A kind of electrolytic cell for electrolytic manganese production

An electrolytic cell and electrolytic manganese technology are applied in the field of electrolytic cells to achieve the effects of reducing electrolysis energy consumption, improving production efficiency, and reducing oxygen evolution overpotential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The solution of the present invention will be described in further detail below in conjunction with the examples, but this description will not constitute a limitation of the present invention.

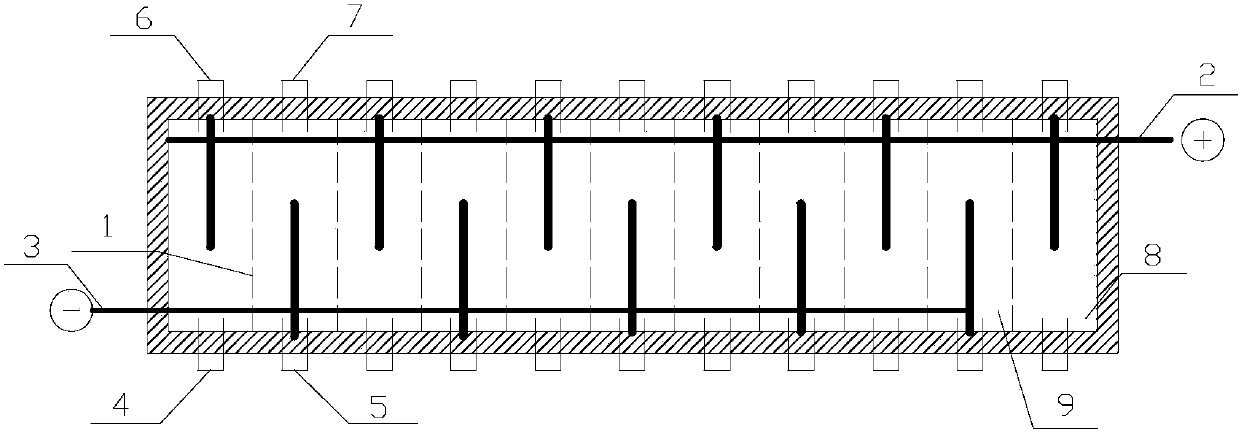

[0015] Such as figure 1 As shown, an electrolytic cell for electrolytic manganese production comprises eleven unit electrolytic cells, an ion diaphragm 1 and a sealing gasket are arranged between each of the unit electrolytic cells, and the ion diaphragm is a highly conductive acid and alkali resistant Polyvinyl fluoride-based or polysulfone-based homogeneous anion-exchange membrane; the interior of the unit electrolyzer is alternately arranged with mesh anodes 2 and plate-shaped cathodes 3, which are called anode chamber 8 and cathode chamber 9 respectively. , the mesh anode is a three-dimensional mesh coating anode composed of two or more mesh coating anodes connected in parallel, and the mesh coating anode is titanium-based, aluminum-based, copper-based or nickel-based Ruth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com