Rotating negative electrode scale scraping and removing device

A technology of rotating cathodes and cathode plates, which is applied in the direction of special treatment targets, water/sewage treatment, electrochemical water/sewage treatment, etc., can solve the problems of limited distance between plates, complex structure, hard scale on the scaling surface, etc., to achieve Reduce electrolysis energy consumption, improve descaling efficiency, and improve the effect of scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

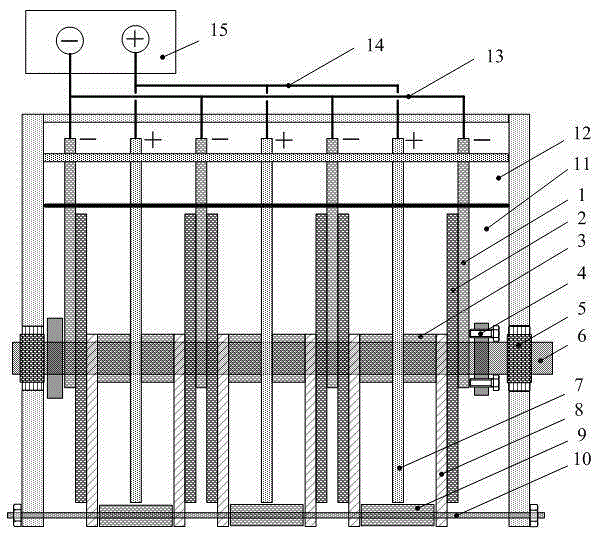

[0019] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0020] Please refer to figure 1 The rotary cathode scraping and descaling device of the present invention includes a cathode conductive column 1, a cathode plate 2, a rotating shaft 6, an anode plate 7, and a scraper 8, wherein the cathode conductive column 1 and the cathode plate 2 are closely attached, and the cathode conductive column 1, the cathode plate 2. There are multiple groups of scrapers 8 and anode plates 7, which are connected in series on the rotating shaft 6 in sequence. A central limit and righting block 3 is provided between the scraper 8 and the anode plate 7, and the cathode plate 2 rotates around the rotating shaft 6. On the cathode conductive column The top wire 4 is installed on the side of 1, and the cathode conductive column 1 guides the current into the cathode plate 2. During the rotation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com