Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

102results about How to "Reduce electrolysis energy consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ion exchange membrane with high current efficiency, and preparation method and application thereof

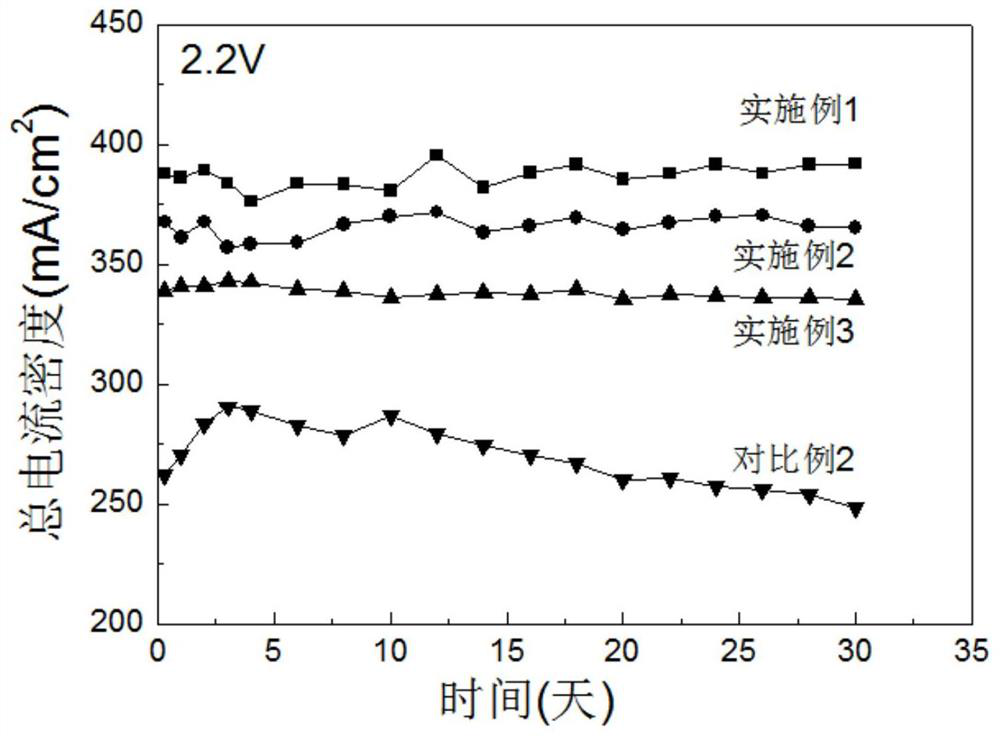

ActiveCN102336043AHigh mechanical strengthImprove current efficiencyCellsSynthetic resin layered productsCarboxylic acidIon-exchange resin

The invention relates to an ion exchange membrane with high current efficiency, and a preparation method thereof, and application of the ion exchange membrane to preparation of caustic soda in a chlor-alkali tank, and belongs to a compound membrane for producing alkali metal hydroxides and chlorine simultaneously in an ion membrane electrolytic tank. The ion exchange membrane with high current efficiency is characterized by being formed by compounding three layers of perfluorinated ion exchange resin base membranes and a reinforcing material; the three layers of perfluorinated ion exchange resin base membranes are sequentially a high-exchange-capacity sulfonic acid layer, a low-exchange-capacity sulfonic acid layer and a high-exchange-capacity carboxylic acid layer; and the reinforcing material is compounded on one side near the high-exchange-capacity sulfonic acid layer. The invention provides the ion exchange membrane which is high in current efficiency, mechanical strength and chemical stability, suitable for high and low alkali liquor concentration, and low in cost; the preparation method is simple; and in an electrolytic process, the electrolytic tank always keeps high current efficiency and low tank pressure; and products hydroxides have few impurities and are high in purity.

Owner:SHANDONG DONGYUE POLYMER MATERIAL

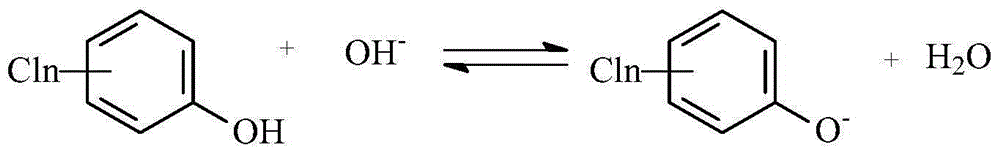

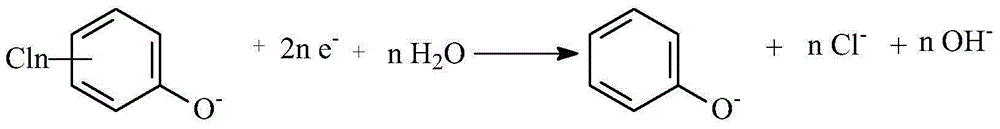

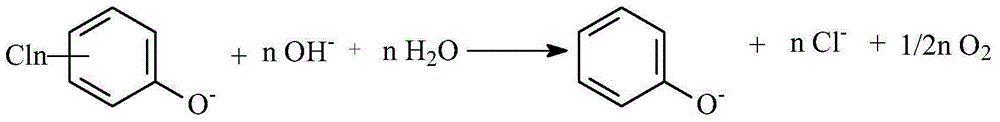

Electrochemical method for hydrodechlorination of chlorinated organic pollutant

ActiveCN105018962AReduce dosageLow costElectrolysis componentsElectrolytic organic productionHigh current densityPalladium catalyst

The invention discloses an electrochemical method for the hydrodechlorination of a chlorinated organic pollutant. The method comprises: adding the chlorinated organic pollutant into an alkaline solution so as to obtain electrolytic reaction liquid; and carrying out electrolytic reaction in a non-diaphragm electrolytic cell using a conductive material modified by palladium as a cathode and a chemically inert conductive material as an anode so as to obtain a fully dechlorinated compound. The electrochemical method for the hydrodechlorination of the chlorinated organic pollutant, provided by the invention, utilizes the palladium for catalysis, simultaneously realizes high current efficiency, high current density and low electrolytic voltage and does not use a diaphragm. The electrochemical method for the hydrodechlorination of the chlorinated organic pollutant not only can greatly reduce the usage quantity of the palladium catalyst and reduce the volume of the electrolytic cell, but also can simplify the structure of the electrolytic cell, reduce the cost of the electrolytic cell and reduce electrolytic energy consumption.

