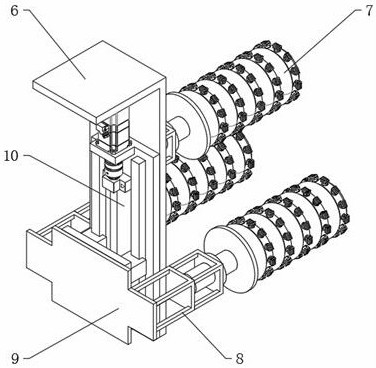

Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

64results about How to "Improve scraping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

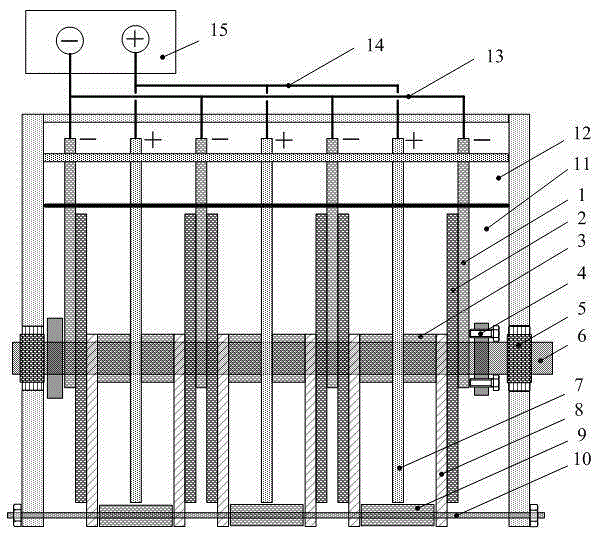

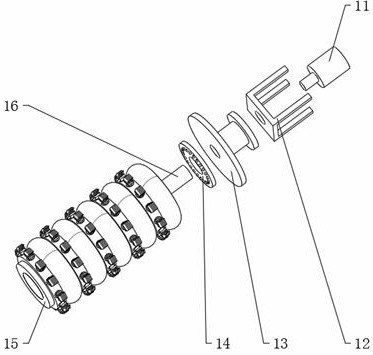

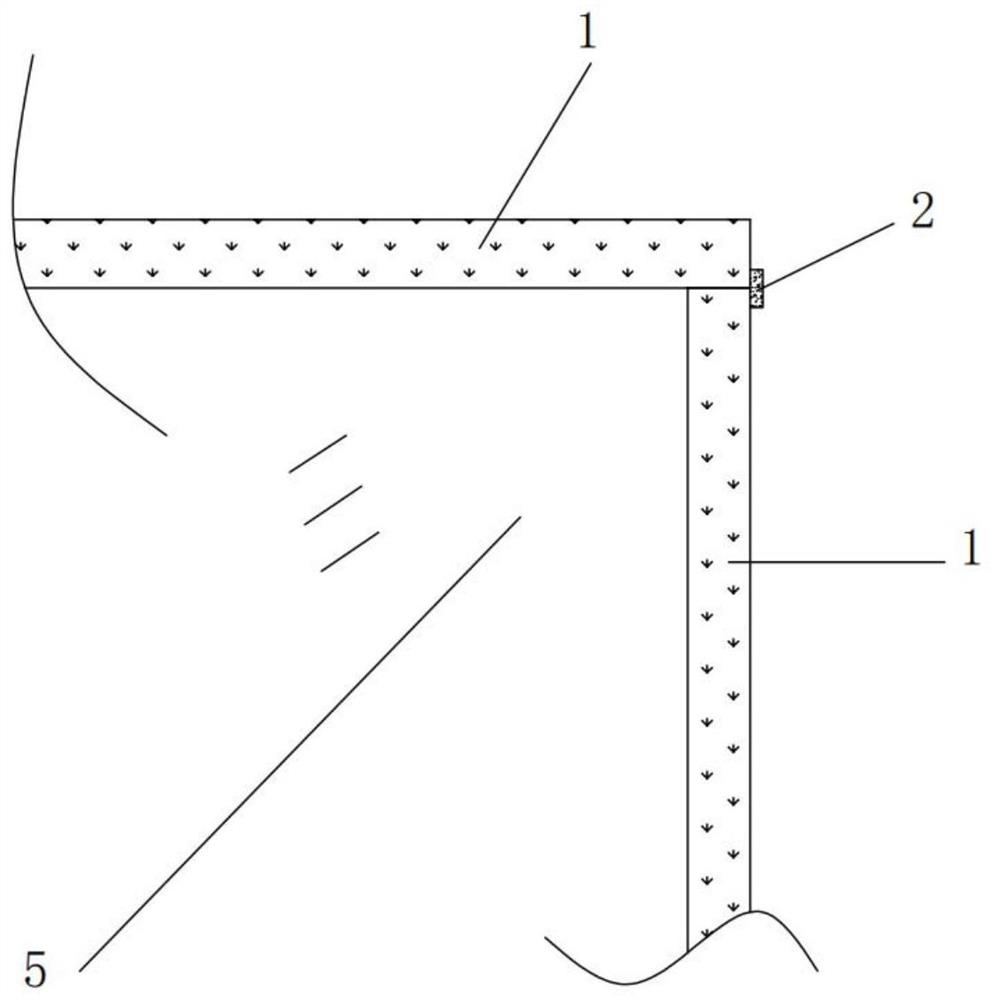

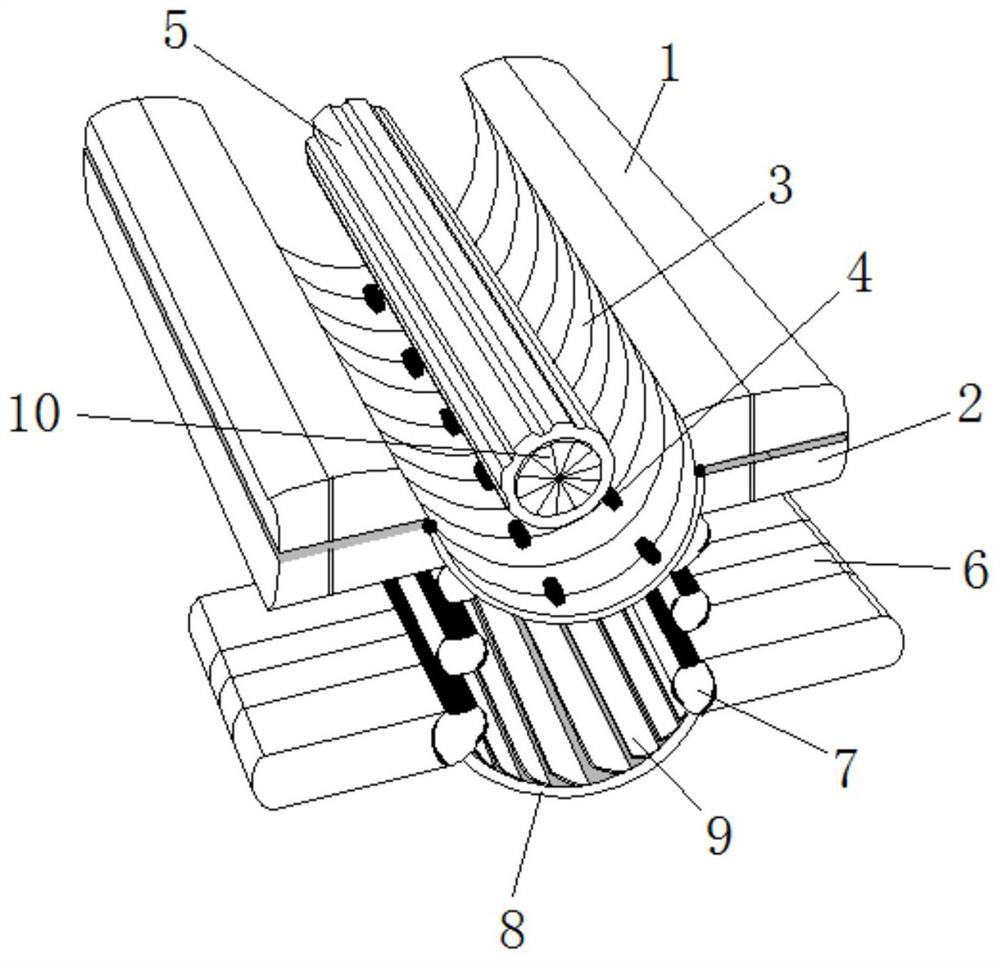

Rotating negative electrode scale scraping and removing device

InactiveCN105329985AImprove scrapingGood descaling effectSpecific water treatment objectivesWater/sewage treatment by electrochemical methodsPower flowPhysics

The invention relates to a rotating negative electrode scale scraping and removing device which comprises negative electrode conductive columns 1, negative electrode plates 2, a rotating shaft 6, positive electrode plates 7 and scrapers 8. The negative electrode conductive columns 1 are closely attached to the negative electrode plates 2. The negative electrode conductive columns 1, the negative electrode plates 2, the scrapers 8 and the positive electrode plates 7 are sequentially connected to the rotating shaft 6 in series. A central limiting and correcting block 3 is arranged between the scrapers 8 and the positive electrode plates 7. The negative electrode plates 2 rotate around the rotating shaft 6. A jackscrew 4 is arranged on one side of each negative electrode conductive column 1. Currents are guided into the negative electrode plates 2 by the negative electrode conductive columns 1. In the rotating process of the negative electrode plates 2, the scrapers 8 are closely attached to and scrap the surfaces of the negative electrode plates 2. The purpose of inputting currents to the rotating negative electrode plates without electric brushes is achieved, electrode intervals are easily decreased to the maximum degree, and the scale scraping and removing effects of the negative electrode plates are improved.

Owner:卫士循环水处理(北京)有限公司

Horizontal magnetic bar filter

The invention discloses a horizontal magnetic bar filter and belongs to the field of filtering equipment. The horizontal magnetic bar filter comprises a filter main body, wherein a transmission deviceis arranged on the filter main body; the transmission device comprises a transmission shaft, a chain and magnetic bars; a variable-frequency speed regulation speed reducer, a chain transmission reduction gearbox, a spring type chain tensioner, a draining transmission reduction gearbox and a magnetic bar dirt scraping opening and closing actuating mechanism are arranged at the outer side of the filter main body; the draining transmission reduction gearbox is connected with a screw rod, and an iron powder sludge outlet is arranged at the outer end of the screw rod; and a groove is arranged below the movement path of a magnetic bar dirt scraping rake, and the magnetic bar dirt scraping opening and closing actuating mechanism is connected with the magnetic bar dirt scraping rake. The horizontal magnetic bar filter has the advantages of long service life, smooth running and low noise, and besides, is large in absorbing area and great in separating effect as a large magnetic field is produced due to the high density of the magnetic bars. Besides, the horizontal magnetic bar filter has a certain dirt floating oil removing function, and at the same time, is convenient to clean and maintain as the transmission system is separate from a box body.

Owner:宁波甬为机电科技有限公司

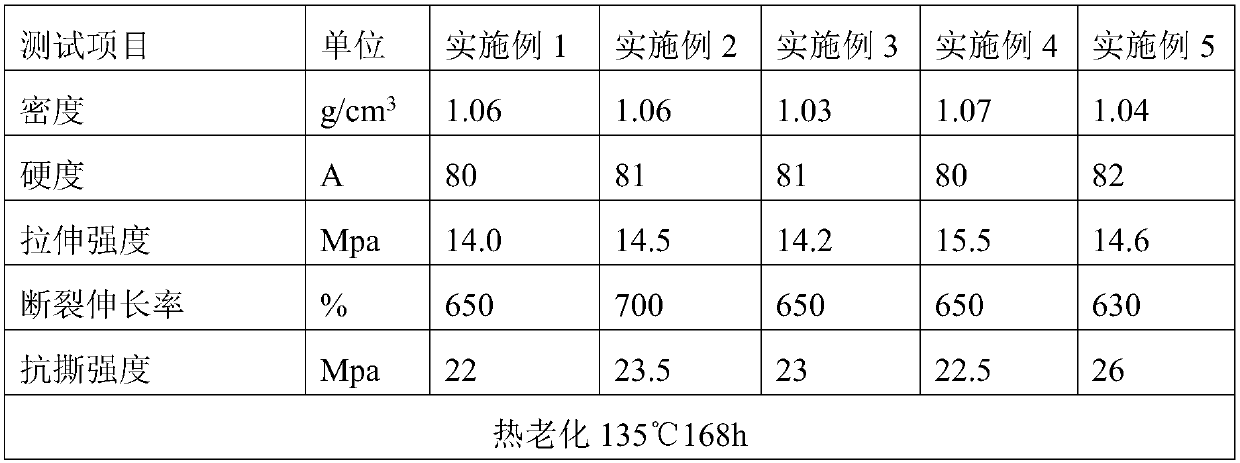

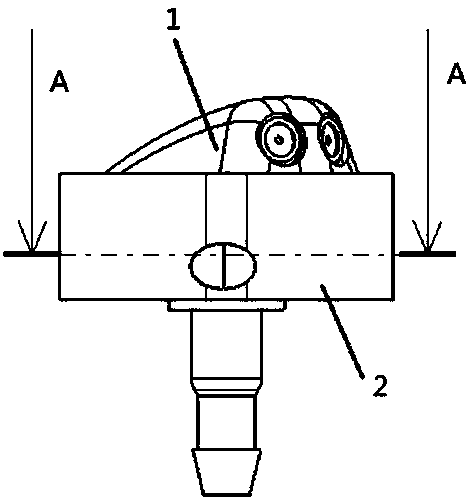

Halogen-free flame-retardant thermoplastic elastomer sheath material and preparation method thereof

InactiveCN110527237AImprove mechanical propertiesEasy to processPlastic/resin/waxes insulatorsThermoplastic elastomerAntioxidant

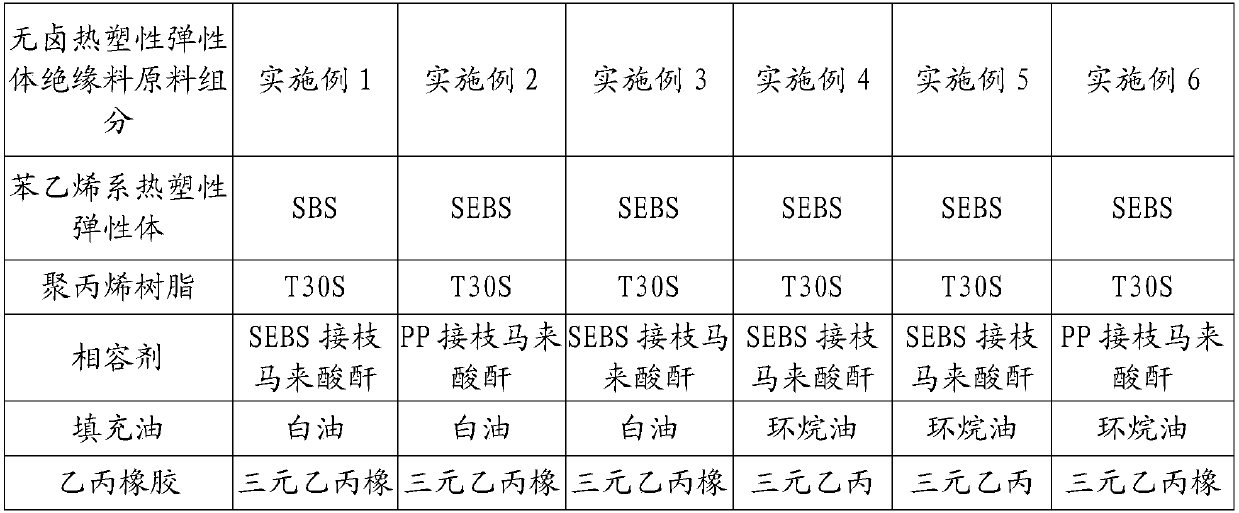

The invention relates to a halogen-free flame-retardant thermoplastic elastomer sheath material and a preparation method thereof. The halogen-free flame-retardant thermoplastic elastomer sheath material comprises the following components: a styrene thermoplastic elastomer, polypropylene resin, a compatilizer, filling oil, ethylene-propylene rubber, a flexibilizer, a halogen-free flame retardant, polyphenyl ether resin, a smoke suppressant, an antioxidant and a lubricating aid. The preparation method comprises the following steps: 1) filling the styrene thermoplastic elastomer with the fillingoil; 2) after oil filling is completed, adding the styrene thermoplastic elastomer and other components into a high-speed mixer for mixing; 3) adding the mixture into an internal mixer for internal mixing; and 4) feeding the internally mixed mixture into a twin-screw extruder, and performing stranding and pelletizing at 160-200 DEG C. The halogen-free flame-retardant thermoplastic elastomer sheathmaterial disclosed by the invention is low in processing temperature and low in hardness, has good scratch resistance and flame retardance, still has a cable folding and winding function in a low-temperature environment, is excellent in comprehensive performance, and is suitable for cables for electric automobile charging piles.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

