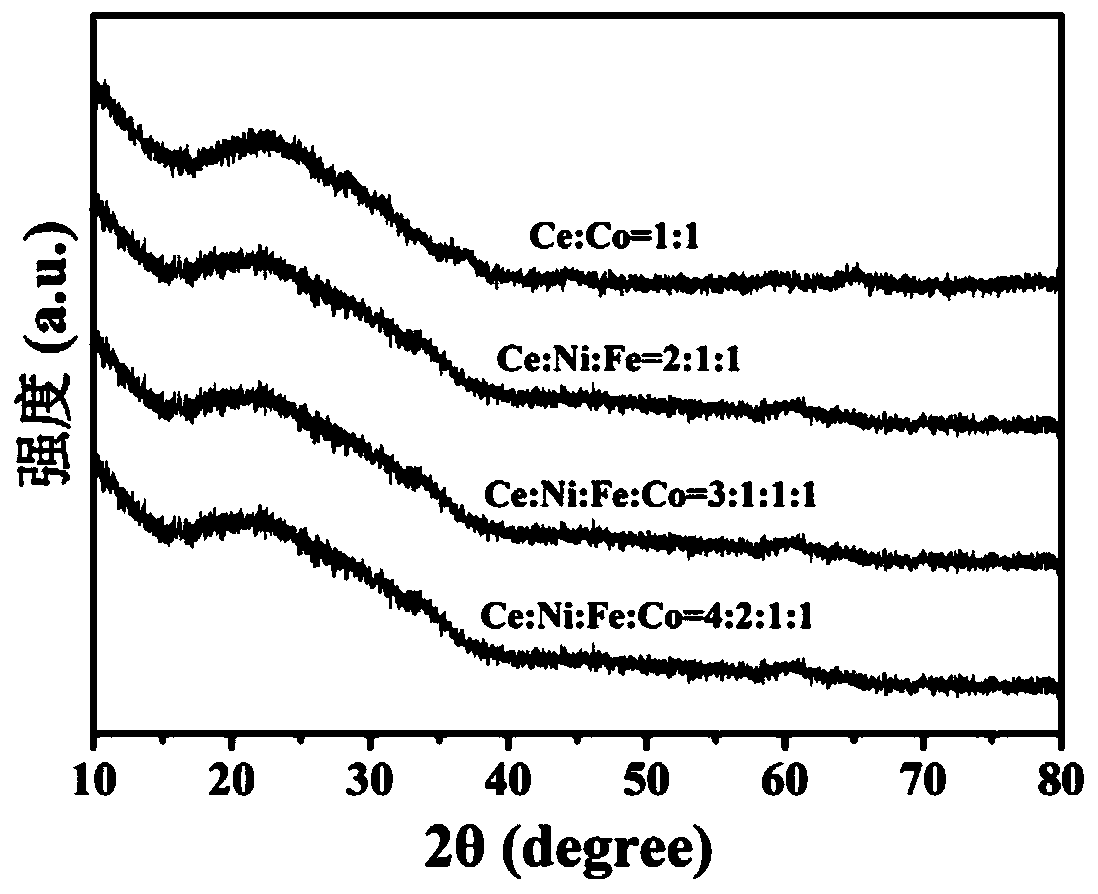

Preparation method of Ni-Fe-Co-Ce quaternary PB oxygen evolution catalyst

A ni-fe-co-ce, catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low loading, high apparent activity, etc., to achieve the preparation process Simple and feasible, mild reaction conditions, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh the medicine containing four elements of Ce-Co-Ni-Fe with analytical purity, cerium nitrate, cobalt nitrate, iron nitrate, nickel chloride according to the ratio of cerium element, cobalt element, iron element and nickel element 3:1:1:1 Weigh the molar ratio (the masses of cerium nitrate, cobalt nitrate, ferric nitrate and nickel chloride are 0.035g, 0.031g, 0.043g, 0.025g respectively), put it into a 20ml beaker, add 10ml of water to dissolve. Add 800 μl H to the above solution 2 o 2 Let it stand for five minutes until the solution turns orange-yellow, then adjust the pH of the solution to 10.5 with ammonia water, then add 0.1g / ml NaBH 4 Solution 2.5ml and 0.25g / ml NaH 2 PO 2 2.5ml of the solution was uniformly stirred at 25°C for 6 hours. Let the above solution stand for 6 hours, centrifuge and wash to neutrality, and place the obtained sample in a vacuum drying oven at 70°C for 12 hours in vacuum to obtain an amorphous Ni-Fe-Co-Ce quaternary with low overpo...

Embodiment 2

[0038] Weigh the medicine containing Ce-Ni-Fe-Co four elements of analytical purity, cerium chloride, cobalt chloride, nickel nitrate, iron nitrate according to cerium element, nickel element, iron element and cobalt element 4:2:1: 1 molar ratio (the mass of cerium chloride, nickel chloride, ferrous chloride, and cobalt chloride are 0.035g, 0.038g, 0.016g, 0.019g respectively), put into a 20ml beaker by weighing, add 10ml of water to dissolve. Add 800 μl H to the above solution 2 o 2 Until the solution turns orange-yellow, adjust the pH of the solution to 11 with ammonia water, then add 0.1g / ml NaBH 4 Solution 2.5ml and 0.25g / ml NaH 2 PO 2 2.5ml of the solution was uniformly stirred at 25°C for 6 hours. The above solution was left to stand for 6 hours, centrifuged and washed to neutrality, and the obtained sample was placed in a vacuum drying oven at 70°C for 12 hours in vacuum to obtain an amorphous Ni-Fe-Co-Ce quaternary with low overpotential PB oxygen evolution catal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com