the n-type silicon wafer can be prolonged, and thus the conversion efficiency of a solar cell can be improved.

Owner:ZHONGWEI NEW ENERGY CHENGDU CO LTD

Cleaning technology after polycrystalline silicon solar cell silicon wafer acid texturing

ActiveCN103394484AImprove photoelectric conversion efficiencyReduced compound centerAfter-treatment detailsFinal product manufactureSurface structureOxidizing agent

The invention discloses a cleaning technology after polycrystalline silicon solar cell silicon wafer acid texturing. A polycrystalline silicon wafer is cleaned through an acid solution containing an oxidizing agent or a base solution containing the oxidizing agent after acid texturing. According to the cleaning technology, the surface structure of the silicon wafer is optimized, residual composition on the surface of the silicon wafer is removed, texturing liquid remaining on the surface of the silicon wafer after the silicon wafer is textured can be cleaned, porous silicon can be removed as well, so that the recombination centers on the surface of the silicon wafer are greatly reduced, the short-circuit current and start voltage are improved, and the effect that the photoelectric conversion efficiency of a solar cell is improved is achieved. After the cleaning technology after polycrystalline silicon solar cell silicon wafer acid texturing is adopted, the porous silicon generated after acid texturing can be removed, pointed structures on the textured face are reduced, the color and the luster of the appearance of the silicon wafer are even, the difference between different crystalline grains is small, and the polycrystallization degree is not enhanced. In addition, the cleaning technology after polycrystalline silicon solar cell silicon wafer acid texturing is simple, easy to operate, compatible with an existing technology and good in repeatability.

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Crystalline silicon PERC cell alkali polishing method not influencing front surface

InactiveCN105845778AReduced compound centerImprove spectral responseFinal product manufacturePhotovoltaic energy generationCell preparationCrystalline silicon

The invention belongs to the manufacturing technology of a photovoltaic solar cell and relates to a crystalline silicon PERC cell alkali polishing method not influencing the front surface. The method comprises the following steps: a) enabling an original silicon wafer to react for 160-180 s in a polishing solution, of which the KOH mass ratio is 10-20%, and the temperature is 78-83 DEG C, for polishing; b) plating a 100-120 nm SiNx film, serving as a mask, on the polished silicon wafer through PECVD; c) enabling the plated silicon wafer to be soaked in HF for 80-100s to remove the SiNx film plated on the front surface thoroughly; d) texturing the plate-removed silicon wafer in a texturing tank, of which the KOH mass ratio is 1.5-3%, and the temperature is 80-82 DEG C, the texturing time being 1100-1300 s; and e) finishing the follow-up steps by the textured silicon wafer according to a conventional PERC cell preparation method. The method can obtain a relatively-uniform polished surface, and meanwhile, can prevent causing influence on the front surface, thereby improving cell performance.

Owner:JINENG CLEAN ENERGY TECH LTD

Double-layer doping-layer silicon-based film solar cell

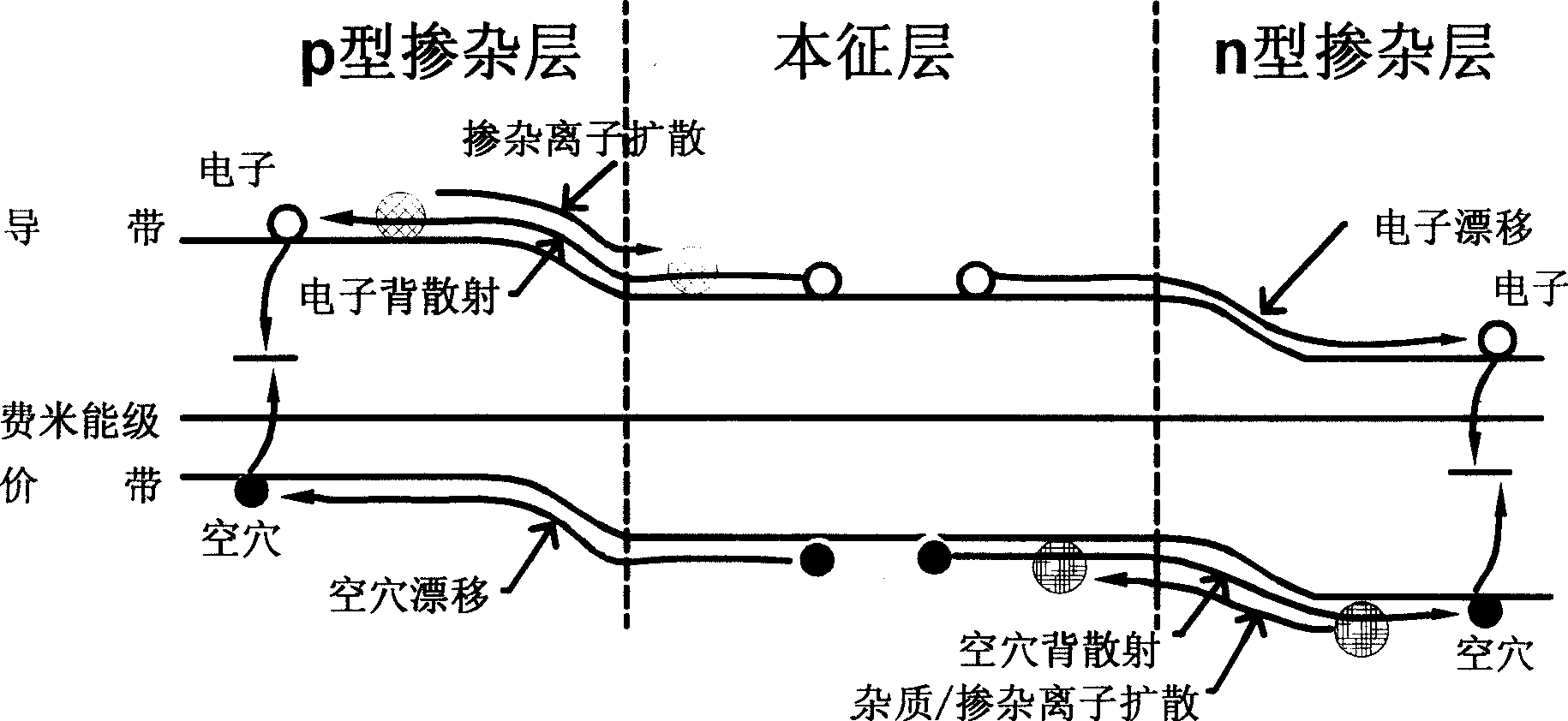

InactiveCN101373799AIncrease the open circuit voltageImprove stabilityPhotovoltaic energy generationSemiconductor devicesDopantParticle interaction

The invention relates to a double doped layer silicon-based film solar cell. In a p type doped layer and an n type doped layer, the optical band gap of the layer closely adjacent to an intrinsic layer is larger than that of the layer far away from the intrinsic layer, but the difference value of the band gaps is not larger than 0.45 eV. The difference of the optical band gaps of the double doped layer structure is realized by arranging different materials according to the matching principle, or by changing the growth technology parameter of the identical material to control the optical band gaps. According to the invention, the inhibition to the particle interaction at the interface between the doped layers and the intrinsic layer and the control to the dopant particles and the accumulation and the distribution of defects can be realized simultaneously, excessive defects in the intrinsic layer can be reduced, simultaneously, the initial photoelectric conversion efficiency and the irradiation stability of the solar cell can be improved, the production cost for the silicon-based film solar cells can be further reduced, therefore, the structure can be applied to any silicon-based single-junction solar cell, laminated solar cell and multi-junction solar cell with p-i-n structure and n-i-p structure.

Owner:SOUTH WEST INST OF TECHN PHYSICS

Boron gettering method for metallurgical N-type polycrystalline silicon chip

InactiveCN102153090AEfficient removalQuality improvementSilicon compoundsHydrofluoric acidOptoelectronics

The invention discloses a boron gettering method for a metallurgical N-type polycrystalline silicon chip, and relates to polycrystalline silicon. The invention provides the boron gettering method for the metallurgical N-type polycrystalline silicon chip, which has good gettering effect, low cost and simple operation and is suitable for industrialized production. The method comprises the followingsteps of: cleaning and drying the metallurgical N-type polycrystalline silicon chip; introducing gas to the obtained silicon chip at the temperature of between 700 and 1,200 DEG C to perform boron diffusion gettering heat treatment, and then cooling the silicon chip; soaking the obtained silicon chip into hydrofluoric acid (HF) solution; and corroding the gettering layer on the obtained silicon chip by using acid corrosive liquid, and cleaning, drying and baking the obtained silicon chip to obtain a boron gettered polycrystalline silicon chip.

Owner:XIAMEN UNIV

Texturing technology and diffusion technology of diamond wire solar cell pieces

InactiveCN107195706AHigh reactivityReduce reflectivityAfter-treatment detailsFinal product manufactureHydrofluoric acidDiffusion

The invention provides a texturing technology and a diffusion technology of diamond wire solar cell pieces. The technical problems that the antireflection effect of an existing conventional chemical method is not obvious, the cost is increased by more than ten times after the whole set of a black silicon technology is matched and an existing diffusion technology is not matched with a texturing technology of diamond wires are solved. The texturing technology of the diamond wire solar cell pieces provided by the invention comprises the following steps: a, texturing; b, silicon wafer surface washing with ultrapure water; c, alkaline washing; d, silicon wafer surface washing with ultrapure water; e, mixed acid solution washing of hydrofluoric acid and hydrochloric acid; and f, ultrapure water washing and drying. The texturing technology has the advantage of low polycrystalline silicon reflectivity.

Owner:ZHEJIANG GUANGLONG ENERGY TECH

Manufacturing method of N type all-aluminum back emitter solar cell and solar cell prepared by the same

InactiveCN104868011AAvoid leakage currentImprove energy conversion efficiencyFinal product manufacturePhotovoltaic energy generationSilver pasteSilver electrode

The invention discloses a manufacturing method of an N type all-aluminum back emitter solar cell and a solar cell prepared by the same. The manufacturing method comprises: providing an N type semiconductor substrate, removing a surface damage layer, and preparing a surface pile face; carrying out phosphorus diffusion to form an n<+> doping layer and etching and removing the parts, formed at the edge and the back, of the n<+> doping layer; preparing an antireflection layer at the front side; printing a back aluminium paste and carrying out sintering to form a full-area aluminum back emitter; carrying out etching at the back and removing the aluminium paste and keeping the aluminum back emitter; preparing a back passivation layer at the back; printing a front electrode silver paste and carrying out drying, printing a back electrode silver-aluminium paste and carrying out drying, and carrying out sintering to form electrode ohmic contact. According to the invention, a problem of leak current existence at the boundary of the local back aluminium emitter and the back silver electrode can be solved; the solar cell quality is improved; and the conversion efficiency is improved by increasing the effective area of the PN node. With the back passivation layer, the open-circuit voltage and short-circuit current of the cell are increased. Moreover, the dual-face solar cell can be manufactured, so that the cell energy output is enhanced and the conversion efficiency is improved.

Owner:DK ELECTRONICS MATERIALS INC

Method for gettering phosphorus in N-type polysilicon slice by metallurgical method

InactiveCN102153089AEfficient removalQuality improvementSilicon compoundsHydrogen fluorideThermal treatment

The invention provides a method for gettering phosphorus in an N-type polysilicon slice by a metallurgical method, and relates to polysilicon. The method is good in gettering effect, low in cost and simple in operation, and is suitable for industrial production. The method for gettering phosphorus in the N-type polysilicon slice by the metallurgical method comprises the following steps of: washing and drying the N-type polysilicon slice; feeding a gas into the obtained polysilicon slice at the temperature of 700 to 1,200 DEG C, performing phosphorous diffusion gettering thermal treatment, and cooling the polysilicon slice; immersing the obtained polysilicon slice into hydrogen fluoride (HF) solution; and corroding a gettering layer on the polysilicon slice by using acid corrosive liquid, washing and drying, and baking so as to obtain the phosphorous-gettered polysilicon slice.

Owner:XIAMEN UNIV

Solar panel preparing method

ActiveCN102315309AImpurities are simpleSolve the problem of impuritiesFinal product manufacturePhotovoltaic energy generationOptoelectronicsSolar battery

The invention provides a solar panel preparing method, which comprises the steps of: a, preparing a-Si:H film on the surface of a silicon chip after texturing; b, treating the silicon chip containing the a-Si:H film on the surface obtained in the step a at 800 to 900 DEG C for 60 to 120 min; and c, carrying out corrosion treatment on the surface of the silicon chip treated through high temperature. The solar panel preparing method has the advantages that a layer of a-Si:H film is deposited on the back surface of the silicon chip after the texturing, the problems of many impurities and micro defects in the silicon chip can be perfectly solved, the electrochemical performance such as the service life, the photoelectric conversion efficiency and the like of solar panels is improved, in addition, good back side and body passivation effects can be realized, the current and voltage (I-V) character of solar batteries is improved, and simultaneously, the process is simple and is easy to implement.

Owner:BYD CO LTD

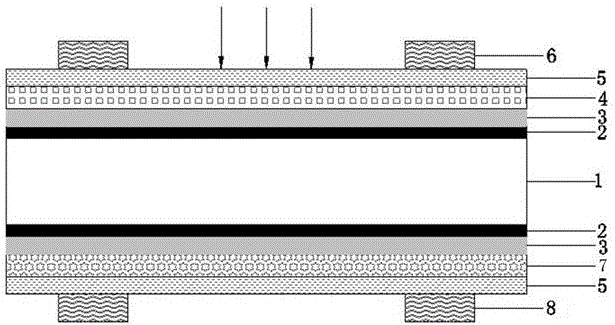

PERC double-sided solar cell and manufacturing method thereof

PendingCN112382672AImprove conversion efficiencyAvoid shunt resistors to reduceFinal product manufactureSemiconductor/solid-state device manufacturingPhysicsSilicon chip

The invention relates to a PERC double-sided solar cell and a manufacturing method thereof. The solar cell is characterized by comprising a front electrode, a back electrode and a P-type silicon wafersubstrate, an N-type doping layer, a front silicon dioxide layer and a front silicon nitride layer are sequentially arranged on one surface of the P-type silicon wafer substrate from inside to outside, and a back aluminum oxide layer, a back silicon nitride layer and a back silicon dioxide layer are sequentially arranged on the other surface of the P-type silicon wafer substrate from inside to outside; the front electrode sequentially penetrates through the front silicon nitride layer and the front silicon dioxide layer; the front electrode is connected with the N-type doped layer; the back electrode sequentially penetrates through the back silicon dioxide layer, the back silicon nitride layer and the back aluminum oxide layer; and the back electrode is connected with the P-type silicon wafer substrate. The problems that black spots and black spots cannot be fundamentally eliminated, and the manufacturing cost of a silicon wafer is increased in the prior art are solved.

Owner:中建材浚鑫(桐城)科技有限公司

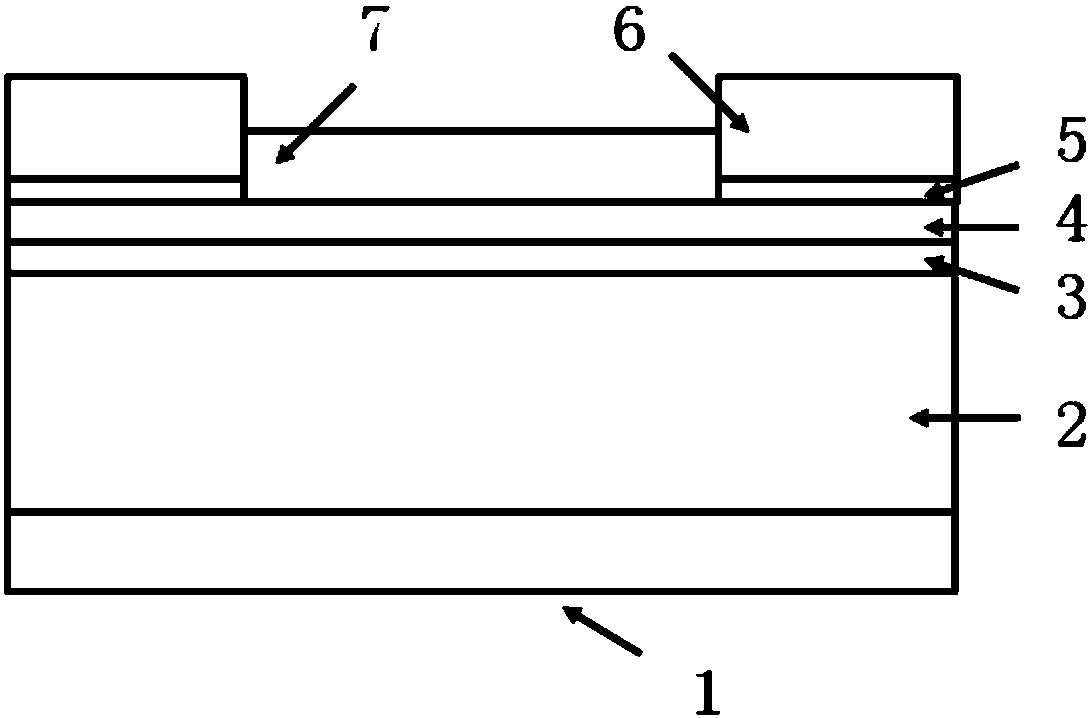

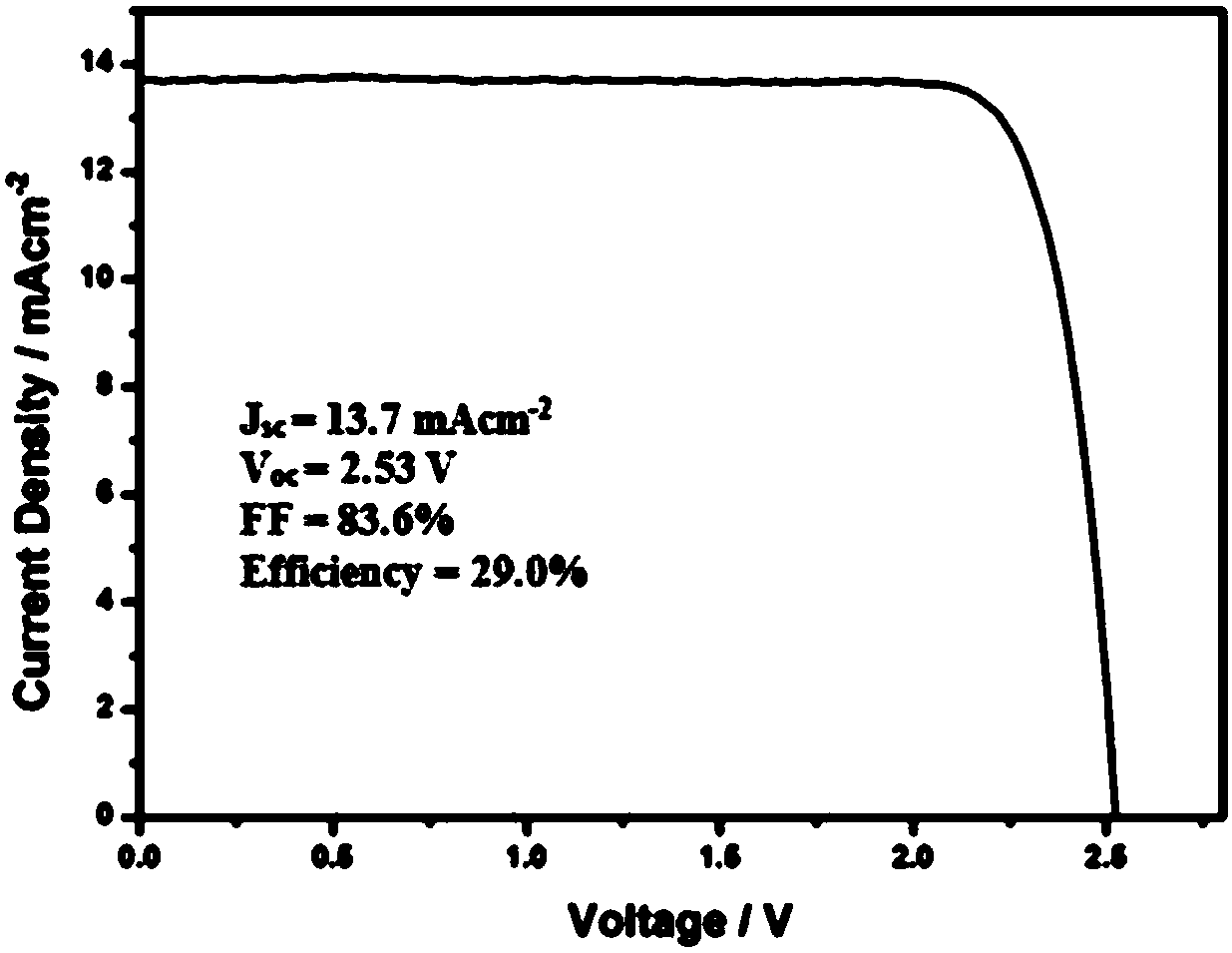

Graphene/gallium arsenide solar battery

InactiveCN106449790AFacilitates lateral transportReduced compound centerPhotovoltaic energy generationSemiconductor devicesEngineeringFilling factor