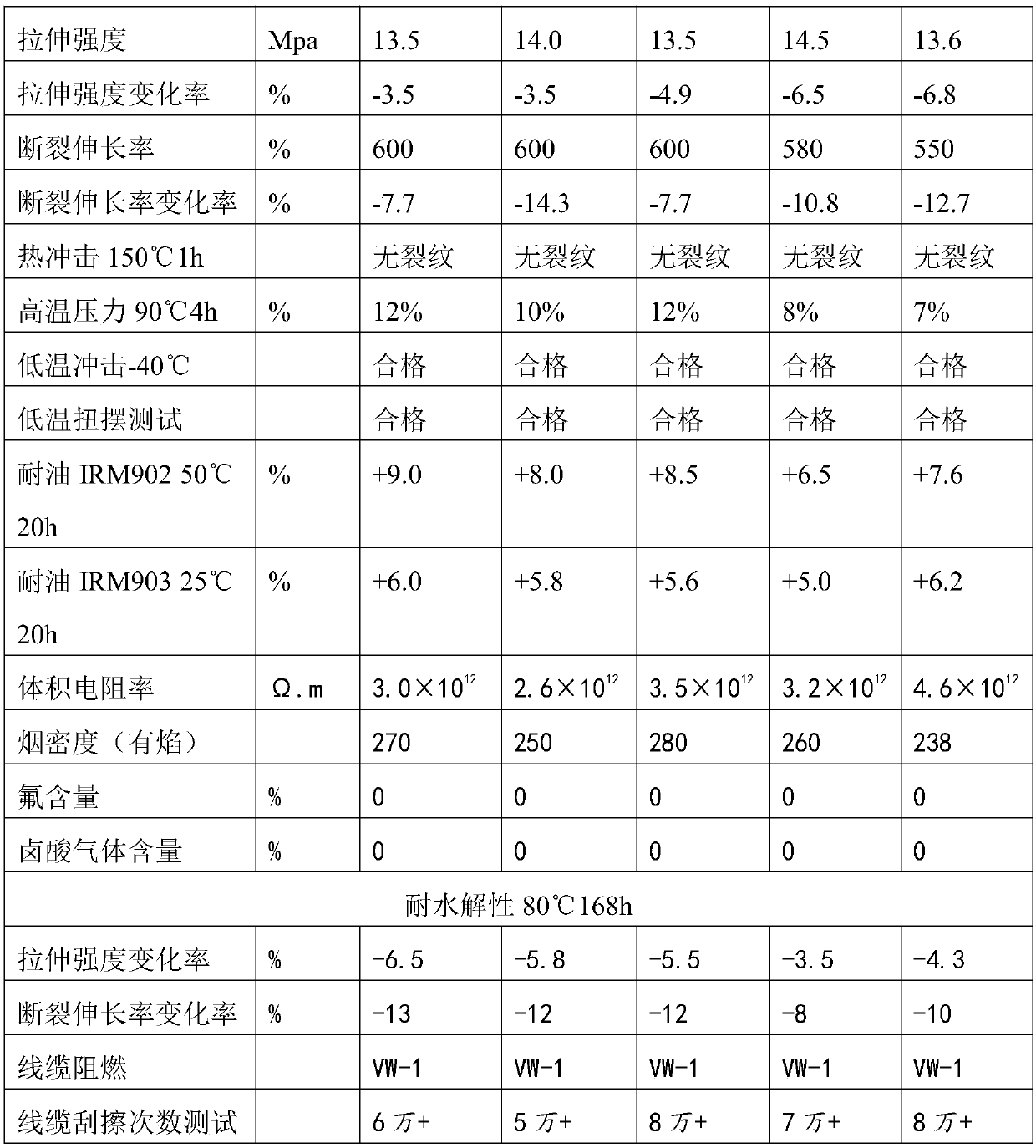

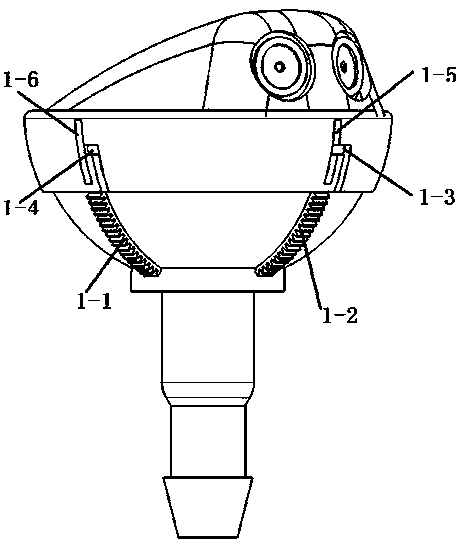

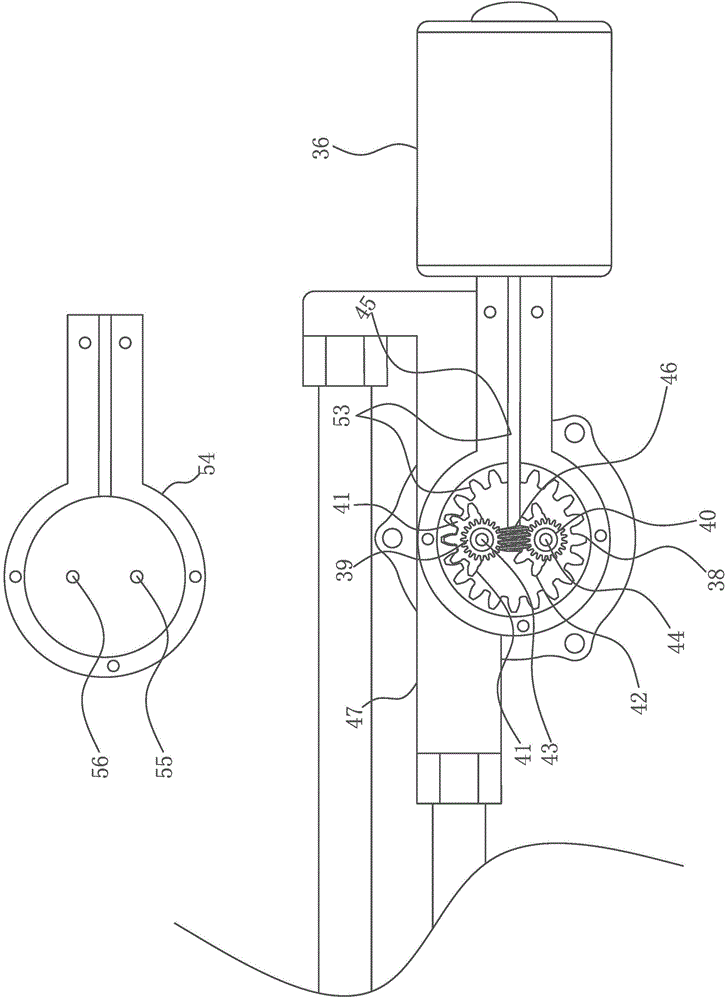

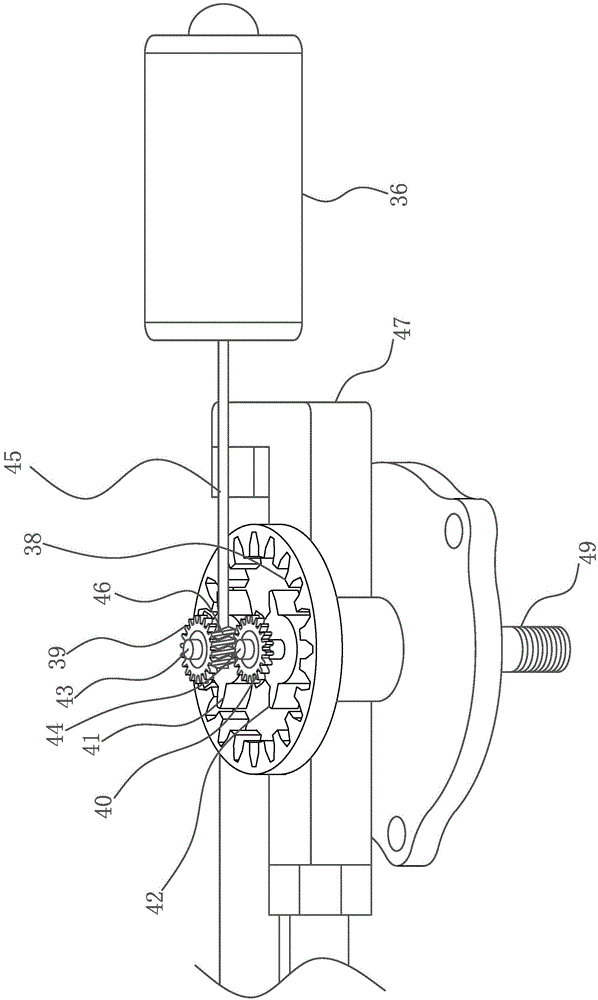

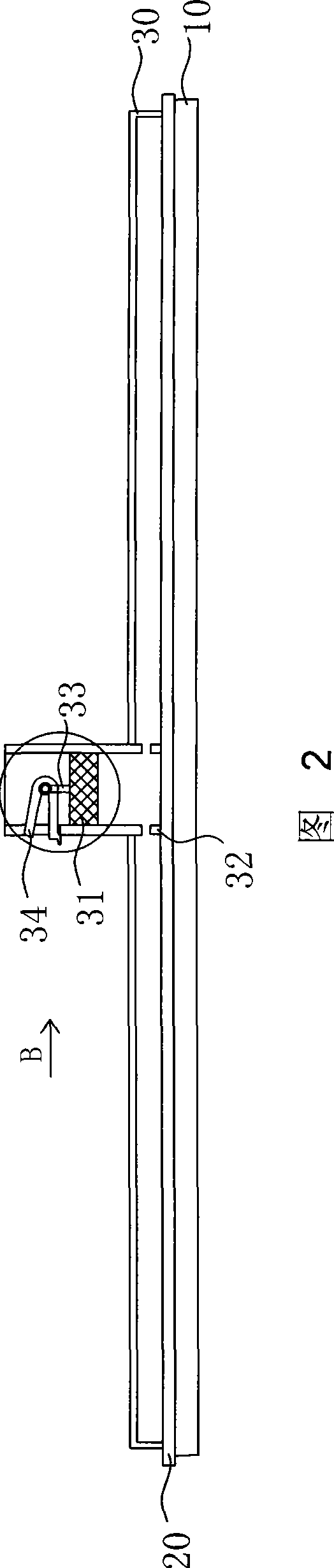

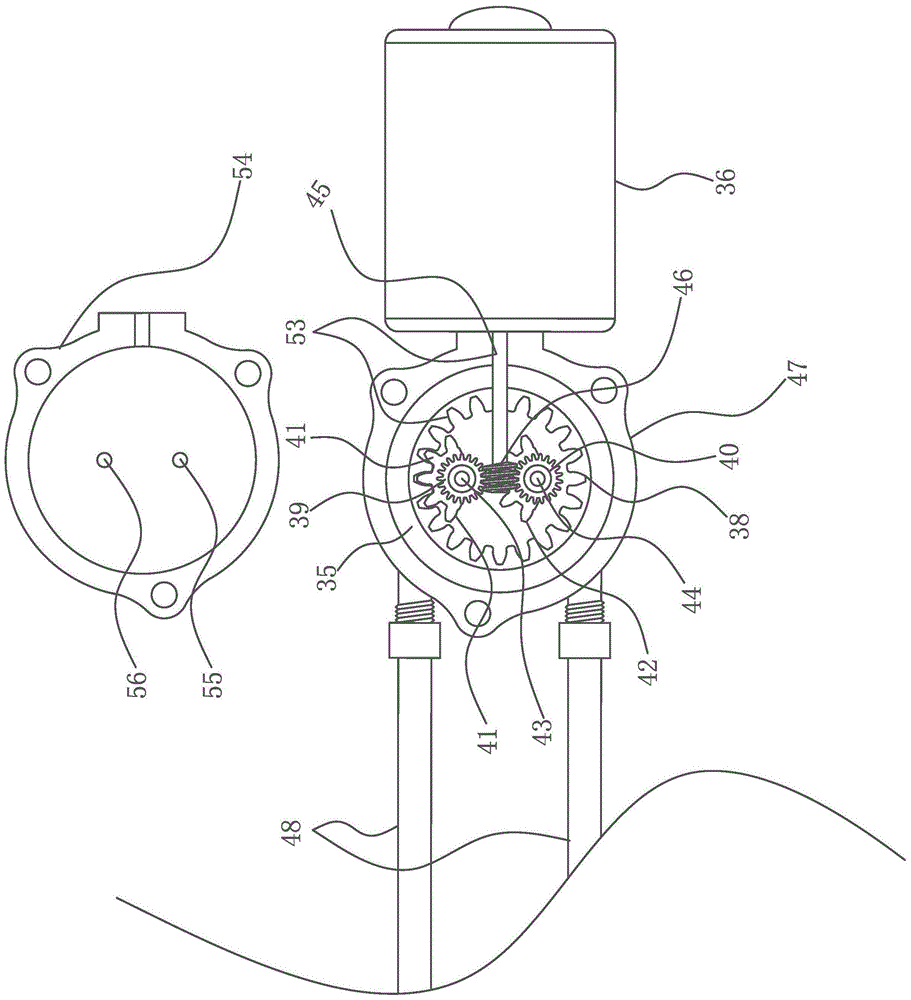

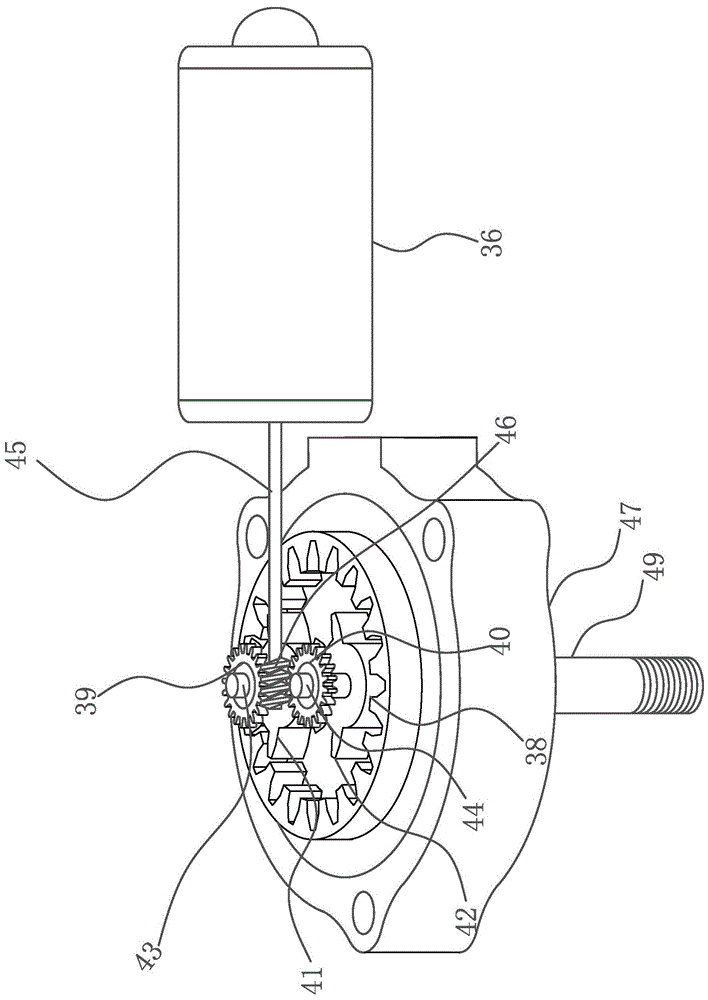

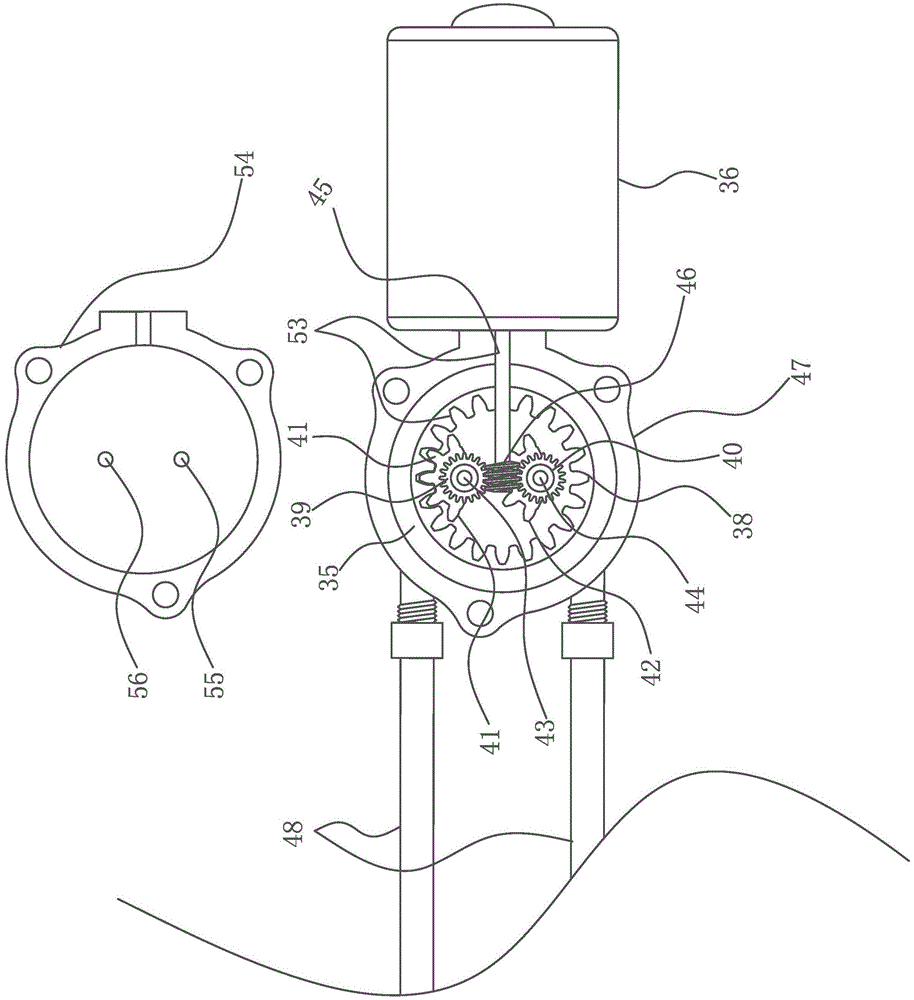

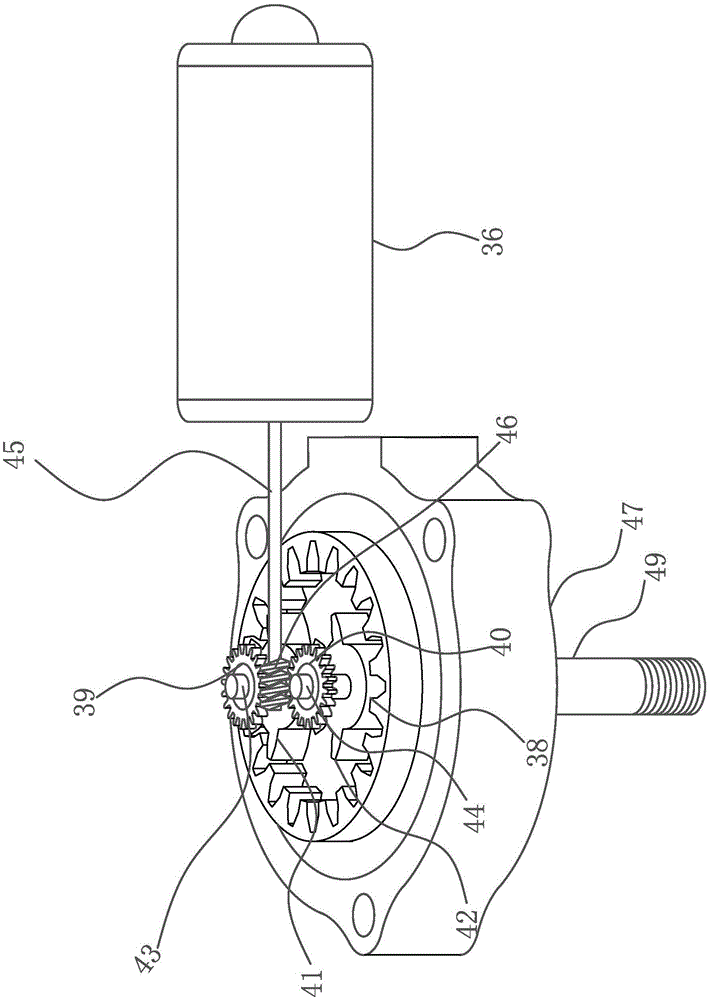

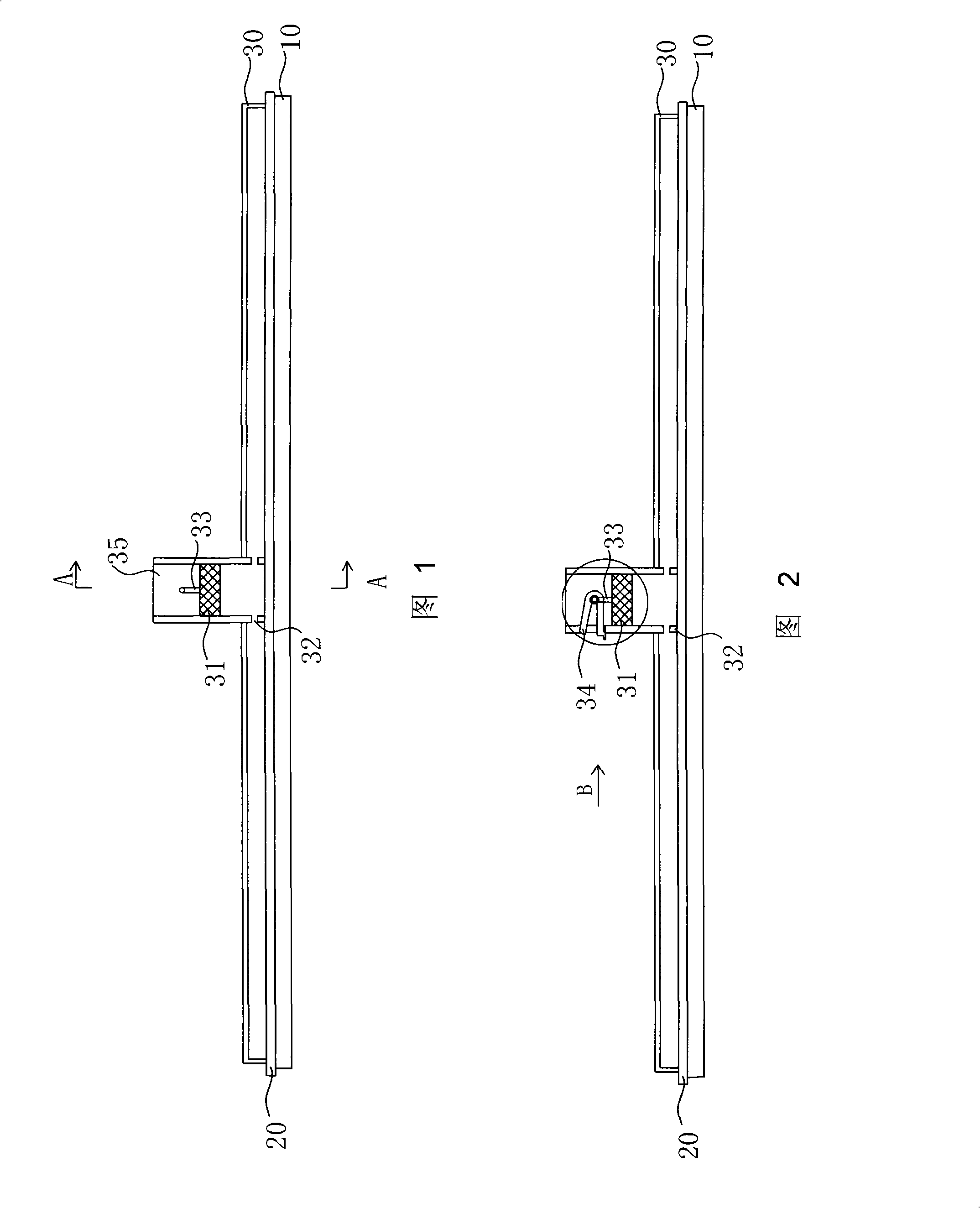

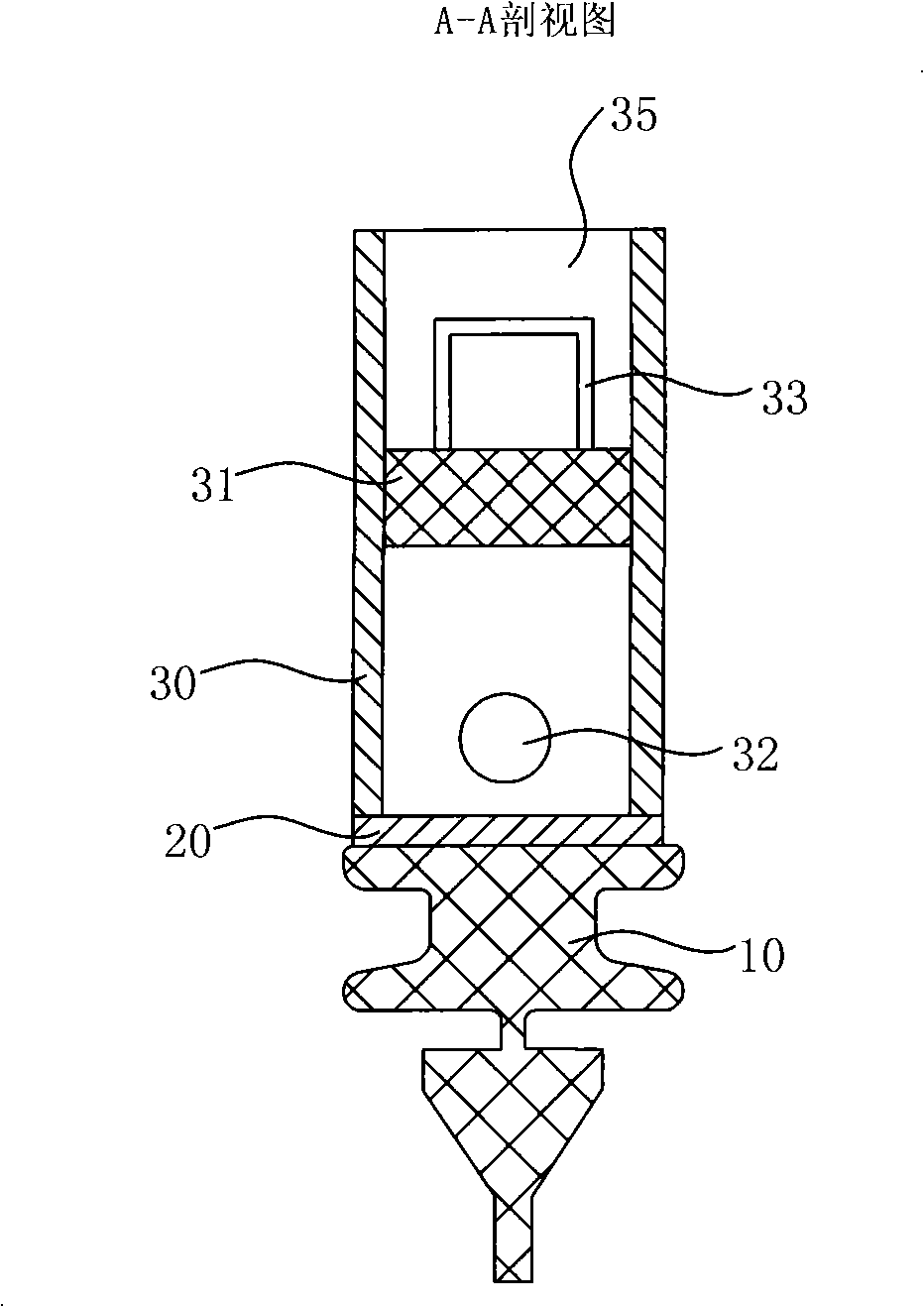

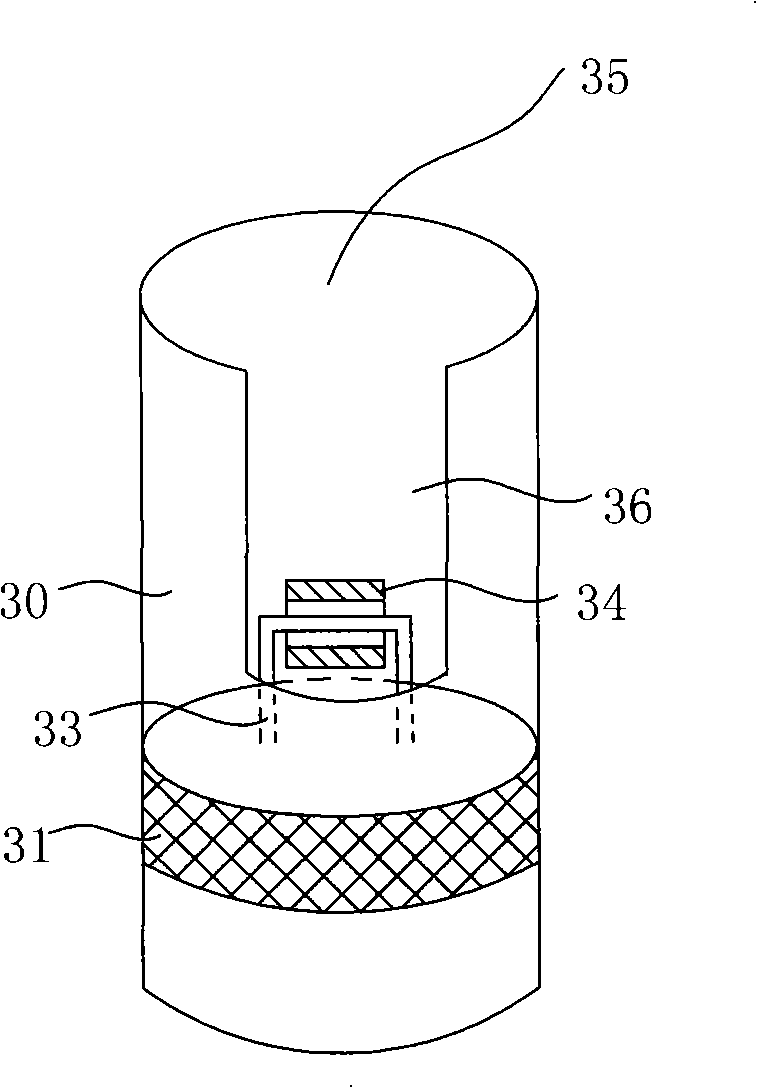

Automobile washing nozzle assembly capable of automatically adjusting spraying direction of nozzle

PendingCN107757560ASave calibration timeRealize automatic adjustmentVehicle cleaningSpray nozzleIntegrated controller

The invention relates to an automobile washing nozzle assembly capable of automatically adjusting the spraying direction of a nozzle. The automobile washing nozzle assembly capable of automatically adjusting the spraying direction of the nozzle comprises a nozzle body and a nozzle controller and is characterized in that the nozzle body is coated on the internal side of the nozzle controller; the coated part is a spherical structure and fixed on an exterior trim cover plate; a clamping structure and a rotating shaft guide rail structure are arranged on the peripheral spherical structure betweenthe nozzle body and the nozzle controller; two micro adjusting motors capable of realizing top, bottom, left and right stepless adjustments of the nozzle are also integrated in the nozzle controller;the micro adjusting motors are engaged with gears, which are arranged on the spherical structure of the nozzle body, through output shafts and motor gears; and a cab adjusting switch comprises top, bottom, left and right adjusting gears. The automobile washing nozzle assembly capable of automatically adjusting the spraying direction of the nozzle can automatically adjust the spraying direction and can be suitable for different windscreens of any automobile model; therefore, the nozzle spraying direction checking time is saved for property developers and the development period is also reducedfor the property developers.

Owner:BRILLIANCE AUTO

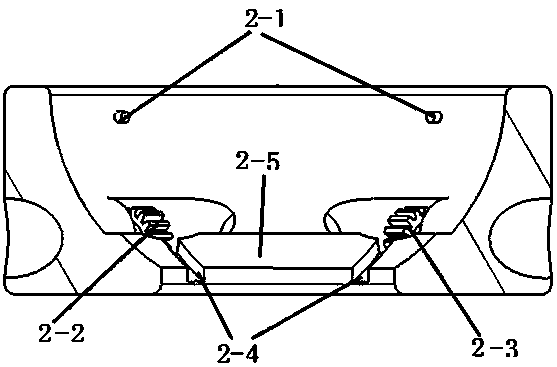

Graphene modified low-smoke halogen-free flame-retardant polyolefin semiconductive material and preparation method thereof

InactiveCN109880204AImprove performanceLow pricePlastic/resin/waxes insulatorsEnvironmental resistancePolyolefin

