Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Reduce thermal contraction coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Special material for UHMWPE (Ultrahigh molecular weight polyethylene) alloy capacity increasing and toughening modified polypropylene corrugated pipe and preparation method of special material

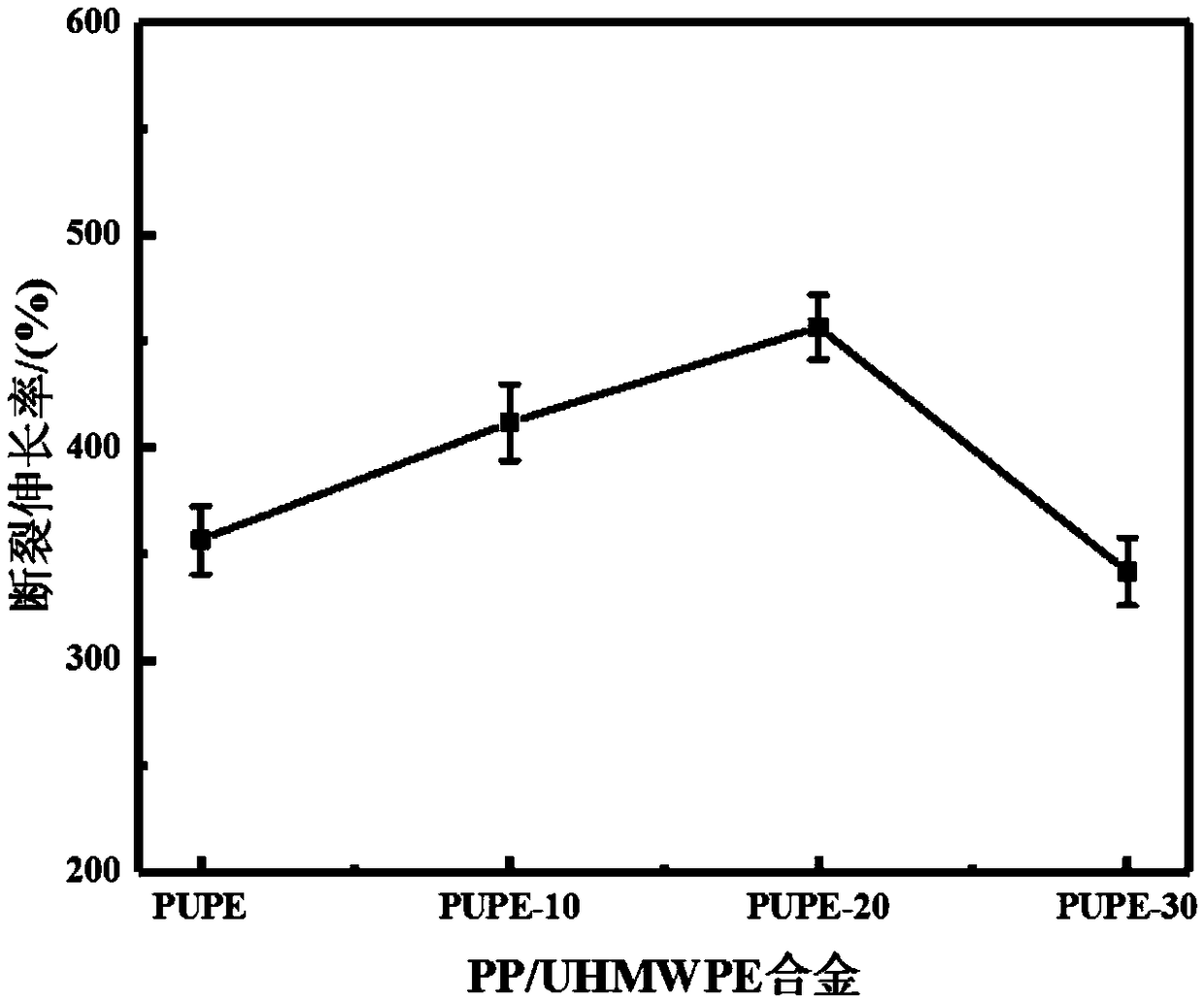

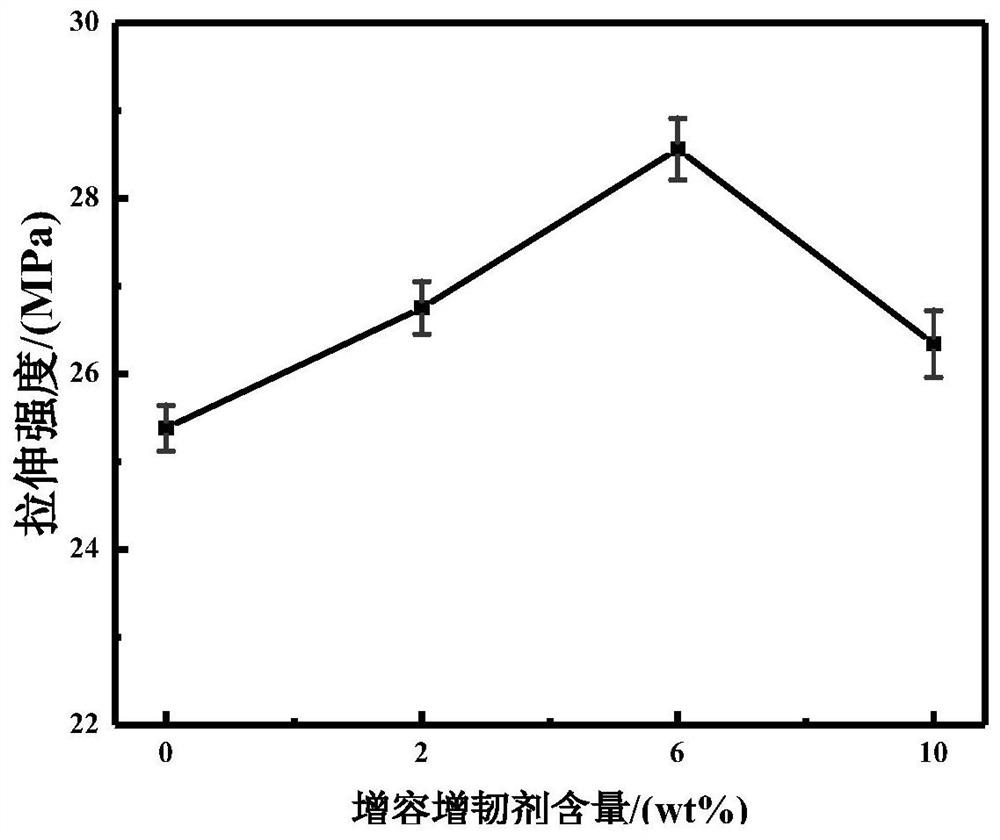

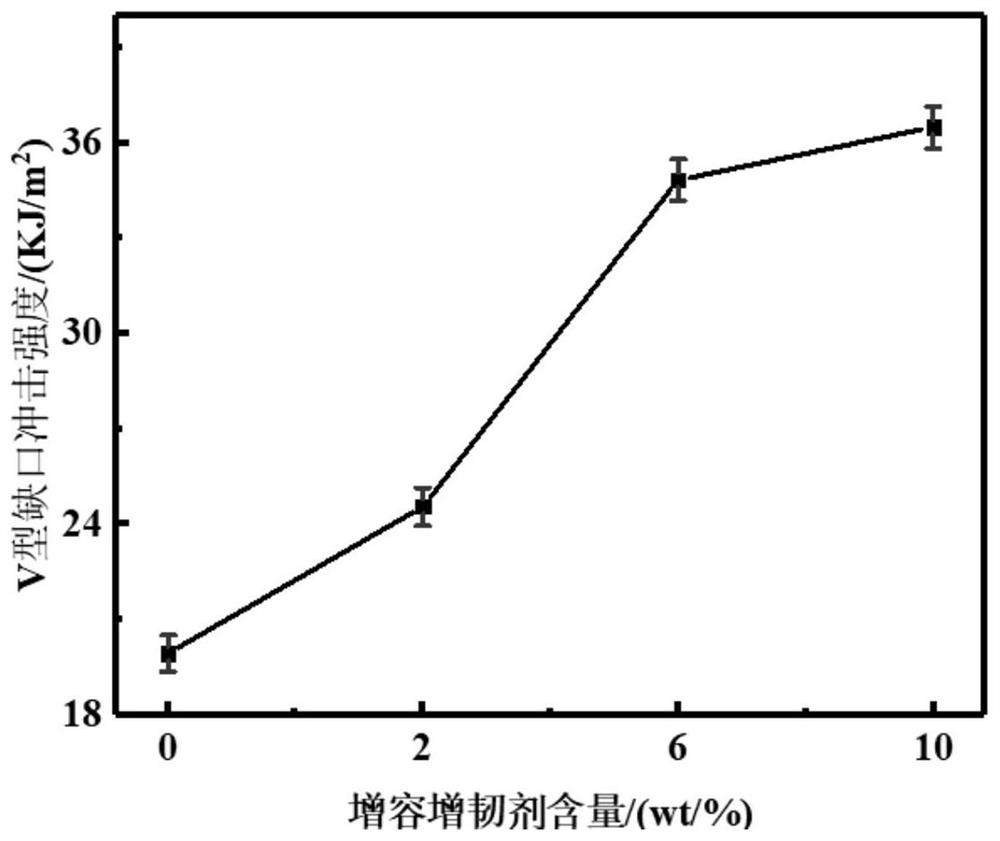

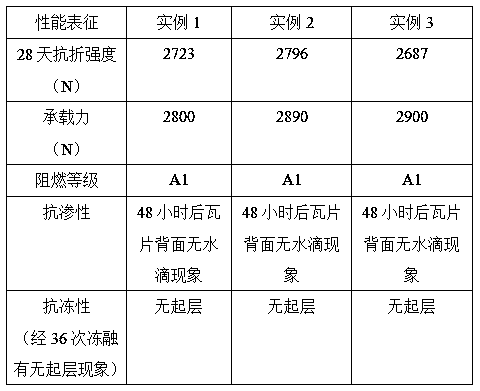

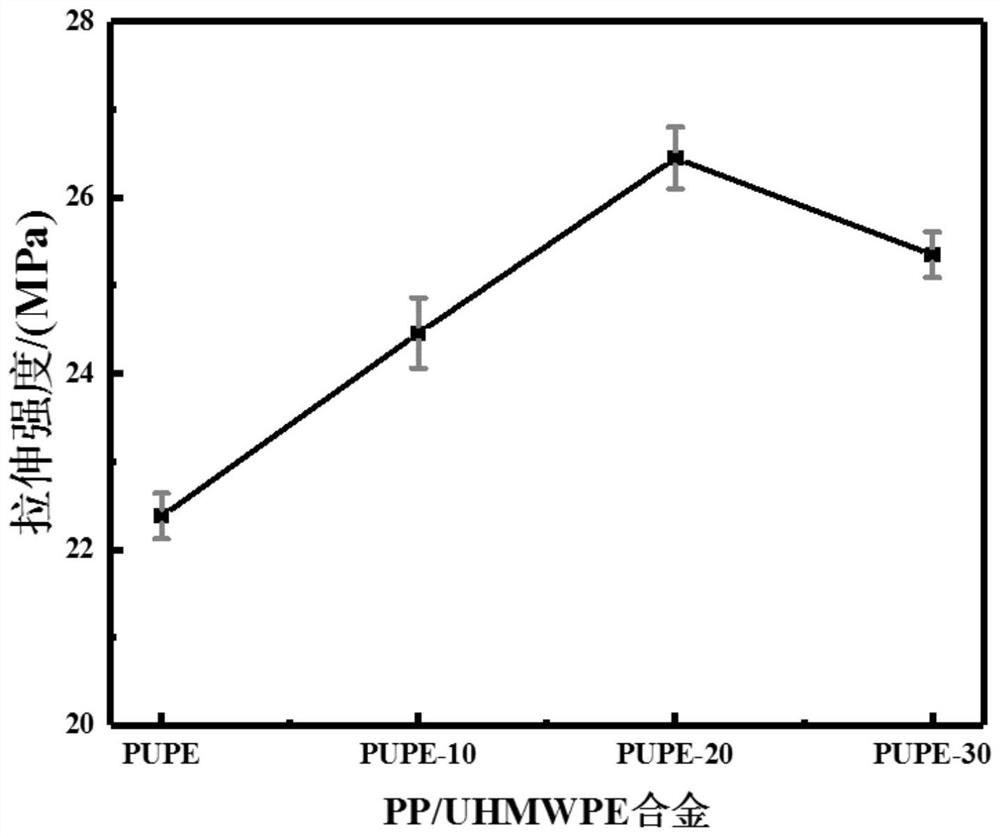

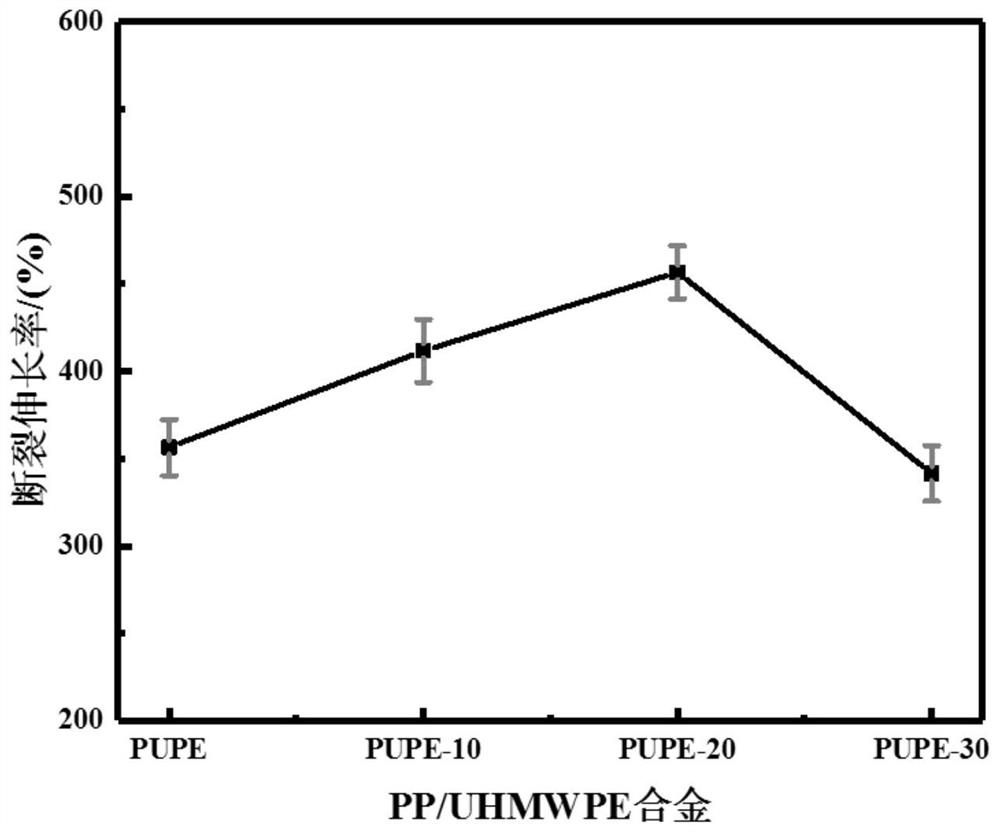

The invention discloses a special material for an UHMWPE (Ultrahigh molecular weight polyethylene) alloy capacity increasing and toughening modified polypropylene corrugated pipe and a preparation method of the special material. The special material comprises, by weight, 60-85 parts of block co-polypropylene granules, 5-10 parts of fillers, 5-30 parts of capacity increasing and toughening agents and 1-5 parts of flowability modifiers. The corrugated pipe produced by the special material has the advantages of good mechanical properties, better low-temperature impact resistance, high heat distortion temperature, high heat conductivity coefficient, good flame resistance, good surface glossiness, good production stability and the like.

