Photocatalyst as well as preparation method and application thereof

A photocatalyst and protonization technology, applied in chemical instruments and methods, physical/chemical process catalysts, inorganic chemistry, etc., can solve problems such as poor photocatalytic performance, achieve simple operation, reduce recombination centers, and improve interfacial transfer effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

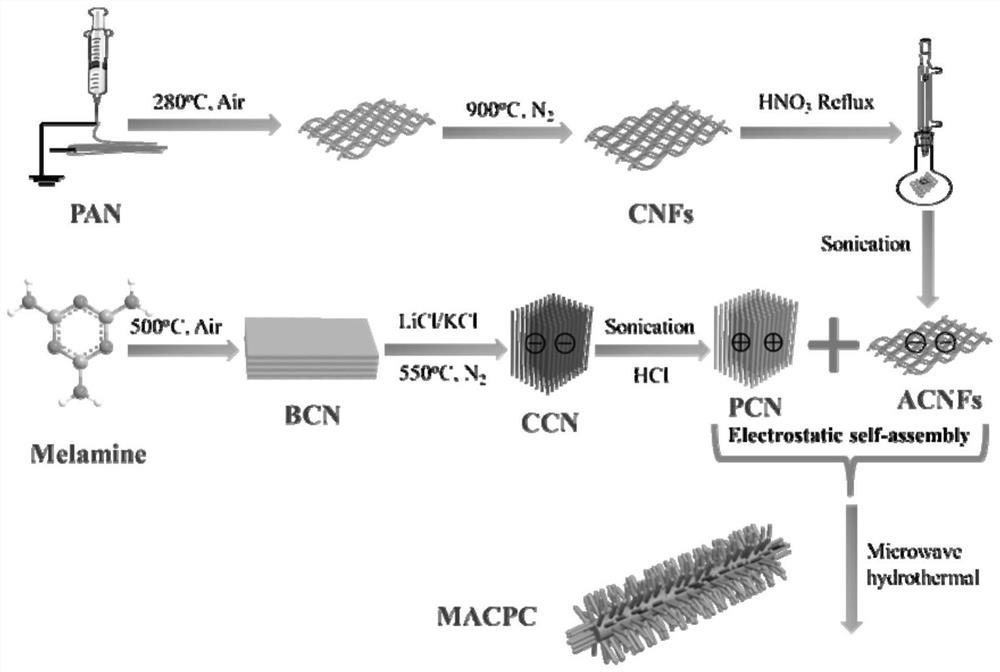

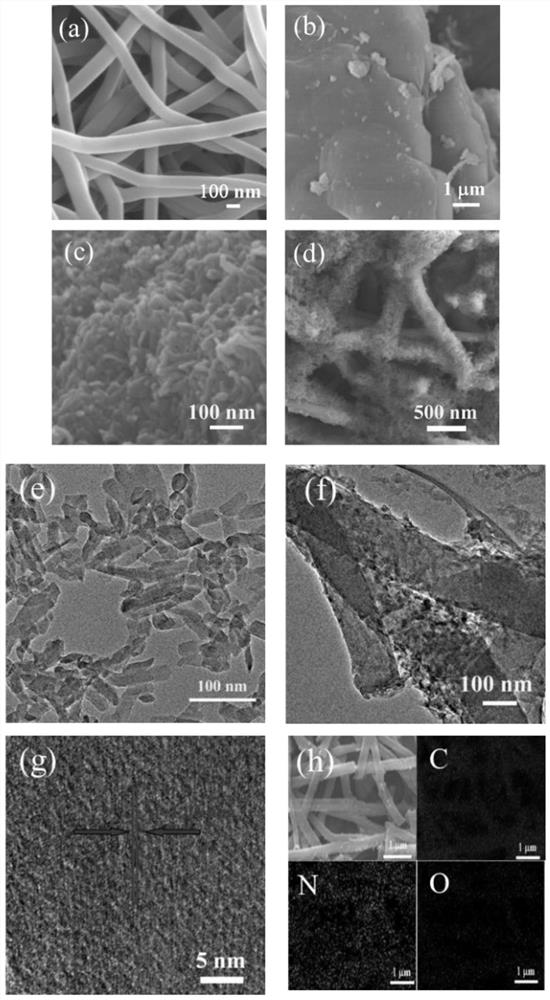

[0072] This embodiment relates to a photocatalyst, such as figure 1 As shown, it is prepared according to the following steps:

[0073] S1, BCN (block g-C 3 N 4 ) preparation:

[0074] 5 g of melamine was calcined at 500° C. for 4 hours at a heating rate of 10° C. / min under an air atmosphere in a muffle furnace to obtain a pale yellow product BCN.