The invention discloses a graphene modified low-smoke halogen-free flame-retardant polyolefin semiconductive material and a preparation method thereof. The graphene modified low-smoke halogen-free flame-retardant polyolefin semiconductive material comprises the following components in parts by weight: 100 parts of polyolefin resin, 1.0-4.5 parts of a lubricant, 0.15-0.45 part of an antioxidant, 6-20 parts of graphene and 28-50 parts of a flame retardant; the invention further provides a preparation method of a modified low-smoke halogen-free flame-retardant polyolefin conductive material. Thegraphene modified low-smoke halogen-free flame-retardant polyolefin semiconductive material provided by the invention has excellent mechanical properties and electrical conductivity, is completely environment-friendly, fine and smooth in extruded surface, small in fuming, and suitable for a semi-conductive outer shielding layer of a medium-high voltage cable with higher requirements on flame retardance, environmental protection and light transmittance, and can better guarantee normal use and operation of the cable by being matched with a flame-retardant sheath.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

Flexible wall supported wiper hydraulic swing windscreen wiper

ActiveCN104554159AReduce noiseAvoiding the Cons of Burning OutVehicle cleaningEngineeringInterior noise

A flexible wall supported wiper hydraulic swing windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that two gear rack swing oil cylinders are communicated through a hydraulic oil pipe and transfer torque, and a forward and reverse rotating gear intermittent drive mechanism is arranged on the driving gear rack swing oil cylinder. The flexible wall supported wiper hydraulic swing windscreen wiper has the advantages that the wiper driving mechanism of the windscreen wiper performs hydraulic drive through a flexible pipe, is large in transfer torque, small in size and quick in response, is small in structural limitation during installation due to the fact that the hydraulic drive by means of the flexible pipe is adopted, is completely of a closed structure, is low in noise during working, is especially suitable for a complicated external environment structure and remote transmission, can adapt to vehicle of different models and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, interior noise is effectively reduced, the interior comfort of a vehicle in running is improved, and a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen.