Owner:FUJIAN NORMAL UNIV

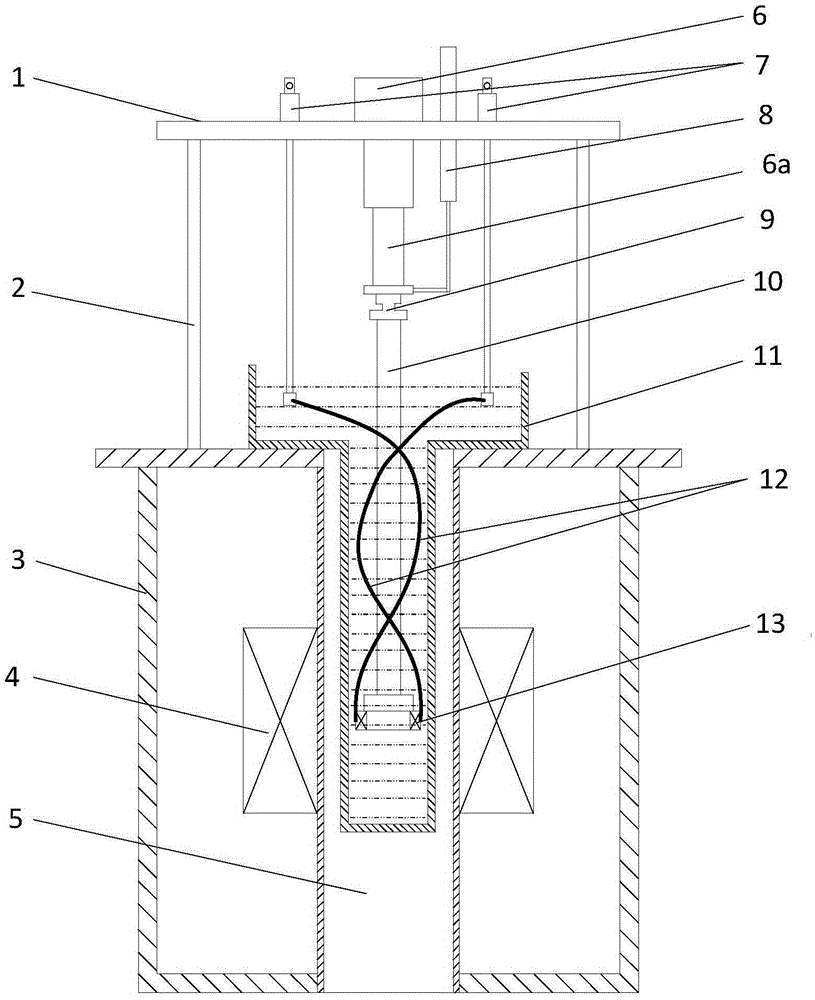

Device for testing magnetic levitation characteristics of high-temperature superconducting coil in variable high magnetic field

InactiveCN105372608AReliable magnetic levitation performance test dataTest magnetic levitation performanceMeasurements using levitation techniquesLiquid nitrogen containerEngineering

The invention discloses a device for testing magnetic levitation characteristics of a high-temperature superconducting coil in a variable high magnetic field. The device is characterized in that an insulated support plate is fixed at the top of a Dewar through support rods, a servo motor is arranged on the support plate, and a downward motor shaft of the servo motor sequentially passes through a guide rod, a tri-axial force sensor and a dowel bar to be connected with the high-temperature superconducting coil; a sensing head of a displacement sensor on the support plate is connected with the guide rod; a T-shaped liquid nitrogen container with open upper part is laid in a room temperature hole in the middle of the Dewar, the high-temperature superconducting coil is located at the middle-lower part of the inner chamber of the T-shaped liquid nitrogen container, and terminals of the high-temperature superconducting coil are connected with current lead junction poles on the support rod through current leads; an annular superconducting magnet is arranged on a chamber wall, surrounding the room temperature hole, of the Dewar. The device can test the magnetic levitation characteristics of the high-temperature superconducting coil in the variable high magnetic field, so that reliable magnetic levitation characteristic test data can be provided for design and development of high-temperature superconducting magnetically levitated trains.

Owner:SOUTHWEST JIAOTONG UNIV

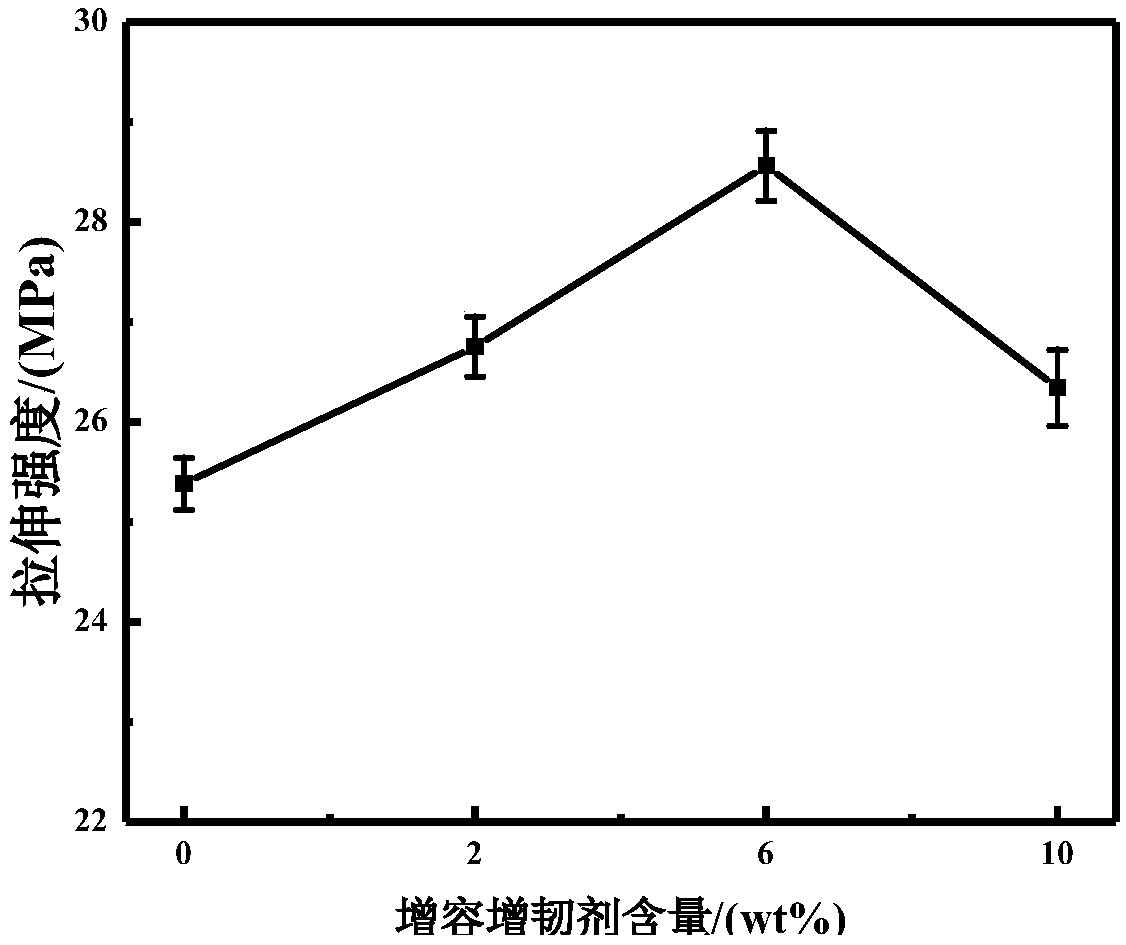

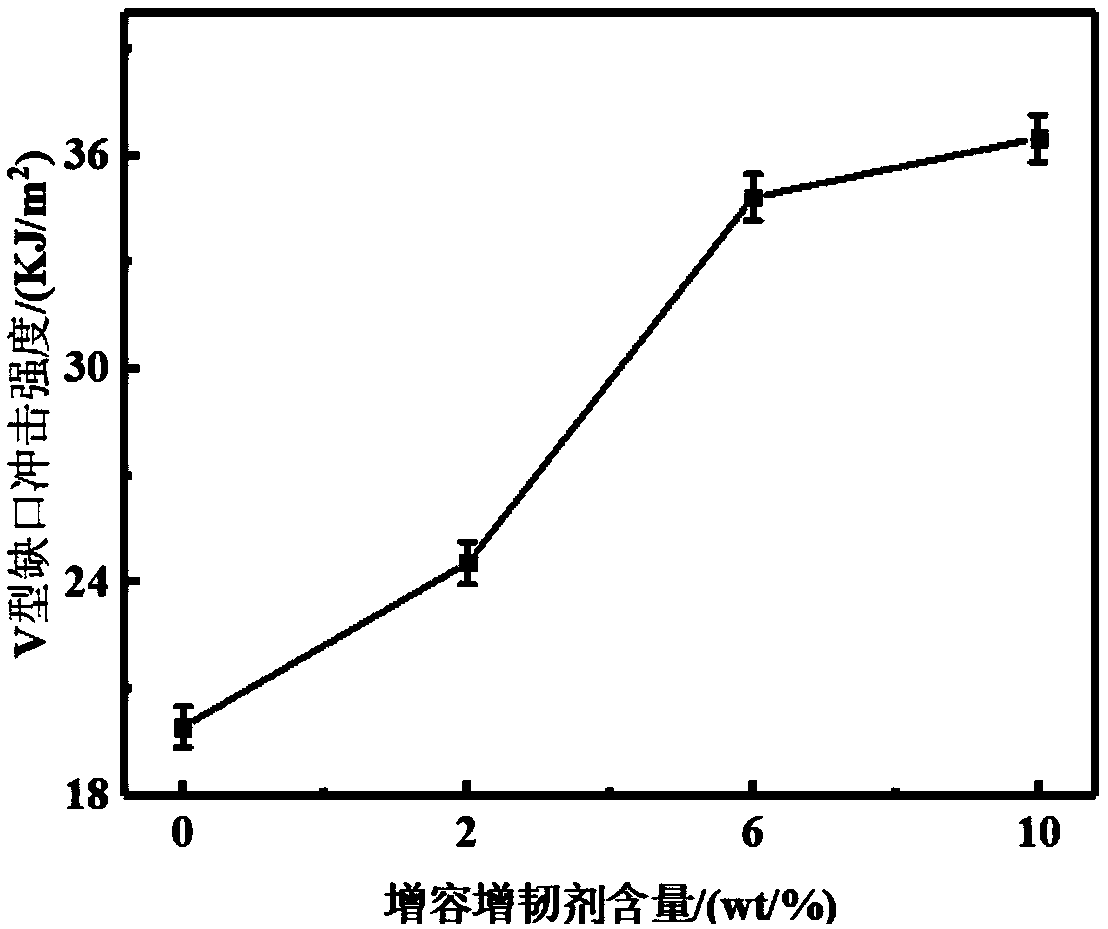

High-performance functionalized alloy modified polypropylene corrugated pipe special-use material and preparation method thereof

