Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

45results about How to "Reduce oxygen evolution overpotential" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

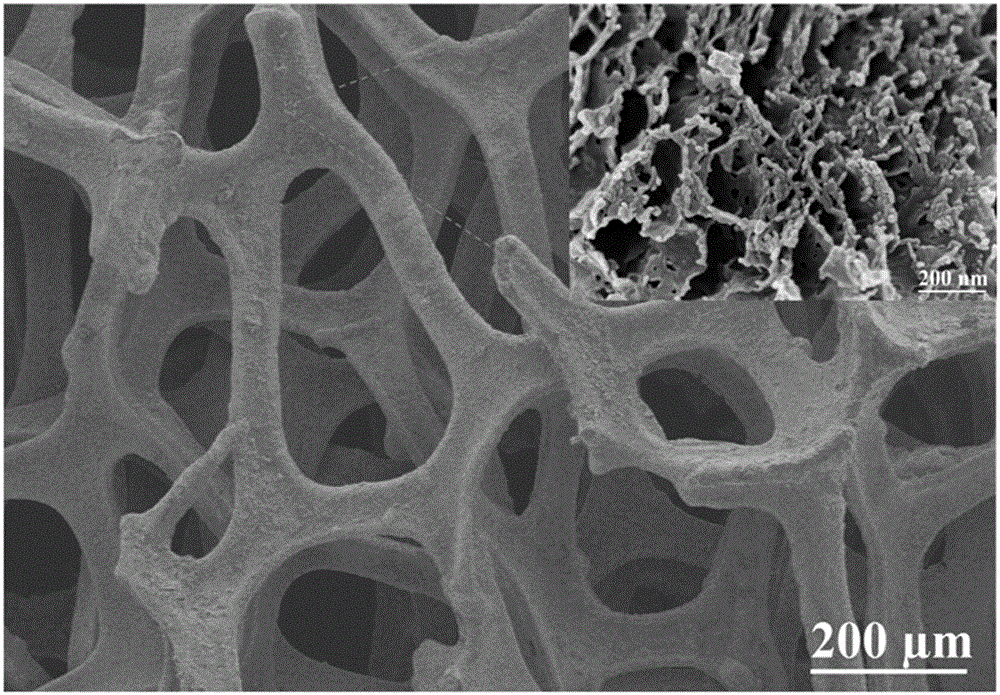

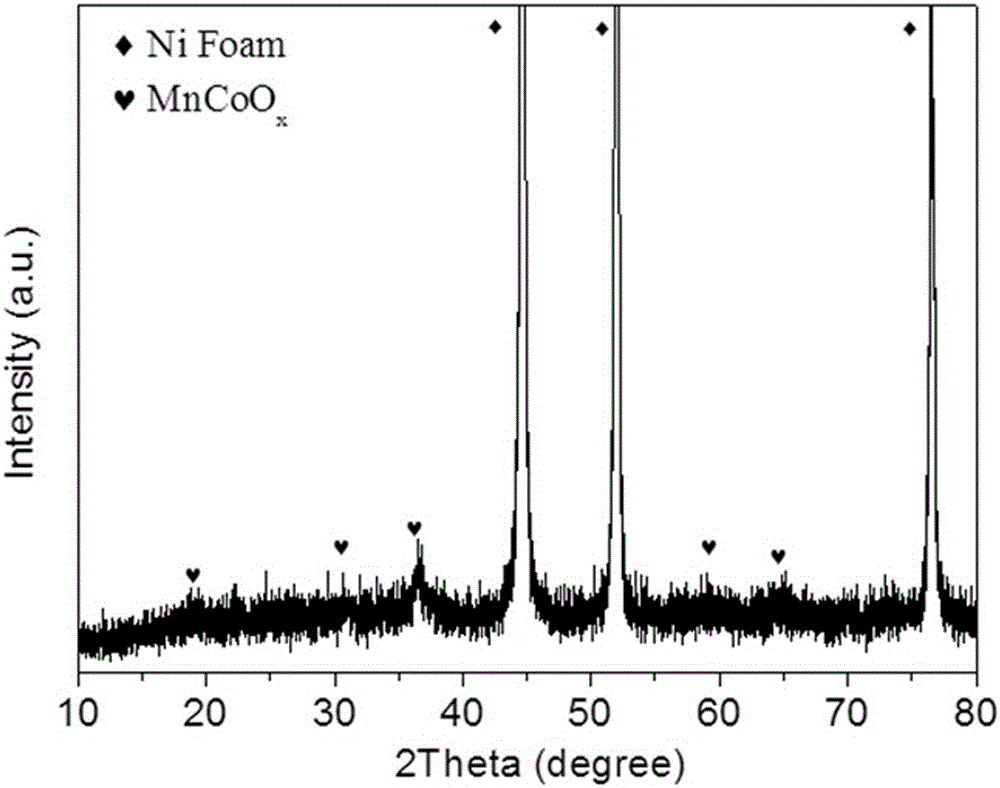

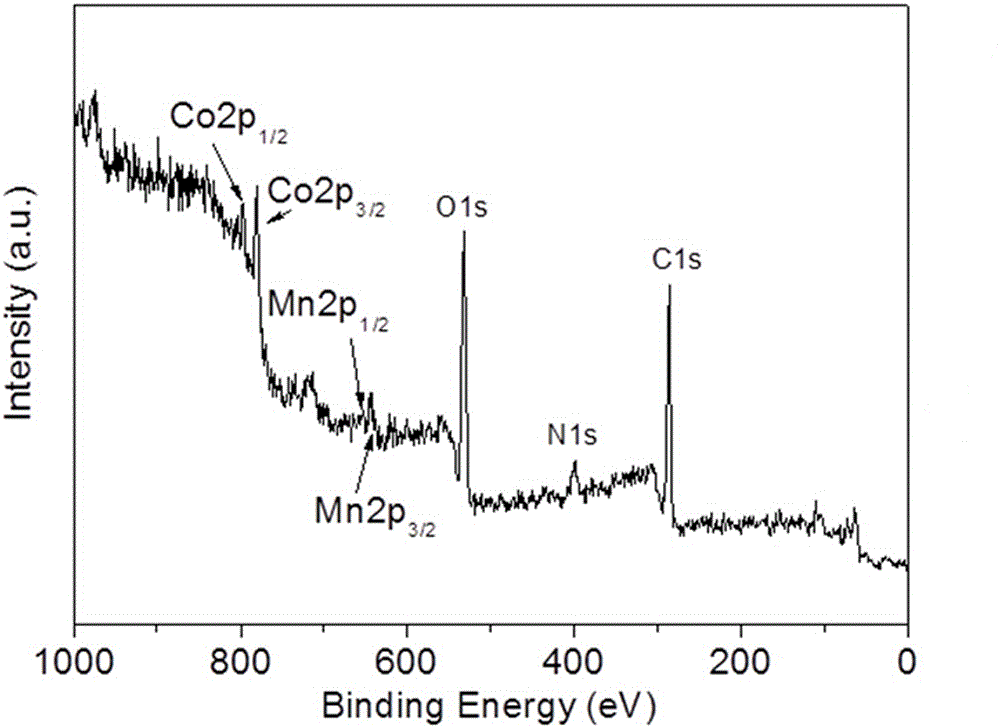

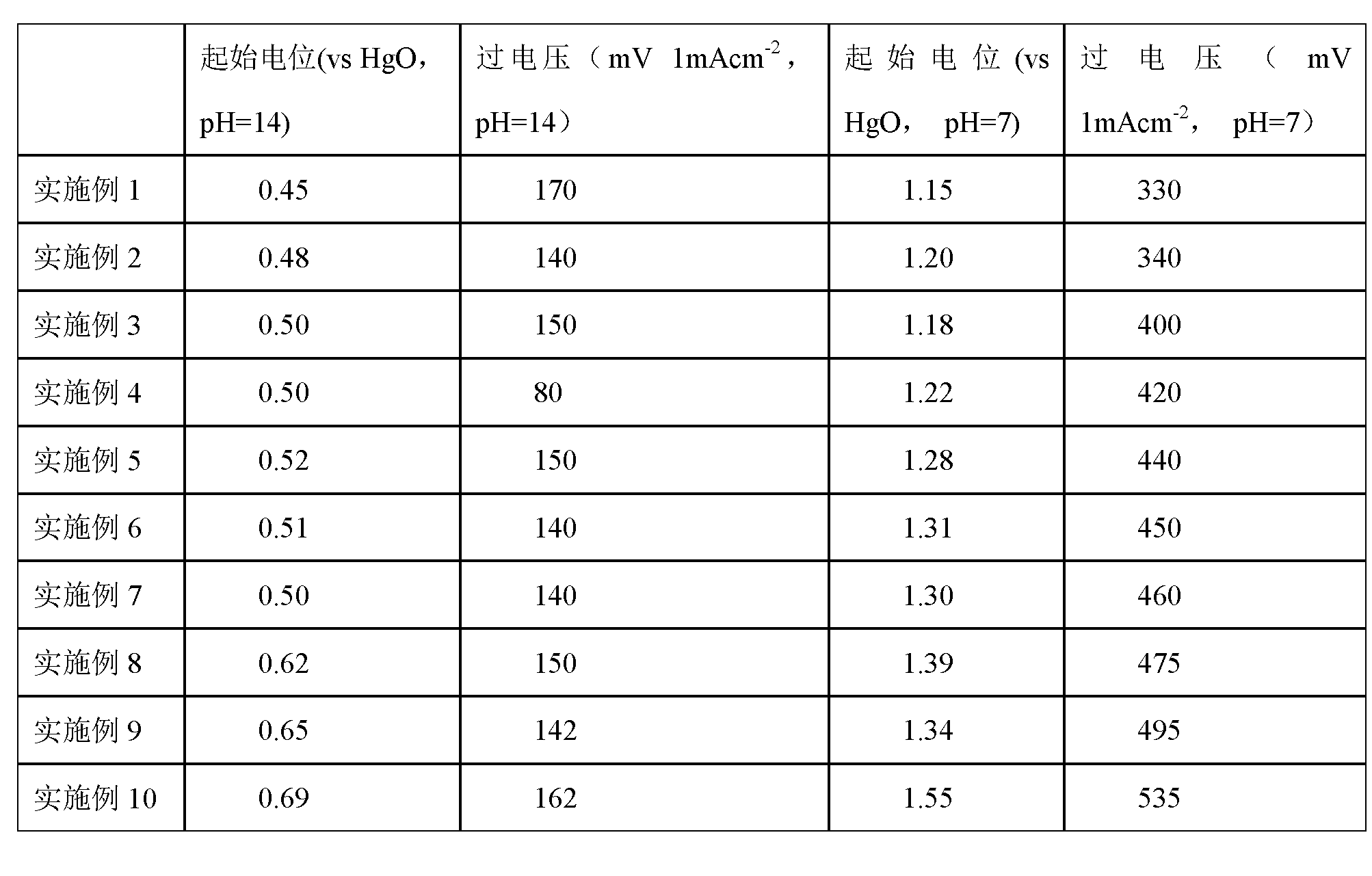

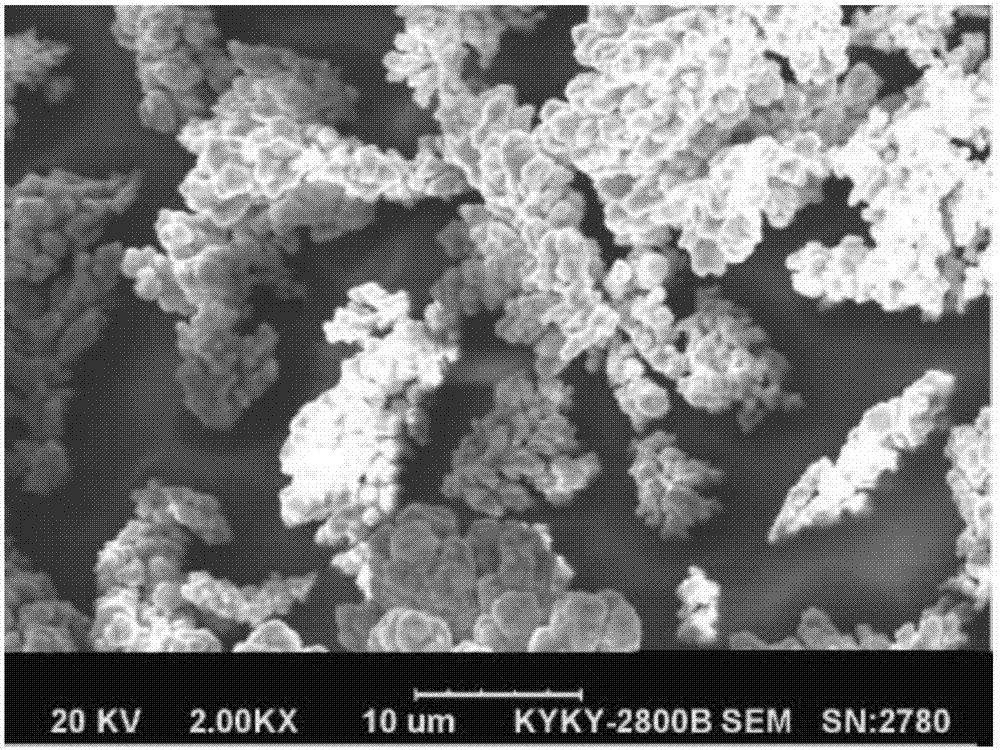

Three-dimensional anode material for hydrogen production by water electrolysis and preparation method of three-dimensional anode material