Owner:TONGLING HUIYU IND CO LTD

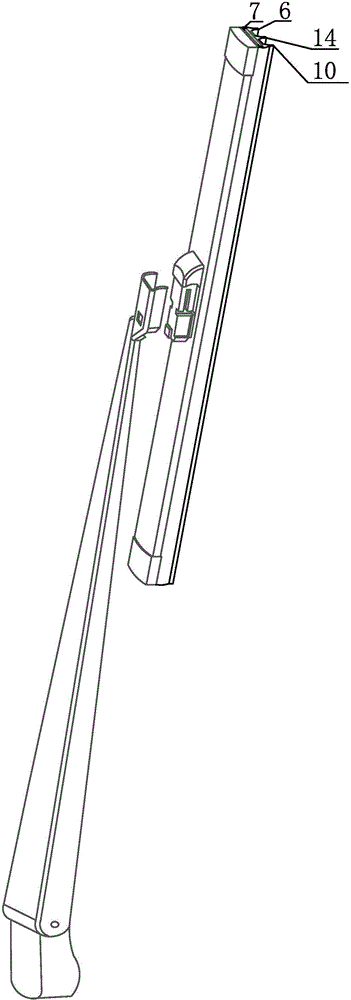

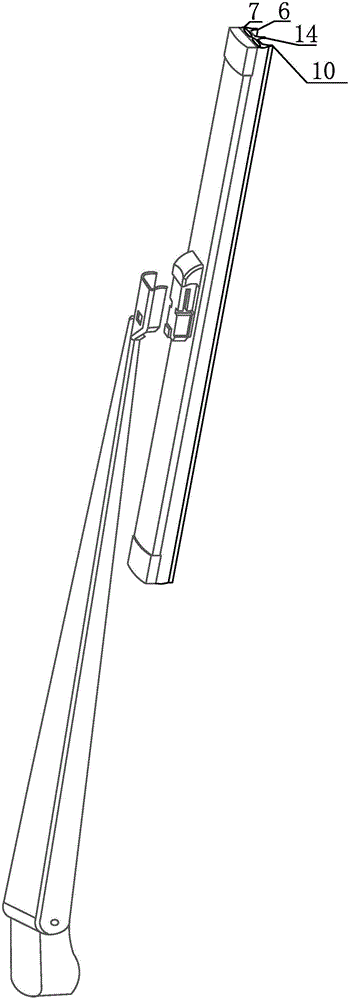

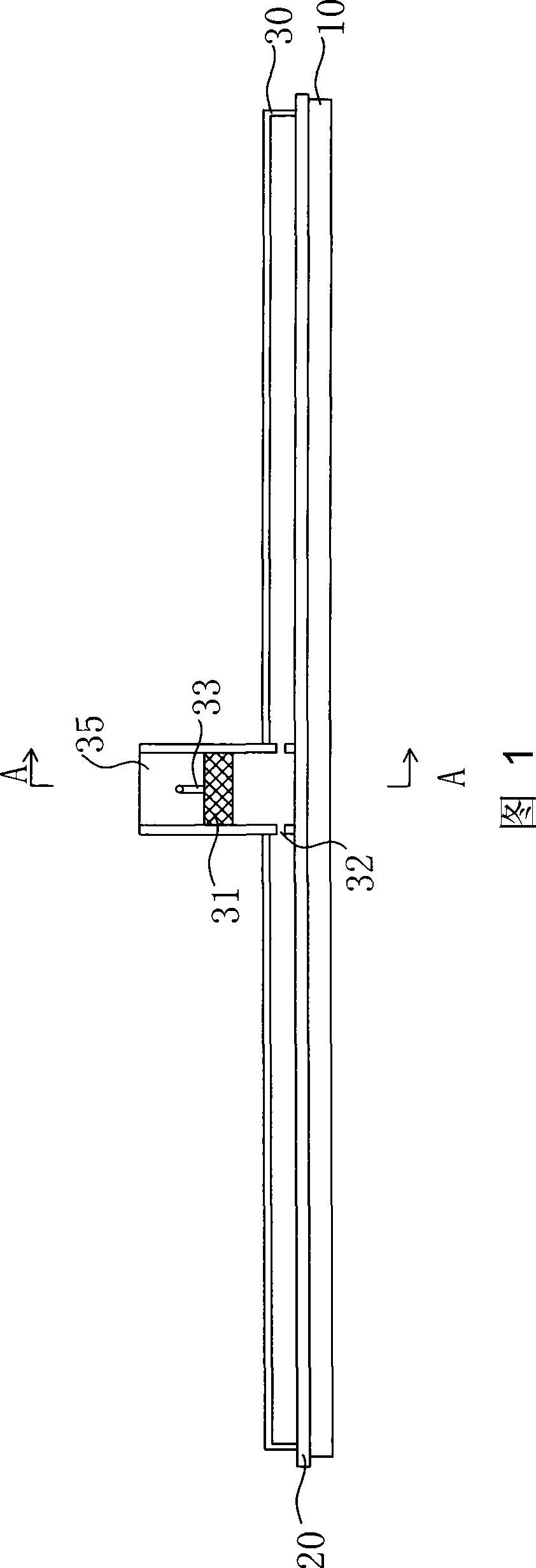

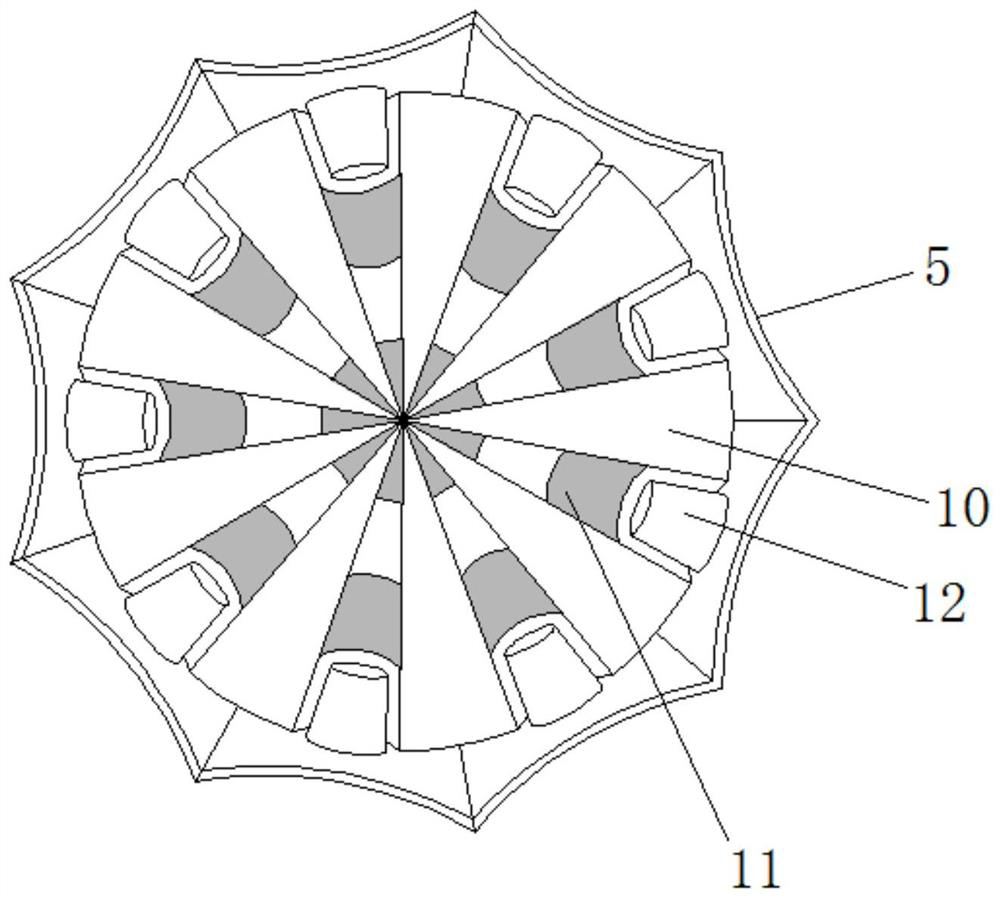

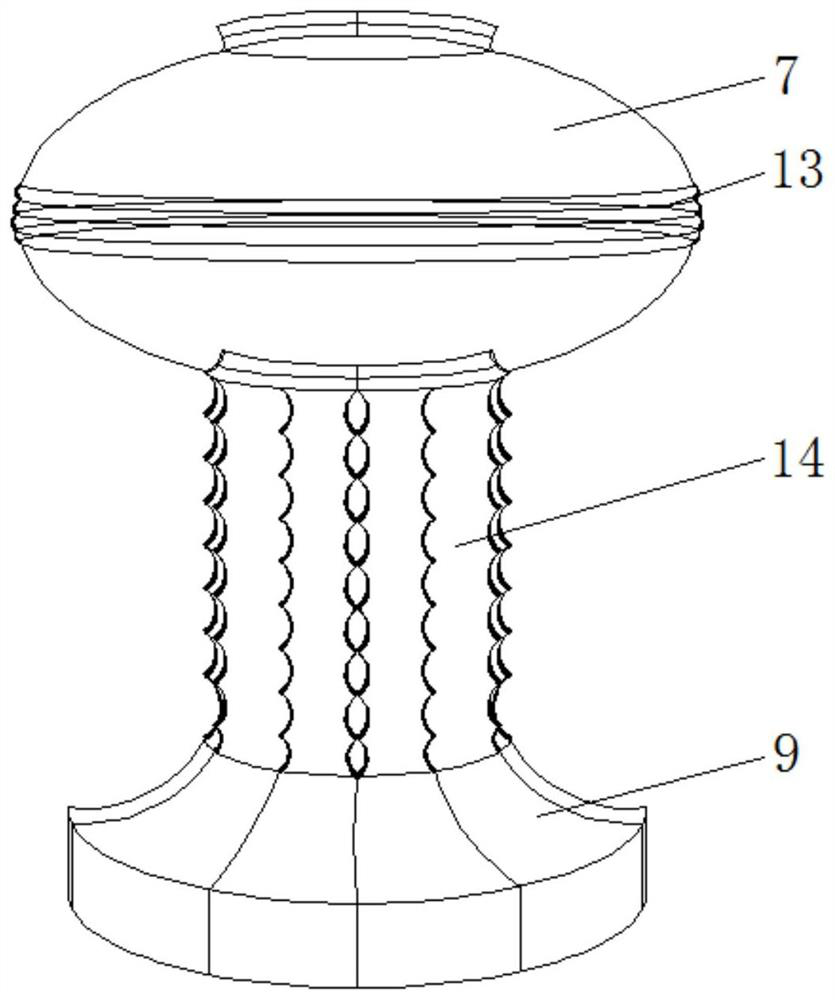

Flexible wall supporting windshield wiper rubber strip with three scraping pieces

InactiveCN104527604AImprove scrapingImprove scraping efficiencyVehicle cleaningStructural engineeringWindshield

Disclosed is a flexible wall supporting windshield wiper rubber strip with three scraping pieces. A windshield wiper rubber strip fixing clamping groove (2) is formed in the upper portion of the windshield wiper rubber strip (1), and the scraping pieces (6) are arranged on the lower portion. The flexible wall supporting windshield wiper rubber strip with the three scraping pieces is characterized in that the two sides of a bottom plate (3) of the windshield wiper rubber strip fixing clamping groove (2) extend downwards to form a left flexible wall (4) and a right flexible wall (5) respectively, and the left flexible wall, the right flexible wall and the two sides of a flexible wall bottom plate (13) arranged at the upper ends of the scrapping pieces (6) are converged to form a hollow flexible wall supporting structure (7). The left scraping piece (10), the right scraping piece (11) and the middle scraping piece (14) parallel with the axial direction of the flexible wall supporting structure (7) are arranged on the two sides and the middle of the lower portion of the flexible wall bottom plate (13) respectively. The flexible wall supporting windshield wiper rubber strip with the three scraping pieces has the advantages that the scrapping pieces are better attached to the curved surface of windshield glass under the supporting of the flexible wall supporting structure, and therefore the scraping degree of the scraping pieces is improved, and the scraping efficiency of the three-scraping-piece structure is three times that of a common single scraping piece.

Owner:陈学琴

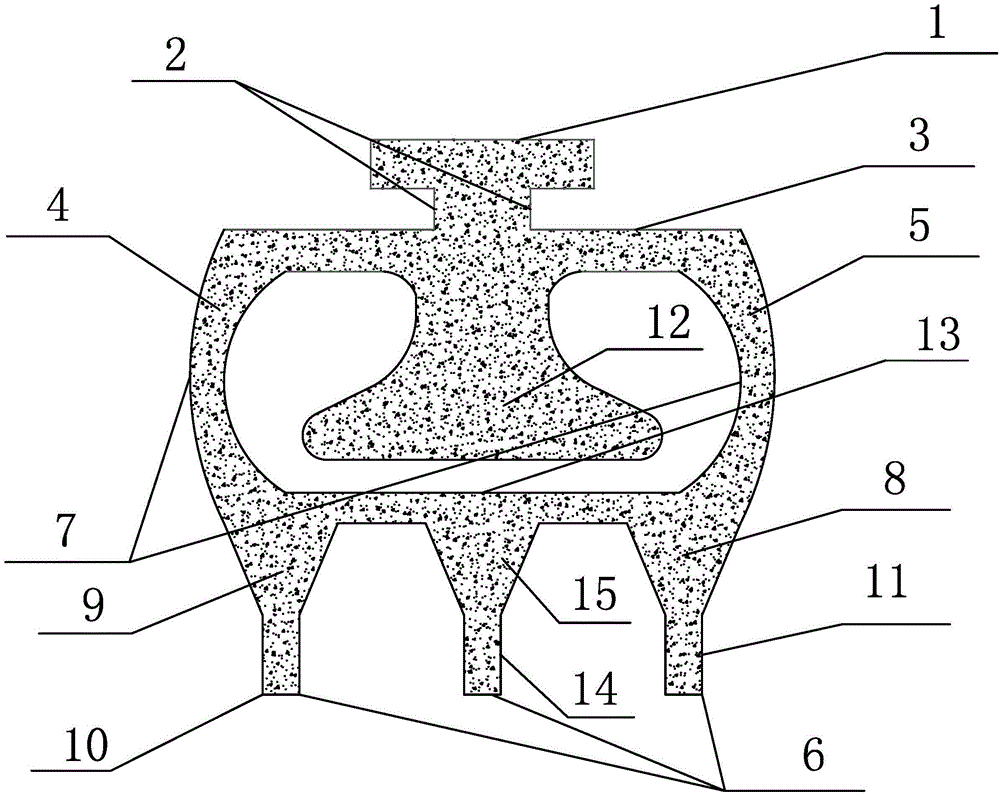

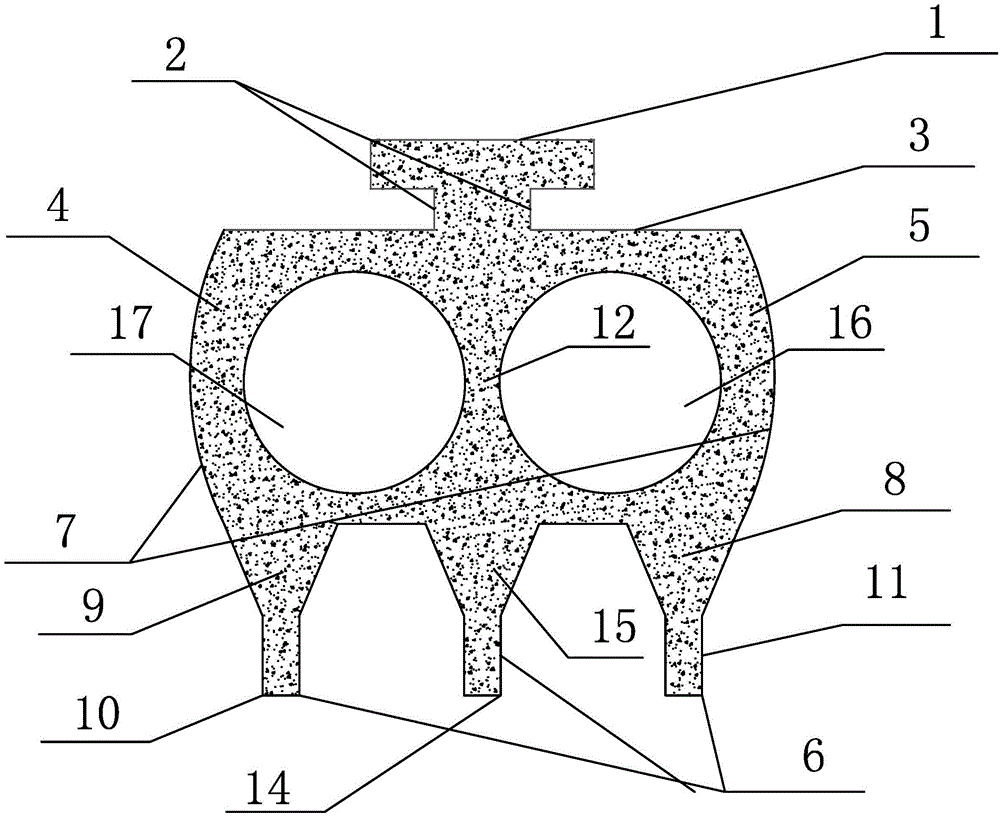

Three-scraper round hole inner support windscreen wiper rubber strip supported by flexible walls

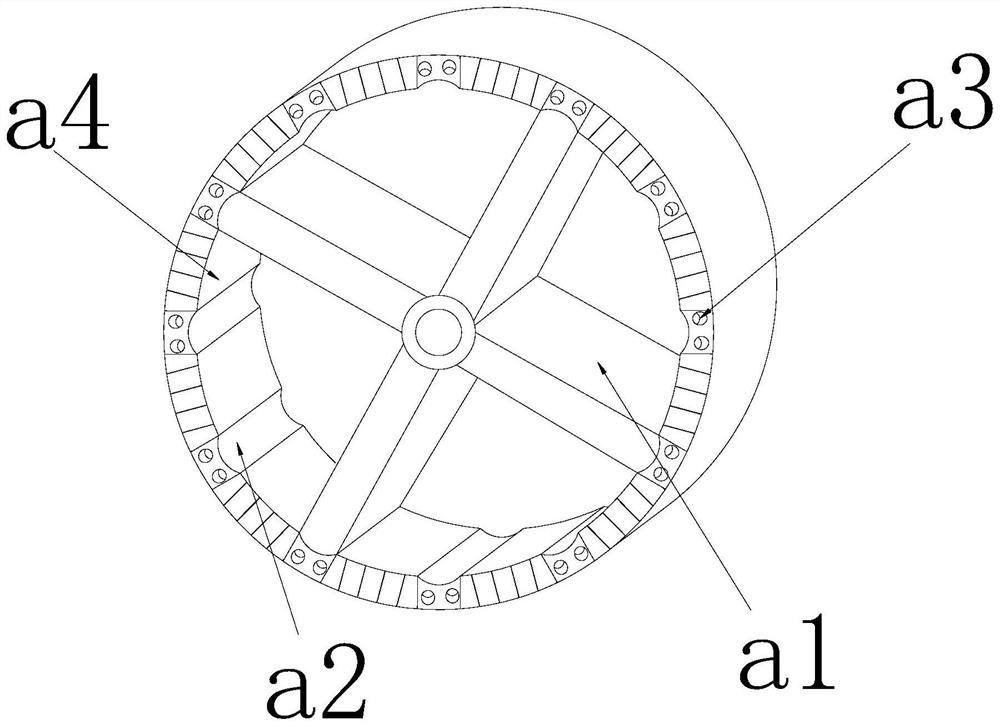

InactiveCN104527603AImprove scrapingGuaranteed flexibilityVehicle cleaningEngineeringBilateral symmetry

The invention relates to a three-scraper round hole inner support windscreen wiper rubber strip supported by flexible walls. Windscreen wiper rubber strip fixing clamping grooves (2) are formed in the upper portion of the windscreen wiper rubber strip (1), and scrapers (6) are arranged on the lower portion of the windscreen wiper rubber strip (1). The windscreen wiper rubber strip is characterized in that two tubular cavities are formed in parallel in bottom plates (3) of the windscreen wiper rubber strip fixing clamping grooves (2) in a bilateral symmetry mode in the axial direction of the windscreen wiper rubber strip (1) and comprise the left cavity (17) and the right cavity (16), the left flexible wall (4) and the right flexible wall (5) and a middle partition wall (12) are formed, and the bottom plates (3), the left cavity (17) and the right cavity (16) form a flexible wall supporting structure (7); the left scraper (10), the right scraper (11) and the middle scraper (14) are arranged in parallel at the lower ends of the two sides of the bottom plates (3) in the axial direction of the flexible wall supporting structure (7) respectively. The three-scraper round hole inner support windscreen wiper rubber strip has the advantages that under the supporting of the flexible supporting structure, the fitting degree of the scrapers is higher, the cleaning degree is higher, and the three-scraper efficiency is higher.

Owner:陈学琴

Halogen-free thermoplastic elastomer insulating material and preparation method thereof

The invention relates to a halogen-free thermoplastic elastomer insulating material and a preparation method thereof. The halogen-free thermoplastic elastomer insulating material comprises the following components: styrene thermoplastic elastomer, polypropylene resin, compatilizer, filling oil, ethylene propylene rubber, toughening agent, halogen-free flame retardant, antioxidant, copper resistantagent and lubricant. The preparation method comprises the following steps: 1) filling styrene thermoplastic elastomer with filling oil; 2) adding that oil and other components into a high-speed mixerfor mixing after the oil filling is completed; 3) adding that mixture into an internal mixer for internal mixing; 4) feeding the mixture after internal mixing into a twin-screw extruder to draw the strip and cut the grain at 160-200 DEG C. The halogen-free thermoplastic elastomer insulating material disclosed by the invention has low processing temperature, low hardness, superior insulation performance, high temperature resistance grade, scratch resistance, environmental protection, flame retardancy and excellent comprehensive performance, and is suitable for charging pile cables of electricvehicles.

Owner:SHANGHAI KAIBO SPECIAL CABLE FACTORY

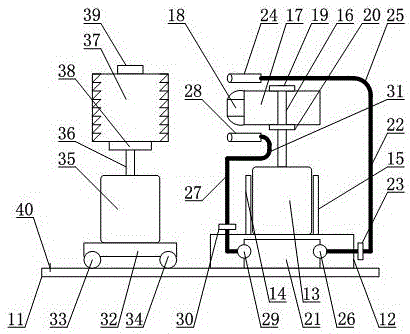

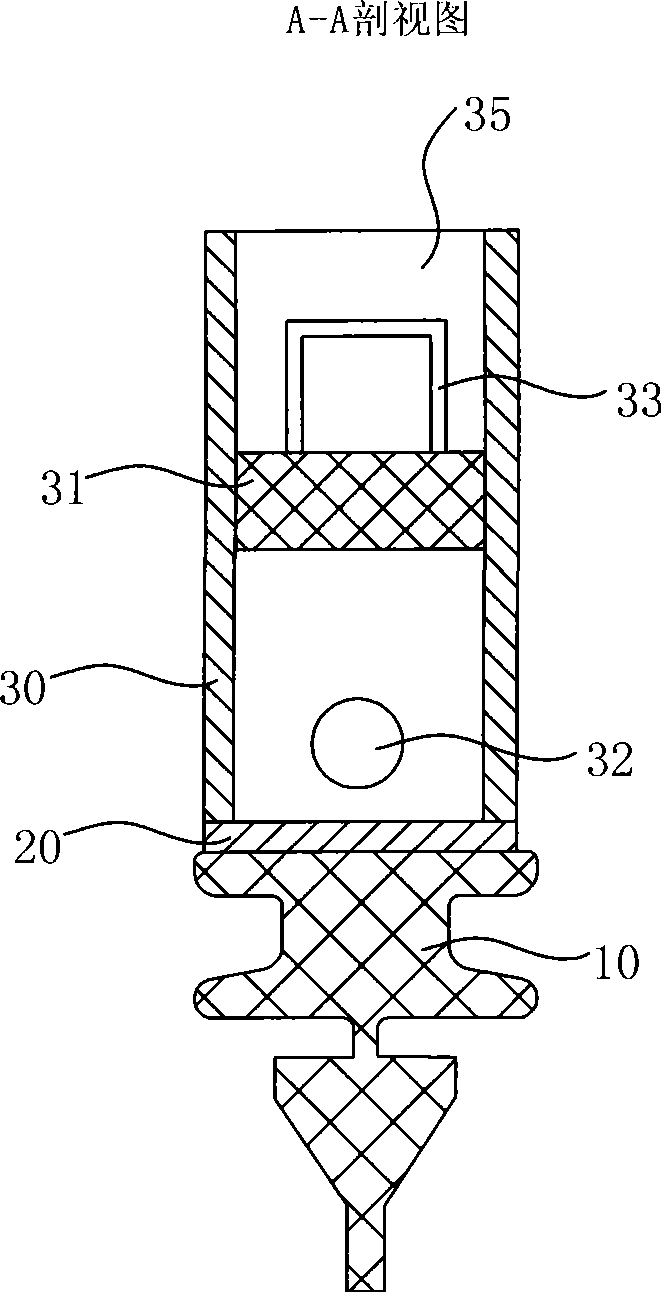

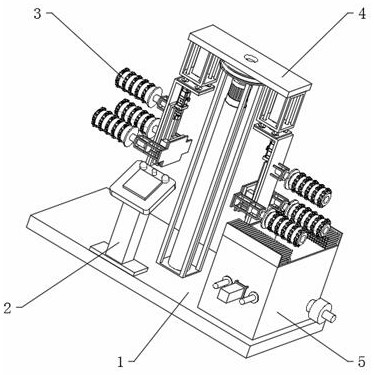

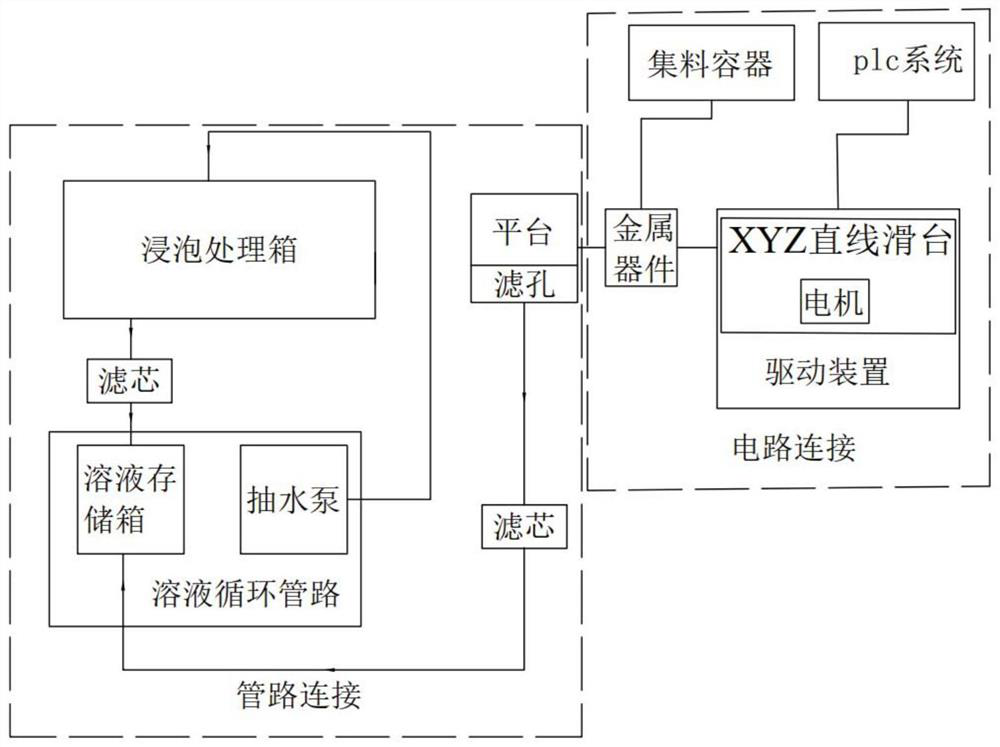

Batch recovery process and equipment for preparing membrane electrode catalyst by spraying method

