A raw material plastic granule color mixing machine for the production and processing of automobile plastic parts

A technology of plastic granules and plastic parts, which is applied in the field of plastic granule color mixing machines used in the production and processing of automotive plastic parts. It can solve the problems of uneven color mixing of plastic granules, lower quality of production and processing yields, and reduced toner content, so as to speed up coloring. Powder drop, yield improvement, cleanliness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] as attached figure 1 to attach Figure 5 Shown:

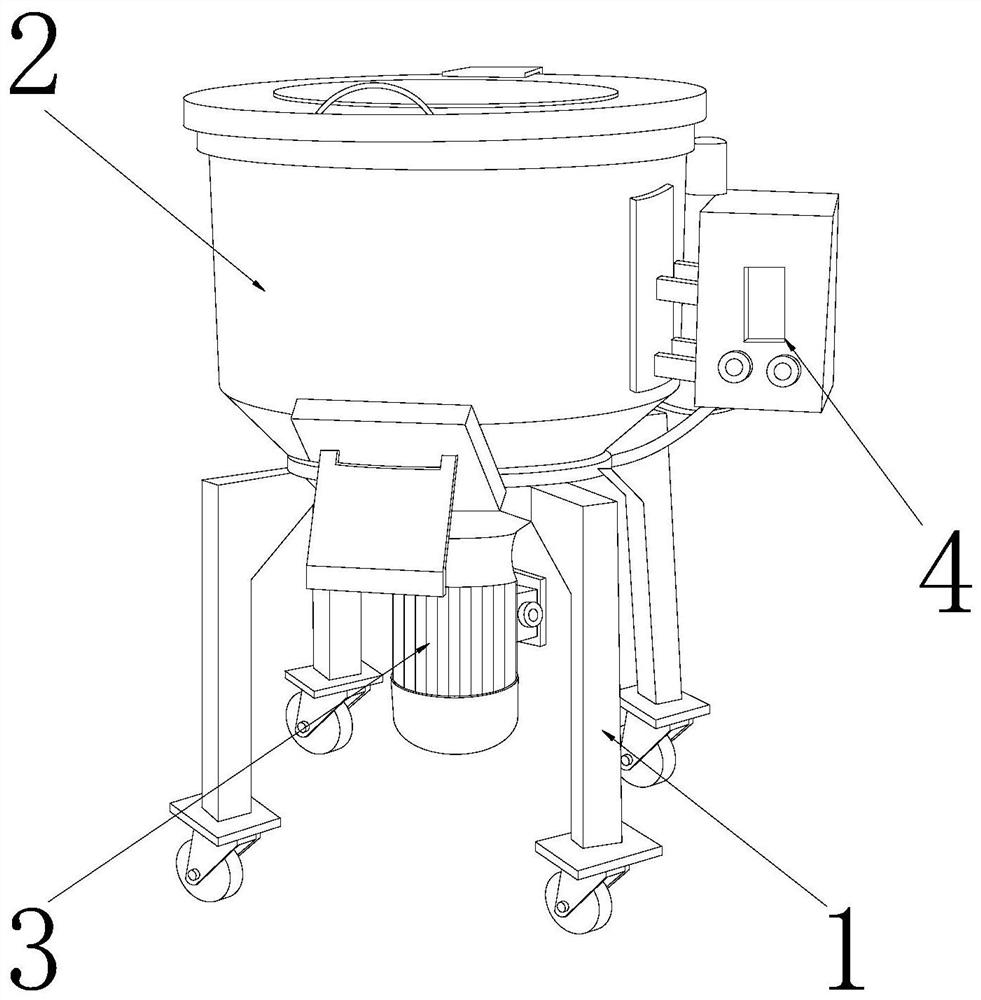

[0028] The invention provides a raw material plastic particle color mixing machine for the production and processing of automobile plastic parts. Its structure includes a bracket 1, a roller 2, a motor 3, and a distribution box 4. The roller 2 is welded on the top of the bracket 1, and the motor 3 is fixed on the The inner bottom of the support 1, the distribution box 4 is installed on the right side of the drum 2.