Owner:SHANGHAI LINKCHEM TECH CO LTD

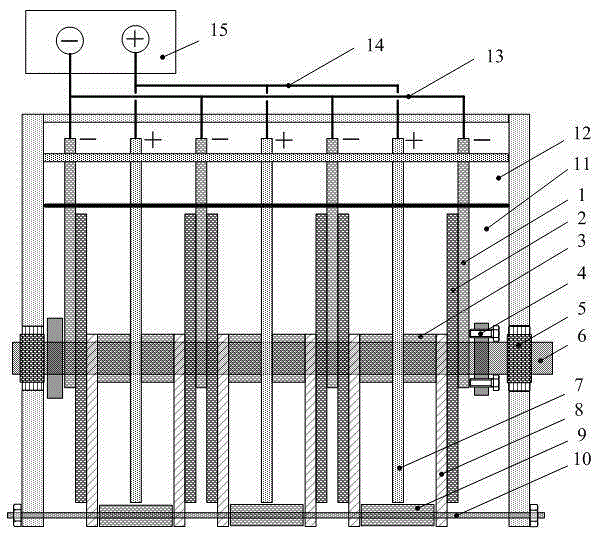

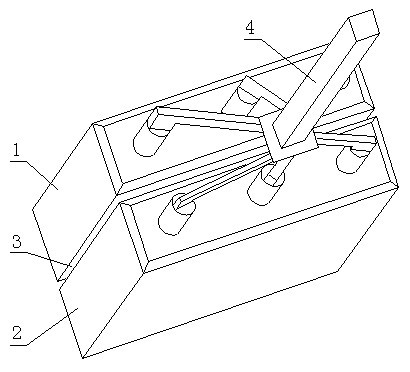

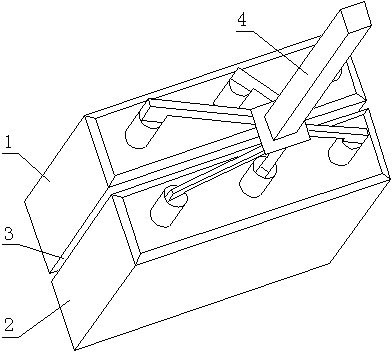

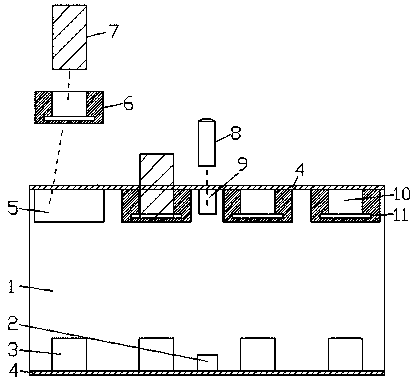

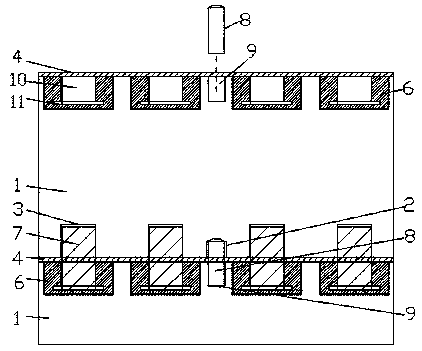

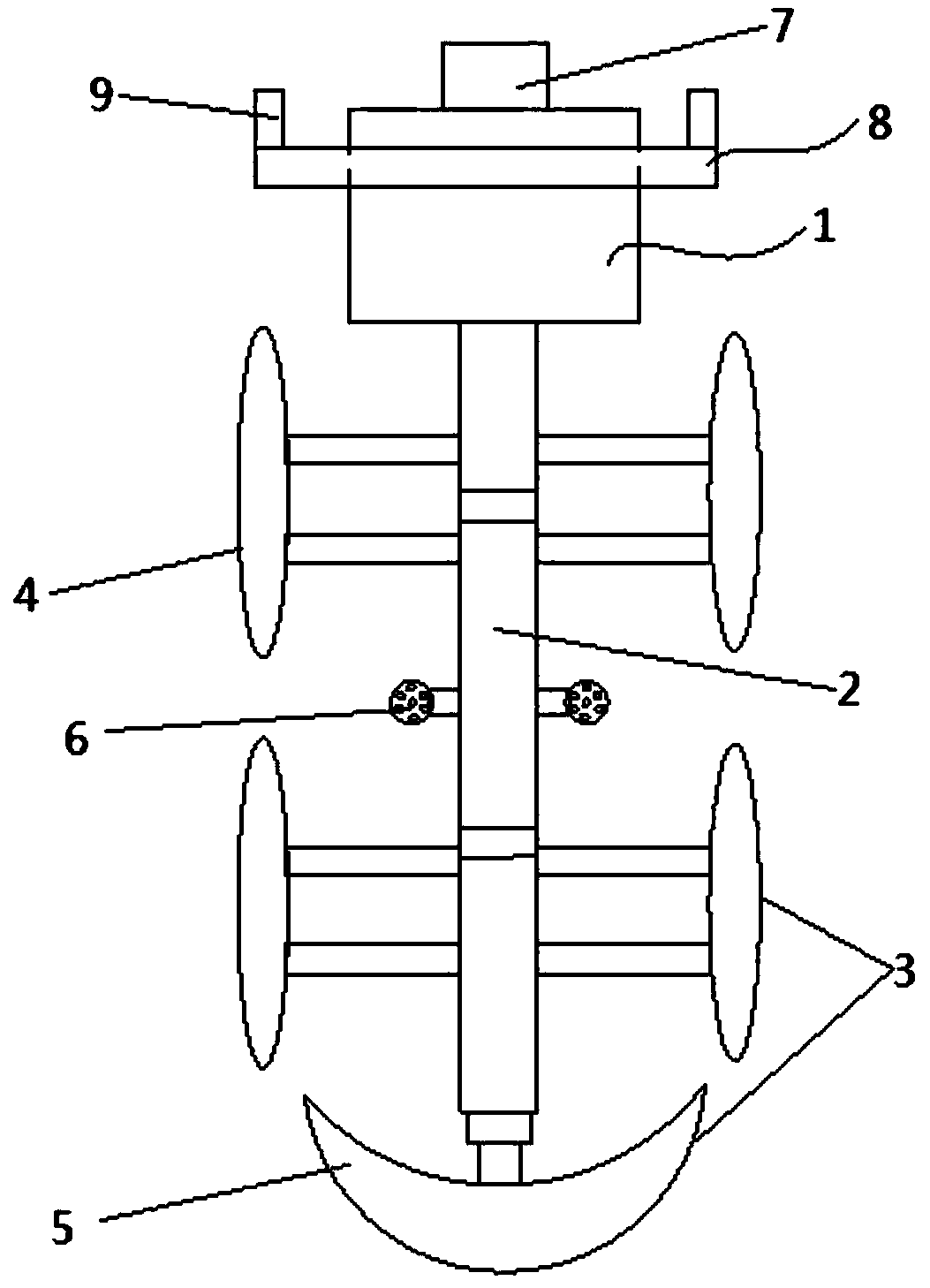

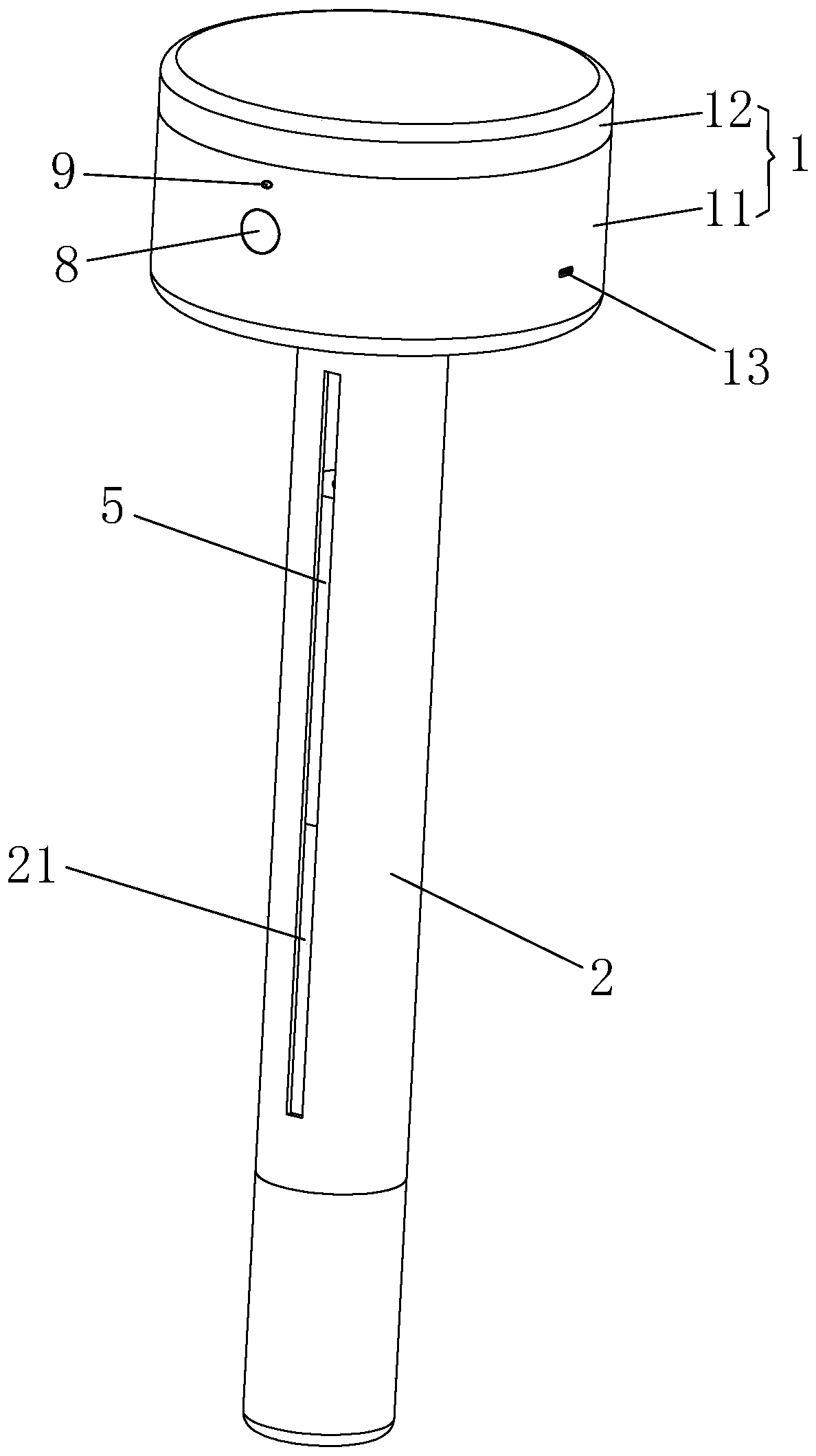

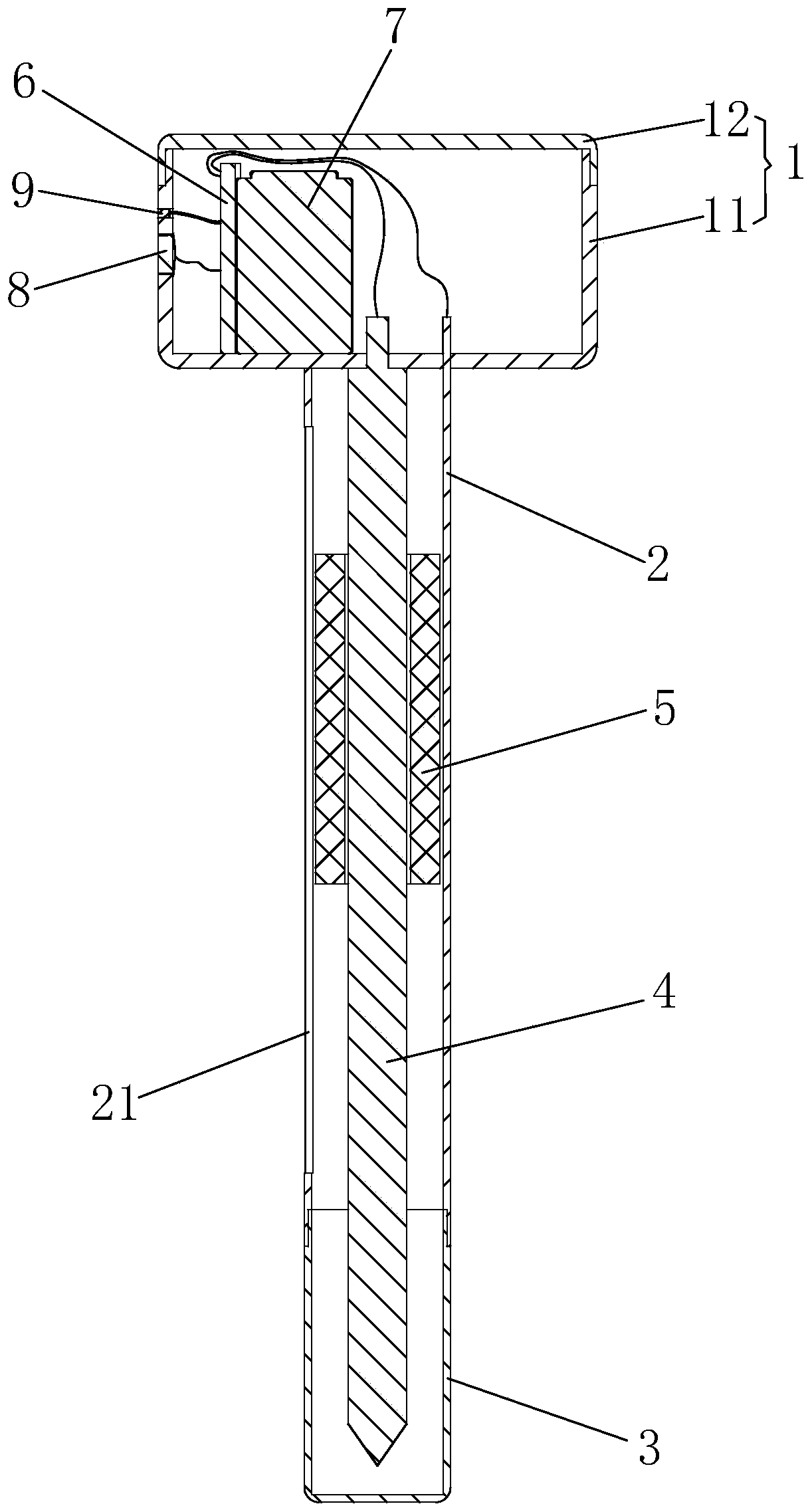

Rotating negative electrode scale scraping and removing device

InactiveCN105329985AImprove scrapingGood descaling effectSpecific water treatment objectivesWater/sewage treatment by electrochemical methodsPower flowPhysics

The invention relates to a rotating negative electrode scale scraping and removing device which comprises negative electrode conductive columns 1, negative electrode plates 2, a rotating shaft 6, positive electrode plates 7 and scrapers 8. The negative electrode conductive columns 1 are closely attached to the negative electrode plates 2. The negative electrode conductive columns 1, the negative electrode plates 2, the scrapers 8 and the positive electrode plates 7 are sequentially connected to the rotating shaft 6 in series. A central limiting and correcting block 3 is arranged between the scrapers 8 and the positive electrode plates 7. The negative electrode plates 2 rotate around the rotating shaft 6. A jackscrew 4 is arranged on one side of each negative electrode conductive column 1. Currents are guided into the negative electrode plates 2 by the negative electrode conductive columns 1. In the rotating process of the negative electrode plates 2, the scrapers 8 are closely attached to and scrap the surfaces of the negative electrode plates 2. The purpose of inputting currents to the rotating negative electrode plates without electric brushes is achieved, electrode intervals are easily decreased to the maximum degree, and the scale scraping and removing effects of the negative electrode plates are improved.

Owner:卫士循环水处理(北京)有限公司

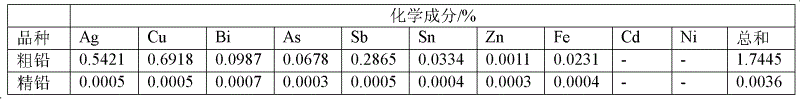

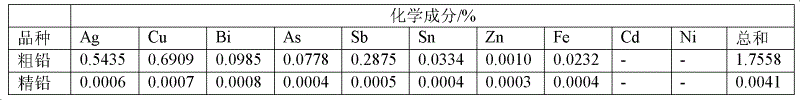

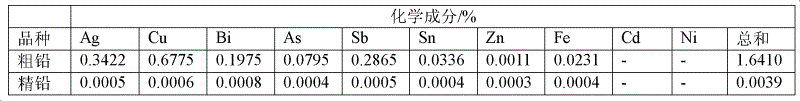

Method for direct electrolytic refining of crude lead

ActiveCN102618883AImprove solubilityImprove conductivityPhotography auxillary processesElectrolysisEconomic benefits

The invention relates to a method for direct electrolytic refining of crude lead, and belongs to the technical field of lead refining. According to the method, the crude lead prepared by pyrometallurgy is casted into a crude lead anode, wherein the crude lead anode is sleeved inside an anode bag; and electrolysis is performed in an additive-containing perchloric acid-lead perchlorate solution electrolyte to electrically deposit the lead in the anode on the cathode, such that the high purity electrolyzed lead and the anode mud are respectively obtained from the cathode and the anode. With the present invention, the lead without a pre-refining treatment can be directly subjected to electrolytic refining to obtain the pure lead with the purity more than 99.99% and the anode mud doped with noble metals, such that the recovery rate of the noble metals can be substantially improved so as to provide greater economic benefits.

Owner:BEIJING UNIV OF CHEM TECH

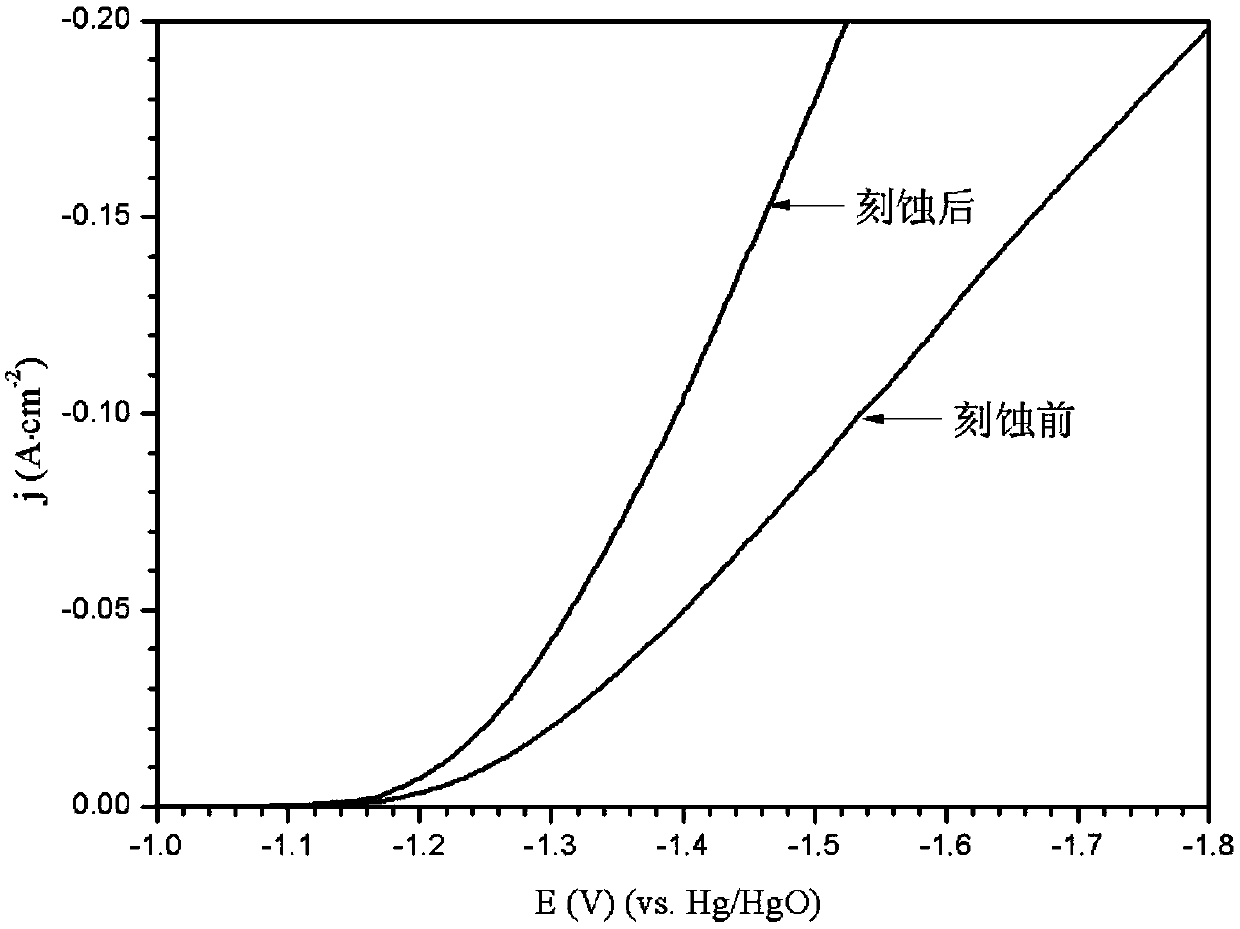

Etching method capable of increasing electrochemical active area of nickel foam electrode

The invention relates to an etching method capable of increasing the electrochemical active area of a nickel foam electrode, belonging to the fields of surface treatment technology for materials and electrocatalysis. According to the invention, a chemical etching solution with hydrochloric acid and an oxidizing agent as main components is used for soaking and etching of the nickel foam electrode,and the nickel foam electrode with a large active area and high stability is prepared by controlling etching time and the concentration of the etching solution. The prepared nickel foam electrode canprovide more active sites for hydrogen evolution and oxygen evolution of electrolysed water and reduce energy consumption in electrolysis. The etching method is simple in process and suitable for large-scale industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

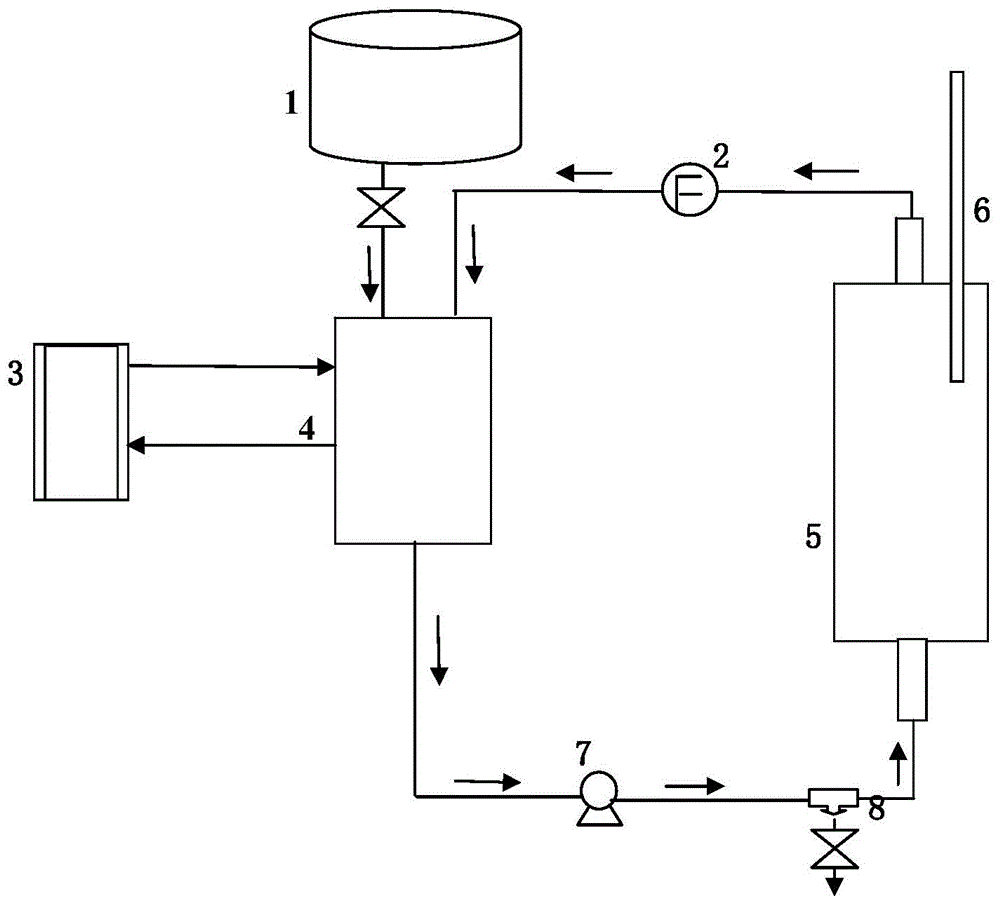

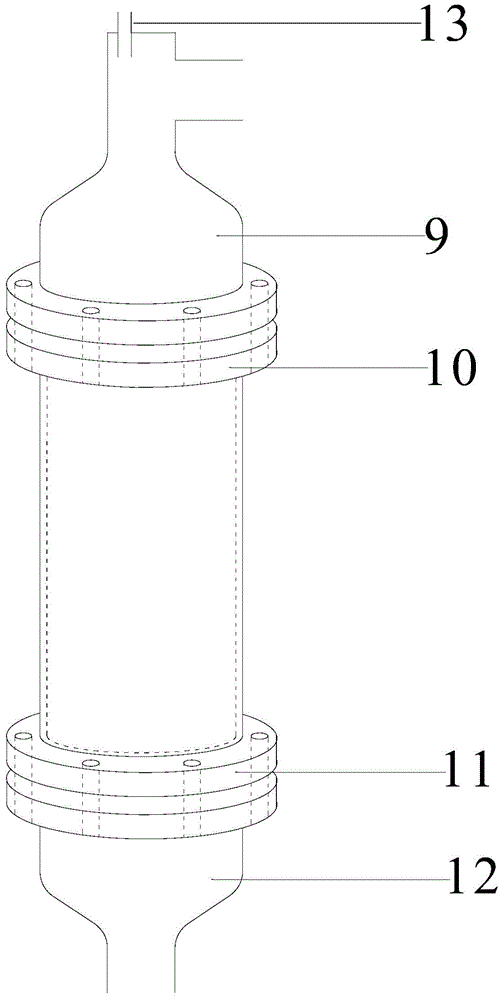

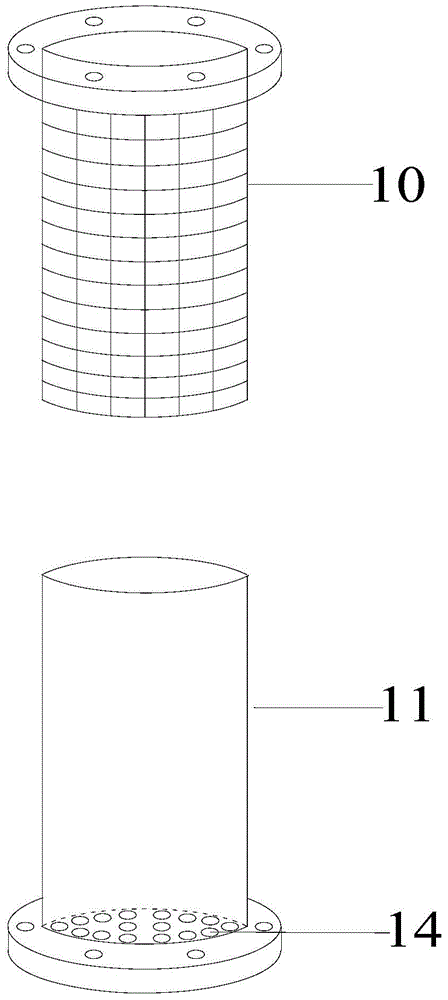

Method for electrolytic synthesis of butanedioic acid and fixed bed electrochemical reaction device

ActiveCN104947138AEasy to assembleAvoid emissionsElectrolysis componentsElectrolytic organic productionElectrolytic agentButanedioic acid

The invention provides a method for electrolytic synthesis of butanedioic acid and a fixed bed electrochemical reaction device. The method comprises the following steps: by taking a maleic anhydride solution with the mass concentration of 5-20% and a sulfuric acid solution with the mass concentration of 3-15% as an electrolyte, introducing the electrolyte into a circulating tank by virtue of a liquid storage tank; inputting the electrolyte into an electrolytic tank by virtue of a magnetic circulating pump; controlling the temperature of the electrolytic tank to be 30-80 DEG C and the current density to be 200-1000A / m<2>, and electrifying for electrolysis; after reaction, discharging the obtained reaction solution from a liquid outlet of a three-way valve, and performing cooling crystallization on the electrolyte, filtration and drying to obtain butanedioic acid; and recovering the filtrate after filtering out butanedioic acid, adding an appropriate amount of raw materials of maleic anhydride and concentrated sulfuric acid to re-prepare the filtrate into an electrolyte for cycle use. The device comprises the electrolytic tank, the liquid storage tank, the circulating tank, the heat exchanger and the magnetic circulating pump. The method and the device provided by the invention have the beneficial effects of improving the productivity and achieving energy conservation and high efficiency.

