Composite electrode for electrodialysis as well as preparation method and application thereof

A composite electrode and application technology, applied in the field of electrodialysis, can solve the problems of cumbersome operation process, no industrial production application, high oxygen evolution overpotential, and achieve good electrochemical stability, good chemical stability, and good electrocatalytic performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

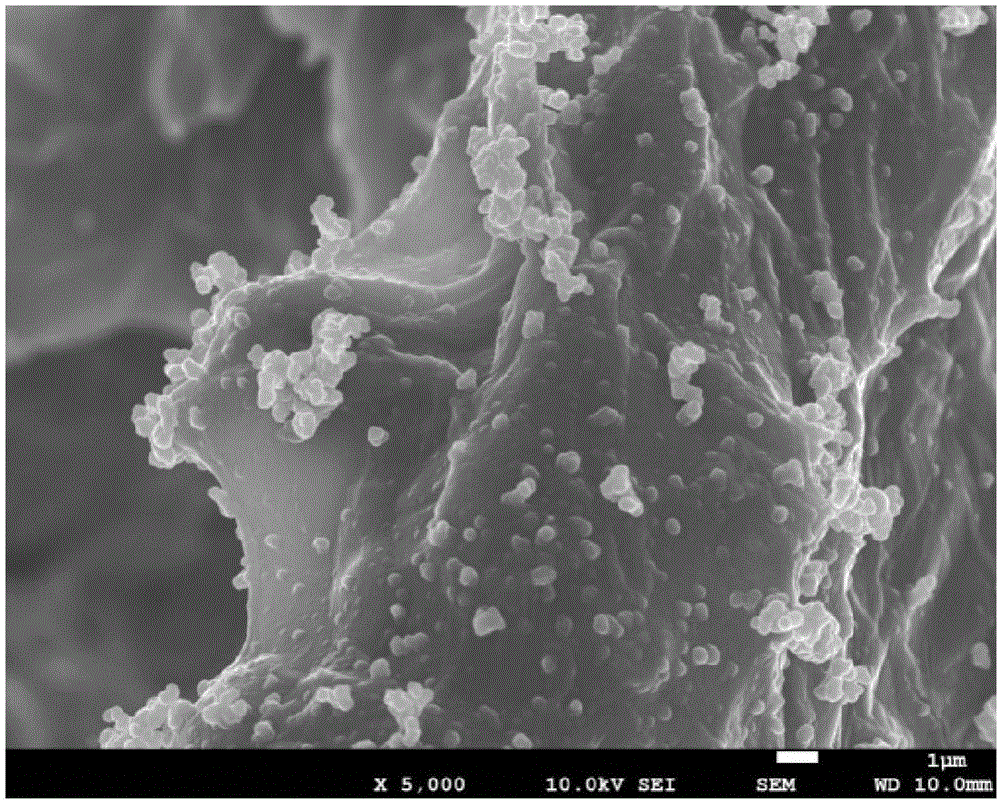

[0079] (1) Preparation of conductive substrate / graphene electrode

[0080] Use 3M adhesive tape to fix the exposed area of the titanium plate (1.4cm×1.5cm) to 0.7cm 2 , drop 50μl (1mgml -1 ) graphene oxide (GO) solution, placed in the air to dry naturally, to prepare a conductive substrate / graphene oxide Ti / GO electrode, and further prepare a conductive substrate / graphene electrode by electrochemical reduction, named Ti / rGO electrode.

[0081] (2)': Preprocessing

[0082] Before electrodeposition, apply 60% PTFE solution to the place where there is no rGO on the Ti / rGO electrode (that is, the working area of the fixed electrode is 0.7cm 2 ), and placed in the air to dry naturally to form a film for later use.

[0083] (2) Preparation of conductive substrate / graphene / metal oxide composite electrodes by electrodeposition

[0084] Add 5mM RuCl to the electrolyte (composed of 0.01M HCl and 0.1M KCl) 3 ·xH 2 O solution with 0.5 mM IrCl 3 ·xH 2 O solution, with the Ti / rG...

Embodiment 2

[0090] (1) Preparation of conductive substrate / graphene electrode

[0091] The preparation method and conditions are the same as in Example 1, and a conductive substrate / graphene electrode is prepared, named Ti / rGO electrode;

[0092] (2)': Preprocessing

[0093] The method and condition of pretreatment are identical with embodiment 1;

[0094] (2) Preparation of conductive substrate / graphene / metal oxide composite electrodes by electrodeposition

[0095] To the electrolyte (the composition is 0.01MH 2 SO 4 and 0.2MKCl) by adding 5mM RuCl 3 ·xH 2 O solution with 0.5 mM IrCl 3 ·xH 2 O solution, with the Ti / rGO electrode that step (1) obtains as working electrode, adopts the method for electro-deposition to deposit metal oxide on the surface of Ti / rGO electrode, described metal oxide is ruthenium, iridium oxide, named after ( Ru+Ir)O x mH 2 O, that is, cyclic voltammetry was used to continuously scan 150 cycles between the potential of -0.3 and +1.0Vvs.SCE, and the elec...

Embodiment 3

[0099] (1) Preparation of conductive substrate / graphene electrode

[0100] The preparation method and conditions are the same as in Example 1, and a conductive substrate / graphene electrode is prepared, named Ti / rGO electrode;

[0101] (2)': Preprocessing

[0102] The method and condition of pretreatment are identical with embodiment 1;

[0103] (2) Preparation of conductive substrate / graphene / metal oxide composite electrodes by electrodeposition

[0104] Add 5mM RuCl to the electrolyte (composed of 0.1M HCl and 0.5M KCl) 3 ·xH 2 O solution with 1 mM IrCl 3 ·xH 2 O solution, with the Ti / rGO electrode that step (1) obtains as working electrode, adopts the method for electro-deposition to deposit metal oxide on the surface of Ti / rGO electrode, described metal oxide is ruthenium, iridium oxide, named after ( Ru+Ir)O x mH 2 O, that is, cyclic voltammetry was used to continuously scan 150 cycles between the potential of -0.3 and +1.0Vvs.SCE, and the electrolyte was placed in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com