[0075] S2, PCN (protonated crystal g-C 3 N 4 ) preparation:

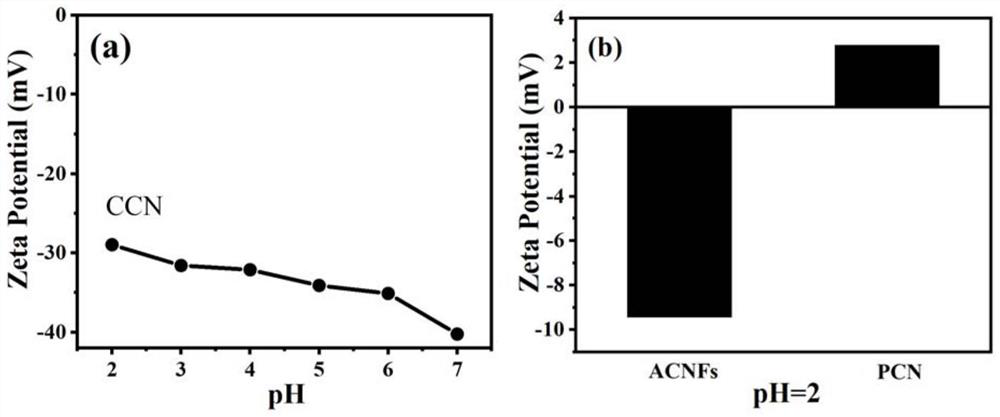

[0076] The product BCN obtained in step S1 was ground to obtain powder A; 1 g of powder A was thoroughly ground in a glove box with 5.5 g KCl and 4.5 g LiCl, and then the mixture was heated to 550 ° C in a tube furnace under a nitrogen atmosphere and kept for 4 hours, to obtain mixture B; the cooled mixture B was washed with a large amount of boiling deionized water to the neutrality of the supernatant, filtered and centrifuged and then vacuum-dried at 80°C to obtain CCN (crystalline carbon nitride); 100 mg of CCN was ultrasonically dispersed in 50 ml of PH=2 hydr...

Embodiment 2

[0097] This embodiment relates to a kind of photocatalyst, and the difference between this embodiment and Embodiment 1 is that, in this embodiment, S4, MACPC (acidic carbon nanofiber / protonated crystallization g-C 3 N 4 Photocatalyst) preparation comprises the following steps:

[0098] Sonicate 5 mg of acidic carbon nanofibers in 2 mL of deionized water for 3 min to form a black suspension D; transfer 80 μl of suspension D to the protonated crystalline carbon nitride solution and continue to sonicate for 10 min to obtain a mixture E; Mixture E was transferred to a 35 ml quartz container and treated in a microwave instrument with a power of 50 W at 120 °C for 20 minutes to obtain product F; product F was washed several times with deionized water and then dried under vacuum at 80 °C , get MACPC. The acidic carbon nanofiber content in the obtained MACPC is 0.5%.

Embodiment 3

[0100] This embodiment relates to a kind of photocatalyst, and the difference between this embodiment and Embodiment 1 is that, in this embodiment, S4, MACPC (acidic carbon nanofiber / protonated crystallization g-C 3 N 4 Photocatalyst) preparation comprises the following steps:

[0101] Sonicate 8 mg of acidic carbon nanofibers in 2 mL of deionized water for 3 min to form a black suspension D; transfer 80 μl of suspension D to the protonated crystalline carbon nitride solution and continue sonication for 10 min to obtain a mixture E; Mixture E was transferred to a 35 ml quartz container and treated in a microwave instrument with a power of 50 W at 120 °C for 20 minutes to obtain product F; product F was washed several times with deionized water and then dried under vacuum at 80 °C , get MACPC. The acidic carbon nanofiber content in the obtained MACPC is 2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com