Owner:ZHEJIANG UNIV OF TECH

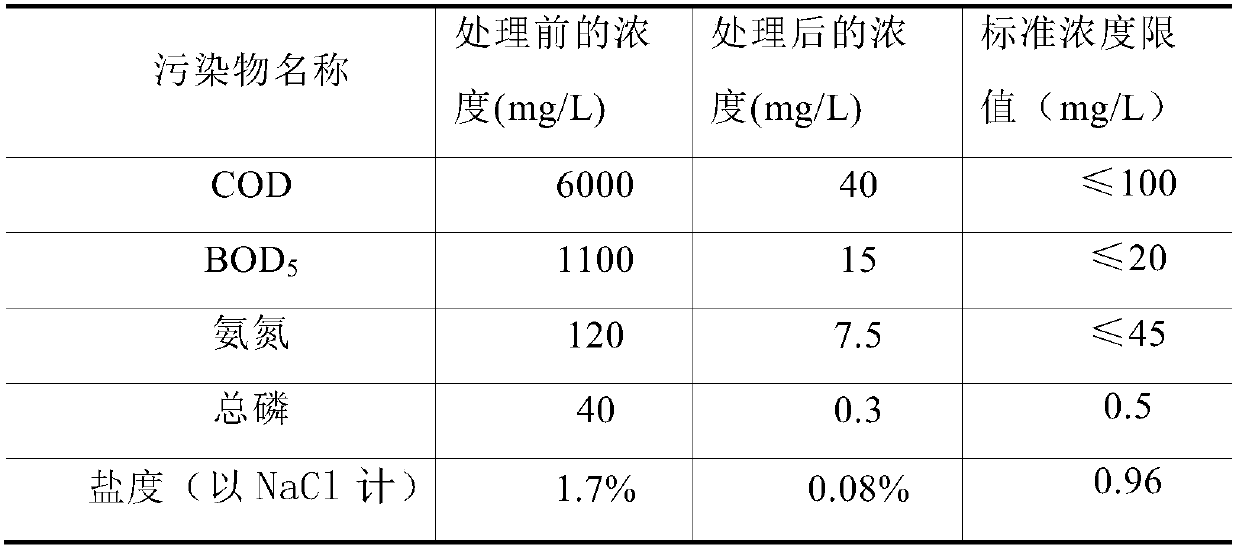

Deep treating method of sewage, such as percolate for urban refuse filling area

InactiveCN1579966AMeet the secondary emission standardReduce electrolysis energy consumptionMultistage water/sewage treatmentElectricityIron salts

Belonging to the field of environment protection, the invention relates to an approach of deeply processing percolate of landfill of refuse field and other sewages. Through adjusting PH value of percolate, add iron salt and use electrobath with a water-fast anode to conduct electroanalysis. Adjust the PH value of percolate to neutrality, deposit iron ion and the deposited iron can be used circularly. After the treatment, CODcr chroma of supernatant is less than 250mg / L which can reach discharging standard grade 2 of percolate. It can reach grade 1 that chroma is less than 10 times and chroma of NH3-N is less than 10mg / L. The invention remarkably reduces electricity consumption and reaches the level of engineering application.

Owner:TONGJI UNIV

Method for recovering lead from waste lead paste by solid phase electrolysis method

ActiveCN111455404AReduce consumptionSimple processPhotography auxillary processesWaste accumulators reclaimingElectrolytic agentLead dioxide

The invention discloses a method for recovering lead from waste lead paste by a solid phase electrolysis method, and belongs to the technical field of lead resource recovery. The method for recoveringthe lead from the waste lead paste by the solid phase electrolysis method comprises the steps that the waste lead paste is first made into a paste waste lead paste electrolytic material and a cathodeplate is coated with the waste lead paste electrolytic material; electrolyte is added to an electrolytic cell; the cathode plate coated with the electrolytic material is inserted into the electrolyte, and an anode is inserted into the electrolyte; the anode is an electrode with oxygen evolution electrocatalysis; the cathode plate and the anode are connected with a negative electrode and a positive electrode of a direct current power supply separately to make electrolysis in the electrolytic cell; and water at the anode loses electrons and precipitates oxygen, the electrolytic material on thecathode plate obtains the electrons and is reduced in situ to a lead single substance and attached to the cathode plate, that is, the lead is recovered from the waste lead paste. The method for recovering the lead from the waste lead paste by the solid phase electrolysis method directly electrolyzes the waste lead paste after simple pulping, lead sulfate, lead dioxide and lead oxide in the waste lead paste obtain the electrons and form in situ the lead simple substance, a large number of pretreatment processes are saved, the consumption of reagents is reduced, the process is simple, and the cost is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH

Green energy-saving photoelectrocatalysis water treatment system and water treatment method thereof

ActiveCN111646632AImprove removal rateReduce electrolysis energy consumptionTreatment using aerobic processesWater treatment compoundsSolar lightDiamond electrodes

The invention discloses a green energy-saving photoelectrocatalysis water treatment system and a water treatment method thereof. The green energy-saving photoelectrocatalysis water treatment system comprises a liquid storage tank, a particle filter plate, a degradation tank and a microbiological treatment module, an intelligent temperature control module and a solar light-electricity-heat intelligent conversion module; the degradation tank is composed of a plurality of treatment units, and any treatment unit comprises an anode, a cathode and a stirring device; wherein the anode is a boron-doped diamond electrode loaded with a photocatalyst, the anode and the cathode are connected to a power supply through wires, and the power supply is connected to a solar power generation unit; the degradation tank further comprises a plurality of ultraviolet lamps, and the ultraviolet lamps directly irradiate the anode; through organic combination of photocatalytic oxidation and electrochemical oxidation, the removal rate of organic pollutants is remarkably increased, electrolysis energy consumption is reduced, reaction conditions are mild, environment friendliness is achieved, and operation is easy, therefore the system is suitable for water treatment under various water quality conditions.

Owner:NANJING DAIMONTE TECH CO LTD

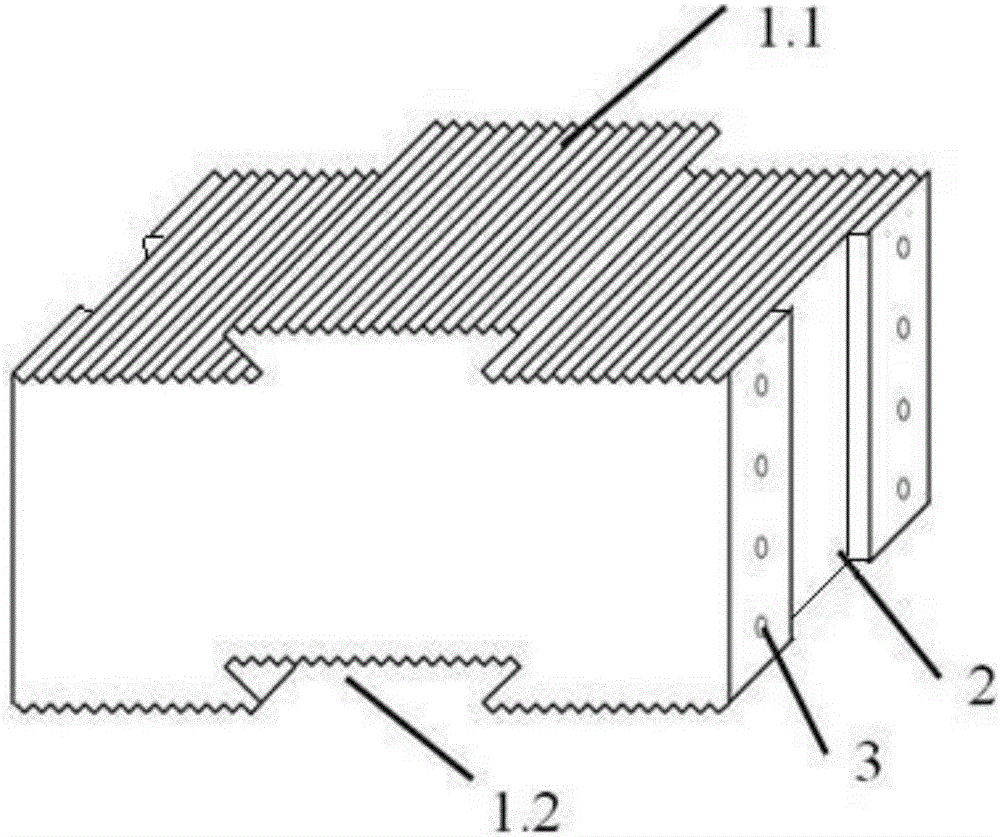

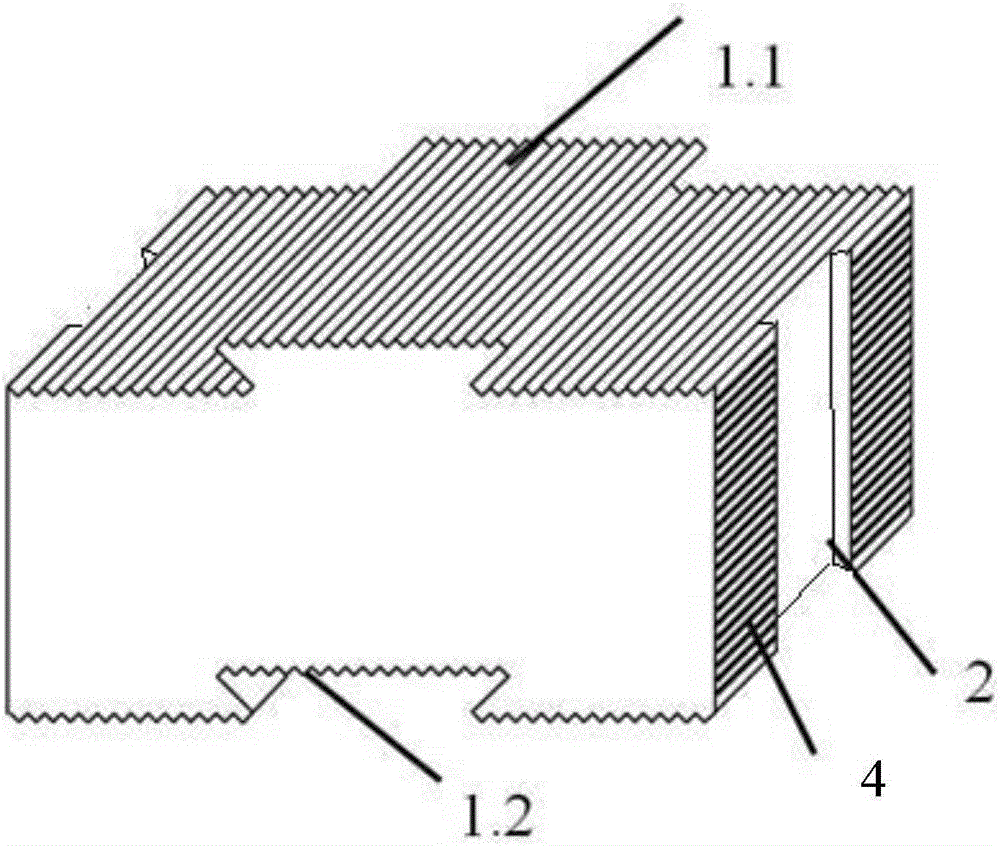

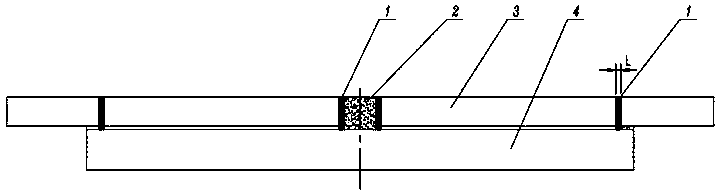

Anode used for aluminum electrolysis

InactiveCN101892497AReduced bottom coverage areaIncreased strength and rigidityElectrical resistance and conductanceEnergy consumption

The invention relates to an anode used for aluminum electrolysis. The anode comprises a first carbon block and a second carbon block, wherein the first carbon block and the second carbon block are arranged in parallel; a channel for exhausting air is reserved between the first carbon block and the second carbon block; both the first carbon block and the second carbon block are connected with a power supply by steel talons; and the width range of the first carbon block and the second carbon block is between 360 and 430 mm. The anode used for the aluminum electrolysis of the invention can quicken the exhausting speed of the air at the bottom of an anode block, greatly reduce the coverage area of the bottom of the anode block and efficiently prevent air bubbles from forming an air bubble layer, so that the aims of reducing a resistance value in an electrolytic tank and reducing the electrolytic energy consumption are fulfilled.