ActiveCN112542594AAvoid damageAvoid accumulationFuel cells disposal/recyclingFinal product manufacturePtru catalystFuel cells

The invention discloses a batch recovery process and equipment for preparing a membrane electrode catalyst by a spraying method. According to the invention, a catalyst exceeding a spraying area in a spraying process is recovered; before the catalyst layer is prepared, the auxiliary equipment is completely coated with a carrier sheet, it is guaranteed that catalyst slurry completely falls on the carrier sheet outside an effective area, and then efficient recovery of the catalyst adhering to hardware auxiliary equipment such as a clamp is achieved through the procedures of soaking, scraping, collecting, washing and vacuum drying. The cost is reduced, and meanwhile, the air environment pollution is reduced. Meanwhile, the invention further discloses batch recovery equipment for the fuel cellcatalyst, which can achieve batch work of the catalyst recovery method, improve the working efficiency, increase the utilization rate of raw materials in production, and reduce the manufacturing cost.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

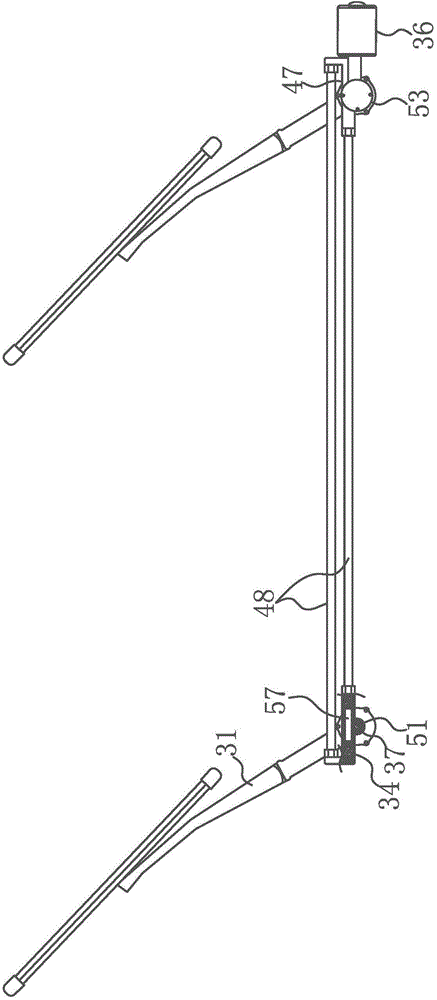

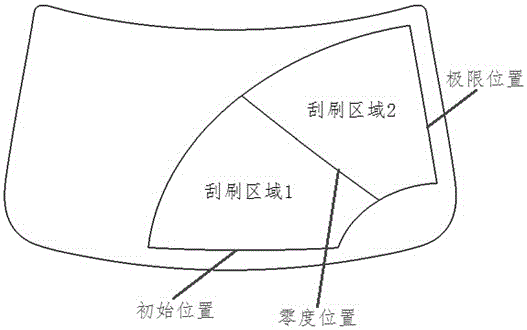

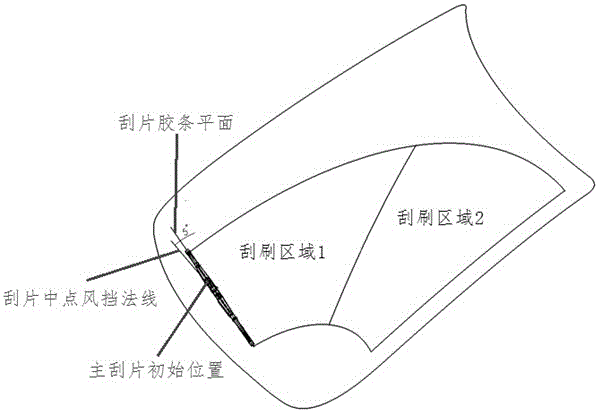

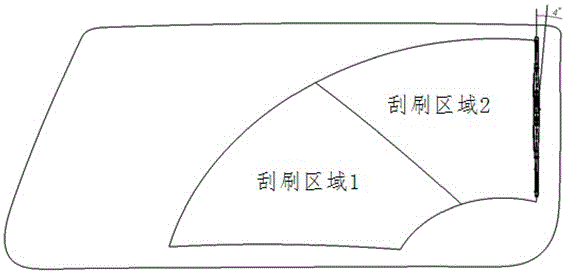

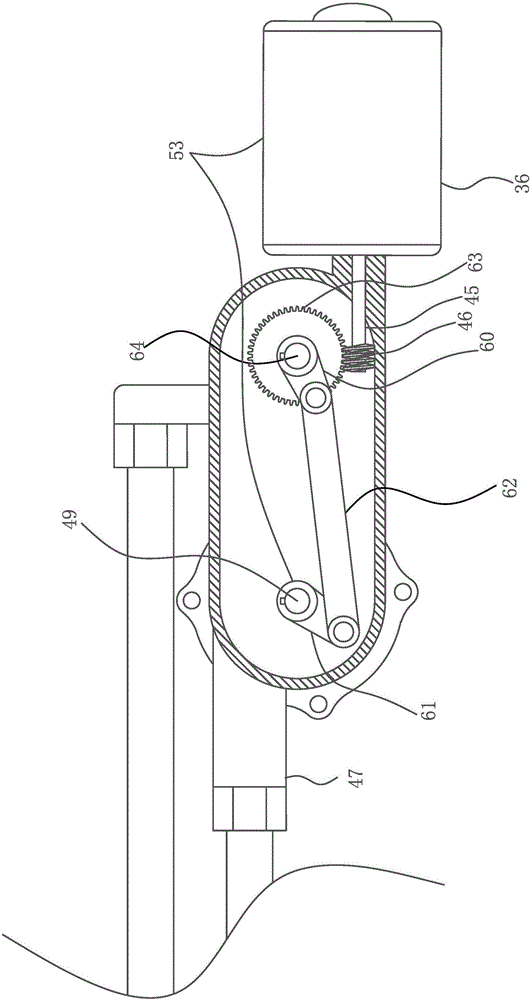

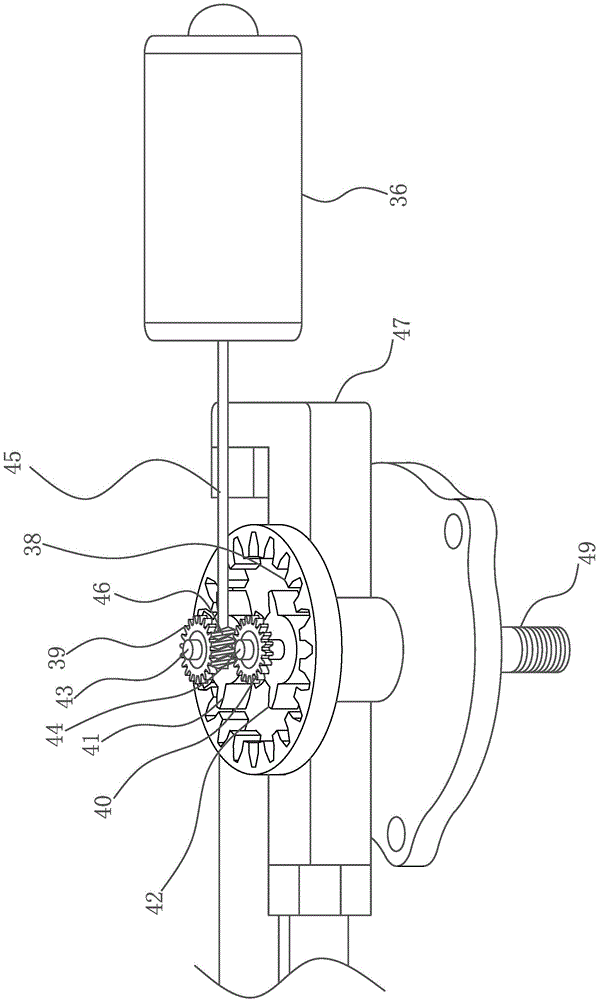

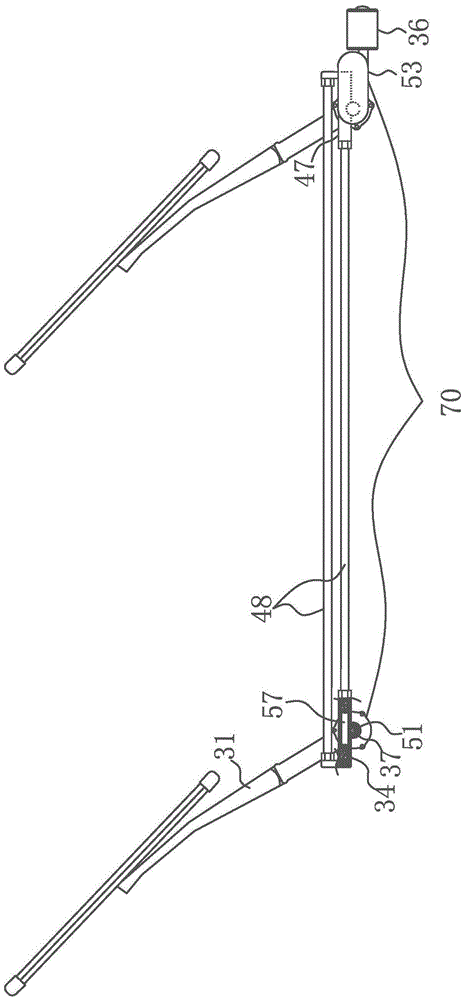

Automotive wiper system capable of automatically adjusting attack angle and wiping method thereof

The invention relates to an automotive wiper system capable of automatically adjusting an attack angle and a wiping method thereof. The automotive wiper system comprises an automotive wiper motor connecting rod structure, a wiper arm, a wiper blade and a controller; the automotive wiper motor connecting rod structure consists of a motor connecting rod assembly, a main output shaft and an auxiliary output shaft, wherein the main output shaft and the auxiliary output shaft are respectively arranged at the two ends of the motor connecting rod assembly. The automotive wiper system is characterized in that the wiper arm consists of an arm seat, an arm plate, a wiping rod, an output shaft, a motor and a spring, wherein the arm seat is hinged to the main output shaft and the auxiliary output shaft; the arm plate is hinged to the other end of the arm seat; the wiping rod is arranged at the other end of the arm plate; the output shaft arranged on the inner side of the arm plate; the motor is connected with the end part of the wiping rod; the spring is connected between the arm seat and the motor; a main angle sensor and an auxiliary angle sensor are respectively arranged at the end parts of the main output shaft and the auxiliary output shaft. The automotive wiper system is simple in structure design and reliable to use, and fundamentally solves the problem that a wiper blade rubber strip of an existing wiper reversely wipes on a windscreen, thereby being good in wiping effect and ensuring safety in driving.