The invention provides a graphene / gallium arsenide solar battery, sequentially comprising a back electrode, a gallium arsenide epitaxial slice, a window layer, a graphene layer, a heavily-doped gallium arsenide cap layer, and a front electrode; the heavily-doped gallium arsenide cap layer has a hollowed-out area which corresponds to an area outside grating lines of the front electrode; the graphene / gallium arsenide solar battery also comprises an antireflection layer filling the hollowed-out area of the heavily-doped gallium arsenide cap layer and contacting the graphene layer. The graphene layer is used as a transparent conductive layer, single layer or multiple layers of graphene are transferred between a window layer and heavily-doped gallium arsenide cap layer of a traditional single-junction or multi-junction gallium arsenide solar battery by means of graphene transfer process, transverse transport of photon-generated carriers can be promoted, photo-generated carrying combined center is decreased, serial resistance is decreased, filling factor is increased, and it is also possible to effectively reduce the grating line density and width of the front electrode, decrease shading loss and increase short-circuit current and open-circuit voltage.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

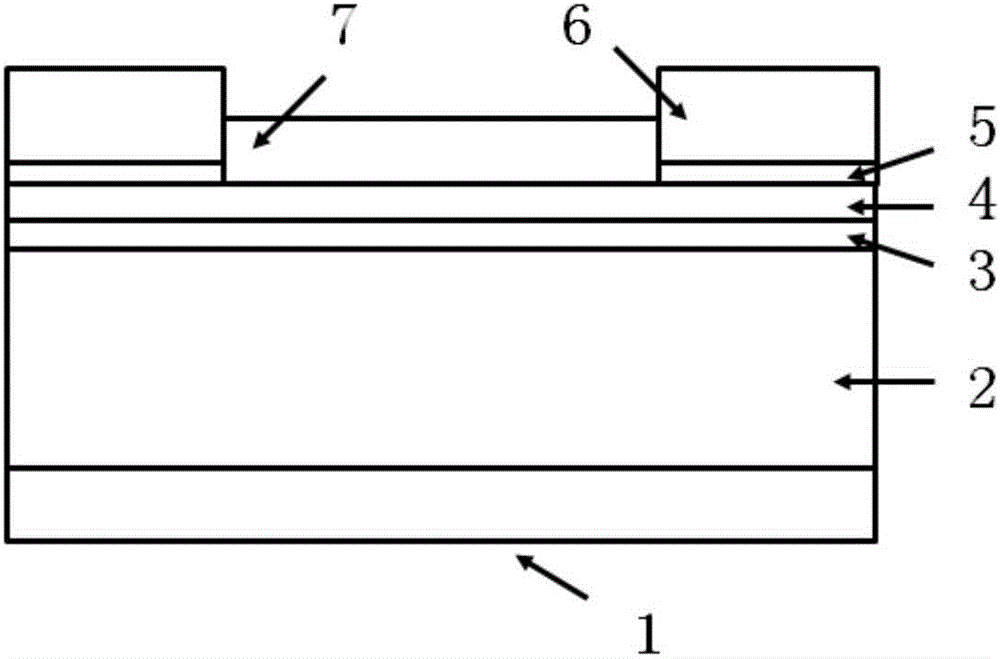

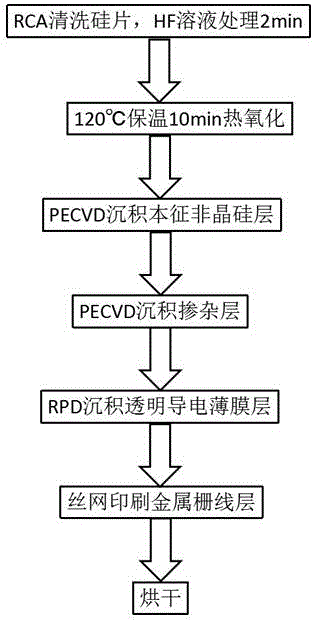

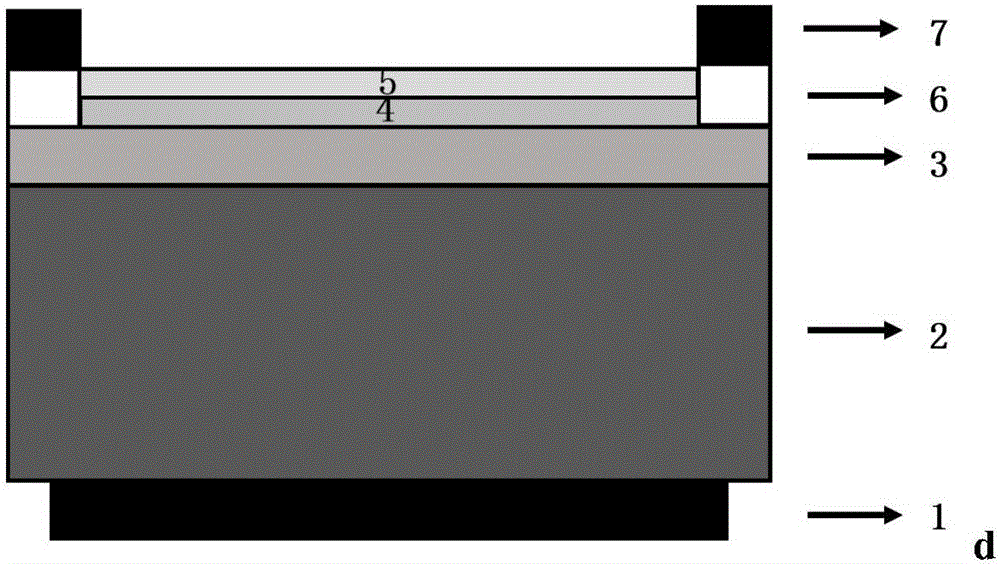

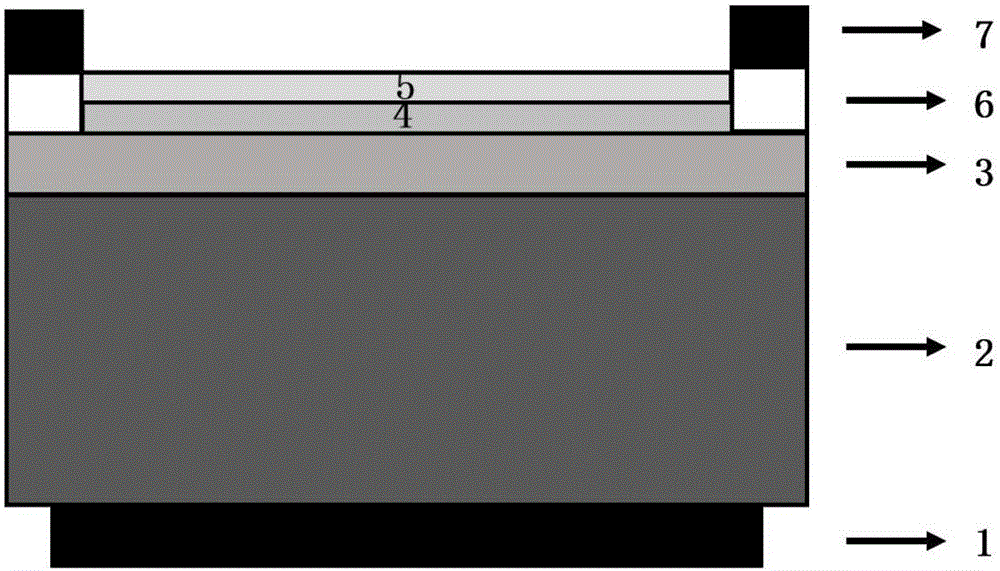

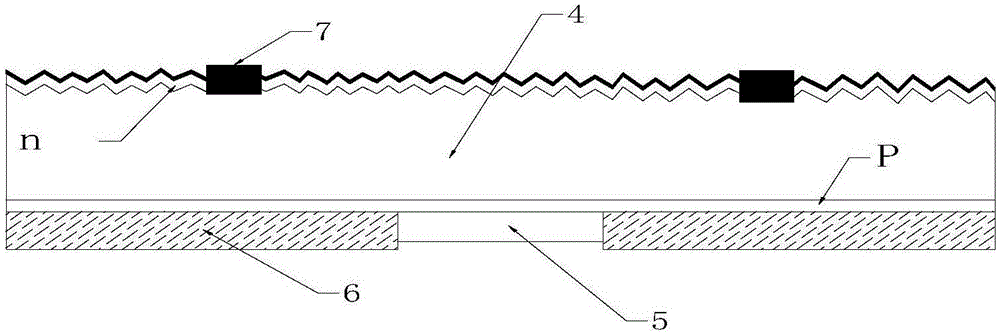

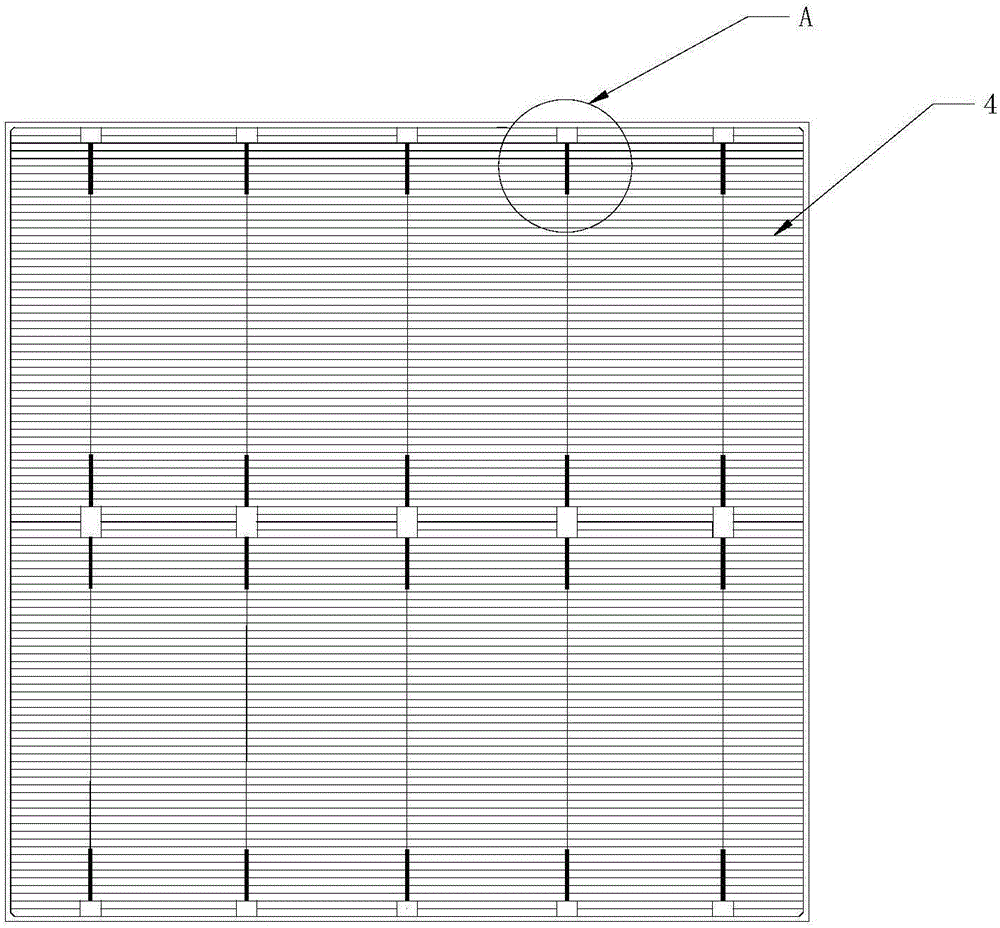

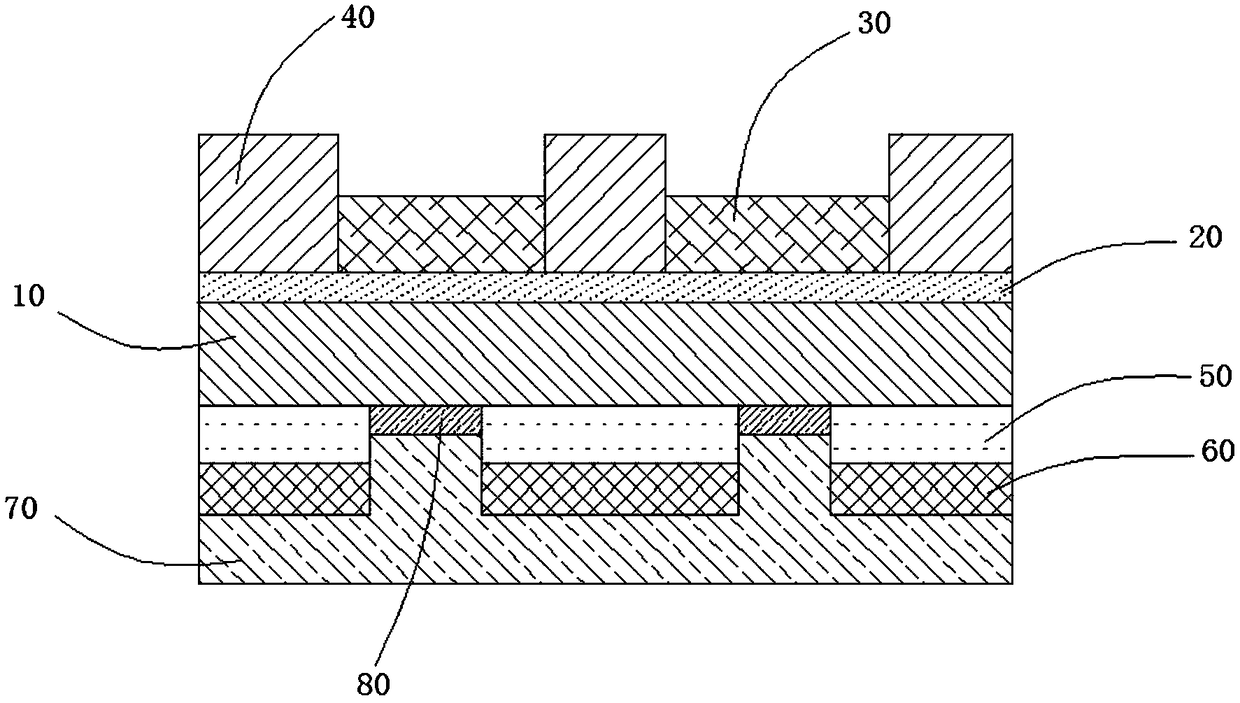

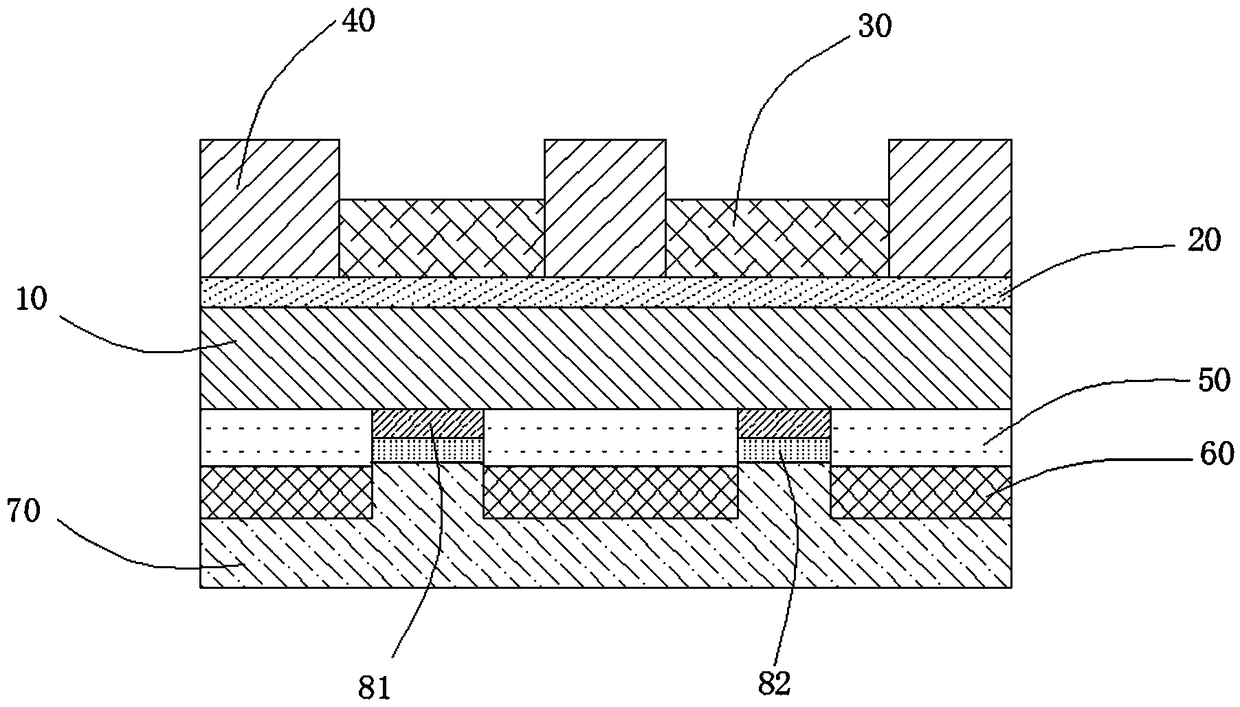

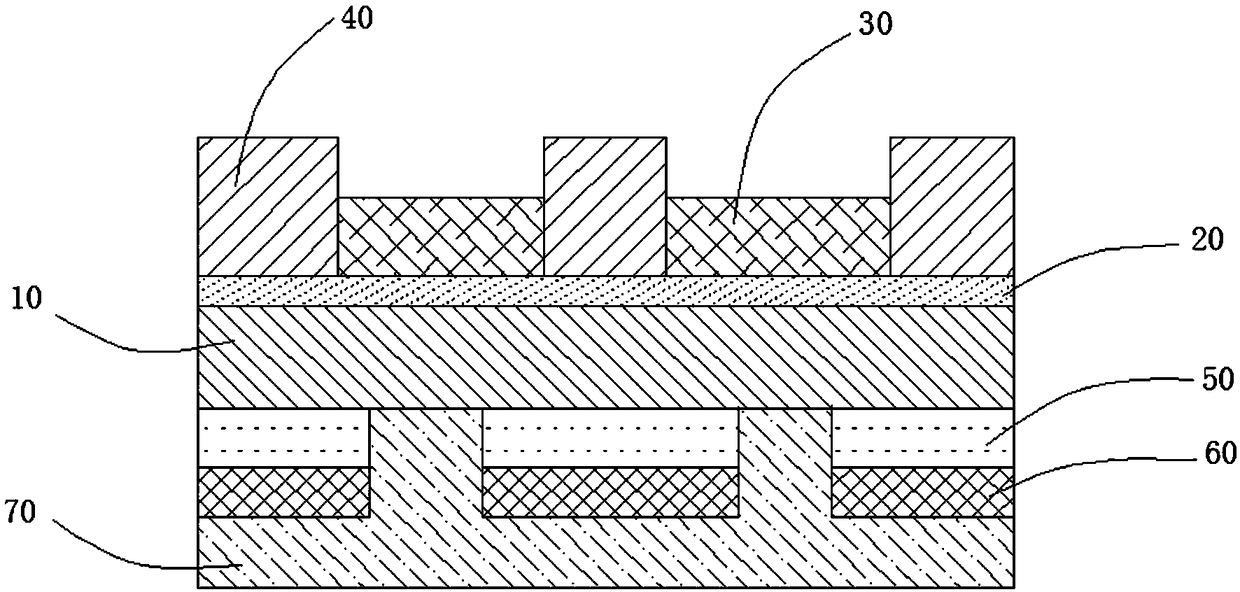

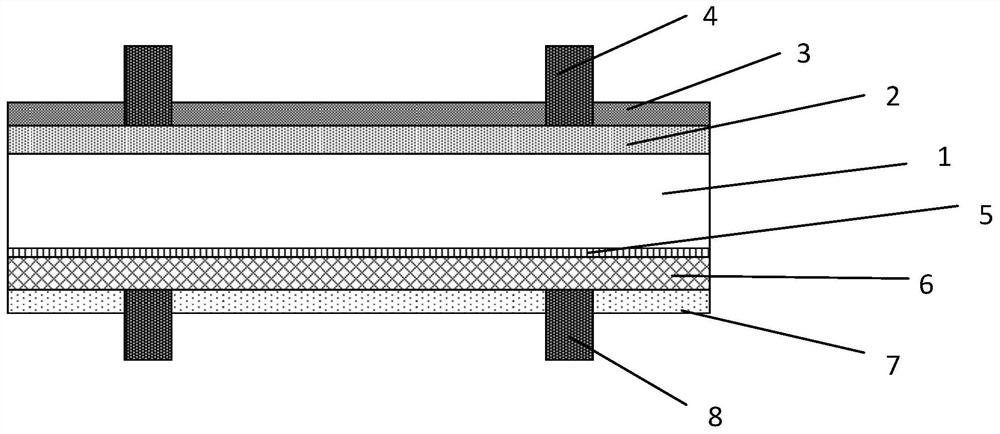

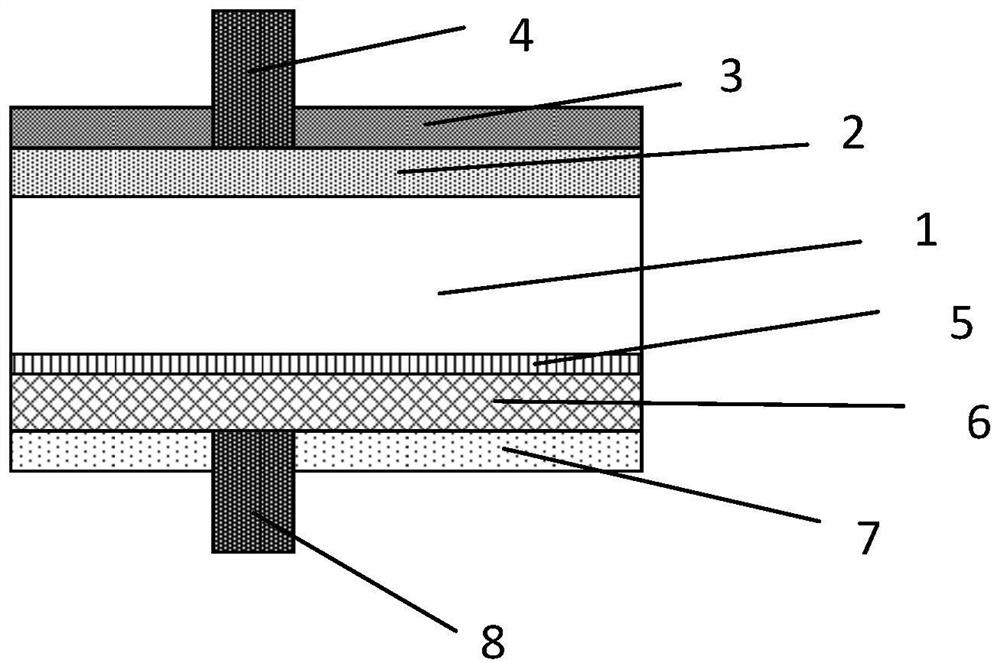

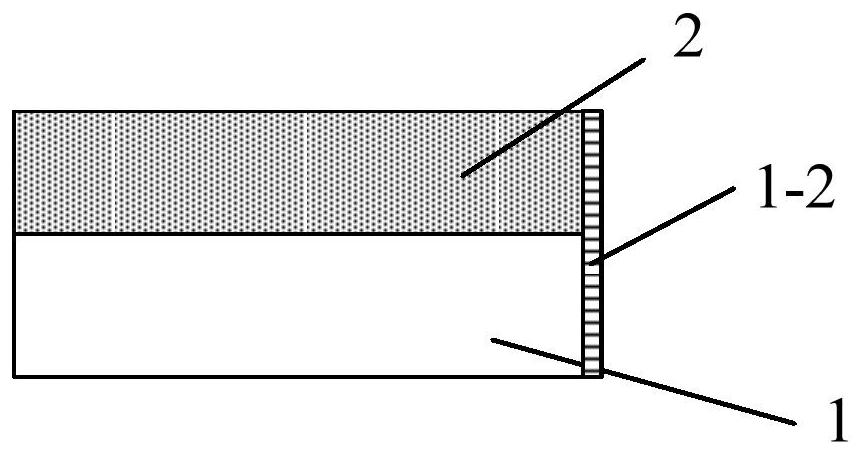

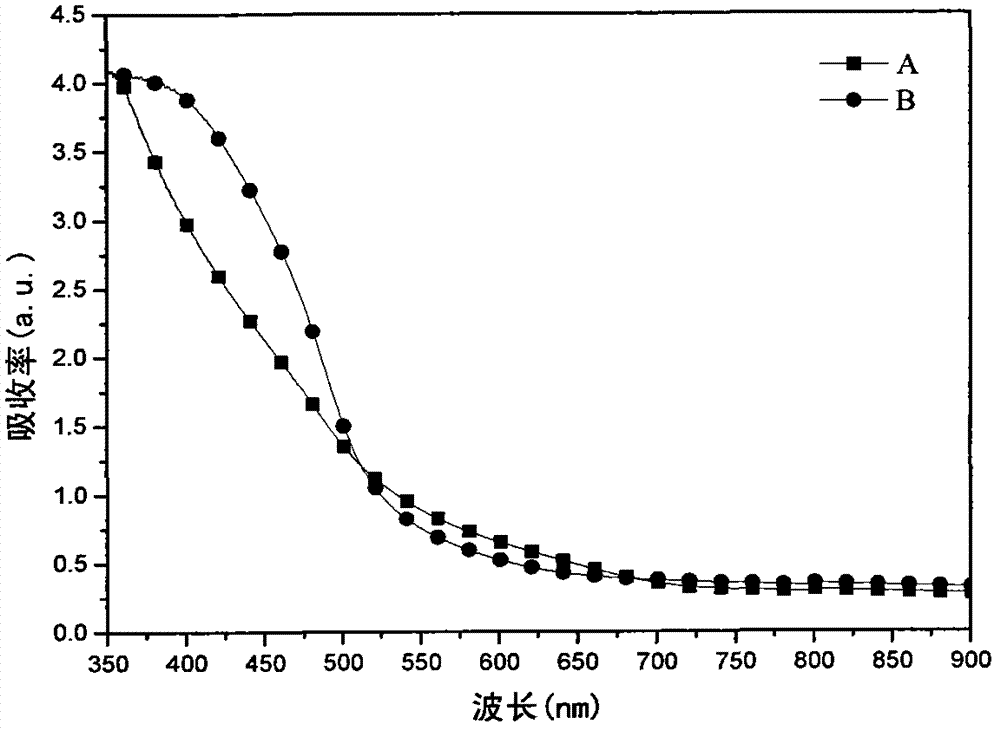

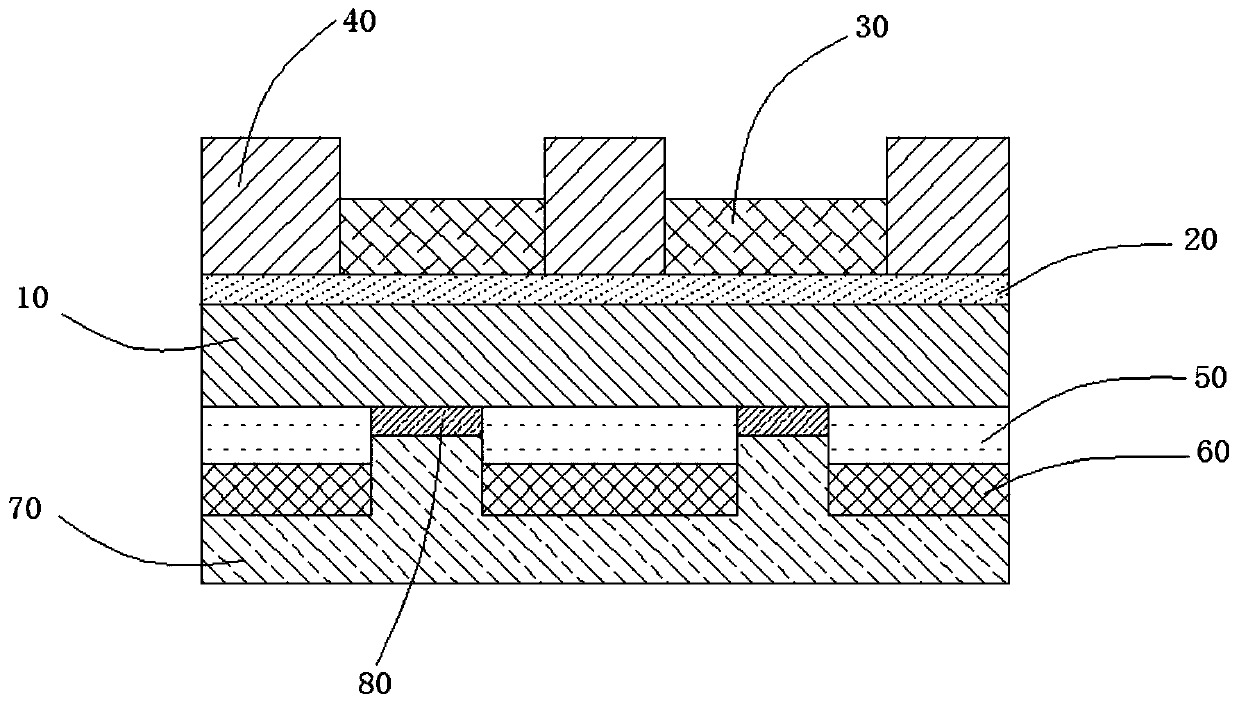

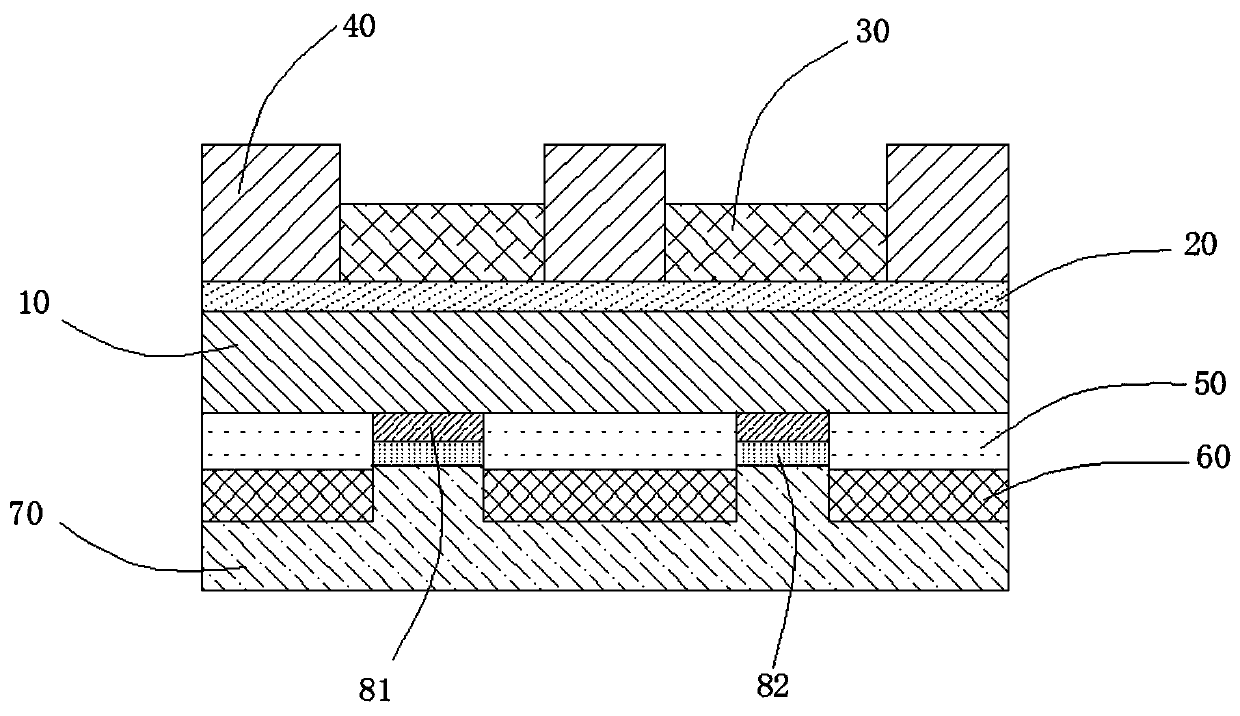

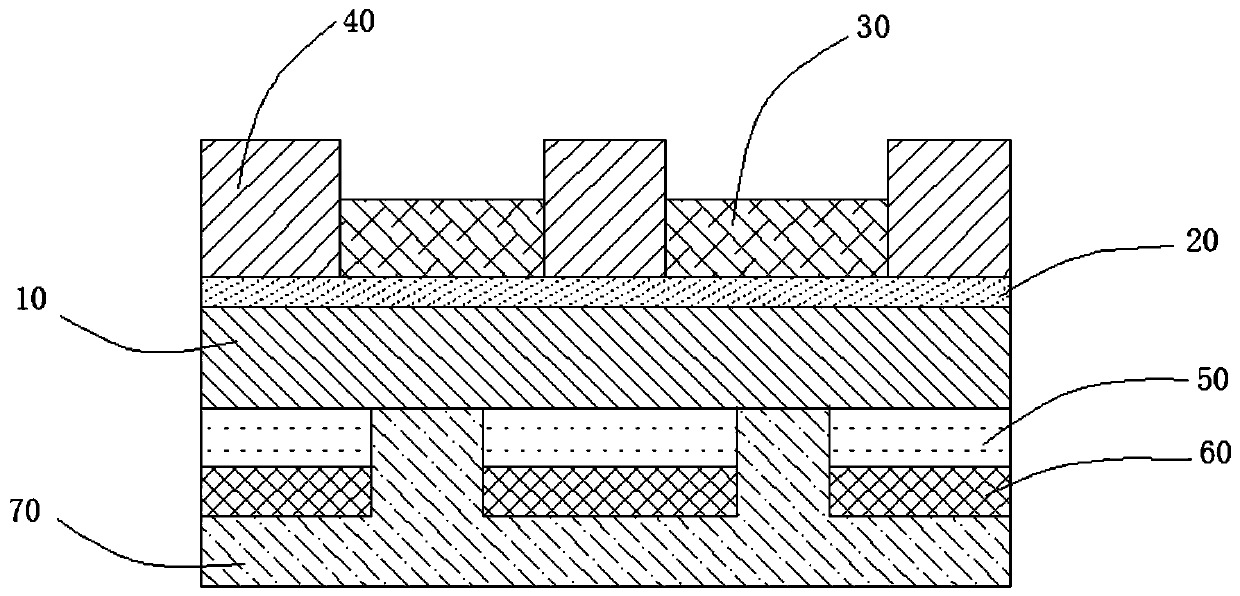

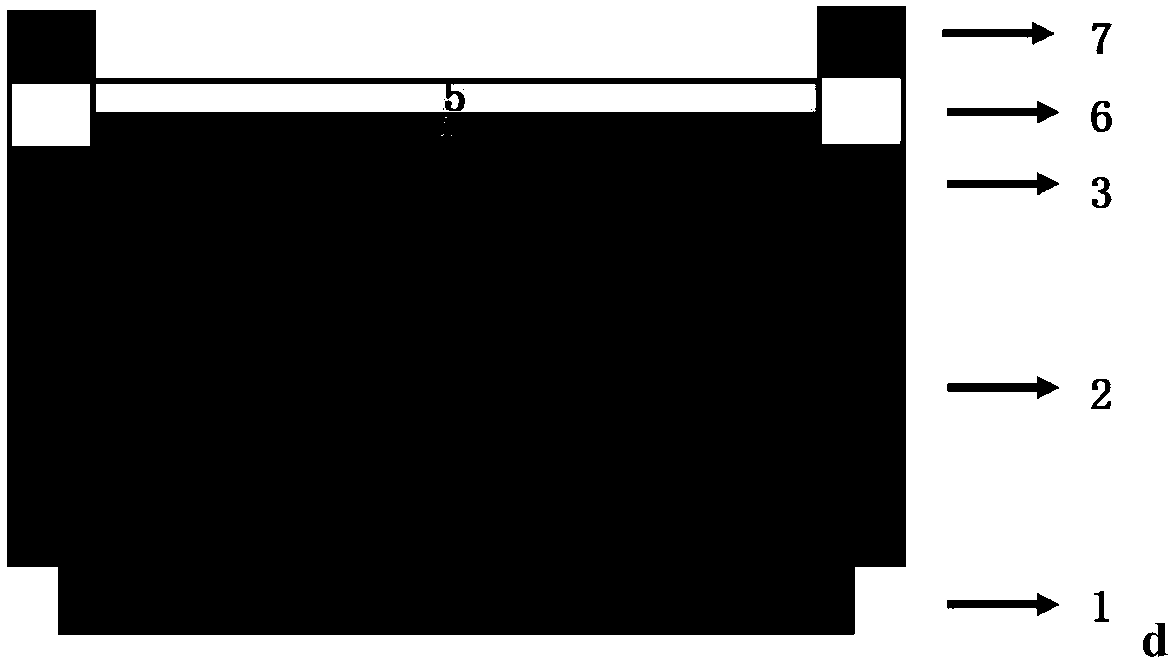

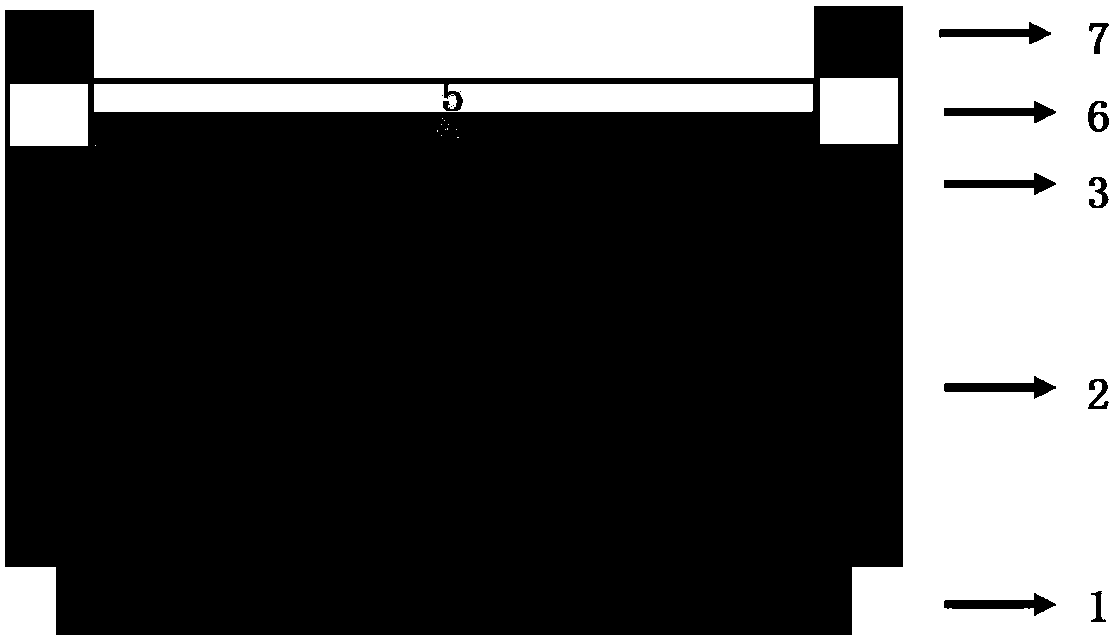

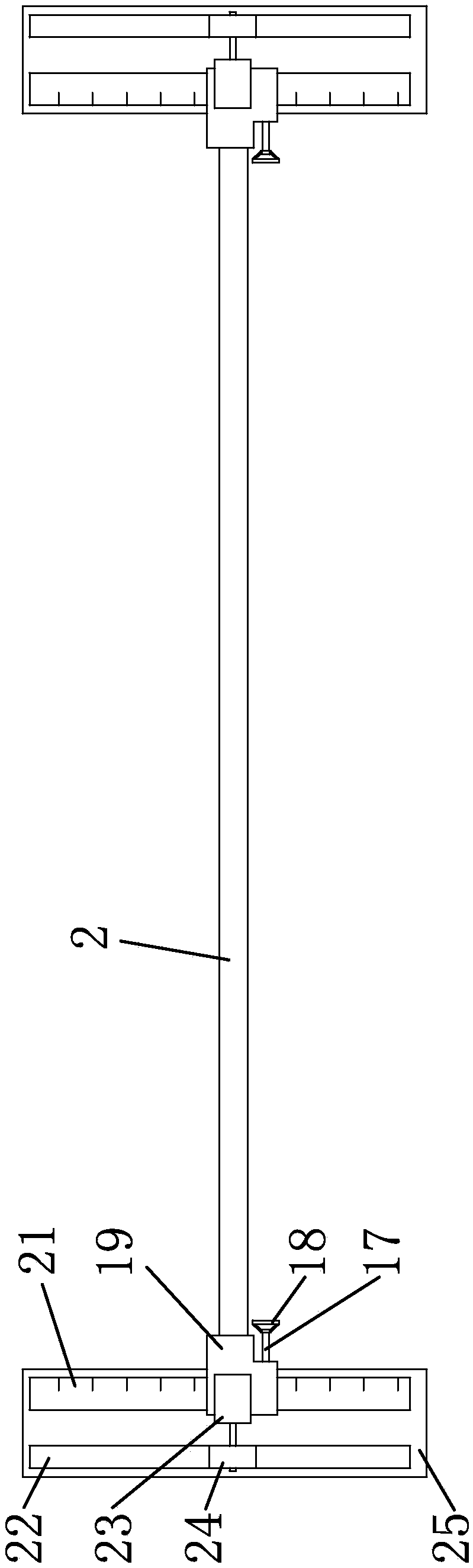

Heterojunction cell with thermal oxidation improved passivation layer interface and preparation method of heterojunction cell

InactiveCN106252424AImprove surface defect structureReduced compound centerFinal product manufacturePhotovoltaic energy generationMonocrystalline siliconCrystalline silicon

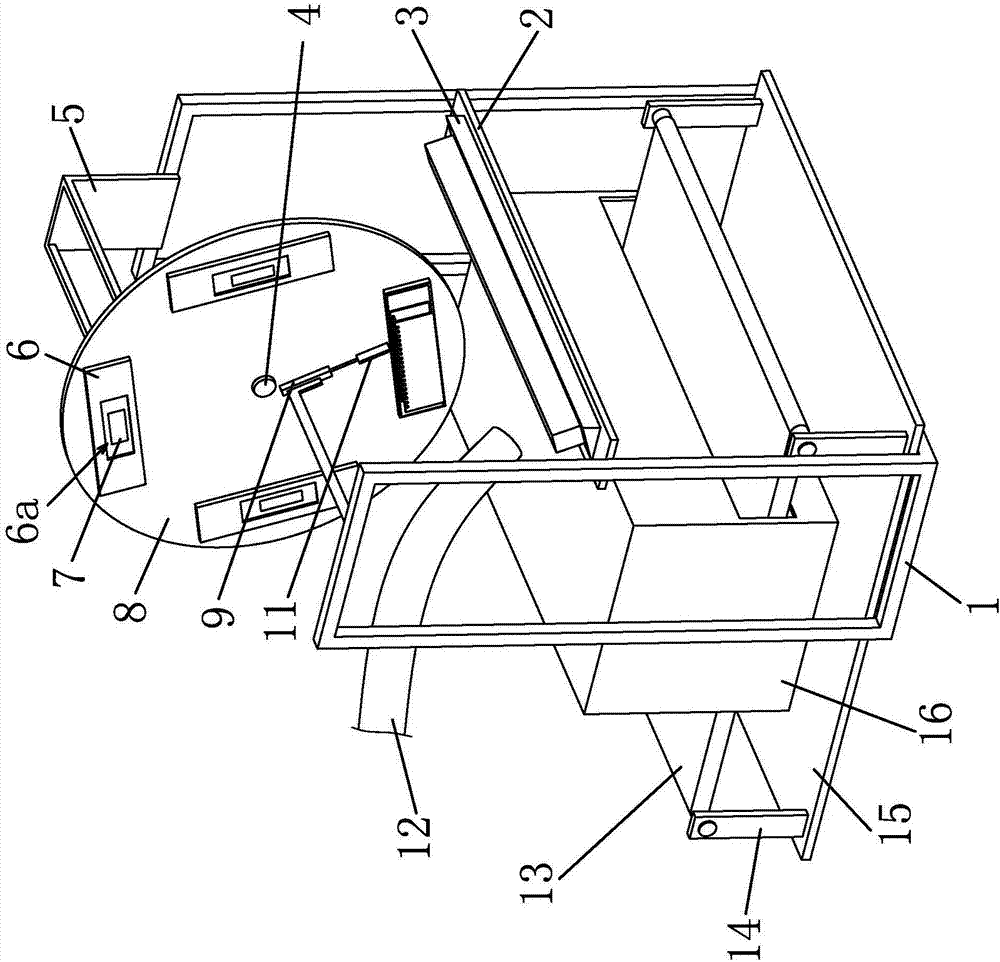

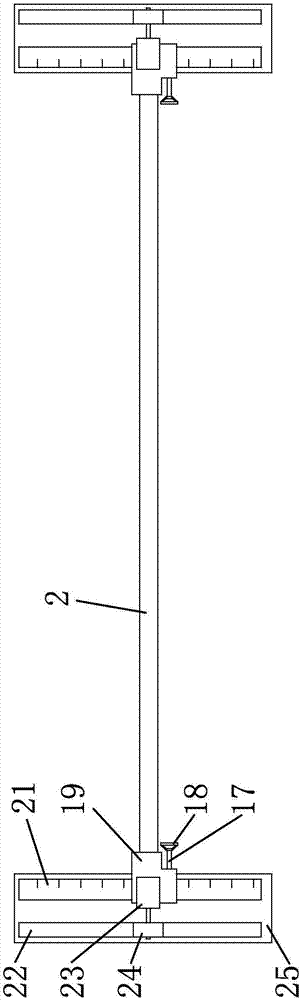

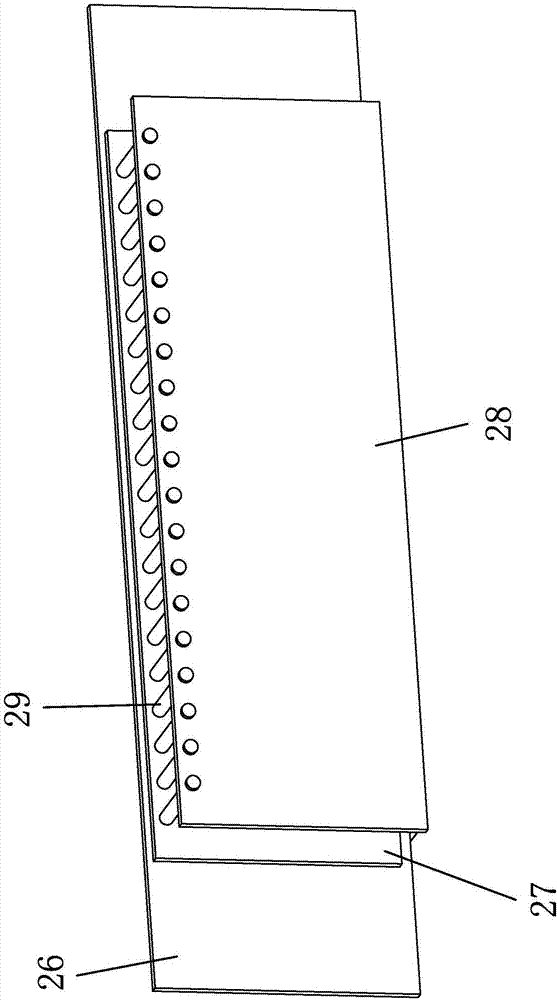

The invention relates to a heterojunction solar cell with a thermal oxidation improved passivation layer interface. The heterojunction solar cell comprises a crystal silicon substrate (1) which is provided with a front surface and a back surface. The heterojunction solar cell is characterized in that the front surface of the crystal silicon substrate (1) is provided with a thermal oxidation layer (2), an intrinsic amorphous silicon thin film layer (3), a front surface doped layer (4), a transparent conductive film layer (5) and front surface metal gate lines (6) sequentially; and the back surface of the crystal silicon substrate (1) is provided with a thermal oxidation layer (2), an intrinsic amorphous silicon thin film layer (3), a back surface doped layer (7), a transparent conductive film layer (5) and back surface metal gate lines (8) sequentially. The invention also discloses a preparation method of the heterojunction solar cell. With the heterojunction solar cell and the preparation method adopted, the surface defect of a monocrystalline silicon sheet can be eliminated, a better passivation effect can be obtained, the minority carrier life time of the heterojunction solar cell can be prolonged, and the conversion efficiency of the cell can be improved.