Owner:重庆天泰铝业股份有限公司

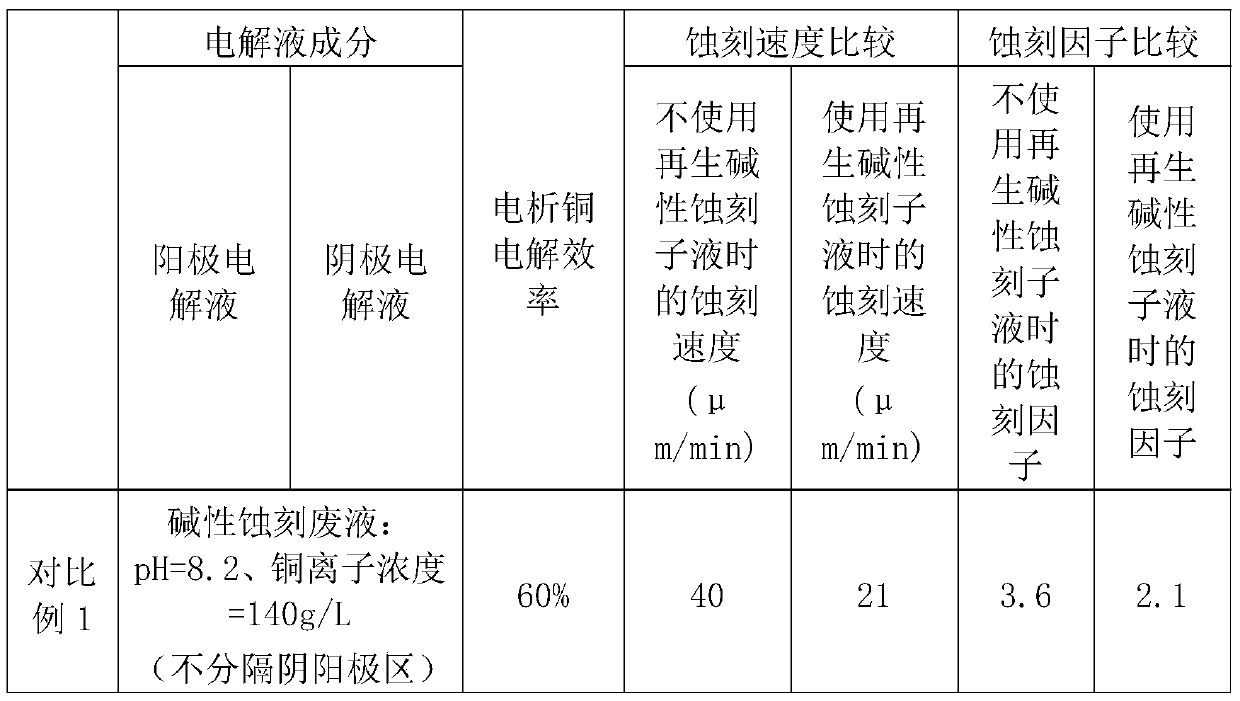

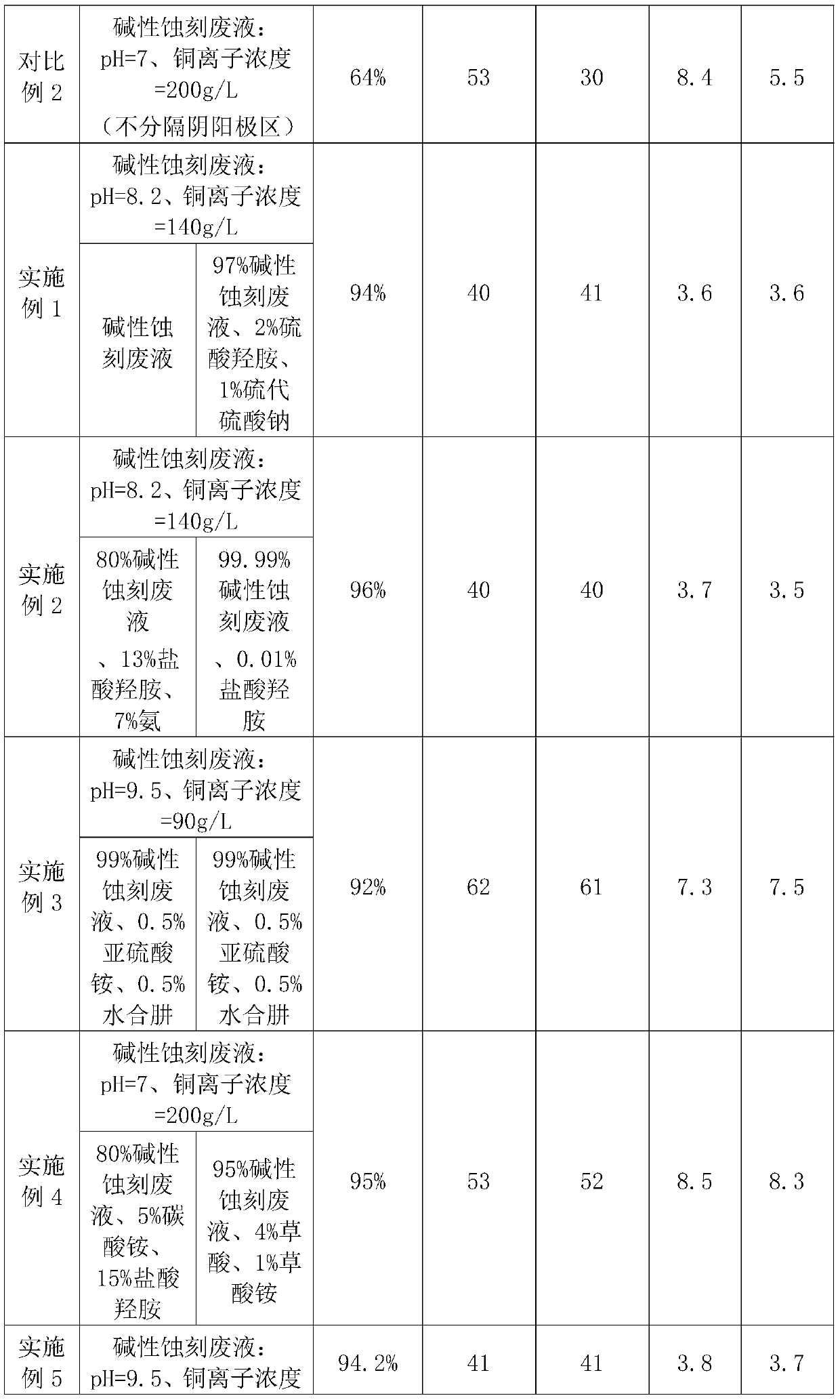

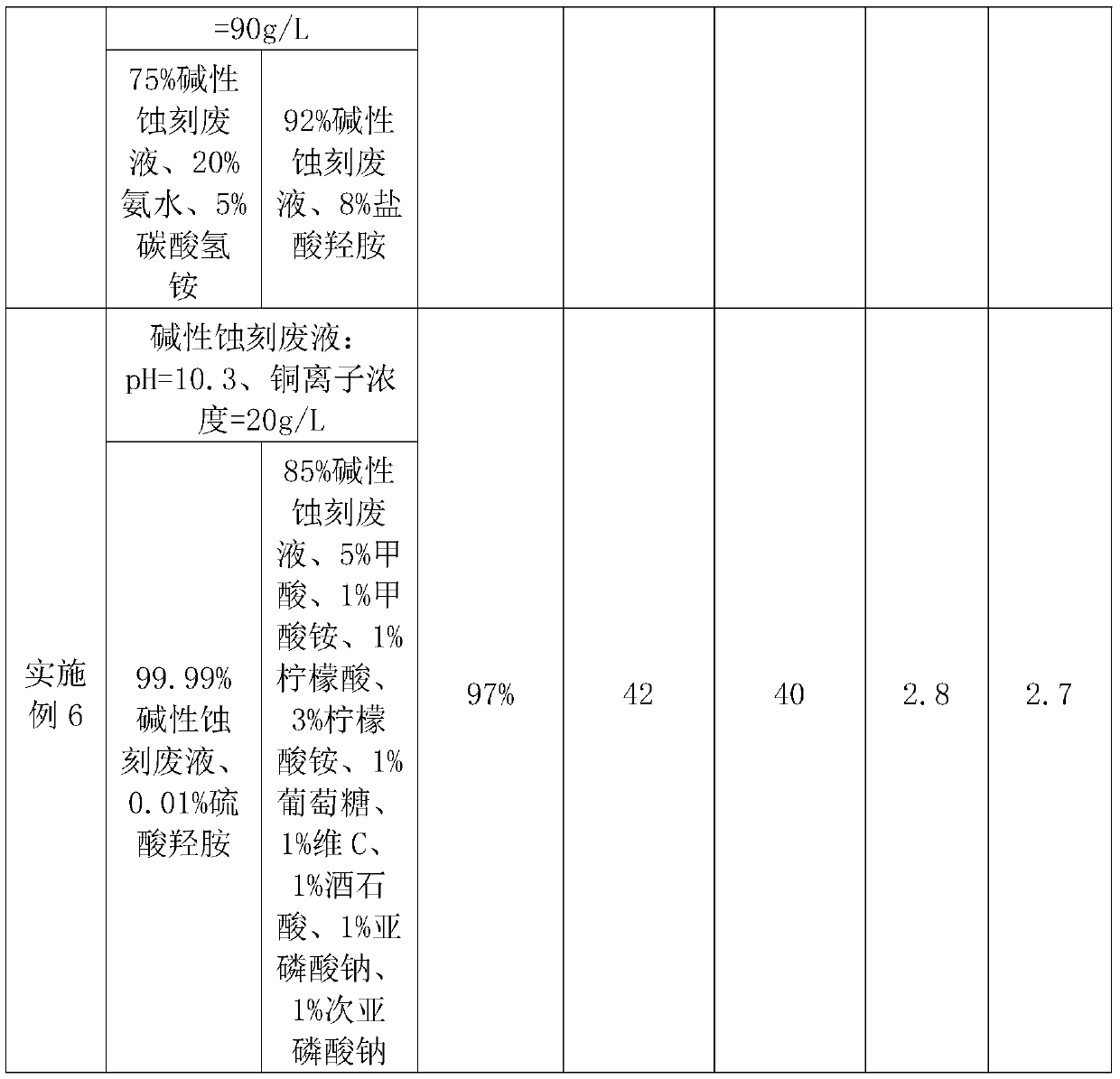

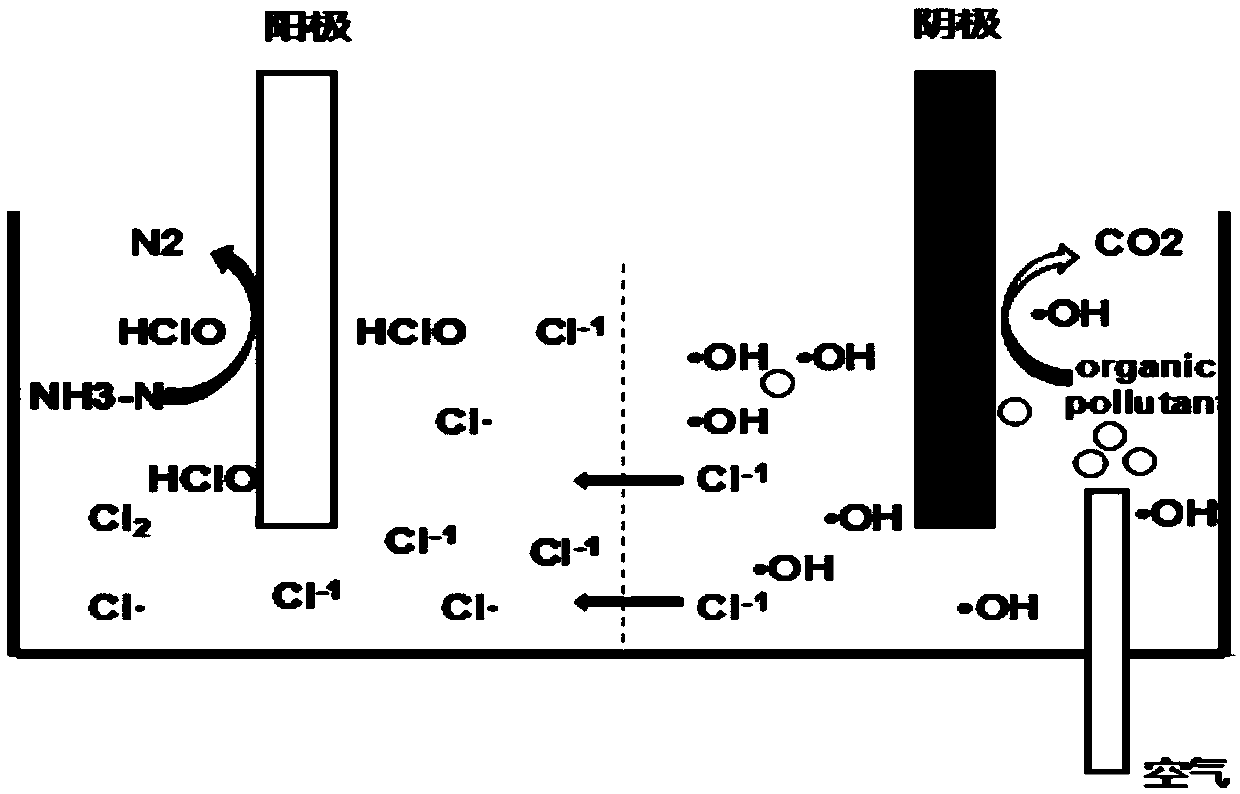

Method for electrolysis reuse of alkaline etching waste liquid

PendingCN111304657ACompact structureSmall spike current effectPhotography auxillary processesElectrolysis componentsAmmonium chloride mixtureElectrolysis operation

The invention provides a method for electrolysis reuse of alkaline etching waste liquid. The method comprises the following steps that (1) the alkaline etching waste liquid or mixed liquid of the alkaline etching waste liquid and a reducing agent serves as anode electrolyte to be added into an anode region, and the mixed liquid of the alkaline etching waste liquid and the reducing agent serves ascathode electrolyte to be added into a cathode region; (2) an electrolysis power supply is started for electrolysis operation, and metal copper is separated out on an electrolysis cathode; and (3) according to a specific alkaline etching process, ammonium chloride, ammonia, water and one or more of components contained in other alkaline etching liquid are added into anode liquid and / or cathode liquid after electrolysis operation in the step (2) to prepare regenerated alkaline etching sub-liquid capable of being reused on an alkaline etching production line. According to the method, the electrolysis copper separate-out efficiency can be improved, and the waste liquid can be prepared to form the regenerated alkaline etching sub-liquid capable of maintaining the ideal etching effect after electrolysis reuse.

Owner:叶旖婷

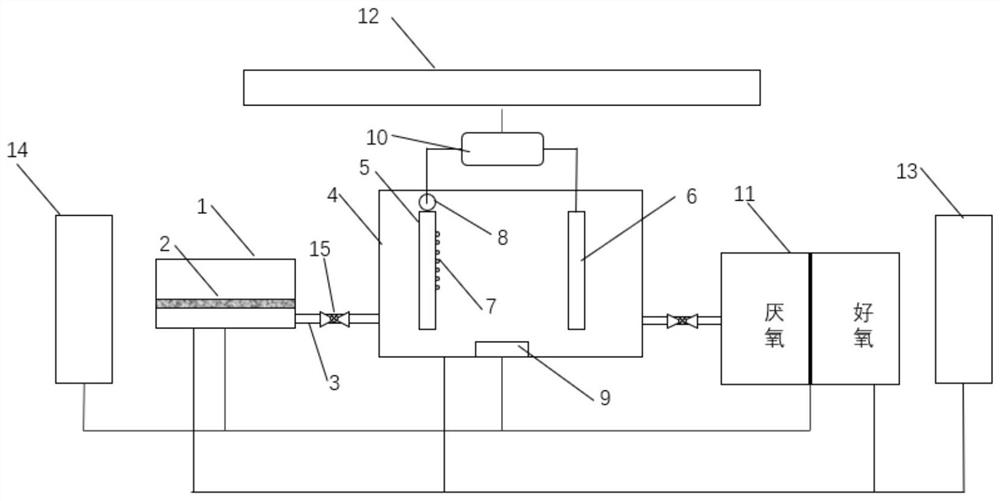

Electrocatalytic oxidation-biochemical coupling method for treating high-salinity high-concentration organic wastewater

ActiveCN109516641AEfficient processingReduce electrolysis energy consumptionWater contaminantsMultistage water/sewage treatmentIonPollutant

Owner:南通寰宇博新化工环保科技有限公司

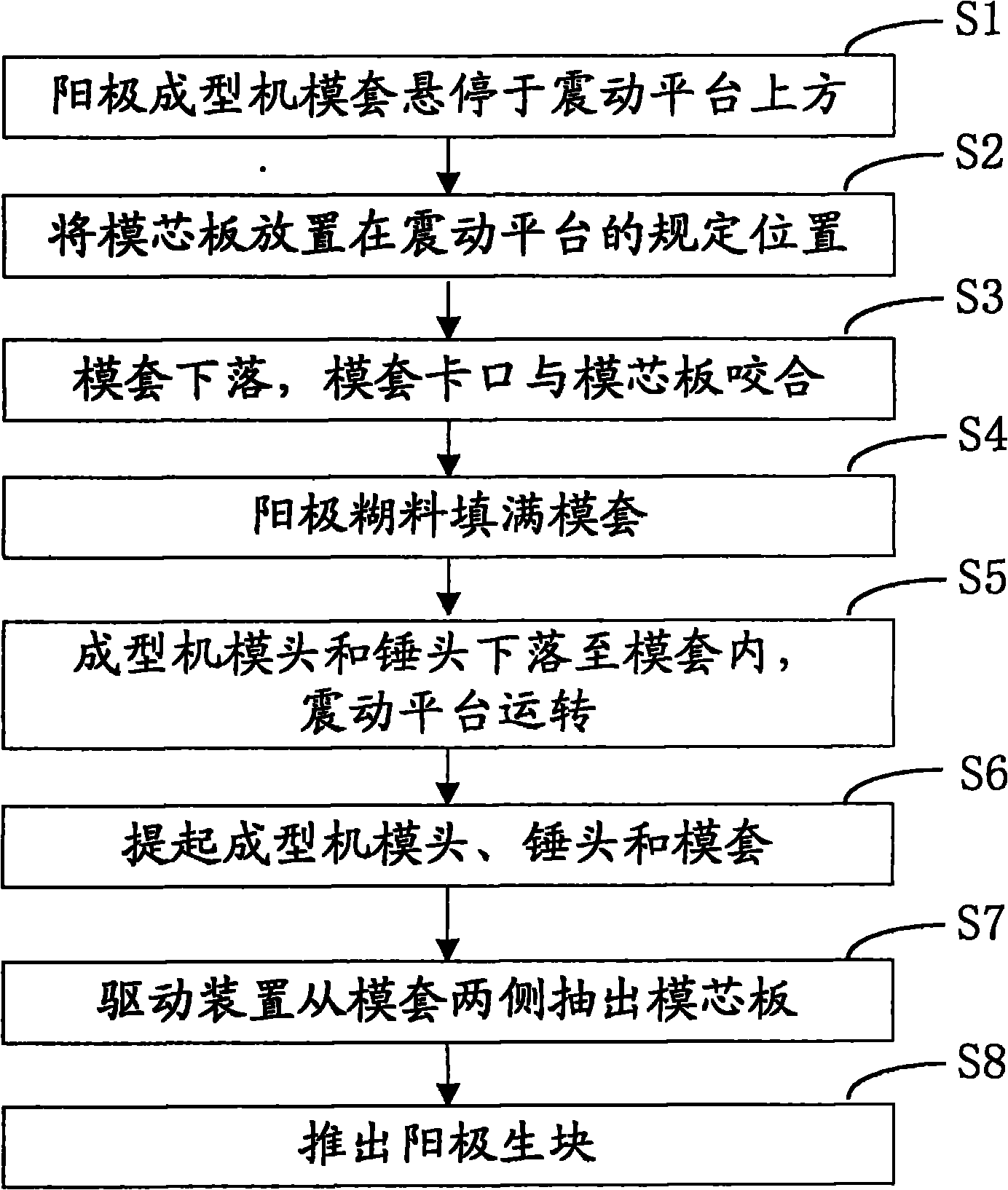

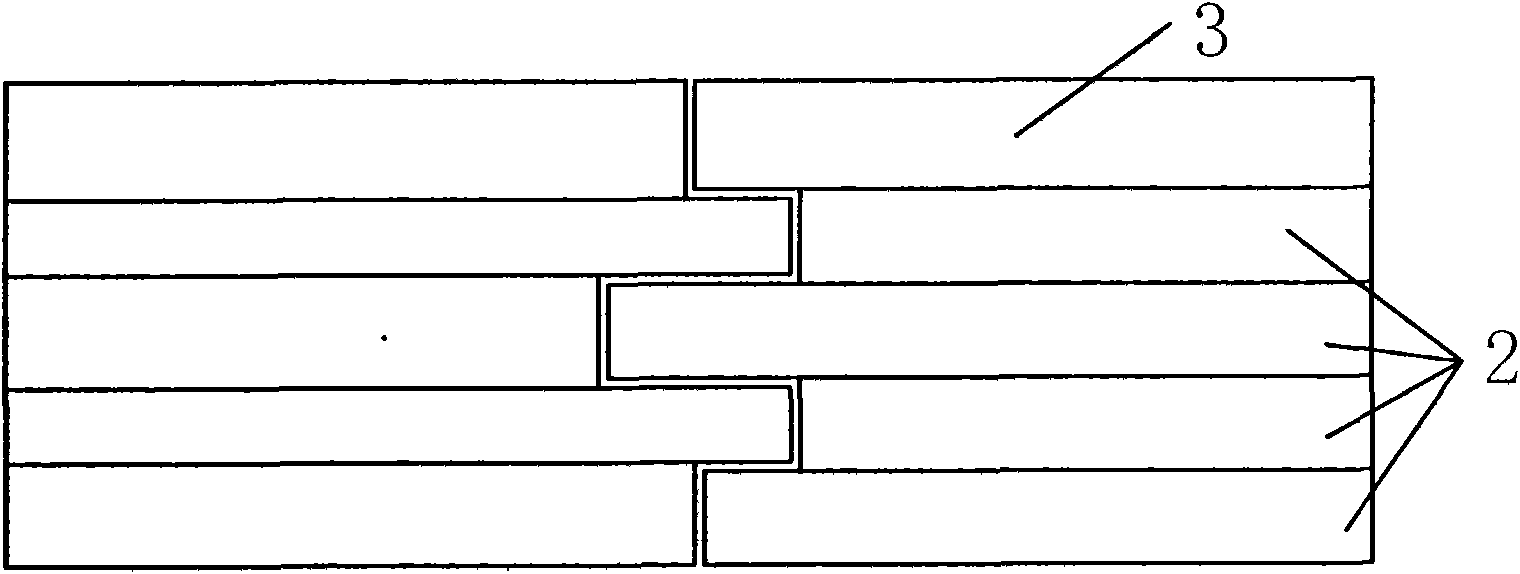

Method for slotting anode

InactiveCN101927526ALeave quicklyReduce overvoltageCeramic shaping apparatusAluminum industryMaterials science

The invention discloses a method for slotting an anode in the electrolytic aluminum industry. The technical scheme is that: the method comprises the following steps of: placing a die core plate consisting of a left part and a right part in an anode molding die sleeve; and after the anode is made into a block and molded, pulling the die core plate out from the two sides of the die sleeve by using a drive device. The slotting method has good effect, namely, irregularly-shaped slots of which middle parts are lower than tops at two ends can be reserved, and compared with straight slots, are more favorable for driving CO2 foams to quickly leave the bottom of the anode; and the slotting method also has the advantages of simple process, convenient use and raw material saving.