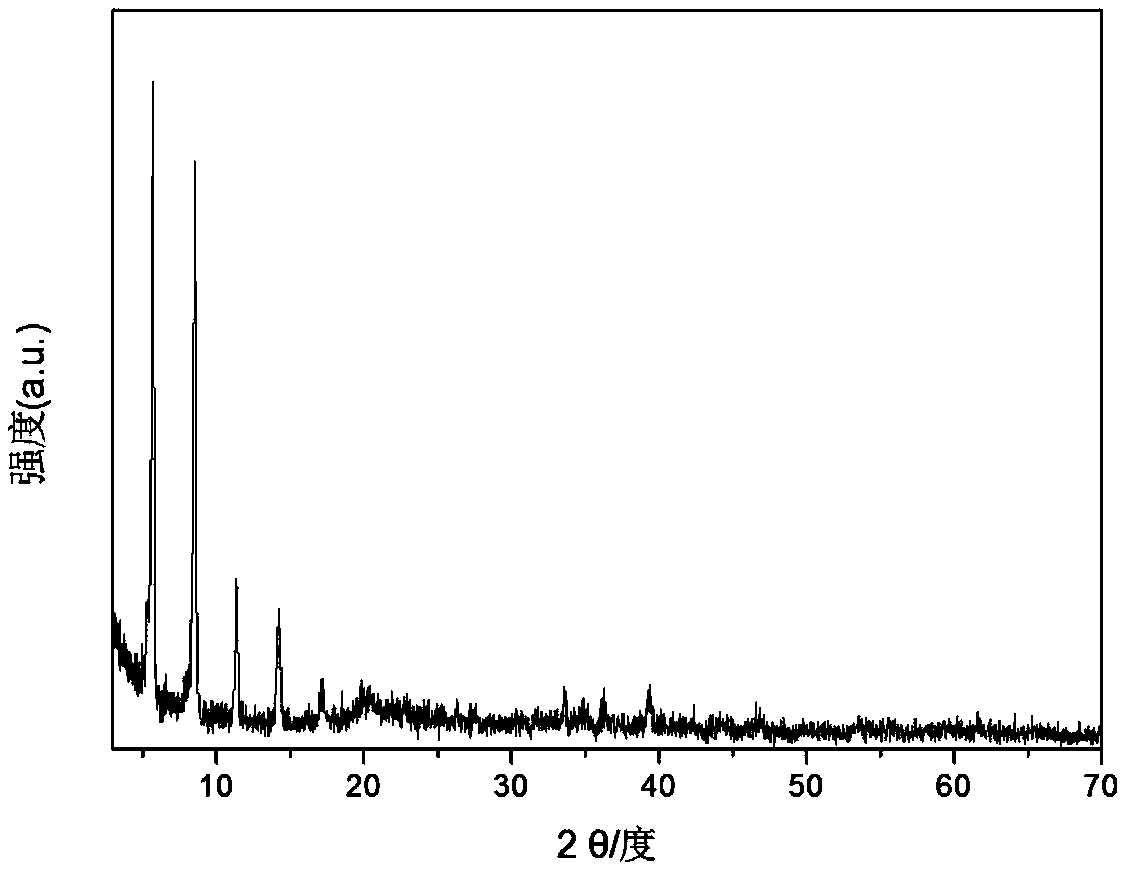

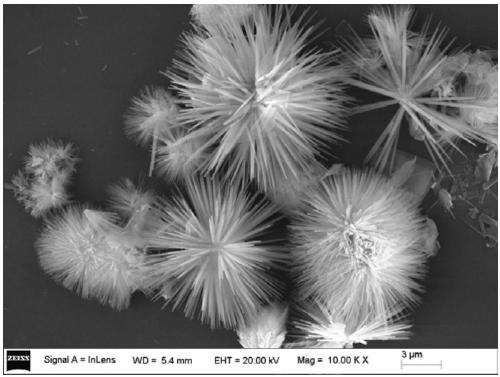

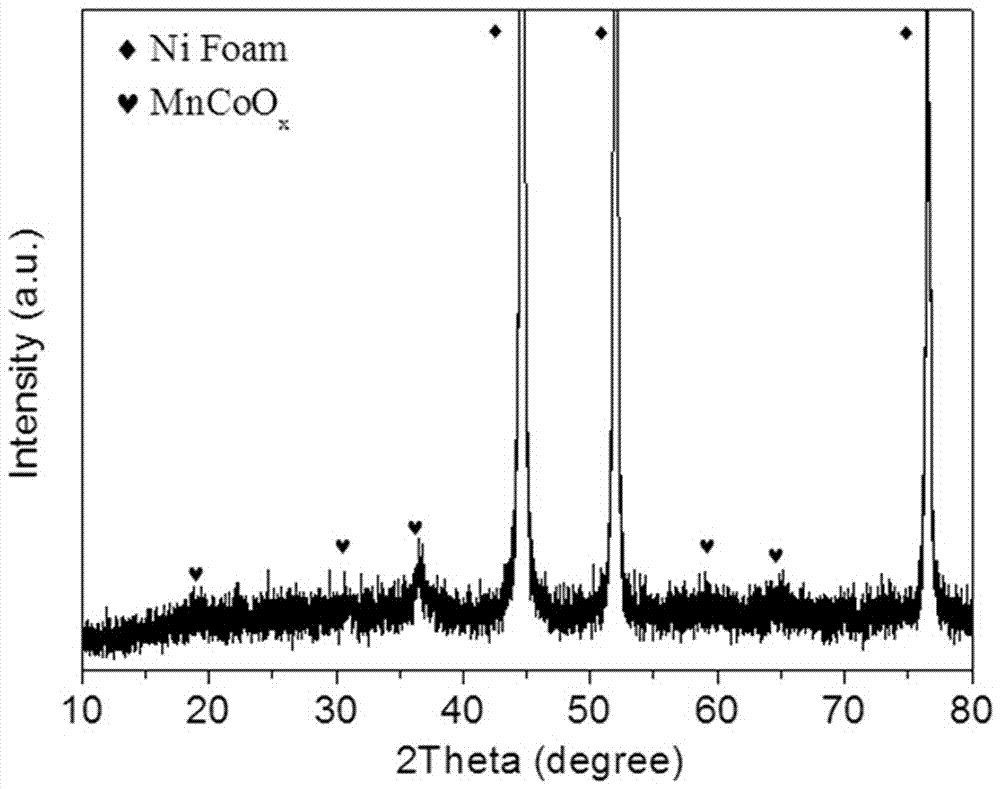

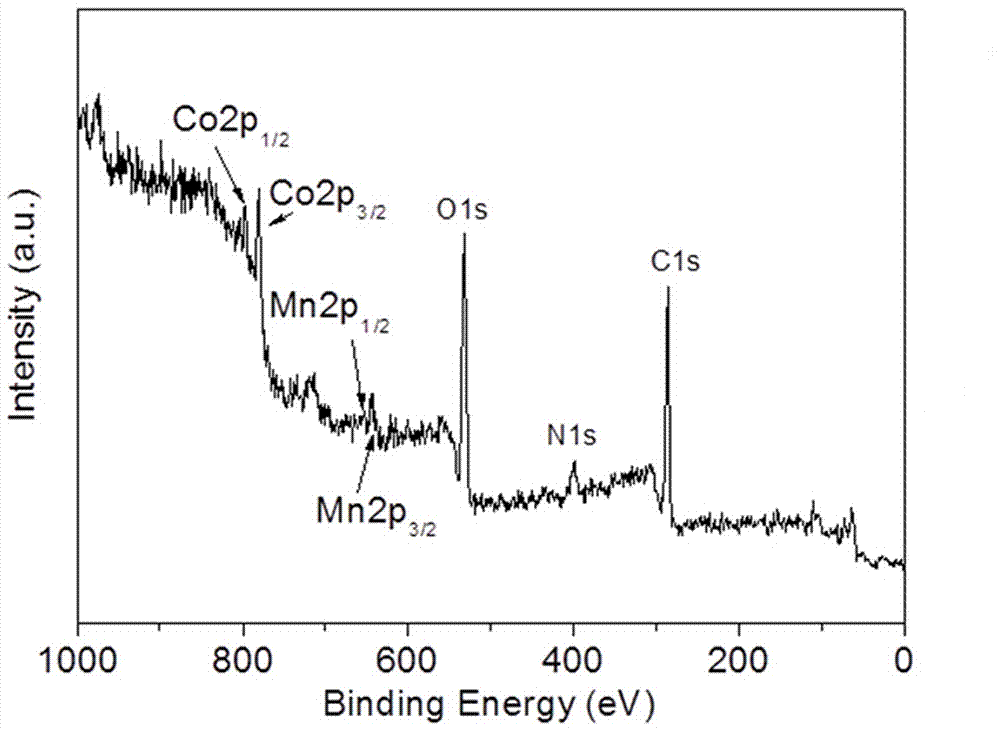

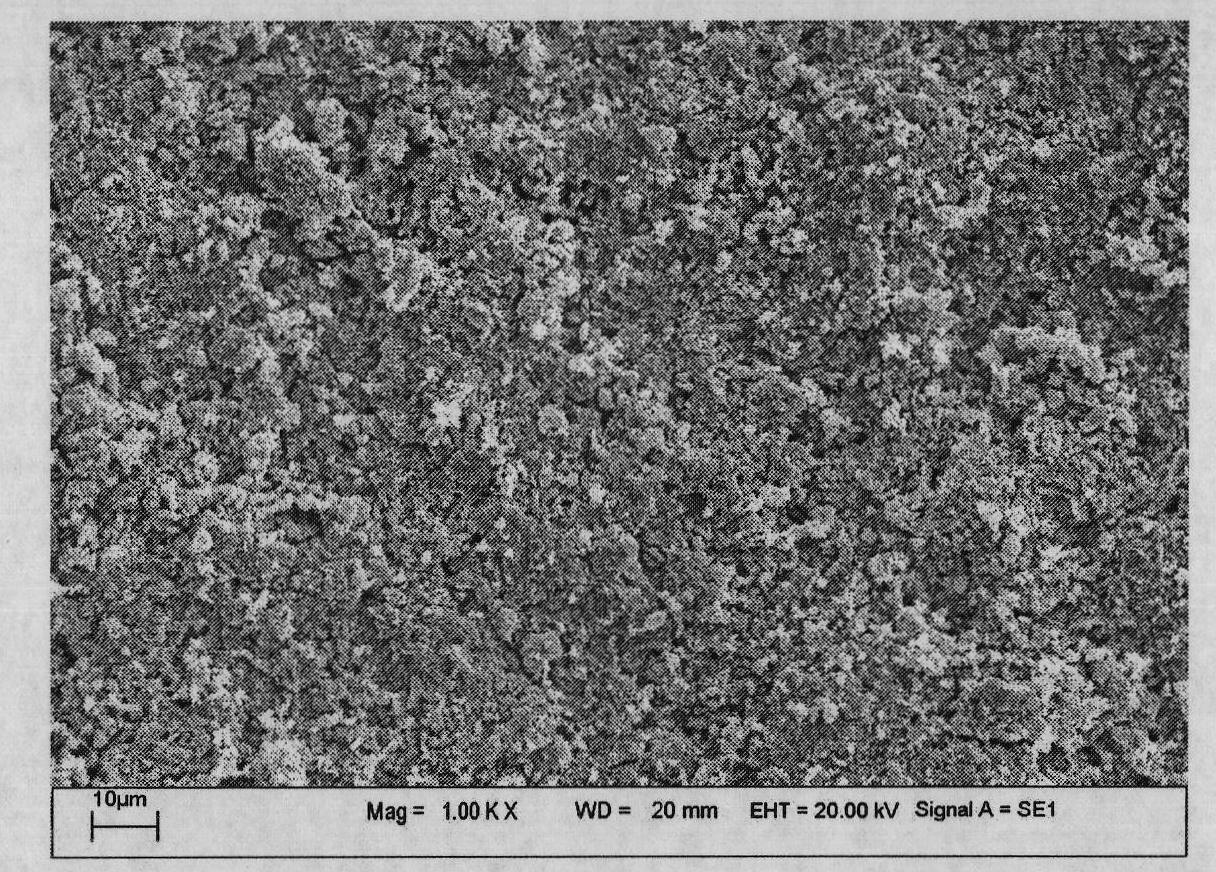

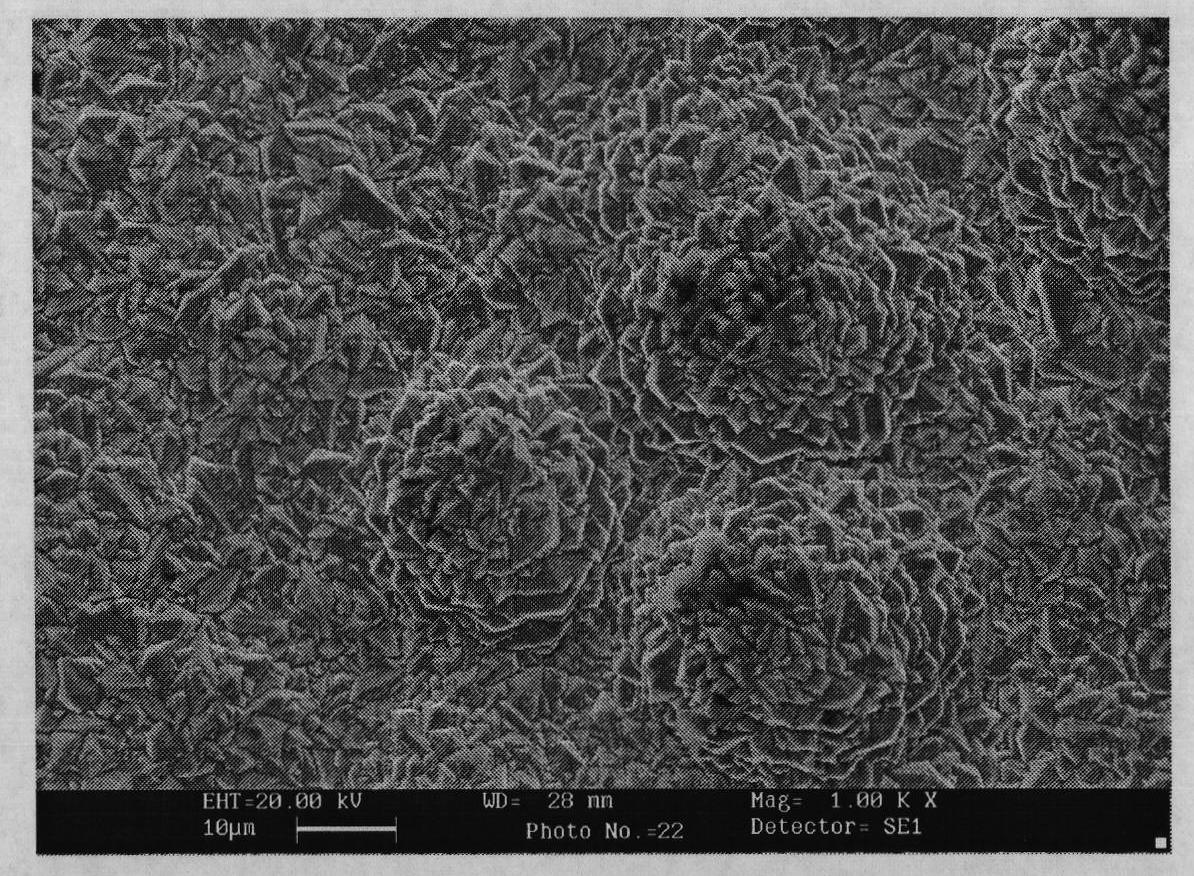

ActiveCN105140531AReduce oxygen evolution overpotentialImprove structural stabilityCell electrodesElectrolysisOxygen evolution

The invention provides a novel three-dimensional anode material for hydrogen production by water electrolysis. The novel three-dimensional anode material comprises nickel foam loaded N-doped carbon / transition metal oxide prepared in situ according to a liquid-solid synthesis method as well as a three-dimensional anode piece used for hydrogen production through water electrolysis. A preparation method of the three-dimensional anode material particularly comprises the following steps: (1) immersing clean nickel foam into a mixed solution, containing transition metal salt, a silicon source and a nitrogen source, of water and ethanol, taking out the nickel foam for airing, and repeating for three times; (2) calcining the nickel foam piece obtained in the step (1) for 1-6 h at 600-800 DEG C under the protection of inert gas, and then heating for 1-1.5 h at 200-250 DEG C in the atmosphere of O2, so as to obtain a nickel foam loaded N-doped carbon / transition metal oxide three-dimensional electrode. The three-dimensional electrode produced according to the preparation method has relatively low oxygen evolution overvoltage, has relatively high structural stability and oxygen evolution catalytic activity under long-term alkaline electrolysis condition, is simple in production process and adjustable in electrode component and variety, and has wide application prospects.

Owner:TAIYUAN UNIV OF TECH

Method for producing hydrogen by water electrolysis assisted with photocatalysis

InactiveCN102534645AReduce voltageImprove hydrogen evolution efficiencyElectrodesElectrolysed waterHydrogen

The invention relates to a method for producing hydrogen by water electrolysis assisted with photocatalysis. The method specifically comprises the following steps of: based on an industrialized device for producing the hydrogen by the water electrolysis, modifying an anode of an electrolytic cell through photocatalysis material, and adopting a light source to irradiate the anode; and coupling a photocatalysis process in the process of water electrolysis so as to achieve the purpose of producing the hydrogen by the water electrolysis assisted with the photocatalysis. The method is characterized in that the photocatalysis and the water electrolysis are organically coupled together to generate a synergistic effect; the defects of low efficiency of producing the hydrogen by the water photolysis and high power consumption of producing the hydrogen by the water electrolysis are overcome, the voltage of an electrolytic cell is reduced, and the efficiency of hydrogen producing is increased. The method for producing the hydrogen by the water electrolysis assisted with the photocatalysis provided by the invention has simple process and is easy to realize industrialization.

Owner:EAST CHINA UNIV OF SCI & TECH +1

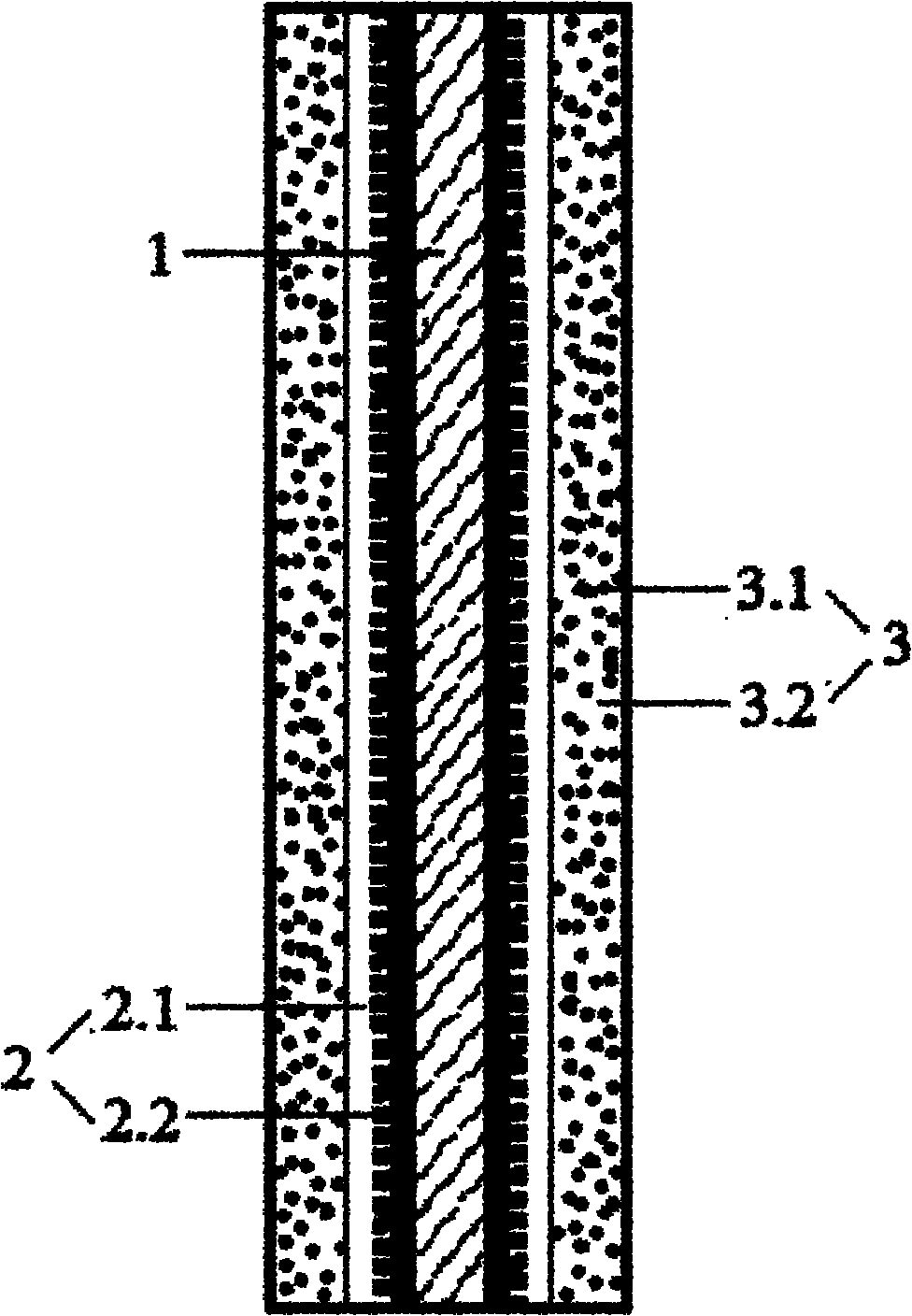

Light composite electro-catalysis energy-saving anode for non-ferrous metal electro-deposition and preparation method thereof

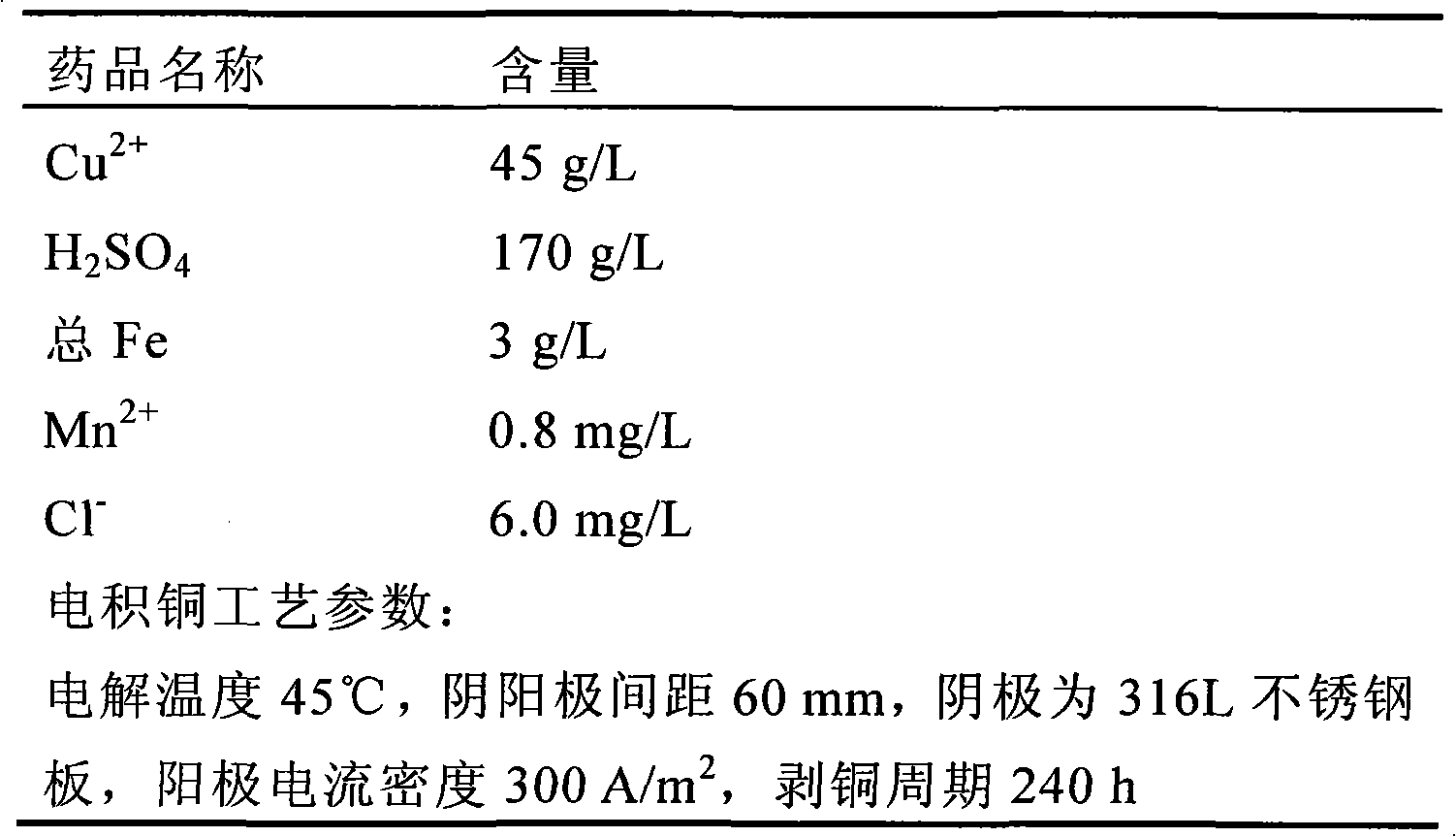

The invention relates to a light composite electro-catalysis energy-saving anode for non-ferrous metal electro-deposition, which is composed of a metal substrate, an interlayer and a composite electro-catalysis superficial layer in sequence from inside to outside, wherein the metal substrate is Al or Al base alloy (Al-M1), the interlayer is a composite layer Al2O3-(Pb-M2) composed of Al2O3 or Pb base alloy, and the composite electro-catalysis superficial layer is a composite deposite (Pb-M2)-M3Ox composed of Pb or Pb base alloy and oxide catalyst or a composite deposite PbO2-M3Ox composed of PbO2 and oxide catalyst. The preparation method of the anode comprises the following steps: preparation of the metal substrate: carrying out anodic oxidation on the metal substrate surface and prefabricating a multihole Al2O3 layer; then performing an electro-deposition Pb or Pb base alloy layer on the multihole Al2O3 layer; and plating a (Pb-M2)-M3Ox or PbO2-M3Ox composite superficial layer on the surface of the Pb or Pb base alloy layer. The anode prepared by the invention can effectively reduce production energy consumption, improve cathode product quality, lower labor intensity, is suitable for industrialized production and can replace the Pb base alloy anode applied in the existing industry.