ActiveCN109401045AImprove low temperature toughnessHigh surface glossHeat deflection temperatureAntioxidant

The invention discloses a high-performance functionalized alloy modified polypropylene corrugated pipe special-use material and a preparation method thereof. The special-use material includes, by weight, 40-70 parts of homo-polypropylene powder, 15-25 parts of block-copolymerized polypropylene powder, 3-15 parts of filler, 2-10 parts of a compatibilizing and toughening agent, 1-5 parts of a flowability modifier, 1-5 parts of a flame retardant, 0.1-1.2 parts of an antioxidant, and 0.05-0.5 parts of an ultraviolet absorber. The corrugated pipe manufactured from the special-use material has goodmechanical performance and low-temperature anti-impact effect, is high in thermal-deformation temperature and heat-conductivity, and has good flame retarding effect, excellent surface glossiness and production stability.

Owner:FUJIAN NORMAL UNIV

Wave-absorbing radiation-barrier concrete

InactiveCN106699033AImprove surface physical and chemical propertiesImprove sound absorptionCeramicwareAntimony trioxideFumed silica

The invention relates to a wave-absorbing radiation-barrier concrete which comprises the following components in parts by mass: 15 parts of diatomite, 12 parts of triethylenetetramine-modified durian shell, 8 parts of chestnut shell cellulose, 1.5 parts of aerated aluminum powder, 5 parts of hollow glass microsphere, 4 parts of monoalkoxy titanate, 4 parts of polytetrafluoroethylene granule, 0.6 part of melamine, 1.2 parts of meerschaum wool, 110 parts of cement, 70 parts of natural sand stone, 6 parts of fluorogypsum, 6 parts of modified sawdust, 2.4 parts of aluminum sulfate, 2.2 parts of fly ash hollow microbead, 0.7 part of fumed silica, 1.2 parts of triethanolamine, 0.85 part of silicon nitride powder, 1.25 parts of antimony trioxide, 1 part of halogen flame retardant, 0.8 part of titanium dioxide, 0.75 part of zinc oxide, 1.5 parts of expanded perlite, 4 parts of diatomite-carried nano TiO2 material, 0.4 part of modified nano titanium dioxide, 0.25 part of conductive graphite, 1.4 parts of sodium dodecyl benzene sulfonate and 1.1 parts of isooctyl triethoxy silane.

Owner:王建英

Processing method of light-weight environment-friendly concrete

InactiveCN106630795AImprove surface physical and chemical propertiesReduce corrosionCeramicwareCelluloseMicrosphere

The invention relates to light-weight environment-friendly concrete, which is prepared from the following ingredients in parts by mass: 15 parts of diatomite, 12 parts of triethylene tetramine modified durian shells, 8 parts of chestnut shell cellulose, 1.5 parts of aerated aluminum powder, 5 parts of hollow glass microspheres, 4 parts of mono-alkoxy titanate, 4 parts of polytetrafluoroethylene particles, 0.6 part of tripolycyanamide, 1.2 parts of sepiolite fabric, 110 parts of cement, 70 parts of natural sand gravel, 6 parts of fluorgypsum, 6 parts of modified sawdust, 2.4 parts of aluminum sulfate, 2.2 parts of fly ash hollow microspheres, 1.2 parts of triethanolamine, 0.85 part of silicon nitride powder, 1.25 parts of antimonous oxide, 1 part of halogenated flame retardants, 0.8 part of titanium dioxide, 0.75 part of zinc oxide, 1.5 parts of alunite expanding agents, 1.4 parts of sodium dodecyl benzene sulfonate and 1.1 parts of isooctyltriethoxysilane.

Owner:施冬美

Processing method of antibacterial and wear-resistant aerated brick

InactiveCN106639120ATaking into account strengthTake into account the requirementsCeramic shaping apparatusBuilding componentsCelluloseBrick

The invention relates to an antibacterial and wear-resistant aerated brick. The aerated brick is characterized by being prepared from a normal triangular pyramid inner core and a square outer core, wherein the normal triangular pyramid inner core is prepared from the following raw materials in parts by mass: 10-20 parts of kieselguhr, 10-20 parts of triethylene tetramine-modified durian shell, 5-10 parts of chestnut shell cellulose, 1-2 parts of aerated aluminum powder, 3-6 parts of hollow glass microspheres, 3-5 parts of mono-alkoxy titanate, 3-5 parts of polytetrafluoroethylene particles, 0.5-1 part of melamine and 1-1.5 parts of sepiolite amianthine; the square outer core is prepared from the following raw materials in parts by mass: 12-18 parts of cement, 5-8 parts of fluorgypsum, 5-8 parts of tea dust, 2-2.5 parts of aluminum sulfate, 2-3 parts of hydroxyethyl cellulose, 1-1.4 parts of triethanolamine, 0.8-1 part of shale powder, 1-1.5 parts of antimonous oxide, 0.8-1.2 parts of a halogenated flame retardant, 0.5-1 part of titanium dioxide, 0.5-1 part of nano-zinc oxide, 1-2 parts of alpha-Al2O3 micro-powder, 1-1.5 parts of sodium dodecyl benzene sulfonate and 1-1.2 parts of isooctyl triethoxysilane. The antibacterial and wear-resistant aerated brick is prepared by arranging the normal triangular pyramid inner core in the square outer core by means of one-piece autoclaved curing molding.

Owner:孟志美

Design method of secondary cooling water in continuous casting process of high-carbon steel and preparation method of continuous casting billet

ActiveCN111590043ASmall amount of shrinkageReduce thermal contraction coefficientCarbon steelContinuous casting

The invention relates to the field of iron and steel smelting, and in particular relates to a design method of secondary cooling water in a continuous casting process of high-carbon steel and a preparation method of continuous casting billet. The cooling water quantity of each area of a secondary cooling area is distributed according to the formula A*V<2>+B*V+C, wherein for the foot roller area, Ais 0.18 to 0.22, B is 1.39 to 1.43, and C is 0.92 to 0.96; for the area I, A is 0.82 to 0.86, B is -0.97 to -1.01, and C is 2.75 to 2.79; for the area II, A is 0.45 to 0.49, B is -0.25 to -0.29, andC is 0.75 to 0.79; and for the area III, A is 0 to 0.04, B is 1 to 1.05, and C is -1.1 to -1.16. With the methods, when the pulling speed of the high-carbon steel casting billet is controlled to be 1.1 m / min-2.1 m / min, the casting billet has no surface or internal cracks or center segregation, and the bleed-out rate during pouring is the minimum.

Owner:SGIS SONGSHAN CO LTD

Processing method of low-shrinkage concrete

InactiveCN106587775AImprove physical and chemical propertiesImprove shrinkageCeramicwareFiberAntimony trioxide

The invention relates to low-shrinkage concrete. The low-shrinkage concrete comprises the following components in parts by mass: diatomite 10-20 parts, triethylene tetramine modified durian shells 10-20 parts, chestnut shell cellulose 5-10 parts, aerated aluminium powder 1-2 parts, hollow glass microbeads 3-6 parts, monoalkoxy type titanate 3-5 parts, polytetrafluoroethylparticle particles 3-5 parts, melamine 0.5-1 part, a sepiolite fabric 1-1.5 parts, cement 100-120 parts, flyash 5-8 parts, natural sand stone 75-88 parts, aluminum sulfate 2-2.5 parts, brucite fibers 2-3 parts, triethanolamine 1-1.4 parts, eakleite powder 0.8-1 part, antimonous oxide 1-1.5 parts, a halogenated flame retardant 0.8-1.2 parts, titanium dioxide 0.5-1 part, zinc oxide 0.5-1 part, modified bentonite 1-2 parts, sodium dodecylbenzene sulfonate 1-1.5 parts and isooctyltriethoxysilane 1-1.2 parts.