Owner:TRINASOLAR CO LTD

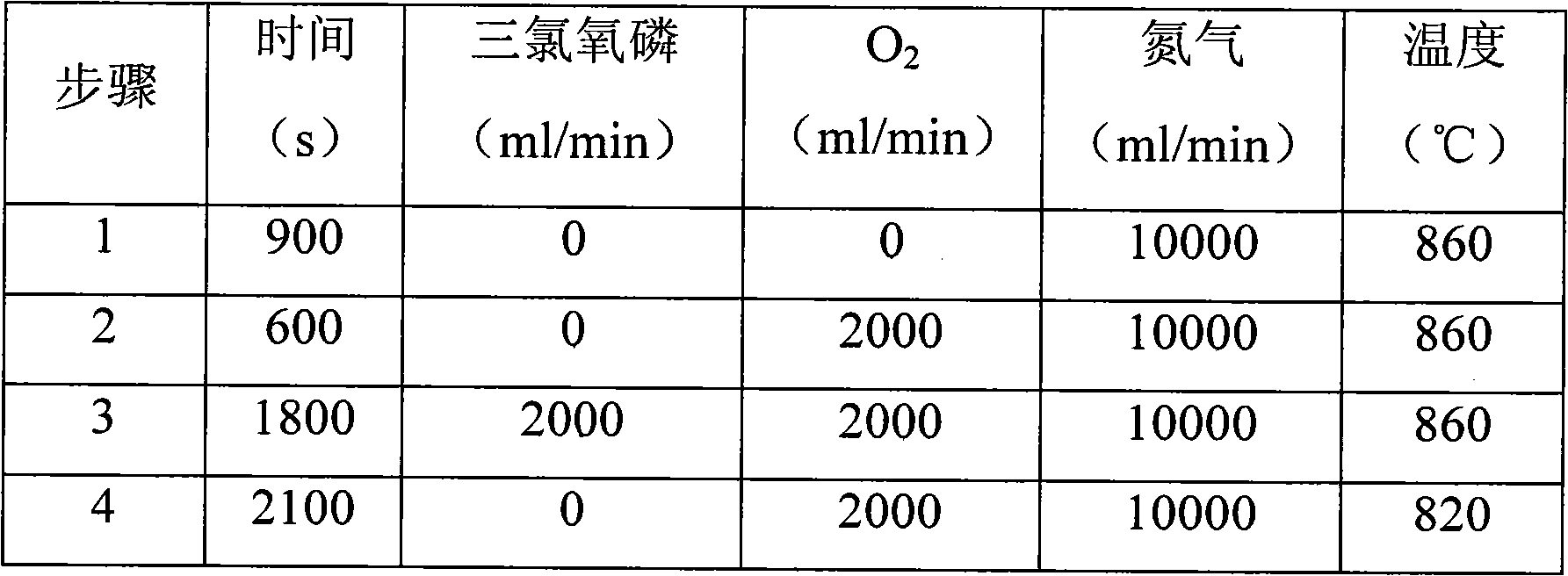

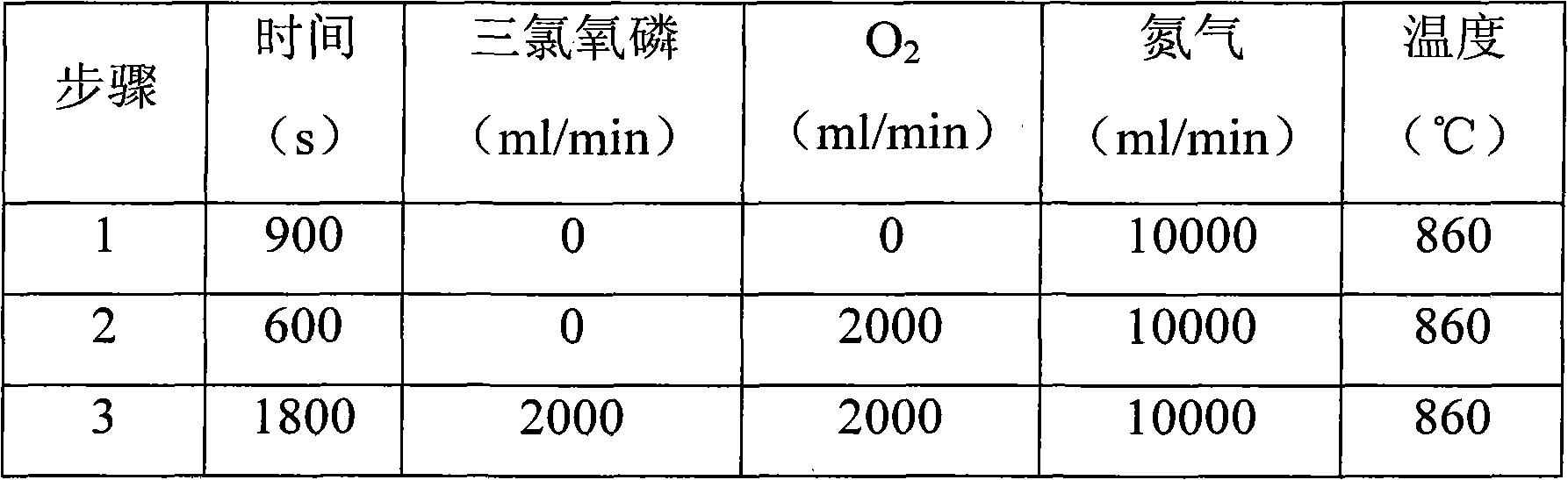

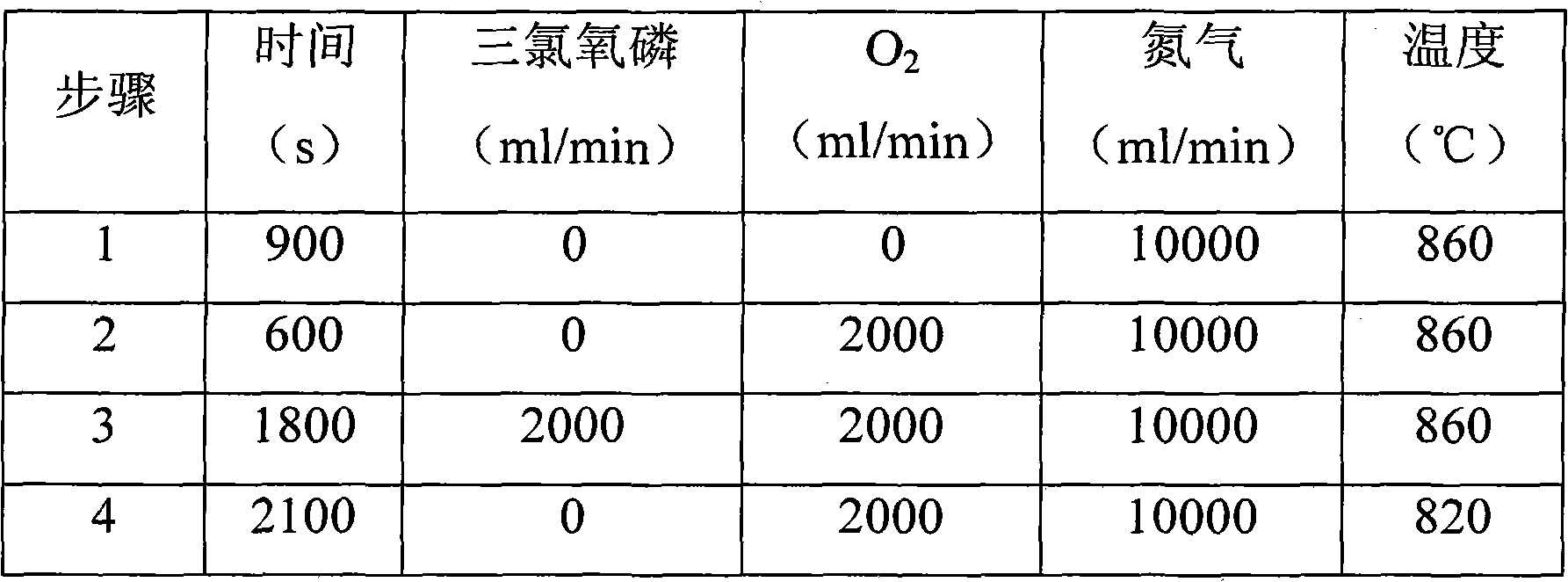

A kind of heat treatment method of n-type silicon chip

ActiveCN105624795BExtend your lifeImprove conversion efficiencyPolycrystalline material growthAfter-treatment detailsSilicon oxideSolar cell

The invention provides a heat treatment method for an n-type silicon wafer. The heat treatment method at least includes the steps that the n-type silicon wafer to be treated is provided, the n-type silicon wafer is put into a heat treatment furnace with a certain temperature, and the temperature is increased to a certain value; oxygen is introduced into the heat treatment furnace; a dispersing agent containing n-type doping elements is supplied to the surface of the n-type silicon wafer so that a silicon oxide layer and an n-type doping layer can be formed on the surface of the n-type silicon wafer; the silicon oxide layer and the n-type doping layer are removed after heat treatment is completed. After the n-type silicon wafer is subjected to heat treatment, recombination centers, caused by the concentration of the doping elements and heat stress, in the n-type silicon wafer can be reduced, the quality and uniformity of the n-type silicon wafer can be improved, the service life of current carriers in the n-type silicon wafer can be prolonged, and thus the conversion efficiency of a solar cell can be improved.

Owner:ZHONGWEI NEW ENERGY CHENGDU CO LTD

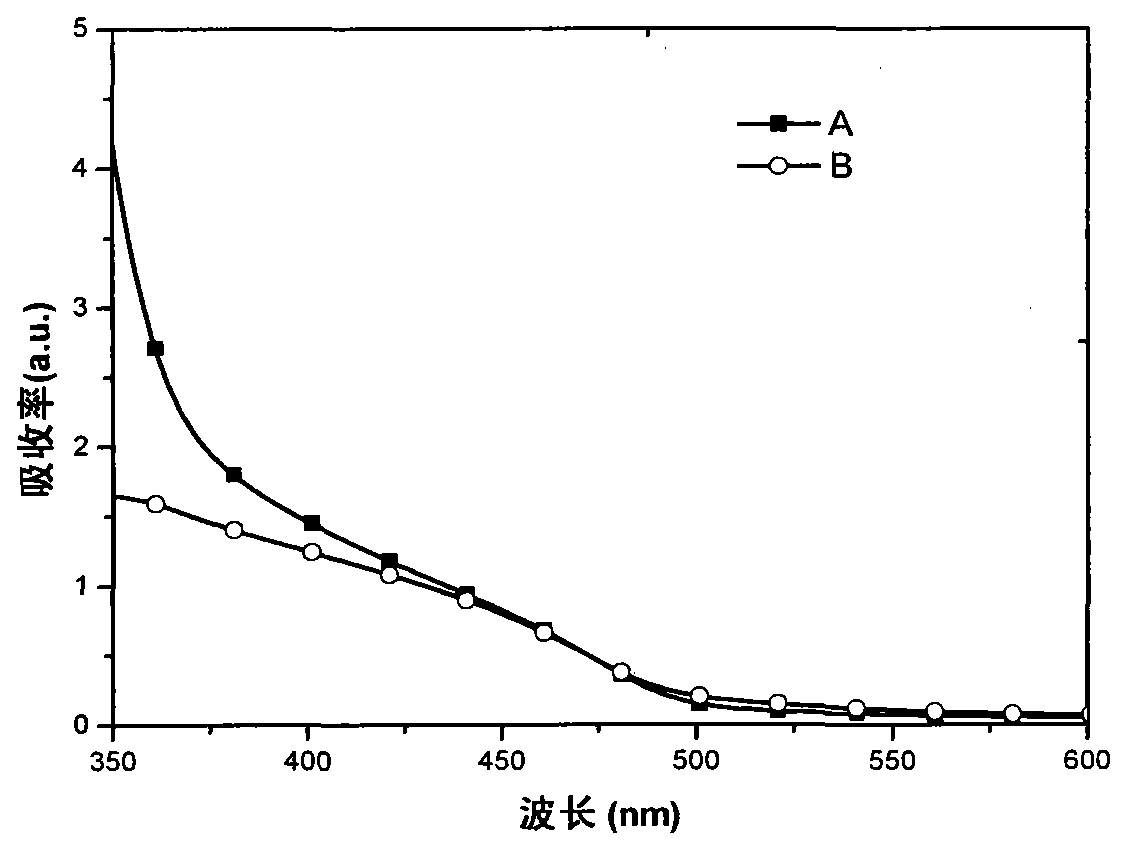

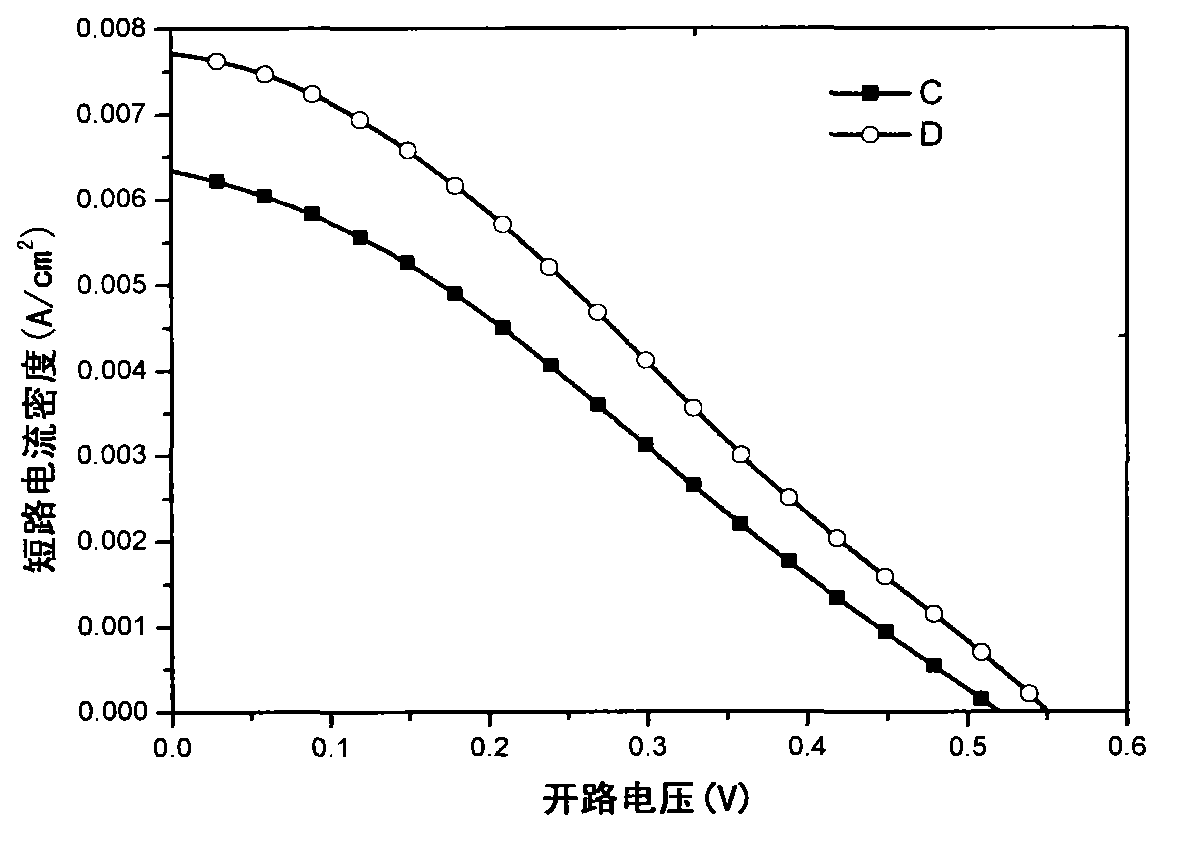

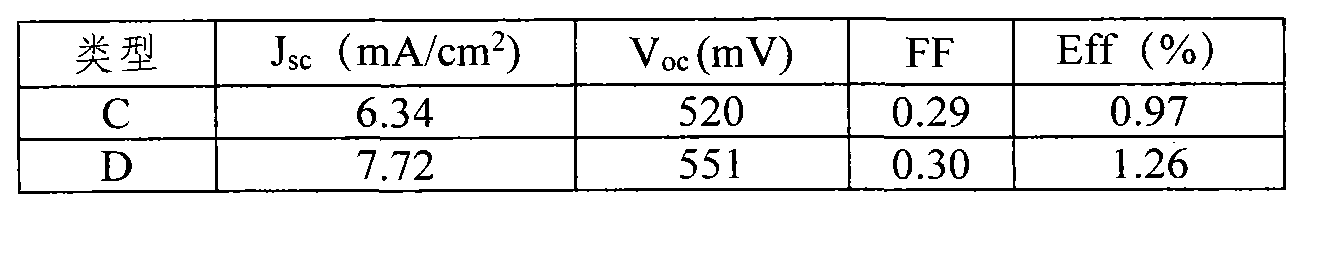

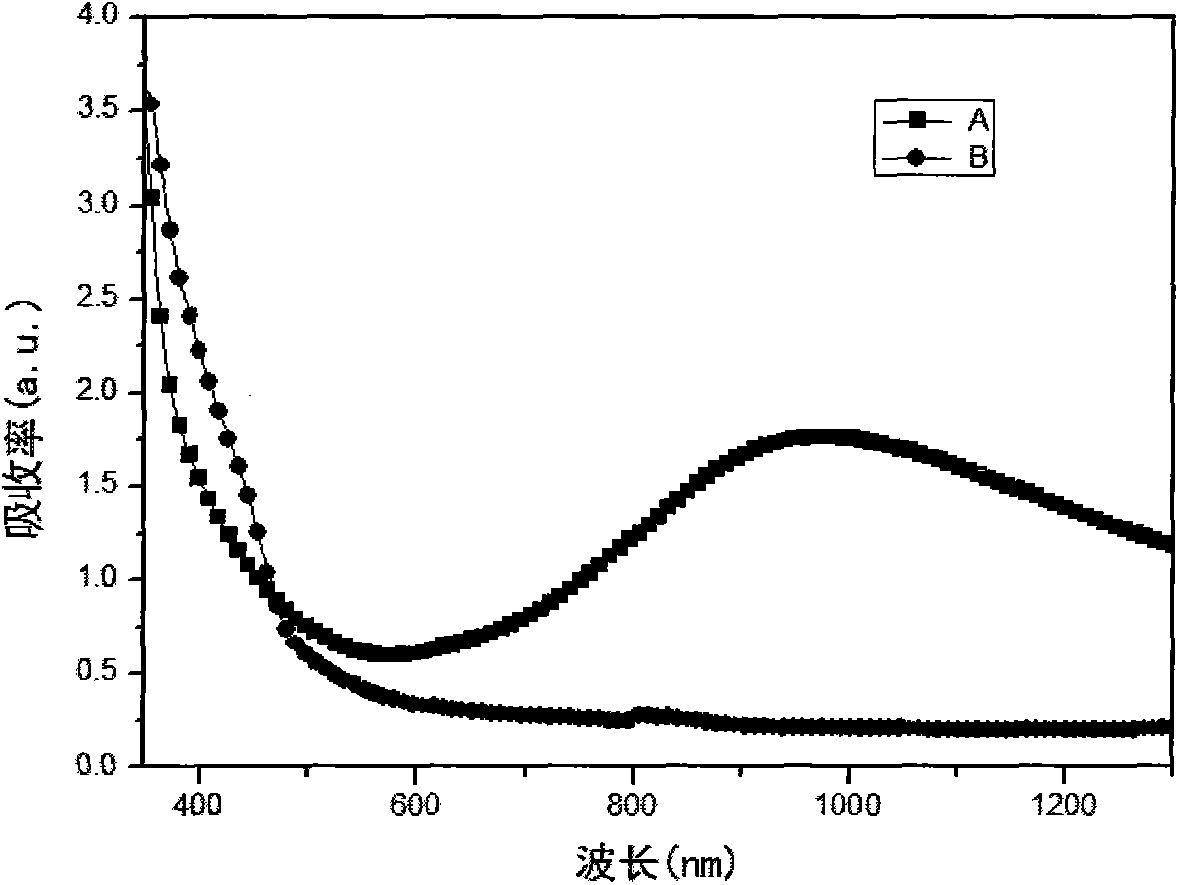

Copper-doped cadmium sulfide quantum dot sensitizer of solar cell and preparation method thereof

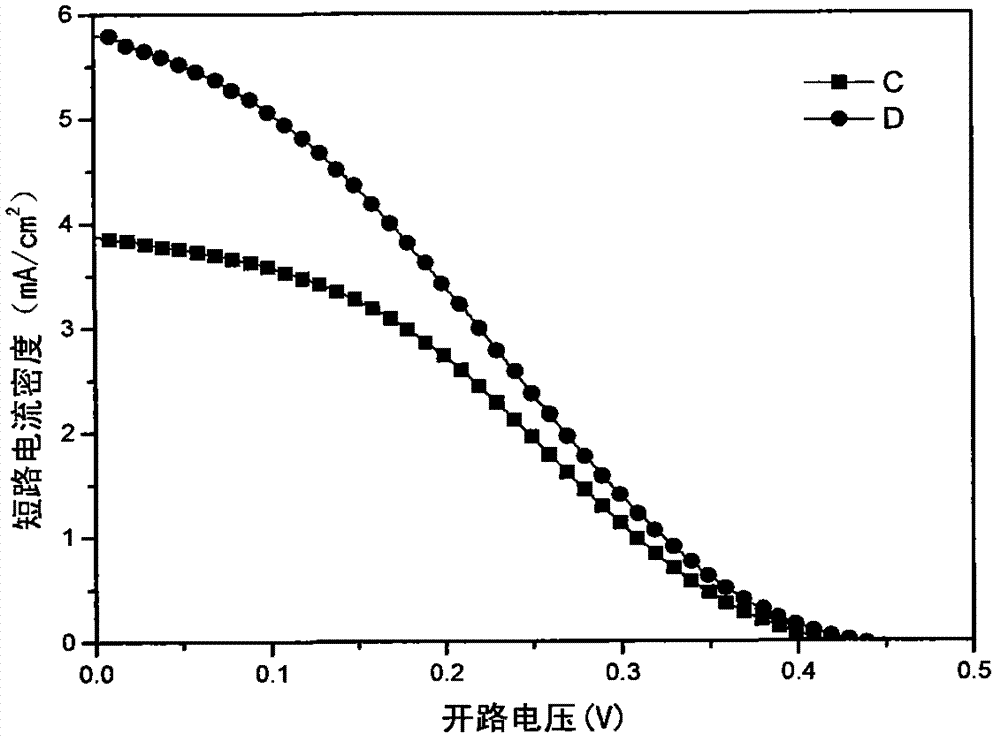

InactiveCN103854862AIncrease short circuit currentIncrease the open circuit voltageLight-sensitive devicesCadmium sulfideImpurity

The invention relates to a Cu-doped CdS quantum dot sensitizer of a solar cell and a preparation method thereof. According to the preparation method, Cu impurity atoms are doped into a CdS semi-conductor quantum dot to serve as the sensitizer to be assembled into the quantum dot sensitized solar cell. By optimizing a transmission path of an electron hole in the cell, an electron hole can be separated quickly, electrons can be injected into a conduction band of TiO2 effectively, dark current is reduced, and short-circuit current, open-circuit voltage and photoelectric conversion efficiency of the solar cell can be increased. The preparation method is simple, easy to operate, low in cost and capable of performing large-area preparation.