Owner:BRILLIANCE AUTO

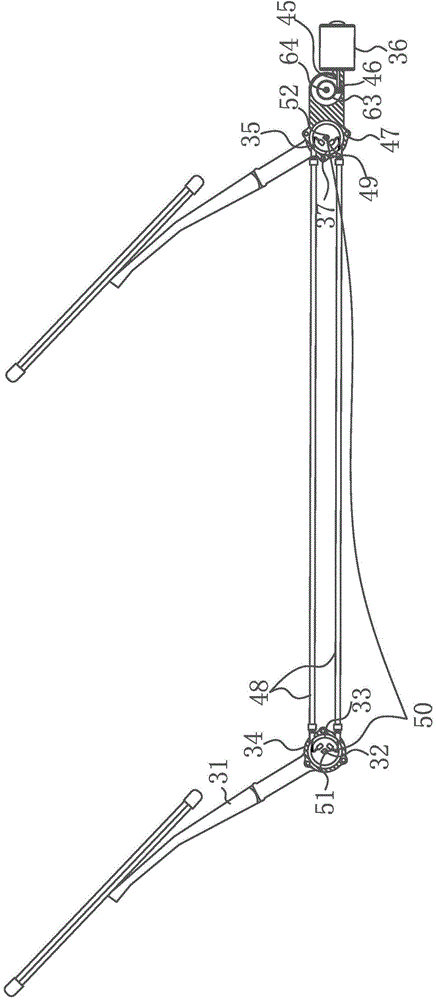

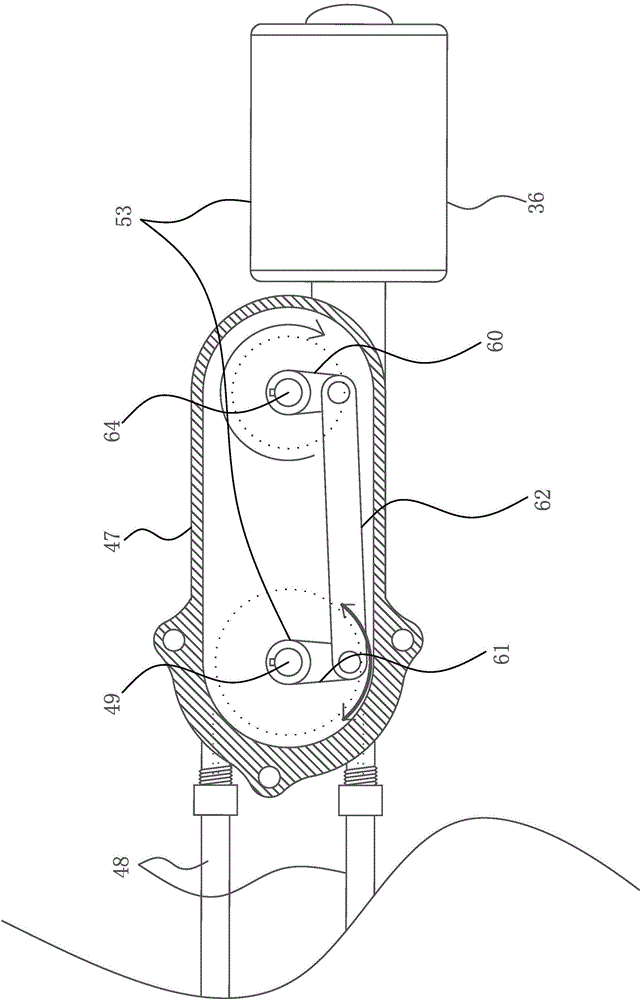

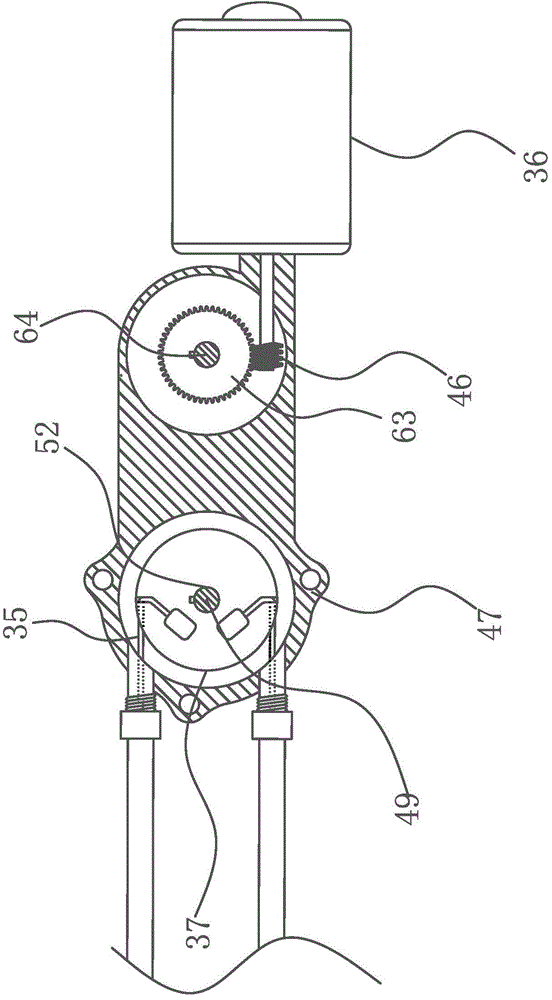

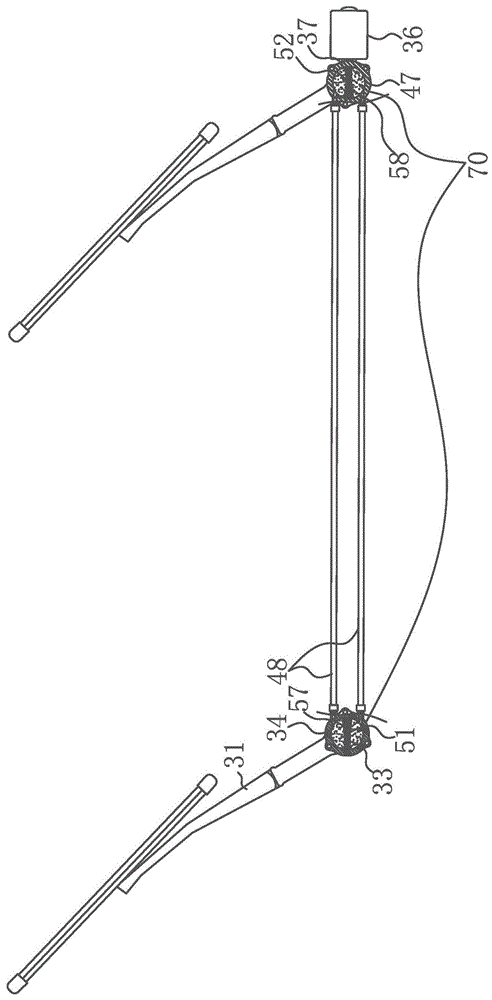

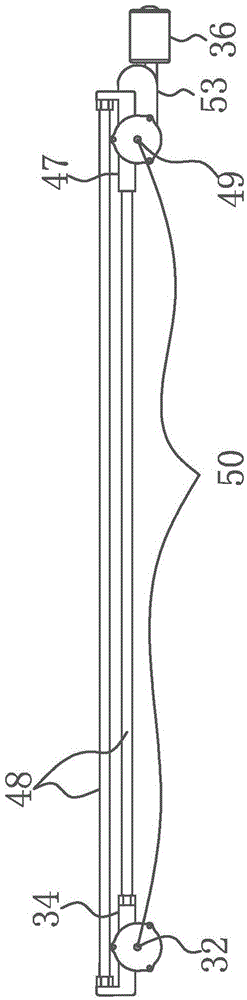

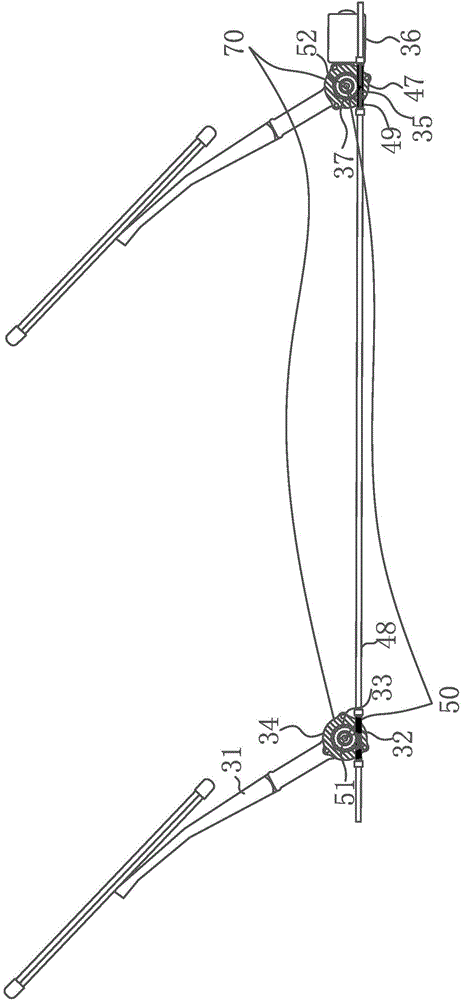

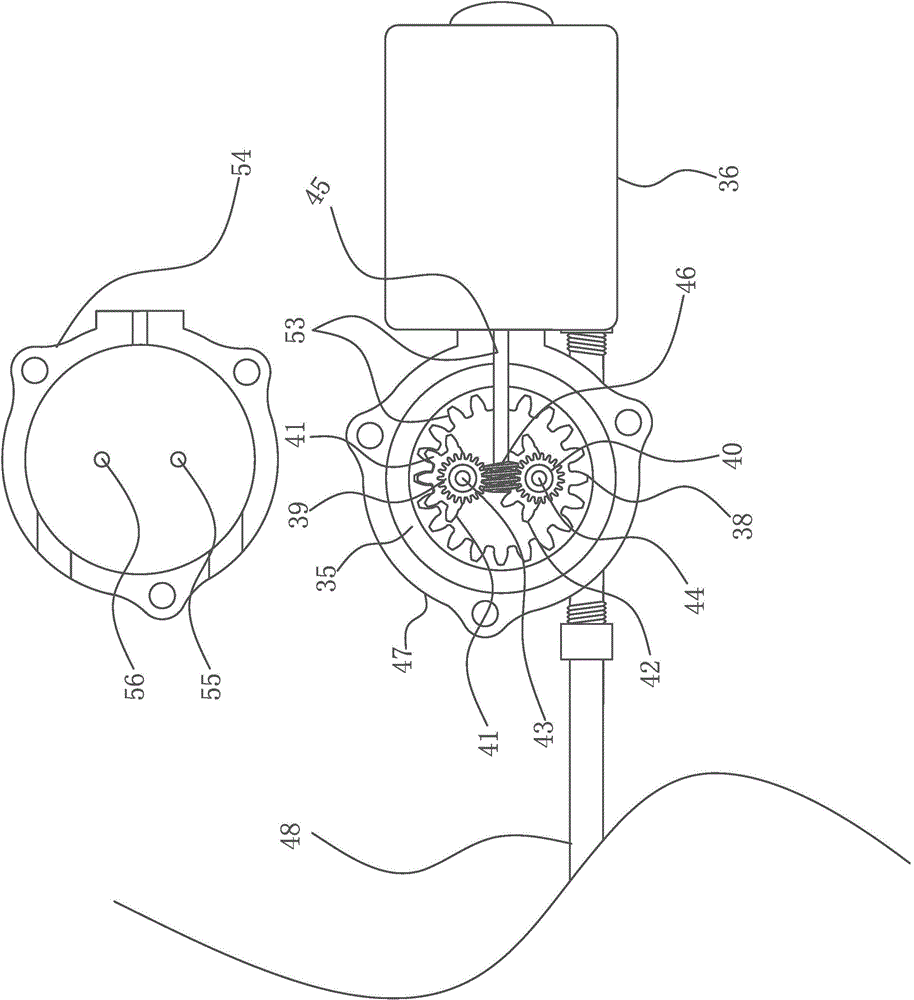

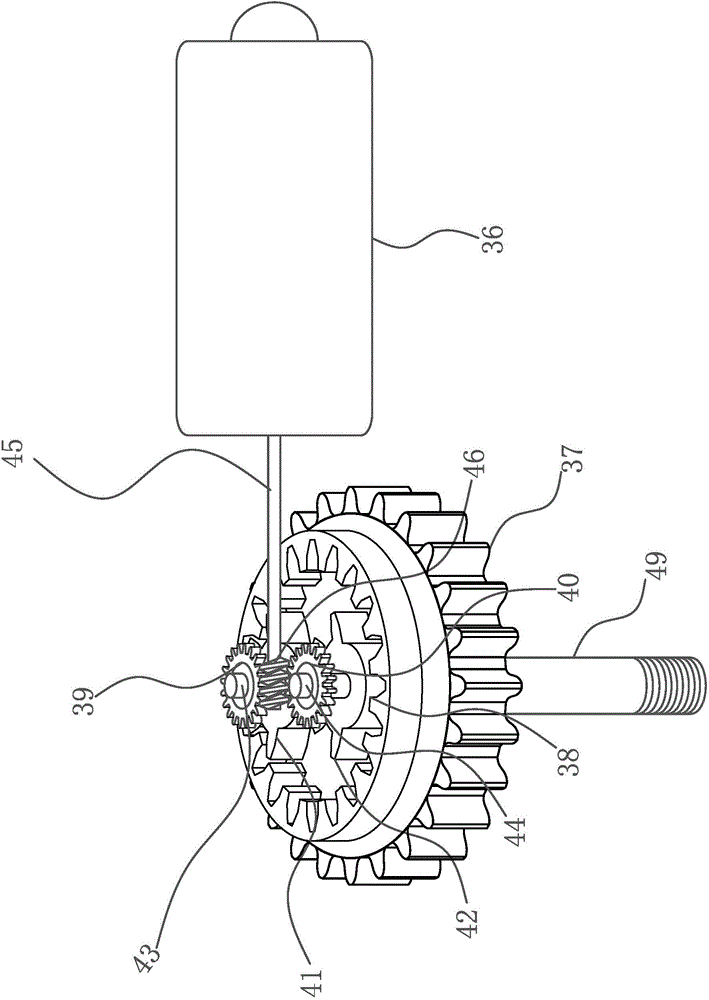

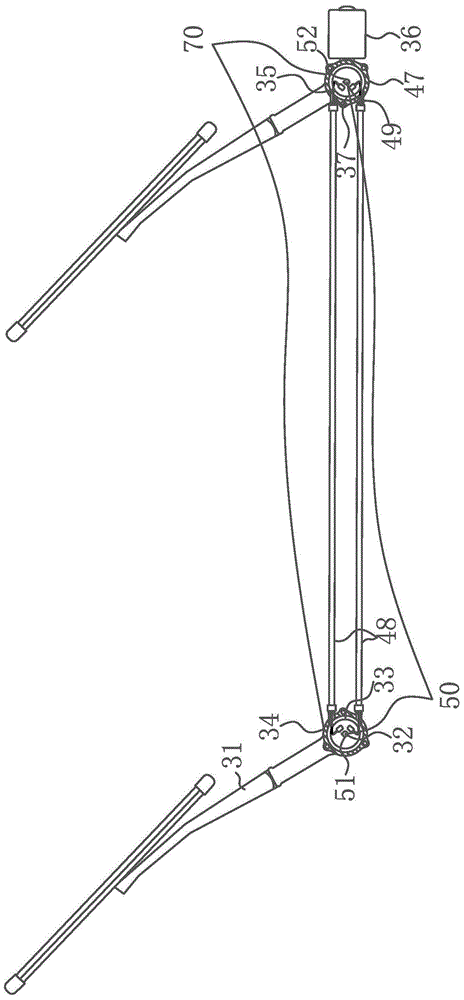

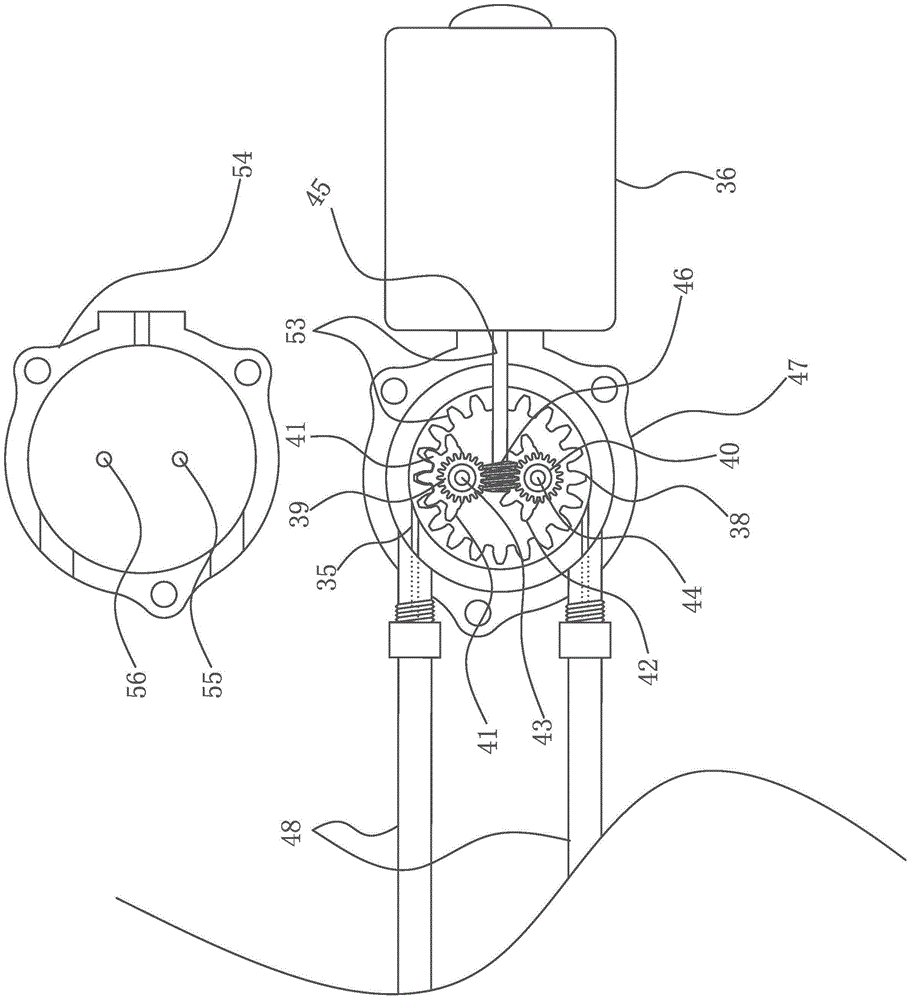

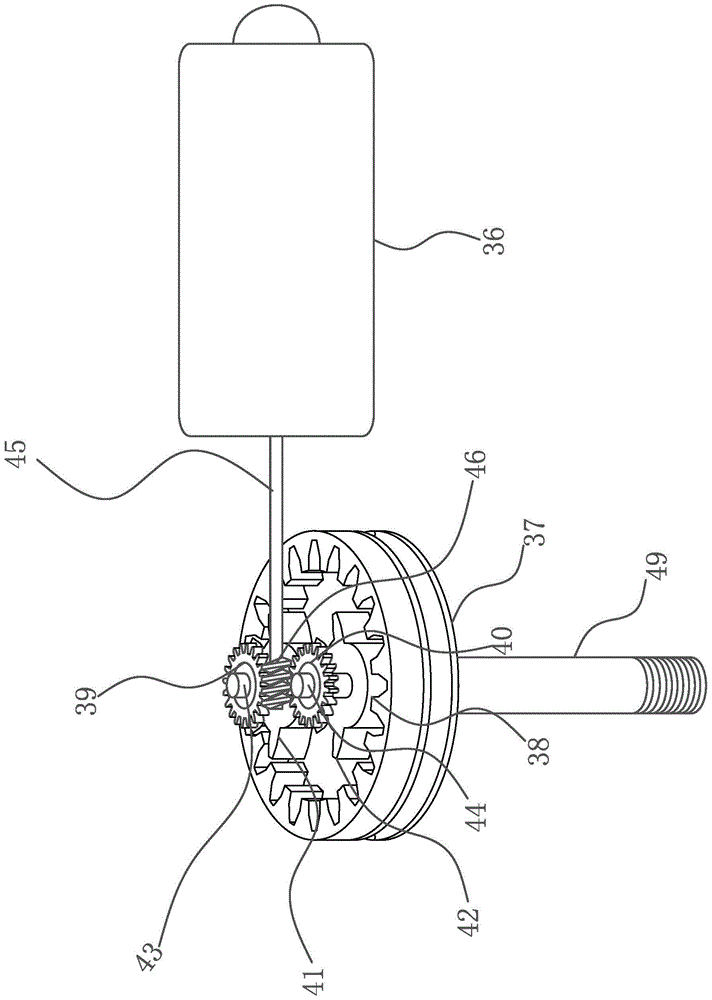

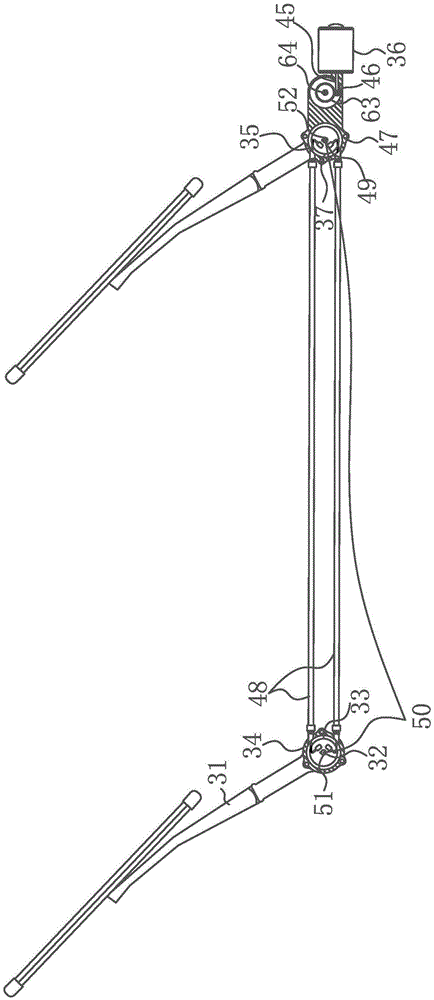

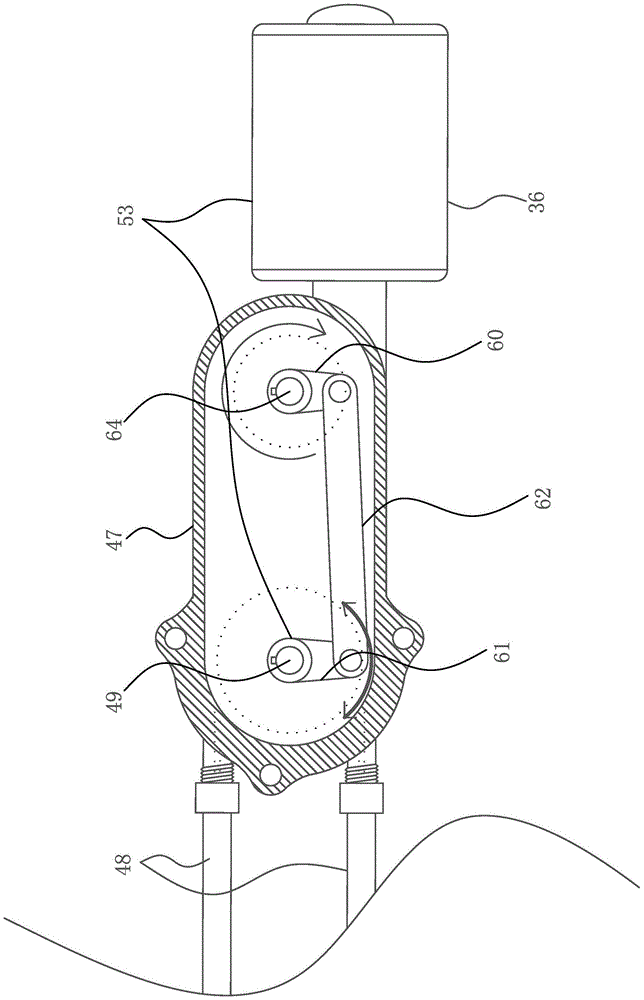

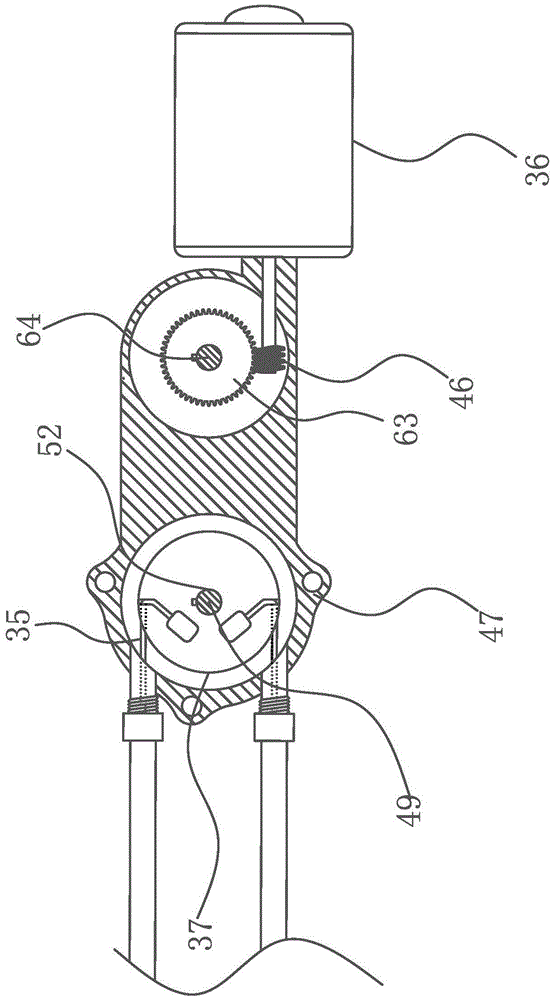

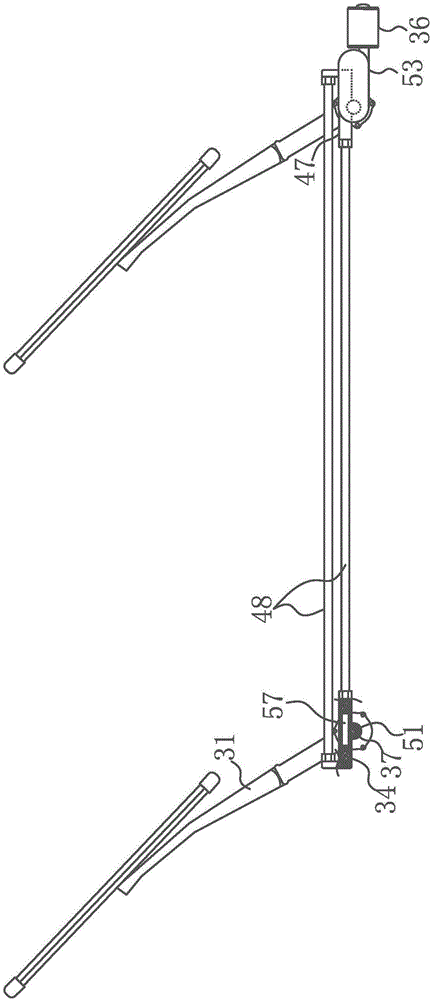

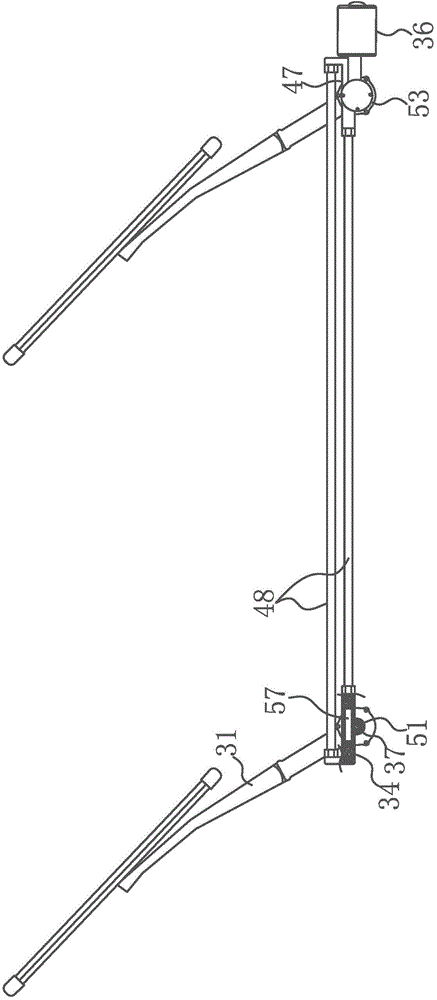

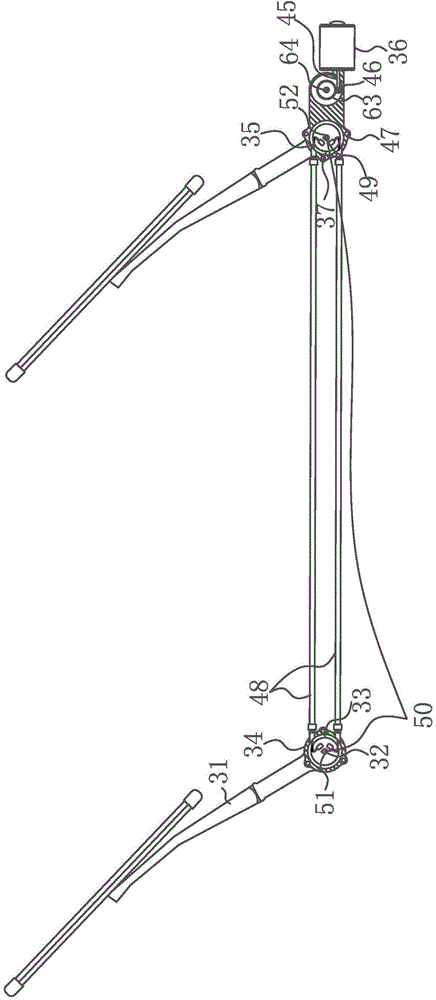

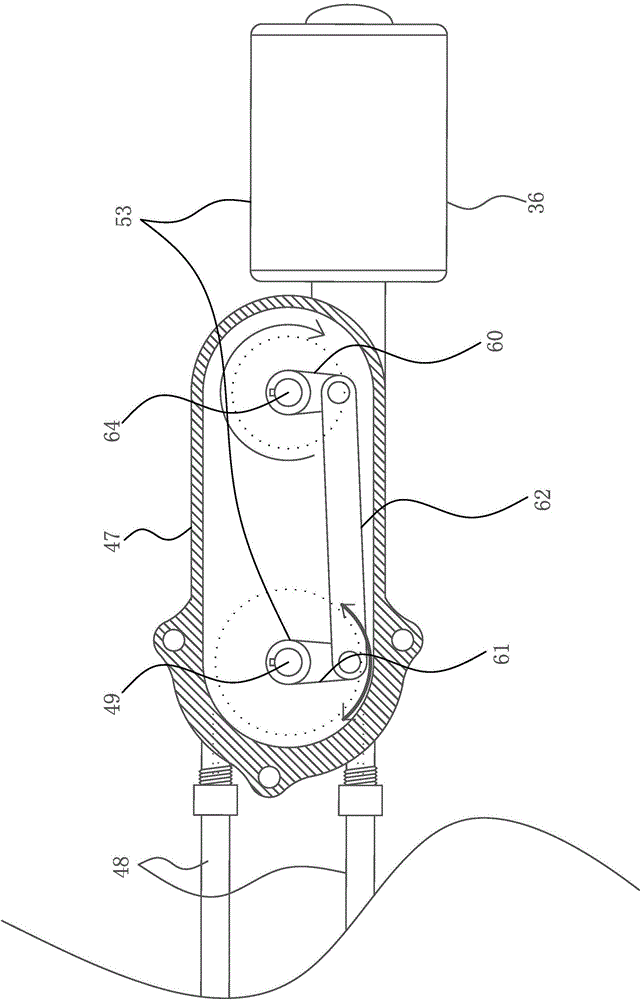

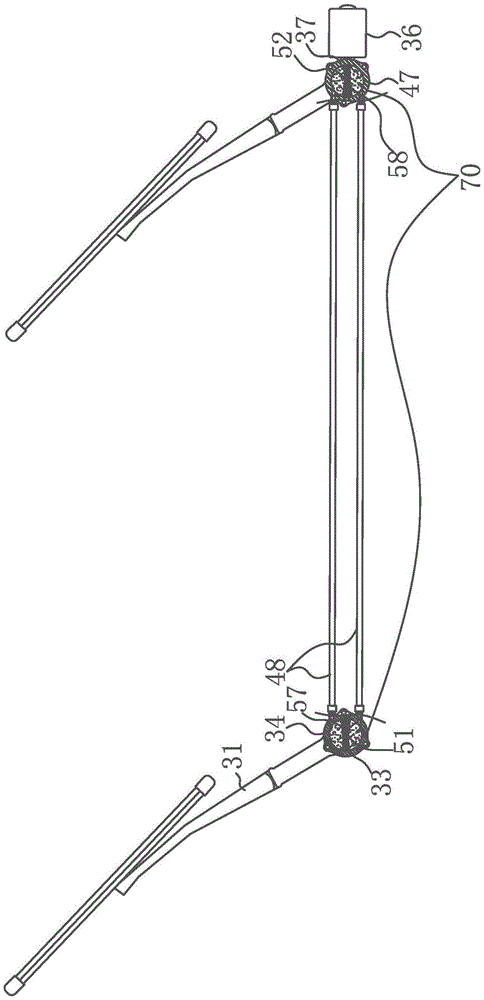

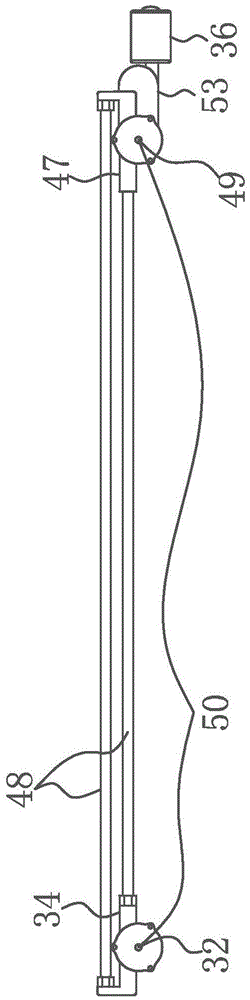

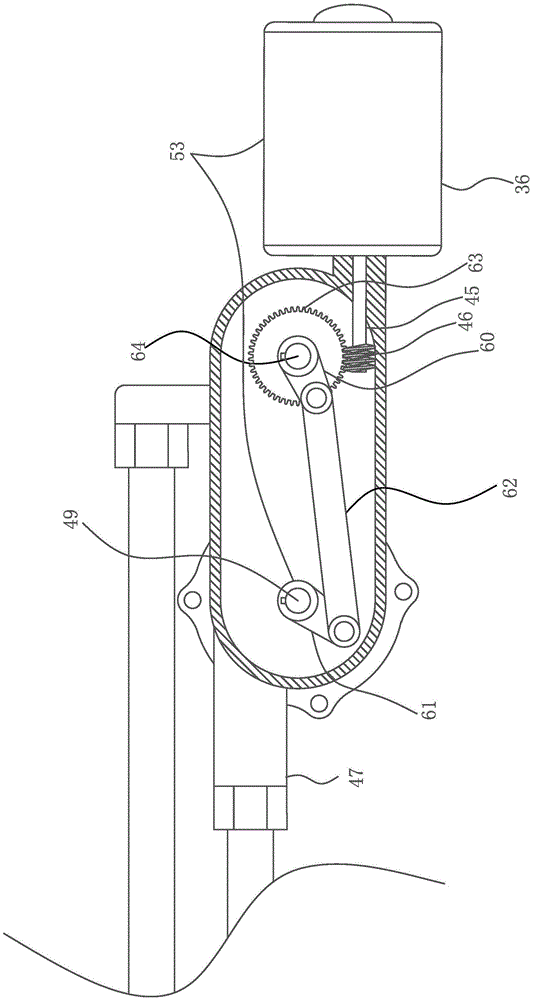

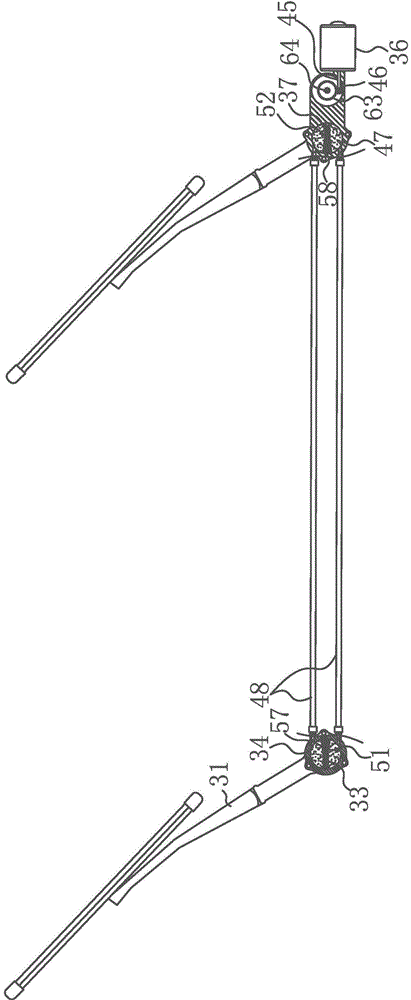

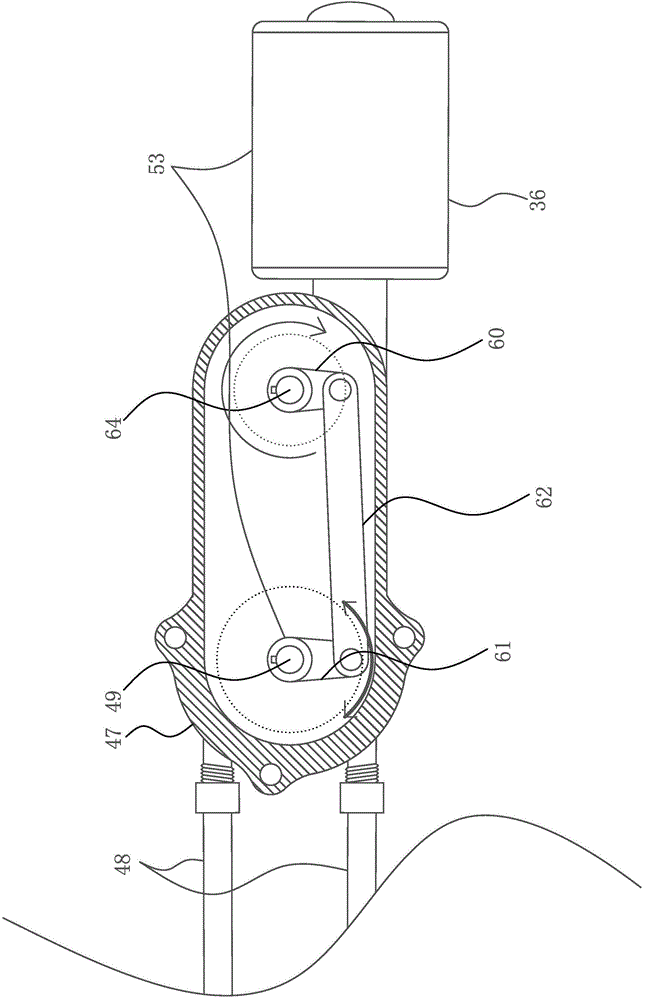

Three-scraping-piece flexible wall round hole internal-supported connecting rod wire wheel type windscreen wiper

A three-scraping-piece flexible wall round hole internal-supported connecting rod wire wheel type windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that a wiper drive shaft is divided into a driven wheel wiper drive shaft and a driving wheel wiper drive shaft, and the driven wheel wiper drive shaft and the driving wheel wiper drive shaft are respectively arranged in a driven wheel wiper drive shaft hole formed in a driven wheel fixing seat and a driving wheel wiper drive shaft hole formed in a driving wheel fixing seat. A driven winding wheel and a driving winding wheel are respectively arranged on the driven wheel wiper drive shaft and the driving wheel wiper drive shaft, are connected through a flexible rope and transfer torque. A closed connecting rod rocker arm driving mechanism is arranged on the driving winding wheel. The connecting rod wire wheel type wiper driving mechanism of the windscreen wiper is of a closed structure, is especially suitable for a complicated external environment structure and remote transmission and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and the efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:靖江智云信息科技有限公司

Synchronizer oil stain washing and scraping device

InactiveCN106670146AImprove efficiencyImprove scrapingCleaning using toolsCleaning using liquidsPulp and paper industry

The invention discloses a synchronizer oil stain washing and scraping device which comprises a base plate. The base plate is provided with a fixed shell. A first driving motor is arranged at the end of the fixed shell. A first driving shaft is arranged on the upper portion of the first driving motor. The upper end of the first driving shaft is sleeved with a rotating wheel. A scraper blade is arranged on the outer side wall of the rotating wheel. A washing machine is arranged inside the fixed shell. A first washing pipe is arranged at one side of the fixed shell. One end of the first washing pipe is connected with the washing machine, and a first washing head is arranged at the other end of the first washing pipe. The first washing head is arranged above the rotating wheel. A second washing pipe is arranged at the other side of the fixed shell, and a second washing head is arranged at the end of the second washing pipe. The second washing head is arranged below the rotating wheel. According to the synchronizer oil stain washing and scraping device, the rotating wheel can scrape oil stains on the outer circumferential face of a synchronizer through the scraper blade, and therefore scraping and washing treatment efficiency for the oil stains of the synchronizer can be greatly improved.

Owner:SUZHOU GUOZHIXIN NETWORK COMM CO LTD

Hydraulic wiper blade

ActiveCN101445096AImprove scrapingExtended service lifeVehicle cleaningEngineeringMechanical engineering