Owner:于银兰

Processing method of sound-proof combined aerated brick

InactiveCN106699032APrecise positioningEasy to useConstruction materialNon-macromolecular adhesive additivesPrismAntimony trioxide

The invention relates to a sound-proof combined aerated brick. The sound-proof combined aerated brick comprises a normal-triple-prism inner core and a square outer core, wherein the normal-triple-prism inner core is prepared from components in parts by mass as follows: 15 parts of diatomite, 12 parts of triethylene tetramine modified durian shells, 8 parts of chestnut shell cellulose, 1.5 parts of aerated aluminum powder, 5 parts of hollow glass beads, 4 parts of mono-alkoxy titanate, 4 parts of polytetrafluoroethylene particles, 0.6 parts of melamine and 1.2 parts of sepiolite fabric; the square outer core is prepared from components in parts by mass as follows: 16 parts of cement, 6 parts of fluorgypsum, 6 parts of modified saw dust, 2.4 parts of aluminum sulfate, 2.2 parts of hollow fly-ash beads, 0.7 parts of fumed silica, 1.2 parts of triethanolamine, 0.85 parts of silicon nitride powder, 1.25 parts of antimonous oxide, 1 part of a halogenated flame retardant, 0.8 parts of titanium dioxide, 0.75 parts of zinc oxide, 1.5 parts of expanded perlite, 1.4 parts of sodium dodecyl benzene sulfonate and 1.1 parts of isooctyltriethoxysilane.

Owner:施冬美

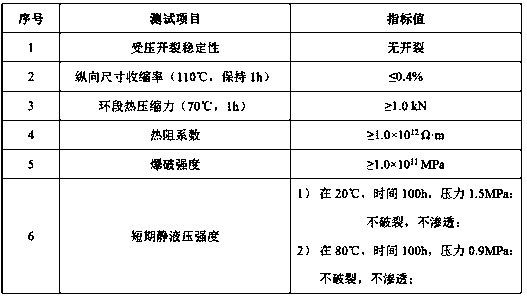

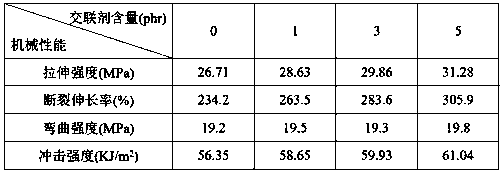

Special material for heatproof polyethylene steel skeleton reinforced composite pipeline, and preparation method thereof

InactiveCN110746679AImprove low temperature toughnessHigh surface glossHeat deflection temperaturePolymer science

The invention discloses a special material for a heatproof polyethylene steel skeleton reinforced composite pipeline, and a preparation method thereof. The special material comprises, by weight, 70-90parts of polyethylene (PE), 5-15 parts of a filler, 3-10 parts of a chain extender, 1.5-5 parts of a fluidity modifier, 0.3-1.2 parts of an antioxidant, 0.2-0.5 part of an ultraviolet absorber and 3-5 parts of a crosslinking agent. The heatproof polyethylene steel skeleton reinforced composite pipeline produced from the special material has the characteristics of good mechanical properties, goodlow-temperature impact resistance, high heat deformation temperature, good surface gloss, good production stability and the like.

Owner:FUJIAN NORMAL UNIV

Method for processing insect prevention and insect repelling integrated aerated bricks

InactiveCN106588112APrecise positioningEasy to useConstruction materialCeramicwareSodium BentoniteAntimony trioxide

The invention relates to a method for processing insect prevention and insect repelling integrated aerated bricks. The aerated bricks are prepared from, by mass, 10-20 parts of diatomite, 10-20 parts of triethylene tetramine modified durian shells, 5-10 parts of chestnut shell cellulose, 1-2 parts of aerated aluminum powder, 3-6 parts of hollow glass microspheres, 3-5 parts of mono-alkoxy titanate, 3-5 parts of polytetrafluoroethylene particles, 0.5-1 part of melamine, 1-1.5 parts of sepiolite fabric, 100-120 parts of cement, 5-8 parts of coal ash, 75-88 parts of natural gravels, 2-2.5 parts of aluminum sulfate, 2-3 parts of brucite fibers, 1-1.4 parts of triethanolamine, 0.8-1 part of xonotlite powder, 1-1.5 parts of antimonous oxide, 0.8-1.2 parts of halogen flame retardants, 0.5-1 part of titanium dioxide, 0.5-1 part of zinc oxide, 1-2 parts of modified bentonite, 1-1.5 parts of sodium dodecyl benzene sulfonate and 1-1.2 parts of isooctyl triethoxy silane.

Owner:于银兰

Processing method of air entrained brick used for sunny slope wall body

InactiveCN106699019APrecise positioningEasy to useConstruction materialNon-macromolecular adhesive additivesPolyesterAntimony trioxide

The invention relates to an air entrained brick used for a sunny slope wall body. The air entrained brick comprises a normal triple prism inner core and a square outer core, wherein the normal triple prism inner cover comprises the following components in parts by mass: 15 parts of diatomite, 12 parts of triethylene tetramine modified durian shells, 8 parts of chestnut shell cellulose, 1.5 parts of air entrained aluminum powder, 5 parts of hollow glass beads, 4 parts of mono-alkoxy type titanate, 4 parts of polytetrafluoroethylene, 0.6 part of melamine and 1.2 parts of sepiolite fabric; and the square outer core comprises the following components in parts by mass: 16 parts of cement, 6 parts of fluorgypsum, 6 parts of cocoanut charcoal modified polyester fiber, 2.4 parts of aluminum sulfate, 2.2 parts of hydroxyethyl cellulose, 1.2 parts of triethanolamine, 0.85 part of shale powder, 1.25 parts of antimony trioxide, 1 part of a halogen flame retardant, 0.8 part of titanium dioxide, 0.75 part of zinc oxide, 1.5 parts of an alunite expanding agent, 1.4 parts of sodium dodecyl benzene sulfonate and 1.1 parts of isooctyl triethoxy silane.

Owner:沈爱琴

Processing method of concrete for anti-scaling wall

InactiveCN106588114AImprove surface physical and chemical propertiesImprove high temperature resistanceCeramicwareCelluloseFiber

The invention relates to concrete for an anti-scaling wall. The concrete for the anti-scaling wall is prepared from diatomite, triethylene tetramine modified durian shell, chestnut shell cellulose, aerated aluminum powder, hollow glass beads, mono-alkoxy titanate, polytetrafluoroethylene particles, melamine, a sepiolite fabric, cement, pulverized fuel ash, natural gravels, aluminum sulfate, brucite fiber, triethanolamine, shale powder, antimony trioxide, a halogen flame-retardant, titanium dioxide, zinc oxide, modified bentonite, sodium dodecyl benzene sulfonate and isooctyl triethoxy silane. A triangular pyramid inner core is arranged in a square outer core for integrated autoclaved curing and forming.

Owner:朱海东

Processing method of high-toughness combined aerated brick

The invention relates to a high-toughness combined aerated brick. The high-toughness combined aerated brick comprises a regular triangular pyramid inner core and a square outer core, wherein the regular triangular pyramid inner core is prepared from the following raw materials in parts by mass: 15 parts of kieselguhr, 12 parts of triethylene tetraamine modified durian shell, 8 parts of chestnut shell cellulose, 1.5 parts of aerated aluminum powder, 5 parts of hollow glass beads, 4 parts of mono-alkoxy type titanate, 4 parts of polytetrafluoroethylene particles, 0.6 part of melamine and 1.2 parts of sepiolite fabric; the square outer core is prepared from the following raw materials in parts by mass: 16 parts of cement, 6 parts of fluorgypsum, 6 parts of ceramic fiber, 2.4 parts of aluminum sulfate, 2.2 parts of hollow fly-ash beads, 1.2 parts of triethanolamine, 0.85 part of silicon nitride powder, 1.25 parts of antimonous oxide, 1 part of halogenated flame retardant, 0.8 part of titanium dioxide, 0.75 part of zinc oxide, 1.5 part of expanded perlite, 1.4 parts of sodium dodecyl benzene sulfonate and 1.1 parts of alkyl succinimide.