Owner:KUNMING HENDERA SCI & TECH

Energy-saving anode for non-ferrous metal electrodeposition

An energy saving anode used in electro-deposition of nonferrous metal is characterized in that the energy saving anode used in electro-deposition of nonferrous metal comprises a metal-conductive base-plate and at least one block of composite structure which is compounded by a metal layer with porous structure, wherein the structure is frame type, sandwich type and slab lattice type. The energy saving anode not only can effectively reduce true current density of the anode in electro-deposition of the nonferrous metal, reduce overpotential for oxygen evolution of the anode and lower energy consumption, but also can reduce the quality of the anode, reduce the creep deformation and the deformation of the anode, form a more dense oxydic film on the surface, reduce the corrosion rate of the anode, extend the service length of the anode and improve the quality of the cathode products. The energy saving anode can make a full use of the existing anode without changing the structure of the groove and have no effect to the process flow, and the energy saving anode has low preparing cost and low investment.

Owner:CENT SOUTH UNIV

Composite electrode for electrodialysis as well as preparation method and application thereof

The invention provides a composite electrode for electrodialysis, which has low hydrogen evolution over-potential and low oxygen evolution over-potential, as well as a preparation method and an application thereof. A metal oxide material is deposited and prepared on the surface of a conductive base / graphene electrode through an electrolytic deposition method, so that a conductive base / graphene electrode / metal oxide composite electrode is obtained. The method provided by the invention is simple and easy to operate and low in preparation cost; the prepared composite electrode has good chemical stability and electrochemical stability, and also has good electrocatalytic properties and conductivity and a long service life. The composite electrode provided by the invention has the very low hydrogen evolution over-potential and oxygen evolution over-potential and can be used for carrying out a linear circulating volt-ampere test in a 0.5M H2SO4 solution; and under the condition of 10mAcm<-2>, the hydrogen evolution over-potential can be as low as 100mV and the oxygen evolution over-potential can be as low as 260mV.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Method for preparing novel anode material for non-ferrous metal electrodeposition

ActiveCN102206838AImprove corrosion resistanceGood corrosion resistanceElectrodesElectrometallurgyCorrosion

The invention discloses a method for preparing an anode material for non-ferrous metal electrodeposition. The invention is characterized in that: the anode material is prepared from the following materials in percentage by weight: 0.1 to 0.2 percent of silver, 0.05 to 0.1 percent of cobalt, 0.1 to 0.5 percent of tin, 0.05 to 0.09 percent of calcium, 0.1 to 1 percent of stibium and the balance of lead. The method comprises the following steps of: melting the lead, and adding a silver-cobalt intermediate alloy containing 0.1 to 0.2 percent of silver and a tin-cobalt intermediate alloy; melting, adding a lead-calcium intermediate alloy, an antimony block and the residual lead, stirring for at least 10 minutes, standing for 5 minutes, descumming, casting into an alloy plate blank; and cooling, rolling, performing surface treatment on a lead alloy plate, leveling, and shearing the plate into alloy anodes with required size. The prepared anode has good mechanical properties and corrosion resistance, and can greatly reduce cell voltage and energy consumption in the electrolysis process in the electrometallurgy process of wet electrodeposition of zinc, copper, nickel and the like.

Owner:晋宁理工恒达科技有限公司

Oxygen evolution catalyst, preparation method thereof and anode for water electrolysis

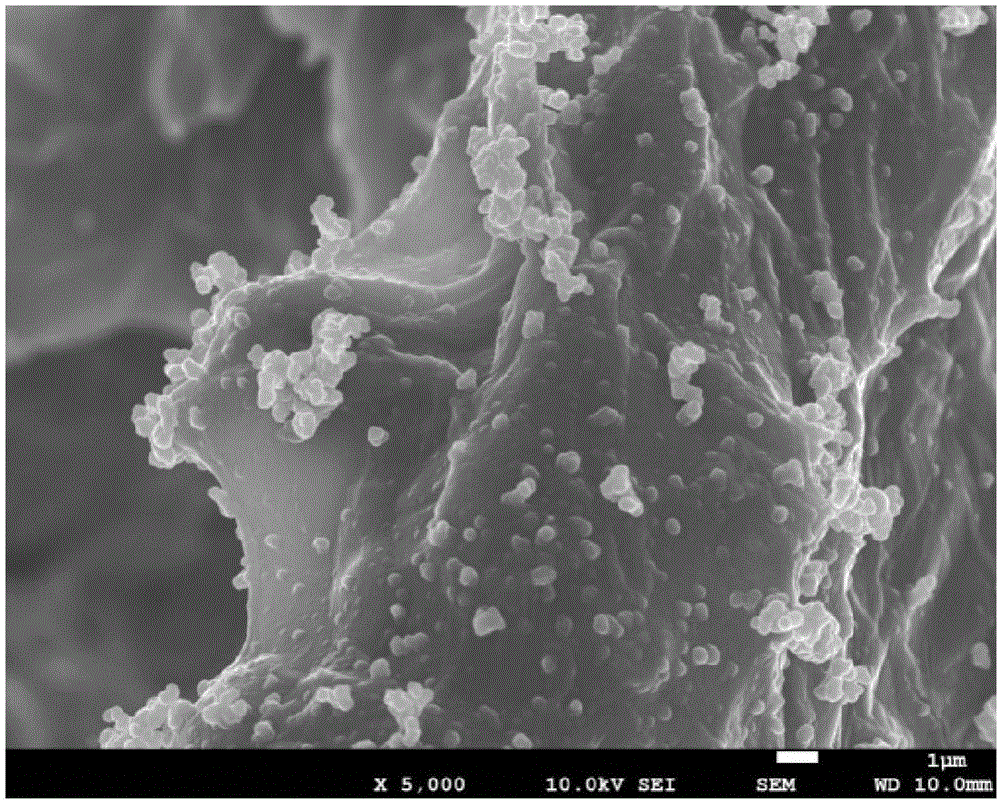

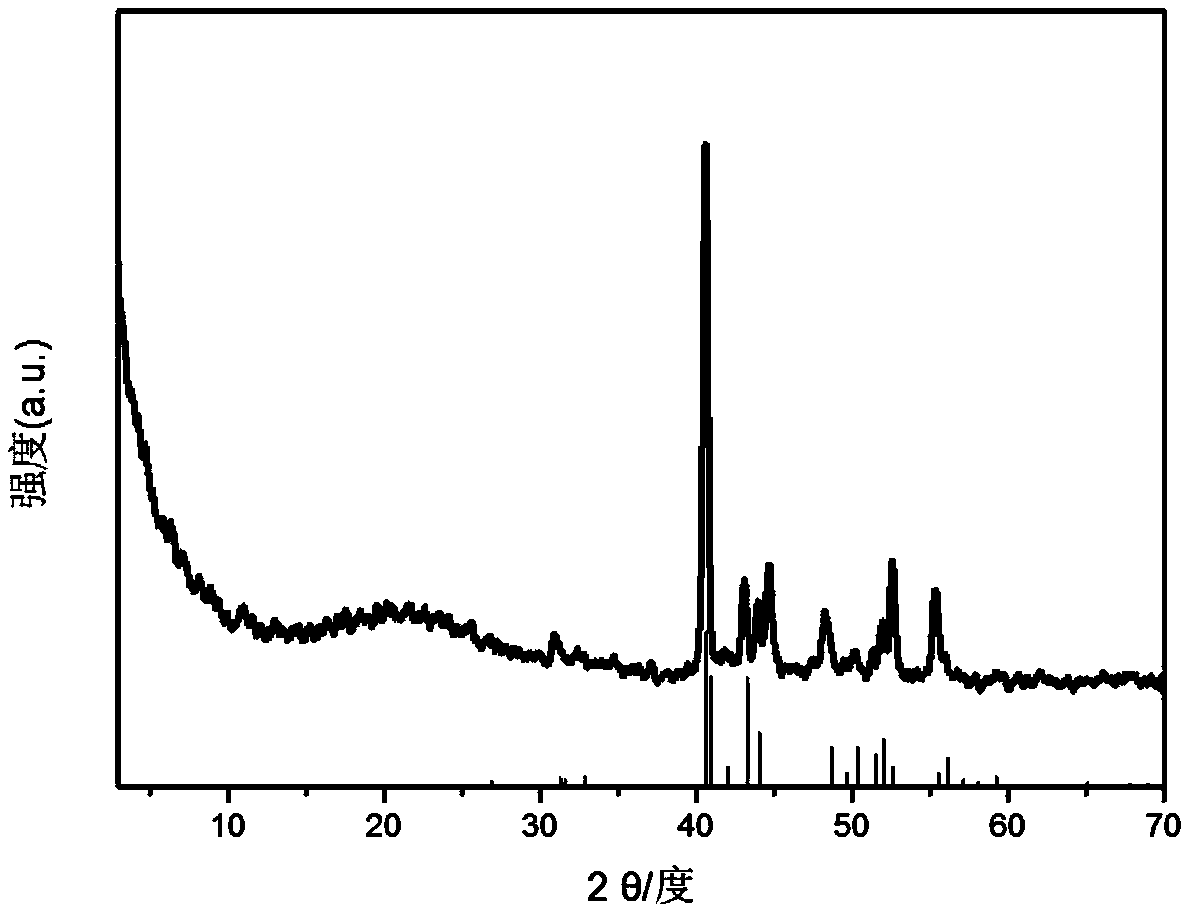

InactiveCN109701540AReduce oxygen evolution overpotentialLower impedanceMetal/metal-oxides/metal-hydroxide catalystsElectrodesElectrolysisFerrous salts

The invention belongs to the technical field of electrochemistry, and particularly relates to an oxygen evolution catalyst, a preparation method thereof and an anode for water electrolysis. The preparation method of the oxygen evolution catalyst comprises the following steps: providing foamed nickel, putting the foamed nickel into a ferrous salt solution for mixing treatment, then adding a bicarbonate solution, and carrying out an in-situ co-precipitation reaction on the surface of the foamed nickel to obtain the oxygen evolution catalyst. The preparation method has mild conditions, the foamednickel is not required to be pretreated, a nickel ion raw material is not needed to be additionally added, and harsh growth conditions such as a hydrothermal condition and the like are avoided, so that the preparation process is effectively simplified, production efficiency is improved, preparation cost is reduced, and the finally obtained oxygen evolution catalyst has the characteristics of lowoxygen evolution over-potential, small impedance, and stable oxygen evolution activity.

Owner:SHENZHEN UNIV

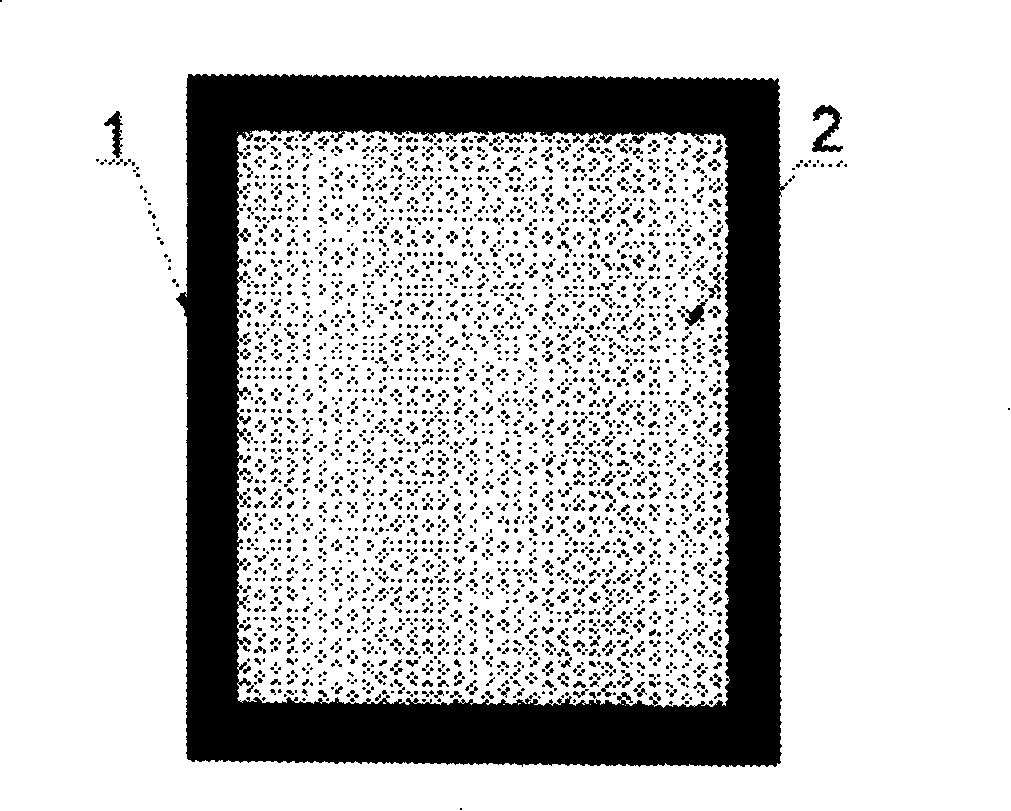

Metal anode for aqueous solution electrolysis system

InactiveCN102212840AIncreased electrochemically active surface areaConducive to loadElectrode shape/formsElectrolysisOver potential

The invention provides a metal anode for an aqueous solution electrolysis system. The metal anode is characterized in that a porous metal material is adopted to serve as a matrix, and the surface of the porous metal material is loaded with a highly active catalyst. The porous metal material has a large specific surface area and is advantageous for increasing electrode active area, reducing current density and loading the catalyst. The porous metal material can be prepared by adopting a powder metallurgic method. The metal anode provided by the invention can be used for the aqueous solution electrolysis system, particularly a membrane electrolytic sodium carbonate solution system, and can be used for decreasing e oxygen evolution over potential to reduce power consumption.

Owner:BEIJING UNIV OF CHEM TECH

Porous catalyst used for photo-electrolysis water oxygen evolution reaction and preparation method of porous catalyst

InactiveCN103007974AHigh activityImprove stabilityPhysical/chemical process catalystsElectrodesPorous catalystElectrolysis

The invention discloses a porous catalyst used for photo-electrolysis water oxygen evolution reaction, which belongs to the technical field of oxygen evolution photo-electrolysis porous catalysts, and also provides a preparation method of the porous catalyst. The porous catalyst used for photo-electrolysis water oxygen evolution reaction has amorphous or crystallization characteristic, has the chemical formula of K(CoxNi[1-x])PO4, wherein x is equal to 0-1, and the structure of the porous catalyst has a plurality of crystal water molecules. The porous catalyst is prepared by using a two-stage precipitation method. The porous catalyst and the preparation method have the following advantages that the oxygen evolution reaction electrode catalysts and the composite electrodes with excellent performance are prepared by cheap raw materials and simple steps, thus the expensive Ir and Ru series compounds are not required.

