Perovskite solar cell with high short-circuit current and high conversion efficiency and preparation method thereof

A solar cell and short-circuit current technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as unfavorable commercialization and unfavorable environment, and achieve the effects of reducing dark current, reducing non-radiative recombination, and improving conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

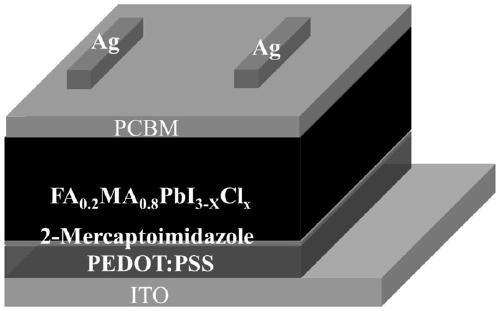

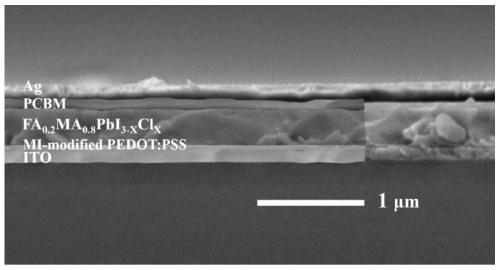

[0048] Preparation of perovskite solar cells with high short-circuit current and high conversion efficiency

[0049] (1) Wash the 15mm×15mm ITO with detergent, deionized water, absolute ethanol, acetone, and isopropanol for 30 minutes, then dry it with a nitrogen gun, and then treat it with UV for 30 minutes;

[0050] (2) Drop the PEDOT:PSS solution filtered through a 0.25 μm syringe filter onto the ITO treated in step (1), then spin-coat at 8000 rpm for 40 seconds, and finally anneal at 125°C for 15 minutes to prepare Obtain PEDOT:PSS hole transport layer;

[0051] (3) After preheating the composite layer formed by ITO and PEDOT:PSS hole transport lamination at 50 °C for 3 min, add 70 μL of 2-mercaptoimidazole isopropanol solution with a concentration of 1 mg / mL dropwise into step (2) PEDOT: On the PSS hole transport layer, then spin-coat 30s with the speed of 6000rpm, make the 2-mercaptoimidazole layer of thickness≤1nm;

[0052] (4) The composite layer formed by laminating...

Embodiment 2

[0057] Preparation of perovskite solar cells with high short-circuit current and high conversion efficiency

[0058] (1) Wash the 15mm×15mm ITO with detergent, deionized water, absolute ethanol, acetone, and isopropanol for 30 minutes, then dry it with a nitrogen gun, and then treat it with UV for 30 minutes;

[0059] (2) Add the PEDOT:PSS solution filtered through a 0.25 μm syringe filter dropwise onto the ITO treated in step (1), then spin-coat at 6000 rpm for 60 seconds, and finally anneal at 130°C for 25 minutes to prepare Obtain PEDOT:PSS hole transport layer;

[0060] (3) After preheating the composite layer formed by ITO and PEDOT:PSS hole transport lamination at 70 °C for 5 min, add 80 μL of 2-mercaptoimidazole isopropanol solution with a concentration of 3 mg / mL dropwise into step (2) On the PEDOT:PSS hole transport layer, spin coating 40s with the speed of 8000rpm then, make the 2-mercaptoimidazole layer of thickness≤1nm;

[0061] (4) The composite layer formed by ...

Embodiment 3

[0066] Preparation of perovskite solar cells with high short-circuit current and high conversion efficiency

[0067] (1) Wash the 15mm×15mm ITO with detergent, deionized water, absolute ethanol, acetone, and isopropanol for 30 minutes, then dry it with a nitrogen gun, and then treat it with UV for 30 minutes;

[0068] (2) Drop the PEDOT:PSS solution filtered through a 0.25 μm syringe filter onto the ITO treated in step (1), then spin-coat at 4000 rpm for 50 seconds, and finally anneal at 120 ° C for 20 minutes to prepare Obtain PEDOT:PSS hole transport layer;

[0069] (3) After preheating the composite layer formed by ITO and PEDOT:PSS hole transport lamination at 60 °C for 4 min, add 60 μL of 2-mercaptoimidazole isopropanol solution with a concentration of 6 mg / mL dropwise into step (2) PEDOT: on the PSS hole transport layer, spin coating 35s with the speed of 4000rpm then, make the 2-mercaptoimidazole layer of thickness≤1nm;

[0070] (4) The composite layer formed by lamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com