Owner:朱海东

Processing method of straw gypsum board

The invention relates to a straw gypsum board. The straw gypsum board is characterized by comprising the following components in parts by mass: 35 to 50 parts of gypsum powder, 10 to 20 parts of straws which are crushed into a size of 4 to 8 cm, 5 to 10 parts of clay, 1 to 2 parts of aerated aluminum powder, 3 to 6 parts of aluminum silicate fibers, 1 to 1.5 parts of sepiolite fabric, 5 to 8 partsof fluorgypsum, 5 to 8 parts of modified sawdust, 2 to 2.5 parts of aluminum sulfate, 2 to 3 parts of activated basic magnesium sulfate whisker, 0.5 to 0.8 part of gaseous silicon dioxide, 1 to 1.4 parts of triethanolamine, 0.8 to 1 part of silicon nitride powder, 1 to 1.5 parts of antimony trioxide, 0.8 to 1.2 parts of halogen flame-retardant agent, 0.5 to 1 part of titanium dioxide, 0.5 to 1 part of zinc oxide, 1 to 2 parts of an alunite expanding agent, 5 to 8 parts of aluminum sol, and 10 to 20 parts of white latex.

Owner:于银兰

Design method of secondary cooling water and preparation method of continuous casting slab in high carbon steel continuous casting process

ActiveCN111590043BSmall amount of shrinkageReduce thermal contraction coefficientMaterials scienceContinuous casting

The present application relates to the field of iron and steel smelting, and in particular, to a method for designing secondary cooling water in a continuous casting process of high carbon steel and a method for preparing a continuous casting billet. The amount of cooling water in each zone of the secondary cooling zone is based on the formula A×V 2 +B×V+C allocation. Foot roller area: A is 0.18-0.22; B is 1.39-1.43; C is 0.92-0.96; Area 1: A is 0.82-0.86; B is -0.97--1.01; C is 2.75-2.79; Area 2: A 0.45-0.49; B is -0.25--0.29; C is 0.75-0.79; three zones: A is 0-0.04; B is 1-1.05; C is -1.1--1.16. The method can ensure that when the pulling speed of the high carbon steel billet is controlled within 1.1m / min to 2.1m / min, the billet has no surface, internal cracks, no center segregation, and the leakage rate during casting is minimal.

Owner:SGIS SONGSHAN CO LTD

Processing method of aerated brick for wall body in tropical-marine-climate region

InactiveCN106631125APrecise positioningEasy to useConstruction materialCeramic shaping apparatusCelluloseBrick

The invention relates to an aerated brick for a wall body in a tropical-marine-climate region. The aerated brick comprises a regular-triangular-pyramid inner core and a square outer core, wherein the regular-triangular-pyramid inner core is prepared from the following materials in parts by mass: 15 parts of diatomite, 12 parts of triethylene tetramine modified durian shell, 8 parts of chestnut shell cellulose, 1.5 parts of aerating aluminum powder, 5 parts of hollow glass bead, 4 parts of mono-alkoxy titanate, 4 parts of polytetrafluoroethylene particle, 0.6 part of melamine and 1.2 parts of sepiolite floss; the square outer core is prepared from the following materials in parts by mass: 16 parts of cement, 6 parts of fluorgypsum, 6 parts of modified saw powder, 2.4 parts of aluminum sulfate, 2.2 parts of hydroxyethyl cellulose, 1.2 parts of triethanolamine, 0.85 parts of silicon nitride powder, 1.25 parts of antimonous oxide, 1 part of halogen fire retardant, 0.8 part of titanium dioxide, 0.75 part of zinc oxide, 1.5 parts of expanded perlite, 1.4 parts of sodium dodecyl benzene sulfonate and 1.1 parts of isooctyl triethoxysilane.

Owner:孟志美

A processing technology of stone composite board

ActiveCN112976707BPreserve the decorative beautification effectOvercome the defect of easy breakageAntifouling/underwater paintsLayered productsCoated surfaceAdhesive

The invention relates to the technical field of building decoration materials, and provides a processing technology for stone composite boards, which includes the following steps: (1) polishing both sides of marble to make the surface of the marble have a certain roughness, and then cleaning and drying the marble; (2) Apply adhesive on one side of the marble, and then bond the substrate on this surface of the marble; (3) Repeat step (2) on the other side of the marble; (4) Cut in half from the middle of the marble , forming two identical semi-finished stone composite boards; (5) coating the cut surface of the marble with an anti-slip composition, and performing fine grinding and polishing on the coated surface to obtain a stone composite board. It solves the problem that the function of the stone composite board made of existing marble is relatively single.

Owner:盛达建材集团有限公司

A kind of high-performance functionalized alloy modified polypropylene bellows special material and preparation method thereof

Owner:FUJIAN NORMAL UNIV

Processing technology of stone composite board

ActiveCN112976707APreserve the decorative beautification effectOvercome the defect of easy breakageAntifouling/underwater paintsLayered productsCoated surfaceAdhesive

The invention relates to the technical field of building decoration materials, and provides a processing technology of a stone composite board, which comprises the following steps: (1) polishing two surfaces of marble to enable the surface of the marble to have certain roughness, and then cleaning and drying the marble; (2) coating one surface of the marble with an adhesive, and then bonding a base plate on the surface of the marble; (3) repeating the operation in the step (2) on the other side of the marble; (4) performing half-and-half cutting from the middle of the marble to form two identical stone composite board semi-finished products; and (5) coating an anti-skid composition on the cutting surface of the marble, and carrying out fine grinding and polishing treatment on the coated surface to obtain the stone composite plate. The problem that an existing stone composite board made of marble is relatively single in function is solved.

Owner:盛达建材集团有限公司

Straw gypsum board

The invention relates to a straw gypsum board which is characterized by comprising the following components in parts by mass: 35-50 parts of gypsum powder, 10-20 parts of straws ground into 4-8cm, 5-10 parts of clay, 1-2 parts of aerated aluminum powder, 3-6 parts of alumina silicate fibers, 1-1.5 parts of sepiolite fabric, 5-8 parts of fluorgypsum, 5-8 parts of modified sawdust, 2-2.5 parts of aluminum sulfate, 2-3 parts of activated basic magnesium sulfate whiskers, 0.5-0.8 part of fumed silica, 1-1.4 parts of triethanolamine, 0.8-1 part of silicon nitride powder, 1-1.5 parts of antimonous oxide, 0.8-1.2 parts of a halogen flame-retardant, 0.5-1 part of titanium dioxide, 0.5-1 part of zinc oxide, 1-2 parts of an alunite expanding agent, 5-8 parts of alumina sol and 10-20 parts of white latex.

Owner:于银兰

Processing method of anti-freezing concrete

InactiveCN106587779AImprove surface physical and chemical propertiesReduce corrosionDiimideAntimony trioxide

The invention relates to anti-freezing concrete which comprises the following components, by mass, 15 parts of kieselguhr, 12 parts of triethylene tetramine modified durian shells, 8 parts of chestnut shell cellulose, 1.5 parts of air-entrapping aluminum powder, 5 parts of hollow glass microspheres, 4 parts of single alkoxy type titanate, 4 parts of teflon particles, 0.6 part of tripolycyanamide, 1.2 parts of sepiolite fabric, 95 parts of cement, 65 parts of natural sand gravel, 6 parts of fluorgypsum, 6 parts of modified saw dust, 2.4 parts of aluminum sulfate, 2.2 parts of pulverized fuel ash hollow microspheres, 1.2 parts of triethanolamine, 0.85 part of silicon nitride powder, 1.25 parts of antimony trioxide, 1 part of halogenated flame retardant, 0.8 part of titanium dioxide, 0.75 parts of zinc oxide, 1.5 parts of expanded perlite, 1.4 parts of sodium dodecyl benzene sulfonate and 1.1 parts of alkyl succinimide.

Owner:施冬美

Polypropylene-based non-woven sound absorption material coated with nanometer molybdenum disulfide and styrene-acrylate composite emulsion for automotive interior decoration

InactiveCN104746333AHigh porosityReduce thermal contraction coefficientFibre typesNon-woven fabricsEmulsionPolypropylene

The invention relates to a non-woven sound absorption material, and particular relates to a polypropylene-based non-woven sound absorption material coated with nanometer molybdenum disulfide and styrene-acrylate composite emulsion for automotive interior decoration. The polypropylene-based non-woven sound absorption material is prepared from the following raw materials in parts by weight: 8-10 parts of polyvinyl chloride, 24-28 parts of polypropylene, 3-5 parts of oxidized starch, 1-2 parts of polydimethylsiloxane, 2-3 parts of ethylene glycol dimethacrylate, 4-6 parts of 400-600-mesh zinc oxide, 2-3 parts of a silane coupling agent kh550, 2-4 parts of 400-600-mesh aluminum hydroxide, 12-14 parts of a sepiolite fabric, 1-2 parts of antioxidant 1010, 0.1-0.2 part of nanometer molybdenum disulfide, 1-2 parts of nano-silicon, 12-14 parts of styrene-acrylate emulsion of which the solid content is 8-10 percent and 1-2 parts of an auxiliary. The polypropylene-based non-woven material is high in flame retardance and waterproof property, free of pollution of inside-car environment, good in cold and heat stability, and easy for recycling degradation; therefore, the material is the novel practical automotive sound absorption material.