Owner:BEIJING INFORMATION SCI & TECH UNIV

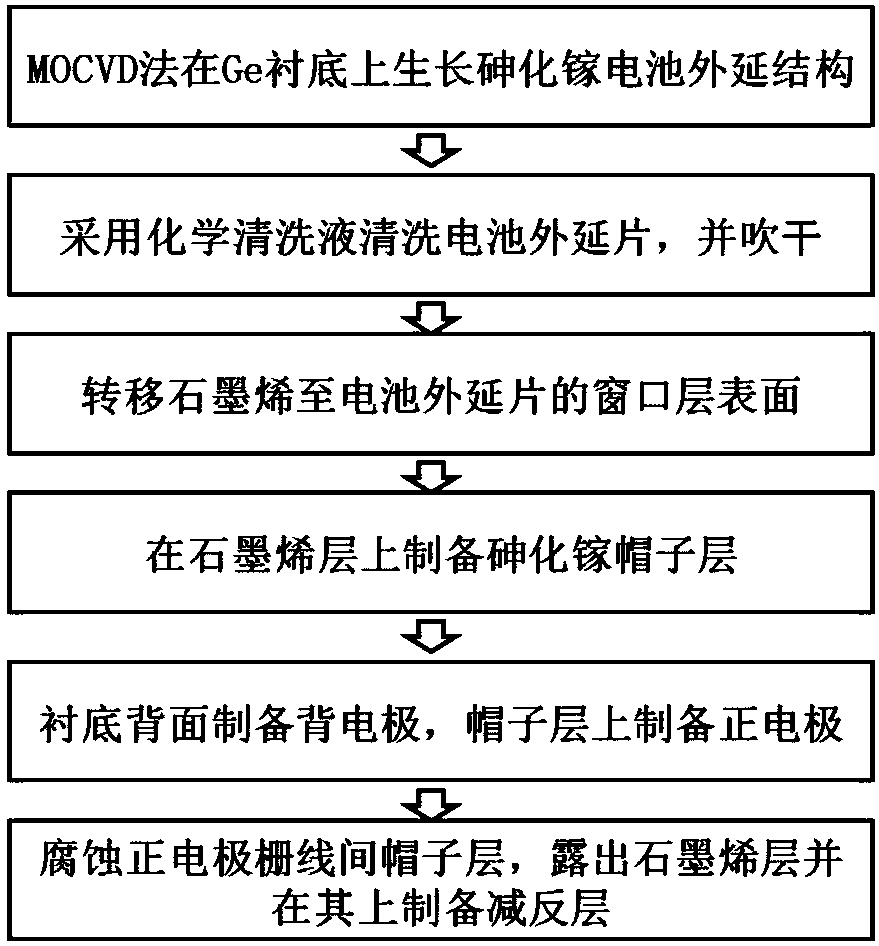

Graphene/gallium arsenide solar cell preparation method

ActiveCN106409988AFacilitates lateral transportReduced compound centerFinal product manufacturePhotovoltaic energy generationConductive materialsSolar cell

The invention provides a graphene / gallium arsenide solar cell preparation method. The graphene / gallium arsenide solar cell preparation method comprises the following steps of: 1) preparing a window layer on the surface of a gallium arsenide epitaxial wafer and then preparing a heavily-doped gallium arsenide cap layer on the surface of the window layer; 2) preparing a positive electrode on the surface of the heavily-doped gallium arsenide cap layer, and preparing a negative electrode on the surface of the gallium arsenide epitaxial wafer away from the window layer; 3) etching the heavily-doped gallium arsenide cap layer between positive electrode grid lines by the chemical etching method so as to expose the window layer; 4) preparing a graphene layer on the surface of the exposed window layer; 5) preparing an anti-reflection layer on the surface of the graphene layer to obtain a graphene / gallium arsenide solar cell. In the invention, graphene is applied to the gallium arsenide solar cell as a transparent conductive material, so the conversion efficiency of the gallium arsenide solar cells is further improved and is much higher than that of graphene / gallium arsenide Schottky junction solar cells. In addition, the cost for solar cell preparation is low and the process is simple, which is conducive to industrialization application.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Preparation method of Cu/Ca doped cadmium sulfide co-sensitizer for solar battery

InactiveCN103632849AIncrease short circuit currentIncrease the open circuit voltageElectrolytic capacitorsCadmium sulfideImpurity

The invention relates to a preparation method of a Cu / Ca doped CdS co-sensitizer for a solar battery. The method comprises the steps of doping Cu impurity atoms to a CdS semiconductor quantum dot, and then, assembling a quantum dot sensitized solar battery by taking the Cu impurity atom doped CdS semiconductor quantum dot and a Ca impurity atom doped CdS semiconductor quantum dot as co-sensitizers. Electron holes can be more rapidly separated through optimizing the transmission paths of charges inside the battery, so that electrons are more effectively injected to a TiO2 conduction band, the dark current is reduced, and the short-circuit current density, open-circuit voltage and photoelectric conversion efficiency of the solar battery are increased. The method is simple, easy to operate, low in cost and capable of realizing large-area production.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Solar aluminum-back full-coverage main-grid-free crystallization silicon cell piece and production technology thereof

InactiveCN106784050AImprove back passivation effectReduce compoundingFinal product manufacturePhotovoltaic energy generationElectricityEngineering

The invention provides a solar main-grid-line-free crystallization silicon cell piece which can reduce production cost and improve generating capacity and a production technology thereof. Two ends in the perpendicular direction of a thin grid line of the cell piece are provided with rectangular thin grid line end sockets, a thickened thin grid line perpendicular to the thin grid line is arranged between the rectangular thin grid line end sockets, main grid line retaining portions are arranged between the rectangular thin grid line end sockets and the thickened thin grid line, a back electrode is arranged corresponding to the main grid line remaining portions on the front side of the cell piece, the cell piece is all covered by an aluminum back, and the back electrode is arranged on the aluminum back. The production technology comprises the steps of firstly printing aluminum back field of the cell piece, namely fully covering the surface of a silicon wafer; then printing the back electrode, namely printing on the surface of the aluminum back field; putting into an oven to be dried and sintered; then printing a front-side electrode of the cell piece; finally sintering and forming. The solar main-grid-line-free crystallization silicon cell piece disclosed by the invention reduces the cost, improves the generating capacity and has a good market popularization prospect.