Owner:TSINGHUA UNIV

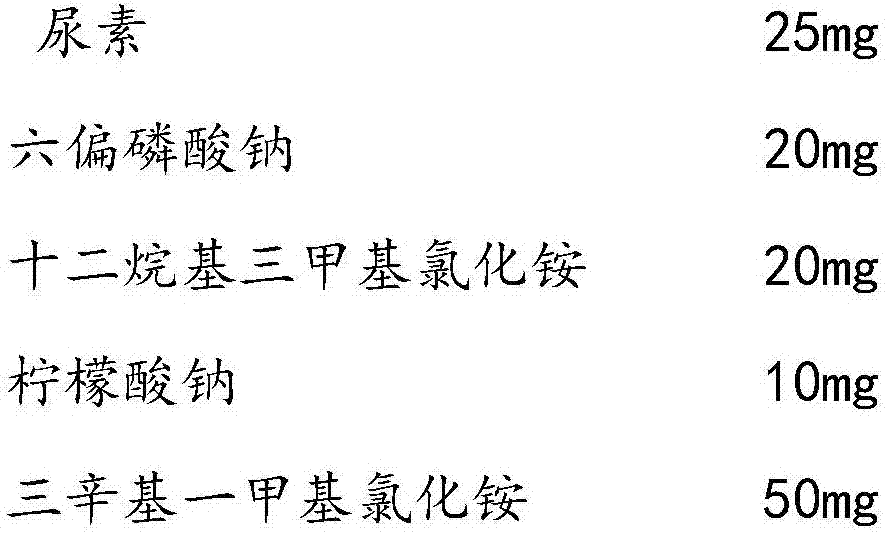

Mixed additive for electrolyzing acid etching waste liquid and method of preparing copper powder by using mixed additive

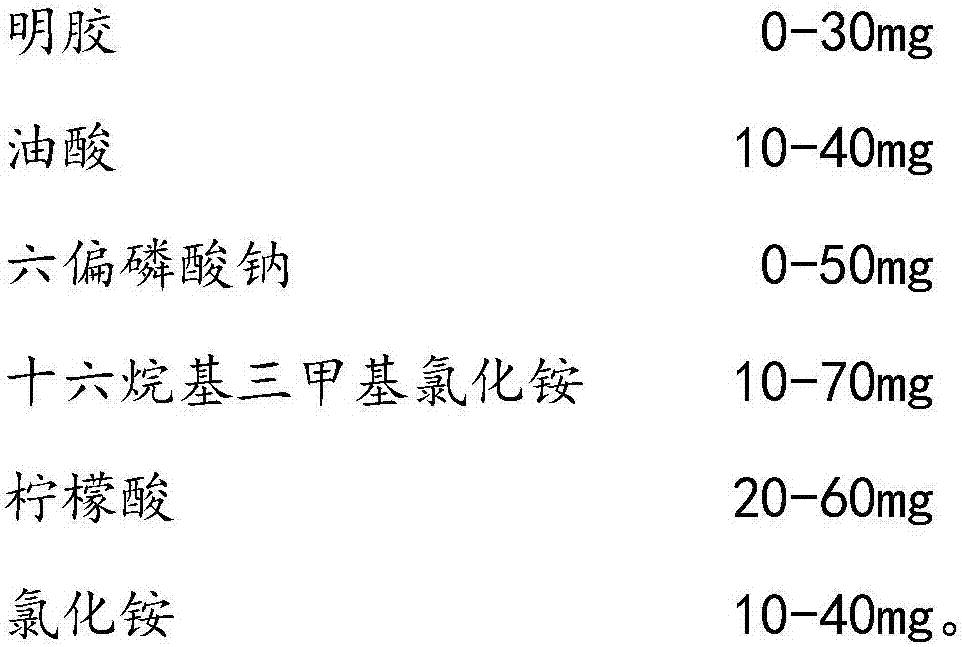

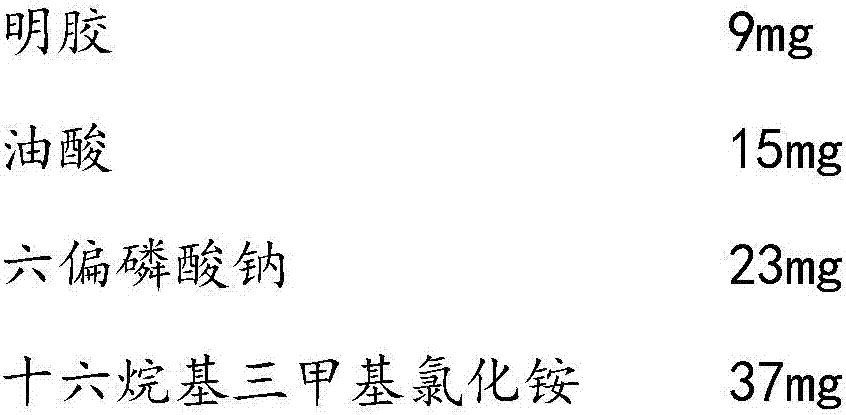

The invention relates to a mixed additive for electrolyzing acid etching waste liquid to prepare copper powder and a preparation method of the copper powder. Per liter of a mixed additive aqueous solution comprises the following components: 0-30mg gelatin, 10-40mg oleic acid, 0-50mg sodium hexametaphosphate, 10-70mg hexadecyl trimethyl ammonium chloride, 20-60mg citric acid and 10-40mg ammonium chloride. With the adoption of the mixed additive for electrolysis copper deposition treatment on the etching waste liquid, the superfine copper powder having high added value can be prepared, and recycling of the etching waste liquid is realized. A titanium base oxygen evolution electrode is taken as an electrolytic anode, and no chlorine is liberated during electrolytic regeneration, so that the recycling of the etching waste liquid is realized, and no harm to the environment is caused.

Owner:SHANDONG JINBAO ELECTRONICS

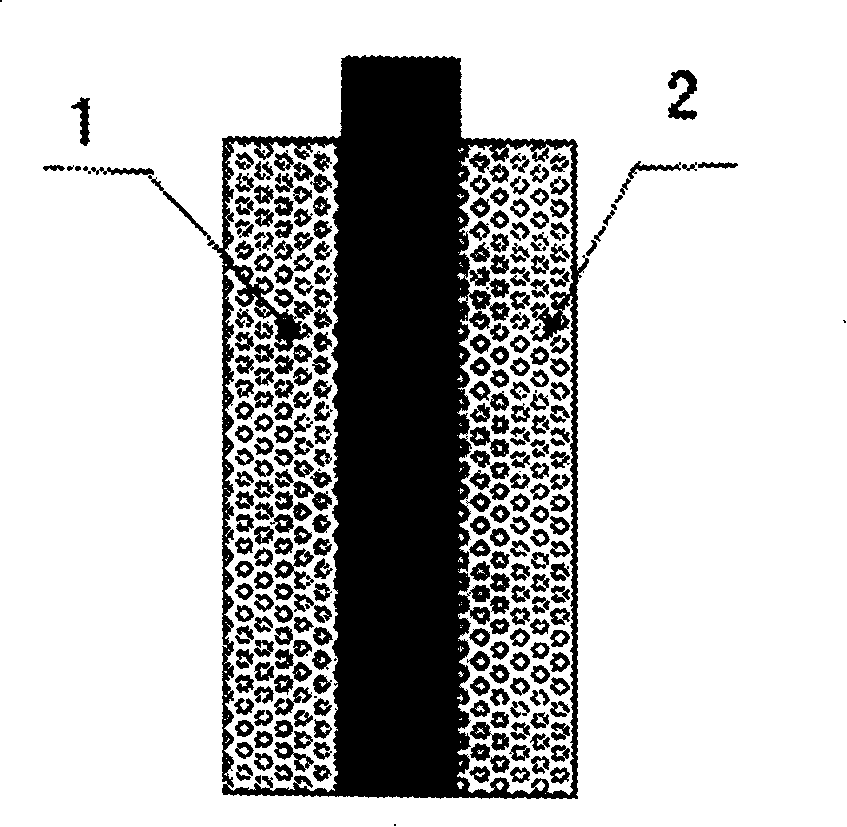

Composite anode for hydrometallurgy and preparation method and application thereof

ActiveCN111926349AHigh oxygen evolution activityLow anode overpotentialElectrodesGalvanic depositionOxide

The invention discloses a composite anode for hydrometallurgy and a preparation method and application thereof. The composite anode structure is a metal substrate / non-oxide intermediate layer / selective electrocatalytic oxygen evolution layer, wherein the non-oxide intermediate layer can isolate oxygen from diffusing to the metal substrate to avoid passivation of the metal substrate; the selectiveelectrocatalytic oxygen evolution layer can selectively catalyze the oxygen evolution while suppressing the depletion of Mn2+ in the electrolyte. The composite anode can be used in the electrochemicalmetallurgical process of metallic zinc, manganese, copper and other non-ferrous metals. When used in the electrodeposition of metallic manganese, the current density of the cathode and anode and theelectrowinning without diaphragm can be realized, the energy in the electrowinning process is greatly reduced, the oxidation loss of Mn2+ at the anode is suppressed, and the cathode current efficiencyis improved.

Owner:CENT SOUTH UNIV

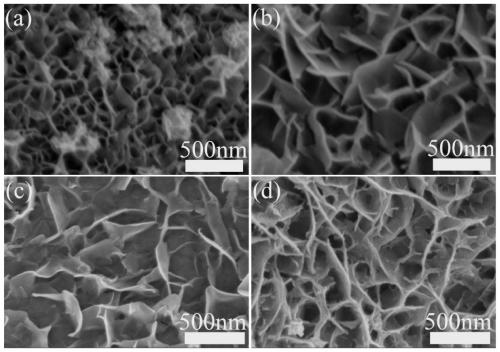

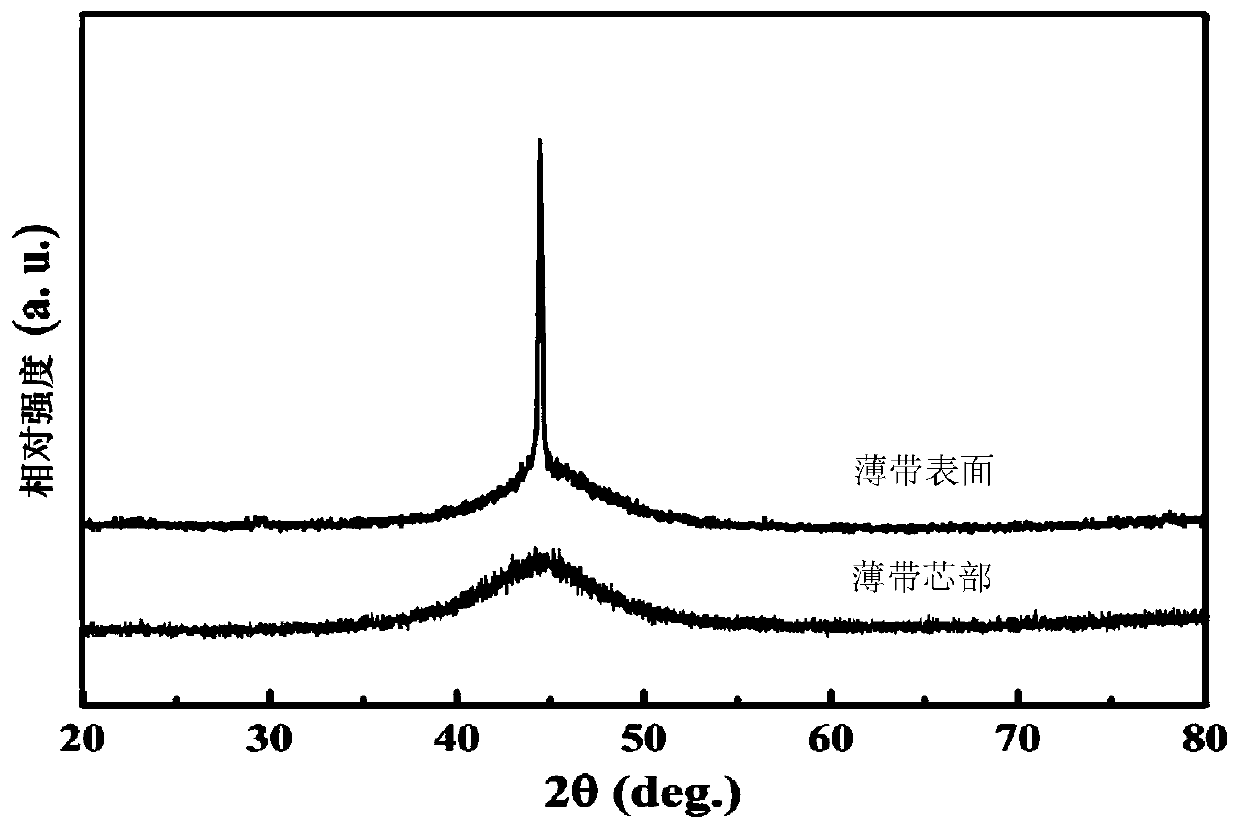

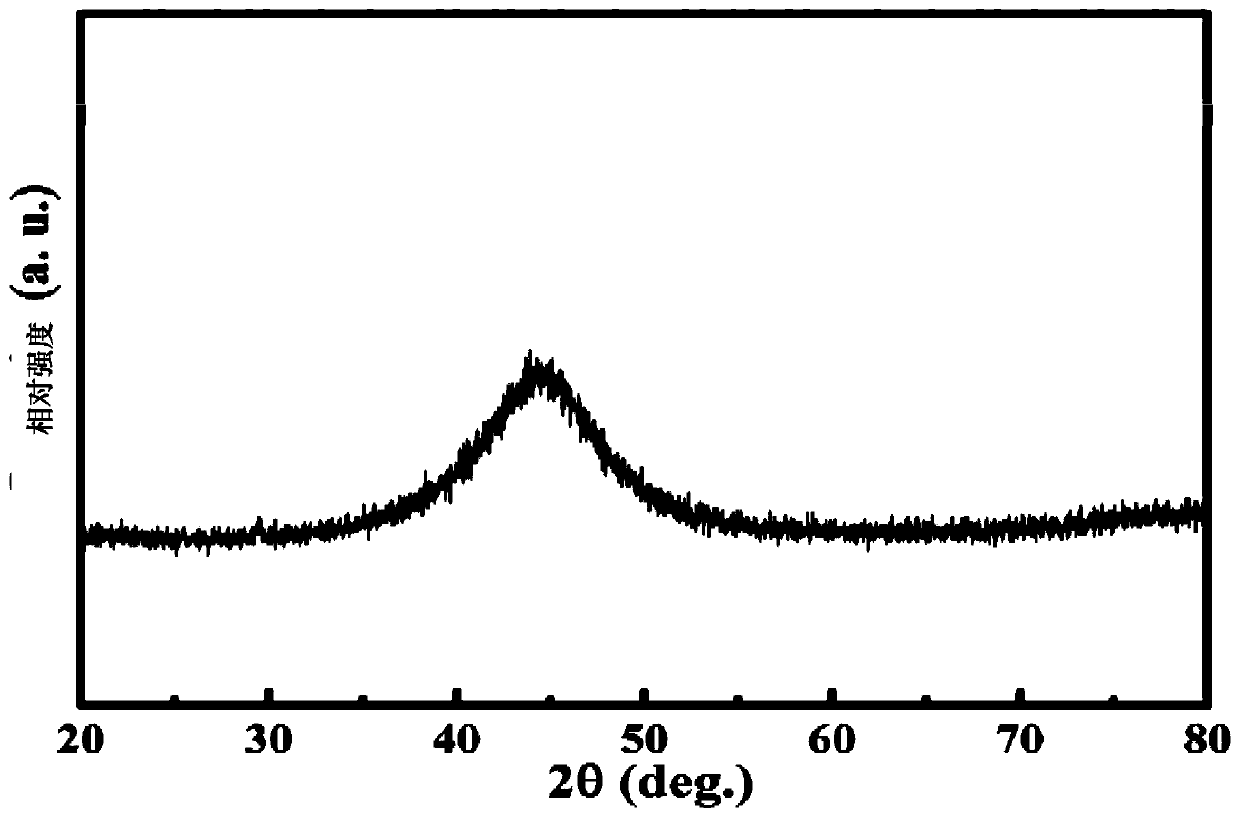

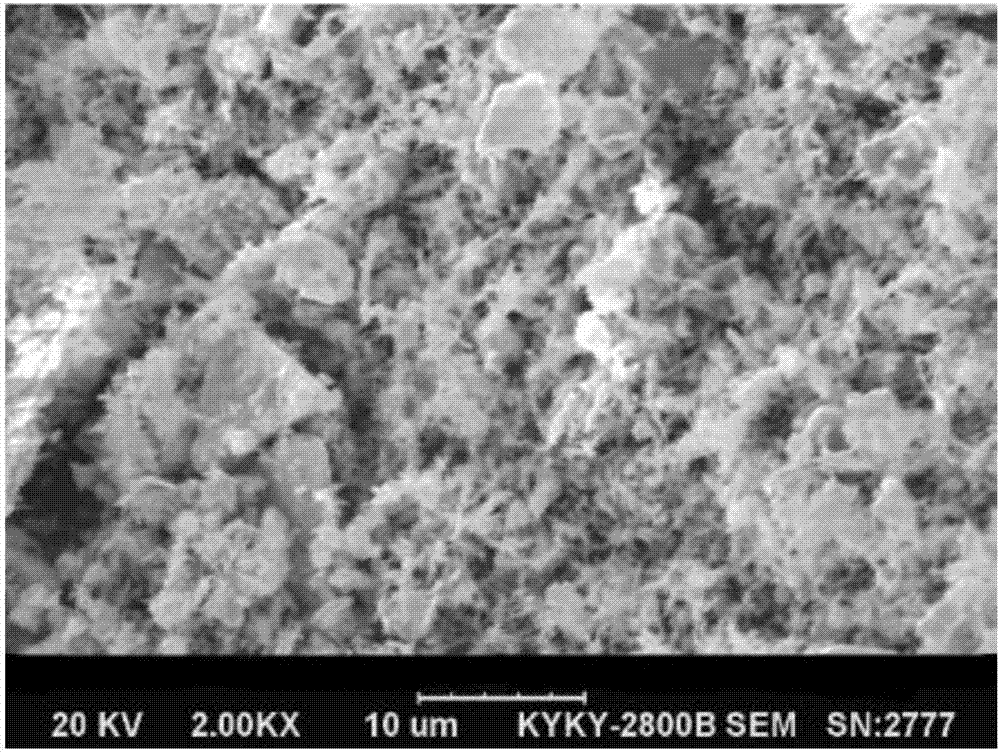

Integrated transition metal series oxygen evolution catalytic material and preparation method

ActiveCN110791771AImproved Amorphous Formation AbilityComposition controllableElectrodesOxidePrecious metal

The invention discloses an integrated transition metal series oxygen evolution catalytic material and a preparation method. The prepared (TmNm)<x>Rm<y> series oxygen evolution catalytic materialis composed of a thin alloy strip formedby compounding a two-layer structure. One layer is a nano-porous layer doped with transition metal oxides or hydroxides with high catalytic activity and precious metals on the surface, and the other layer is a highly conductive amorphous alloy matrix. According to the oxygen evolution catalytic material, a (TmNm)<x>Rm<y> alloy with an amorphous nanocrystalline composite structure is directly used as a precursor, wherein Tm is one or more of Fe, Ni and Co, Nm is one or more of P, C, Si and B, and Rm is one or more of the precious metals Ru, Rh, Os,Ir, Pt, Pd, Ag and Au. According to the preparation method, integrated preparation of a catalyst and a conductive carrier is realized, and the obtained catalytic material can be directly used as an anode for water electrolysis and has excellent oxygen evolution catalytic performance. The preparation method is convenient, the process is simple and easy to control, and the integrated transition metal series oxygen evolution catalytic material is suitable for large-scale production.