The invention relates to a hydraulic wiper blade which comprises a rubber strip. The back surface of the rubber strip is fixedly connected to a pressure spring; a hydraulic chamber is formed by surrounding a cavity casing with rod-shaped outer appearance and groove-shaped cross section and the pressure spring and filled with liquid; a cylinder part for accommodating a piston is arranged on the cavity casing; and the piston is positioned at the exposed outer part and matched with a wiper rod in a clipping manner. The invention adopts the cavity casing to replace the prior framework structure and utilizes the principle of hydraulic power transmission to ensure that the pressure from a wiper arm uniformly acts on the rubber strip of the wiper blade, thereby reducing the generation of drain marks and greatly improving the scraping cleanliness and the service life of the wiper blade.

Owner:CHERY AUTOMOBILE CO LTD

Washing device for production of washing machine collars

ActiveCN112517513AGuaranteed coaxialityAvoid bendingCleaning using toolsCleaning using liquidsLaundry washing machineStructural engineering

The invention discloses a washing device for production of washing machine collars, and relates to the field of washing machine production. The washing device aims to solve the problem that an existing device is lack of a collar clamping device. The washing device specifically comprises a bottom plate, a rotating beam assembly and a cleaning assembly are fixedly connected to the outer wall of thetop of the bottom plate, and two clamping mechanisms are fixedly connected to the outer wall of the bottom of the rotating beam assembly; and each clamping mechanism comprises a vertical beam and three sets of single-arm assemblies. According to the washing device, the clamping mechanisms are arranged, one set of the single-arm assembly of each clamping mechanism is fixedly connected to the outerwall of one side of the corresponding vertical beam, and the other two sets of the single-arm assemblies are fixedly connected to the outer wall of one side of a connecting frame of a supporting plate; a washing machine collar is placed on the outer walls of the two single-arm assemblies on the lower portion, the two single-arm assemblies are used for lifting the collar to move, and meanwhile, theupper single-arm assembly is in a fixed posture, and cooperates with the lower single-arm assemblies to clamp the collar; and meanwhile, elastic telescopic frames in the single-arm assemblies are incontact with the collar firstly for damping contact, and then supporting rings are attached and fixed.

Owner:安徽舒饰环保科技有限公司

Three-Blade Flexible Wall Support Wiper Blade Hydraulic Wiper

ActiveCN104527590BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningEnvironmental structureWindscreen wiper

A three-scraper wiper blade hydraulic windscreen wiper with flexible wall supporting comprises a windscreen wiper motor, a wiper driving mechanism and a wiper and is characterized in that two blade swing oil cylinders are communicated through a hydraulic oil pipe, torque is transmitted between the two blade swing oil cylinders through the hydraulic oil pipe, and a forward and reverse rotation gear intermittent transmission mechanism is arranged on the driving blade swing oil cylinder. The three-scraper wiper blade hydraulic windscreen wiper has the advantages that as flexible pipeline hydraulic transmission is adopted in the wiper driving mechanism of the windscreen wiper, the transmitted torque is large, and structural limit is small when the windscreen wiper is installed; as the windscreen wiper is of a completely closed structure, the windscreen wiper is particularly suitable for the complex external environmental structure and long-distance transmission and not affected by external factors, and the defect that the windscreen wiper motor is burnt due to external obstacles is overcome; windscreen wiper rubber strips are supported by flexible walls and therefore can fit windscreen better, and the scraping efficiency of the three-scraper structure is three times that of a general single scraper.