Owner:HUNAN CHUANGYUAN NEW MATERIALS

Continuous anode device for intelligent electrolytic baths and application method thereof

ActiveCN106283119ARealize online continuous installationReduce electromagnetic field fluctuationsFixed positionIntelligent control system

The invention relates to a continuous anode device for intelligent electrolytic baths and an application method thereof, belonging to the field of metallurgy. The continuous anode device for intelligent electrolytic baths comprises a continuous anode carbon block, an anode carbon block positioning push system, a continuous anode carbon block crawler-type displacement system, a slide power supply system and an intelligent control system. The application method comprises the following steps: (1) a continuous anode carbon block is installed; (2) the continuous anode carbon block is fixed to the continuous anode carbon block crawler-type displacement system to implement continuous movement; (3) when the crawler operates, the working anode carbon block is driven to move downwards, and the anode carbon block positioning push system can push a standby anode carbon block to the fixed position so as to be connected with the original carbon block; and (4) when the continuous anode carbon block moves downwards, the slide power supply system correspondingly moves upwards so as to implement the connection between the anode carbon block and the anode. The device implements the continuity of the aluminum electrolytic bath anodes, solves the problem of discontinuous anode replacement and stub generation at present, and lowers the cost of the aluminum electrolysis process.

Owner:张廷安

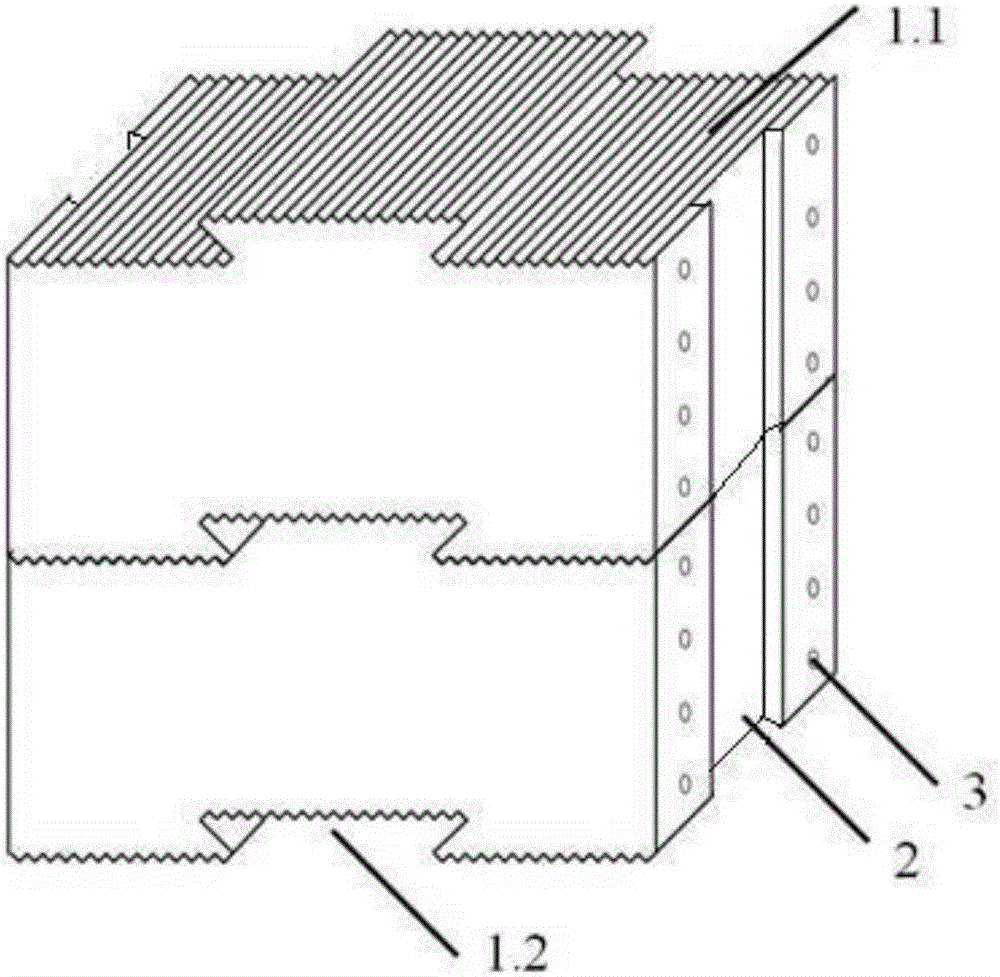

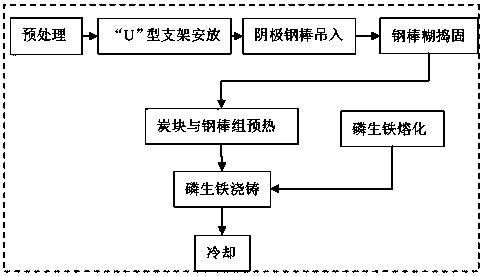

Assembly method for phosphorous pig iron casting cathode for aluminum electrolysis

InactiveCN108221002ALower cathode pressure dropReduce electrolysis energy consumptionElectrolysisEconomic benefits

The invention relates to an assembly method for a phosphorous pig iron casting cathode for aluminum electrolysis. The assembly method is characterized in that in the assembly process, firstly, a same-material U-shaped support of a steel bar is placed at the end of a dovetail groove formed in a cathode carbon block, then a cathode steel bar is hoisted in to be in tight connection with the U-shapedsupport, and the cathode carbon block and the steel bar are preassembled; and the gap of the end of the dovetail groove and the U-shaped support is tamped by steel bar paste, then the preassembled cathode carbon block and steel bar are preheated, and molten phosphorous pig iron casting is conducted. Through the assembly method, assembly efficiency of the phosphorous pig iron casting cathode and casting quality of high-phosphorus pig iron are improved, the problem that preassembly quality is difficult to control due to the influence of human factors and the like when the dovetail groove gap between a carbon block and a steel bar is blocked with an asbestos cord and other refractory materials is solved, and the risk that the end of the carbon block generates a crack due to thermal stress impact during phosphorous pig iron casting is lowered. Cathode drop of aluminum electrolysis can be lowered effectively, energy consumption of aluminum electrolysis lowered, service life of the cathode is prolonged, and economic benefits are significant.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