Owner:BEIHANG UNIV

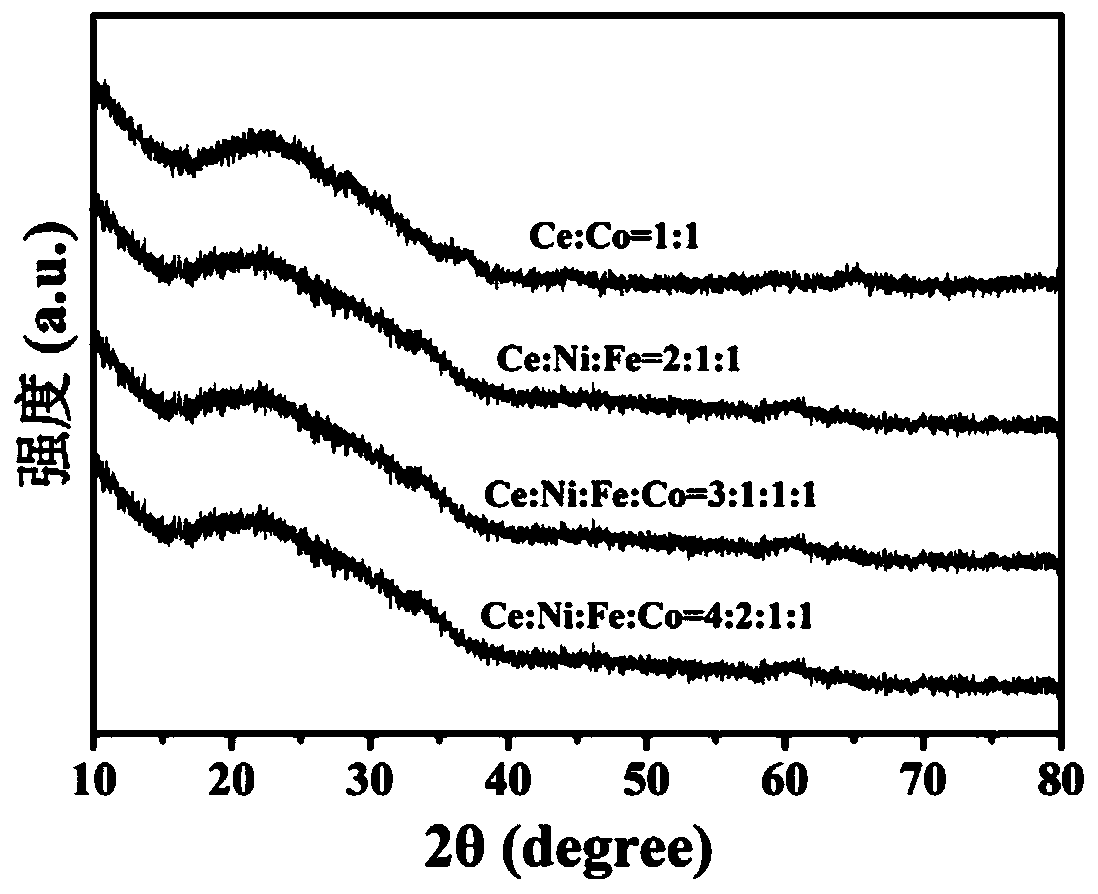

Preparation method of Ni-Fe-Co-Ce quaternary PB oxygen evolution catalyst

ActiveCN110711595ARaw materials are easy to obtainLow pricePhysical/chemical process catalystsElectrodesPtru catalystPhysical chemistry

The invention discloses a preparation method of an amorphous Ni-Fe-Co-Ce quaternary PB catalyst material with low oxygen evolution overpotential. The quaternary PB catalyst is mainly prepared by doping CeCo and other metals through a homogeneous precipitation method at normal temperature and utilizing the synergistic effect of the metals and the combined effect of phosphide borides, so that the oxygen evolution overpotential of electrochemical performance reaches 260 mV, and the quaternary PB catalyst has good performance in the field of electrochemical catalysts. The invention aims to providethe amorphous Ni-Fe-Co-Ce quaternary PB oxygen evolution catalyst which is simple in synthesis process, mild in reaction condition, high in repeatability and low in overpotential, and the amorphous Ni-Fe-Co-Ce quaternary PB oxygen evolution catalyst has important significance in further development of phosphide materials in the field of electrochemical oxygen evolution catalysts.

Owner:YANSHAN UNIV

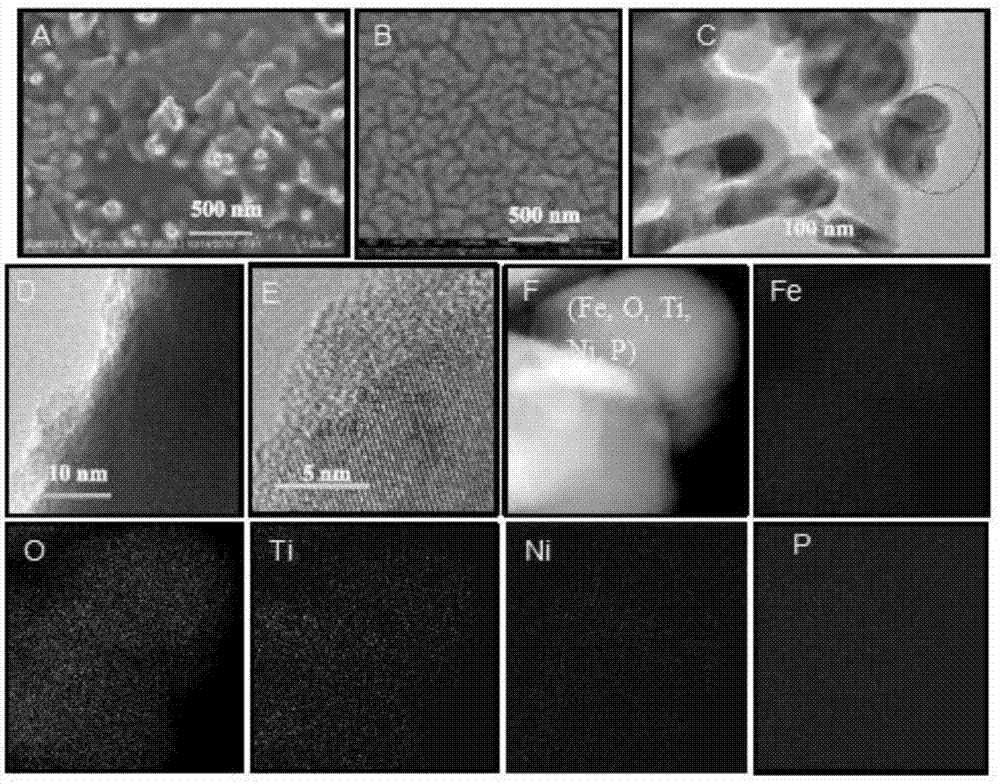

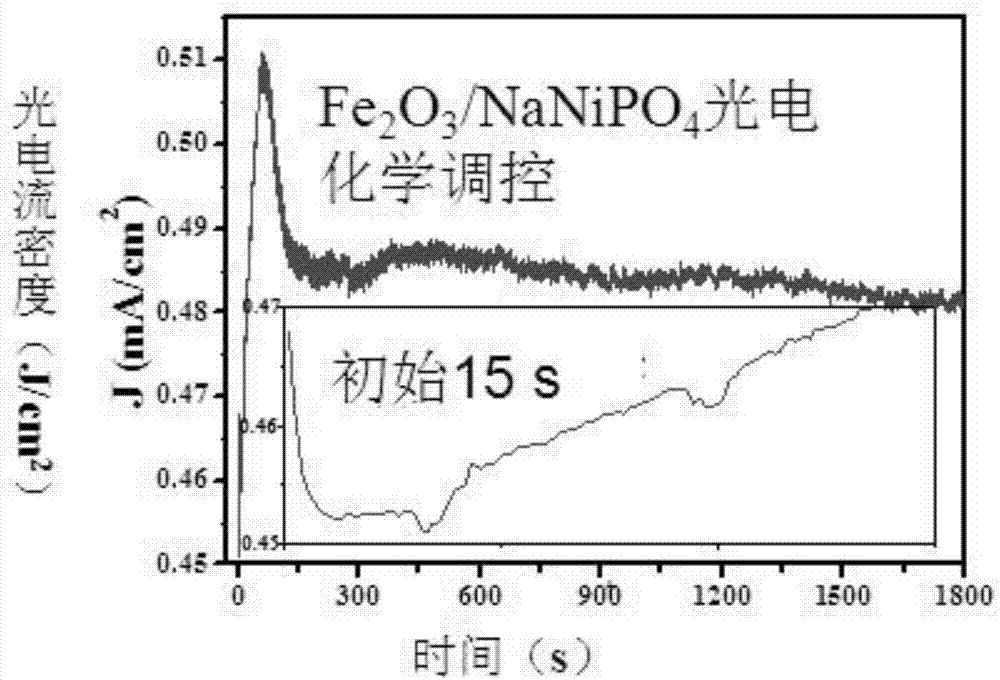

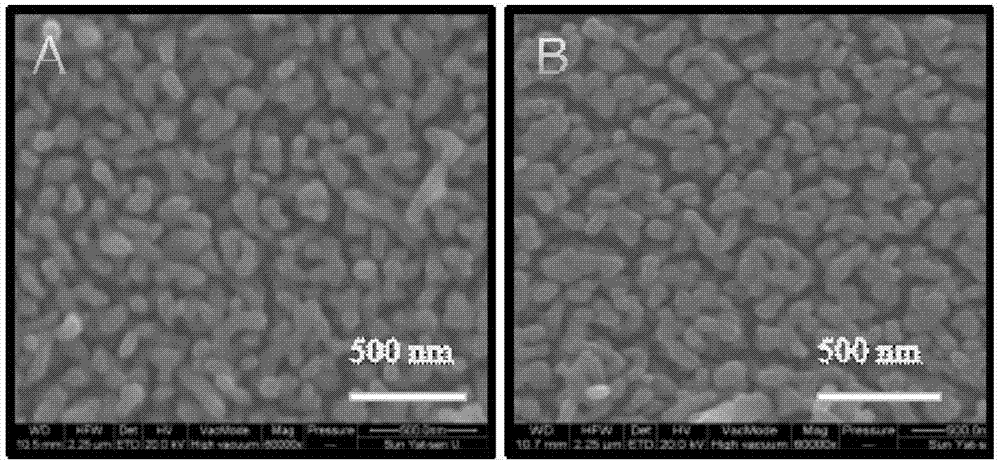

Metal oxide/NiPi photo-anode material and preparation thereof

The invention relates to a metal oxide / NiPi photo-anode material which comprises a metal oxide photo-anode and a NiPi thin film passivation layer, wherein a NiPi thin film is wrapped on the outer side of the metal oxide photo-anode. The preparation method comprises the following steps: (1) preparing a metal oxide photo-anode film; (2) dropwise coating the metal oxide photo-anode film with Ni salt and a neutral phosphate buffer solution, and performing deposition to prepare a NaNiPO4 thin film; and (3) performing photoelectric chemical regulation and control on the metal oxide photo-anode / NaNiPO4 thin film. According to the metal oxide / NiPi photo-anode material, Ti is doped into the surface of pure Fe2O3, so that a rich oxygen vacancy is introduced, which provides an assistance to improvement of conductivity; the NiPi wrapping layer inhibits the surface state of the pure Fe2O3; the NiPi wrapping layer has performance of inhibiting reaction of conduction band electrons and oxygen, so that surface charge transferring of an Fe2O3 electrode is enhanced comprehensively; with a lower oxygen evolution overpotential, the NiPi thin film is an extremely good substitute for CoPi in the aspect of catalytic water decomposition; meanwhile, the metal oxide / NiPi photo-anode material is easy to operate; and a Ni-containing catalyst is prepared at room temperature, so that energy consumption is low, and the operation time is short.

Owner:SHANTOU UNIV

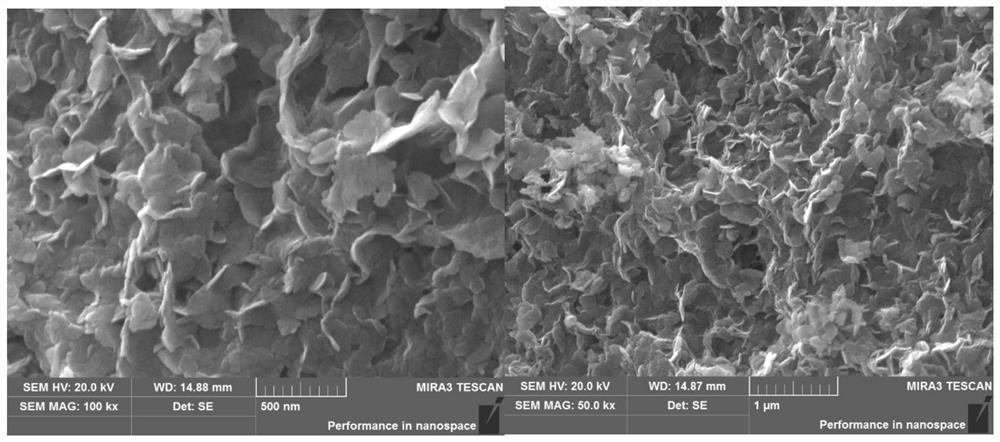

Diselenide/layered double hydroxide composite water electrolysis catalytic material as well as preparation method and application thereof

ActiveCN112076765AExcellent water electrolysis catalytic performanceReduce hydrogen evolutionPhysical/chemical process catalystsCell electrodesMolybdenum diselenideOxygen evolution

The invention discloses a diselenide / layered double hydroxide composite water electrolysis catalytic material which is a material with diselenide growing on the surface of layered double hydroxide in-situ. Diselenide is molybdenum diselenide and / or tungsten diselenide. The invention also provides an in-situ anion intercalation and in-situ self-assembly preparation method of the diselenide / layereddouble hydroxide composite water electrolysis catalytic material under ultrasonic enhancement. The invention also discloses an application of the diselenide / layered double hydroxide composite water electrolysis catalytic material as an HER and / or OER material. The prepared diselenide / layered double hydroxide composite water electrolysis catalytic material not only has a low hydrogen evolution over-potential, but also has oxygen evolution reaction (OER) over-potential basically equivalent to that of noble metal, and is very excellent in performance. Therefore, the catalytic material is of greatsignificance to the improvement of the water electrolysis hydrogen production level.

Owner:CENT SOUTH UNIV

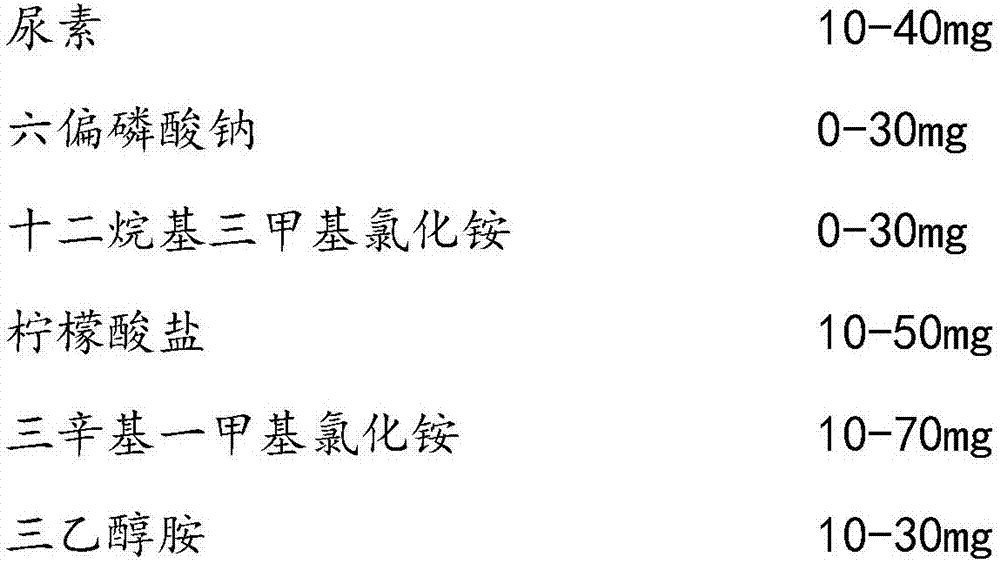

Mixed additive for electrolyzing alkaline etching waste fluid, and method for preparing copper powder with same

The invention relates to a mixed additive for electrolyzing alkaline etching waste fluid, and a method for preparing copper powder with the mixed additive. Every litre of the aqueous solution of the mixed additive comprises the following components of 10 mg to 40 mg of urea, 0 mg to 30 mg of sodium hexametaphosphate, 0 mg to 30 mg of dodecyl trimethyl ammonium chloride, 10 mg to 50 mg of citrate, 10 mg to 70 mg of methyl trioctyl ammonium chloride, and 10 mg to 30 mg of triethanolamine. The mixed additive is adopted for carrying out electrolysis copper deposition treatment on the alkaline etching waste fluid, superfine copper powder with high additional value can be prepared, and recycling of the etching fluid is realized. Because a chlorine inhibition and oxygen evolution electrode is adopted as the electrolysis anode, no chlorine is separated out in the process of electrolysis regeneration, and no damage is caused to the environment while beneficial reuse of the etching waste fluid is realized.

Owner:SHANDONG JINBAO ELECTRONICS

Complex alloy used for anode plate for refining metallic copper by electrolysis and preparation method thereof

InactiveCN101660069AReduce corrosion rateImprove corrosion resistancePhotography auxillary processesProcess efficiency improvementElectrolysisSlag

The invention discloses a complex alloy used for an anode plate for refining metallic copper by electrolysis and a preparation method thereof. The complex alloy consists of the following components byweight percent: 0.3-3% of tin, 0.03-0.1% of calcium or strontium, 0.005-0.08% of cobalt, 0.03-0.09% of rare earth metal and the balance of lead. The preparation method comprises the steps of: smelting and preparing tin and cobalt into preliminary alloy of tin and cobalt in a melting furnace according to weight percent for standby; putting the lead and the preliminary alloy of tin and cobalt intothe melting furnace for melting, and preserving heat after the temperature is raised to be 450-550 DEG C; adding the calcium or the strontium, and the rare earth metal into the lead liquid according to the weight percent and stirring, and applying a 5-36 V direct current potential difference between the fusant and the furnace during the stirring process; and standing for 30-40 minutes after the fusant is alloyed evenly, and removing oxidizing slag on the surface of the fusant, thus obtaining the complex alloy. The invention simplifies the process flow, reduces material consumption, improves corrosion resistance, and simultaneously reduces melting temperature and metallic lead pollution.