Owner:QINGDAO RAYSOLAR NEW ENERGY TECH CO LTD

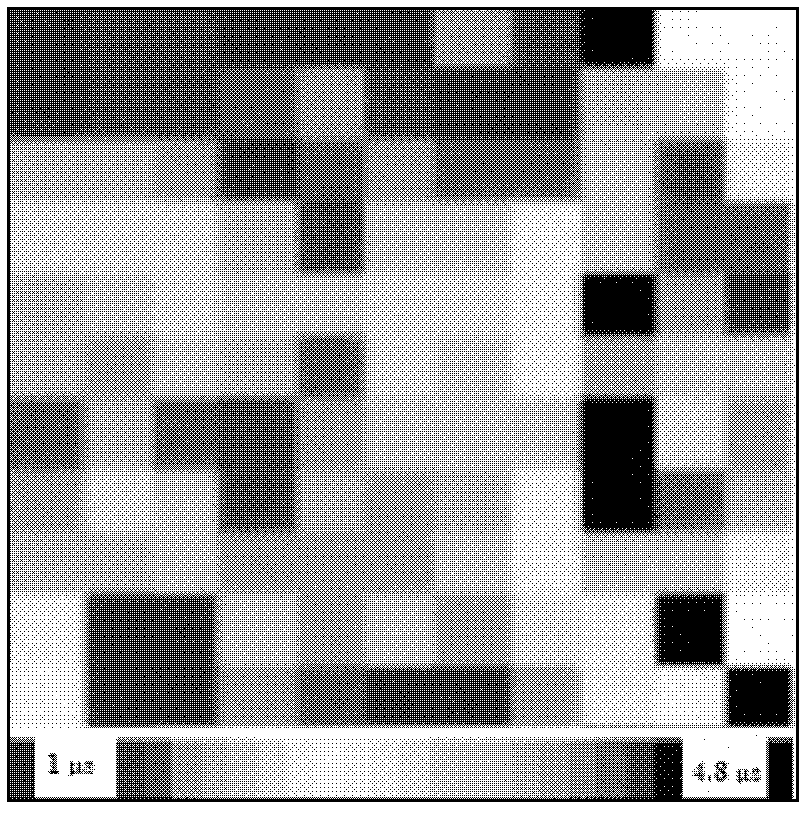

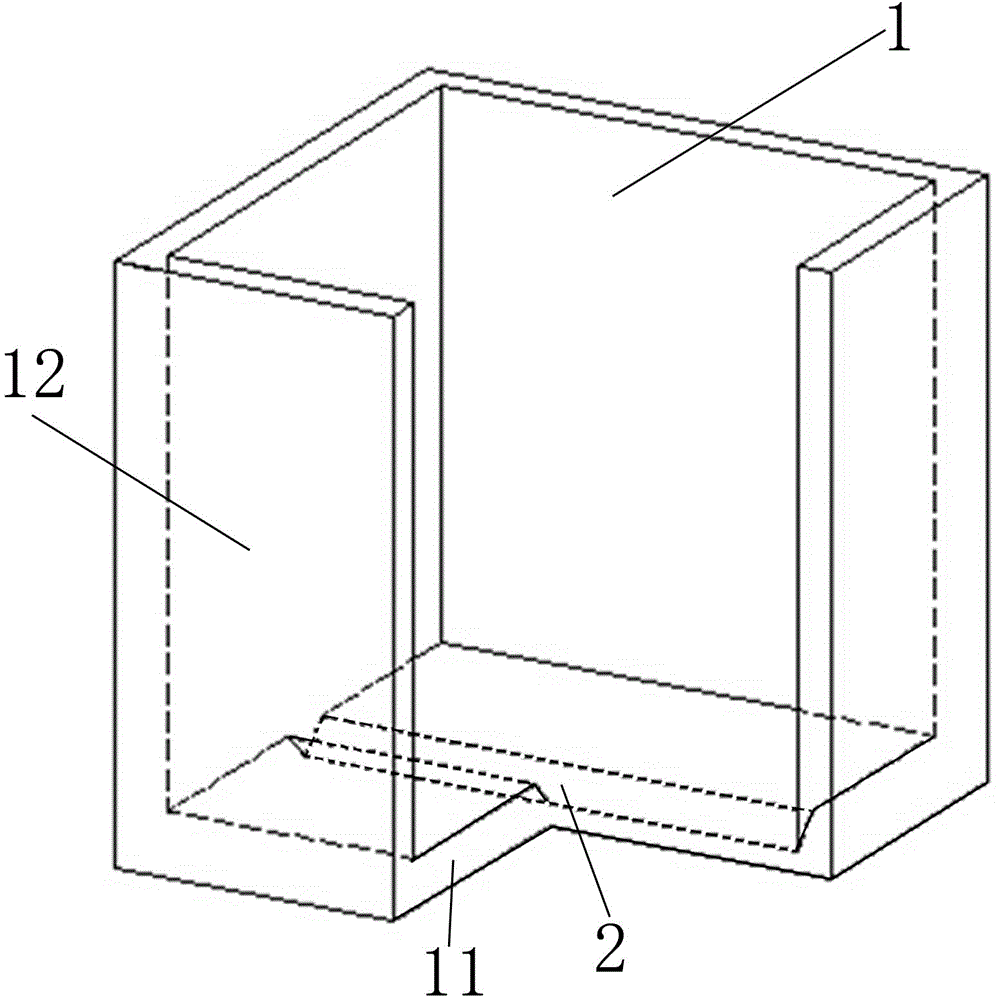

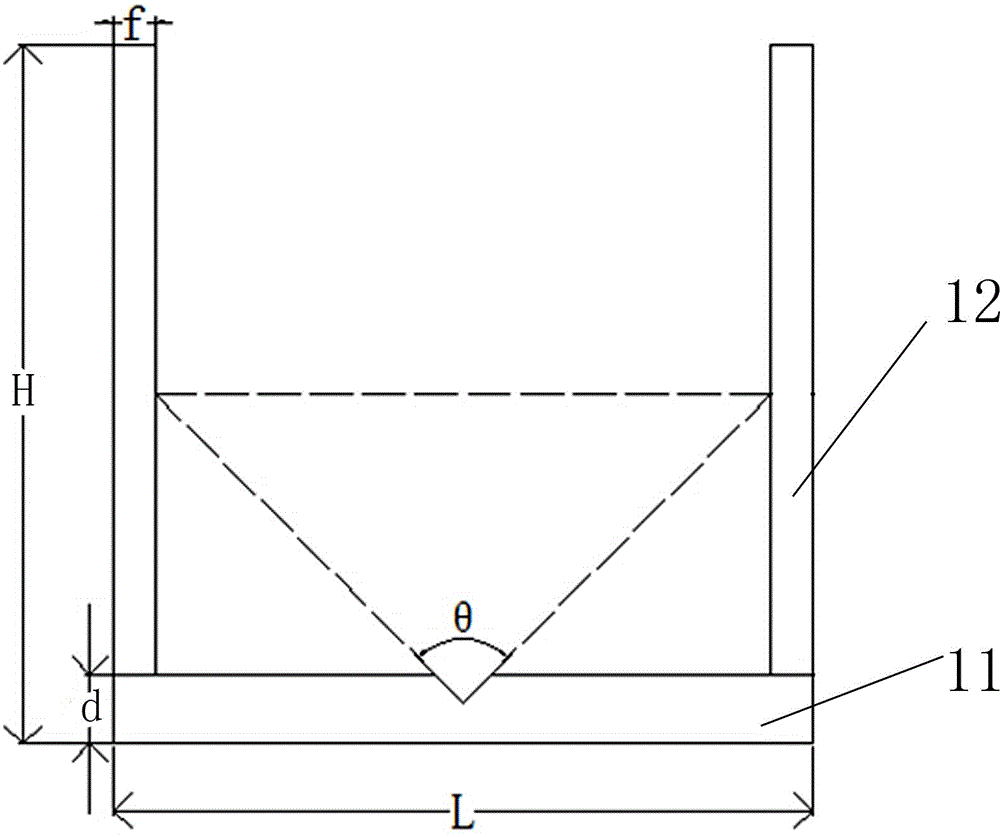

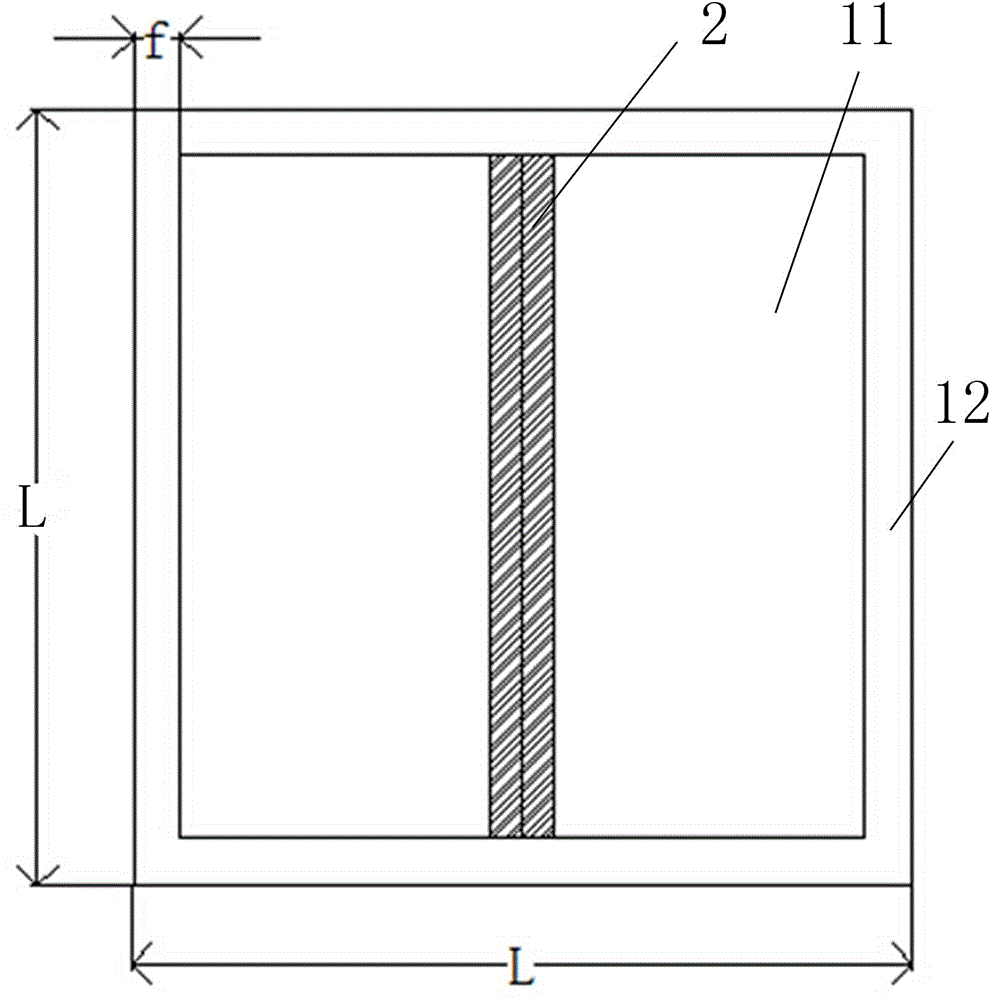

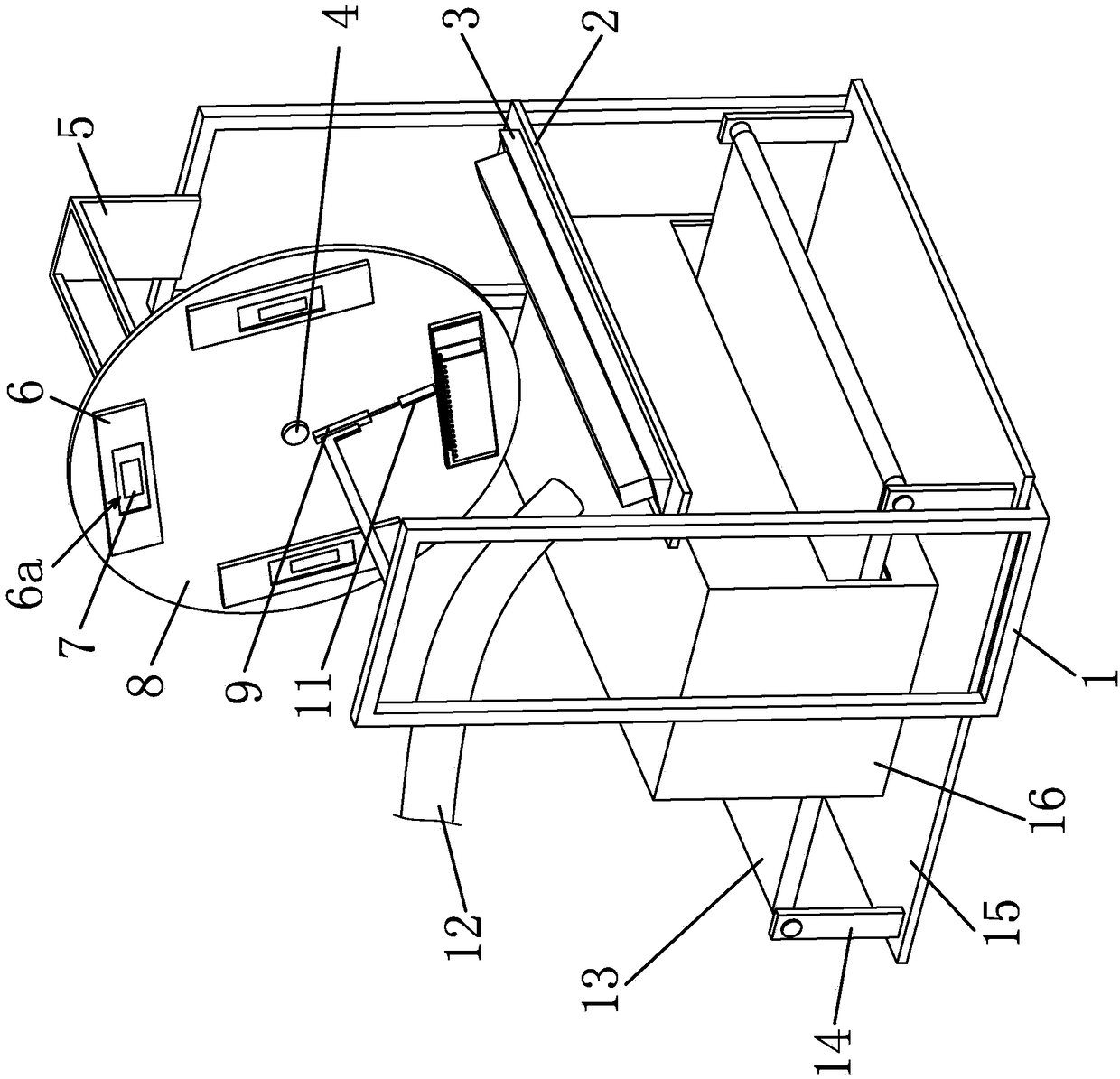

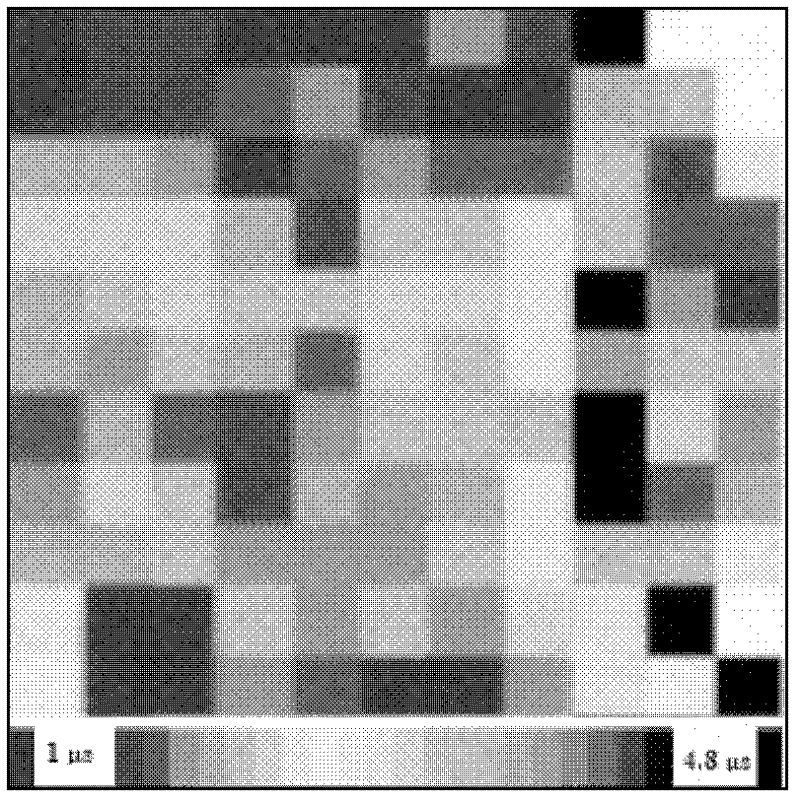

Crucible for preparing polycrystalline silicon ingot and growth method of polycrystalline silicon ingot

ActiveCN104018222AReduce the number of grain boundariesIncrease sizePolycrystalline material growthBy pulling from meltMolten siliconElectric properties

The invention discloses a crucible for preparing a polycrystalline silicon ingot and a growth method of the polycrystalline silicon ingot. The crucible is of a hollow rectangular structure, the bottom side of the crucible takes the shape of a square, and a plurality of right angle V-shaped long grooves are formed in the bottom side of the square. The growth method comprises the following steps: 1) controlling the temperature to firstly reduce the temperature of molten silicon inside the V-shaped long grooves to be 1410 DEG C; 2) lifting an insulation bucket to form the kernel and grow the molten silicon from the bottoms of the V-shaped long grooves; 3) controlling the lifting speed of the insulation bucket, enabling crystal of fast growth speed to achieve the upper top surfaces of the V-shaped long grooves firstly, wherein the crystallization speed of the crystal inside the V-shaped long grooves is 2mm / h; and 4) accelerating the lifting of the insulation bucket, and accomplishing the following crystal growth in a speed of 10mm / h, thereby obtaining columnar crystal. Through crystal guidance functions of the V-shaped long grooves at the bottom of the crucible, accumulation of impurities at crystal defect parts is reduced, the electric properties of the silicon ingot are improved, and the utilization rate of the bottom of the polycrystalline silicon ingot is improved.

Owner:郎溪品旭科技发展有限公司

Solar cell and preparation method thereof

ActiveCN108389928AIncrease the open circuit voltageImprove electrical performanceFinal product manufacturePhotovoltaic energy generationState of artSemiconductor materials

The present invention provides a solar cell and a preparation method thereof, and relates to the technology field of solar cells. The solar cell comprises a cell matrix, a passivating film and a backelectrode. The passivating film is located between the cell matrix and the back electrode, the passivating film is provided with an opening area, and the opening area is internally provided with a high-work-function semiconductor material layer which is located between the cell matrix and the back electrode. The solar cell is employed to relieve the technical problem that there is a high recombination region in a local contact solar cell to cause decreasing of the cell performances in the prior art and achieve the technical effects on reduction of the cell recombination region and improvementof the cell electrical performances in the prior art.

Owner:SHUNDE SYSU INST FOR SOLAR ENERGY

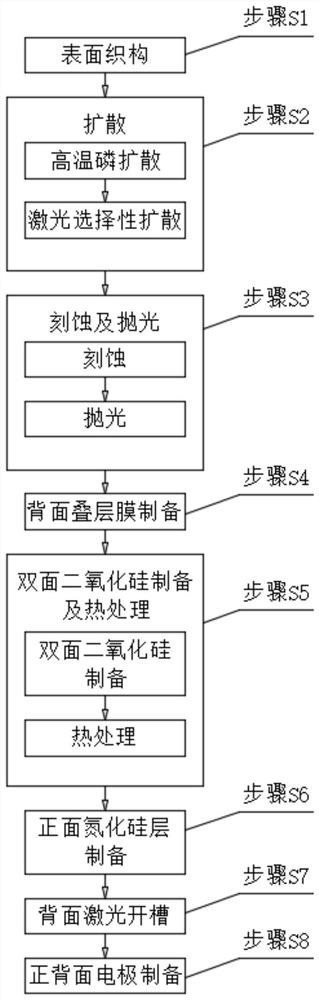

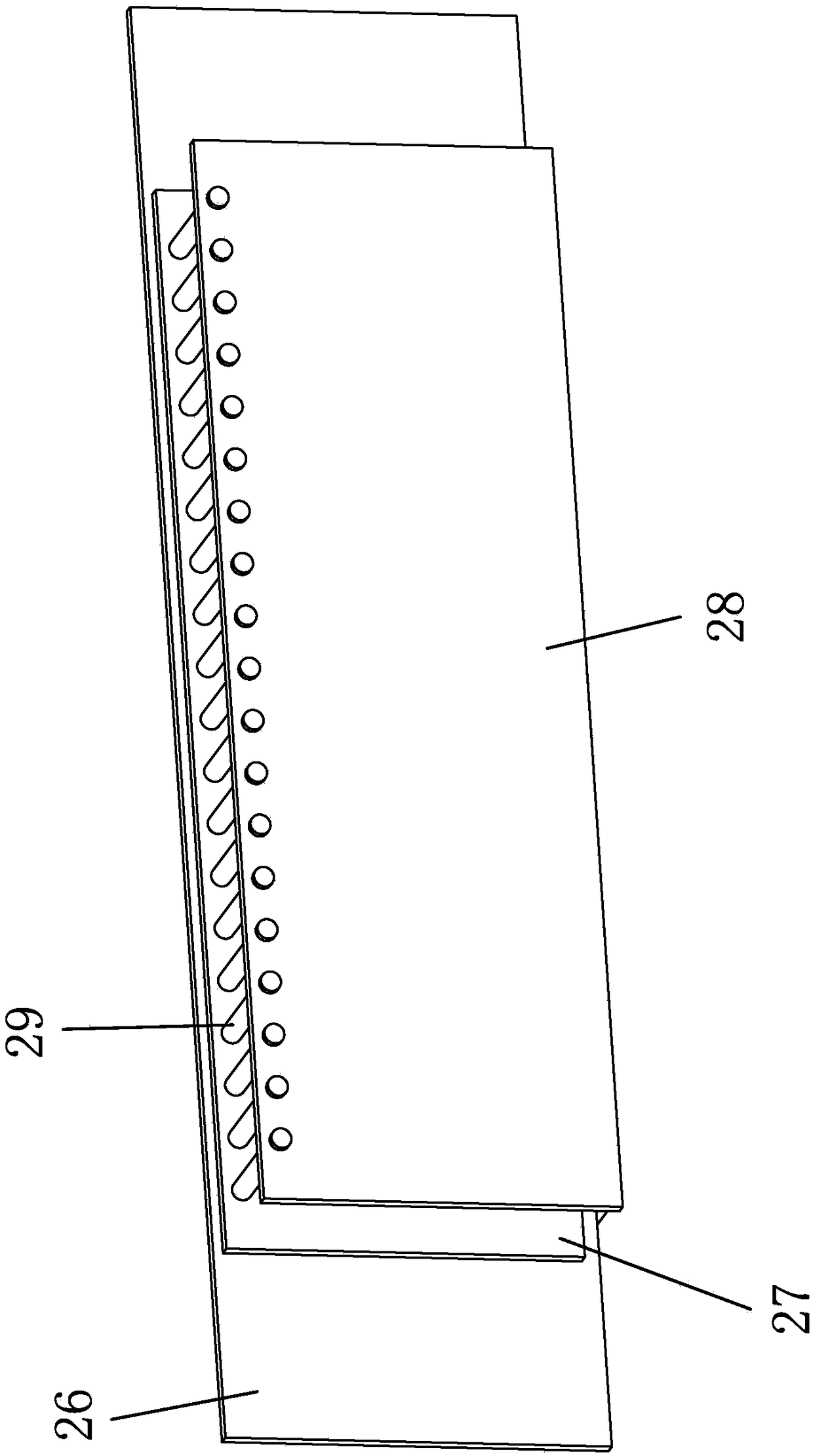

Production method of passivation contact crystalline silicon cell

ActiveCN112687763AReduced compound centerReduce efficiency lossFinal product manufactureSortingCrystallographyCrystalline silicon

The invention provides a production method of a passivation contact crystalline silicon cell. The method comprises the following steps: scribing and cracking a solar cell by a laser to obtain a plurality of cell slices; coating a passivation slurry on a cutting edge of each battery slice; and carrying out hydrogen passivation on the battery slice coated with the passivation slurry, wherein the passivation slurry can be sintered in a hydrogen passivation process.

Owner:TRINA SOLAR CO LTD

Method of preparing La-doped CdS/CdSe sensitizer for solar cell

InactiveCN104779053AIncrease short circuit currentIncrease the open circuit voltageLight-sensitive devicesLanthanumImpurity

The invention relates to a method of preparing La-doped CdS / CdSe sensitizer for a solar cell. According to the method, La impurity atoms are doped in CdS semiconductor quantum dots, co-sensitization with CdSe quantum dots is then carried out to serve as a sensitizer to be assembled to a quantum dot sensitization solar cell. Through optimizing a transmission path of charges inside the cell, electron holes can be separated more quickly, electrons can be injected to a TiO2 conduction band more efficiently, dark current is reduced, and the short circuit current, the open circuit voltage and the photoelectric conversion efficiency of the solar cell are improved. The method is simple, operation is easy, the cost is low, and large-area preparation can be realized.

Owner:BEIJING INFORMATION SCI & TECH UNIV

Solar cell and its preparation method

ActiveCN108389928BIncrease the open circuit voltageImprove electrical performanceFinal product manufacturePhotovoltaic energy generationSemiconductor materialsEngineering

Owner:SHUNDE SYSU INST FOR SOLAR ENERGY

A kind of preparation method of graphene/gallium arsenide solar cell

ActiveCN106409988BReduce processing costsImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationConductive materialsGraphene

The invention provides a graphene / gallium arsenide solar cell preparation method. The graphene / gallium arsenide solar cell preparation method comprises the following steps of: 1) preparing a window layer on the surface of a gallium arsenide epitaxial wafer and then preparing a heavily-doped gallium arsenide cap layer on the surface of the window layer; 2) preparing a positive electrode on the surface of the heavily-doped gallium arsenide cap layer, and preparing a negative electrode on the surface of the gallium arsenide epitaxial wafer away from the window layer; 3) etching the heavily-doped gallium arsenide cap layer between positive electrode grid lines by the chemical etching method so as to expose the window layer; 4) preparing a graphene layer on the surface of the exposed window layer; 5) preparing an anti-reflection layer on the surface of the graphene layer to obtain a graphene / gallium arsenide solar cell. In the invention, graphene is applied to the gallium arsenide solar cell as a transparent conductive material, so the conversion efficiency of the gallium arsenide solar cells is further improved and is much higher than that of graphene / gallium arsenide Schottky junction solar cells. In addition, the cost for solar cell preparation is low and the process is simple, which is conducive to industrialization application.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

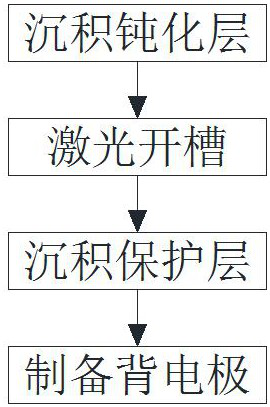

A method for preparing the back of a perc single crystal double-sided solar cell

ActiveCN112614917BImprove conversion efficiencyAvoid damageFinal product manufactureSemiconductor devicesEngineeringLaser light

The invention discloses a method for preparing the back surface of a PERC single crystal double-sided solar cell, comprising the following steps: S1, depositing a passivation layer on the back surface of a silicon substrate; S2, using a low-energy laser to irradiate the passivation layer with laser light, so that the laser irradiates the passivation layer with laser light. The lower passivation layer forms a groove, and the silicon substrate in the groove is exposed; S3, deposit a protective layer on the surface of the groove and the passivation layer, and the protective layer is a silicon nitride film; S4, use electronic paste to burn through the groove The protective layer is prepared, and the back electrode is in contact with the silicon substrate in the groove. In the method for preparing the back of the PERC single crystal double-sided solar cell, immediately after depositing the passivation layer, a low-energy laser is used for grooving, which reduces damage to the silicon substrate and reduces energy consumption, and then deposits a protective layer, which not only realizes the protection of the passivation layer It also has a repairing effect on the surface of the silicon substrate and in the body, reducing the recombination center and improving the conversion efficiency of the battery.

Owner:JETION SOLAR HLDG

Texturing technology of diamond wire solar battery piece

InactiveCN108767025AHigh reactivityReduce reflectivityAfter-treatment detailsFinal product manufactureHydrofluoric acidPolycrystalline diamond

The invention provides a texturing technology of a diamond wire solar battery piece. The texturing technology solves technical problems that an antireflection effect of the existing conventional chemical method is not remarkable, cost of matching of whole technology of a black silicon technology is increased more than ten times, the existing diffusion technology is not matched with a polycrystalline diamond wire texturing technology, and so on. The texturing technology of the diamond wire solar battery piece comprises the following steps: a, texturing; b, washing a surface of a silicon wafer with ultrapure water; c, alkaline washing; d, washing the surface of the silicon wafer with the ultrapure water; e, washing with mixed acid solution of hydrofluoric acid and hydrochloric acid; f, washing with the ultrapure water and drying. The texturing technology of the diamond wire solar battery piece, provided by the invention, has the advantage of low reflectivity of polycrystalline.