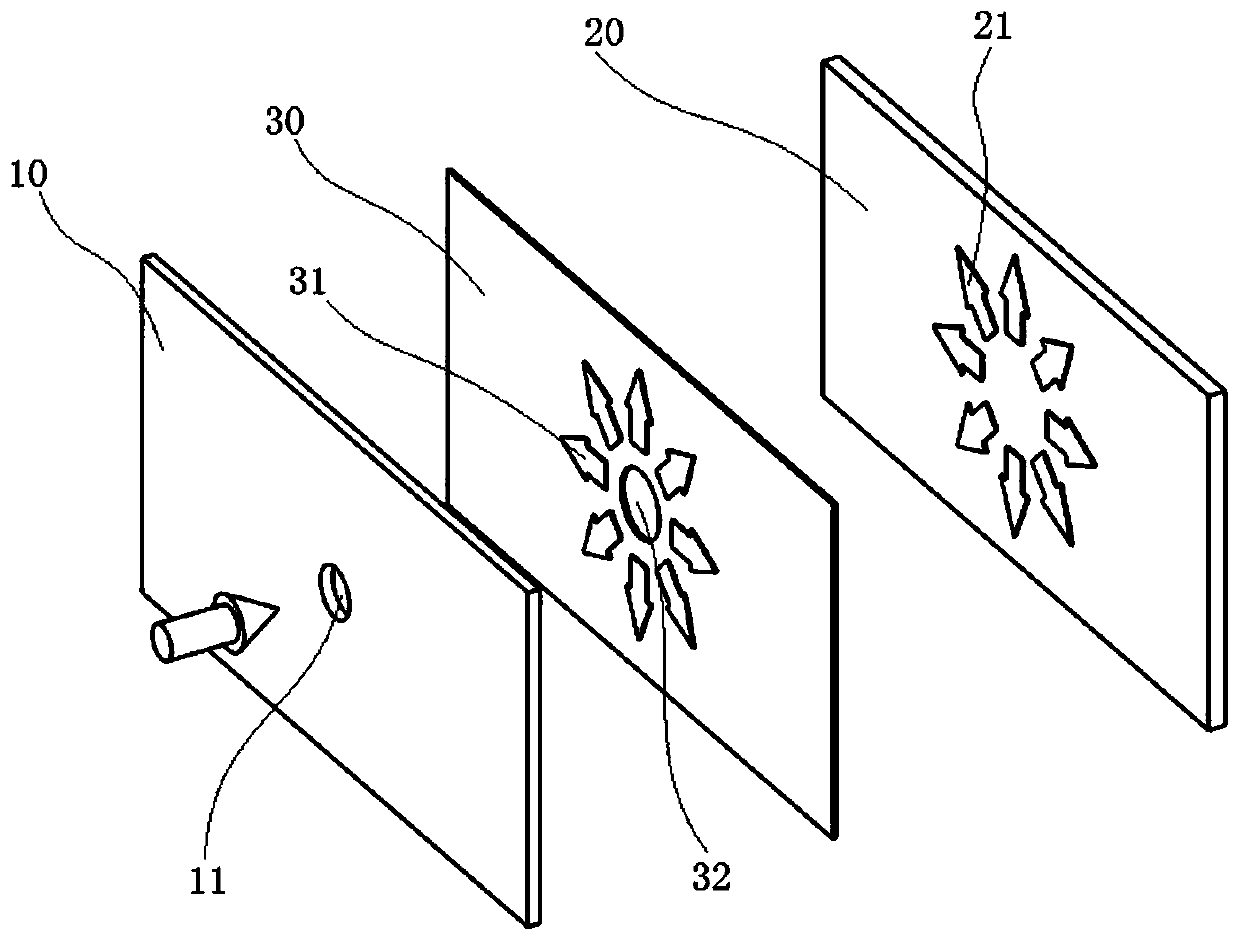

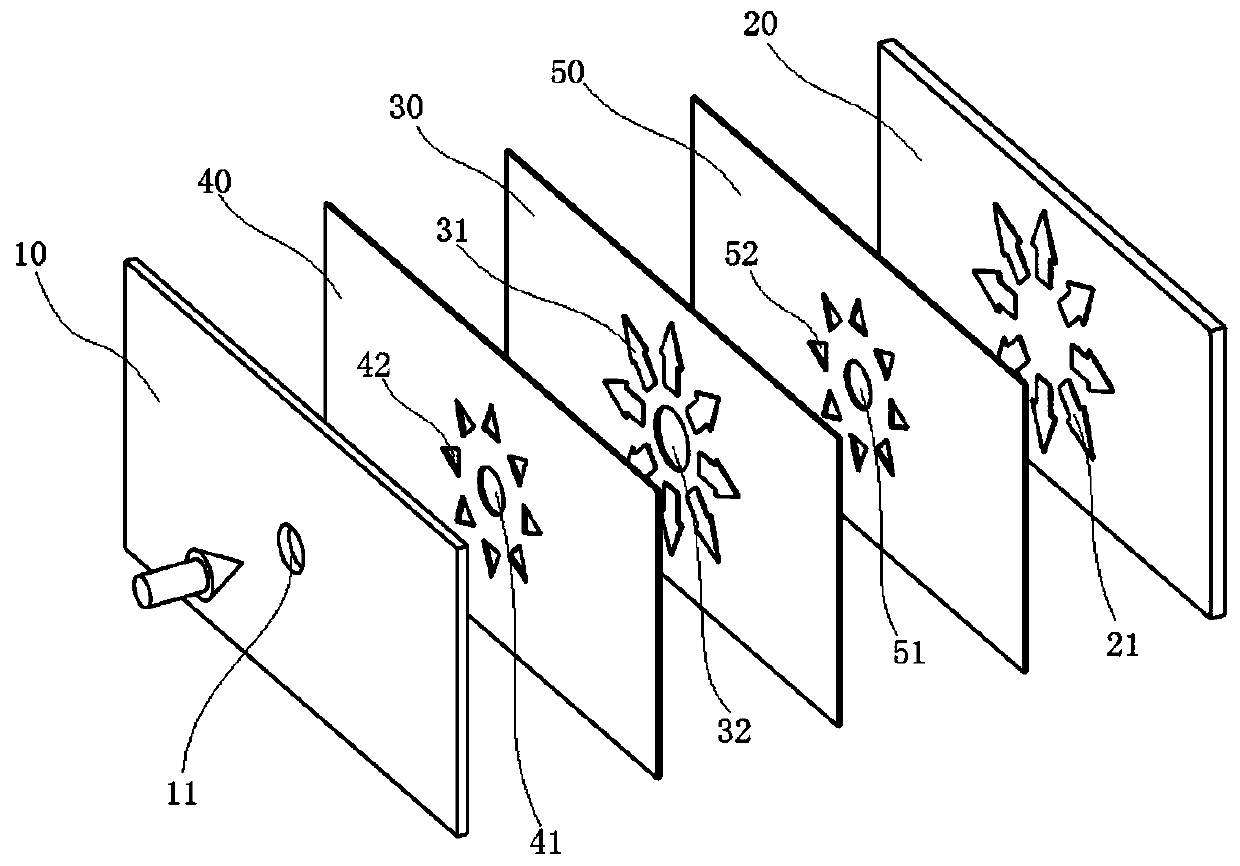

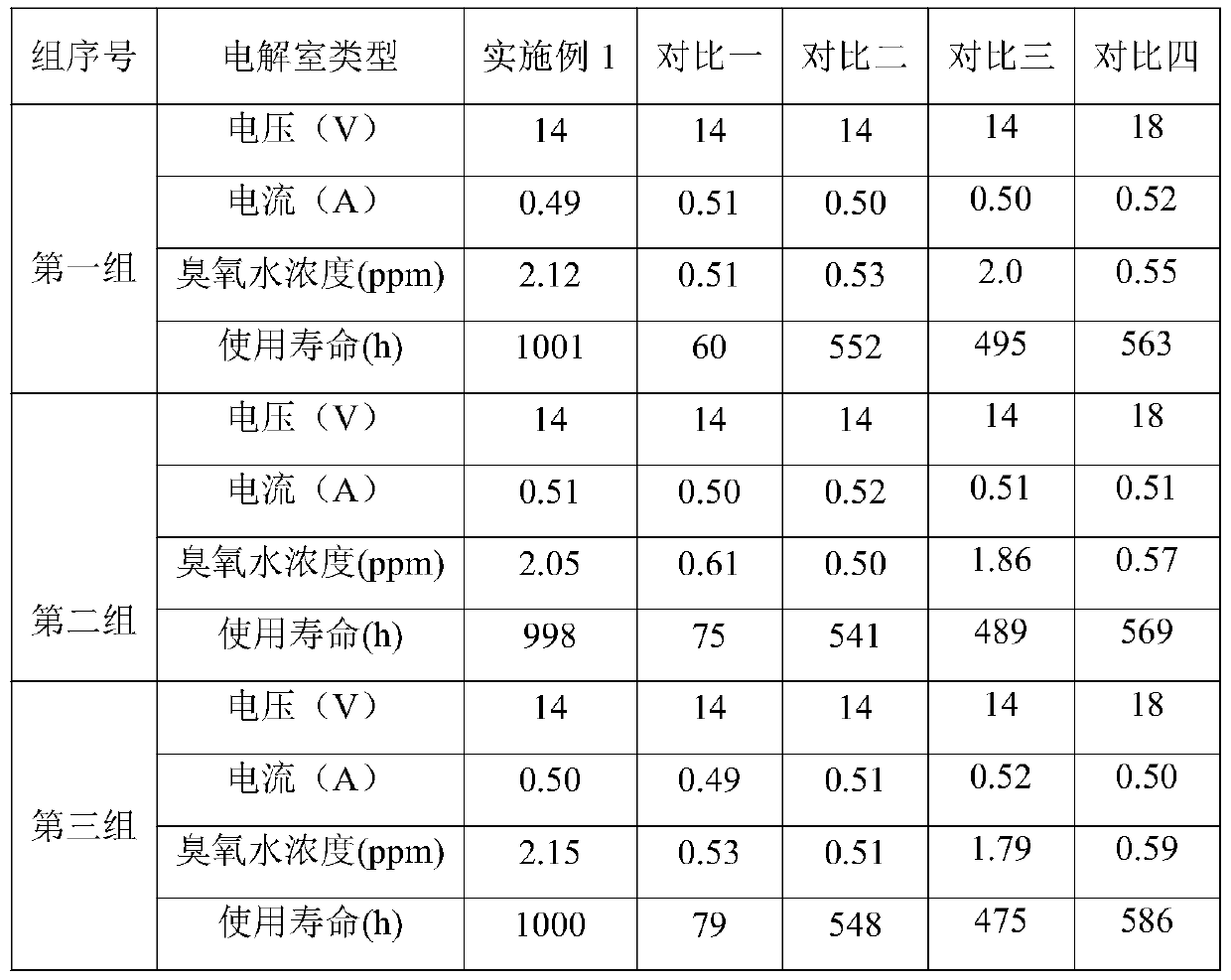

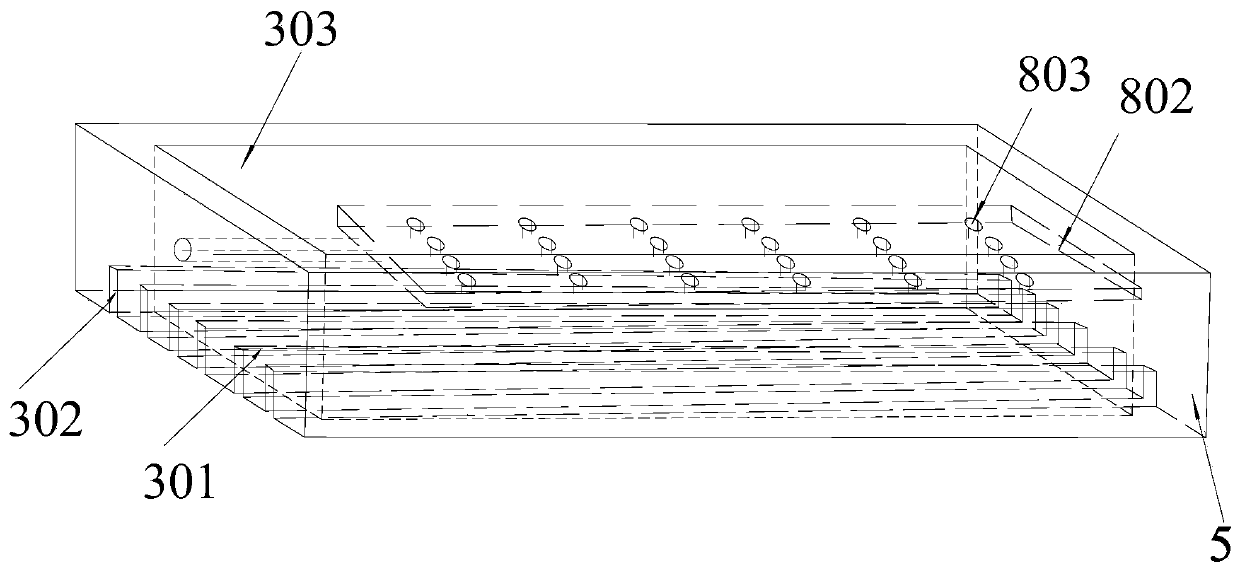

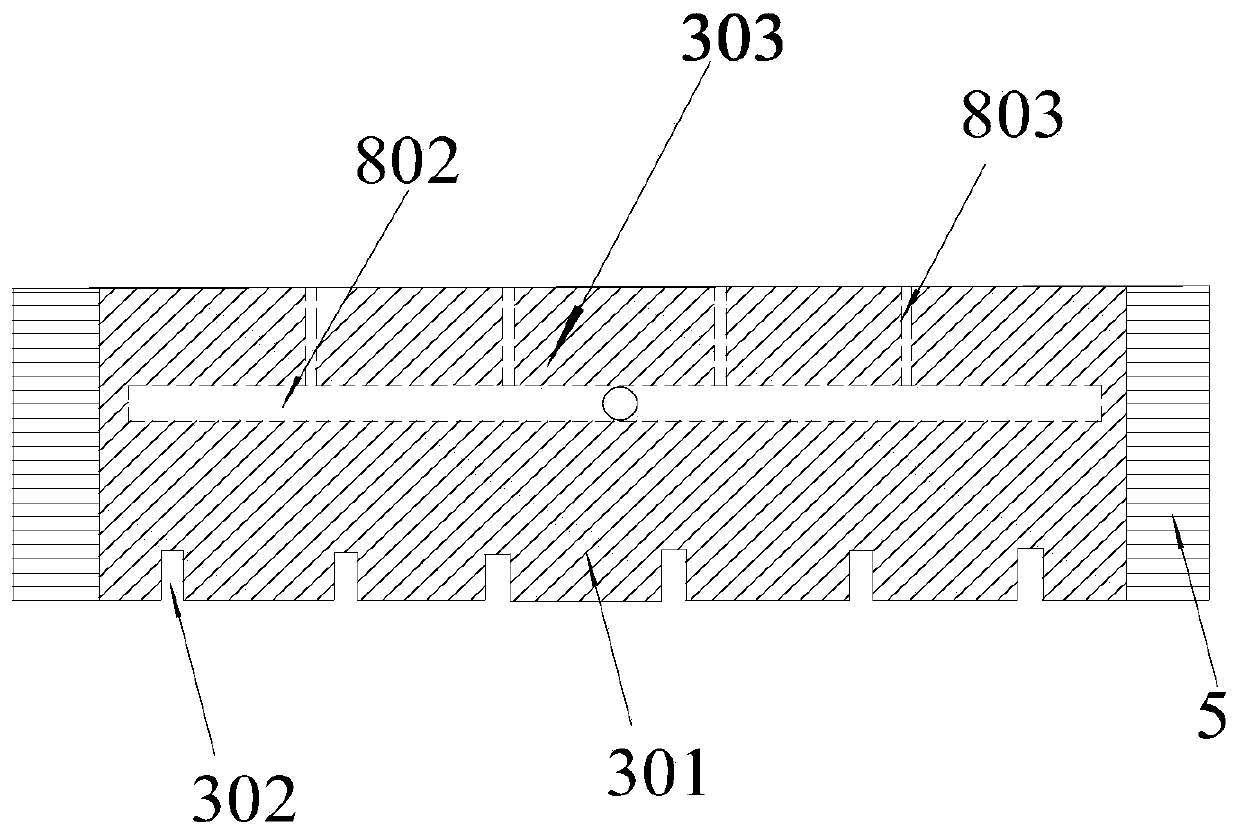

Ozone electrolysis structure and electrolysis chamber

PendingCN110846674AExtended service lifeAvoid accumulationCellsElectrode shape/formsElectrolysisEnvironmental engineering

The invention discloses an ozone electrolysis structure which comprises an anode piece and a cathode piece which are arranged at an interval, the anode piece is located at a water inlet end, the cathode piece is located at a water outlet end, and a main proton exchange membrane is arranged between the anode piece and the cathode piece; a water inlet hole is formed in the anode piece, a water through hole is formed in the main proton exchange membrane, and a bulge structure is arranged on the side surface of a water inlet side of the cathode piece. When the ozone electrolysis structure is usedfor preparing ozone water, incrustation accumulation on electrode surfaces can be avoided, the electrode service life is prolonged, the ozone preparation efficiency is improved, the electrolysis energy consumption is reduced, and the ozone electrolysis structure has the advantages of high ozone water concentration, low energy consumption and long service life.

Owner:GUANGZHOU DEPOSON ELECTRIC TECH

Continuous pre-baked anode carbon block with split type independent carbon bowl and ultra-long filling block structure

ActiveCN110029363ASimple structureHigh green block forming rateElectrical resistance and conductanceContinuous use

The invention discloses a continuous pre-baked anode carbon block with a split type independent carbon bowl and ultra-long filling block structure. The continuous pre-baked anode carbon block comprises a carbon block body, wherein carbon bowl assembly connecting pits are formed in the carbon block body, carbon bowl assemblies are arranged in the carbon bowl assembly connecting pits, carbon bowls are arranged on the carbon bowl assemblies, mechanical steel claw connecting ring grooves are formed in the positions, at the bottoms of the carbon bowls, of the charcoal bowl assemblies, and ultra-long carbon bowl filling blocks are movably arranged in the parts, on the carbon bowl assemblies, of the carbon bowls. The continuous pre-baked anode carbon block cooperates with casting-mechanical steelclaws so that the continuous use of a pre-baked anode can be realized, the time for connecting a new anode carbon block is short, the labor intensity is low, the use is convenient, the filling rate of the continuous pre-baked anode carbon block is improved, the connection strength of the carbon block is improved, the whole resistance of the anode carbon block is reduced, the service life of the single carbon block is prolonged, the production cost is low, moreover, manufacturing, roasting, transportation and use of the carbon block body, the split type independent carbon bowls, and the ultra-long filling blocks are all simple, and the characteristics of being high in manufacturing finished product rate, low in expense is low, low in cost and the like are achieved.

Owner:贵州铝城铝业原材料研究发展有限公司

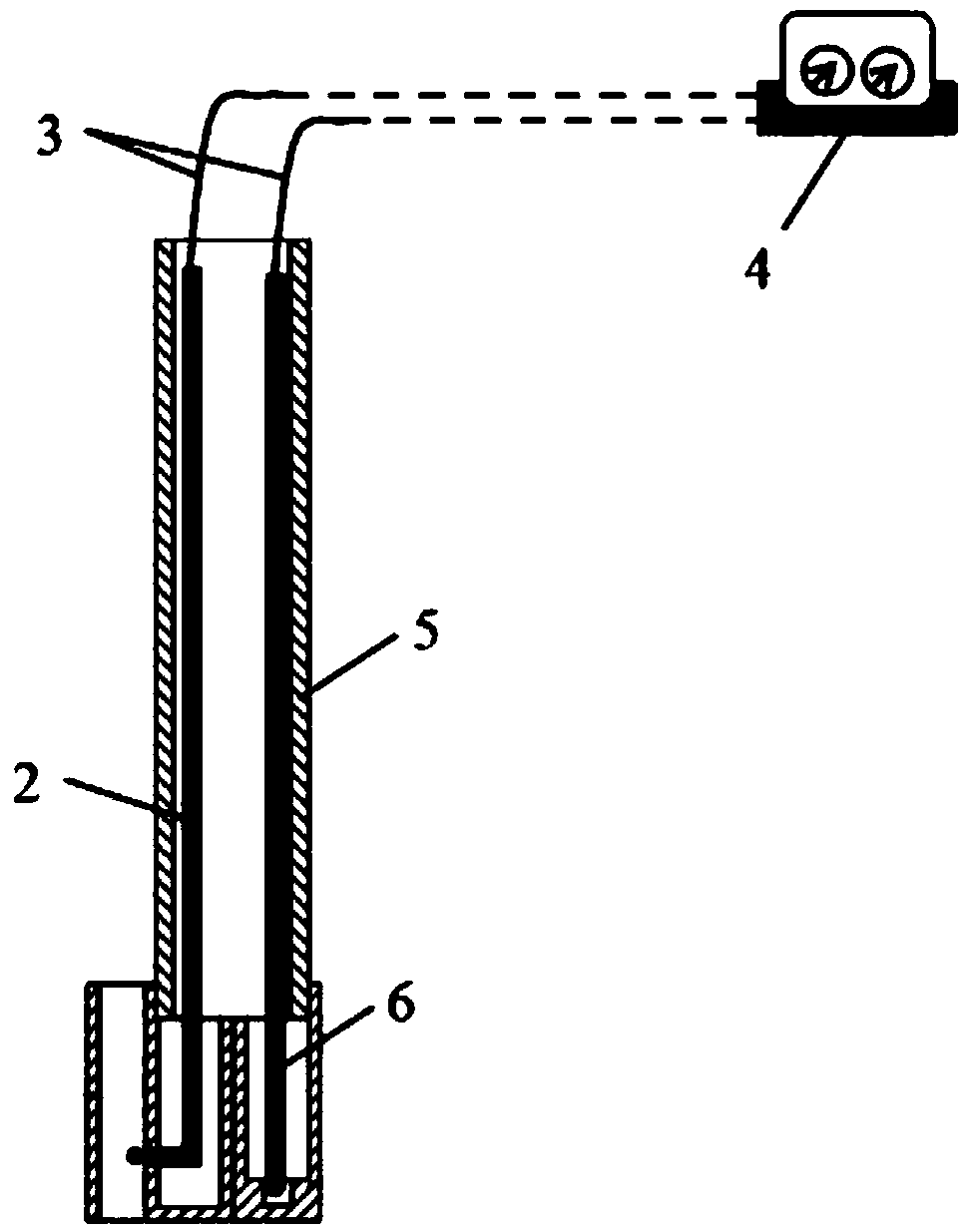

Device and method for automatically detecting superheat degree and electrolysis temperature of aluminum electrolyte

PendingCN109371428AReduce electrolysis energy consumptionReduce consumptionThermometer detailsThermometers using electric/magnetic elementsControl systemData analysis system

The invention belongs to the technical field of inorganic chemistry, and particularly relates to a device and method for automatically detecting the superheat degree and electrolysis temperature of analuminum electrolyte. According to the method, when an anode of an aluminum electrolytic cell is replaced, an aluminum electrolyte superheat degree detecting sensor and an electrolysis temperature detecting sensor are inserted into the electrolyte, measurement data are transmitted to a data analysis system through a data transmission system, through analysis with the data analysis system, the aluminum electrolyte superheat degree and the electrolysis temperature are obtained, and the analysis results are transmitted to an aluminum electrolytic cell control system through the data transmissionsystem. Through the method, the electrolyte superheat degree and electrolysis temperature are monitored in real time, the data are transmitted to the cell control system, the labor intensity of workers is relieved, and the labor productivity and the intelligent control level of the electrolytic cell are improved.

Owner:NORTHEASTERN UNIV

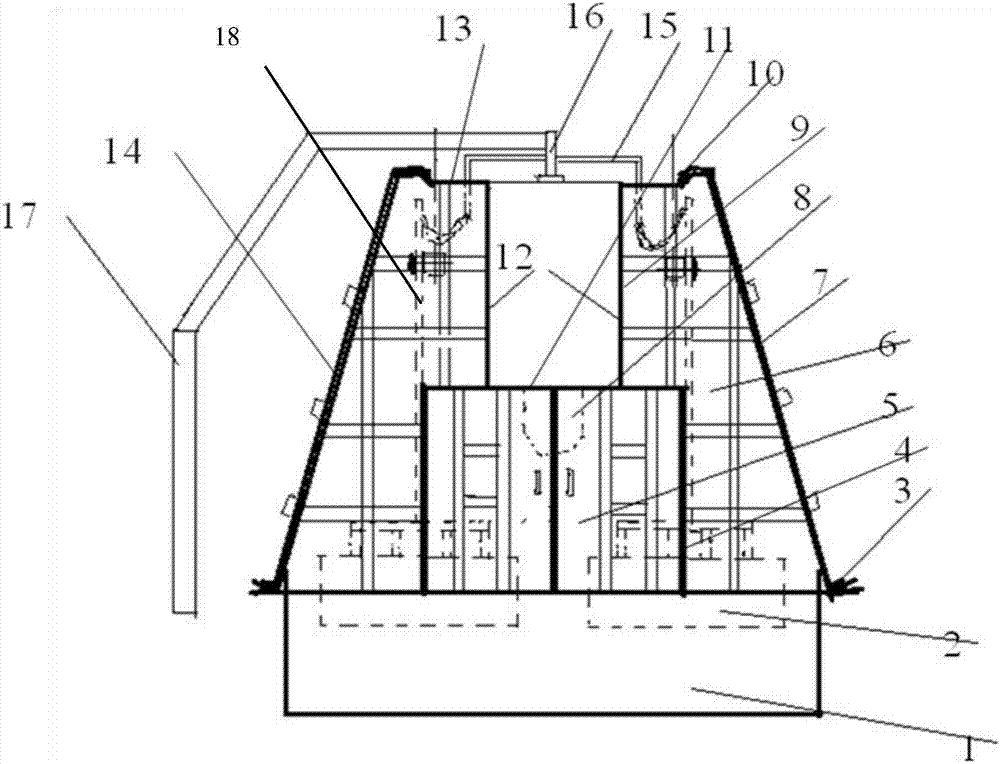

Full-sealing device for upper portion of aluminum electrolytic cell with prebaked anode

The invention provides a full-sealing device for the upper portion of an aluminum electrolytic cell with a prebaked anode. The full-sealing device comprises an anode guide rod, an anode large busbar and a stand column busbar connected with the anode large busbar. The anode large busbar is fixedly arranged in the center of the top of the electrolytic cell. Aluminum small busbars are further symmetrically arranged at the left end and the right end of the anode large busbar and connected with the upper end of the anode guide rod to supply current to an anode system of the electrolytic cell. A sealing cover is further arranged above the electrolytic cell, comprises an end face cover plate and a side face outer cover body and further comprises a top smoke blocking plate, side sealing plates and a bottom smoke blocking plate which are mounted on a bearing truss on the upper portion of the electrolytic cell. The opening end of the upper portion of the electrolytic cell is fully sealed through the sealing cover. According to the full-sealing device, the structure of a traditional anode large busbar is improved, the full-sealing device is provided on the basis of the structure of the improved anode large busbar and fully seals the upper portion of the electrolytic cell, electrolytic smoke leakage and disorganized emission are eradicated, and clean production is achieved.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

Treatment method of EDTA complexing nickel wastewater

ActiveCN112358095AReduce processing operating costsStable removalWater contaminantsTreatment involving filtrationChelating resinChemical agent

The invention discloses a treatment method of EDTA (Ethylene Diamine Tetraacetic Acid) complexing nickel wastewater. The treatment method specifically comprises the following steps: step 1, carrying out acid precipitation separation on organic matters; step 2, carrying out first-time decomplexing; step 3, carrying out second-time decomplexing; the invention belongs to the technical field of complex heavy metal wastewater treatment. Firstly, organic matters are acidified and separated to reduce the energy consumption and medicament consumption of subsequent treatment; by adding ferrous ions, the conductivity of complexing wastewater is improved, the generation rate of hydroxyl radicals is increased by adding hydrogen peroxide, the treatment efficiency is improved, chemicals such as sodium hypochlorite, ferrous sulfate and hydrogen peroxide are common chemicals, the price of the chemicals is low, and the operation cost of wastewater treatment can be reduced; according to the treatment method, complex nickel is stably removed through three times of complex breaking treatment, the nickel emission concentration of treated effluent is 0.2 mg / L or below, and the nickel removal rate reaches up to 99%.