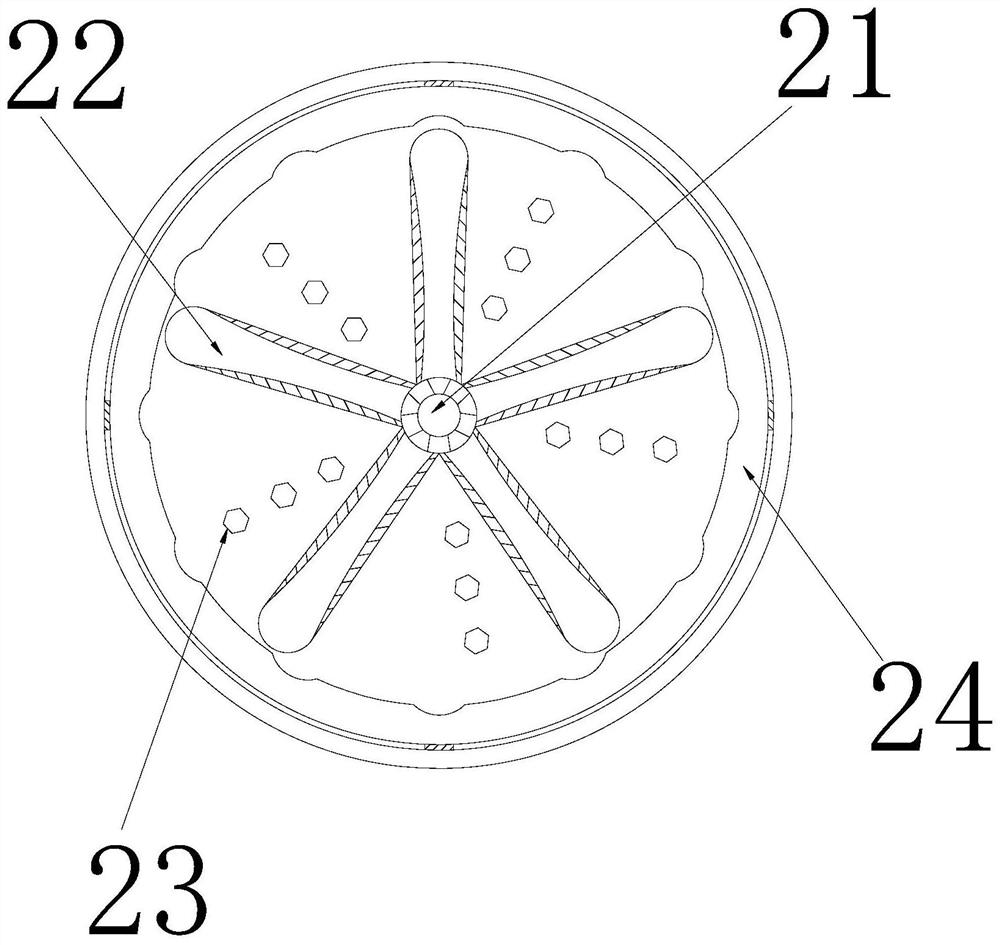

[0029] The drum 2 includes a bearing 21, a blade plate 22, a water outlet hole 23, and a cleaning device 24. The bearing 21 is arranged in the middle of the drum 2 and is movably matched with the blade plate 22. The water outlet hole 23 runs through the inner bottom of the drum 2. The cleaning device 24 is attached to the inner wall of the drum 2 and is movably matched with the bearing 21 .

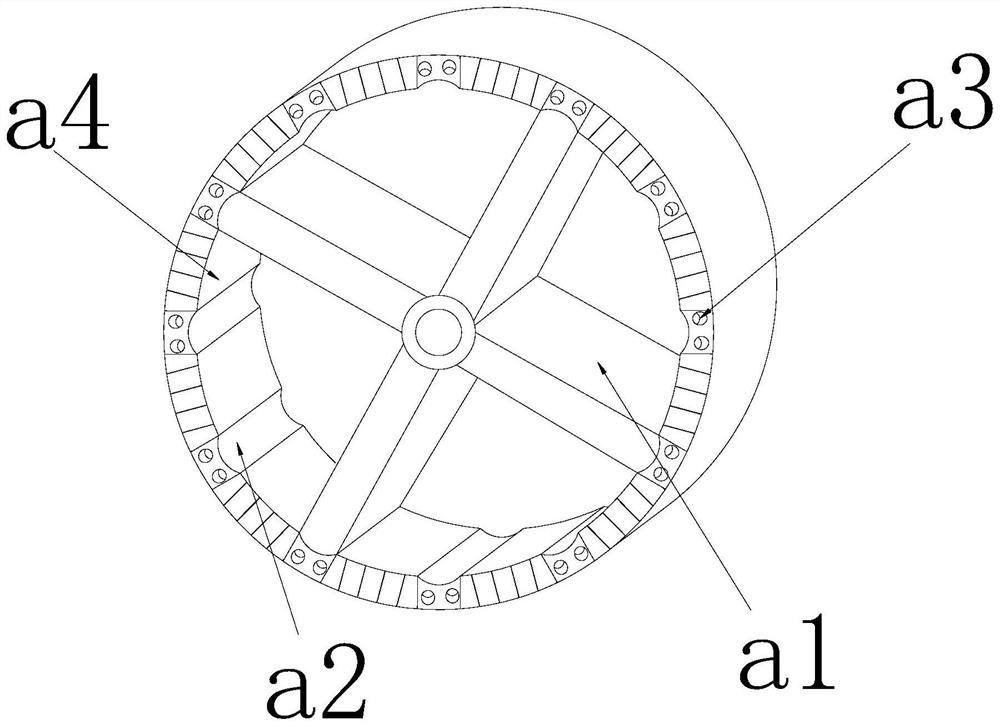

[0030] Wherein, the clearing device 24 is composed of a connecting block a1, a clamping block a2, an air outlet a3...

Embodiment 2

[0036] as attached Image 6 to attach Figure 8 Shown:

[0037]Wherein, the cleaning tooth d4 is composed of an air block f1, a blade f2, a concave groove f3, and an air hole f4. The blade f2 is respectively embedded and fixed on both sides of the cleaning tooth d4, and the concave groove f3 is depressed on the surface of the blade f2. The air hole f4 runs through both sides of the air block f1 and is located between the blades f2. The height of the concave groove f3 gradually decreases from the center to both sides, and it is a smooth surface, which reduces resistance and friction, and is beneficial to speed up the scraping of toner slide.

[0038] Wherein, the air block f1 is composed of a reset block r1, a pressure plate r2, an air chamber r3, and a clamping rod r4. The reset block r1 is clamped on the inner wall between the tops of the pressure plates r2, and the air chamber r3 is located on the inner side between the pressure plates r2. The clamping rod r4 is clamped o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com