Owner:ZHEJIANG GUANGLONG ENERGY TECH

Method for gettering phosphorus in N-type polysilicon slice by metallurgical method

InactiveCN102153089BEfficient removalQuality improvementSilicon compoundsHydrogen fluorideThermal treatment

Owner:XIAMEN UNIV

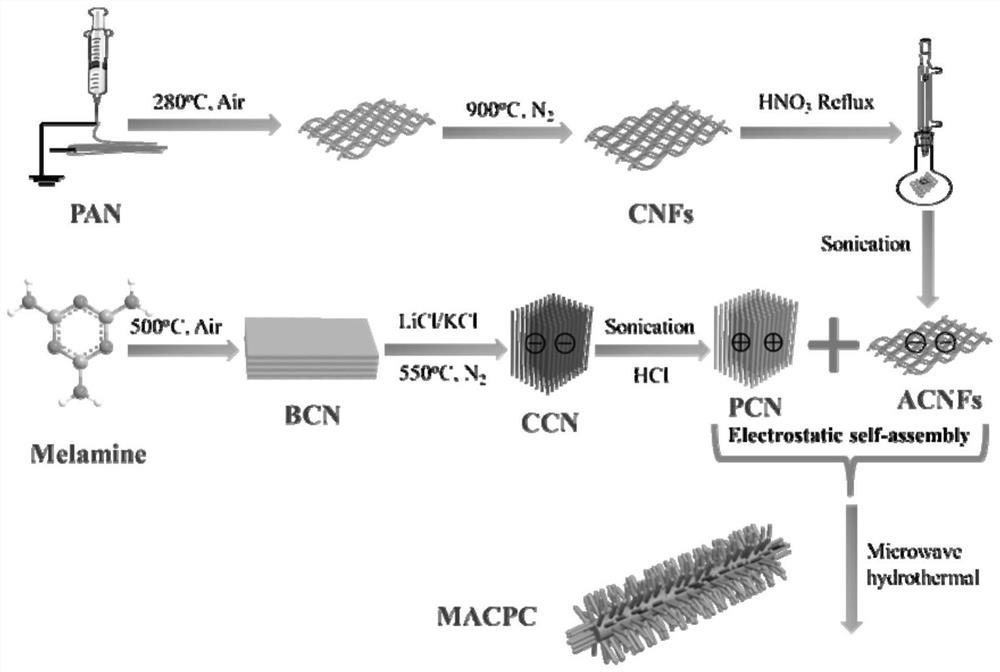

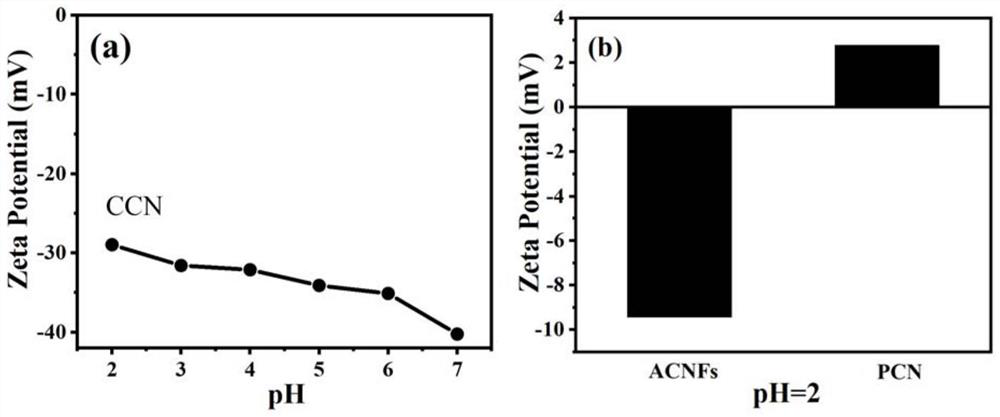

Photocatalyst as well as preparation method and application thereof

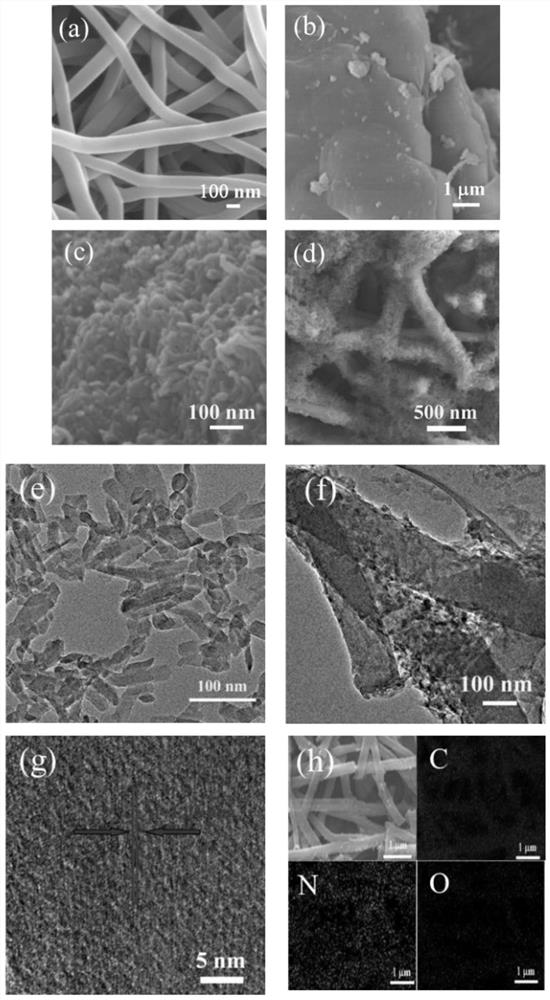

ActiveCN114308100AHigh catalytic activityReduced compound centerHydrogenPhysical/chemical process catalystsFiberCarbon fibers

The invention relates to the field of catalysts, in particular to a photocatalyst and a preparation method and application thereof. The photocatalyst is formed by loading protonated crystal g-C3N4 on acidified carbon nanofibers in an electrostatic self-assembly manner, and the loading capacity of the acidified carbon nanofibers is 0.5-5%. The protonated crystal g-C3N4 can effectively reduce the recombination center of carriers, improve the interface transfer of charges and increase active sites of reaction, the acidified carbon nanofibers can improve the transfer of the carriers and can effectively avoid agglomeration of the one-dimensional nanorod structure of the crystal g-C3N4, and under light illumination, the one-dimensional nanorod structure of the crystal g-C3N4 can be converted into the one-dimensional nanorod structure of the crystal g-C3N4. Electrons and electron hole pairs excited from a valence band to a conduction band are firstly generated in g-C3N4, and the electrons can be transferred from the g-C3N4 to the carbon fiber and stored due to excellent conductivity and charge storage capability of the carbon fiber, so that the catalyst has relatively high catalytic activity.

Owner:SHENZHEN TECH UNIV

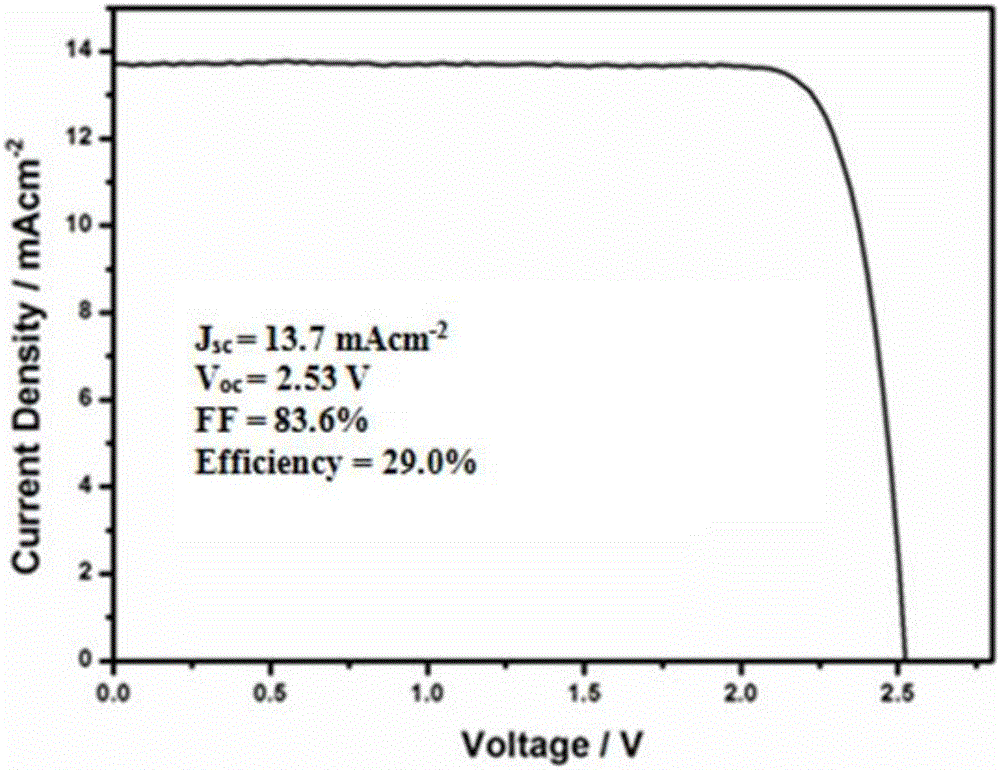

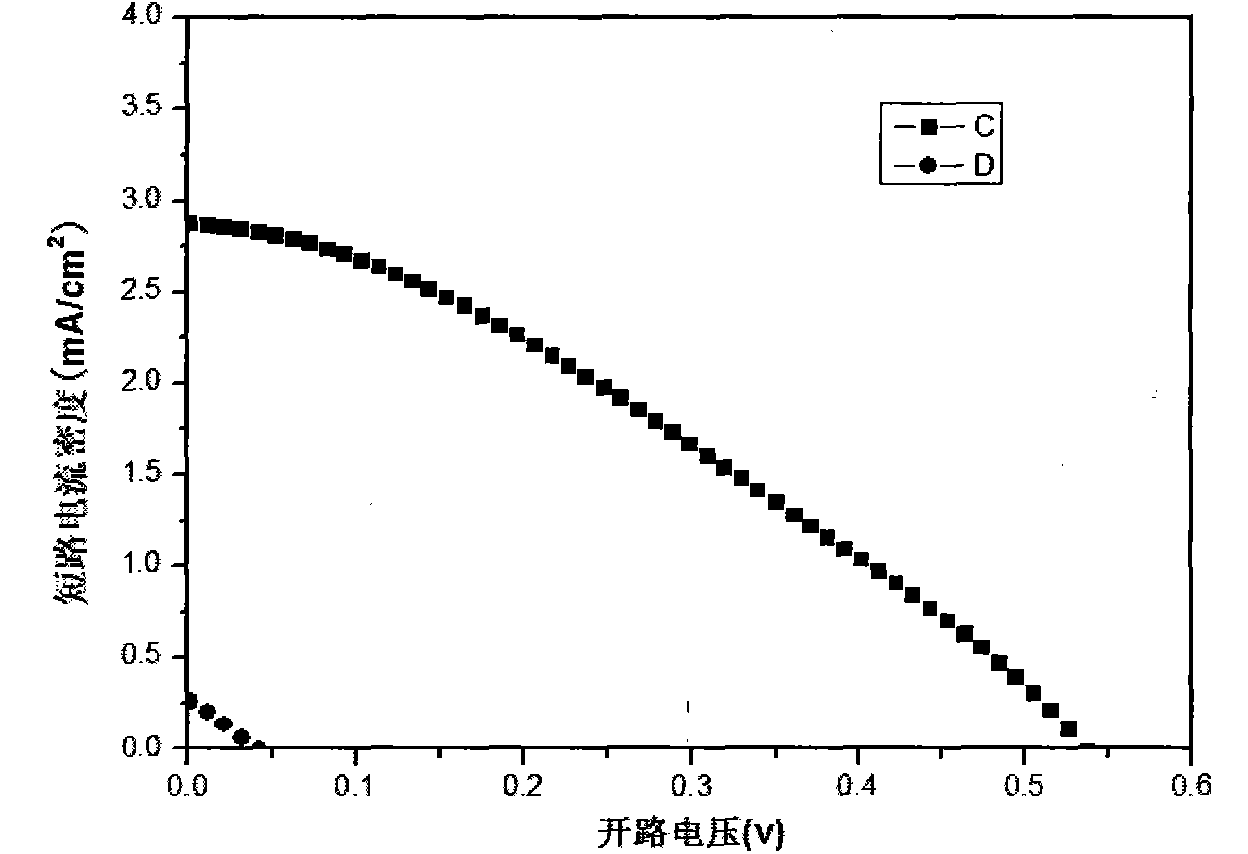

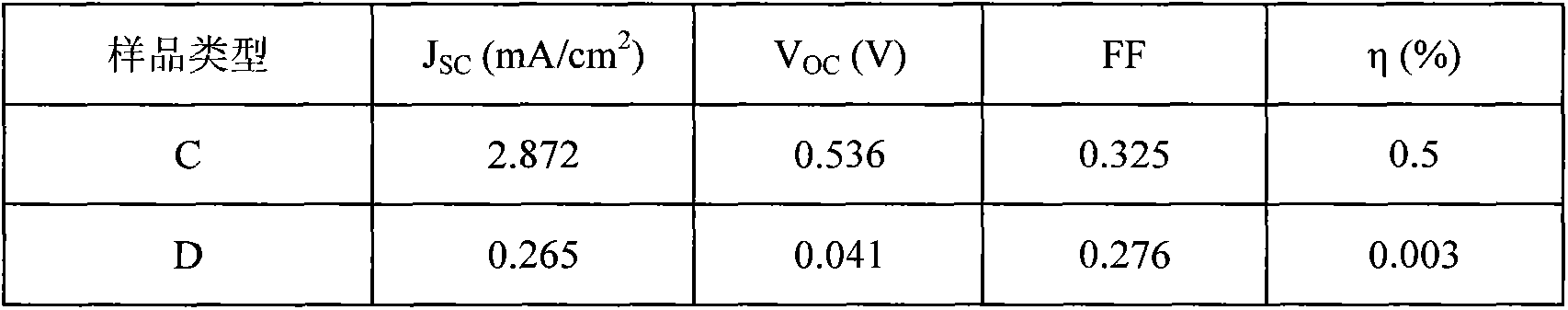

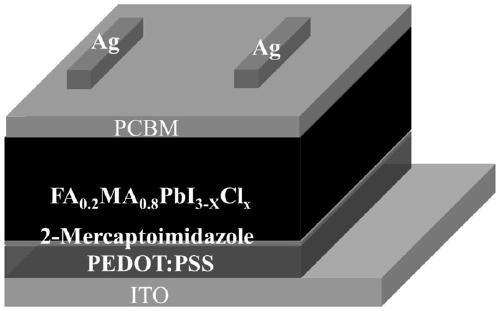

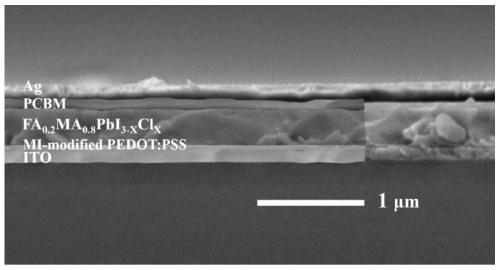

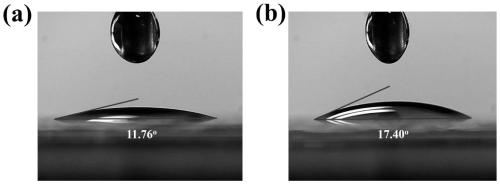

Perovskite solar cell with high short-circuit current and high conversion efficiency and preparation method thereof

ActiveCN111430548AIncrease transfer rateReduced compound centerFinal product manufactureSolid-state devicesElectrical batteryEngineering

The invention relates to a perovskite solar cell with high short-circuit current and high conversion efficiency and a preparation method thereof, and belongs to the technical field of photovoltaics. The perovskite solar cell is formed by stacking a substrate layer, a hole transport layer, a 2-mercapto imidazole layer, an FA0. 2MA0. 8PbI3-xClx perovskite light absorption layer, an electron transport layer and a metal back electrode in sequence from bottom to top. The 2-mercapto imidazole layer in the solar cell can well modify the defects on the FA0. 2MA0. 8PbI3-xClx perovskite light absorptionlayer, and the recombination center on the FA0. 2MA0. 8PbI3-xClx perovskite light absorption layer is reduced, so that the non-radiative recombination is reduced, and the dark current is reduced. Thenon-radiative recombination is reduced, and the hole transmission rate is increased, so that the short-circuit current of the perovskite solar cell is improved, and the conversion efficiency is improved. The preparation method of the perovskite solar cell is simple and easy to operate, can be directly popularized at a large scale in industrial production, and has the potential application value at the aspect of solar cells.

Owner:CHONGQING UNIV

A kind of preparation method of graphene/gallium arsenide solar cell

ActiveCN106449791BLow densityReduce widthFinal product manufacturePhotovoltaic energy generationFill factorGallium arsenide

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Nonpolar self-supporting Gan-based pin ultraviolet photodetector and preparation method

ActiveCN110137277BReduce mismatchImprove quantum efficiencyFinal product manufactureSemiconductor devicesPhotovoltaic detectorsPhotodetector

The invention discloses a nonpolar self-supporting GaN-based pin ultraviolet photodetector and a preparation method thereof. The detector comprises a nonpolar self-supporting GaN substrate, an n-type GaN layer, an n-type Al x1 Ga 1‑x1 N graded layer, intrinsic Al x2 Ga 1‑x2 N layer, p-type Al y1 Ga 1‑y1 N / Al y2 Ga 1‑y2 The N superlattice layer and the p-type GaN capping layer are arranged sequentially from bottom to top; the back of the non-polar self-supporting GaN substrate is connected to the n-type ohmic electrode; the upper surface of the p-type GaN capping layer is connected to the p-type ohmic electrode . The detector solves the problems of large polarization electric field, lattice mismatch between the epitaxial layer and the substrate, difficult p-type doping, and uneven internal electric field, and simplifies the preparation process of the ultraviolet photodetector chip.

Owner:JIANGSU INST OF ADVANCED SEMICON CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com