Owner:中新联科环境科技(安徽)有限公司

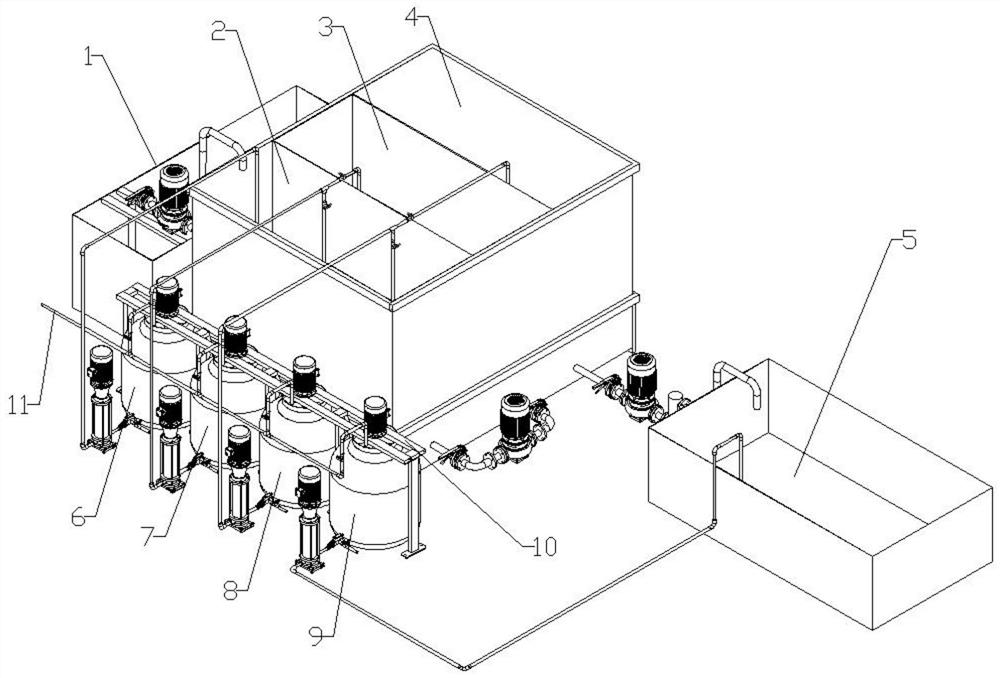

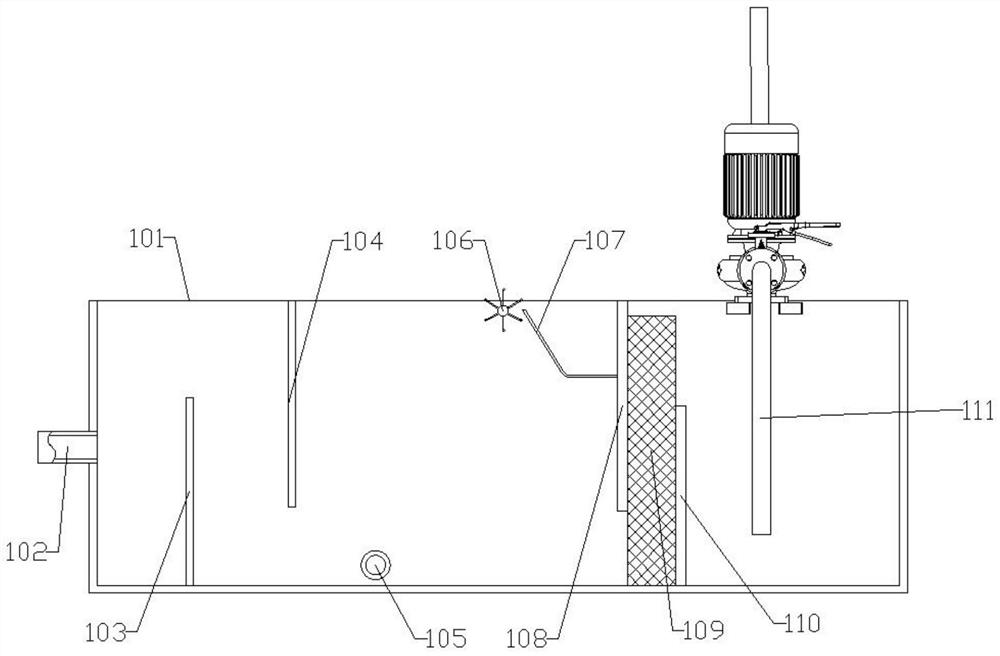

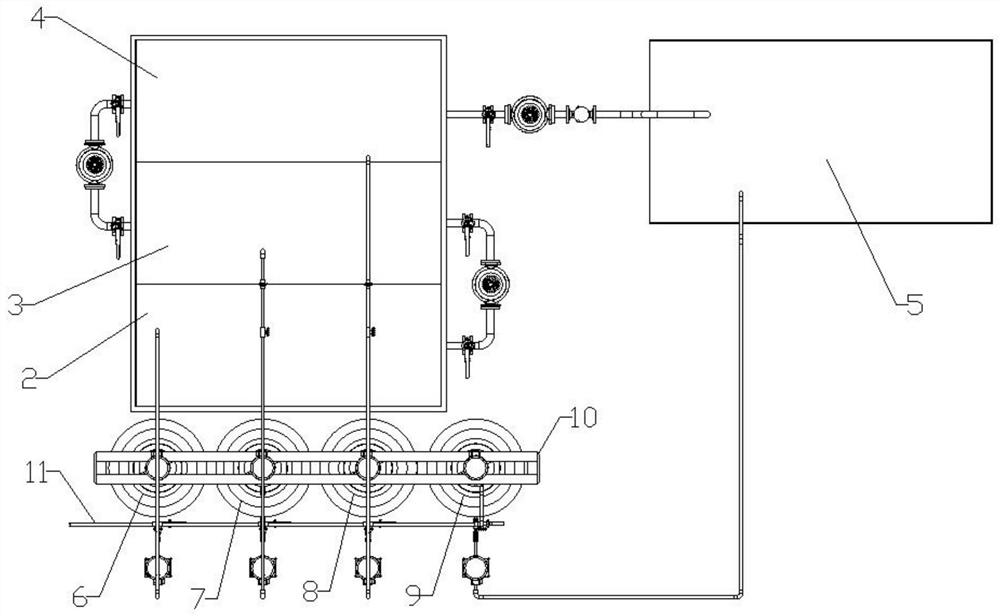

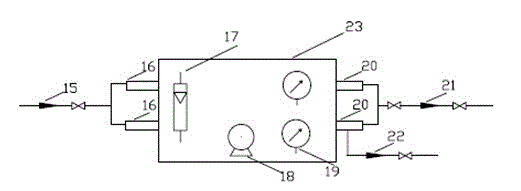

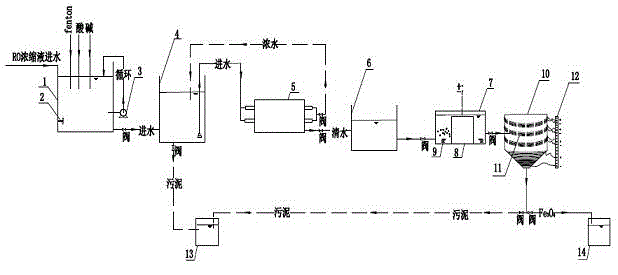

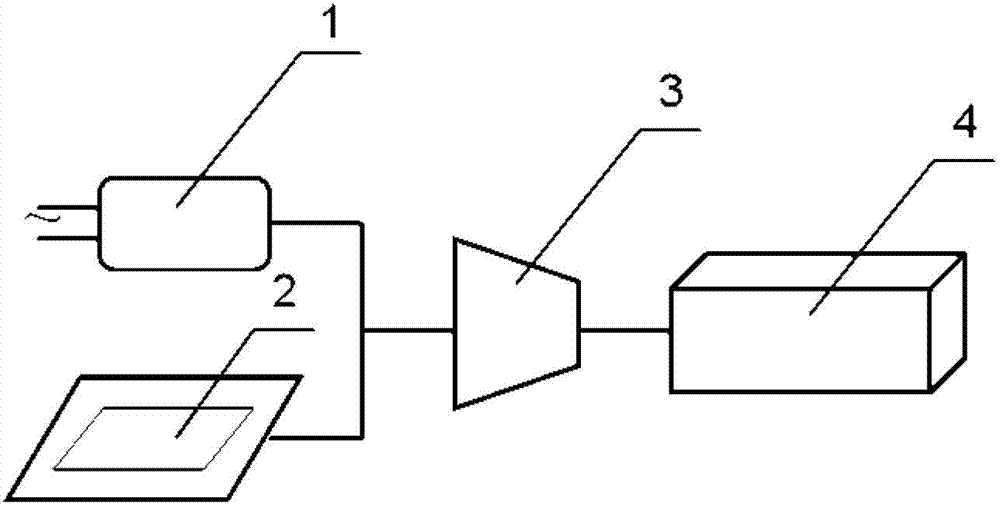

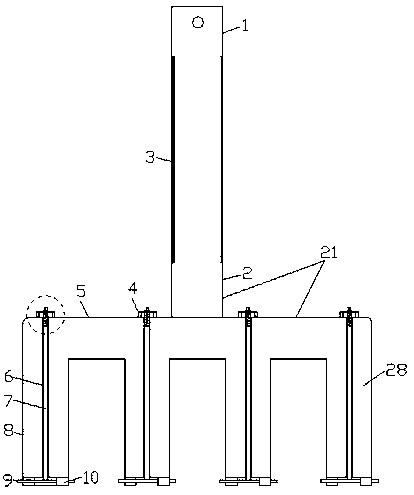

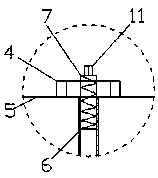

Equipment and combined process for treating RO concentrated solution of high-concentration organic wastewater

ActiveCN104529046AImprove separation efficiencyImprove electrolysis efficiencyMultistage water/sewage treatmentHigh concentrationPre treatment

The invention relates to equipment and a combined process for removing RO concentrated solution in a high-concentration organic wastewater treatment system. The equipment for treating RO concentrated solution of high-concentration organic wastewater comprises a Fenton pretreatment pool 1, membrane system separation equipment 5, a pulsed electrolytic cell 7 and a magnetic settling pond 10 which are sequentially connected by virtue of pipelines, wherein the membrane system separation equipment 5 refers to a tubular coating; the pulsed electrolytic cell 7 is an inverted I-shaped electrolytic cell which consists of two pools 26 and two water tanks 27 and is hollow; and magnets 11 consisting of soft iron and wound coils are arranged on the outer layer of the settling pond wall 28 in a sectional mode. The combined process for treating the RO concentrated solution of high-concentration organic wastewater comprises the following steps: performing chemical Fenton pretreatment; performing membrane separation; forming the pulsed electrolytic cell 7 with the Fe3O4 synergistic effect; forming the magnetic settling pond 10; and performing up-to-standard release on the supernatant. According to the novel equipment and combined process provided by the invention, the equipment is feasible in technology and applicable in economy, and the RO concentrated solution of the high-concentration organic wastewater is efficiently treated.

Owner:中钢集团武汉安全环保研究院有限公司

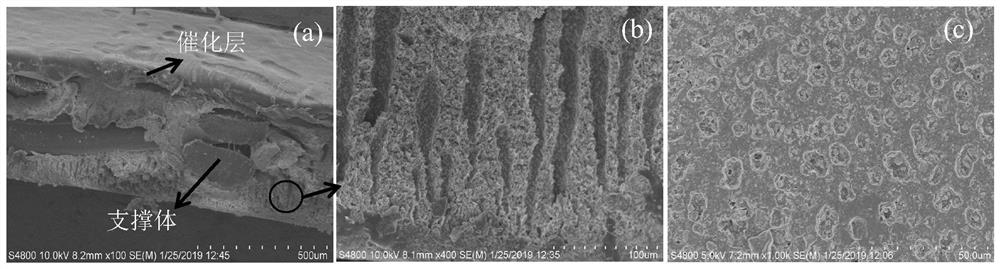

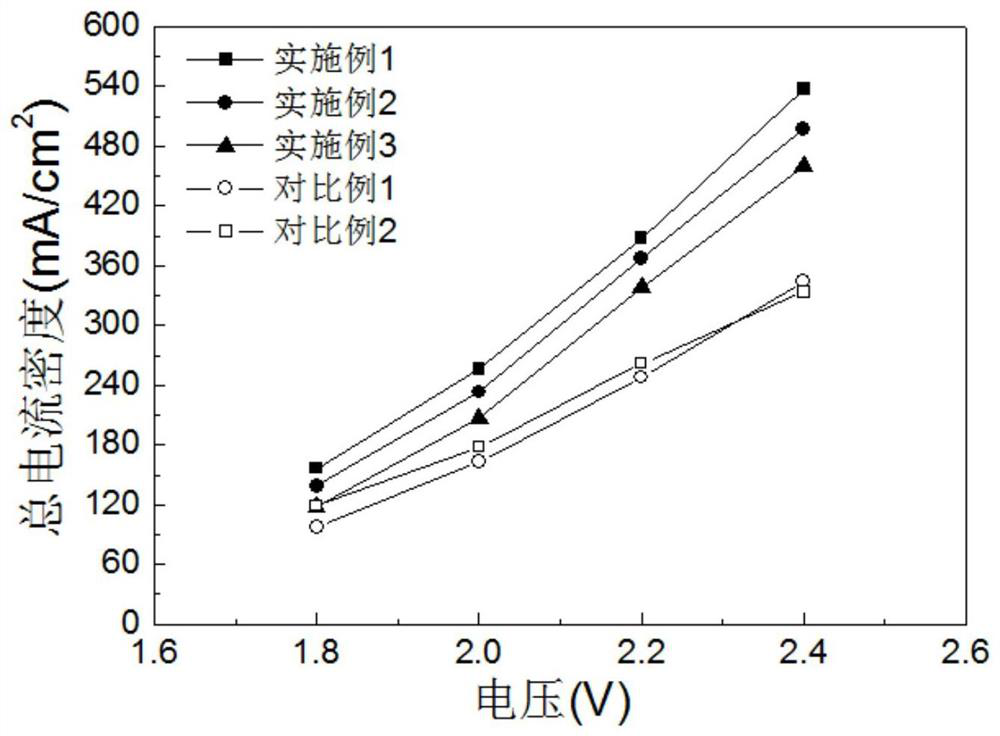

Integrated membrane electrode and preparation method and application thereof

PendingCN112144076AIncrease current densityReduce electrolysis energy consumptionOrganic diaphragmsElectrode shape/formsPorous compositeComposite membrane

The invention provides an integrated membrane electrode. The integrated membrane electrode comprises a porous composite membrane and a porous catalyst layer compounded with the porous composite membrane. Wherein the porous composite membrane contains inorganic powder, polysulfone and a support body, and can greatly improve the current density and reduce the electrolysis energy consumption on the basis of high mechanical strength and product gas purity. The porous catalyst layer contains polysulfone and a a catalyst, and has high catalytic activity and product selectivity. The invention also provides an integrated forming preparation method of the membrane electrode, which comprises the following steps: directly preparing the catalyst layer on the surface of an unformed liquid composite membrane blank, and preparing the integrated membrane electrode in one step by a phase inversion method, thereby greatly enhancing the stability of the membrane electrode.

Owner:BEIJING FUMEIJIA ENERGY TECH CO LTD

Bipolar electrode plate for preparing metal aluminum by aluminum chloride electrolysis and a method of using same

ActiveCN111270271AReduce bypass currentImprove electrolysis current efficiencyElectrodesAluminium chlorideElectrolysis

The invention relates to a bipolar electrode plate for preparing metal aluminum by aluminum chloride electrolysis and a using method of the bipolar electrode plate, and belongs to the technical fieldof electrolytic aluminum. The bipolar electrode plate for preparing metal aluminum by aluminum chloride electrolysis comprises a bipolar electrode plate base block and an insulating block. The bipolarelectrode plate base block is divided into a cathode end and an anode end. In the bipolar electrode plate base block, the remaining periphery is provided with insulating blocks correspondingly exceptthe end surface of the cathode end and the end surface of the anode end. The width of the insulating block needs to comply with the following relation: (Rho<C>*h+2.15 / D*S)<<Rho<L>*(b+h). According tothe bipolar electrode plate, the insulating block is connected to the bipolar electrode plate base block, and the width of the insulating block is defined, so that when the bipolar electrode plate for preparing the metal aluminum by aluminum chloride electrolysis, bypass current can be effectively reduced, current efficiency is improved, and the electrolytic energy consumption is reduced.

Owner:NORTHEASTERN UNIV

Electrolysis method and device for self-cleaning carbon electrode

InactiveCN102807268ARealize self-cleaning functionGood adhesionWater/sewage treatmentEnergy based wastewater treatmentConcentration polarizationEngineering

The invention relates to an electrolysis method and device for a self-cleaning carbon electrode, and belongs to the technical field of electrochemistry electrolysis. A periodic swerving electrolysis device is adopted and comprises an electrolytic cell, a periodic swerving controller and a direct-current power supply system, wherein the positive electrode and the negative electrode of the electrolytic cell are carbon electrodes, and the periodic swerving controller can be used for realizing the circular operations of electrifying, switching off, carrying out swerving electrification and switching off. The electrolysis method comprises the following steps of: 1) introducing materials into the electrolytic cell, wherein the electric conductivity of electrolysis material is more than 0.1S / m; 2) regulating the periodic swerving controller; and 3) electrifying to carry out electrolytic oxidation and reduction reaction. According to the method and the device disclosed by the invention, the carbon electrode can be cleaned by self in the electrolytic oxidation and reduction process, concentration polarization is lowered, the electrolysis efficiency is improved, the electrolysis energy consumption is lowered, and industrial implementation is easily carried out.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Cleaning and descaling device

InactiveCN108383249ASimple structureEasy to operateTreatment using complexing/solubilising chemicalsSurface cleaningEngineering

The invention discloses a cleaning and descaling device, which comprises a descaling driving device, a descaling driving rod and a cleaning mechanism, wherein an acidic electrolyzed water generator isarranged in the scaling driving device; one end of the descaling driving rod is connected with a motor in the scaling driving device; the descaling driving rod can rotate; a rod body of the descalingdriving rod is of a telescopic structure; the cleaning mechanism comprises a side surface cleaning surface and a bottom cleaning surface; a side surface spring mechanism is arranged in a connecting position of the side surface cleaning surface and the scaling driving rod; the bottom cleaning surface is connected with one end, far away from the descaling driving device, of the descaling driving rod; a bottom surface spring mechanism is arranged in the connecting position of the bottom cleaning surface and the descaling driving rod. The cleaning and descaling device has the advantages that thestructure is simple; the operation is convenient; an electrolyzed acidic water solution is used for descaling; the use of chemical agents is not needed; green effect and environment protection are realized; the cleaning and descaling device is provided and connected with the side surface cleaning surface and the bottom cleaning surface; the water scale removing efficiency is high; a spraying mechanism is also connected; the acidic electrolyzed water can also be sprayed onto the side surface; the utilization rate on the water is high.