Owner:苏向东

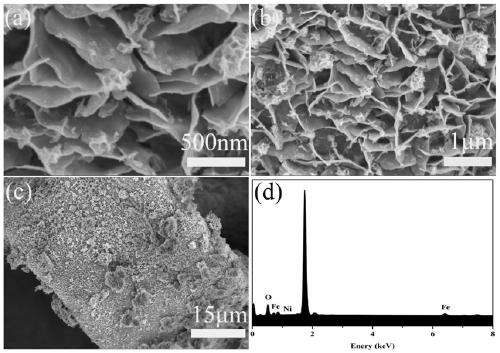

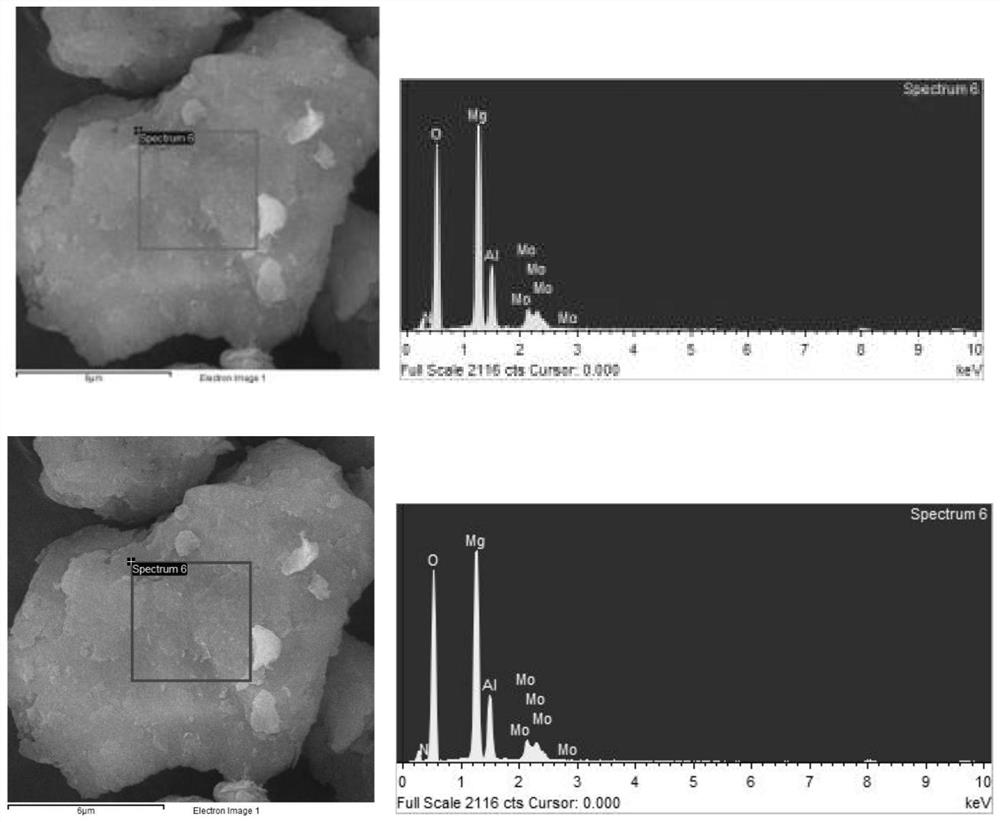

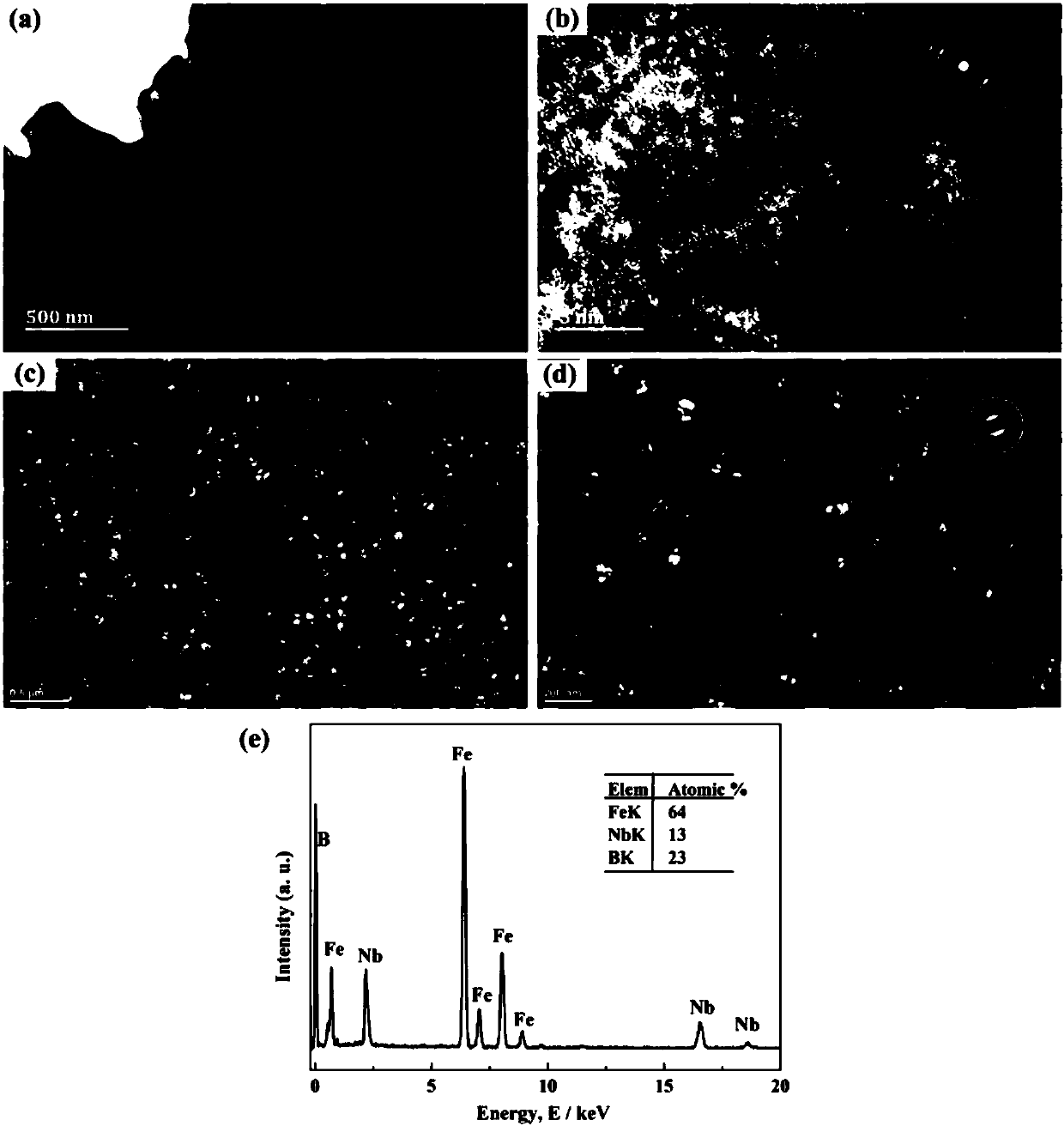

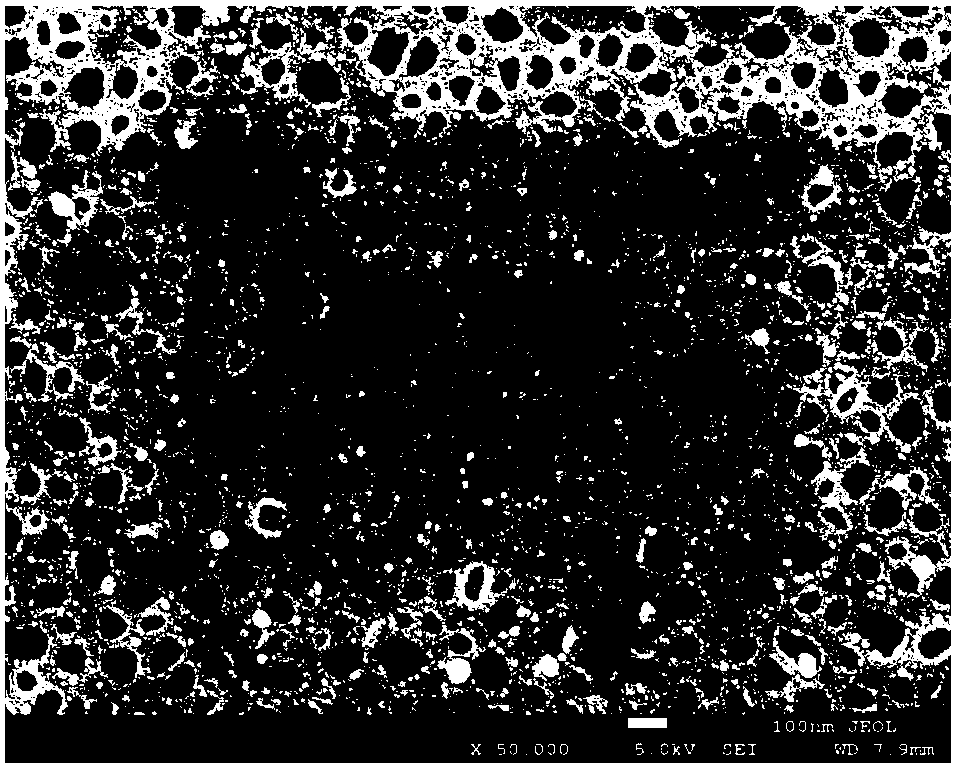

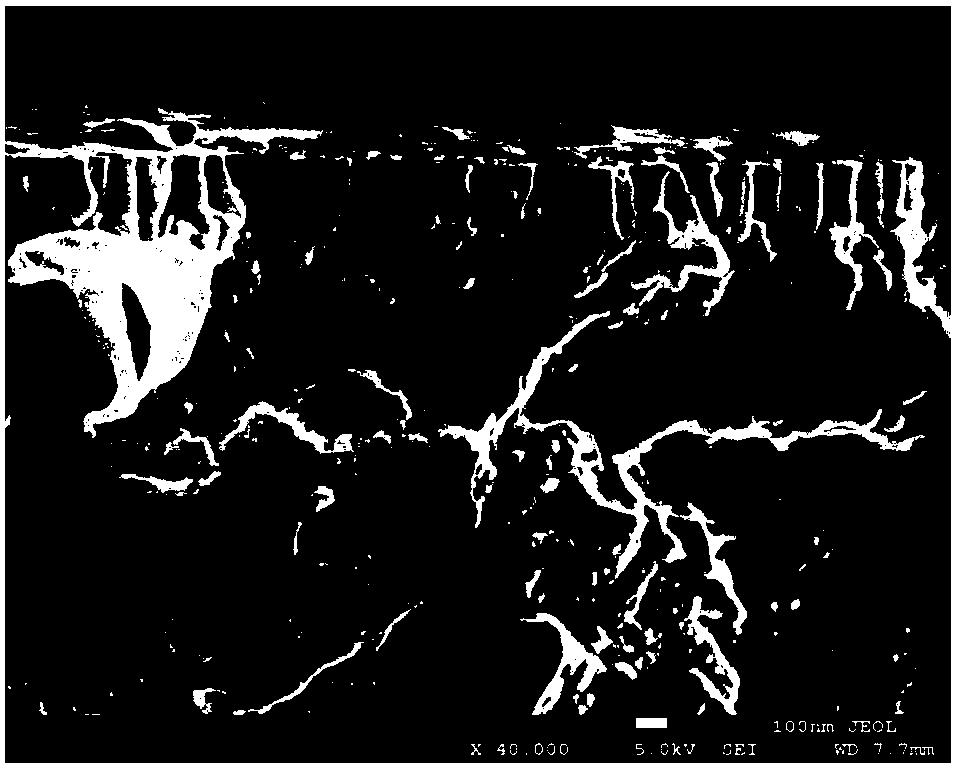

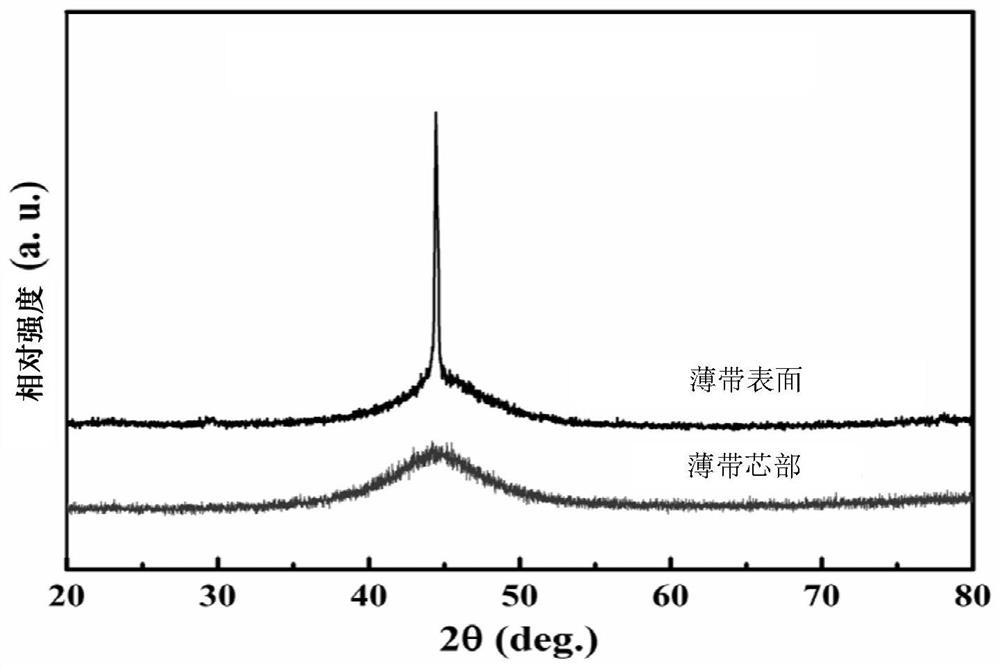

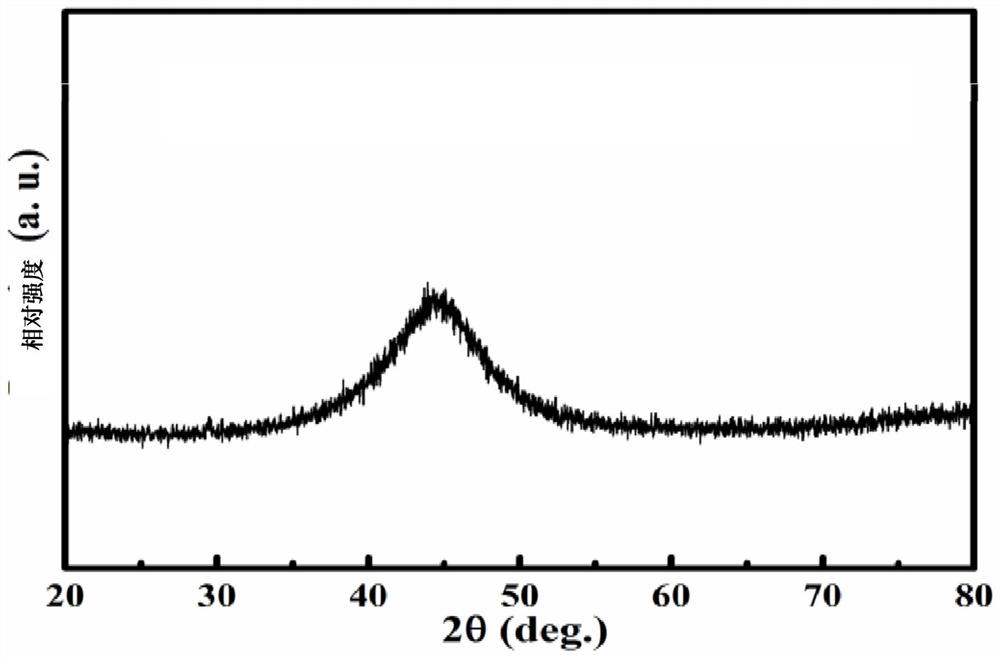

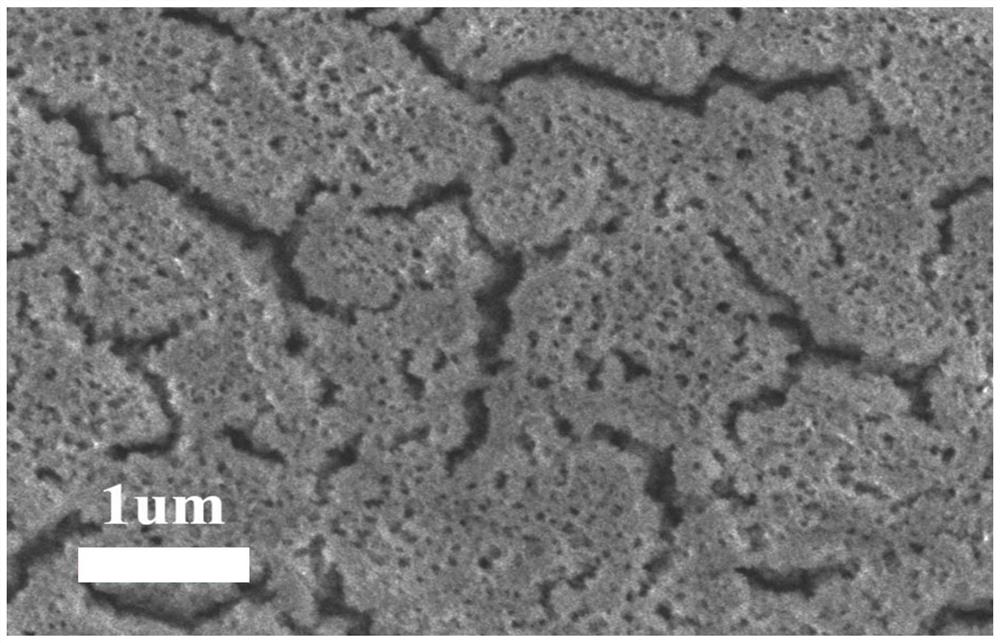

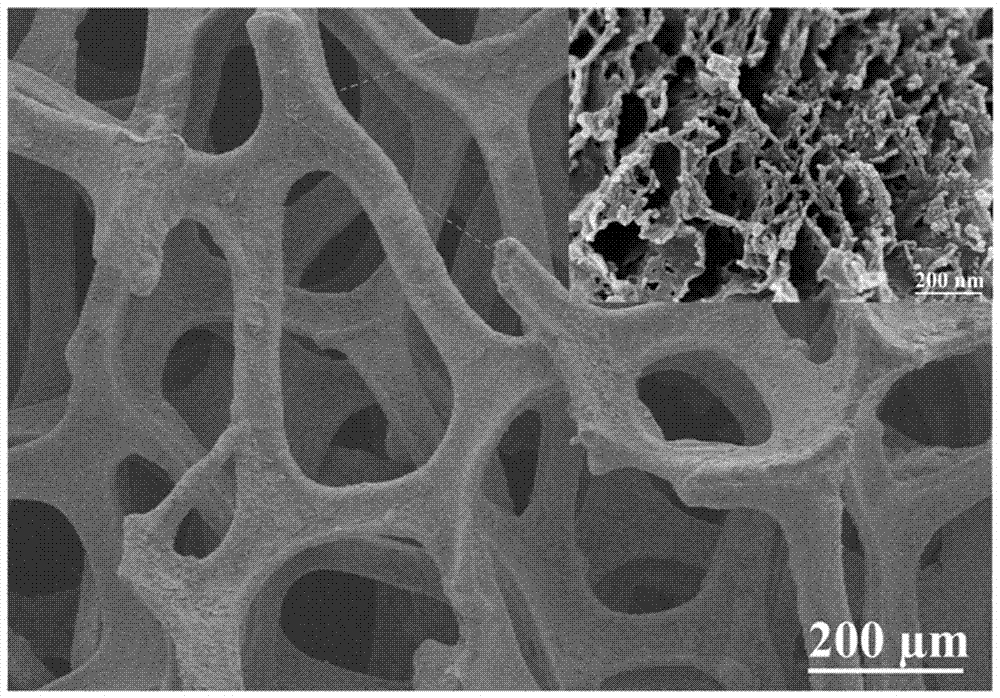

A kind of nanoporous Fe-based amorphous alloy and its preparation method and its application on oxygen evolution catalytic electrode

ActiveCN106222584BShape is easy to controlGuaranteed difference in corrosion resistanceElectrodesElectrolysisSelective leaching

The invention relates to a nanoporous Fe-based amorphous alloy and its preparation method and its application on an oxygen evolution catalytic electrode, specifically: using Fe-based amorphous / nanocrystalline alloy as a precursor, according to the characteristics of an amorphous phase and a nanocrystalline phase Different corrosion resistance, nanoporous Fe-based amorphous alloys prepared by selective etching of nanocrystalline phases. The prepared nanoporous Fe-based amorphous structure is stable, the specific surface area is large, and the composition and morphology can be adjusted. Oxygen catalytic activity, can be widely used in electrolysis of water oxygen evolution electrode and other fields. The preparation method of the invention is simple and has wide applicability.

