Etching method capable of increasing electrochemical active area of nickel foam electrode

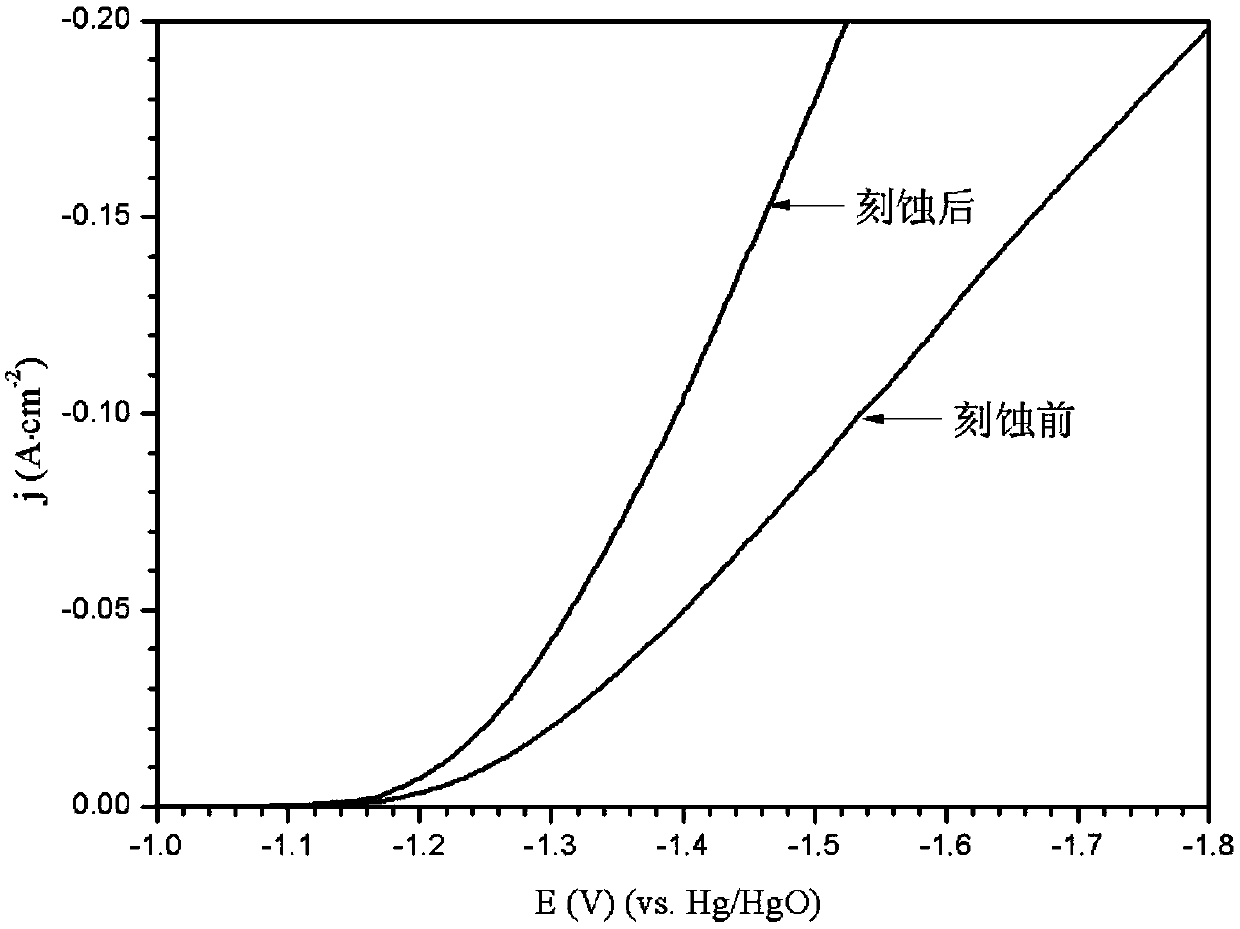

A foamed nickel and electrochemical technology, applied in the field of material surface treatment technology and electrocatalysis, can solve the problems of reduced electrode activity, cumbersome preparation method, weak anti-reverse current ability, etc. The effect of a large active area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] In this embodiment, the etching method for increasing the electrochemically active area of the foamed nickel electrode is to use chemical etching to soak and etch the foamed nickel electrode. The specific steps are as follows:

[0022] (1) At room temperature, degrease and degrease the nickel foam in isopropanol for 10 minutes, and clean it with ultrapure water; then, put it into hydrochloric acid with a molar concentration of 3M for pickling and activation treatment for 5 minutes; finally, put it into ultrapure water Ultrasonic cleaning in medium for 2 minutes and drying for later use;

[0023] (2) configure the chemical etching solution according to the following formula: hydrochloric acid 3M, iron salt 1M, and the rest are deionized water; wherein, the iron salt adopts ferric nitrate;

[0024] (3) immerse the foamed nickel pretreated in step (1) in the etching solution, the etching time is 20s, and the temperature of the etching solution is maintained at 25°C;

[...

Embodiment 2

[0030] The difference from Example 1 is that in this embodiment, the etching method for increasing the electrochemically active area of the foamed nickel electrode uses a chemical etching method to soak and etch the foamed nickel electrode. The specific steps are as follows:

[0031] (1) At room temperature, degrease and degrease the nickel foam in isopropanol for 10 minutes, and clean it with ultrapure water; then, put it into hydrochloric acid with a molar concentration of 3M for pickling and activation treatment for 5 minutes; finally, put it into ultrapure water Ultrasonic cleaning in medium for 2 minutes and drying for later use;

[0032] (2) configure the chemical etching solution according to the following formula: hydrochloric acid 2M, iron salt 0.5M, and the rest are deionized water; wherein, the iron salt is ferric chloride;

[0033] (3) Immerse the foamed nickel pretreated in step (1) in the etching solution, the etching time is 25s, and the temperature of the etc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com