Owner:FOSHAN XIHUA TECH CO LTD

Method and device for electrolysis of self-cleaning composite graphite electrode

InactiveCN102874904ARealize self-cleaning functionGood adhesionWater/sewage treatmentEnergy based wastewater treatmentElectrolysisGraphite electrode

The invention relates to a method and a device for electrolysis of a self-cleaning composite graphite electrode, and belongs to the technical field of electrochemical electrolysis. The device is a periodic turning electrolyzer comprising an electrolysis bath, a periodic turning controller and a direct current supply system, wherein the positive electrode and the negative electrode are made of insoluble metal; a graphite or glass carbon complex pole is arranged in the middle; and the periodic turning controller realizes the circulating operations of power turn-on, power turn-off, turning power turn-on and power turn-off. The electrolysis method comprises the following steps: (1) materials are fed into the electrolysis bath, wherein the electric conductivity for the electrolyzed materials is larger than 0.1 S / m; (2) the periodic turning controller is adjusted; and (3) power is turned on to carry out electrolytic oxidation reduction reaction. The method and the device can realize self-cleaning of the electrode in the electrolytic oxidation reduction process, improve the electrolysis efficiency and reduce the electrolysis energy consumption and are easy for industrial implementation.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

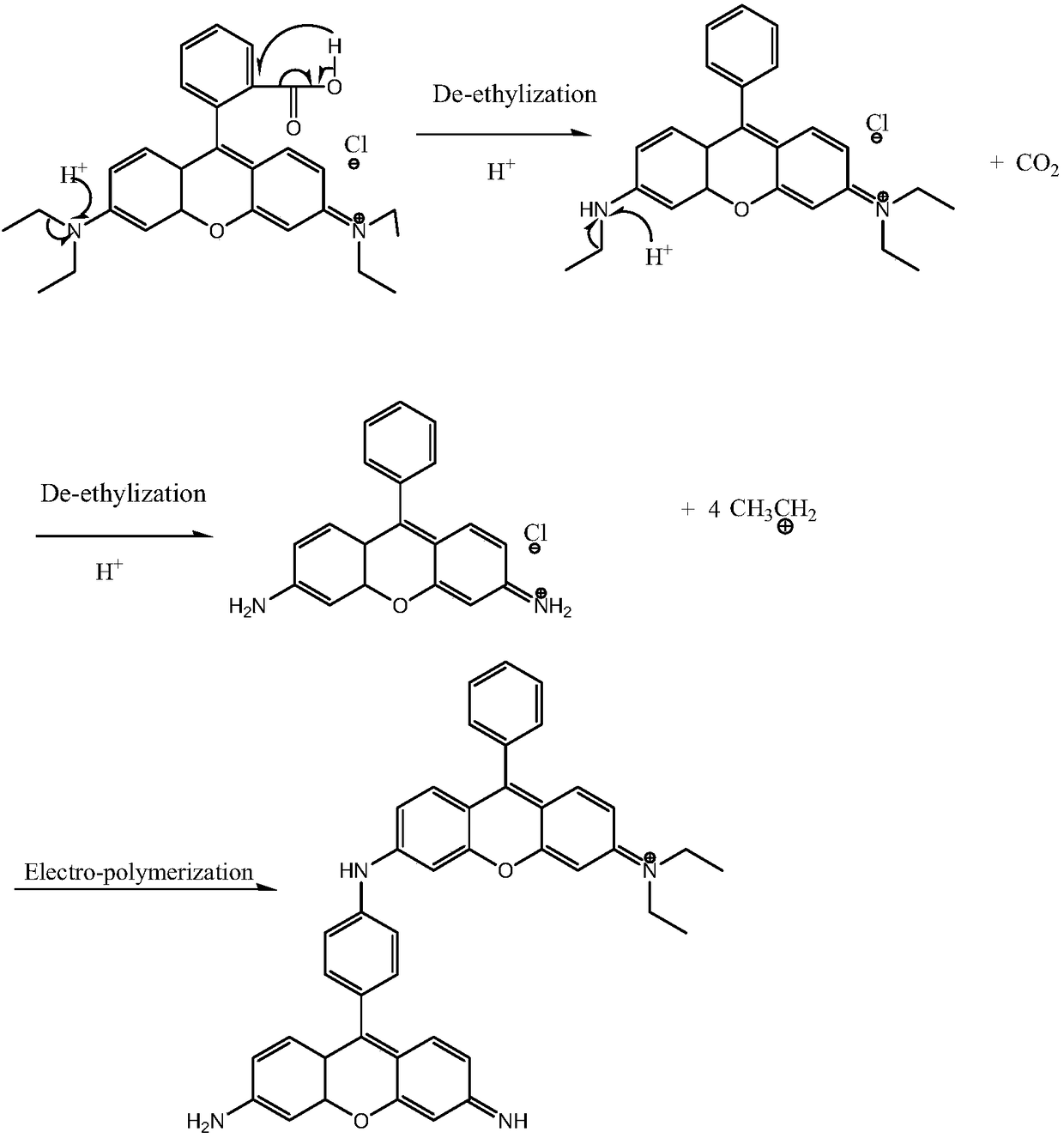

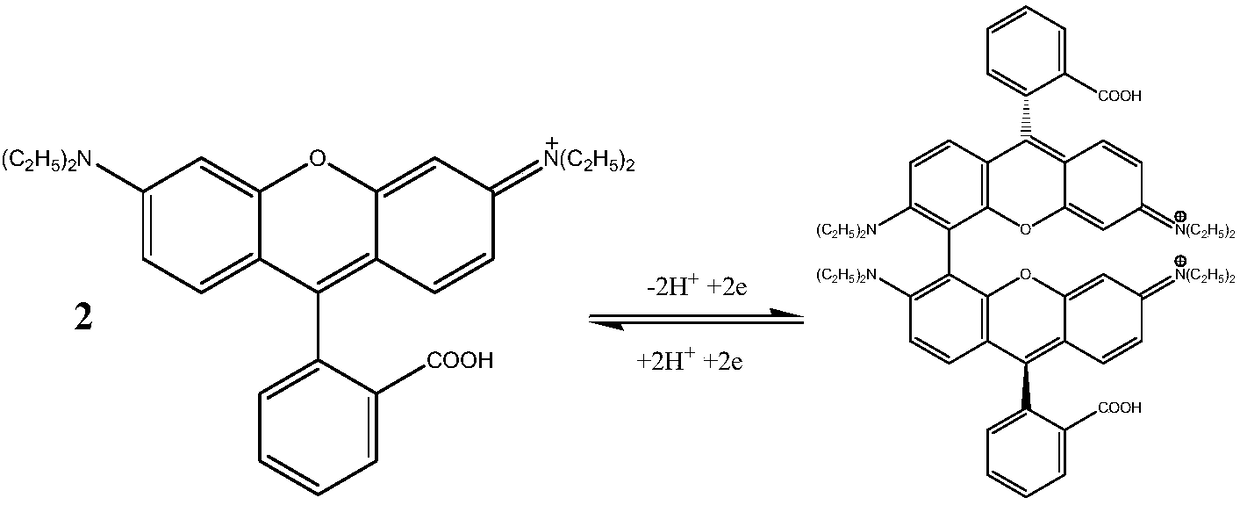

Method for decomposing rhodamine B wastewater

InactiveCN108083519AReduce COD valueFast preprocessingWater treatment parameter controlWater contaminantsGratingElectrolysis

The invention discloses a method for decomposing rhodamine B wastewater. The method comprises steps as follows: firstly, rhodamine B wastewater is desilted through a grating and then heated to 10-60 DEG C, the pH is regulated to 2-7, filtration is performed after 1 h, a filtrate obtained after the filtration is an electrolyte, one of platinum sheet, iron, copper, gold, ruthenium, palladium, aluminum, graphite, lead and BDD (boron-doped diamond) electrodes is taken as an oxidation electrode, a saturated calomel electrode is taken as a reference electrode, oxidation is performed for 5 min underthe condition of oxidation voltage of 1.0-1.5 V, rhodamine B wastewater is subjected to an electropolymerization reaction, and precipitates are produced; an electrolyte obtained after an oxidation reaction is filtered by a 0.22 mu m filter membrane, and a clear liquid is obtained. Compared with other methods for decomposing rhodamine B, the method has the advantages that C-N bonds on ethyl of rhodamine B are broken to generate -NH2, electropolymerization is performed on the electrode, polyaniline-like products are produced, the degradation time can be greatly shortened and electrolysis energyconsumption can be greatly reduced.

Owner:HUANGSHAN UNIV

Sodium hypochlorite disinfectant generator

PendingCN111334819AFast productionEasy to operateCellsElectrode shape/formsElectrolysisSodium chlorate

The invention discloses a sodium hypochlorite disinfectant generator comprising a supporting shell. One end of a tubular body is connected to the supporting shell, the other end of the tubular body isconnected with a barrel for containing sodium chloride, and a through hole communicated with an inner hole of the tubular body is formed in the outer circumferential face of the tubular body. The supporting shell is further fixedly connected with a rod-shaped electrode or two rod-shaped electrodes, and the rod-shaped electrodes are arranged in the middle of the inner hole of the tubular body. When the supporting shell is fixedly connected with one rod-shaped electrode, the tubular body becomes an electrode, and when the tubular body and the barrel body filled with sodium chloride extend intowater together, the rod-shaped electrode and the tubular body are powered by a power supply for electrolysis; and when the two rod-shaped electrodes are fixedly connected to the supporting shell and the tubular body and the barrel body filled with sodium chloride extend into water together, the two rod-shaped electrodes are powered by the power supply for electrolysis. A material storage cavity isformed in the supporting shell, and materials for absorbing chlorine are contained in the material storage cavity. The sodium hypochlorite disinfectant generator is simple and convenient to operate,the preparation speed of the sodium hypochlorite disinfectant is high, and the sodium chloride consumption and the electrolysis energy consumption are reduced.

Owner:吴允苗

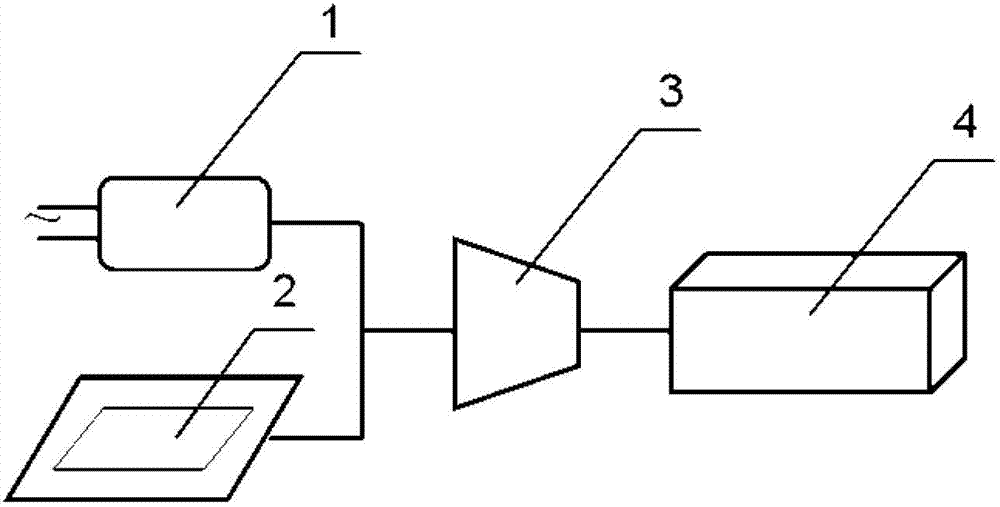

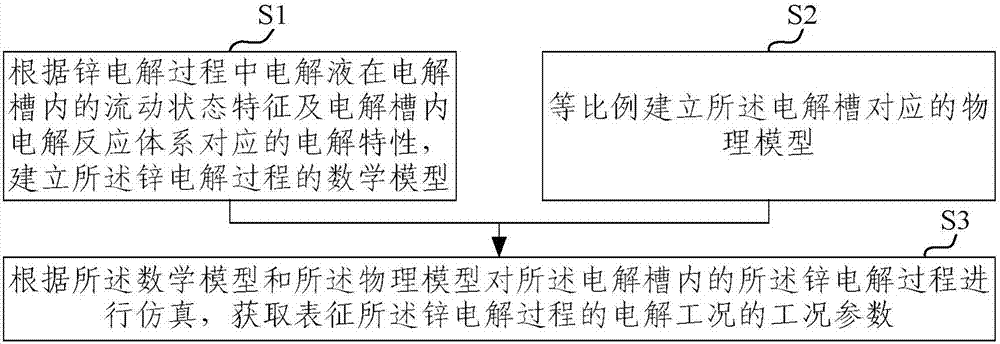

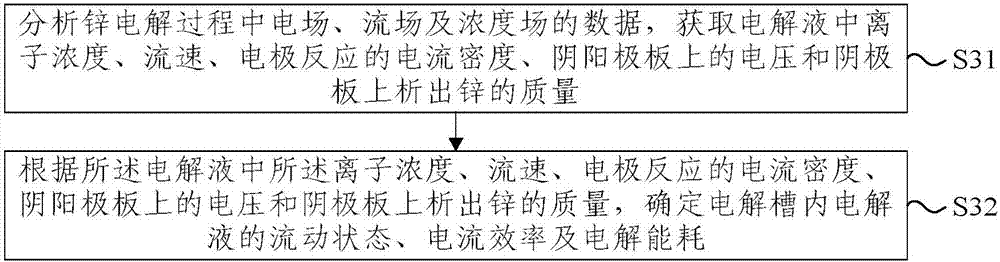

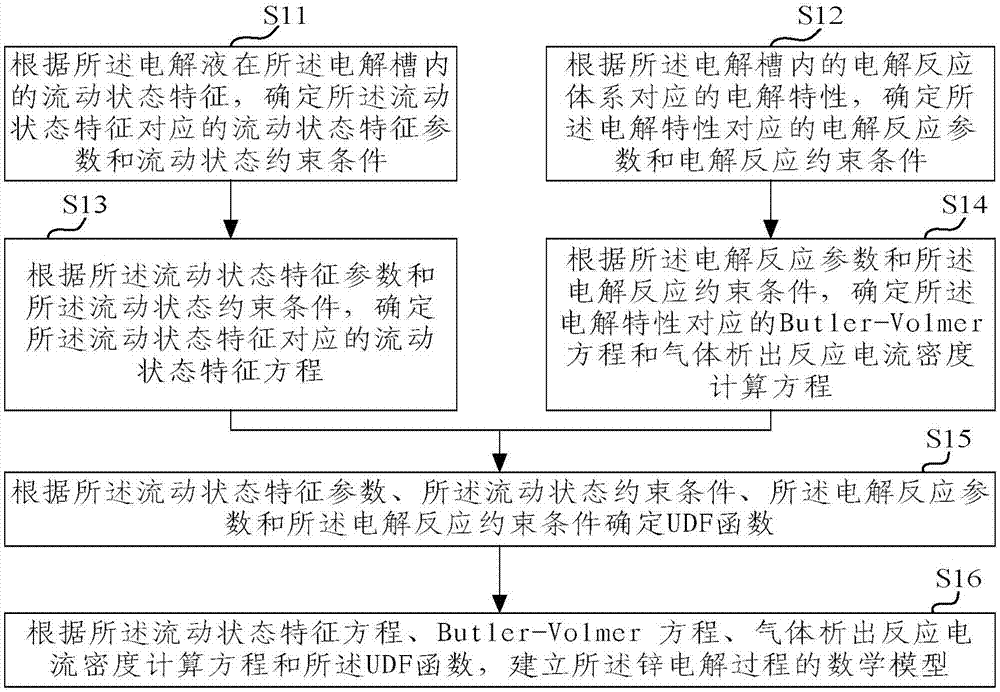

Measurement method and system for electrolysis condition in zinc electrolysis process

InactiveCN107423461AImprove adaptabilityReduce electrolysis energy consumptionDesign optimisation/simulationSpecial data processing applicationsElectrolysisMathematical model

The invention relates to the technical field of nonferrous metallurgy and provides a measurement method and system for an electrolysis condition in a zinc electrolysis process. The method comprises the steps of building a mathematic model of the zinc electrolysis process according to a flow state characteristic of an electrolytic solution in an electrolytic bath and an electrolytic characteristic corresponding to an electrolytic reaction system in the electrolytic bath in the zinc electrolysis process; building a physical model corresponding to the electrolytic bath in an equal-ratio manner; and performing simulation on the zinc electrolysis process in the electrolytic bath according to the mathematic model and the physical model to obtain condition parameters which represent the electrolysis condition of the zinc electrolysis process. According to the measurement method and system for the electrolysis condition in the zinc electrolysis process, provided by the invention, the condition state of the zinc electrolysis process is obtained through modeling and simulation of the zinc electrolysis process, so that the convenience can be provided for optimization control of the zinc electrolysis process, the time is shortened, and the overall efficiency is improved; and meanwhile, a test does not need to be carried out, so that the method is more economic and more flexible in comparison with a conventional method.

Owner:CENT SOUTH UNIV

Production method and structure of aluminum electrolysis continuous prebaked anode

The invention discloses a production method of an aluminum electrolysis continuous prebaked anode. The method comprises a bonding method of stud nut adjustable hollow filling, molten aluminum pouring-mechanical composite steel claws, a new anode carbon block and an old anode carbon block and a heat preservation mode for cooperative use of the stud nut adjustable hollow filling, molten aluminum pouring-mechanical composite steel claws and the anode carbon blocks. According to the production method, the old anode carbon block is consumed, the new anode carbon block is connected and then consumedagain, another new anode carbon block is connected in a circulating mode, so that the production of the continuous prebaked anode is realized, the resistivity of an anode assembly is reduced, hollowfilling, molten aluminum pouring and mechanical composite steel claws and the anode carbon blocks are are convenient to use, the bonding of the new anode carbon block and the old anode carbon block isfirm and reliable, the resistance between the new anode carbon block and the old anode carbon block is small, the electrolysis energy consumption is reduced, the residual electrode is eliminated, theconnection is convenient and safe, the heat insulation effect is good, the heat energy loss is small, the power consumption of an electrolytic cell can be greatly reduced, and the production cost islow.

Owner:贵州铝城铝业原材料研究发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com