Owner:北京自然天空科技发展有限公司

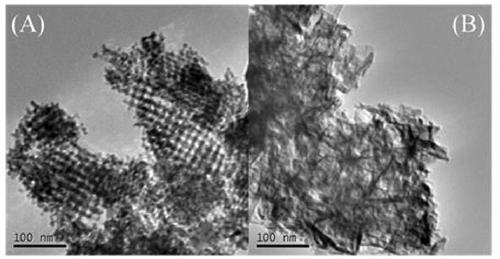

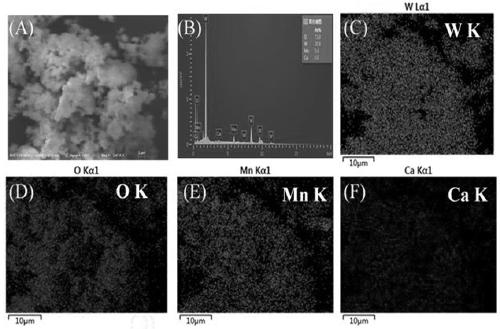

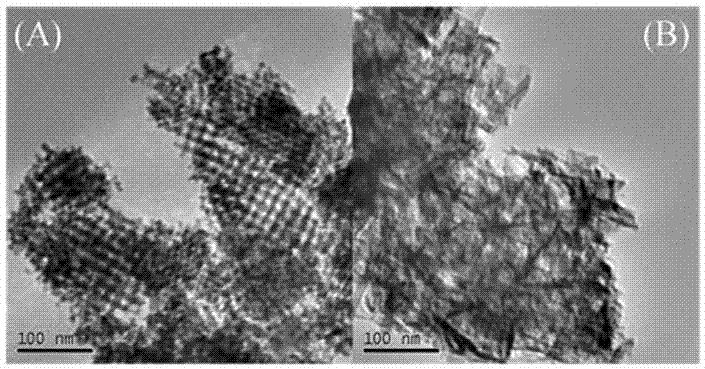

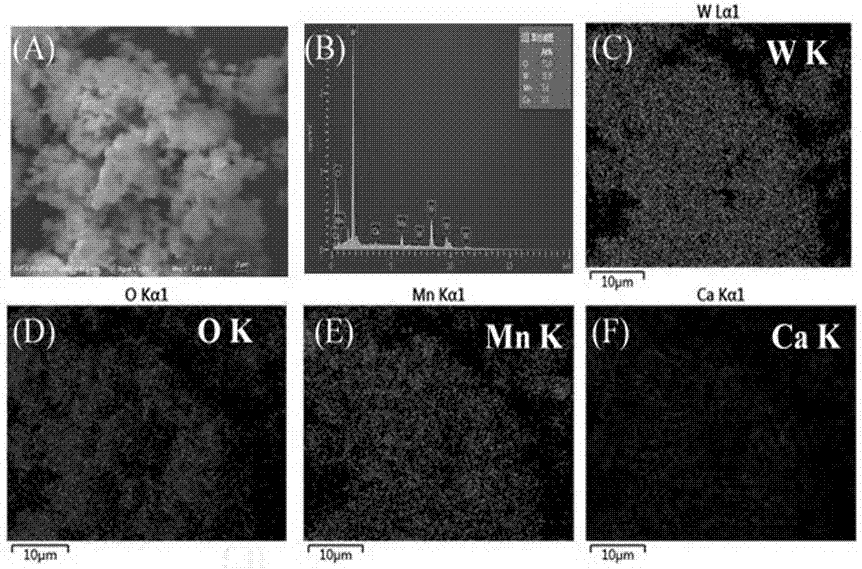

Tungsten-manganese-calcium/mesoporous tungsten trioxide composite that can be used to prepare photoanode and preparation method thereof

ActiveCN107442105BImprove photocatalytic activityImprove stabilityHeterogenous catalyst chemical elementsEnergy inputManganeseCharge separation

The invention discloses a calcium tungsten manganese / mesoporous tungsten trioxide composite that can be used to prepare a photoanode and a preparation method thereof. The calcium tungsten manganese / mesoporous tungsten trioxide composite includes mesoporous tungsten trioxide and calcium manganese. Oxide. Mesoporous tungsten trioxide has a short electron migration distance, and island-shaped tungsten manganese calcium oxide serves as an oxygen-generating active center site and has a low oxygen evolution potential. Therefore, the photoanode made of this composite has a high light intensity. Catalytic oxygen production activity. Compared with the corresponding single-component catalyst, this ternary composite semiconductor catalyst overcomes the shortcomings of a single catalyst through the combination of calcium manganese and tungsten oxide, and has high charge separation efficiency, small oxygen evolution overpotential, and good catalytic activity and stability. With other advantages, it is a promising new catalytic material for preparing photoanode of photochemical cells.

Owner:SUZHOU UNIV

Tungsten manganese calcium/mesoporous tungsten trioxide compound for preparing photo-anode and preparation method thereof

ActiveCN107442105AImprove photocatalytic activityImprove stabilityHeterogenous catalyst chemical elementsEnergy inputManganeseCharge separation

The invention discloses a tungsten manganese calcium / mesoporous tungsten trioxide compound for preparing a photo-anode and a preparation method thereof. The tungsten manganese calcium / mesoporous tungsten trioxide compound is prepared from mesoporous tungsten trioxide and manganese calcium oxide. The mesoporous tungsten trioxide has a shorter electron migration distance, and the island-shaped tungsten manganese calcium oxide is used as an oxygen generation active center sites and has a lower oxygen evolution potential, so that the photo-anode prepared through the compound has higher photocatalysis oxygen generation activity. Compared with a corresponding single-component catalyst, according to a ternary compound semiconductor catalyst, the defects of a single catalyst are overcome through the compounding of manganese calcium and tungsten oxide, and the ternary compound semiconductor catalyst has the advantages of high charge separation efficiency, low oxygen evolution overpotential, good catalytic activity and stability, and the like, and is a promising novel catalytic material for preparing the photo-anode of a photochemical cell.

Owner:SUZHOU UNIV

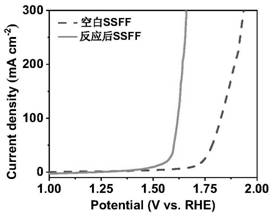

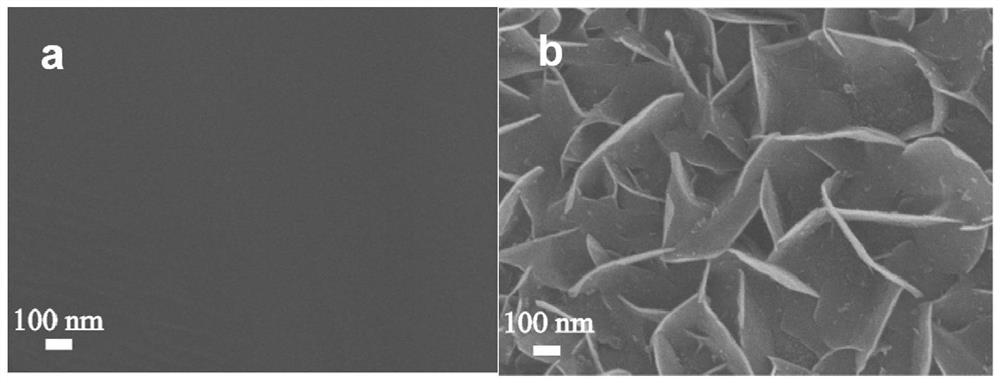

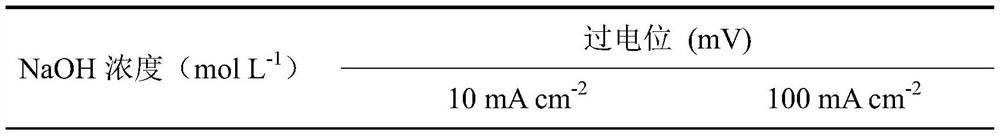

Nanosheet-structured NiFeCr composite hydroxide oxygen evolution material prepared by chemical oxidation method

PendingCN114561663AAchieve growthLower internal resistanceElectrodesPotassium persulfatePtru catalyst

The invention provides a preparation method of an electro-catalytic moisture desorption oxygen desorption catalyst in a carbonate system, and belongs to the field of chemical oxidation and electro-catalytic moisture desorption oxygen desorption. Comprising the steps that a stainless steel material containing a nickel source, an iron source and a chromium source serves as a substrate, oil stains and oxides on the surface of the stainless steel material are removed, then the stainless steel material reacts in an alkaline solution containing a persulfate oxidizing agent at the temperature of 20-110 DEG C for 0.25-3 h, a product is taken out, washed to be clean and then subjected to vacuum drying, and the NiFeCr composite hydroxide oxygen evolution material with the nanosheet structure is obtained. The electrode can greatly reduce the oxygen evolution overpotential for catalyzing water decomposition in a carbonate system, a test result shows that the electrode treated by adopting a potassium persulfate oxidizing agent has excellent oxygen evolution catalytic performance, and the oxygen evolution overpotential is 263 mV and 384 mV respectively when the current density is 10 mA cm <-2 > and 100 mA cm <-2 > in 0.5 mol L <-1 > Na2CO3 / NaHCO3. The stainless steel substrate used in the method is cheap and easy to obtain, the treatment method is simple and easy to operate, conditions are mild, and the method is suitable for large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

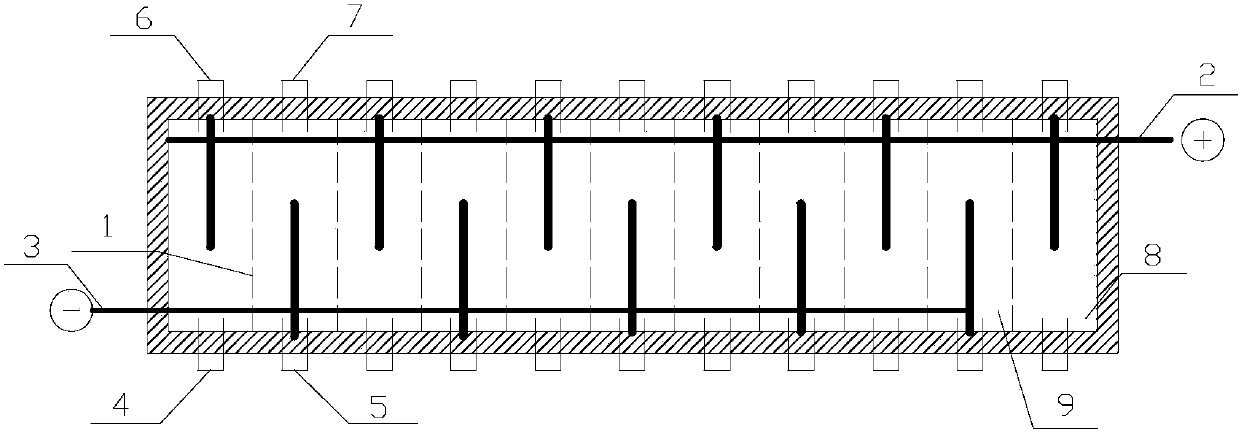

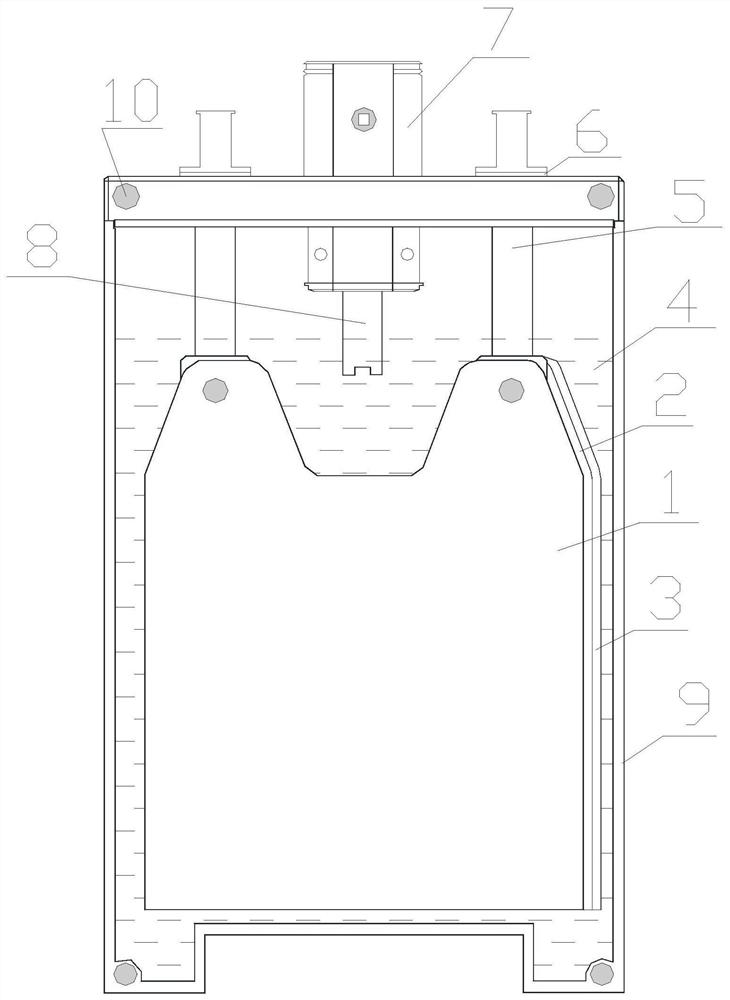

A kind of electrolytic cell for electrolytic manganese production

InactiveCN105603455BIncrease the reaction areaIncrease productivityPhotography auxillary processesDiaphragmsManganeseEngineering

The invention relates to an electrolytic tank for electrolytic manganese production, in particular to an electrolytic tank adopting an anion-exchange membrane and a titanium-based coating anode. The electrolytic tank comprises a plurality of unit electrolytic tank bodies, and an ion diaphragm and a sealing gasket are arranged between every two unit electrolytic tank bodies. The electrolytic tank has the advantages that due to ion selective permeability of the anion-exchange membrane, manganese ions are limited in a cathode chamber, in this way, only deposition of manganese on a cathode occurs in the electrolytic process, and anode mud cannot be generated; 2, due to the fact that a great amount of anode mud is not generated any more, the electrolytic tank does not need to be cleaned frequently, and production efficiency can be greatly improved; 3, a reticular titanium-based coating is adopted to form a three-dimensional electrode to serve as the anode, and the reticular titanium-based coating has a large reaction area and low oxygen evolution potential, so that the electrolytic tank formed in the mode is 0.5-1 V lower than traditional tank pressure, and electrolytic energy consumption can be lowered by 20% and above.

Owner:WUHAN UNIV

Method for preparing novel anode material for non-ferrous metal electrodeposition

ActiveCN102206838BImprove corrosion resistanceReduce oxygen evolution overpotentialElectrodesAlloyCobalt

The invention discloses a method for preparing an anode material for non-ferrous metal electrodeposition. The invention is characterized in that: the anode material is prepared from the following materials in percentage by weight: 0.1 to 0.2 percent of silver, 0.05 to 0.1 percent of cobalt, 0.1 to 0.5 percent of tin, 0.05 to 0.09 percent of calcium, 0.1 to 1 percent of stibium and the balance of lead. The method comprises the following steps of: melting the lead, and adding a silver-cobalt intermediate alloy containing 0.1 to 0.2 percent of silver and a tin-cobalt intermediate alloy; melting, adding a lead-calcium intermediate alloy, an antimony block and the residual lead, stirring for at least 10 minutes, standing for 5 minutes, descumming, casting into an alloy plate blank; and cooling, rolling, performing surface treatment on a lead alloy plate, leveling, and shearing the plate into alloy anodes with required size. The prepared anode has good mechanical properties and corrosion resistance, and can greatly reduce cell voltage and energy consumption in the electrolysis process in the electrometallurgy process of wet electrodeposition of zinc, copper, nickel and the like.

Owner:晋宁理工恒达科技有限公司

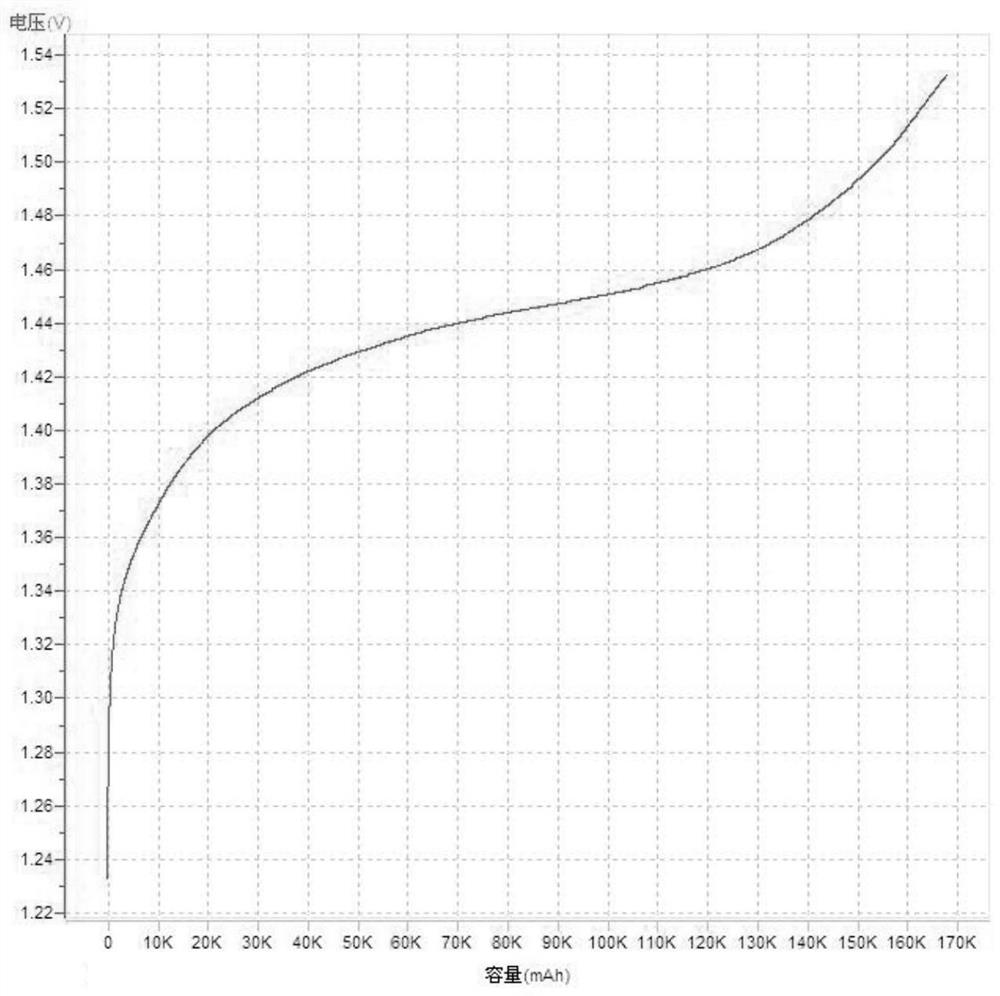

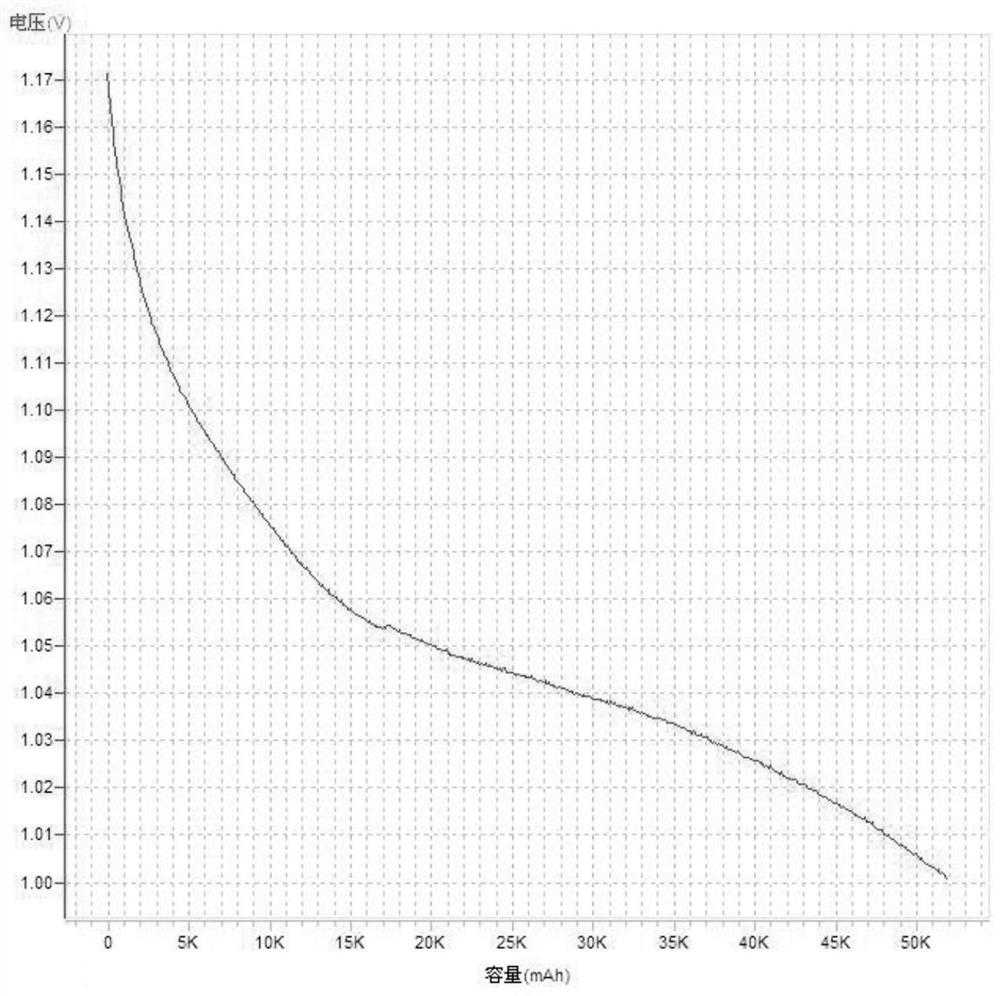

Nickel-metal hydride storage battery

InactiveCN112864373AImprove low temperature performanceMeet the use requirementsCell electrodesSecondary cells servicing/maintenanceElectrolytic agentButadiene-styrene rubber