Owner:WUHU ZHONGLI PARTS

Processing method of fireproof heat-preservation aerated brick for wall body

InactiveCN106631124APrecise positioningEasy to useConstruction materialCeramicwarePolyesterAntimony trioxide

The invention relates to a fireproof heat-preservation aerated brick for a wall body. The fireproof heat-preservation aerated brick comprises a regular-triangular-pyramid inner core and a square outer core, wherein the regular-triangular-pyramid inner core is prepared from the following materials in parts by mass: 15 parts of diatomite, 12 parts of triethylene tetramine modified durian shell, 8 parts of chestnut shell cellulose, 1.5 parts of aerating aluminum powder, 5 parts of hollow glass bead, 4 parts of mono-alkoxy titanate, 4 parts of polytetrafluoroethylene particle, 0.6 part of melamine and 1.2 parts of sepiolite floss; the square outer core is prepared from the following materials in parts by mass: 16 parts of cement, 6 parts of fluorgypsum, 6 parts of coconut charcoal modified polyester fiber, 2.4 parts of aluminum sulfate, 2.2 parts of basalt fiber, 1.2 parts of triethanolamine, 0.85 parts of shale powder, 1.25 parts of antimonous oxide, 1 part of halogen fire retardant, 0.8 part of titanium dioxide, 0.75 parts of magnesium chloride, 1.5 parts of alunite expanding agent, 1.4 parts of sodium dodecyl benzene sulfonate and 1.1 parts of isooctyl triethoxysilane.

Owner:施冬美

High temperature resistance and corrosion resistance concrete for chemistry factory building

InactiveCN106587778AImprove surface physical and chemical propertiesReduce corrosionCeramicwarePolyesterSingle type

The invention relates to high temperature resistance and corrosion resistance concrete for a chemistry factory building. The concrete is prepared from, by mass, 15 parts of kieselguhr, 12 parts of triethylene tetramine modified durain shells, 8 parts of chestnut shell cellulose, 1.5 parts of air-entrapping aluminite powder, 5 parts of hollow glass beads, 4 parts of single type alkoxy titanium acid ester, 4 parts of polytetrafluoroethylene particles, 0.6 part of melamine, 1.2 parts of sepiolite fabric, 110 parts of cement, 80 parts of natural gravel, 6 parts of modified coal ash, 6 parts of coconut charcoal modified polyester fiber, 2.4 parts of aluminum sulfate, 2.2 parts of hydroxyethyl cellulose, 1.2 parts of triethanolamine, 0.85 part of shale powder, 1.25 parts of antimonous oxide, 1 part of halogenated flame retardant, 0.8 part of titanium dioxide, 0.75 part of magnesium chloride, 0.8 part of nano-iron, 1.5 parts of alunite expanding agent, 1.4 parts of sodium dodecyl benzene sulfonate and 1.1 part of isooctyl triethoxy silane.

Owner:沈爱琴

Processing method of aerated brick with composite structure

The invention discloses a processing method of an aerated brick with a composite structure. The aerated brick comprises a normal triple prism inner core and a square outer core, wherein the normal triple prism inner core is prepared from the following components in parts by mass: 10 to 20 parts of diatomite, 10 to 20 parts of triethylene tetramine modified durio zibethinus murr shell, 5 to 10 parts of chestnut shell cellulose, 1 to 2 parts of aerated aluminum powder, 3 to 6 parts of hollow glass microsphere, 3 to 5 parts of monoalkoxy titanate, 3 to 5 parts of polytetrafluoroethylene particle, 0.5 to 1 part of melamine and 1 to 1.5 parts of sepiolite floss; the square outer core is prepared from the following components in parts by mass: 12 to 18 parts of cement, 5 to 8 parts of fluorgypsum, 5 to 8 parts of cocoanut charcoal modified polyester fiber, 2 to 2.5 parts of aluminum sulfate, 2 to 3 parts of basalt fiber, 1 to 1.4 parts of triethanolamine, 0.8 to 1 part of shale powder, 1 to 1.5 parts of antimonous oxide, 0.8 to 1.2 parts of halogenated flame retardant, 0.5 to 1 part of titanium dioxide, 0.5 to 1 part of magnesium chloride, 1 to 2 parts of CTF concrete synergist, 1 to 1.5 parts of powdered sodium silicate and 1 to 1.2 parts of octyl triethoxysilane; the triple prism inner core is arranged in the square outer core and is formed by integrally autoclaved curing.