Owner:泰安泰山科技有限公司

Three-blade flexible wall round hole supports wiper linkage hydraulic swing wiper

ActiveCN104554155BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningEngineeringInterior noise

A three-scraping-piece flexible wall round hole internal-supported wiper connecting rod hydraulic swing windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that two gear rack swing oil cylinders are communicated through a hydraulic oil pipe and transfer torque, and a connecting rod rocker arm drive mechanism is arranged on the driving gear rack swing oil cylinder. The three-scraping-piece flexible wall round hole internal-supported wiper connecting rod hydraulic swing windscreen wiper has the advantages that the wiper driving mechanism of the windscreen wiper performs hydraulic drive through a flexible pipe, is small in structural limitation during installation, is completely of a closed structure, is low in noise during working, is especially suitable for a complicated external environment structure and remote transmission and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, interior noise is effectively reduced, the interior comfort of a vehicle in running is improved, and a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and the efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:齐河智谷产业发展有限公司

Three-scraping-piece flexible wall supported wiper flexible shaft type windscreen wiper

ActiveCN104554164AReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDrive shaftInterior noise

A three-scraping-piece flexible wall supported wiper flexible shaft type windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that a wiper drive shaft is divided into a driven wiper drive shaft and a driving wiper drive shaft, the driven wiper drive shaft and the driving wiper drive shaft are respectively provided with a driven gear and a driving gear, and the driven gear and the driving gear are connected through a flexible shaft and transfer torque. A forward and reverse rotating gear intermittent drive mechanism is arranged on the driving gear. The wiper driving mechanism of the windscreen wiper is of a closed structure, is low in noise during working, is especially suitable for a complicated external environment structure and remote transmission, can adapt to vehicles of different models and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, interior noise is effectively reduced, the interior comfort of a vehicle in running is improved, a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and the efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:龙岩市腾兴机械维修有限公司

Three-blade flexible wall circular hole inner support wire wheel drive wiper

InactiveCN104554161BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDrive wheelDrive shaft

A three-scraping-piece flexible wall round hole internal-supported wire wheel type windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that the wiper driving mechanism is structurally that a wiper drive shaft is divided into a driven wheel wiper drive shaft and a driving wheel wiper drive shaft, and the driven wheel wiper drive shaft and the driving wheel wiper drive shaft are respectively arranged in a driven wheel wiper drive shaft hole formed in a driven wheel fixing seat and a driving wheel wiper drive shaft hole formed in a driving wheel fixing seat. A driven winding wheel and a driving winding wheel are respectively arranged on the driven wheel wiper drive shaft and the driving wheel wiper drive shaft, are connected through a flexible rope and transfer torque. The wiper driving mechanism of the windscreen wiper is of a closed structure, is especially suitable for a complicated external environment structure and remote transmission, the defect that the wiper motor is burned down due to an external obstacle is avoided, a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and the efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:盐城华依鑫机械科技有限公司

Three-blade flexible wall round hole inner support connecting rod wire wheel type wiper

ActiveCN104554165BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDrive wheelDrive shaft

A three-scraping-piece flexible wall round hole internal-supported connecting rod wire wheel type windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that a wiper drive shaft is divided into a driven wheel wiper drive shaft and a driving wheel wiper drive shaft, and the driven wheel wiper drive shaft and the driving wheel wiper drive shaft are respectively arranged in a driven wheel wiper drive shaft hole formed in a driven wheel fixing seat and a driving wheel wiper drive shaft hole formed in a driving wheel fixing seat. A driven winding wheel and a driving winding wheel are respectively arranged on the driven wheel wiper drive shaft and the driving wheel wiper drive shaft, are connected through a flexible rope and transfer torque. A closed connecting rod rocker arm driving mechanism is arranged on the driving winding wheel. The connecting rod wire wheel type wiper driving mechanism of the windscreen wiper is of a closed structure, is especially suitable for a complicated external environment structure and remote transmission and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and the efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:靖江智云信息科技有限公司

A batch recovery process and equipment for membrane electrode catalyst slurry

ActiveCN112542594BAvoid damageAvoid accumulationFuel cells disposal/recyclingFinal product manufacturePtru catalystFuel cells

The invention discloses a batch recovery process and equipment for membrane electrode catalyst prepared by spraying method, and recovers the catalyst beyond the spraying area during the spraying process; before preparing the catalytic layer, the auxiliary equipment is completely covered with a carrier sheet to ensure that all the catalyst slurry is outside the effective area. It falls on the carrier sheet, and then through processes such as soaking, scraping, collecting, washing, and vacuum drying, the efficient recovery of the catalyst adhered to the hardware auxiliary equipment such as fixtures is realized, which reduces the cost and reduces the pollution of the air environment; at the same time, the present invention Also disclosed is a fuel cell catalyst batch recovery device, which can realize the batch work of the catalyst recovery method, improve work efficiency, improve the utilization rate of raw materials in production, and reduce production costs.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Flexible Wall Bearing Wiper Link Hydraulic Oscillating Wiper

ActiveCN104494570BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningEnvironmental structureInterior noise

A hydraulic swing windscreen wiper with a flexible wall supporting wiper connecting rod comprises a wiper motor, a wiper driving mechanism and a wiper. The hydraulic swing windscreen wiper is characterized in that two gear rack swing cylinders are communicated through a hydraulic oil pipe and transmit torque, and a connecting rod swing arm driving mechanism is arranged on a driving gear rack swing cylinder. The hydraulic swing windscreen wiper has the advantages that the wiper driving mechanism of the windscreen wiper is hydraulically driven by a flexible pipeline, high in transmitted torque, small in size and rapid in response, structural limitation is less in mounting owing to hydraulic driving of the flexible pipeline, the windscreen wiper is of a completely closed structure, low in working noise and particularly suitable for complicated external environmental structures and remote driving, external influence is avoided, the shortcoming of burnout of the wiper motor due to external obstacles is avoided, interior noise is effectively reduced, internal comfort of a vehicle in running is improved, and a wiper rubber strip is supported by a flexible wall and can be more effectively fitted with a windscreen.

Owner:山东星奥液压机械有限公司

Three-scraper wiper hydraulic swing windscreen wiper with flexible wall supporting

ActiveCN104527588AReduce noiseAvoiding the Cons of Burning OutVehicle cleaningGear wheelEnvironmental structure

A three-scraper wiper hydraulic swing windscreen wiper with flexible wall supporting comprises a windscreen wiper motor, a wiper driving mechanism and a wiper and is characterized in that two gear and rack swing oil cylinders are communicated through a hydraulic oil pipe, torque is transmitted between the two gear and rack swing oil cylinders through the hydraulic oil pipe, and a forward and reverse rotation gear intermittent transmission mechanism is arranged on the driving gear and rack swing oil cylinder. The three-scraper wiper hydraulic swing windscreen wiper has the advantages that as flexible pipeline hydraulic transmission is adopted in the wiper driving mechanism of the windscreen wiper, structural limit is small when the windscreen wiper is installed; as the windscreen wiper is of a completely closed structure, noise is low when the windscreen wiper works, the windscreen wiper is particularly suitable for the complex external environmental structure and long-distance transmission and not affected by external factors, the defect that the windscreen wiper motor is burnt due to external obstacles is overcome, the noise in a vehicle is effectively lowered, and the comfort in the vehicle is improved when the vehicle operates; windscreen wiper rubber strips are supported by a flexible wall and therefore can fit windscreen better, and the scraping efficiency of the three-scraper structure is three times that of a general single scraper.

Owner:全椒县全动机械有限公司

Flexible wall supporting windshield wiper connecting rod wire wheel type windshield wiper with three scraping pieces

InactiveCN104527582AReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDrive wheelWire wheel

A flexible wall supporting windshield wiper connecting rod wire wheel type windshield wiper with three scraping pieces comprises a wiper motor, a wiper driving mechanism and a wiper, and is characterized in that a wiper driving shaft comprises a driven wheel wiper driving shaft and a driving wheel wiper driving shaft which are arranged in a driven wheel wiper driving shaft hole of a driven wheel fixing seat and a driving wheel wiper driving shaft hole of a driving wheel fixing seat respectively; the driven wheel wiper driving shaft and the driving wheel wiper driving shaft are provided with a driven winding wheel and a driving winding wheel respectively, the driven winding wheel and the driving winding wheel are connected through a flexible rope and transmit torque, and the driving winding wheel is provided with a closed type connecting rod swing arm driving mechanism. The connecting rod line wheel type wiper driving mechanism of the windshield wiper is of a closed structure, is particularly suitable for complex and long-distance transmission of an external environment, is not affected by the outside and avoids the defect that the wiper motor is burnt out due to an external barrier. A wiper rubber strip is supported by a flexible wall and can be better attached to windshield glass. The scraping efficiency of the three-scraping-piece structure is three times that of a common single scraping piece.

Owner:陈学琴

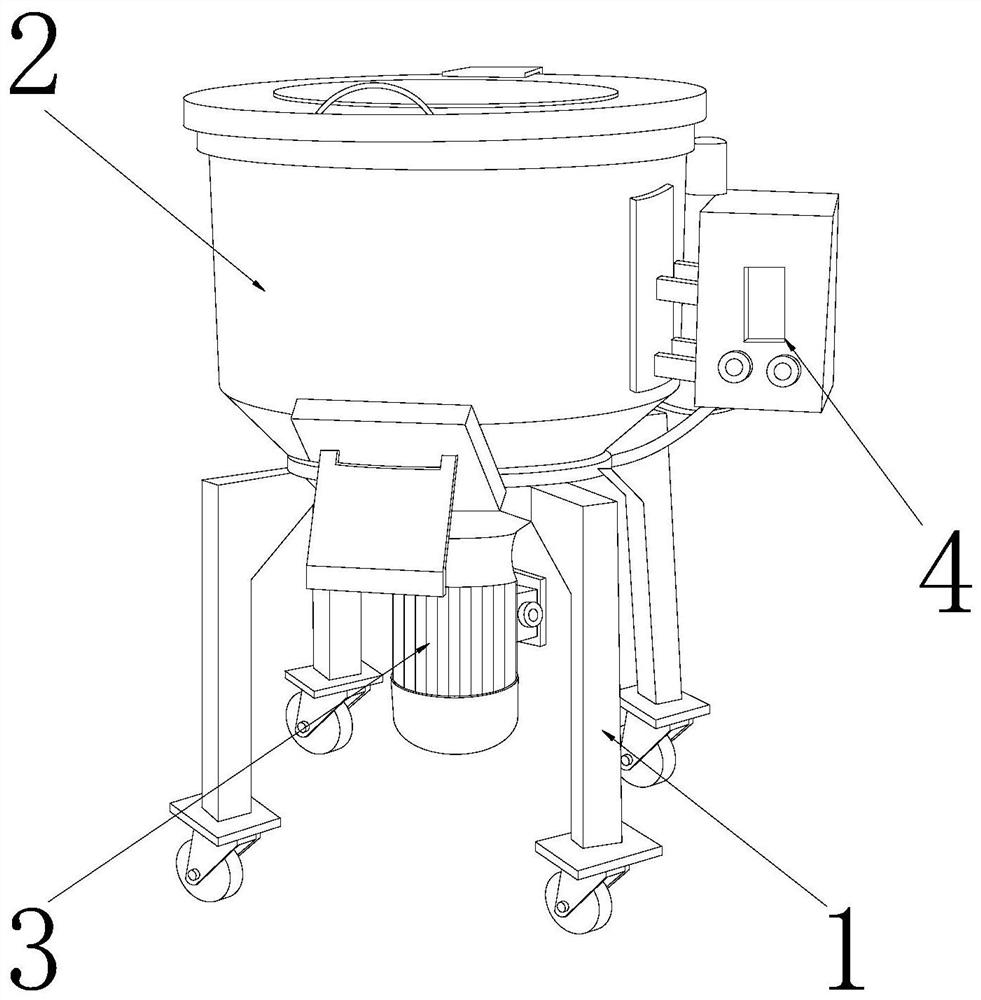

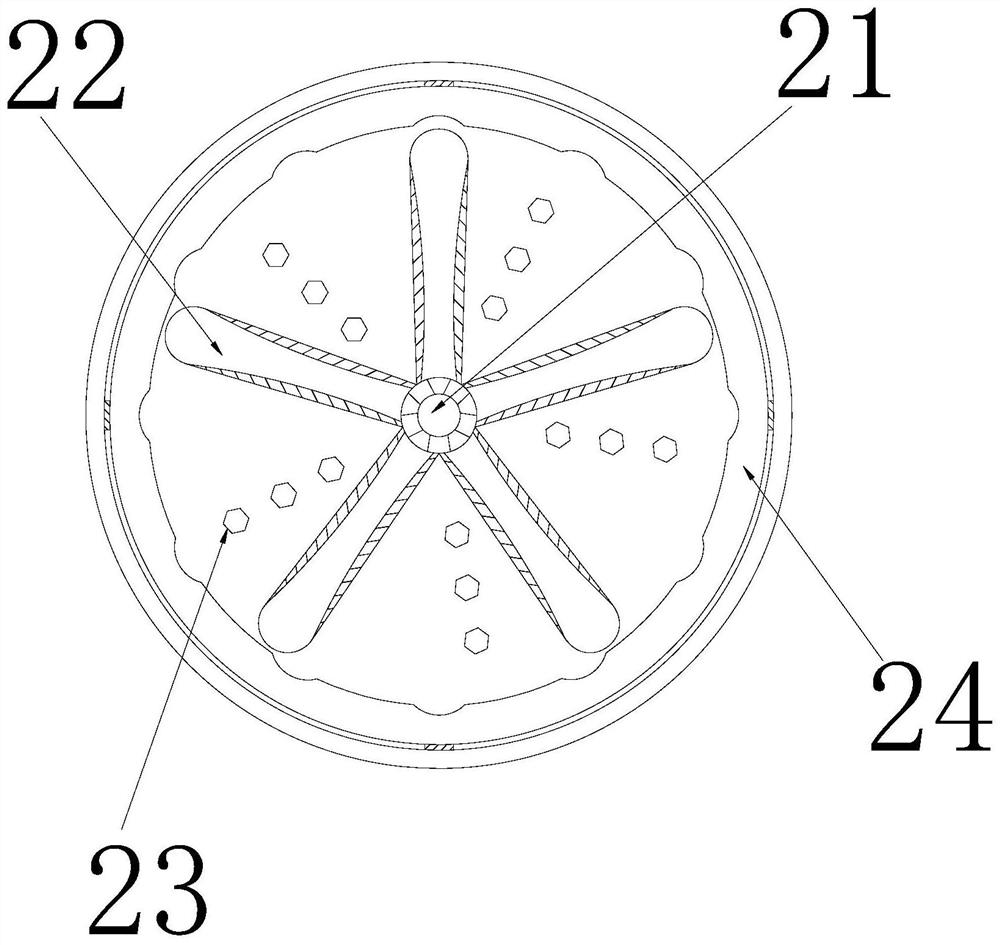

A raw material plastic granule color mixing machine for the production and processing of automobile plastic parts

The invention discloses a raw material plastic granule color mixing machine for the production and processing of automobile plastic parts. Its structure includes a bracket, a roller, a motor, and a distribution box. When mixing with toner, the toner is easily bounced off due to the elasticity of the plastic particles, and the toner sticks to the inner wall of the drum. Through the cooperation between the cleaning device and the bearing, the cleaning teeth inside the device scrape off the toner on the inner wall of the drum, which is beneficial Reduce the condensation of toner on the inner wall of the drum, which is conducive to the full mixing and color mixing of plastic particles and color materials, which improves the yield of plastic parts production and processing. Since part of the toner is easily accumulated outside the blade after being scraped by the tooth-cleaning blade, it can be removed by cleaning The teeth cooperate with the inner wall of the roller, and the inside of the air block is squeezed to generate gas that is blown away to the air holes, which accelerates the falling of the toner on the surface of the blade, helps to keep the outside of the blade clean, and speeds up the scraping of the toner on the inner wall of the roller.

Owner:公主岭市德立智能科技有限公司

Flexible wall supported wiper blade hydraulic wiper

ActiveCN104554166BReduce noiseAvoiding the Cons of Burning OutVehicle cleaningInterior noiseEngineering

A flexible wall supported wiper blade hydraulic type windscreen wiper comprises a wiper motor, a wiper driving mechanism and a wiper and is characterized in that two blade swing oil cylinders are communicated through a hydraulic oil pipe and transfer torque, and a forward and reverse rotating gear intermittent drive mechanism is arranged on the driving blade swing oil cylinder. The flexible wall supported wiper blade hydraulic type windscreen wiper has the advantages that the wiper driving mechanism of the windscreen wiper performs hydraulic drive through a flexible pipe, is large in transfer torque, small in size and quick in response, is small in structural limitation during installation due to the fact that the hydraulic drive by means of the flexible pipe is adopted, is completely of a closed structure, is low in noise during working, is especially suitable for a complicated external environment structure and remote transmission, can adapt to vehicle of different models and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, interior noise is effectively reduced, the interior comfort of a vehicle in running is improved, and a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen.

Owner:通威精密金属(佛山)有限公司

Hydraulic wiper blade

ActiveCN101445096BImprove scrapingExtended service lifeVehicle cleaningEngineeringMechanical engineering

The invention relates to a hydraulic wiper blade which comprises a rubber strip. The back surface of the rubber strip is fixedly connected to a pressure spring; a hydraulic chamber is formed by surrounding a cavity casing with rod-shaped outer appearance and groove-shaped cross section and the pressure spring and filled with liquid; a cylinder part for accommodating a piston is arranged on the cavity casing; and the piston is positioned at the exposed outer part and matched with a wiper rod in a clipping manner. The invention adopts the cavity casing to replace the prior framework structure and utilizes the principle of hydraulic power transmission to ensure that the pressure from a wiper arm uniformly acts on the rubber strip of the wiper blade, thereby reducing the generation of drain marks and greatly improving the scraping cleanliness and the service life of the wiper blade.

Owner:CHERY AUTOMOBILE CO LTD

Double blade flexible wall wiper linkage hydraulic swing wiper

The invention provides a double-scraper flexible-wall and hydraulic swinging wiper brush connecting rod type windscreen wiper. The double-scraper flexible-wall and hydraulic swinging connecting rod type windscreen wiper comprises a wiper motor, a wiper brush driving motor and a wiper brush. The double-scraper flexible-wall and hydraulic swinging wiper brush connecting rod type windscreen wiper is characterized in that two gear rack swinging oil cylinders are communicated through a hydraulic oil pipe to transmit torque; a connecting rod rocker arm driving mechanism is arranged on a driving gear rack swinging oil cylinder. The double-scraper flexible-wall and hydraulic swinging wiper brush connecting rod type windscreen wiper has the beneficial effects that the wiper brush driving mechanism is hydraulically transmitted through a flexible pipeline; the mounting is greatly avoided structural limitation; in addition, the a completely closed structure is provided; the working generates little noise; the complex external environment and long-distance transmission particularly apply, and moreover, outside influence is prevented, so that the shortage that the wiper motor is burnt through an external barrier can be avoided; the noise in a vehicle can be effectively reduced; the internal comfort of the vehicle in running can be improved; rubber strips of the wiper are supported through flexible walls and can be clung to a windscreen; the scraping efficiency of the double-scraper structure is doubled that of the general single-scraper structure.

Owner:烟台鑫运化工有限公司

Building steel bar rust removal device capable of reducing surface abrasion

InactiveCN112917354AReduce surface wearImprove scrapingCleaning using toolsGrinding machinesMining engineeringRebar

The invention relates to the technical field of steel bar rust removal equipment, and discloses a building steel bar rust removal device capable of reducing surface abrasion. The building steel bar rust removal device capable of reducing surface abrasion comprises a movable column; a movable block penetrates through the side wall of the movable column; a connecting block penetrates through the top side wall of the movable block; a movable shaft penetrates through the top side wall of the movable block; and a movable strip penetrates through and is slidably connected to the outer side wall of the movable shaft, and a sliding piece is connected between the side walls of the movable shaft in a penetrating mode. Due to the fact that the side wall of the movable strip wraps the outer side wall of the movable shaft, in the process that the side wall of a steel bar pipe slides downwards along the inner side wall of the movable block, the side wall of the steel bar pipe can be scraped on the outer side wall of the movable strip, and the side wall of the movable strip rotates and slides on the side wall of the movable shaft, as can be seen from the drawing; when the side wall of the movable strip rotates and twists, the sharp corner of the side wall of the movable strip protrudes outwards; and due to the fact that the side wall of a steel bar rod can be scraped right opposite to the sharp corner of the outer side wall of the movable strip, rust at a gap of the side wall of the steel bar rod can be scraped and removed.

Owner:黄千源

Three-scraping-piece flexible wall supported wiper connecting rod blade hydraulic type windscreen wiper

ActiveCN104554170AReduce noiseAvoiding the Cons of Burning OutVehicle cleaningDrive shaftEngineering

A three-scraping-piece flexible wall supported wiper connecting rod blade hydraulic type windscreen wiper comprises a wiper motor and a wiper drive shaft and is characterized in that two blade swing oil cylinders are communicated through a hydraulic oil pipe and transfer torque, and a connecting rod rocker arm drive mechanism is arranged on the driving blade swing oil cylinder. The three-scraping-piece flexible wall supported wiper connecting rod blade hydraulic type windscreen wiper that a wiper driving mechanism of the windscreen wiper performs hydraulic drive through a flexible pipe, is large in transfer torque, small in size and quick in response, is small in structural limitation during installation due to the fact that the hydraulic drive by means of the flexible pipe is adopted, is completely of a closed structure, is low in noise during working, is especially suitable for a complicated external environment structure and remote transmission and is not influenced by the outside, the defect that the wiper motor is burned down due to an external obstacle is avoided, interior noise is effectively reduced, the interior comfort of a vehicle in running is improved, a wiper rubber strip is supported by a flexible wall and can be well fit with a windscreen, and the efficiency of a three-scraping-piece structure is triple of the scraping efficiency of a common single scraping piece.

Owner:齐河智谷产业发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com