A nickel-metal hydride storage battery comprises a shell, an electrode and electrolyte, the electrode comprises a positive electrode plate, a negative electrode plate and a diaphragm, the electrode is completely immersed in the electrolyte, materials of the positive electrode plate comprise a positive active material, a positive conductive agent, a positive additive and a positive adhesive, the positive active material comprises nickel hydroxide, the positive conductive agent comprises cobalt or nickel, the positive electrode additive comprises calcium hydroxide or zinc oxide, the positive electrode plate adhesive comprises carboxymethyl cellulose or polytetrafluoroethylene, the negative electrode plate is prepared from hydrogen storage alloy powder, a negative electrode conductive agent, a negative electrode additive and a negative electrode adhesive, the negative electrode conductive agent comprises conductive carbon or nickel powder, the negative electrode additive comprises zinc oxide or aluminum oxide, the negative electrode adhesive comprises hydroxypropyl methyl cellulose and butadiene styrene rubber, lining plates are arranged on the outer sides of the positive electrode plate and the negative electrode plate respectively, the lining plates are made of elastic materials, and a plurality of through holes are further formed in the lining plates. The invention provides a novel nickel-metal hydride storage battery which is safe, reliable, environment-friendly, pollution-free, long in service life, good in wide-temperature performance and large in capacity ratio.

Owner:中达绿城交通科技有限公司

Composite anode for hydrometallurgy and its preparation method and application

The invention discloses a composite anode for hydrometallurgy and its preparation method and application. The structure of the composite anode is metal substrate / non-oxide intermediate layer / selective electrocatalytic oxygen evolution layer, wherein the non-oxide intermediate layer can isolate Oxygen diffuses to the metal substrate to avoid passivation of the metal substrate, and the selective electrocatalytic oxygen evolution layer can selectively catalyze oxygen evolution while inhibiting Mn in the electrolyte 2+ depletion. The composite anode can be used in the electrochemical metallurgical process of non-ferrous metals such as zinc, manganese, copper, etc., and when it is used for the electrodeposition of metal manganese, it can realize the equal current density of the cathode and the anode and the electrodeposition without diaphragm, which greatly reduces the energy of the electrodeposition process. Consumption, inhibition of Mn 2+ Oxidation losses at the anode improve cathodic current efficiency.

Owner:CENT SOUTH UNIV

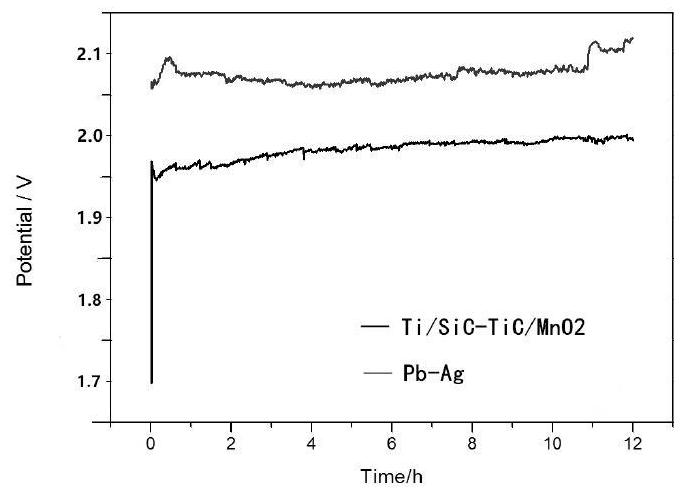

Integrated transition metal-based oxygen evolution catalytic material and preparation method

ActiveCN110791771BComposition controllableHigh catalytic activityNon-noble metal oxide coatingsPtru catalystElectrolysis

The invention discloses an integrated transition metal-based oxygen evolution catalytic material and a preparation method thereof. The prepared (Tm a N m b ) x R m y The oxygen evolution catalytic material is composed of a thin alloy strip composed of two layers of structure. One layer is a nanoporous layer doped with transition metal oxides or hydroxides with high catalytic activity and noble metals on the surface, and the other layer is a highly conductive layer. non-crystalline alloy matrix. The oxygen evolution catalytic material is directly formed with an amorphous-nanocrystalline composite structure (Tm a N m b ) x R m y The alloy is a precursor, where Tm is one or more of Fe, Ni, Co, Nm is one or more of P, C, Si, B, Rm is noble metal Ru, Rh, Os, Ir , one or more of Pt, Pd, Ag, Au. The method of the invention realizes the integrated preparation of the catalyst and the conductive carrier, and the obtained catalytic material can be directly used as an anode for water electrolysis, and has excellent catalytic performance for oxygen evolution. The preparation method of the invention is convenient, the process is simple and easy to control, and is suitable for large-scale production.

Owner:BEIHANG UNIV

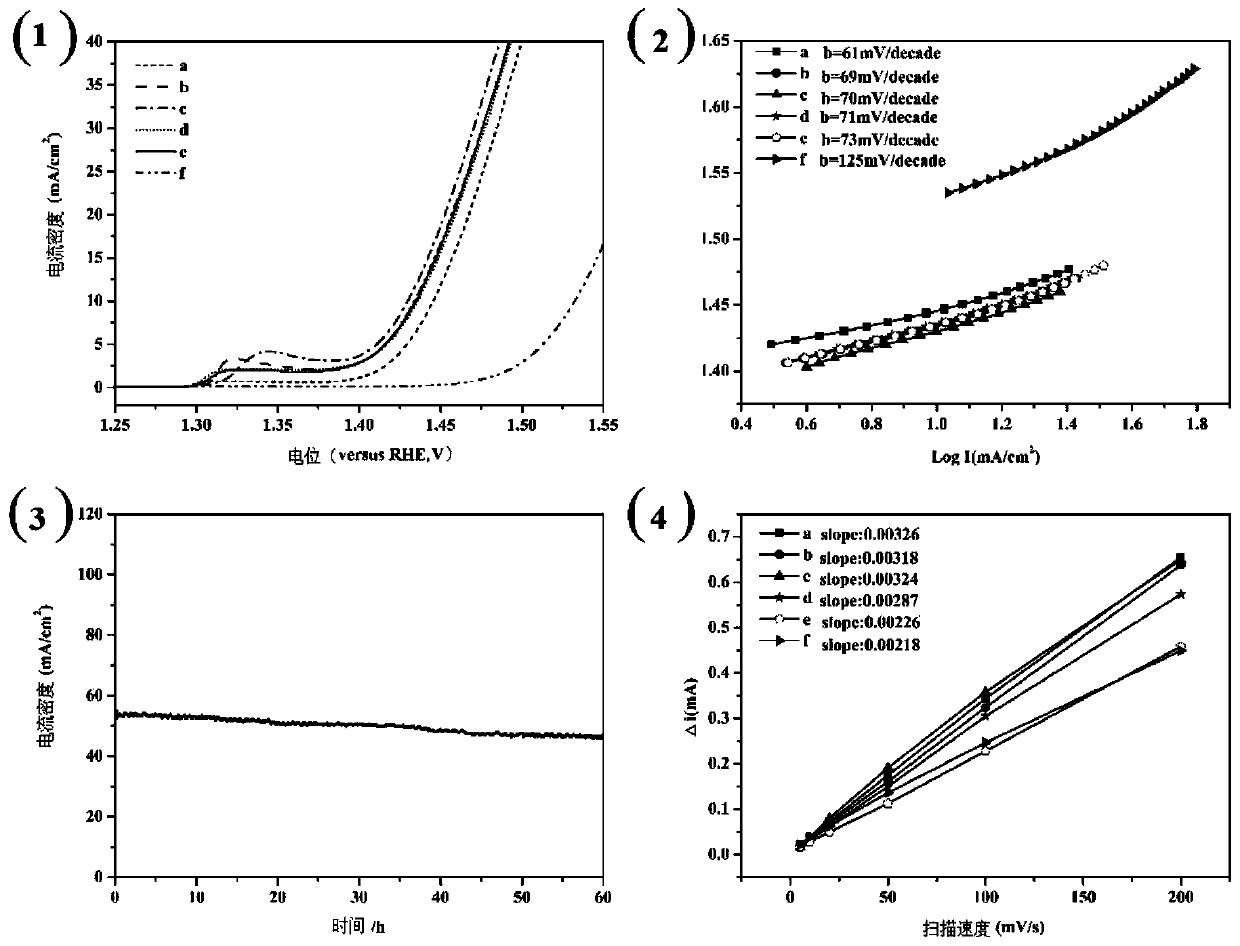

Preparation method of a carbon-coated transition metal phosphide composite and its application in oxygen evolution reaction

ActiveCN106552654BEvenly dispersedImprove conductivityPhysical/chemical process catalystsElectrodesOxygenOxygen evolution

The invention first synthesizes a needle-shaped transition metal hydroxide precursor with anion intercalation containing both a phosphorus source and a carbon source between the layers, and then prepares a pod-shaped carbon-coated transition metal phosphide composite material through high-temperature roasting. This composite material is used in the cathode reaction-oxygen evolution reaction in electrolyzed water, and can effectively improve the performance of the catalyst, that is, reduce the starting potential, improve the catalytic activity, and has a long service life and good stability. At the same time, its raw materials are low in price, abundant in reserves, simple in preparation method and environmentally friendly. Under alkaline conditions of 0.1–1M KOH, the overpotential required to reach a current density of 10mA cm-2 is 280–340mV, the Tafel slope is 60–80mV / dec, and the cycle is performed at a constant voltage of 1.65V. The time is as long as 1-24 hours or more.

Owner:BEIJING UNIV OF CHEM TECH

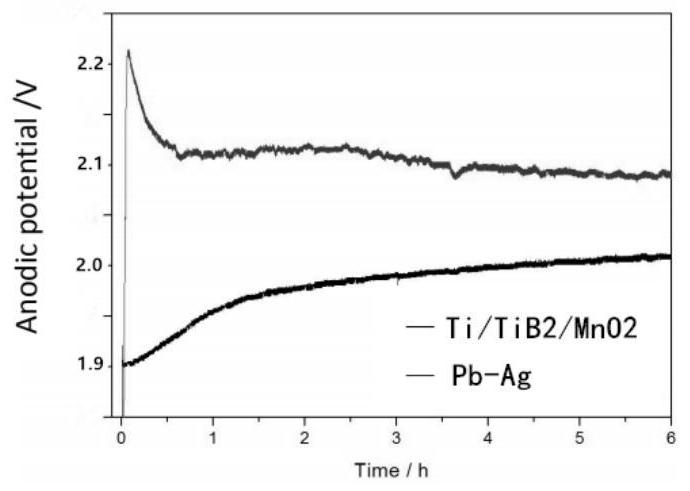

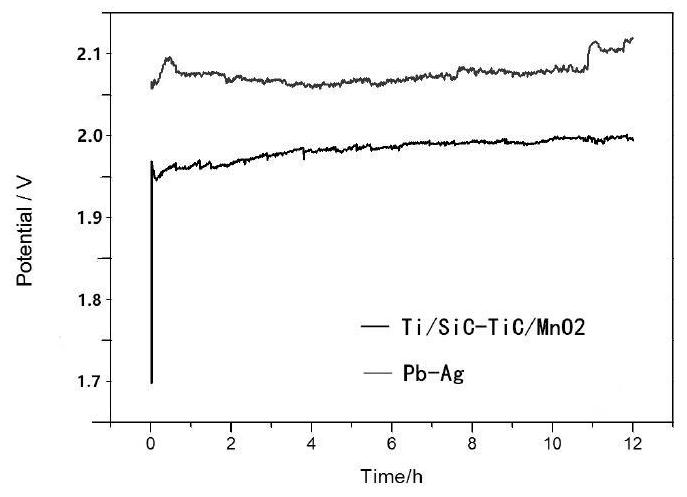

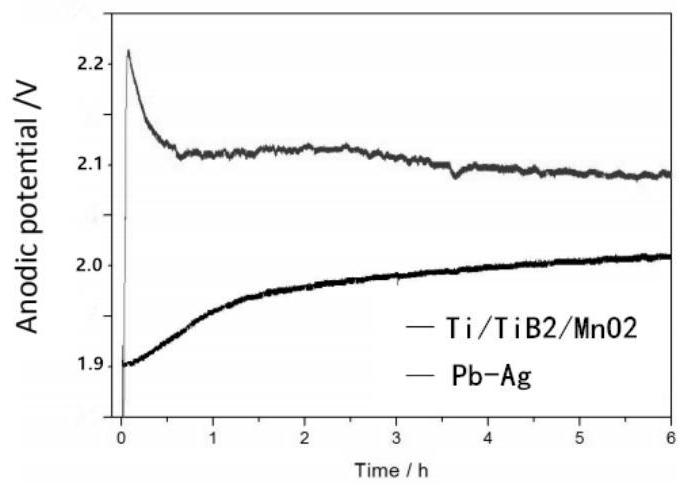

A kind of preparation method of zinc electrowinning anode

ActiveCN109797311BReduce oxygen evolution overpotentialEasy to manufacturePhotography auxillary processesProcess efficiency improvementLead dioxideZinc

The invention discloses a method for preparing a zinc electrodeposited anode, which comprises: batching and mixing powder: batching lead powder, silver powder, and lead dioxide powder, rolling and mixing the batched powder until uniform; in mass percentage, The silver powder is 0.1-1%, the lead dioxide powder is 0.1-10%, and the rest is lead powder; pressing and sintering: pressing the uniformly mixed powder and sintering in a reducing and protective atmosphere; cooling: cooling the sintered material naturally. The invention has low equipment requirements and is easy to prepare the anode. The anode prepared by the invention has the advantages of low oxygen evolution overpotential, high mechanical strength, good corrosion resistance, long service life, etc., and can replace the traditional casting Pb-Ag anode.

Owner:CENT SOUTH UNIV

Three-dimensional anode material and preparation method for hydrogen production by electrolysis of water

ActiveCN105140531BReduce oxygen evolution overpotentialImprove structural stabilityCell electrodesOvervoltageElectrolysis

The invention provides a novel three-dimensional anode material for hydrogen production by water electrolysis. The novel three-dimensional anode material comprises nickel foam loaded N-doped carbon / transition metal oxide prepared in situ according to a liquid-solid synthesis method as well as a three-dimensional anode piece used for hydrogen production through water electrolysis. A preparation method of the three-dimensional anode material particularly comprises the following steps: (1) immersing clean nickel foam into a mixed solution, containing transition metal salt, a silicon source and a nitrogen source, of water and ethanol, taking out the nickel foam for airing, and repeating for three times; (2) calcining the nickel foam piece obtained in the step (1) for 1-6 h at 600-800 DEG C under the protection of inert gas, and then heating for 1-1.5 h at 200-250 DEG C in the atmosphere of O2, so as to obtain a nickel foam loaded N-doped carbon / transition metal oxide three-dimensional electrode. The three-dimensional electrode produced according to the preparation method has relatively low oxygen evolution overvoltage, has relatively high structural stability and oxygen evolution catalytic activity under long-term alkaline electrolysis condition, is simple in production process and adjustable in electrode component and variety, and has wide application prospects.

Owner:TAIYUAN UNIV OF TECH

Method for pretreating lead base inert anode for electro-deposit copper

InactiveCN102465313AReduce contentOptimizing Pretreatment Process ParametersPhotography auxillary processesProcess efficiency improvementPretreatment methodAlloy

The invention relates to a method for pretreating a lead base inert anode for electro-deposit copper. A pretreatment solution comprises cobaltous sulfate, sulfuric acid and distilled water, wherein the temperature of the pretreatment solution is 30-70 DEG C; the anode is to be pretreated, a cathode is a stainless steel plate, space between the anode and the cathode is 3-6cm, the circulating quantity of the pretreatment solution is 0.05-0.5V groove / h, V groove represents the volume of a pretreatment groove; and the pretreatment process is as follows: the current density of the anode is 50-400A / m<2>, and the pretreatment time is 8-24h. By adopting the pretreatment solution containing the cobaltous sulfate, parameters of the pretreatment process are optimized. The pretreatment process is simple, is convenient for operation, is beneficial to industrial application, and can be used for controlling oxygen evolution overpotential of the lead or lead alloy inert anode for the electro-deposit copper to be within 550mV. The lead or lead base anode treated by adopting the method is used as an anode for the electro-deposit copper, and remarkable effects are obtained on the aspects of reducing the content of lead as impurity of the cathode copper and reducing electricity consumption per ton of copper.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com