Owner:沈爱琴

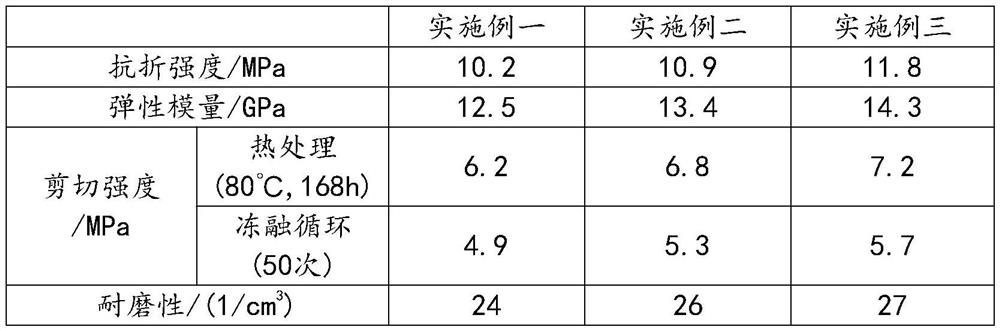

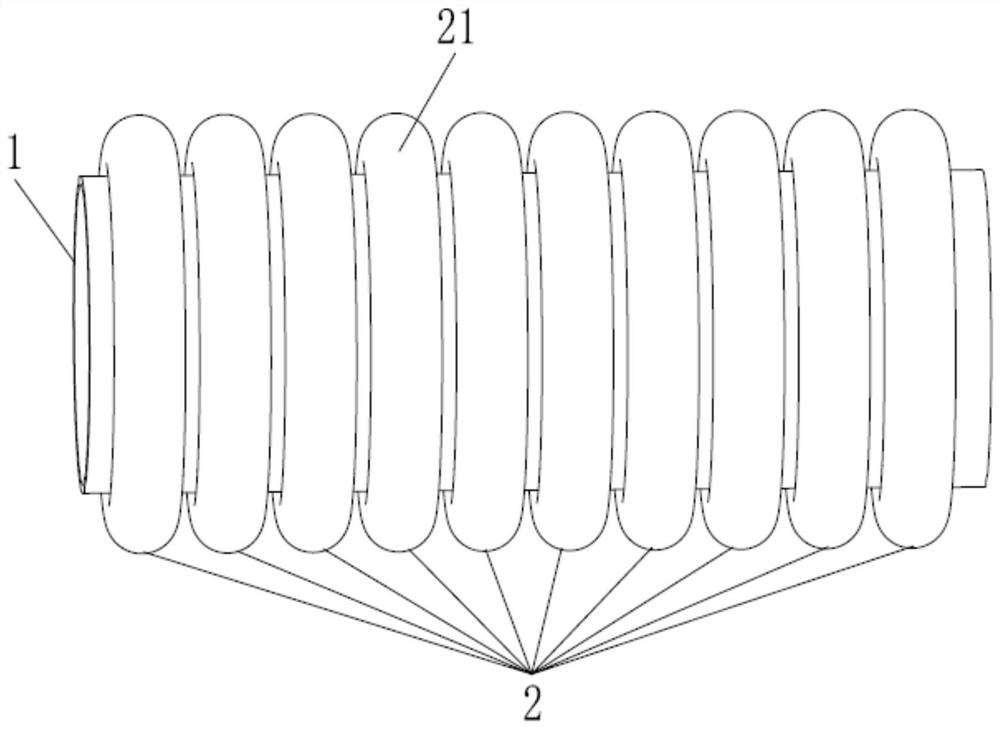

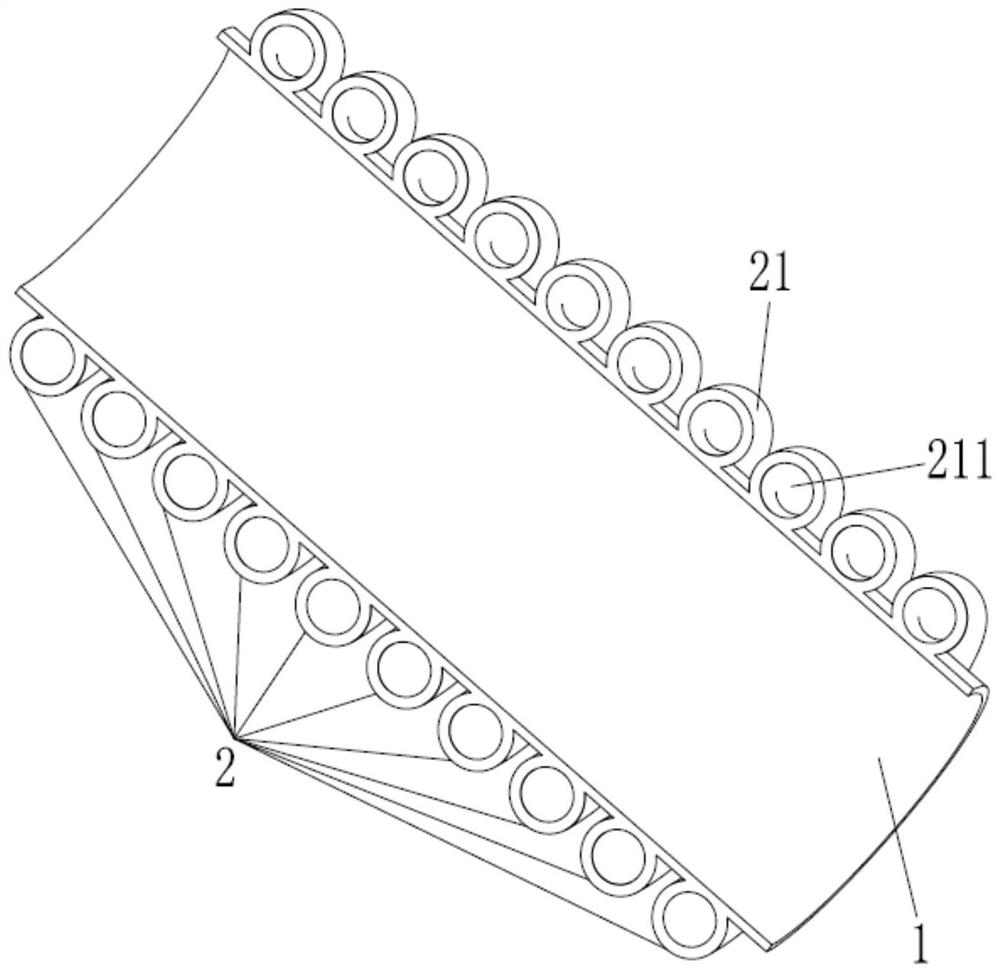

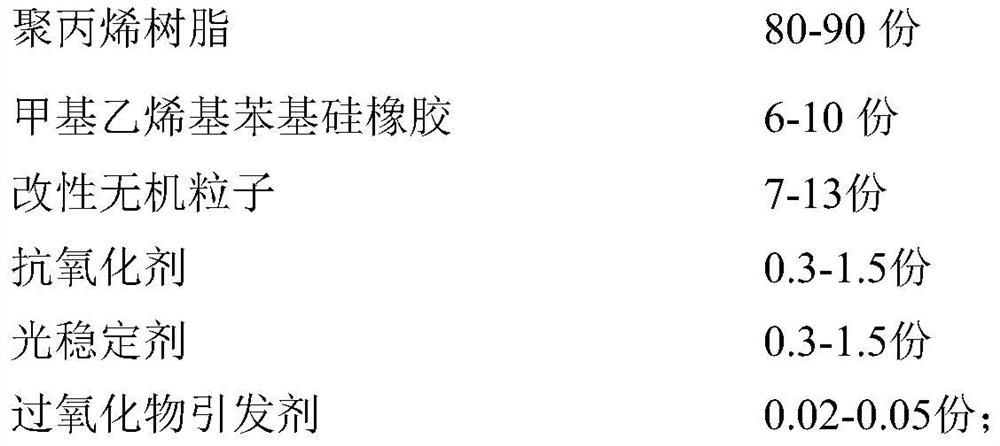

Modified polypropylene wave crest double-wall pipe and preparation method of modified polypropylene material thereof

PendingCN112063053ASimple structureLocal compression performance adjustmentElectrical apparatusPolymer scienceMeth-

The invention provides a modified polypropylene wave crest double-wall pipe and a preparation method of a modified polypropylene material of the modified polypropylene wave crest double-wall pipe. Themodified polypropylene wave crest double-wall pipe comprises an inner pipe and an outer pipe, wherein the outer pipe comprises a plurality of mutually independent wave-crest pipe bodies, the wave-crest pipe bodies are annular so as to enable the wave-crest pipe bodies to surround the outer peripheral wall of the inner pipe, the wave-crest pipe bodies are arranged on the outer circumferential wallof the inner pipe at intervals in the length direction of the inner pipe so as to form wave crests on the outer circumferential wall of the inner pipe. The wave crest pipe body and the inner pipe areboth formed by processing a modified polypropylene material, and the modified polypropylene material is composed of 80-90 parts of polypropylene resin, 6-10 parts of methyl vinyl phenyl silicone rubber, 7-13 parts of modified inorganic particles, 0.3-1.5 parts of an antioxidant, 0.3-1.5 parts of a light stabilizer and 0.02-0.05 part of a peroxide initiator. The modified polypropylene wave crest double-wall pipe is more reasonable in design, and has the advantages of being small in material consumption, light in weight, flexible in application and good in impact resistance and compression resistance.

Owner:鲁姣利

Processing method of insect-proof insect-expelling concrete

InactiveCN106673521AImprove surface physical and chemical propertiesImprove moisture and rain resistanceCeramicwareMicrosphereTriethylenetetramine

The invention relates to an insect-proof insect-expelling concrete which comprises diatomite, triethylenetetramine-modified durian shell, mint powder, aerated aluminum powder, hollow glass microspheres, monoalkoxy titanate, polytetrafluoroethylene particles, melamine, meerschaum wool, cement, natural sand stone, fluorogypsum, pomegranate rind, aluminum sulfate, fly ash hollow microspheres, triethanolamine, silicon nitride powder, antimony trioxide, a halogen flame retardant, titanium dioxide, zinc oxide, expanded perlite, sodium dodecyl benzene sulfonate and isooctyltriethoxysilane.

Owner:王建英

Preparation method of high-strength weather resistant asbestos tile

PendingCN110092617AGood dispersionImprove stabilityRoof covering using tiles/slatesAnti-corrosive paintsFire resistanceAntimony tin oxide

The invention relates to a preparation method of a high-strength weather-resistant asbestos tile, and belongs to the technical field of building materials. A silane coupling agent is used to organically modify the surface of nanometer titanium dioxide, the nanometer titanium dioxide, antimony tin oxide and an acrylate emulsion are compounded to prepare a heat insulating coating, and the surface ofan asbestos tile is uniformly coated with the prepared coating, so the asbestos tile has a good weather resistance and a good heat insulating property; a ferrosilicon nitride block is used as a refractory aggregate, ferrosilicon nitride is a metal-ceramic composite block material prepared by a flash combustion synthesis technology, contains about 85% (w) of silicon nitride, has similar chemical and hot strength with the silicon nitride, and has better sintering properties and heat conductivity than the silicon nitride, so the fireproof property of the asbestos tile is improved; the addition of asphalt improves the waterproof performance of the asbestos tile; and the silicon carbide has stable chemical properties, a high heat conduction coefficient, a small heat expansion coefficient and good wear resistance, so the addition of the silicon carbide enhances the strength and the fire resistance of the asbestos tile.

Owner:何业波

A special material for UHMWPE alloy volume-enhancing and toughening modified polypropylene bellows and its preparation method

ActiveCN109456563BImprove low temperature toughnessHigh surface glossHeat deflection temperatureThermal deformation

The invention discloses a UHMWPE alloy capacity-increasing and toughening modified polypropylene corrugated pipe special material and a preparation method thereof. 5-30 parts of toughening agent, 1-5 parts of fluidity modifier. The corrugated pipe produced by the special material of the present invention has the characteristics of good mechanical properties, good low-temperature impact resistance, high thermal deformation temperature, high thermal conductivity, good flame retardancy, good surface gloss and good production stability, etc. .

Owner:FUJIAN NORMAL UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com